Patents

Literature

74results about How to "Consistent wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

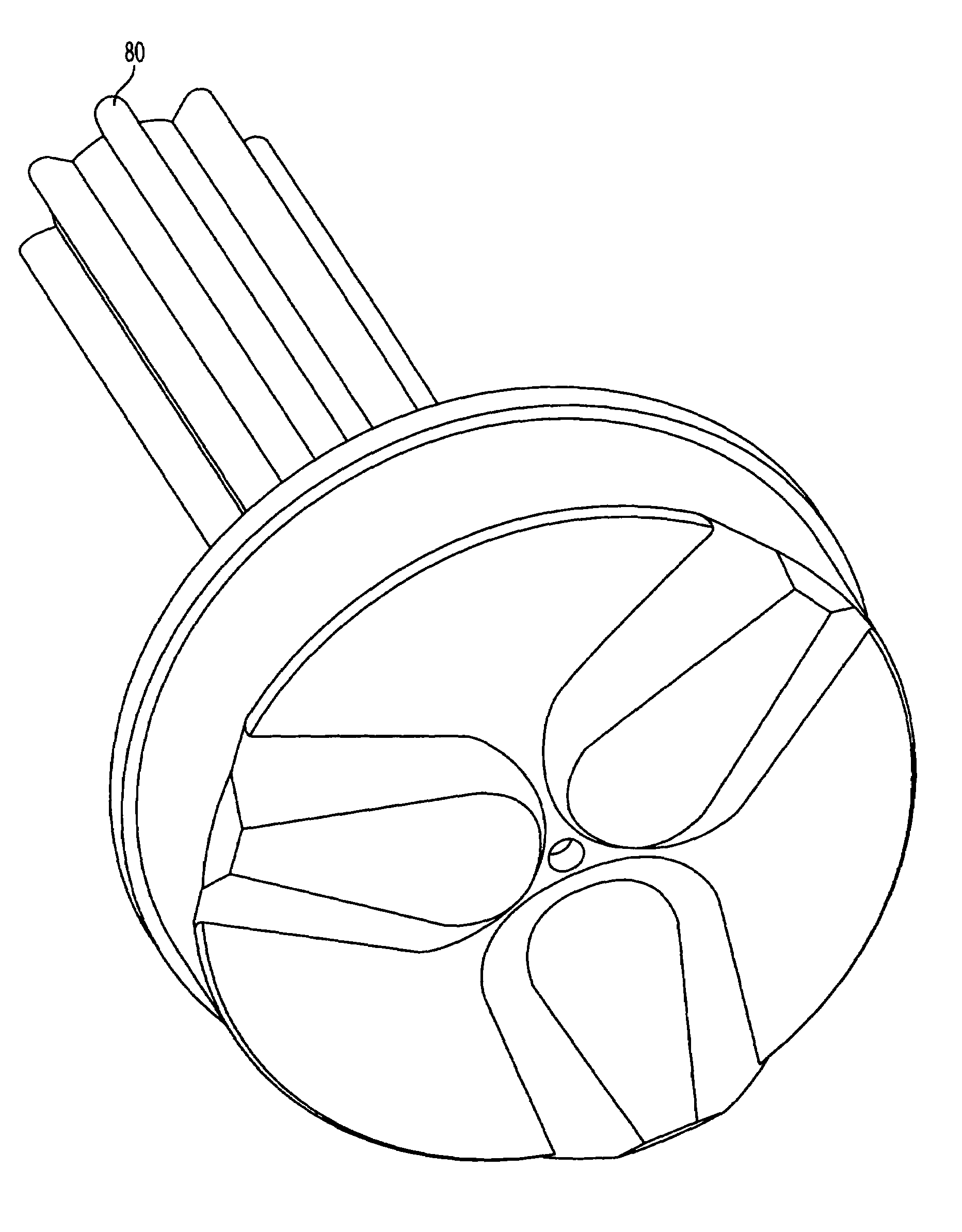

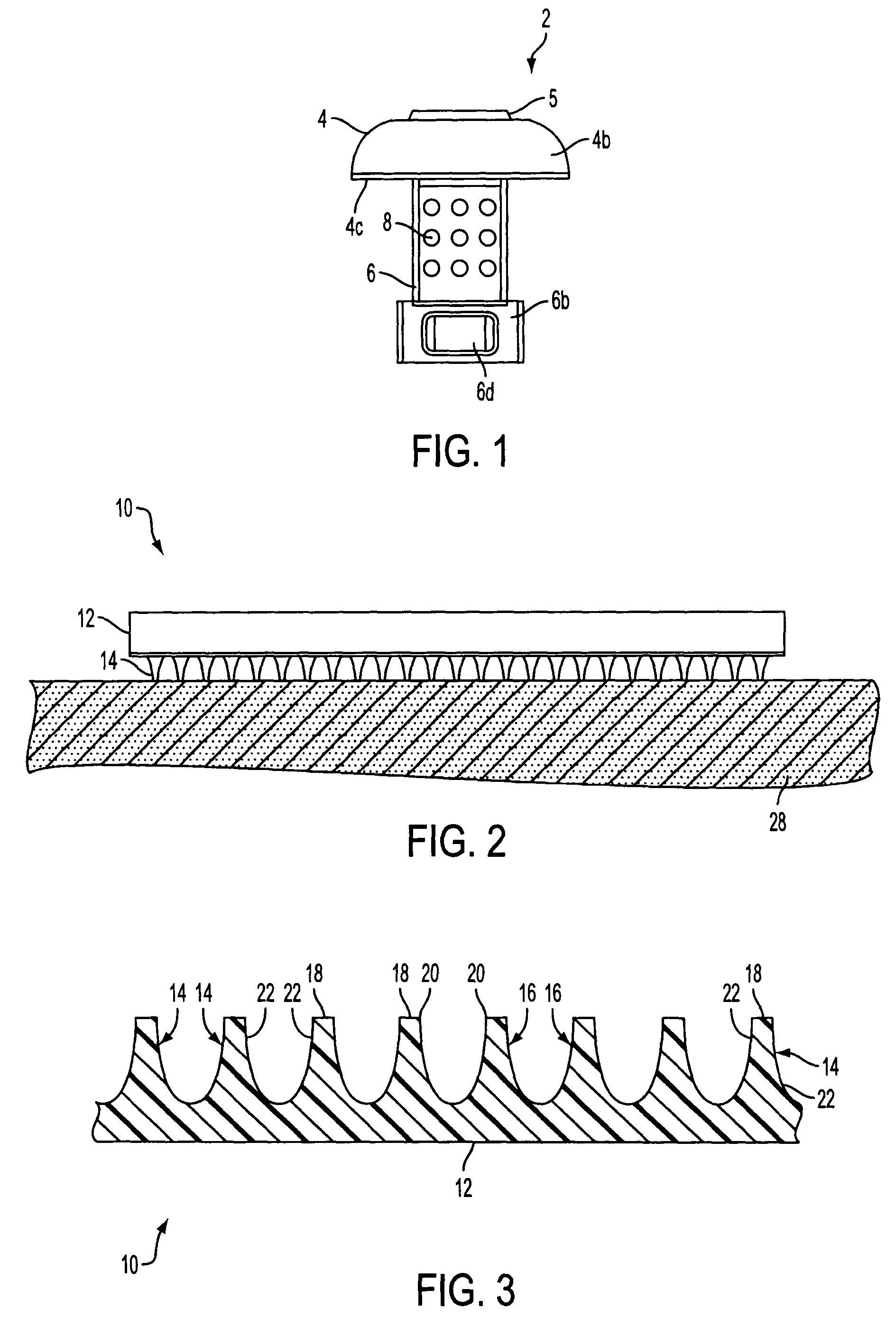

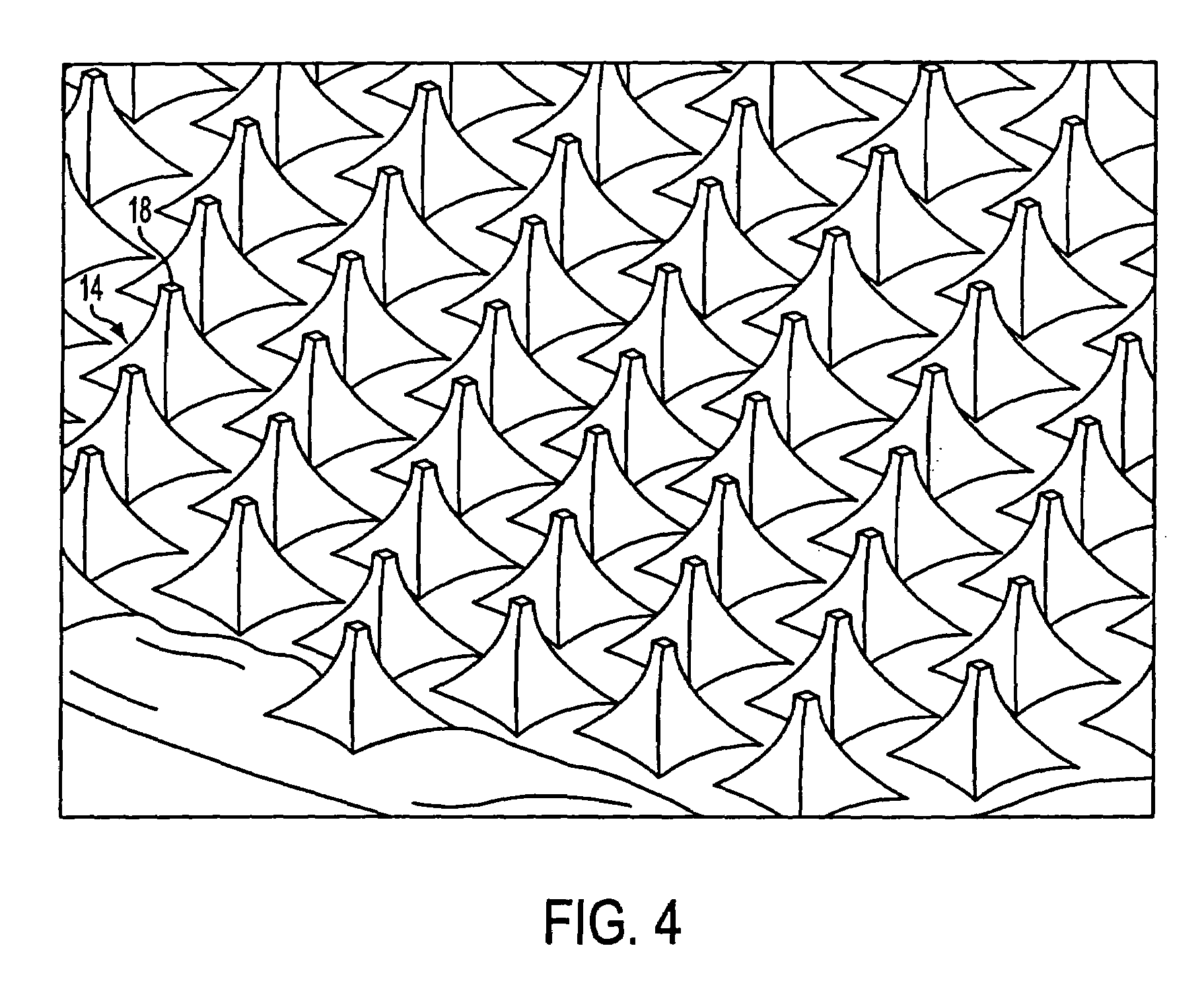

Substance delivery via a rotating microabrading surface

ActiveUS7166086B2Increase gene expressionEnhance immune responseSurgical needlesMicroneedlesPhysical therapyDermatomal

A method and device for the delivery of a substance into skin via the rotational movement of a microabrader device reduces the effects of operator variability. The method includes applying a substance to an area of a patient's skin through the rotational movement of microprotrusions which may be imparted by a spring device present in the microabrader device or the motion of the operator through the handle of the microabrader device. The device may further include system and methods for monitoring pressure of the device against the skin and thereby promote consistency between applications and control of penetration depth. The delivered substance may be placed on the microprotrusions and a reconstituting liquid included in the microabrader device.

Owner:BECTON DICKINSON & CO

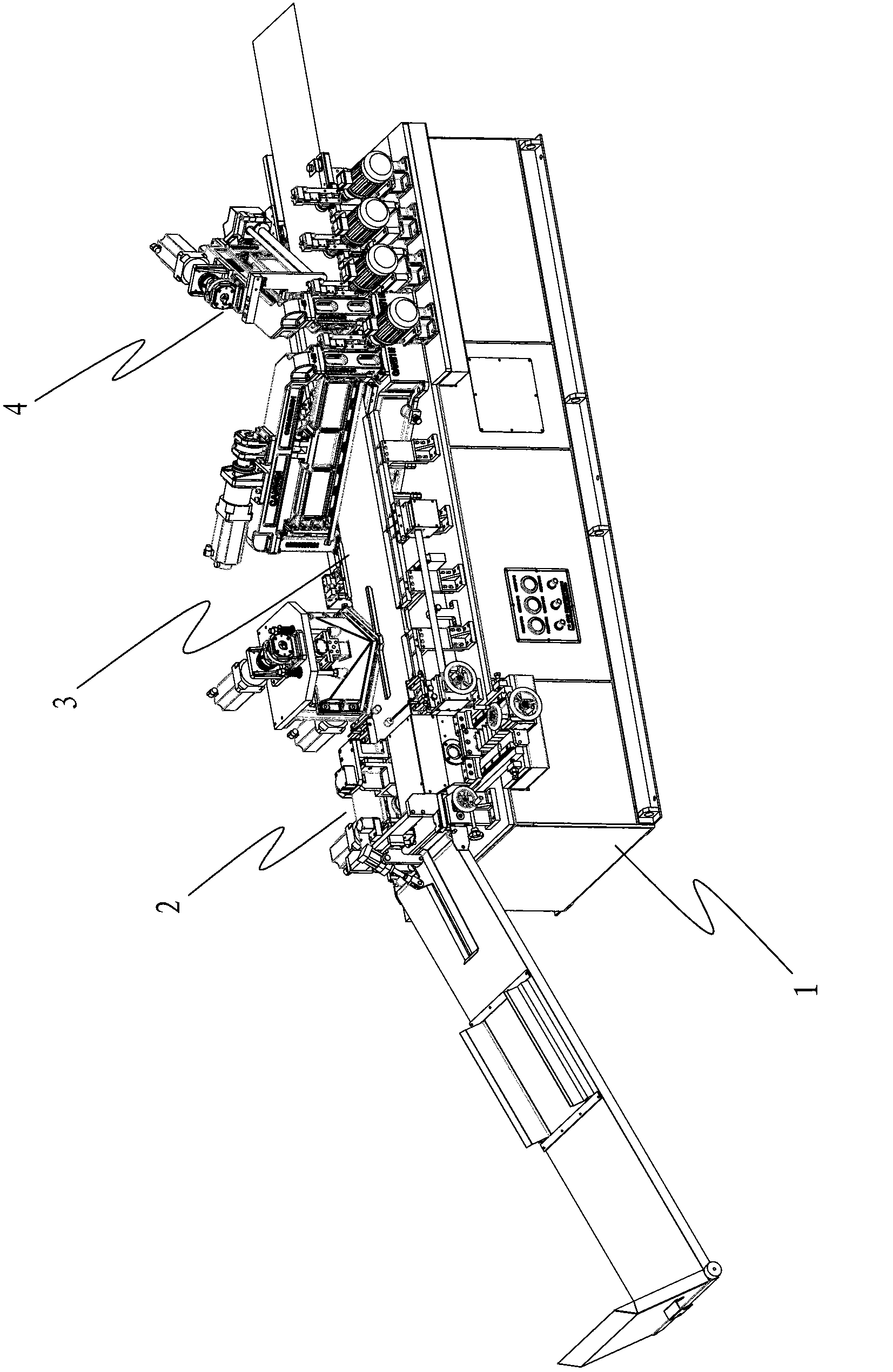

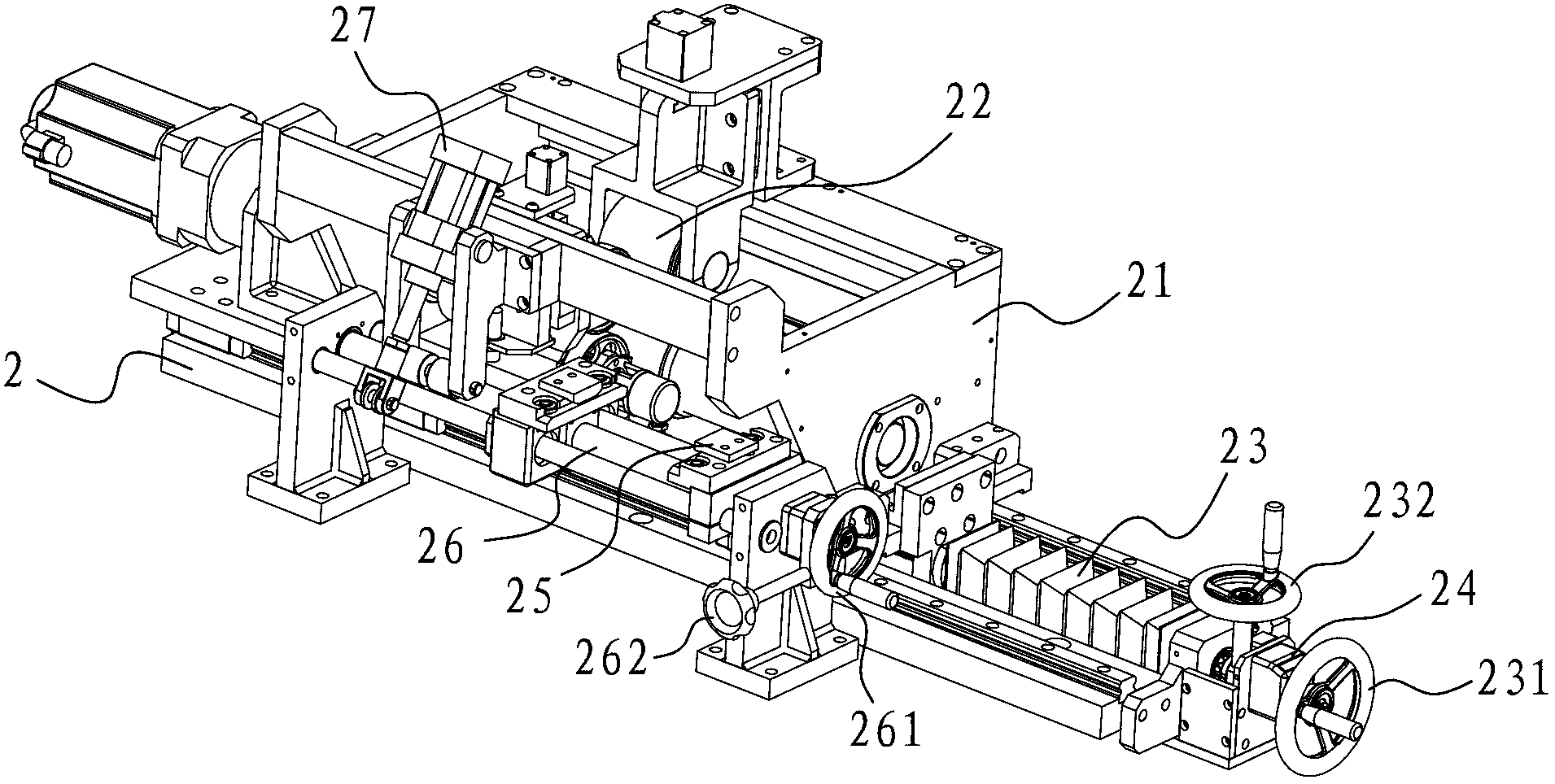

Movable central positioning feeding numerical control shearing machine

ActiveCN103212648AReduced mobilityMove preciselyMetal-working feeding devicesPositioning devicesNumerical controlEngineering

The invention discloses a movable central positioning feeding numerical control shearing machine which comprises a machine base, wherein a feeding mechanism, a conveying channel and a shearing mechanism are installed on the machine base, the feeding mechanism comprises a feeding wheel set driven by a motor, and the feeding mechanism is further provided with a transverse moving mechanism which regulates the transverse distance of the feeding wheel set; the conveying channel is installed behind the feeding mechanism, two sides of the conveying channel are provided with flanges limiting a material conveying route, and the flange on one side is fixed to serve as a material conveying base line; and the shearing mechanism comprises transverse shears and / or inclined shears which are installed above the feeding mechanism. The movable central positioning feeding numerical control shearing machine combines advantages of central positioning and single side positioning, and the feeding mechanism uses central positioning and can transversely move to conduct regulation; the conveying channel uses single side base-line positioning, and the flange on one side is fixed to serve as the base line; and when the shearing mechanism is fixed, the position of the shearing mechanism does not need to be regulated during shearing, moving inconvenience of large mechanisms can be reduced, and production efficiency is improved.

