Large-diameter and high-precision taper hole processing method

A tapered hole processing method and high-precision technology, which is applied in the field of tapered hole processing and manufacturing, can solve the problems of different degrees of reamer wear, small contact surface, and poor roughness of tapered hole processing, and achieve improved reaming efficiency and consistent wear , The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a method for processing large-diameter and high-precision taper holes, comprising the following steps:

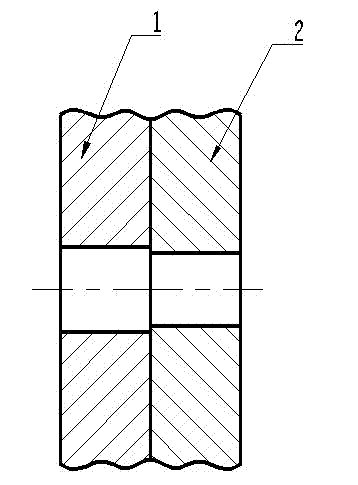

[0032] A. Face and fasten the first part 1 and the second part 2 that make up the tapered hole with tooling bolts (not shown in the figure), as figure 1 shown;

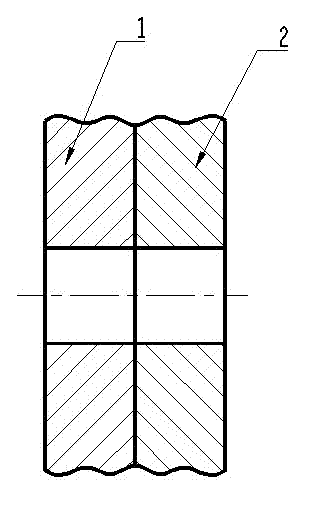

[0033] B. Pre-drill the bottom hole on the drilling machine according to the line, so that the diameter of the bottom hole is 2.5mm smaller than the minimum diameter designed for the small end of the finished taper hole, so as to reduce the cutting stress in the subsequent process, such as figure 2 shown;

[0034] C. On the CNC boring machine, expand the bottom hole to the minimum diameter designed for the small end of the finished tapered hole, and ensure the position accuracy of the hole;

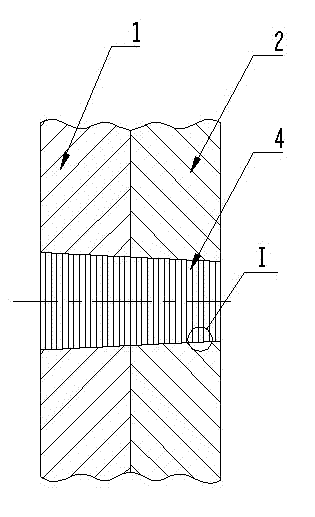

[0035] D. According to the pre-programmed program on the CNC boring machine, the bottom hole is pre-processed into a stepped hole 4 with equal axial distance and equal radial increment, and the proporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com