Optimization method for CFRP (carbon fiber reinforced plastics) and titanium alloy laminated structure reaming process

A stacked structure and optimization method technology, applied in reaming devices, metal processing equipment, manufacturing tools, etc., can solve the problems of incomplete constraint conditions and inability to reasonably optimize stacked structure hole-making process parameters, etc., to achieve improved reaming Efficiency, reasonable optimization results, effect of large reaming capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

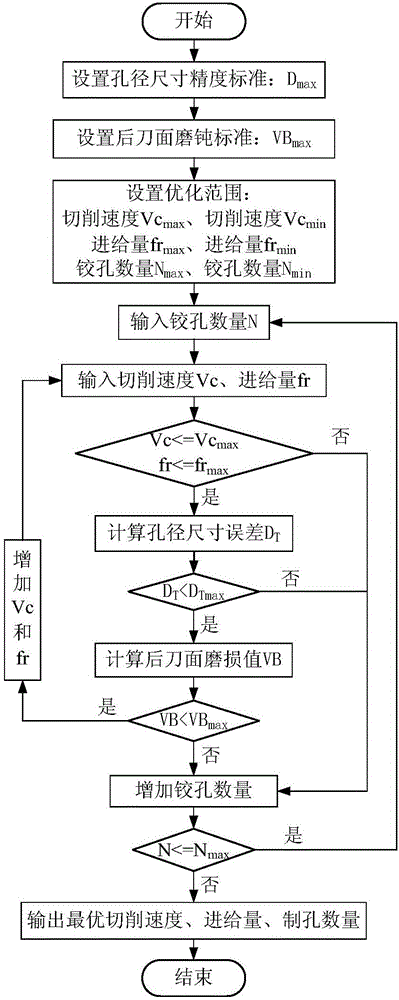

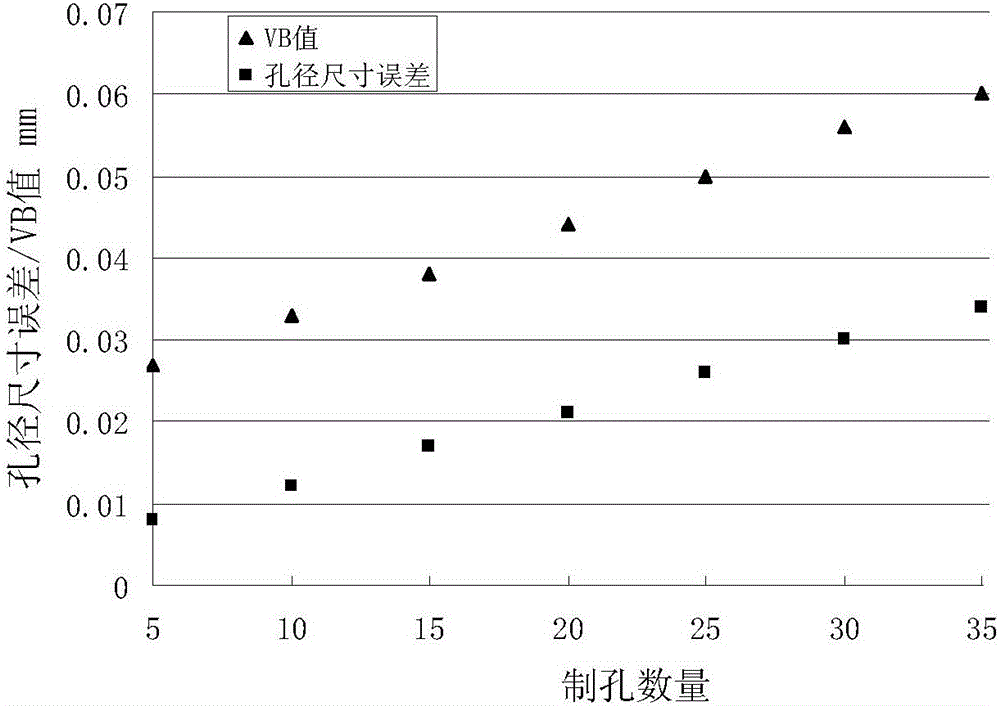

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0032] Taking the reaming process of T300 carbon fiber composite material and TC6 titanium alloy laminated structure as an example, the reaming conditions and accuracy requirements of the laminated structure are as follows:

[0033] (1) Structural geometric parameters of the reamer: the diameter is 6.6mm, the main deflection angle is 45 degrees, and the rear edge angle is 12 degrees;

[0034] (2) The tool material is K6UF (tungsten carbide);

[0035] (3) Reaming hole size accuracy requirements: the hole size meets the H9 accuracy;

[0036] (4) The thickness of the T300 composite material plate is 5mm, and the thickness of the TC6 titanium alloy plate is 3mm.

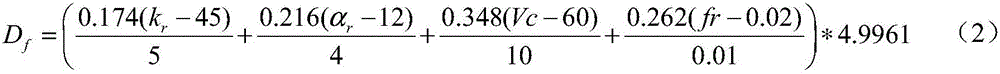

[0037] Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com