Owner:CANWIN AUTOMATIC EQUIP CO LTD

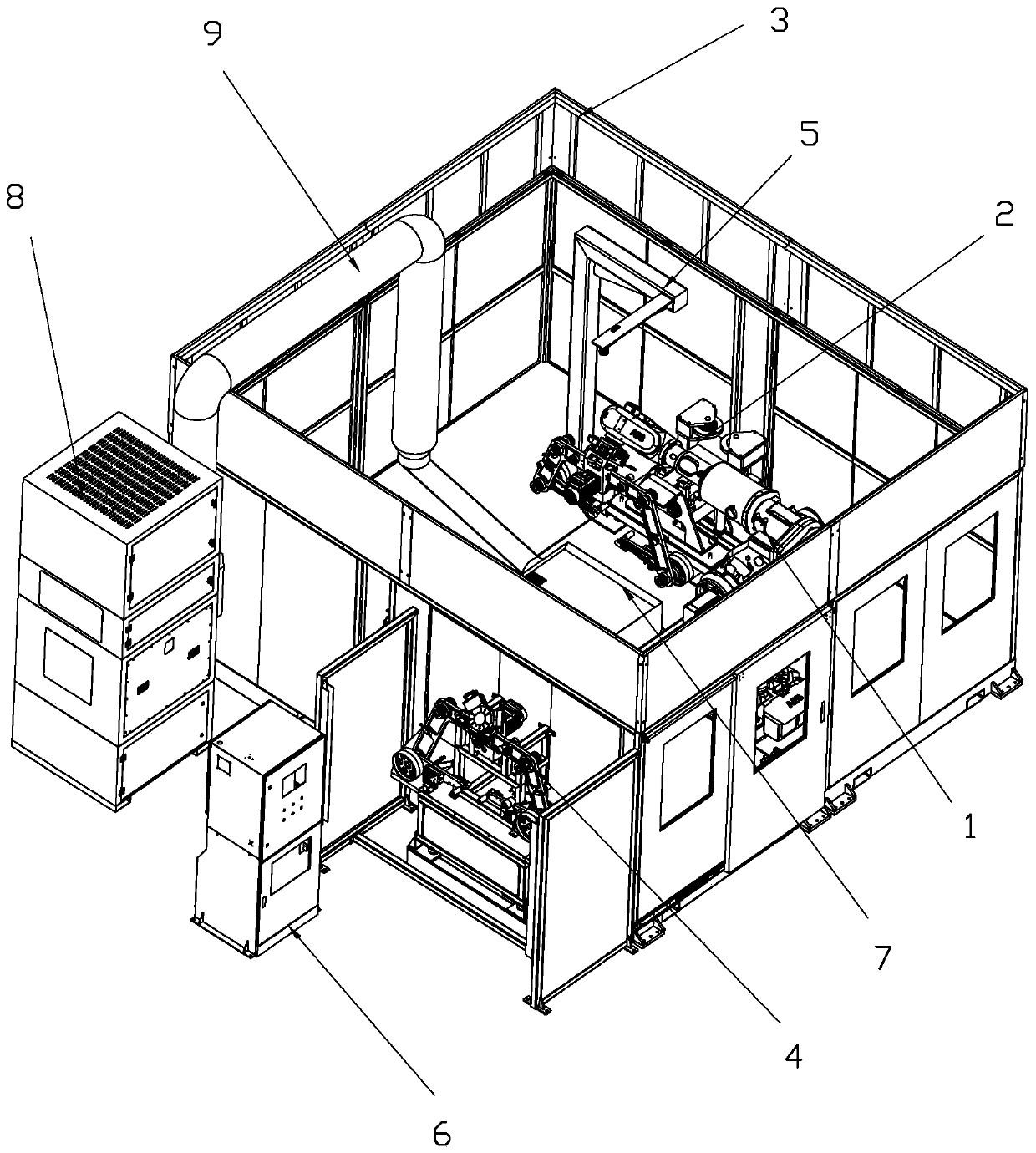

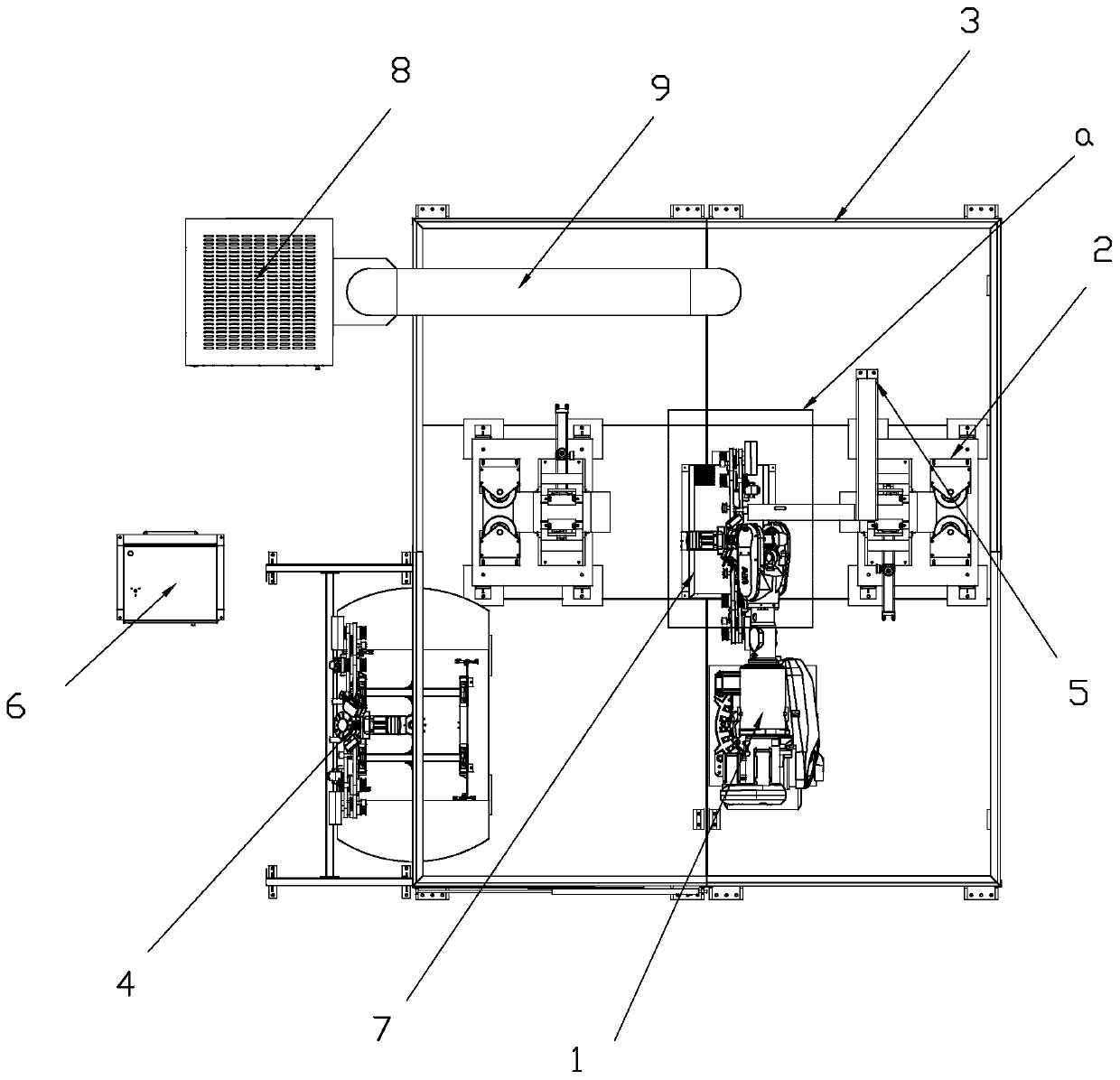

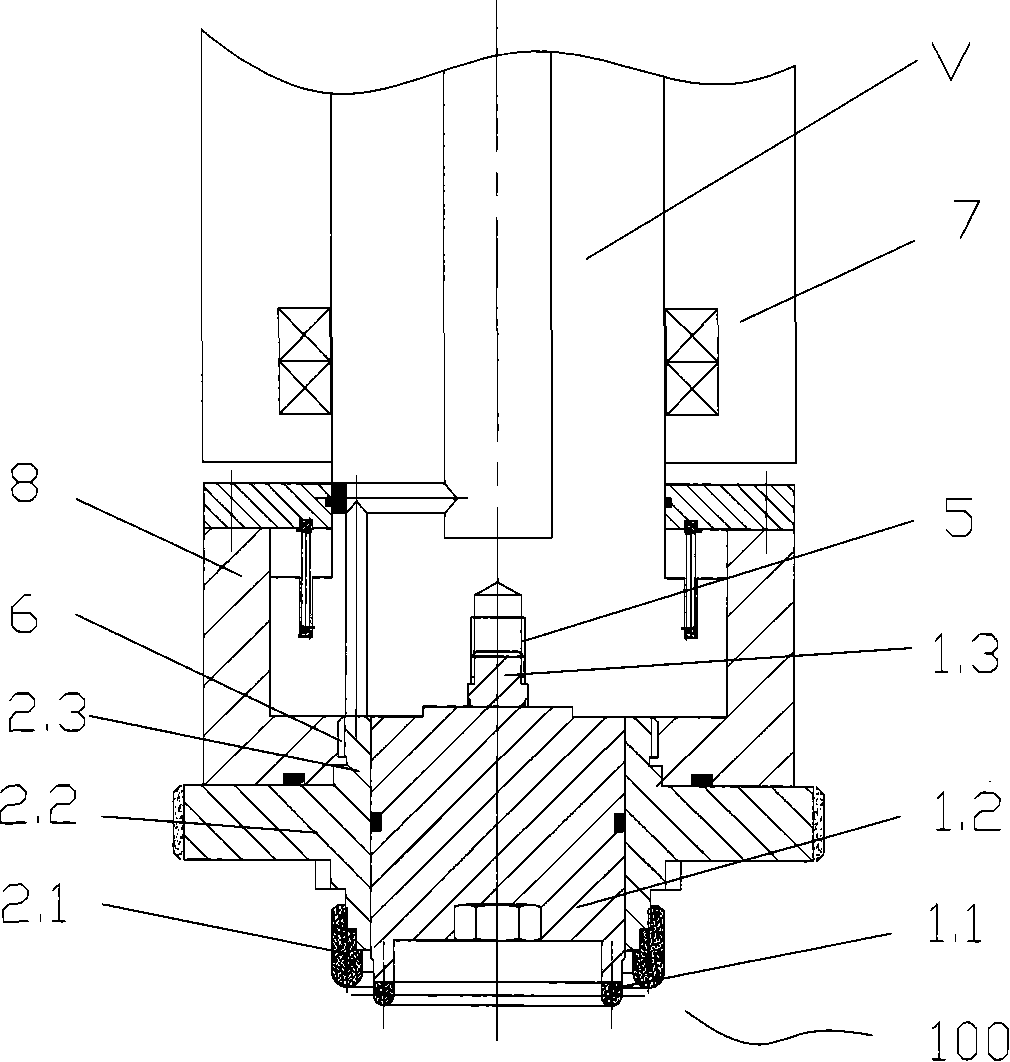

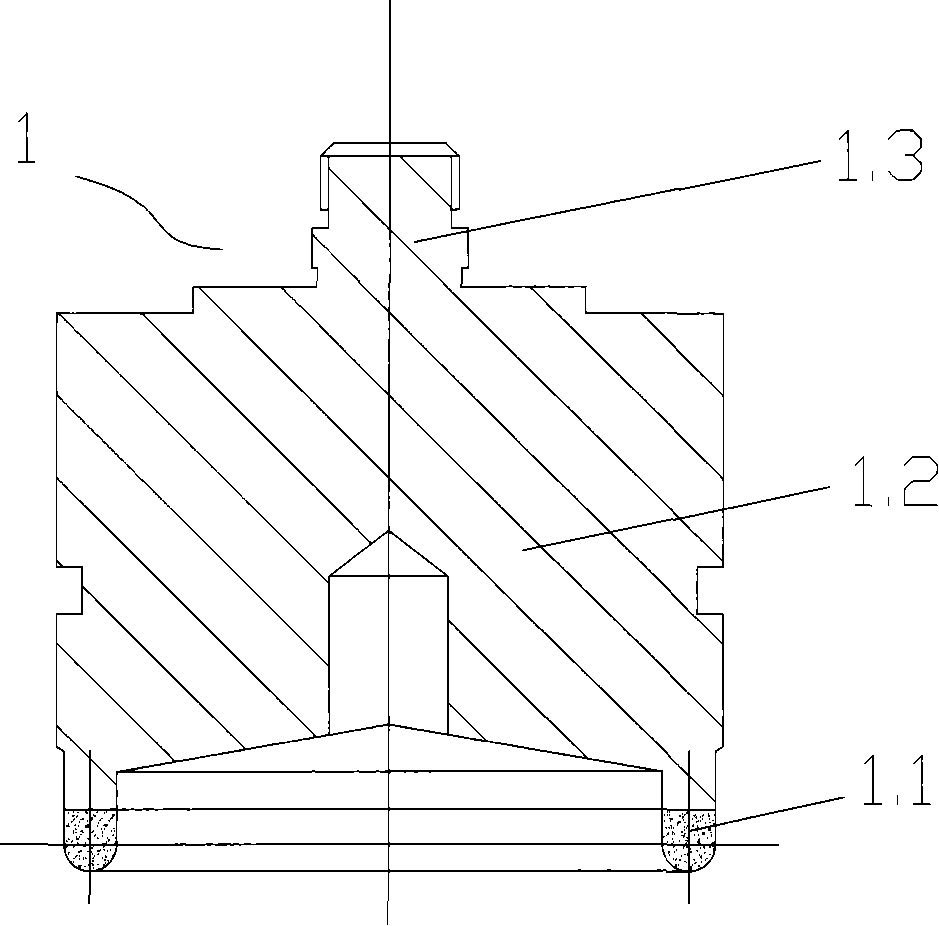

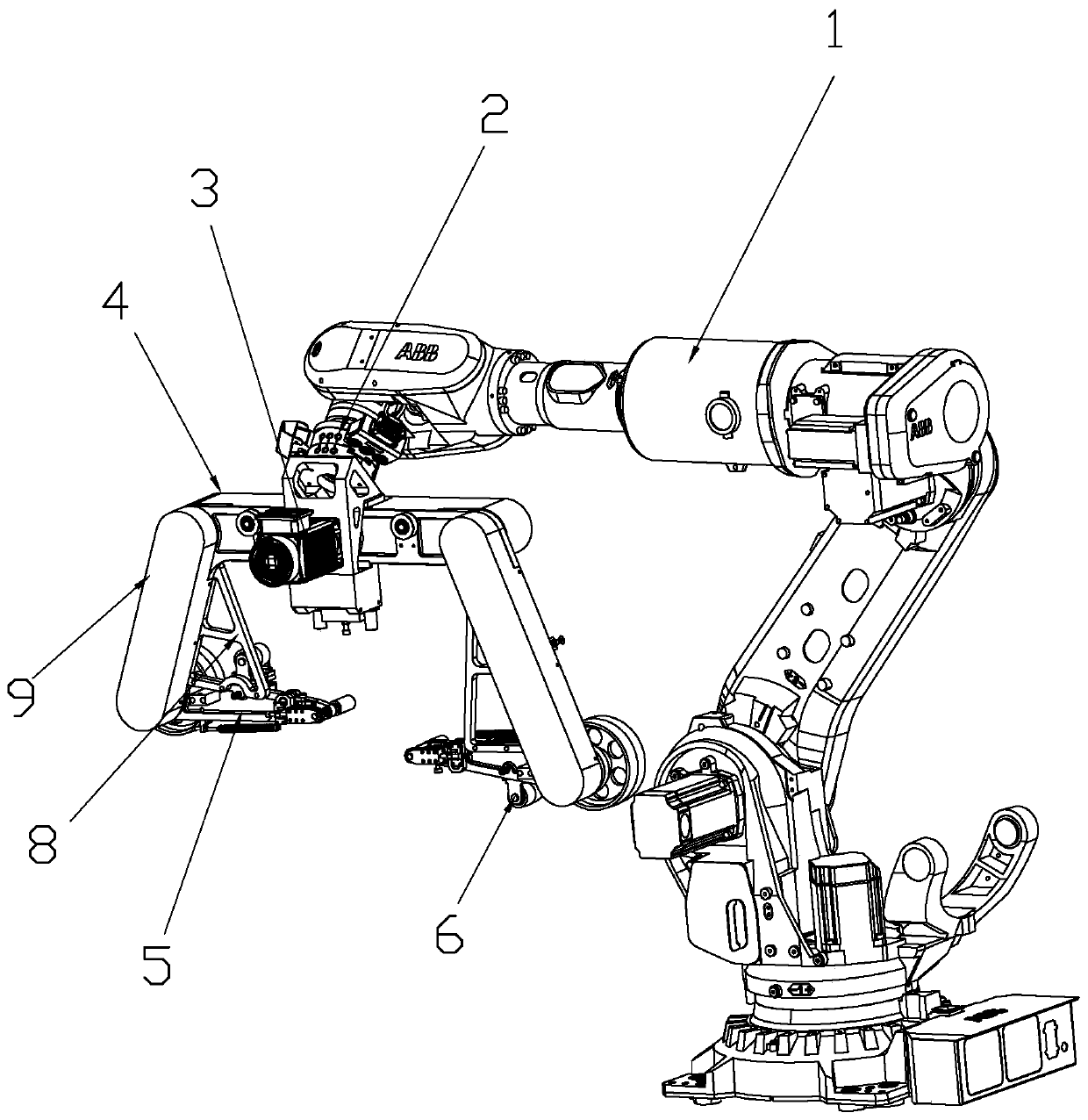

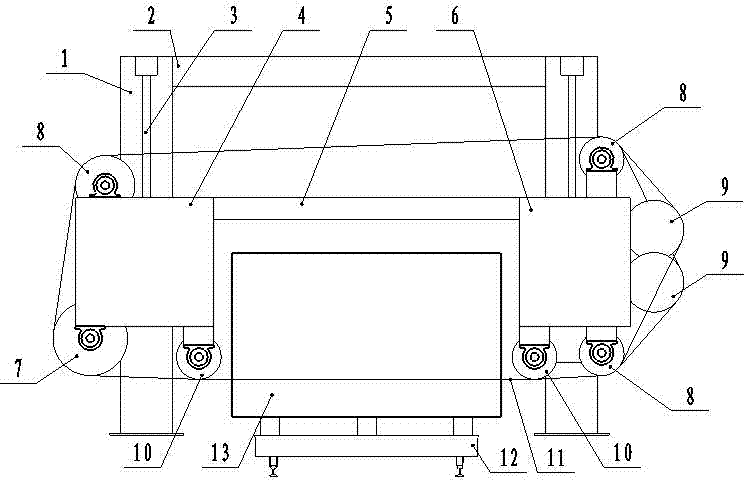

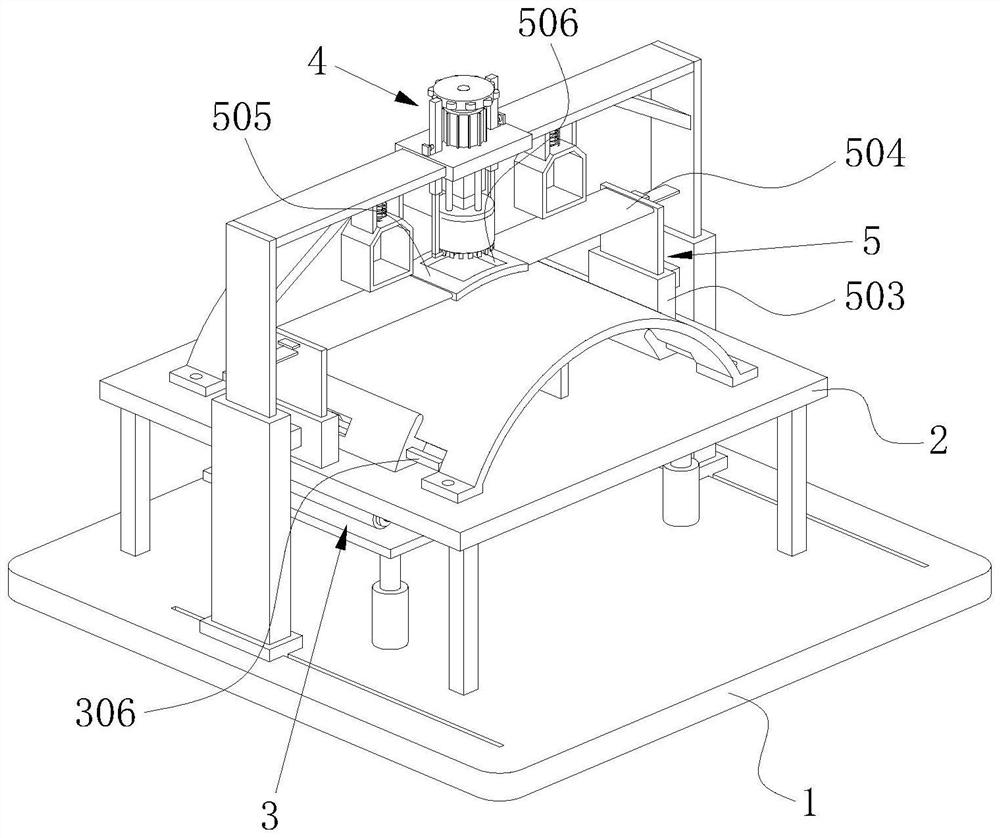

Rail polishing processing line

PendingCN110919500AExtended service lifeImprove the environmentGrinding carriagesBelt grinding machinesDrive wheelPolishing

The invention relates to a rail polishing processing line. The rail polishing processing line comprises a flexible polishing robot and a rail detection fixture. The rail detection fixture is providedwith a weld inspection mechanism and a rail clamping mechanism. The flexible polishing robot comprises an industrial robot and a flexible polishing device. The flexible polishing device comprises a connector, a driving motor, a movable support, an abrasive belt wheel, abrasive belt wheel assemblies and a transmission wheel. An output end of the driving motor penetrates through the movable supportand is provided with a driving wheel. The transmission wheel is driven by the driving wheel to drive the abrasive belt wheel assemblies at the two ends to operate. A flexible polishing space is formedin the connector. The movable support is fixedly arranged in the flexible polishing space through the driving motor and swing laterally with the driving motor as the pivot in the flexible polishing space. After the rail detection fixture finds a weld joint through the weld inspection mechanism, and a rail with the weld joint is enabled to stay in a polishing area of the flexible polishing robot by the rail clamping mechanism.

Owner:浙江珂斯顿机器人科技有限公司

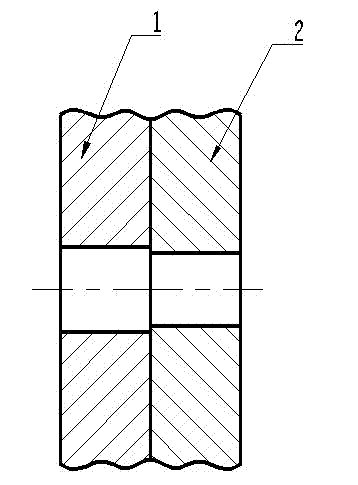

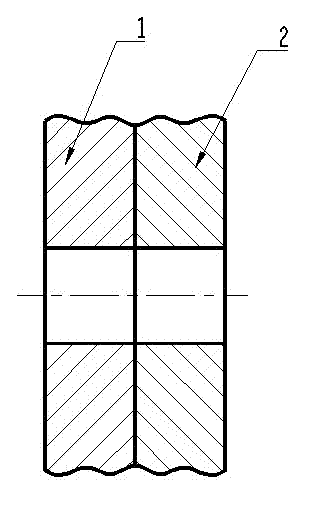

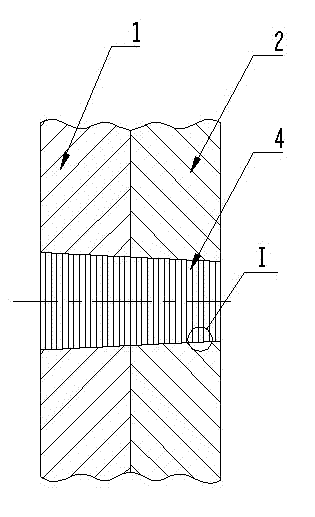

Large-diameter and high-precision taper hole processing method

The invention discloses a large-diameter and high-precision taper hole processing method, which comprises the following steps: A, aligning and tightening two parts constituting a taper hole; B, linearly pre-drilling a bottom hole on a drilling machine; C, enlarging the diameter of the bottom hole to be the same as the minimum diameter of the small end of a finished product taper hole and ensuring the position precision of the hole, D, pre-processing the bottom hole into a stepped hole (steps at all stages of the stepped hole are equidistant in the axial direction and have the same increment in the radial direction), and E, reaming the bottom hole into the finished product. The invention can effectively prevent a reamer from being damaged due to unstable cutting; since all parts of the reamer are consistent in degree of wear and uniformly stressed, the taper hole precision can be ensured stably; meanwhile, the reamer axially feeds at a step depth of the stepped hole formed through pre-processing the bottom hole, so that the reaming efficiency is improved greatly.

Owner:CHONGQING GEARBOX

Grinding device and grinder using the same

ActiveCN101244530ANo gapsImprove processing efficiencyOptical surface grinding machinesEngineeringGrinding wheel

The invention discloses a grinding device, comprising a bowl-shape outer grinding wheel, a bowl-shape inner grinding wheel and a grinding wheel shaft, which is characterized in that: the outer grinding wheel is sleeved on the inner grinding wheel; two mutually independent grinding wheel positioning interfaces are arranged on the grinding wheel shaft, which are used to arranged the outer grinding wheel and the inner grinding wheel; the inner grinding wheel is fixed on the grinding wheel shaft to do fine grinding to the workpiece; the outer grinding wheel can move up on the shaft of the grinding wheel shaft to do coarse grinding to the workpiece. The grinding device has advantages that: the processing precision is improved; the abrasion of the grinding wheel is reduced; and the production efficiency is increased. The invention also discloses a grinder which uses the grinding device.

