Wooden door processing technology for conveniently improving production efficiency

A processing technology and wooden door technology, applied in the direction of wood processing utensils, manufacturing tools, etc., can solve the problems of unreasonable processing procedures, unreasonable pre-processing molding structure, etc., and meet the requirements of easy processing, reduce material size, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

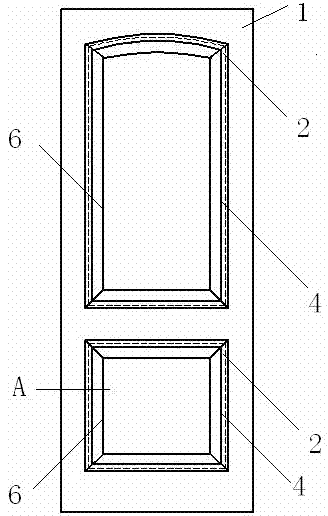

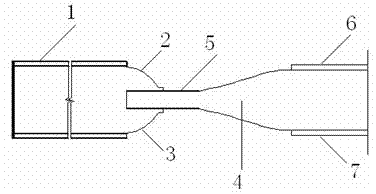

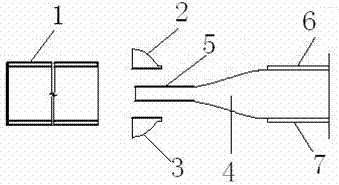

[0050] see figure 1 , image 3 , Figure 4 with Figure 5 As shown, the present invention is convenient to improve wooden door production and processing efficiency, and it comprises following processing steps:

[0051] (1) Processing technology of wooden door leaf

[0052] (1) Processing and molding of wooden door leaf components:

[0053] The wooden door leaf includes each component that constitutes the door leaf frame 1, the door core board 4, the front flower wire frame 2, the rear flower wire frame 3, the core board milling position 5, and the front door core board surface 6 for pasting on the front and rear sides of the door core board. and the rear door core panel surface 7; when processing and forming, the door core panel 4 and the core panel milling position 5 are integrally formed, and the door leaf frame 1, the front flower wire frame 2 and the rear flower wire frame 3 are separately formed;

[0054] (2) The painting process of the wooden door leaf components: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com