A reaming tool as well as a head and a cutting insert therefor

A cutting insert, reaming technology, used in the field of reaming tools and heads and cutting inserts for reaming tools, which can solve problems such as poor bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

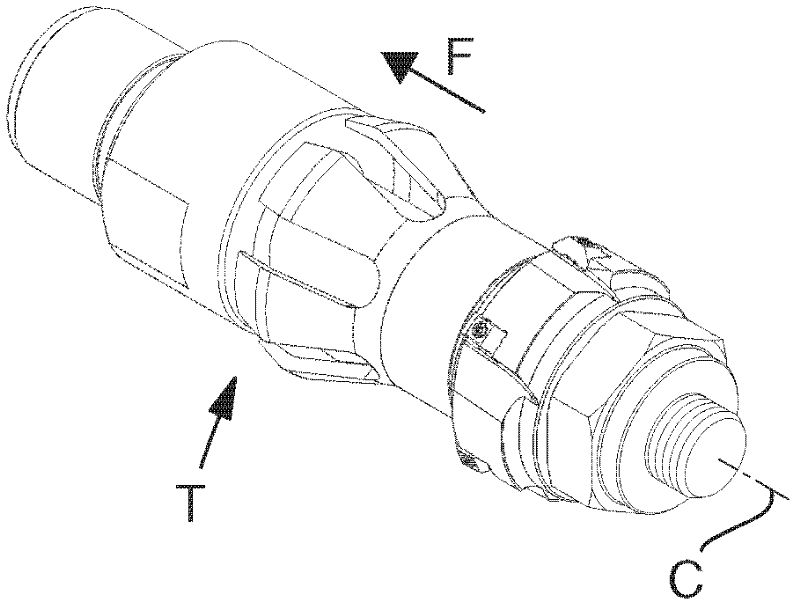

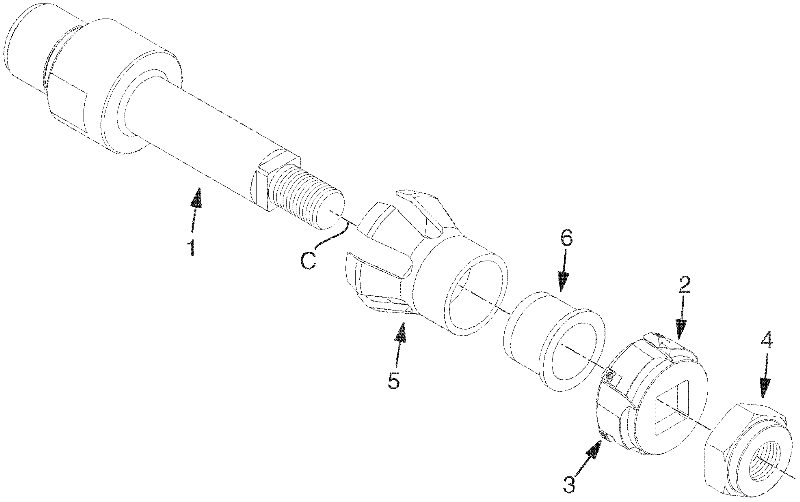

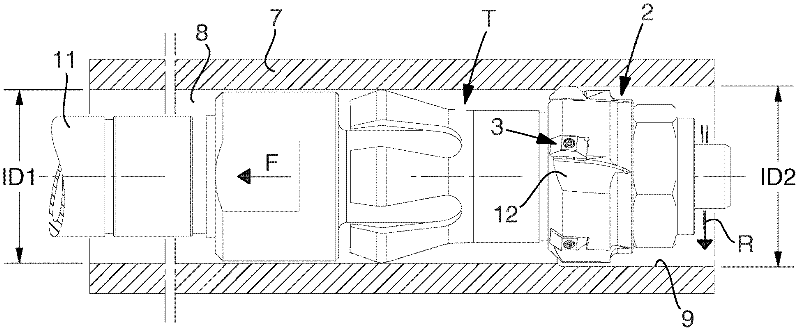

[0034] Figure 1-3The reaming tool T shown in includes three main components, namely a drive rod 1, a head 2 and a plurality of cutting blades 3 detachably mounted on the head. In the embodiment of the tool shown, it further comprises a locking member in the form of a nut 4, a forerunner 5, and a sleeve 6 acting between the forerunner and the drive rod. In operation, the reaming tool can be rotated while the workpiece is fed longitudinally, or the tool can be fed longitudinally while rotating the workpiece, thereby providing the desired relative motion between the reaming tool and the workpiece. In the example shown, the last-mentioned alternative is preferred, namely: while the workpiece 7, shown in the form of a tube blank, is rotating in the direction of arrow R, the tool is fed longitudinally, i.e. in the direction of arrow F give tools. When the terms "front" and "rear", respectively, are used in the following description, these terms are relative to the direction of lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com