Owner:陈耀龙

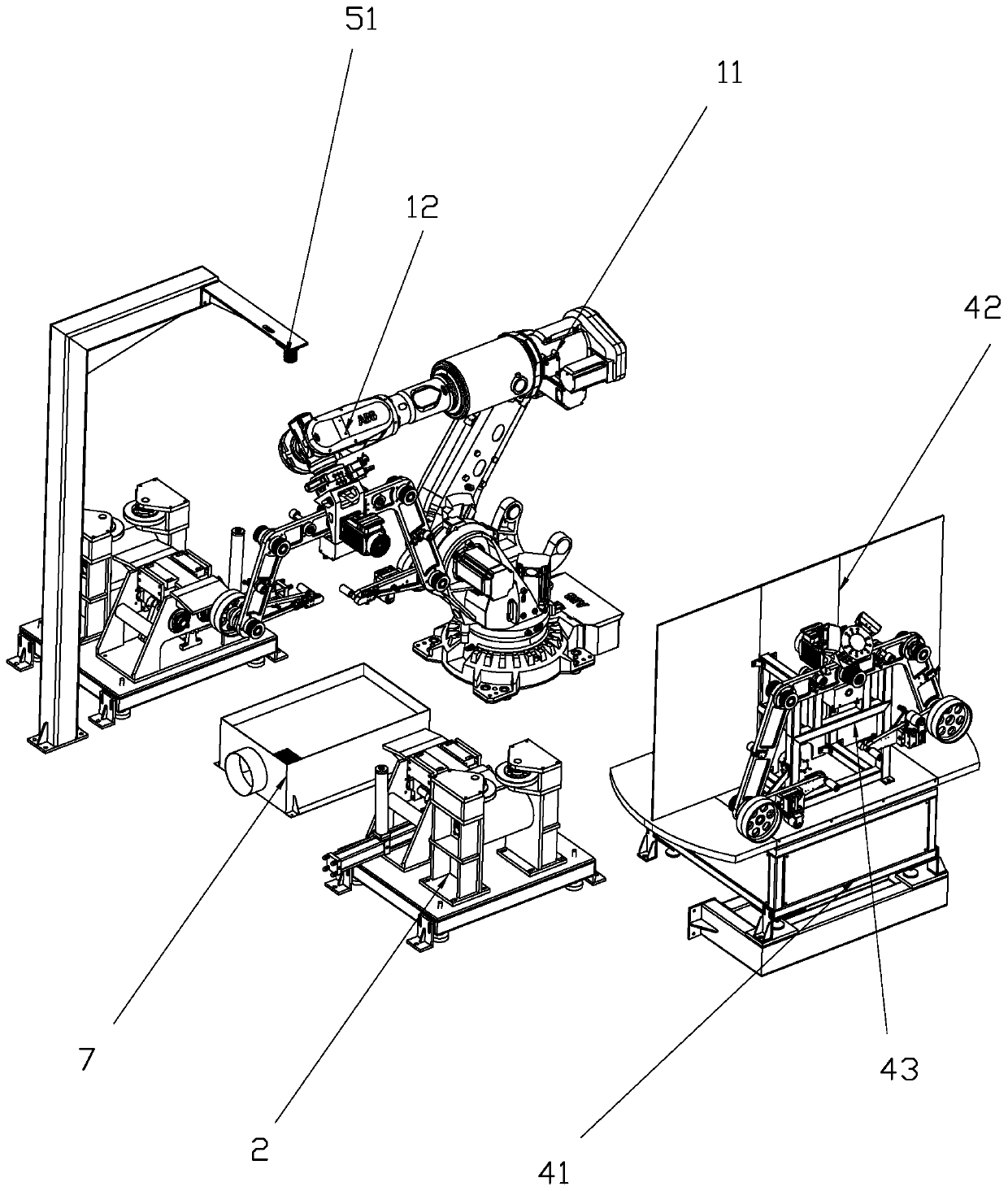

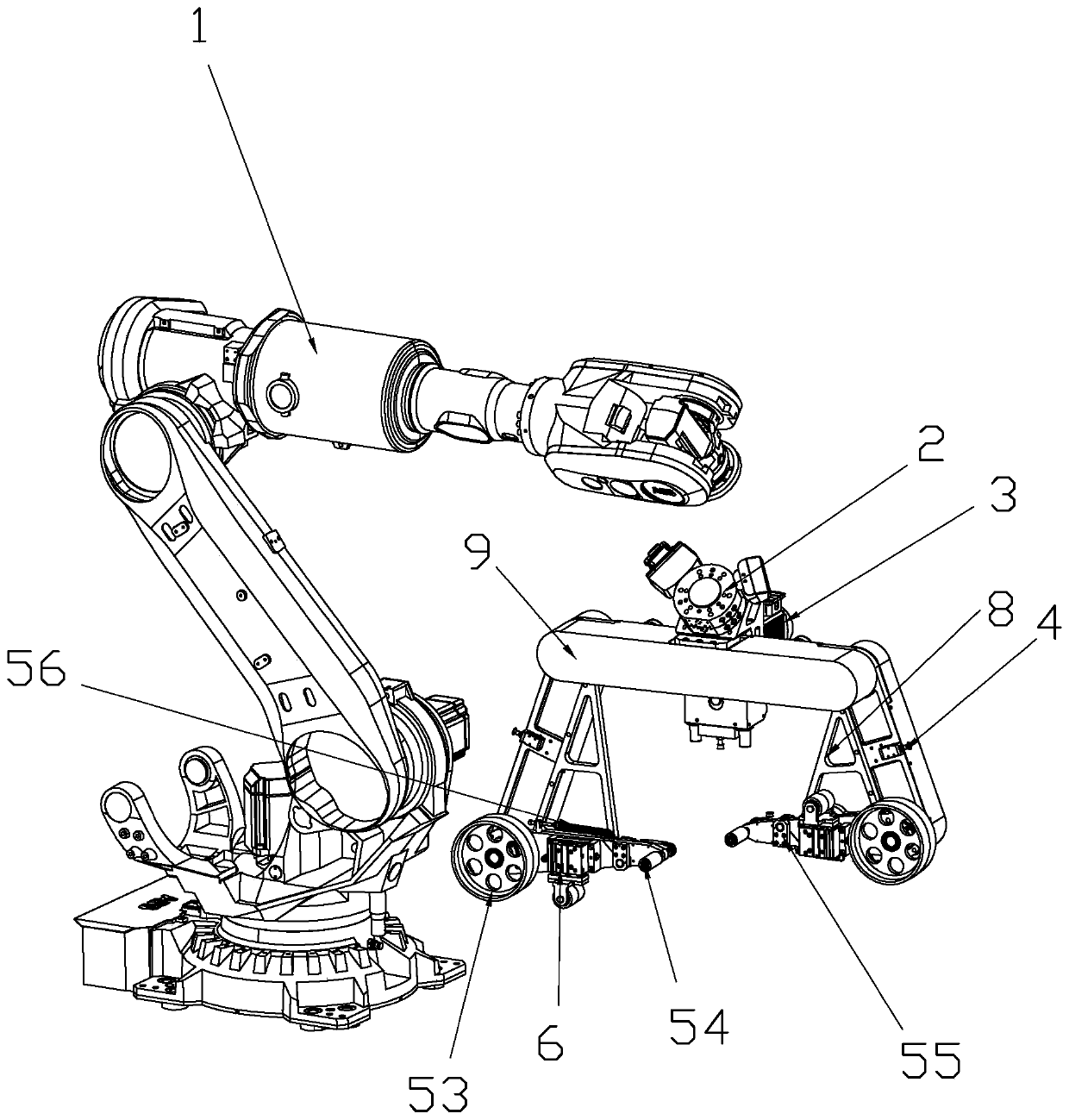

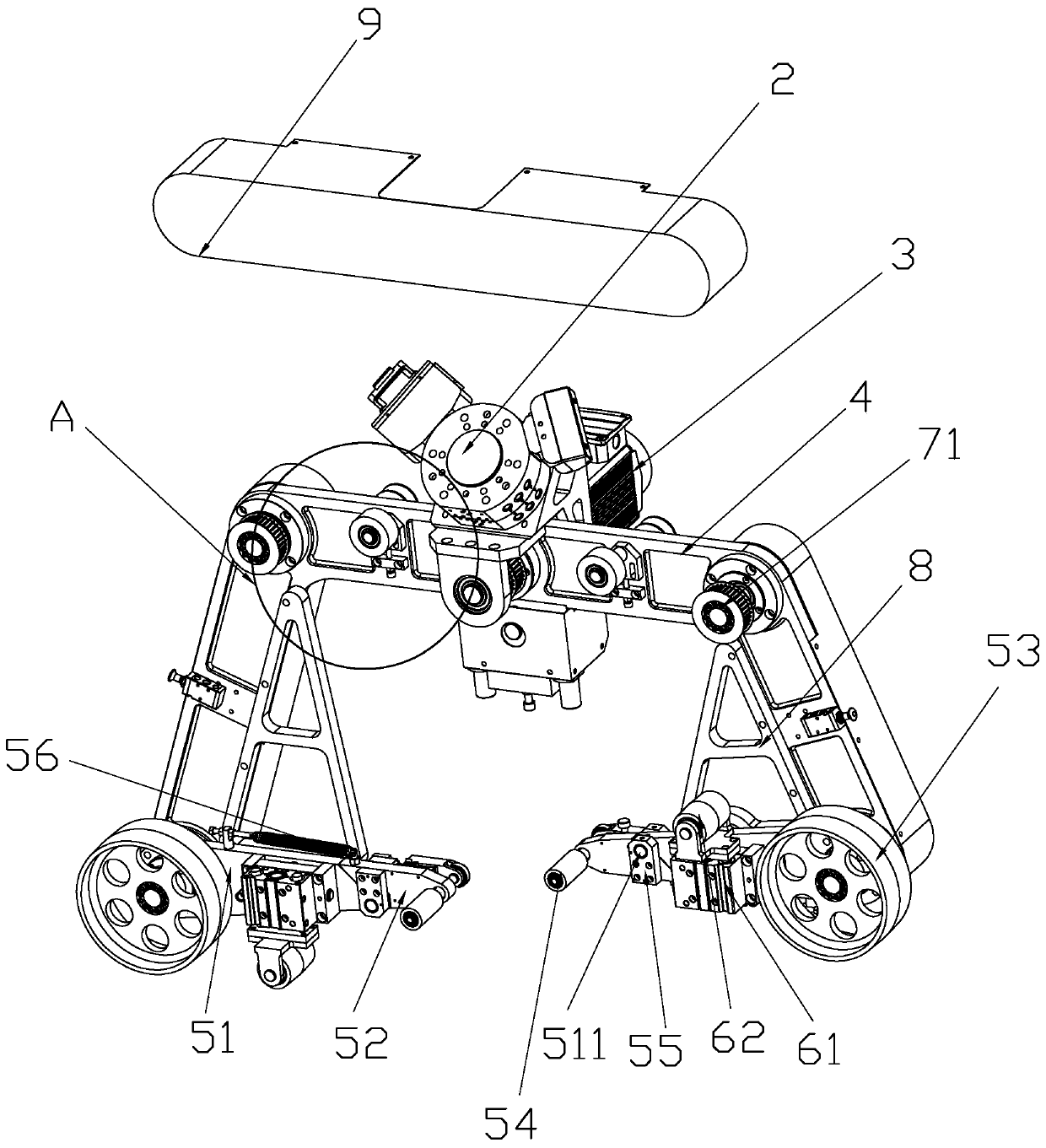

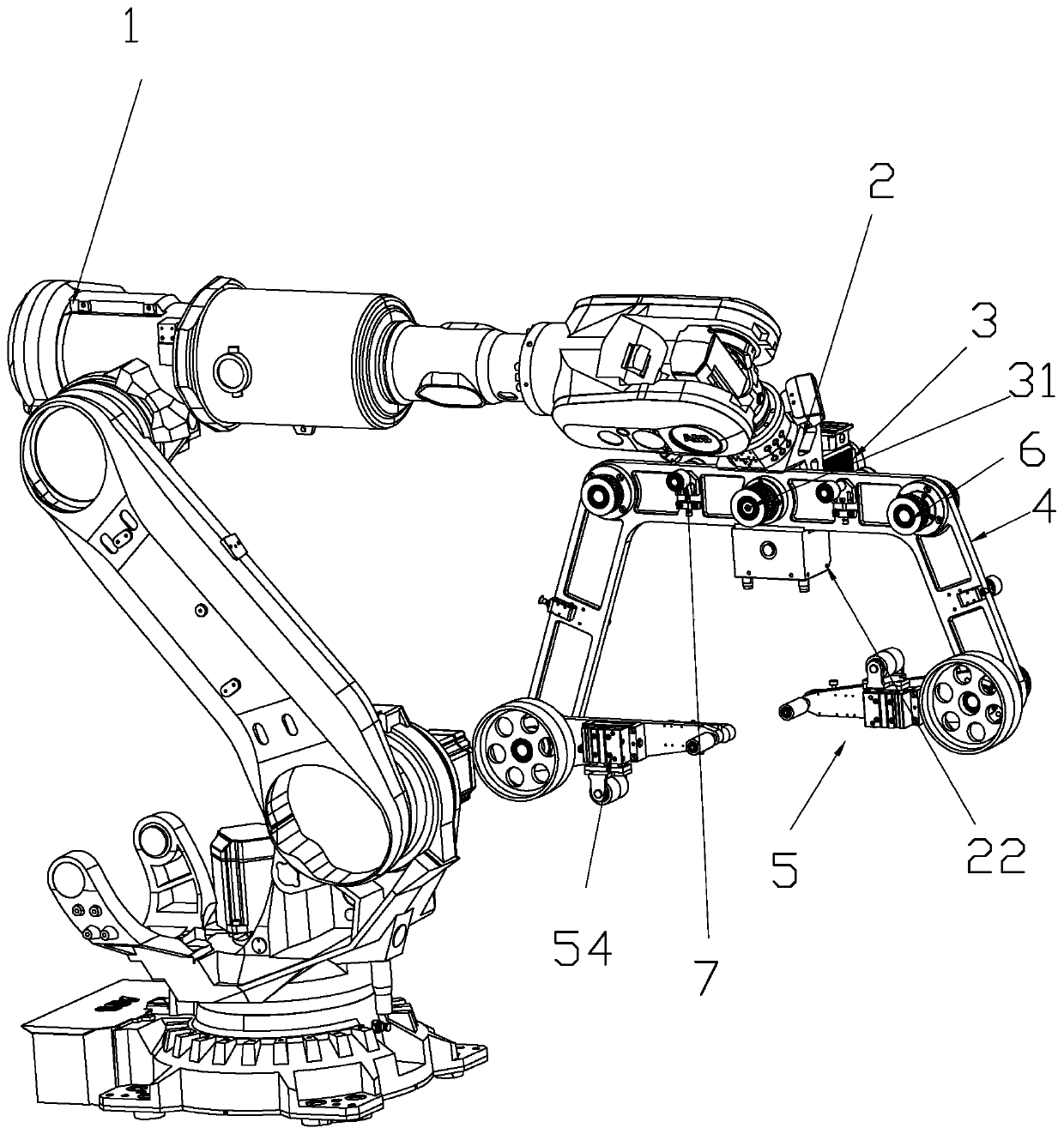

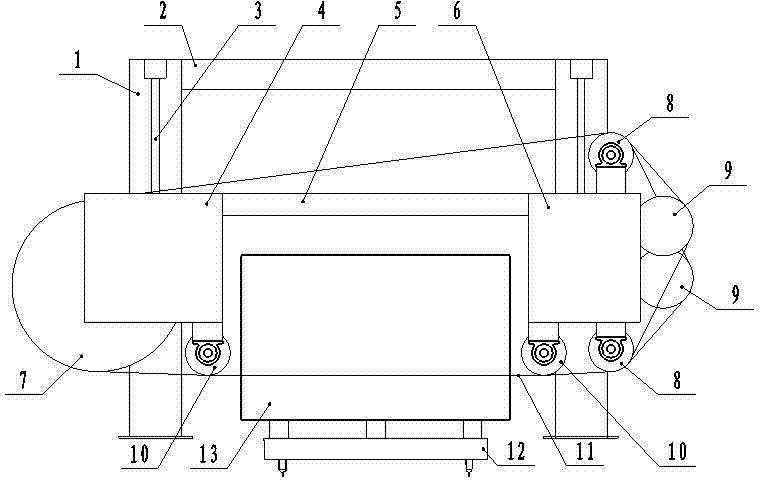

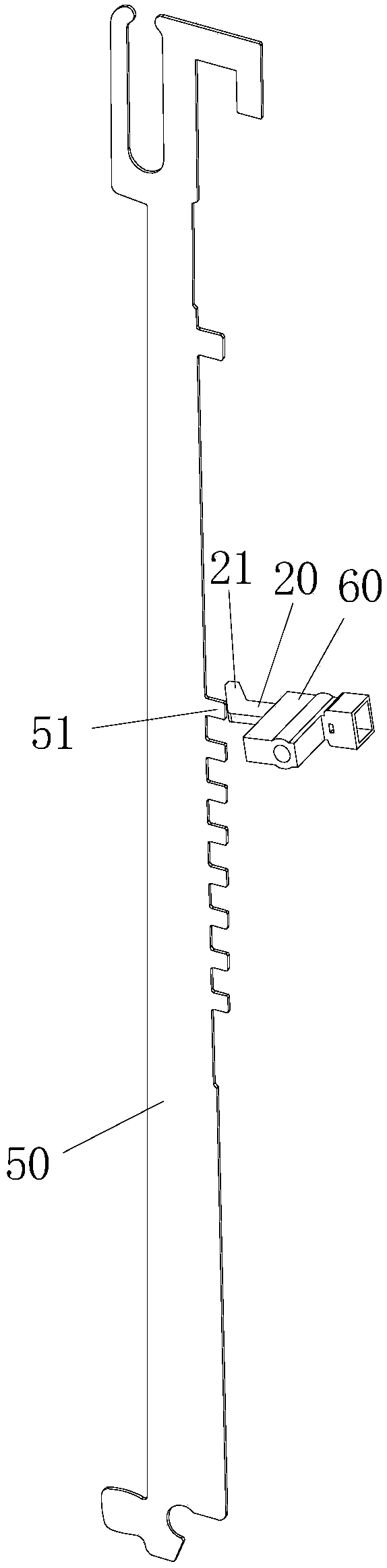

Rail weld joint grinding robot capable of achieving flexible grinding

PendingCN110977702AAvoid damageConsistent wearBelt grinding machinesManipulatorDrive wheelElectric machinery

The invention relates to a rail weld joint grinding robot capable of achieving flexible grinding. The robot comprises an industrial robot and a flexible grinding device. The flexible grinding device comprises a connector, a driving motor, a movable support and an abrasive belt wheel assembly. The output end of the driving motor penetrates through the movable support and then is provided with a driving wheel; the abrasive belt wheel assembly is driven to operate; the abrasive belt wheel assembly comprises an abrasive belt arm and a floating arm. A main wheel, a fixed wheel, a tensioning mechanism and an abrasive belt are included, a rotating column is arranged at one end of the abrasive belt arm corresponding to the floating arm; a swing block is arranged between the abrasive belt arm and the floating arm; the floating arm rotates along the rotating column through the swing block; a tension spring is arranged at the other end of the floating arm corresponding to the rotating column; oneend of the tension spring is connected with the floating arm, the other end of the tension spring is connected with the abrasive belt arm, and the floating arm achieves swing return through the tension spring. The industrial robot clamps the flexible grinding device to grind the rail, the grinding efficiency is improved, excessive grinding is avoided, the movable support can swing leftwards and rightwards, and flexible grinding is achieved.

Owner:浙江珂斯顿机器人科技有限公司

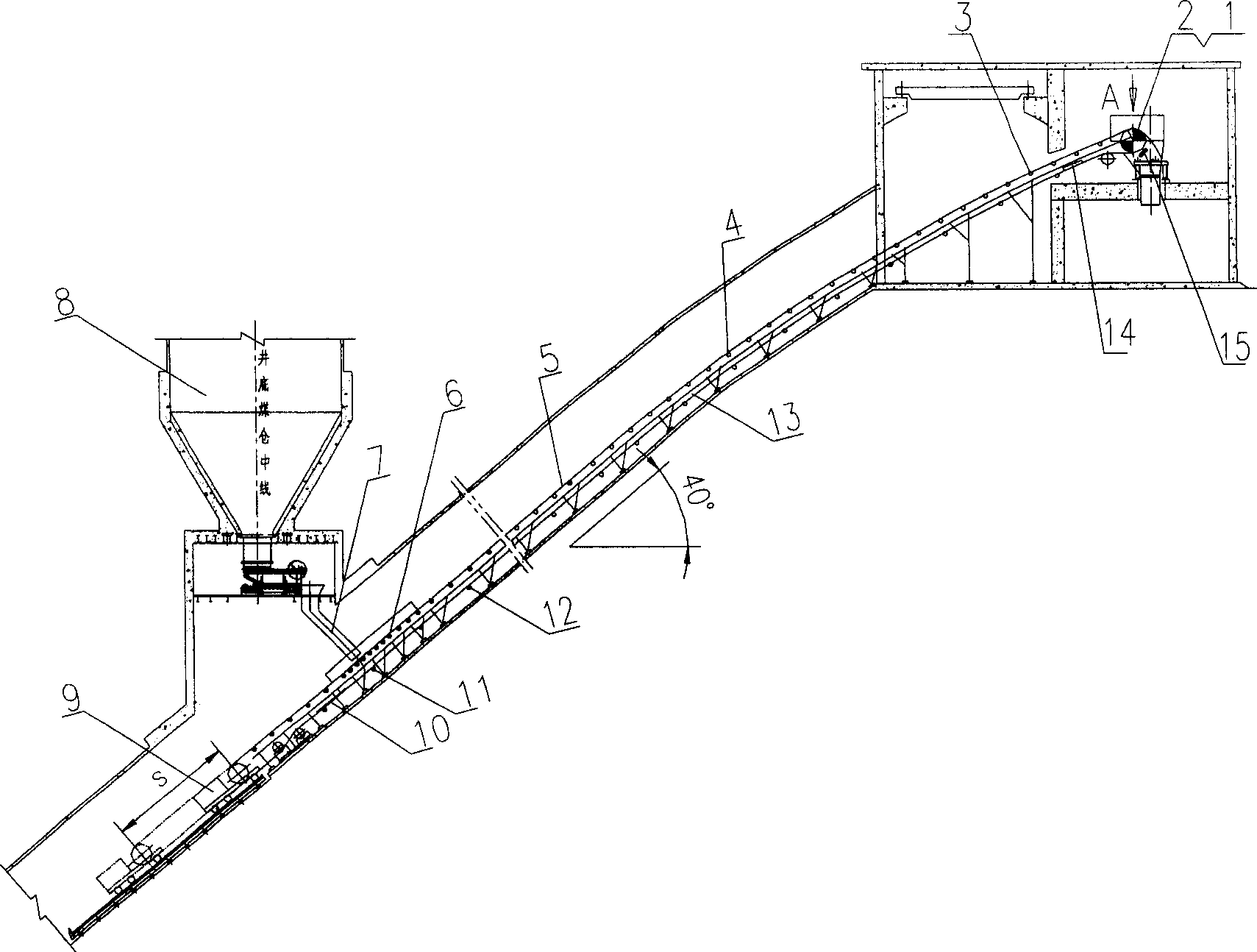

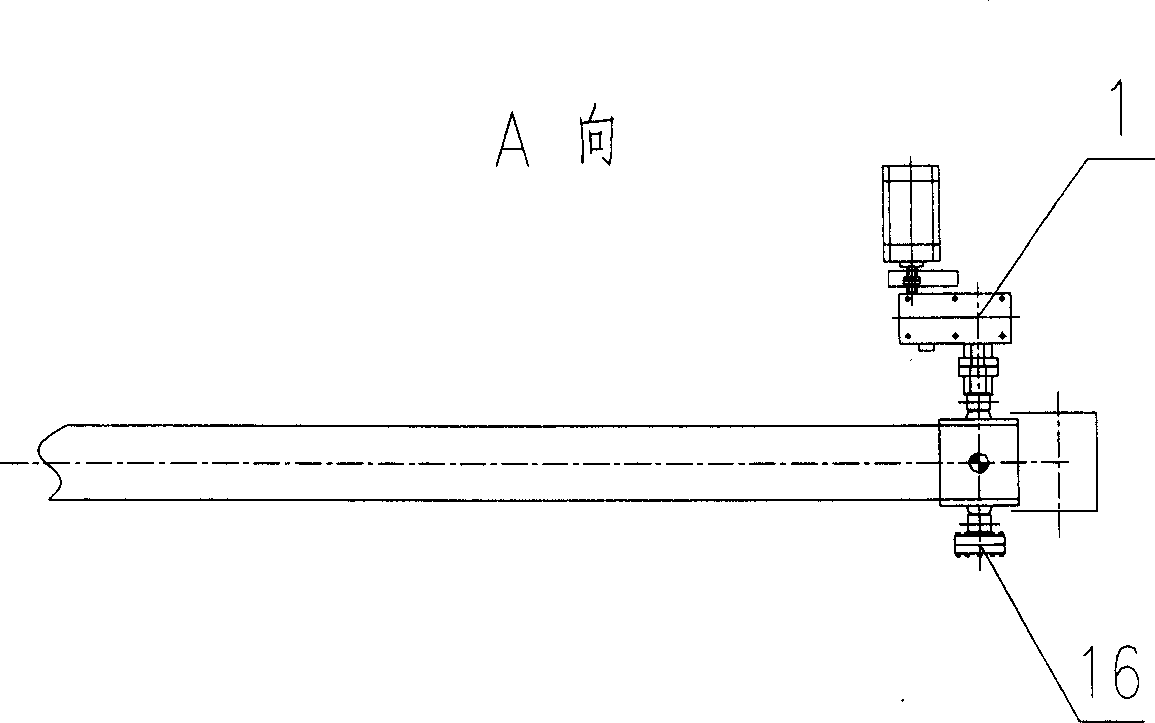

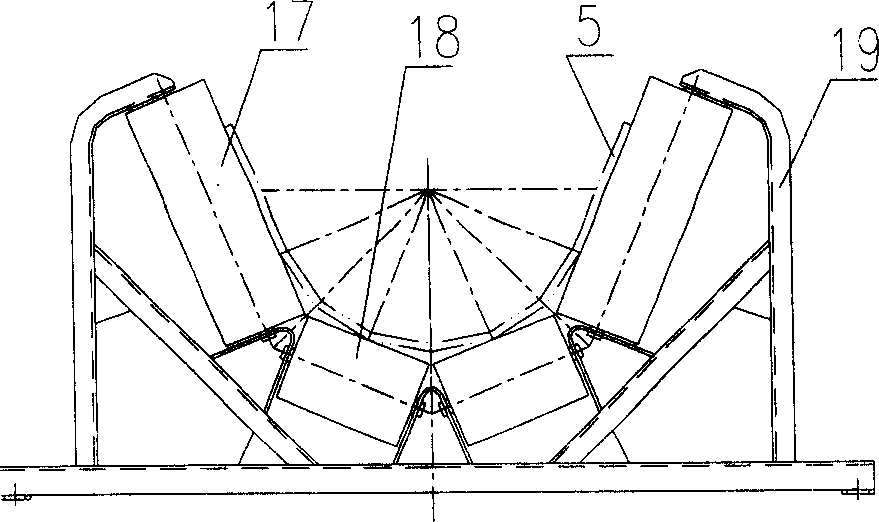

Semicircular belt conveyor with deep groove and big dig

A belt conveyer with deep semi-circular channel and big inclination up to 40 deg is composed of a machine frame, a drum group, a group of supporting rollers including central supporting rollers and side supporting rollers for rolling the conveying belt to become a deep semi-circular channel, a conveying patterned rubber belt, a carriage-type tension unit for the pull drum, and cleaning unit with brush and vibration cleaner.

