Hydraulic through-hole processing method and apparatus

A processing method and technology of hydraulic parts, applied in the direction of metal processing equipment, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve the problems of difficult to achieve finished product quality, complicated process steps, large equipment investment, etc., and achieve low production cost , less process steps, less investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

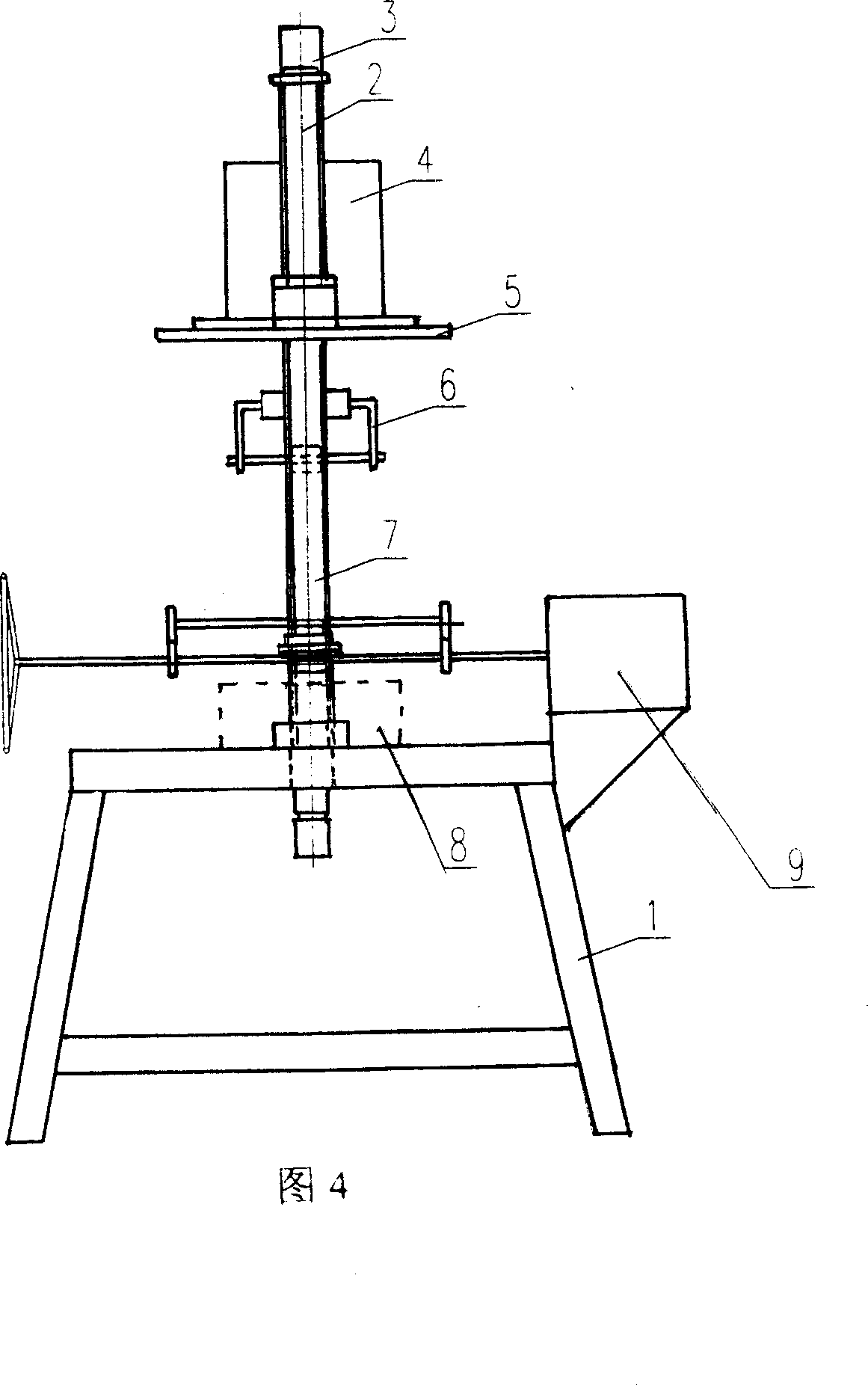

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

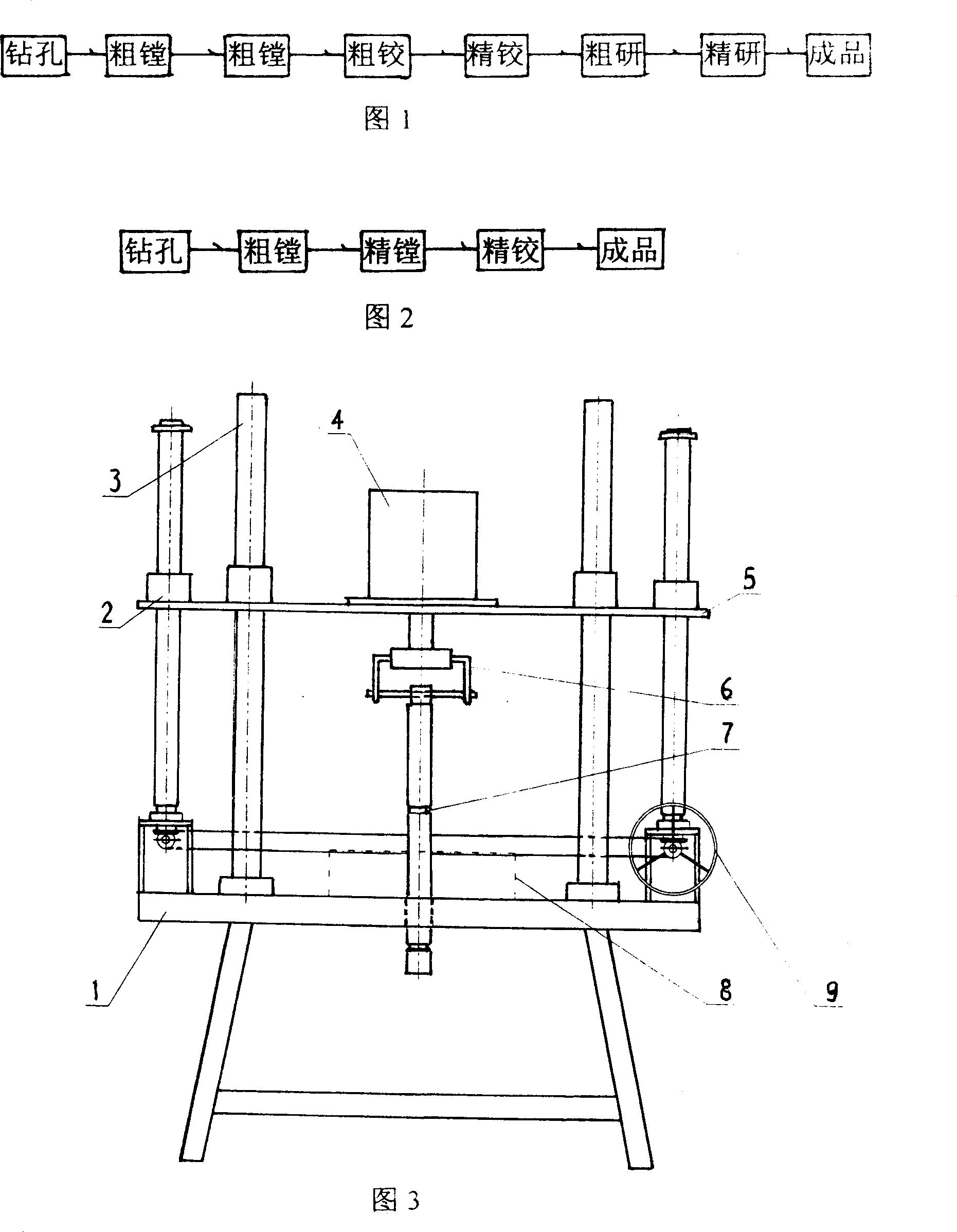

[0025] As shown in Figure 1, the process steps of the traditional through-hole processing method for hydraulic parts are drilling, rough boring, re-rough boring, rough reaming, fine reaming, rough grinding, fine grinding to finished products, and the equipment to realize this processing method is a drilling machine , a boring machine, a fine reaming machine, and a quilting machine, that is, a drilling machine is used to drill holes in the workpiece in turn, a boring machine is used to rough bore the workpiece, and then a rough boring is used to rough the workpiece. Roughly grind and finely grind the workpiece to the finished product. There are many process steps and equipment, and the quality of finished products is difficult to meet the designed smoothness, precision, roundness, and straightness requirements. This comparative exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com