Method for Manufacturing Multi-Finger Pinned Root for Turbine Blade Attached to Turbine Rotor and Turbine Blade

a technology of turbine blades and pin insertion holes, which is applied in the direction of blade accessories, machines/engines, waterborne vessels, etc., can solve the problems of high risk of fatigue damage to the inner surface of each pin insertion hole, and achieve the effect of reducing fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]An embodiment of the present invention will be described below with reference to drawings.

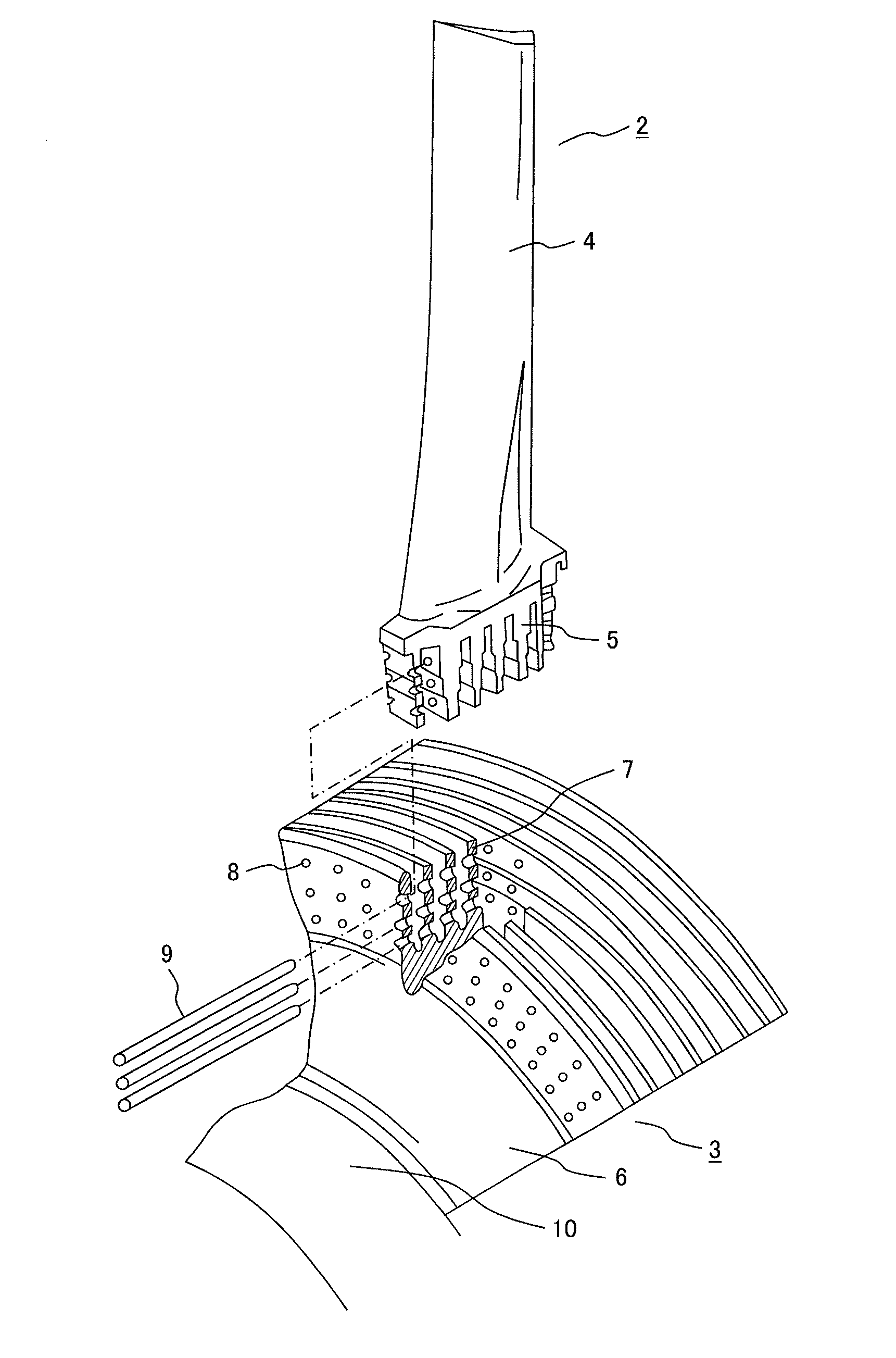

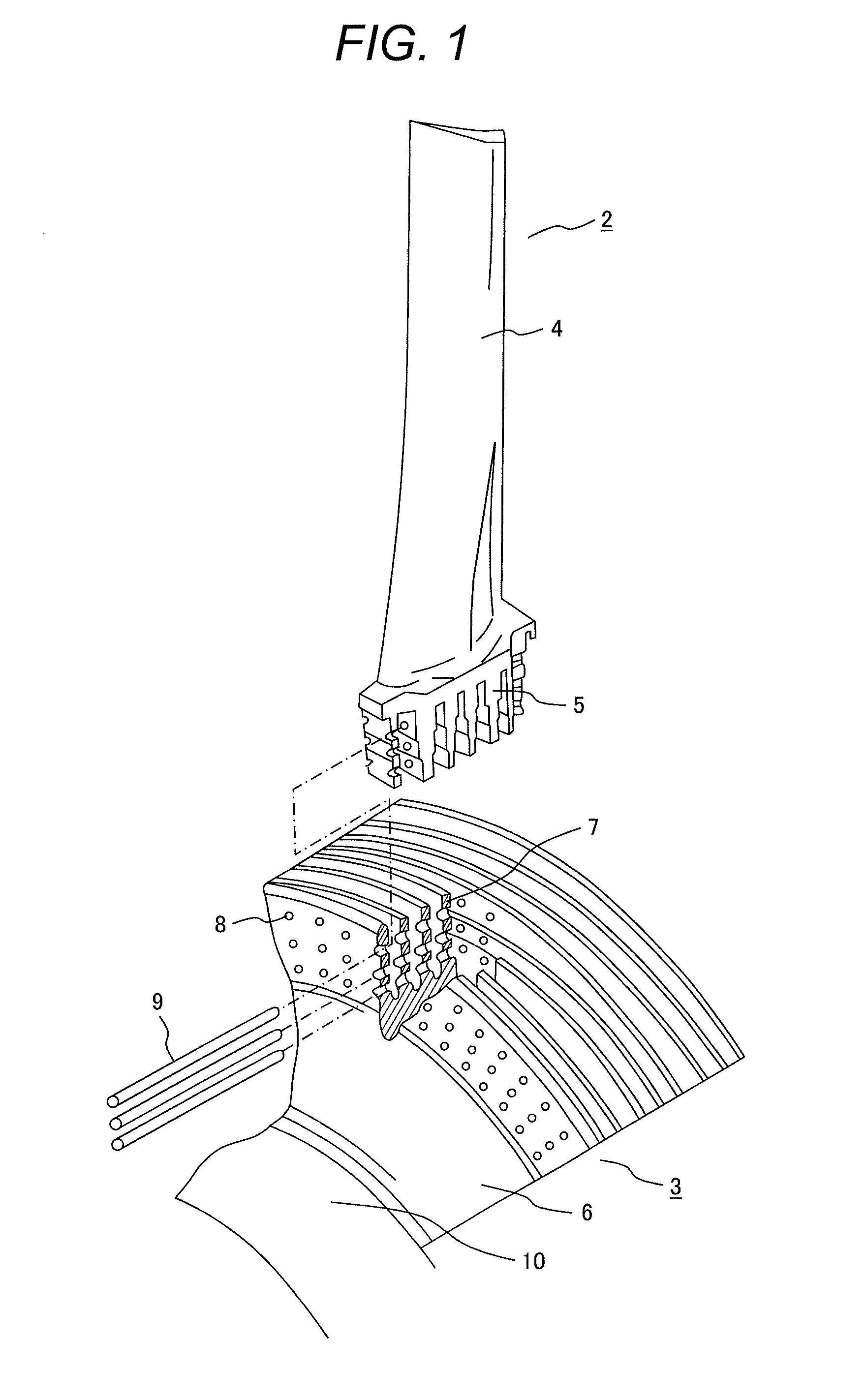

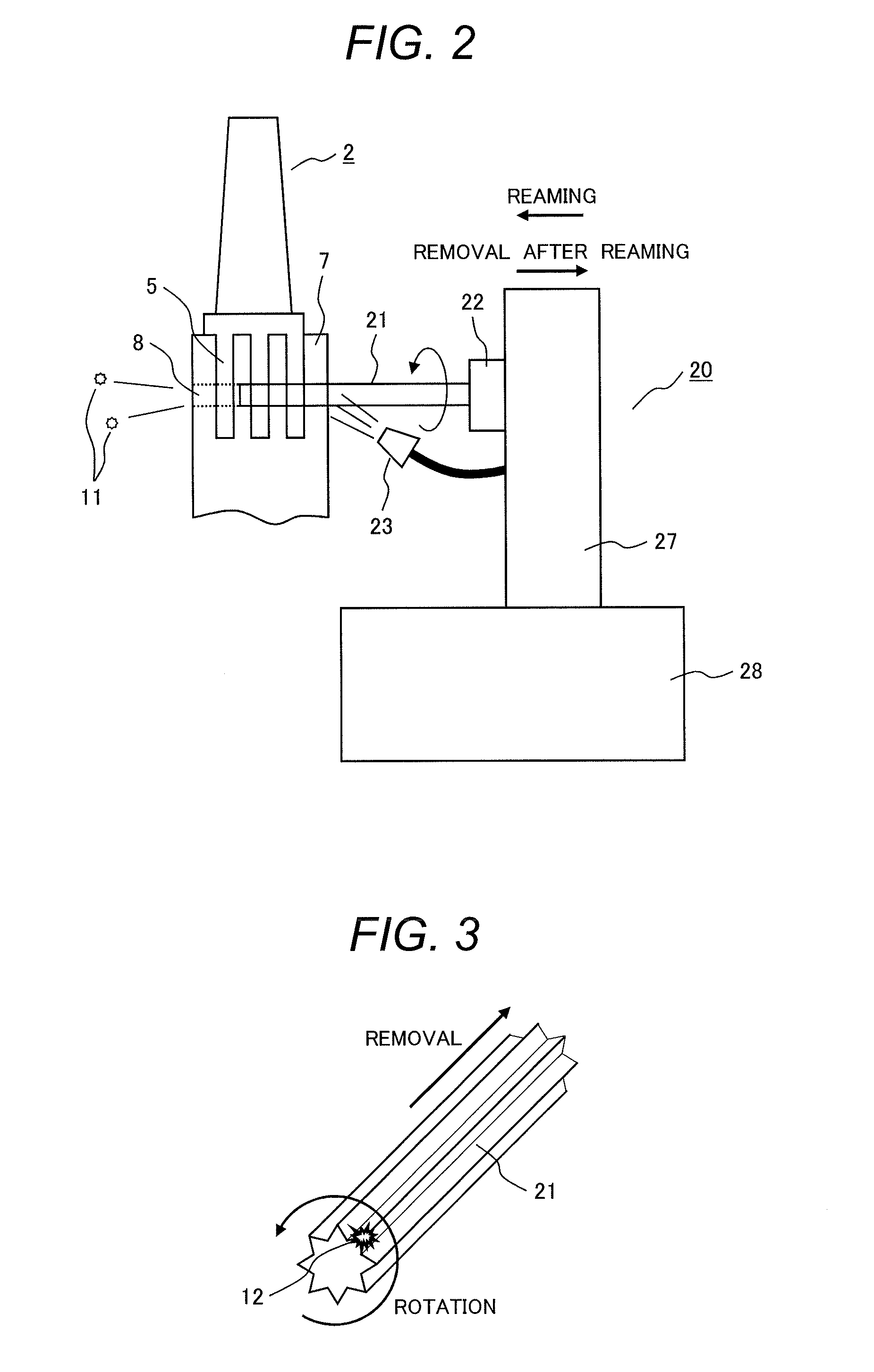

[0025]FIG. 1 is a construction drawing of a turbine blade attachment base. The turbine blade attachment base is comprised of turbine blades 2 and a turbine rotor 3 combined together. Each turbine blade 2 has a blade section 4 which receives a steam flow and converts the energy of the steam flow into a rotational energy for the turbine and a blade fork 5. The turbine rotor 3 has a turbine rotary shaft 10 and a rotor disc 6 provided circumferentially over the turbine rotary shaft 10. The rotor disc 6 has a rotor fork 7 formed thereon.

[0026]The blade fork 5 of the turbine blade 2 and the rotor fork 7 of the turbine rotor 3 are arranged to mesh with each other. The blade fork 5 and the rotor fork 7 have pin insertion holes 8 extending through them in the rotor axis direction. Coupling pins 9 are inserted into the pin insertion holes 8 thereby filling the pin insertion holes 8 and fixing the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com