Owner:SHENYANG MINING MACHINERY GROUP

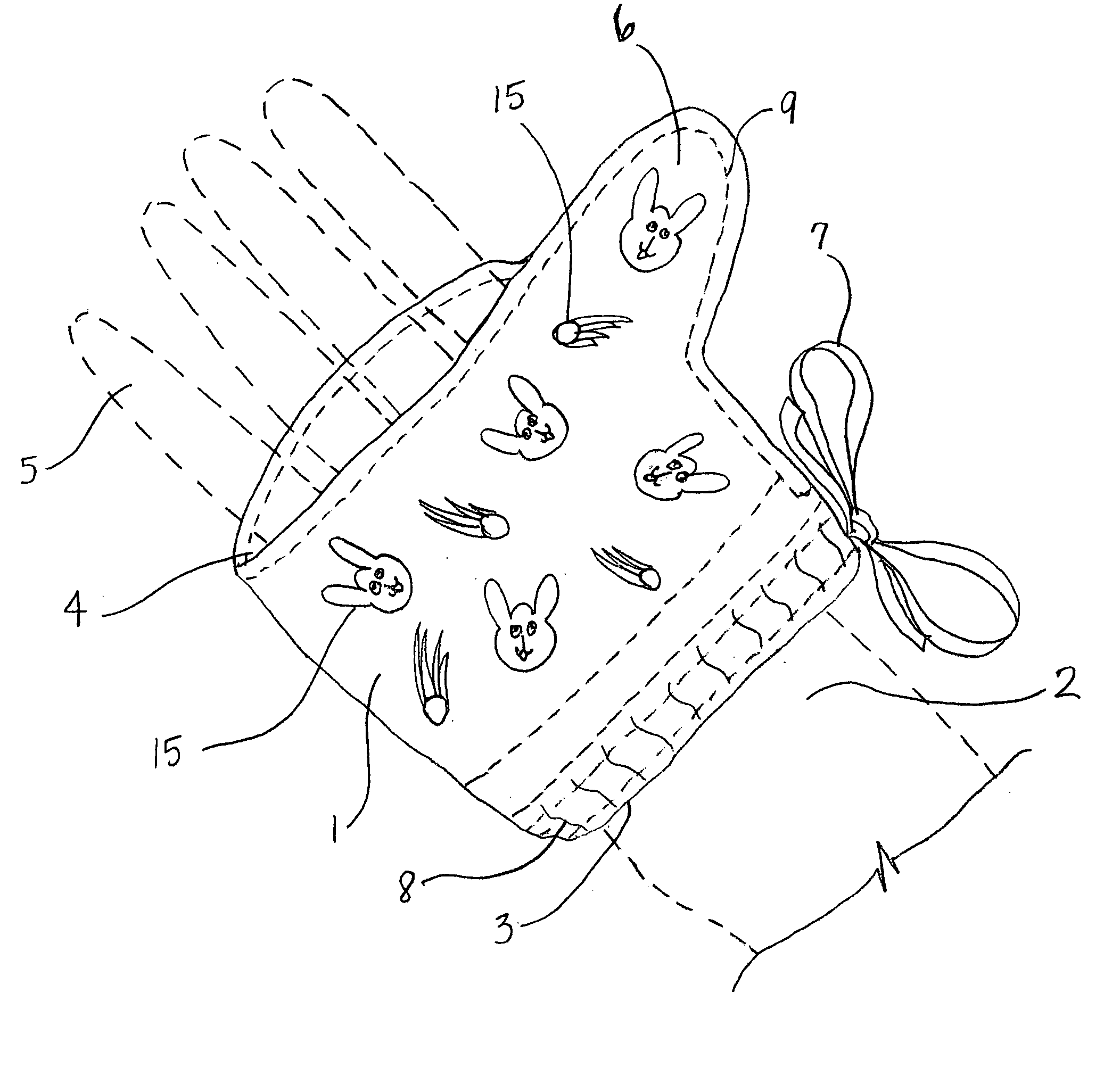

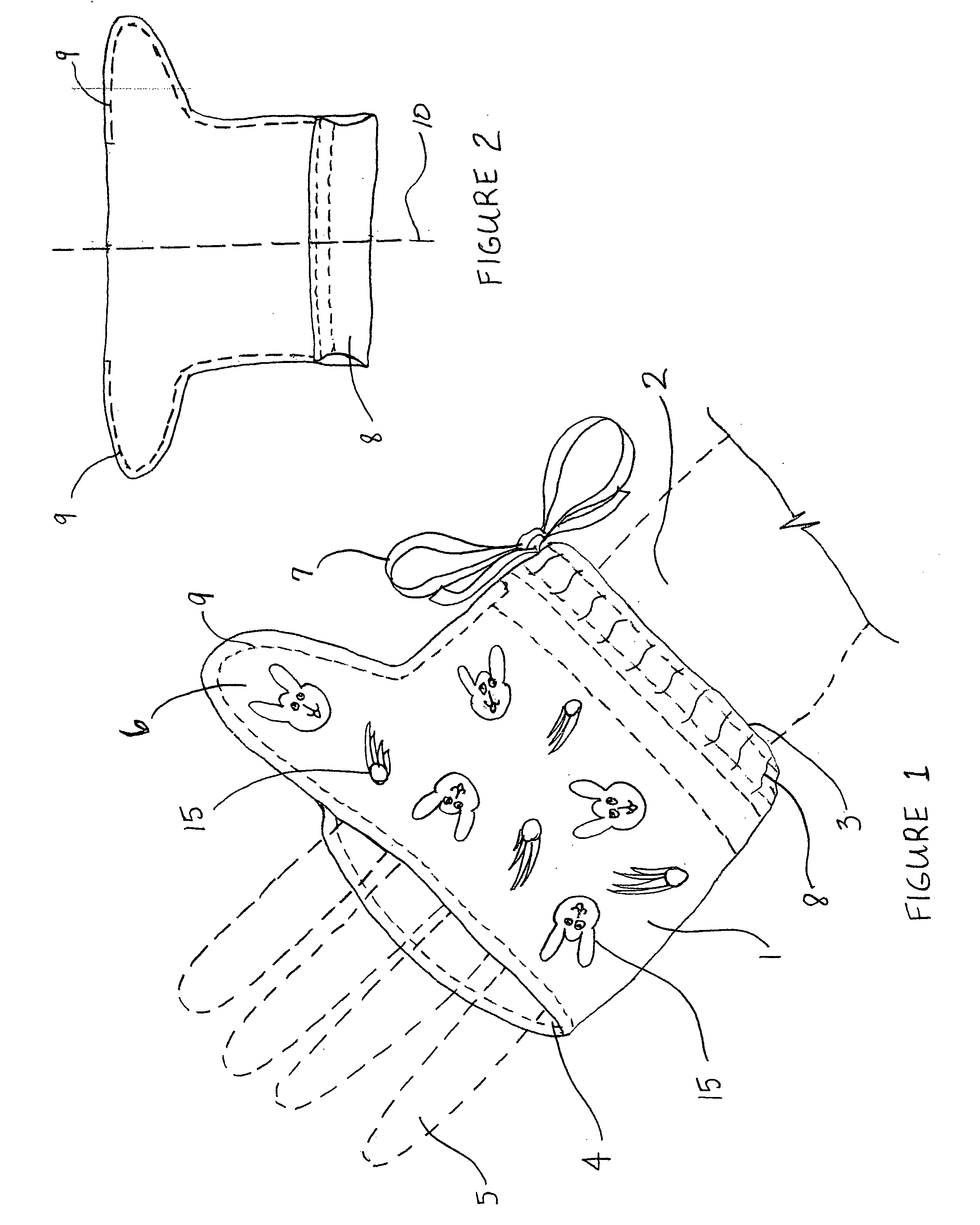

Device for the prevention of thumb sucking

InactiveUS20070028341A1Effective coverageDiscourages thumb suckingFinger sucking preventionEye treatmentThumb suckingEngineering

A device for preventing thumb sucking is provided, comprising a glove worn on a hand, wherein the glove includes a first opening for insertion of the hand, a second opening opposite the first opening for permitting uncovered use of the four fingers of the hand; a thumb covering portion for completely covering the thumb of the hand while the glove is worn on the hand; and a fastening device adjacent to the first opening for preventing removal of the glove from the hand; wherein the glove is constructed from a material containing one or more designs which are attractive to a child wearing the glove.

