Novel plunge type inner/outer curved surface cutting/grinding/polishing process and system

A technology of outer curved surface and new technology, which is applied in the direction of grinding/polishing equipment, grinding equipment, grinding machine tools, etc., can solve the problem that the accuracy of the workpiece cannot be within a preset range, reduce the failure rate, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

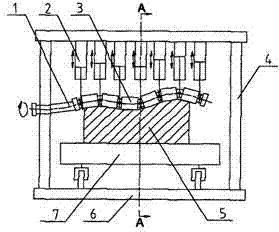

[0047] see Figure 6 , a plunge-cut grinding / grinding / polishing system for machining inner / outer surfaces, which includes:

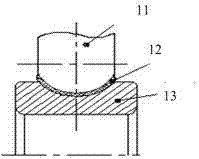

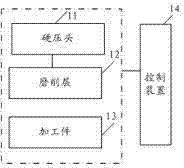

[0048] Hard indenter 11: the shape of the end of the hard indenter matches the curved surface of the workpiece, and the hardness of the hard indenter is equal to or greater than that of the workpiece. The hardness of the hard indenter is equivalent to the hardness of the workpiece means that the hardness of the hard indenter is the same as that of the workpiece, or the hardness difference between them is within a preset range. The design of this hardness mainly means that the hard indenter does not Deformation, wear resistance. The shape of the end of the hard indenter 11 matches the curved surface of the workpiece, so that when the hard indenter 11 grinds the workpiece by pressing the grinding layer, the corresponding curved surface can be ground out of the workpiece.

[0049] Hard indenter linkage mechanism 24: connected with the hard indenter 11, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com