Press molding method

A technology of stamping forming and vertical wall, which is applied in the field of stamping and forming, and can solve problems such as cracks on the outer panel and poor stamping formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

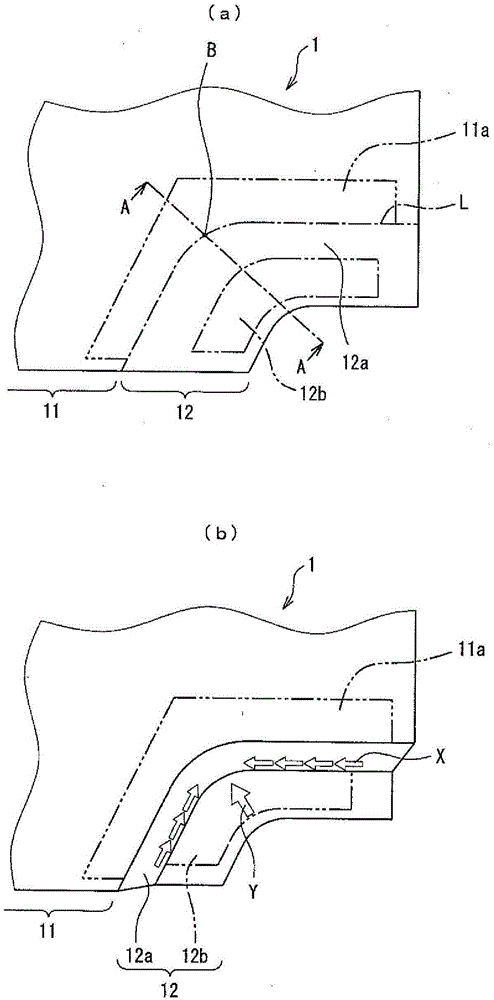

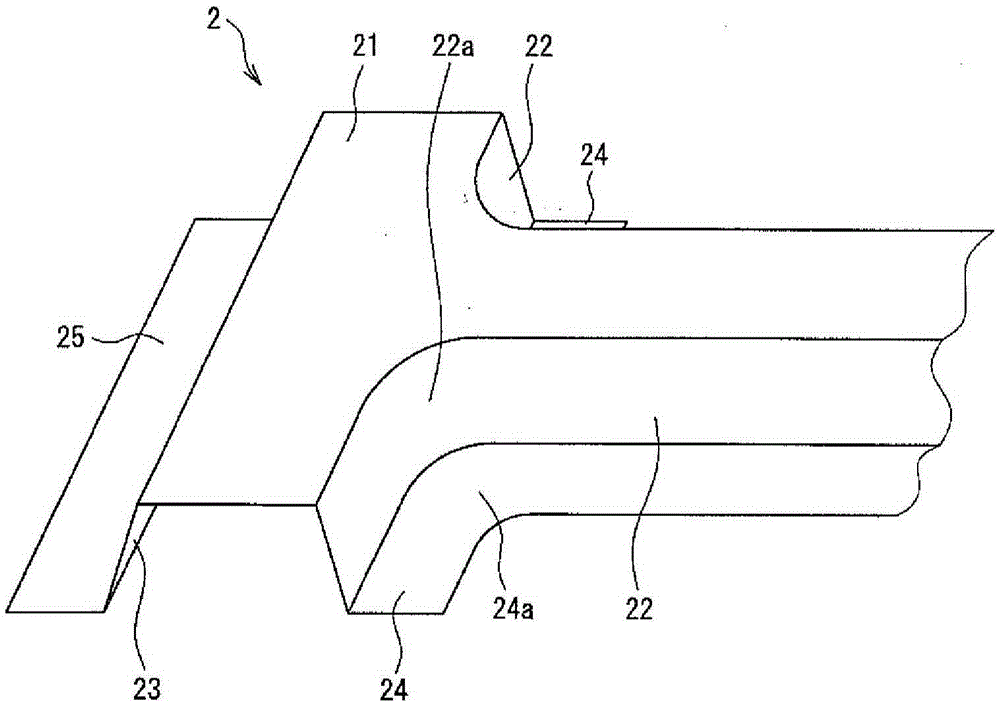

[0072] In this embodiment, making image 3 Curved pipe parts of the shape shown. Such a curved duct member is used, for example, as a center pillar member of an automobile.

[0073] Such as image 3As shown, the curved duct member 2 consists of a top plate portion 21 corresponding to the base, a vertical wall portion 22 having a curved portion 22a, a vertical wall portion 23 without a curved portion, and a flange portion continuous with the vertical wall portion 22 having a curved portion 22a. 24 and a flange portion 25 that is continuous with the vertical wall portion 23 without a bend. The flange portion 24 has a curved portion 24 a at a portion continuous with the curved portion 22 a of the vertical wall portion 22 .

[0074] The vertical wall portion 22 having the bent portion 22 a of the curved duct member 2 and the flange portion 24 continuous thereto are formed by the following method. Here, portions other than the bent portion 22a may be formed by a normal drawing ...

no. 2 approach

[0084] Also in this embodiment, it is produced in the same manner as in the first embodiment image 3 The curved pipe part 2 of the shape shown. The vertical wall portion 22 having the curved portion 22a of the curved pipe member 2 and the flange portion 24 continuous therewith pass through Figure 6 The following method is shown for formation.

[0085] The method of this embodiment differs from the method of the first embodiment in the method of moving the wrinkle-preventing plate 33 and the second backing plate 34 that restrain the outer portion 12b, and other parts are the same as the method of the first embodiment.

[0086] First, if Figure 6 As shown by the solid line in the center, the boundary side portion 11a of the base 11 of the blank 1 is clamped and constrained by the punch 31 and the first backing plate 32, and the deformation portion 12 is clamped and constrained by the anti-wrinkle pressure plate 33 and the second backing plate 34. Outer part (portion to be ...

no. 3 approach

[0096] Also in this embodiment, it is produced in the same manner as in the first embodiment image 3 The curved pipe part 2 of the shape shown. The vertical wall portion 22 having the curved portion 22a of the curved pipe member 2 and the flange portion 24 continuous therewith pass through Figure 7 The following method is shown for formation.

[0097] The metal mold used in stamping is basically the same as Figure 4 same, but as Figure 7 As shown, a punch 35 having a convex portion 35 a on a side surface (a pressing surface that contacts the vertical wall portion) is disposed below the blank 1 . A second backing plate 36 having a concave portion 36 a on a side surface is disposed above the anti-crease platen 33 . Other parts are the same as the second embodiment.

[0098] Similar to the method of the second embodiment, the anti-crease plate 33 and the second backing plate 36 constraining the outer portion 12b are oriented at an angle (θ) of 30° to 60° with respect to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com