Owner:SMITH MICHELLE

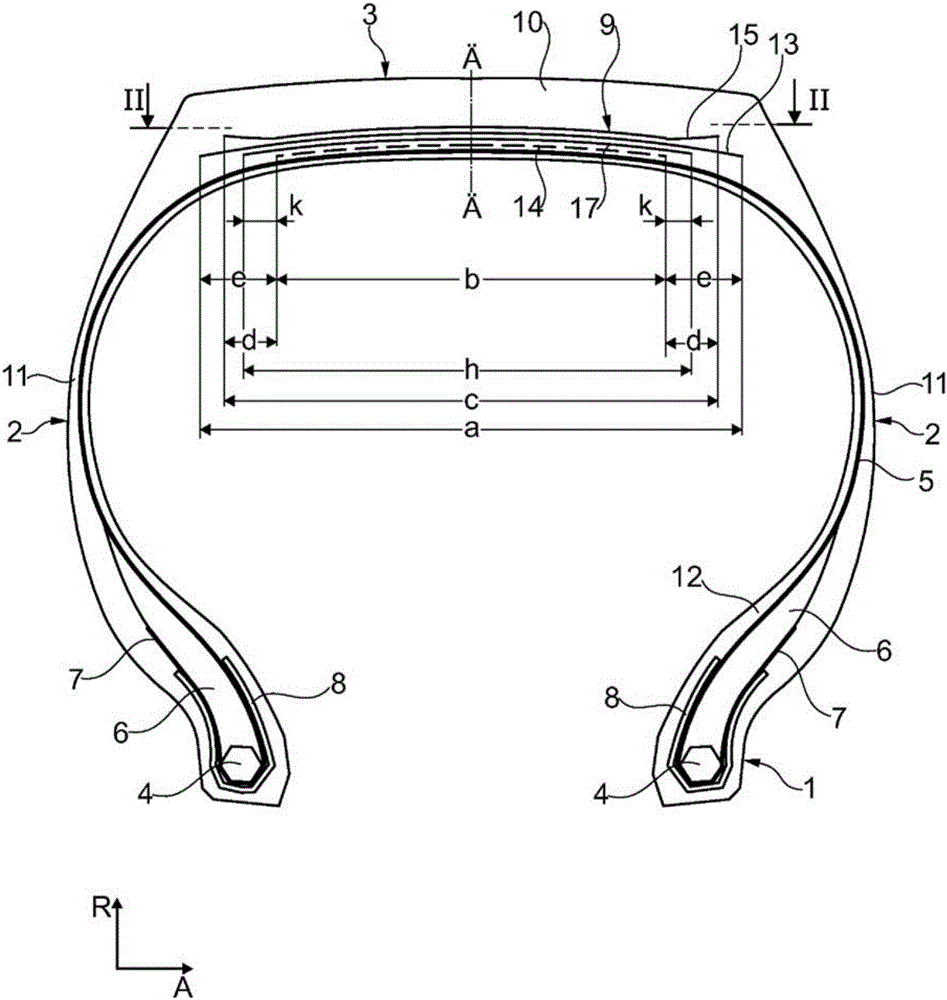

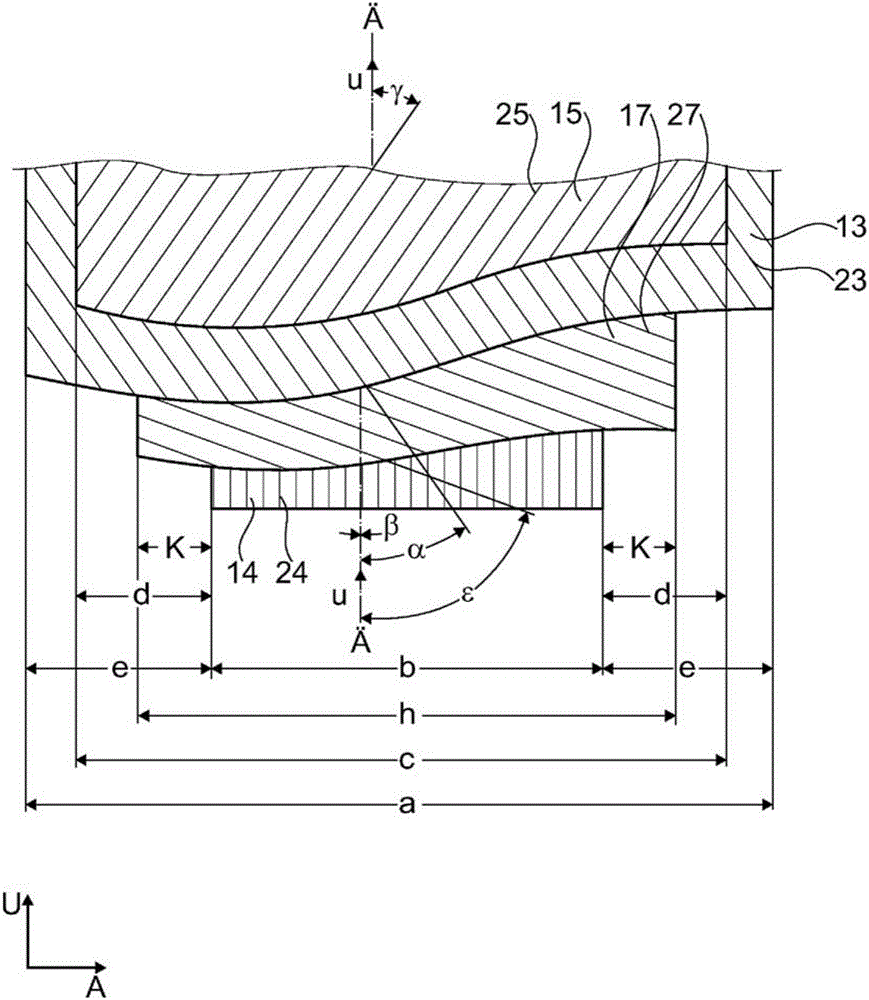

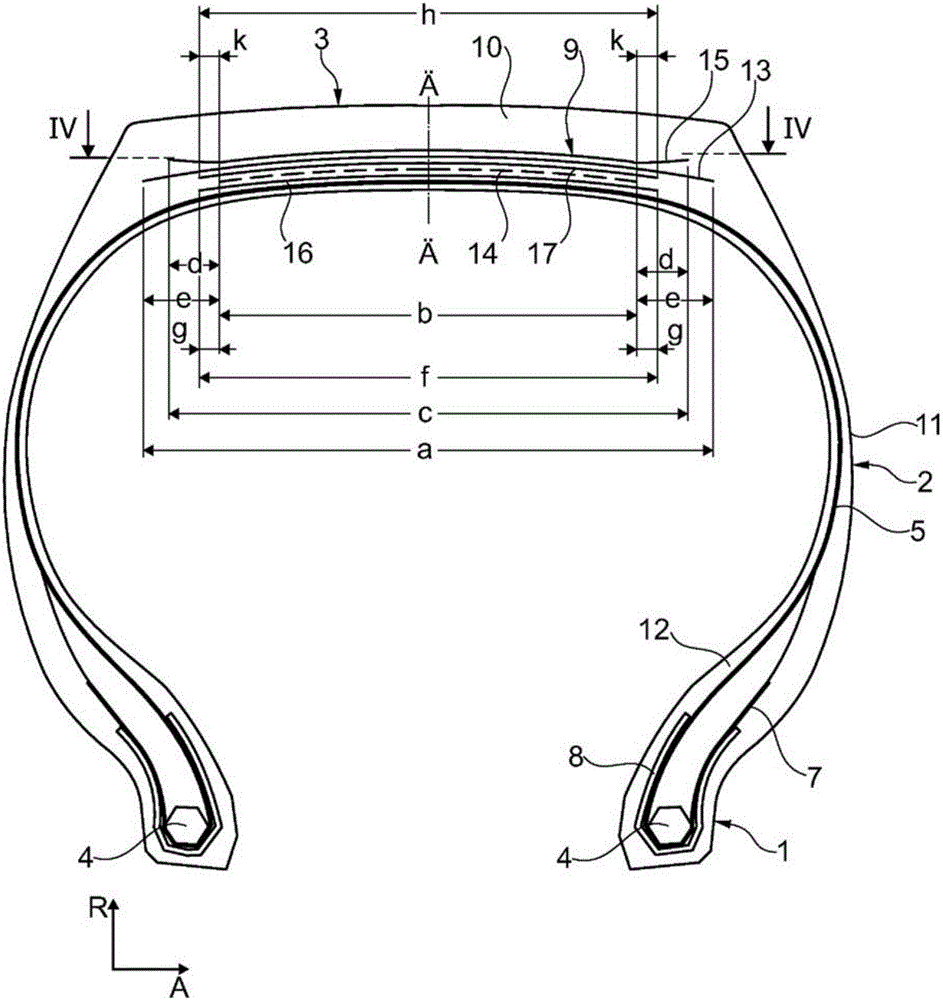

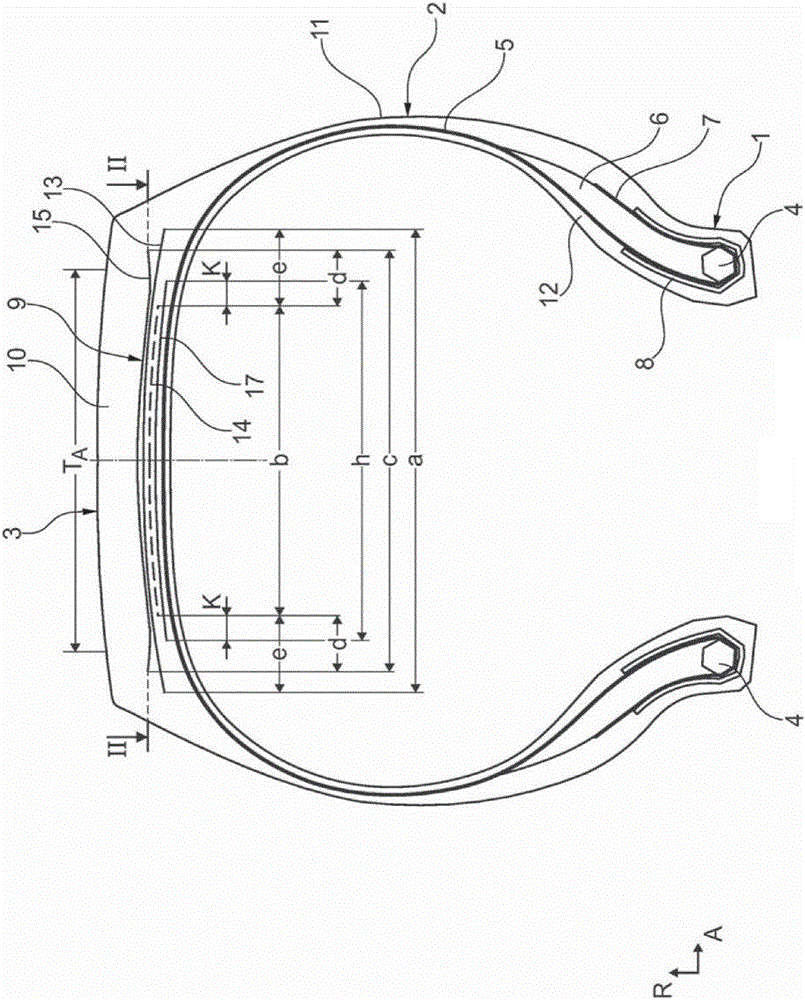

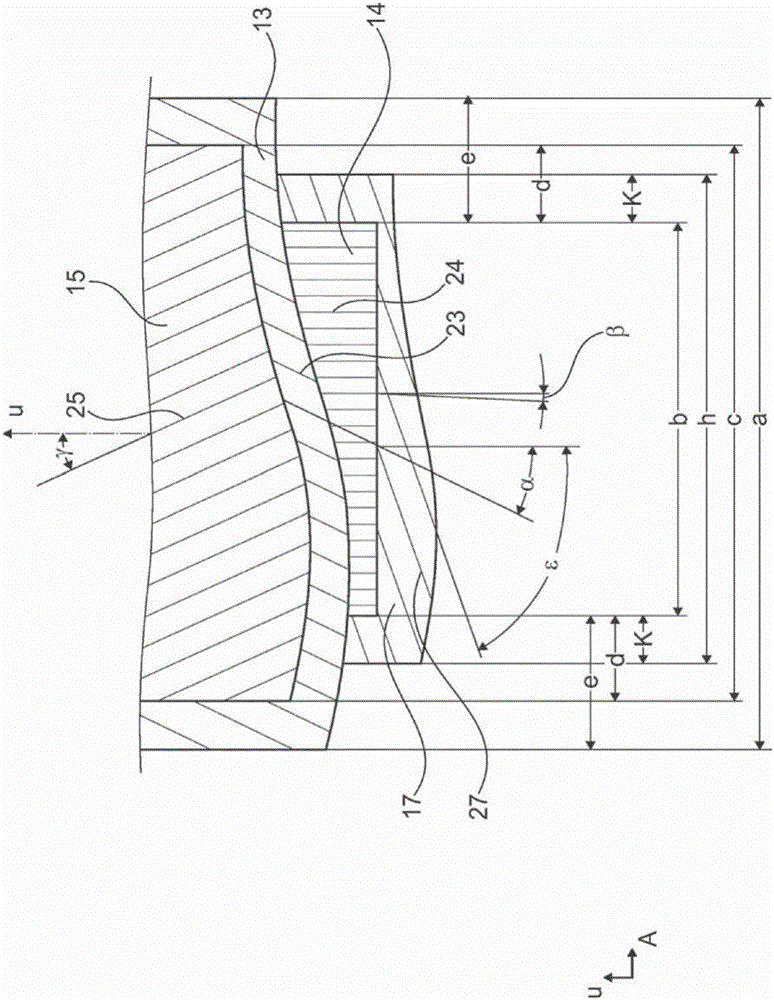

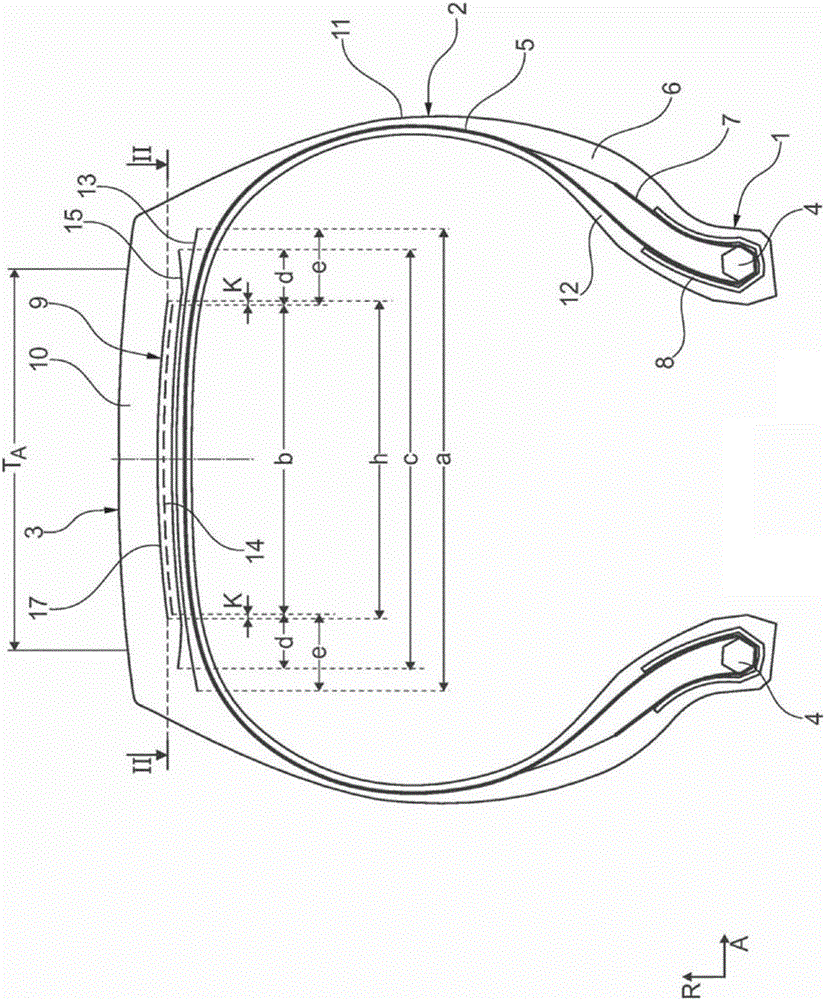

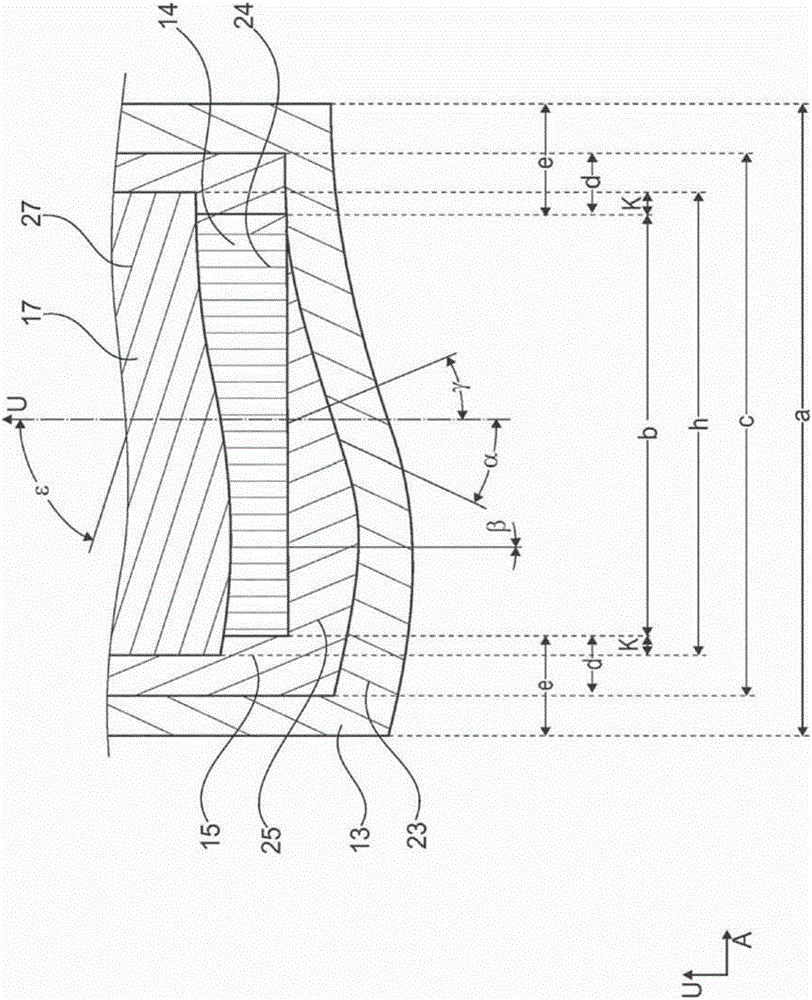

Vehicle pneumatic tyre

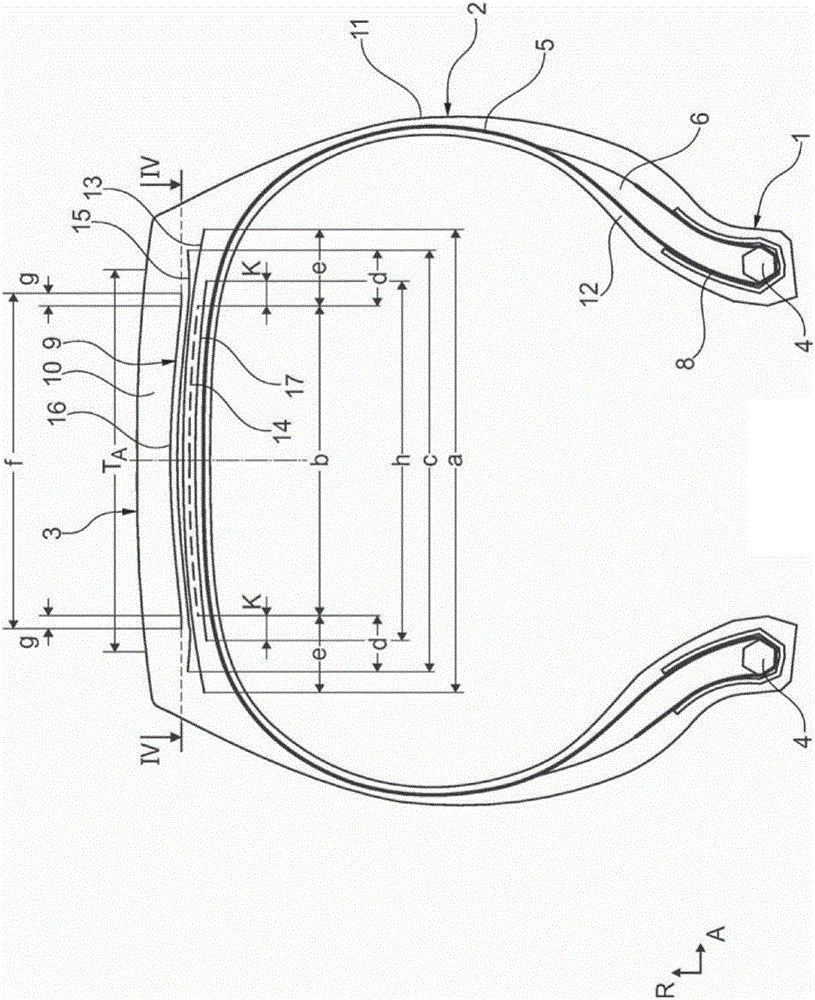

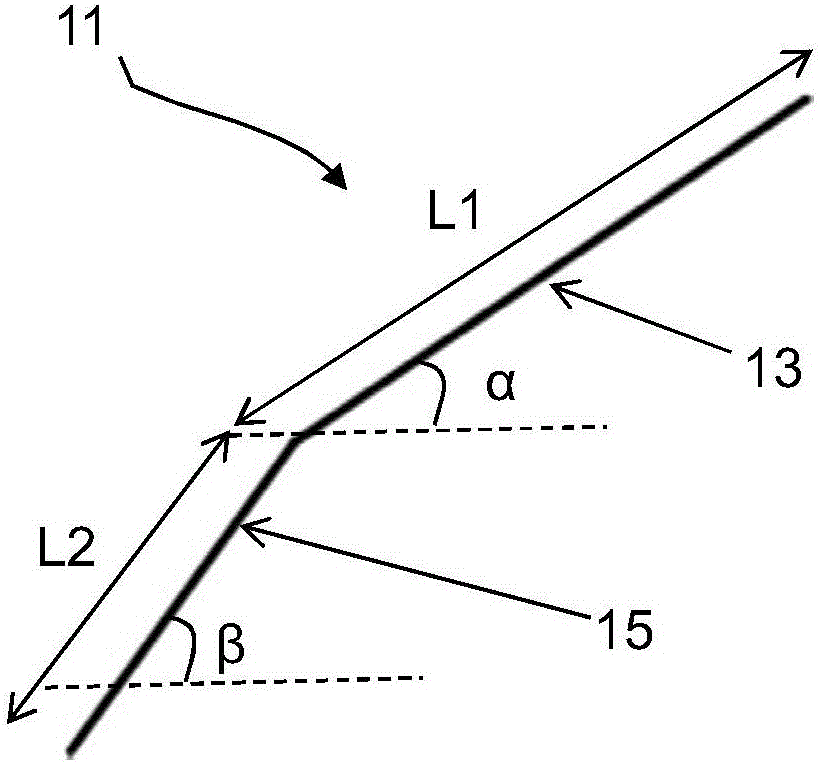

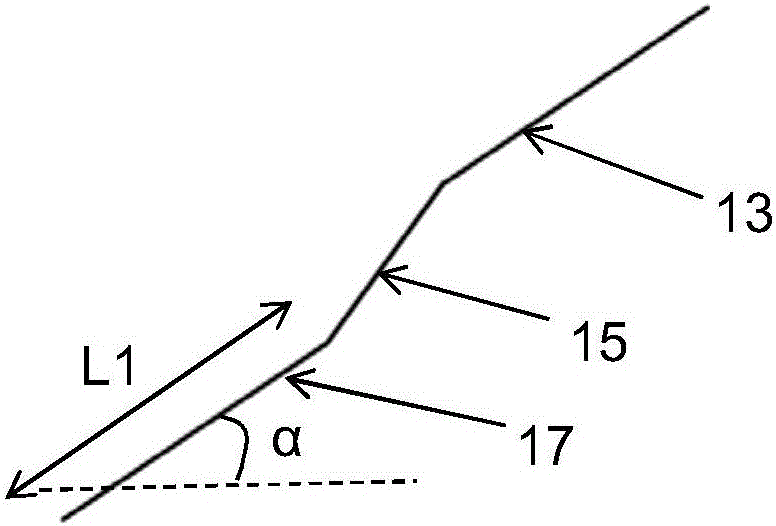

ActiveCN106457914AHomogenization of wear behaviorRigid Controlled AdjustmentHeavy duty tyresHeavy duty vehicleEngineeringGreek letter epsilon

Vehicle pneumatic tyre for utility vehicles having a carcass (5), having a belt (9) which is built up radially outside the carcass (5) and having a profiled tread (10) which is built up on the belt (9), radially outside the belt (9), wherein the belt (9) is formed from at least four belt layers (14, 17, 13, 15) arranged lying one on the other from radially on the inside to radially on the outside, wherein the first belt layer (14) which is arranged furthest on the inside in the radial direction R is embodied with parallel strength members (24) embedded in rubber, the second belt layer (17) which is arranged on the first belt layer (14) is embodied with parallel strength members (27) embedded in rubber, the third belt layer (13) arranged on the second belt layer (17) is embodied with parallel strength members (23) embedded in rubber, and the fourth belt layer (15) arranged on the third belt layer (13) is embodied with parallel strength members (25) embedded in rubber, characterized in that the third belt layer (13) and the fourth belt layer (15) are working layers in which the strength members (23) of the third belt layer (13) enclose in their orientation an angle alpha with respect to the circumferential direction U where 10 degrees < alpha < 45 degrees and the strength members (25) of the fourth belt layer (15) enclose in their orientation in each case an angle gamma with respect to the circumferential direction U where 10 degrees <= gamma <= 45 degrees, wherein, when viewed in the circumferential direction U of the vehicle tyre, the strength members (23) of the third belt layer (13) have an opposed axial direction of inclination to that of the strength members (25) of the fourth belt layer (15), in that the strength members (24) of the first belt layer (14) enclose in their orientation an angle beta with respect to the circumferential direction U where 0 degrees <= beta <= 5 degrees, and the strength members (27) of the second belt layer (17) enclose in their orientation an angle epsilon with respect to the circumferential direction U where 40 degrees <= epsilon <= 75 degrees.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

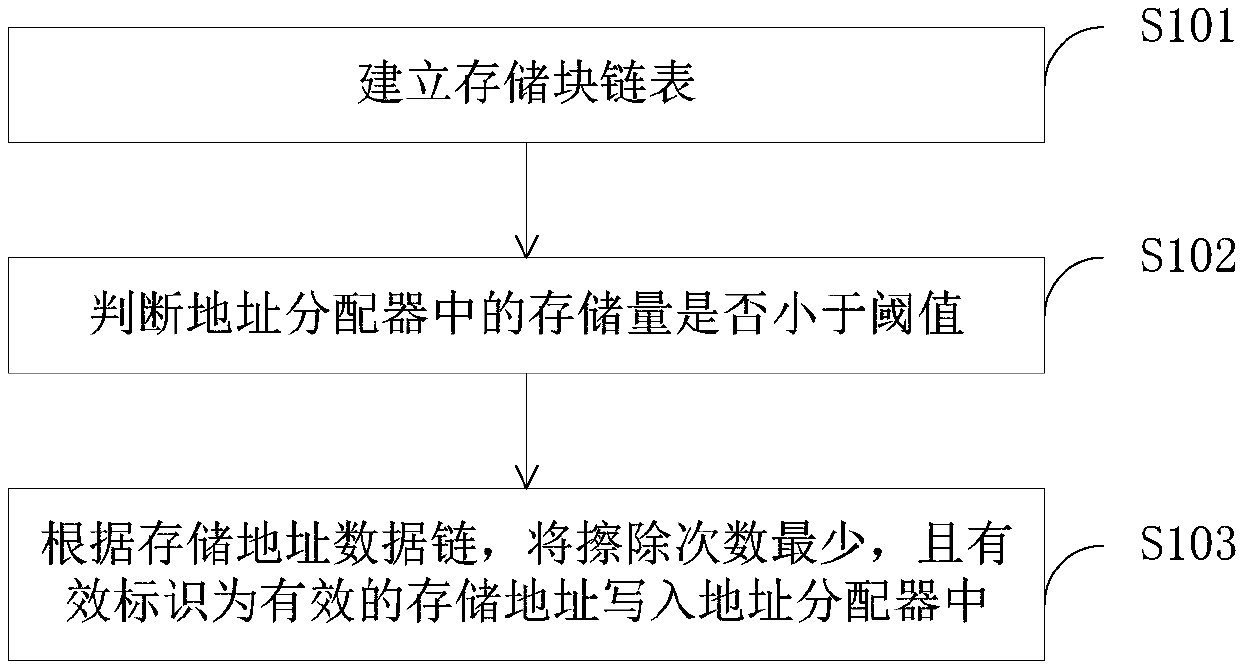

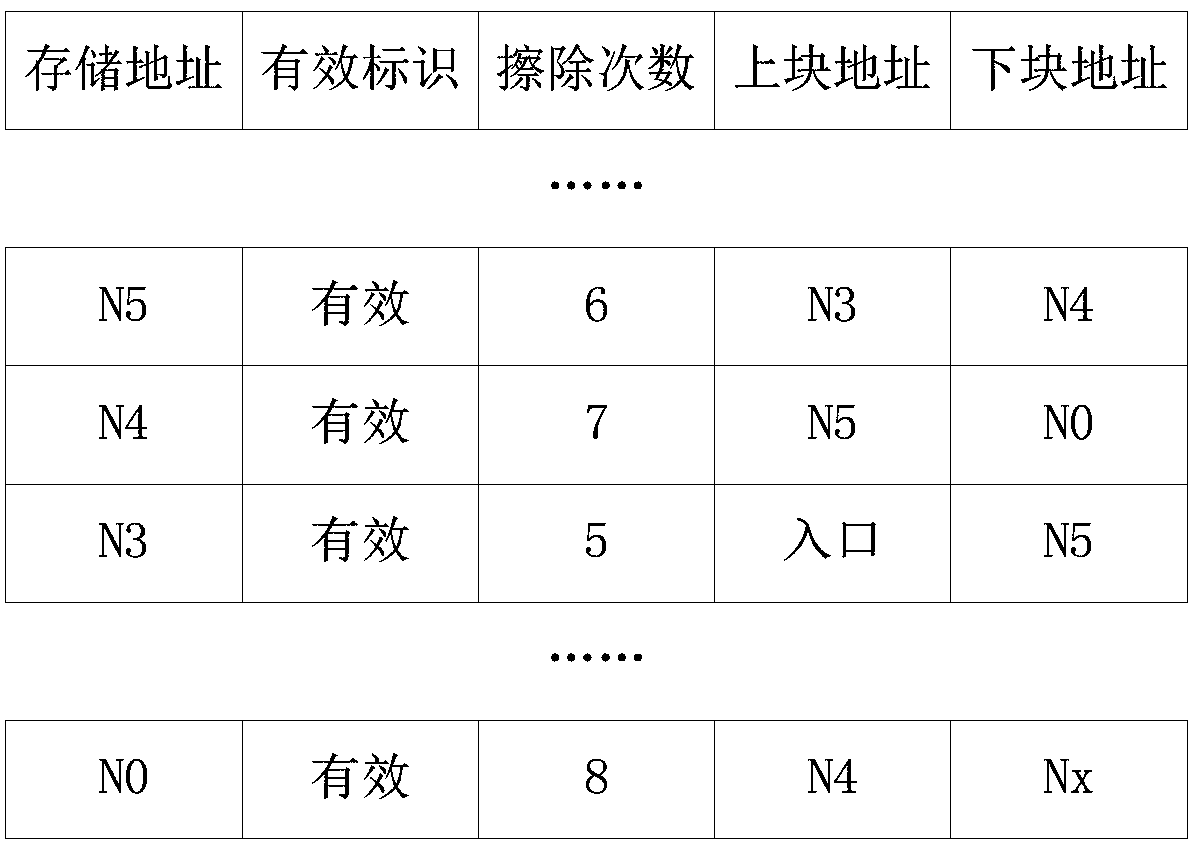

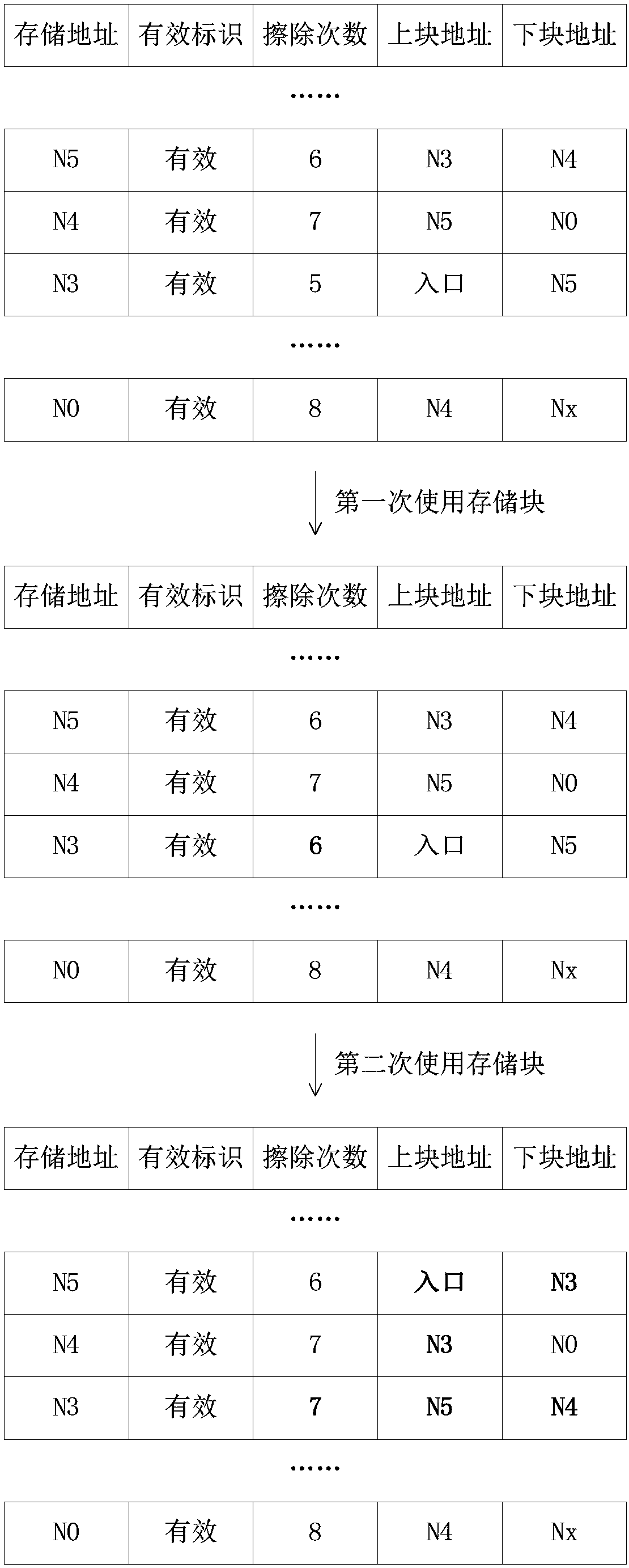

Wear leveling method and system for storage space, and device

InactiveCN107562641AConsistent wearUse priorityMemory adressing/allocation/relocationSpatial partitionDistributor

The invention discloses a wear leveling method and system for storage space, and a device. The storage space is divided into a plurality of storage blocks. The wear leveling method comprises the following steps that: establishing a storage block linked list, wherein the storage block linked list comprises the storage addresses, the erasure frequencies and the effective identification of all storage blocks, and the storage addresses, the erasure frequencies and the effective identification are mutually related; linking the storage addresses of all storage blocks in sequence according to the erasure frequencies to form a storage address data link; judging whether storage capacity in an address distributor is smaller than a threshold value or not, wherein the address distributor comprises thestorage address of a storage block to be used; and if the storage capacity in the address distributor is smaller than the threshold value, according to the storage address data link, writing the storage address which has the minimum erasure frequency and is effectively identified as an effective storage address into the address distributor. By use of the wear leveling method disclosed by the invention, the degree of wear of the storage block in the storage space can be consistent so as to prolong the service life of a memory with the storage space.

Owner:JRD COMM (SHENZHEN) LTD

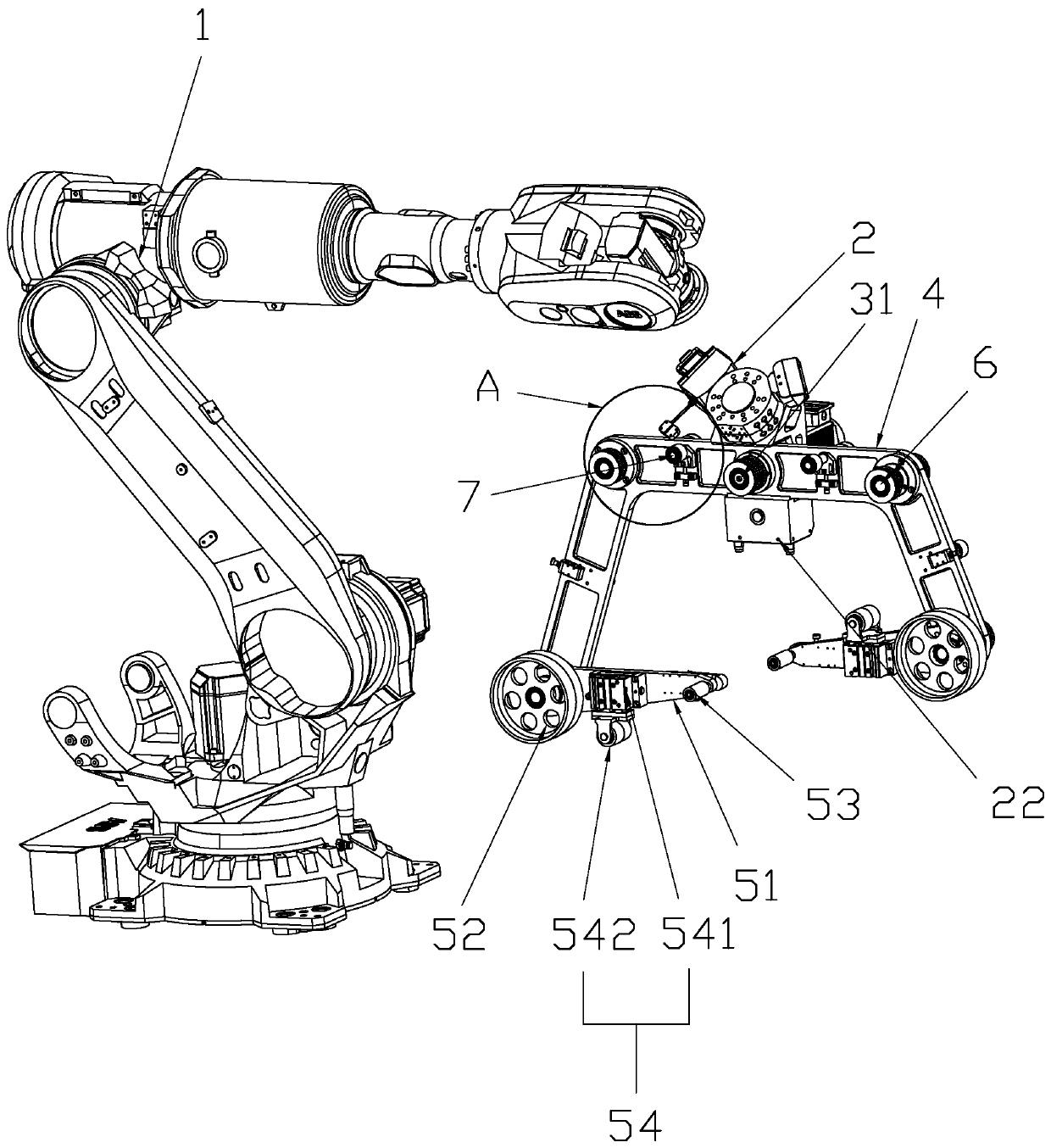

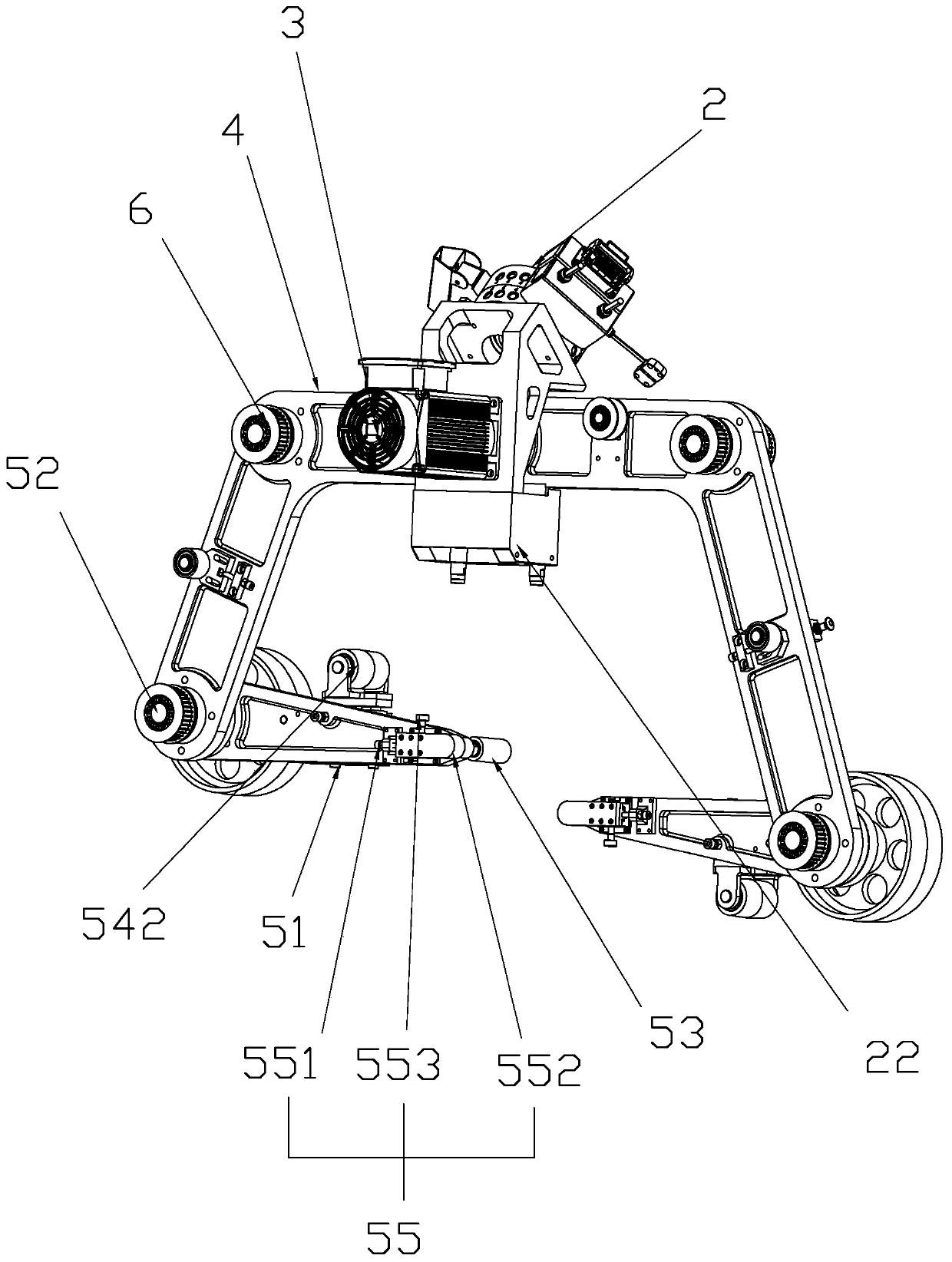

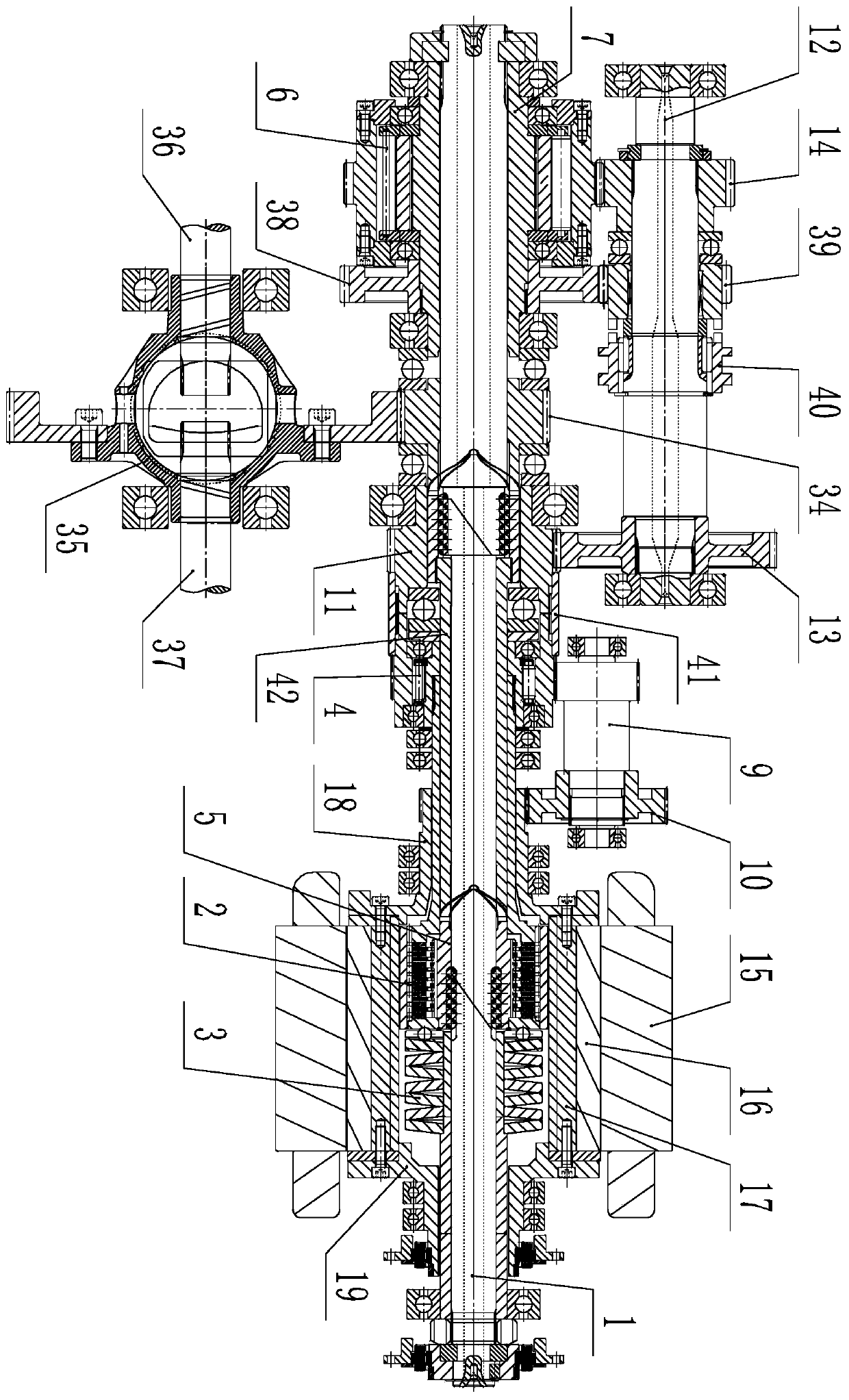

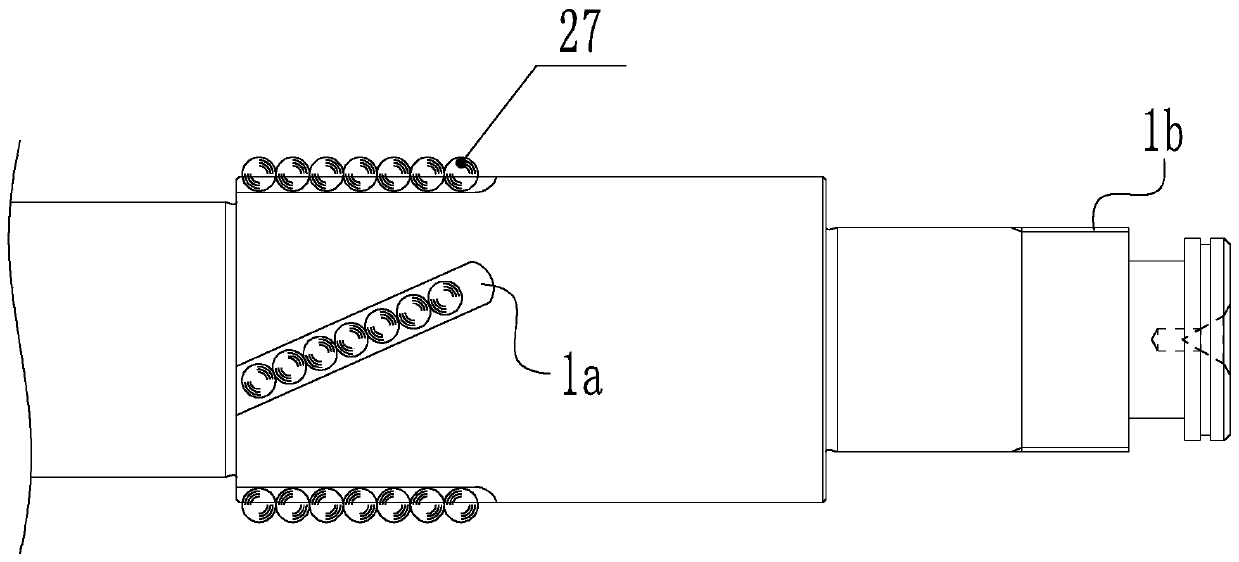

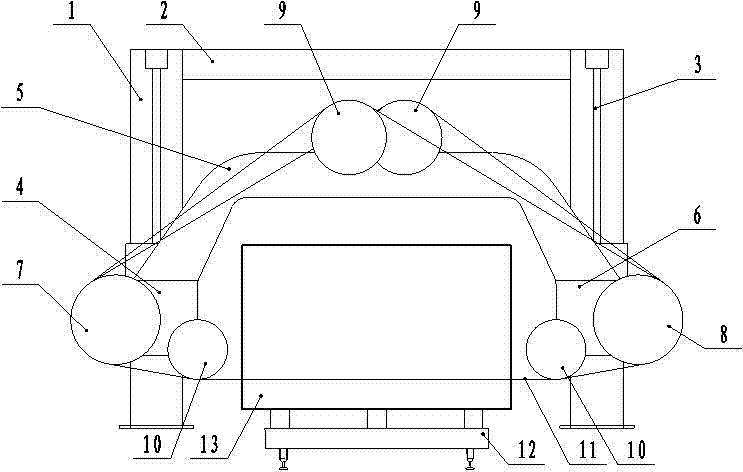

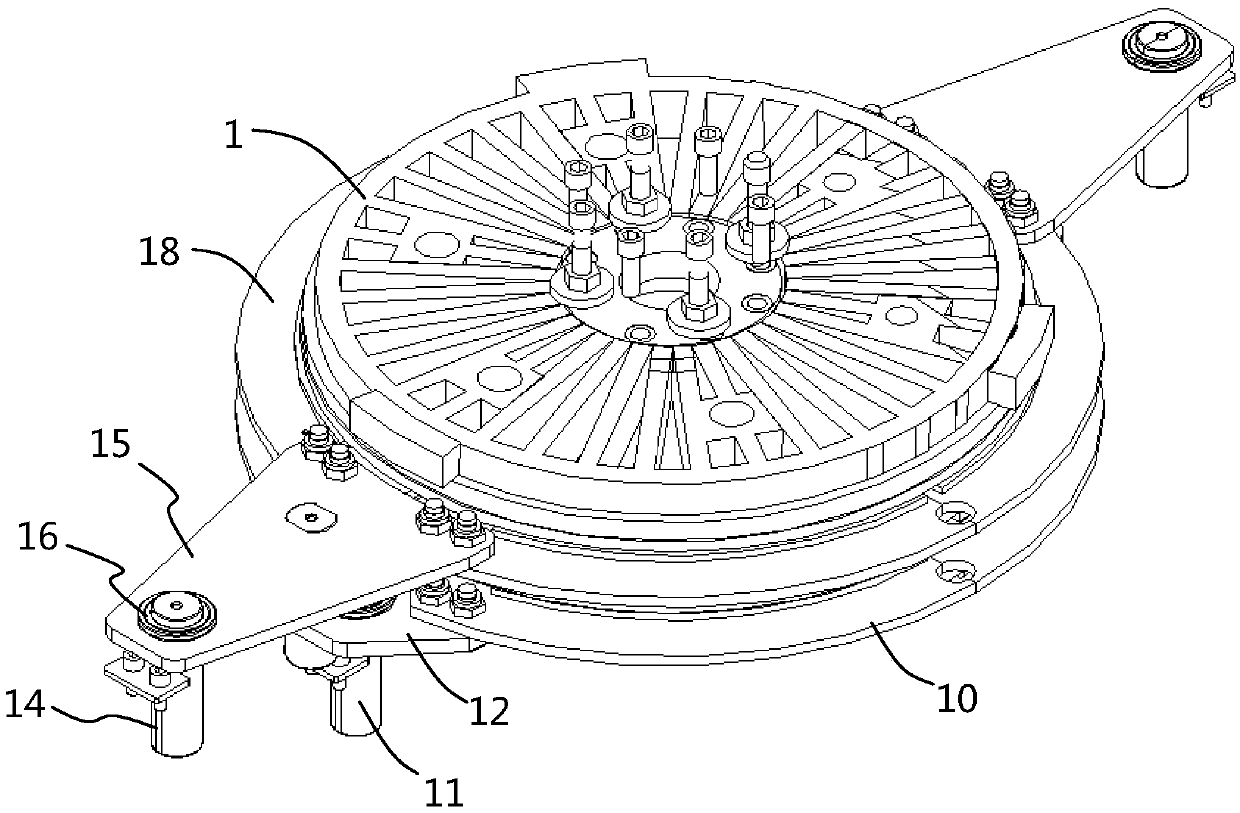

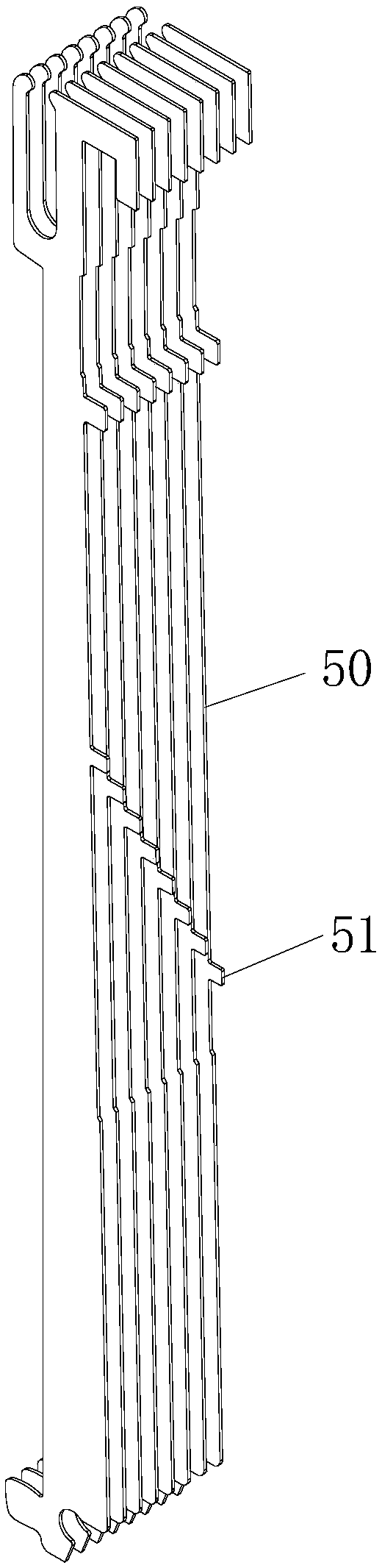

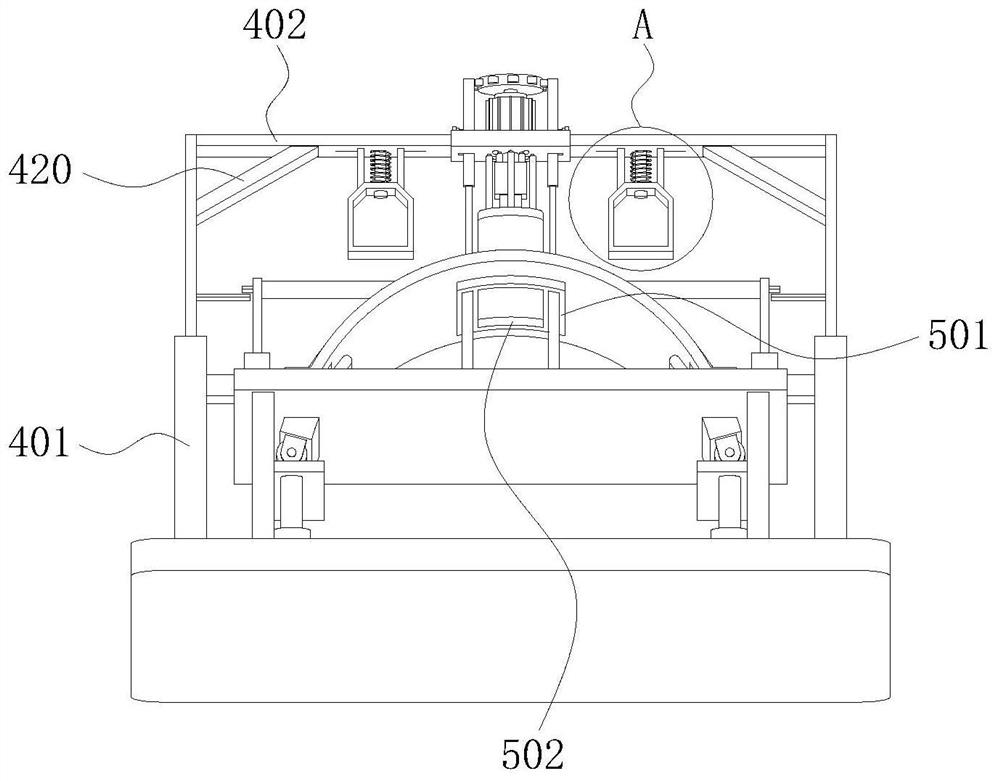

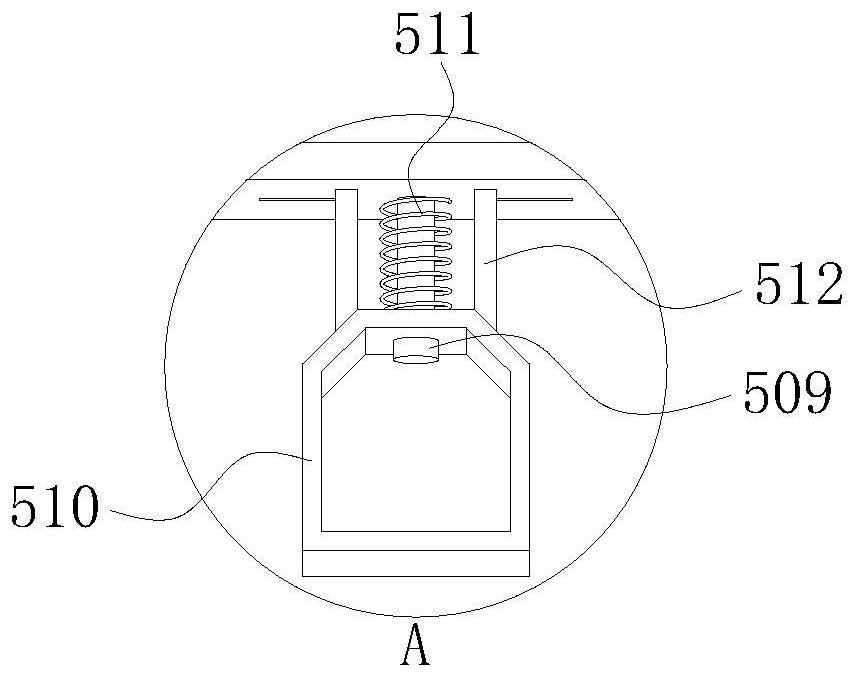

Flexible grinding robot for track grinding machining assembly line

PendingCN110919504AConsistent wearEasy to grind separatelyBelt grinding machinesManipulatorDrive wheelElectric machinery

The invention relates to a flexible grinding robot for a track grinding machining assembly line. The flexible grinding robot comprises an industrial robot and a flexible grinding device, wherein the flexible grinding device comprises a connector, a drive motor, a movable support, abrasive belt wheel assemblies and a transmission wheel; the output end of the drive motor penetrates through the movable support and is provided with a driving wheel, and the driving wheel drives the transmission wheel to drive the abrasive belt wheel assemblies at the two ends to operate; and the connector is provided with a flexible grinding space, and the movable support is fixed in the flexible grinding space and swings left and right in the flexible grinding space. The flexible grinding device is clamped through an industrial robot to grind the track, so that the grinding efficiency is improved; the movable support can swing left and right, so that flexible grinding is achieved, and track damage is avoided; and meanwhile, the abrasive belt wheel assemblies at the two ends are functionally distinguished, the two sides of the track are conveniently ground separately, and a machine arm does not need tobe rotated greatly, so that the grinding efficiency is improved, it is guaranteed that the abrasion of abrasive belts at the two ends is consistent, and uniform replacement is convenient.

Owner:浙江珂斯顿机器人科技有限公司

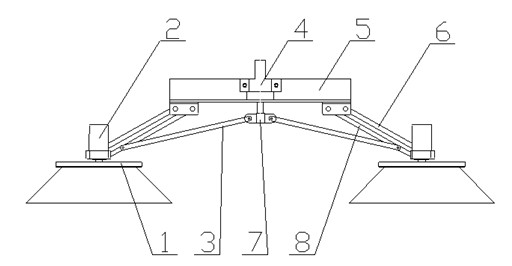

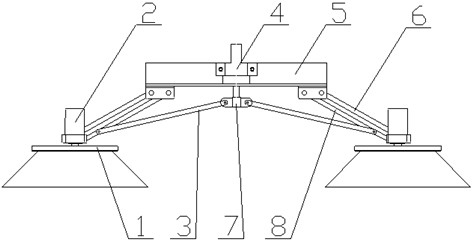

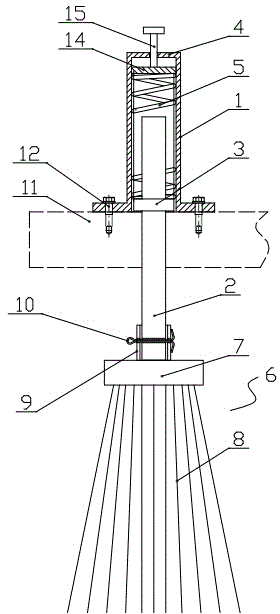

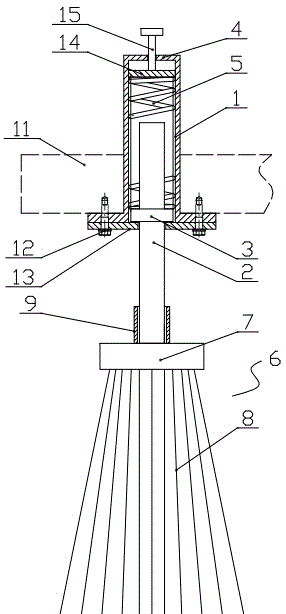

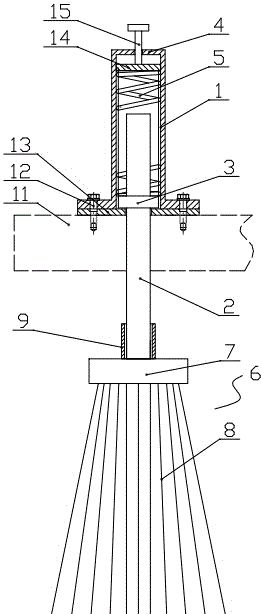

Lifting mechanism for small electric sweeper disc brushes

The invention provides a lifting mechanism for small electric sweeper disc brushes. The lifting mechanism comprises a bracket, an electric push rod and planar six-rod mechanisms, wherein each planar six-rod mechanism consists of a parallelogram mechanism, a connecting rod and a connector; and the parallelogram mechanisms and the electric push rod are both fixed to the bracket. The lifting mechanism for the small electric sweeper disc brushes has the following technical effects: 1) disc brushes are guided to perform translational lifting by adopting the planer six-rod mechanisms which are formed by the parallelogram mechanisms, so that the cleaning effect of the disc brushes is improved, the service life of the disc brushes is prolonged, and the aims of raising efficiency and saving energy are fulfilled; 2) by adopting the electric push rod and two planar six-rod mechanisms which are arranged symmetrically, the synchronous linkage lifting of the disc brushes on the two sides is realized, the consistency of the heights and the inclination angles of the disc brushes on the two sides is ensured, and the cost is reduced; 3) the electric push rod serves as a drive source, the power is taken from a storage battery of an electric vehicle very conveniently; and 4) the lifting mechanism is compact in structure, reasonable in layout and is matched with a vehicle frame conveniently.

Owner:NANTONG FUSHITE ENVIRONMENTAL PROTECTION MACHINERY

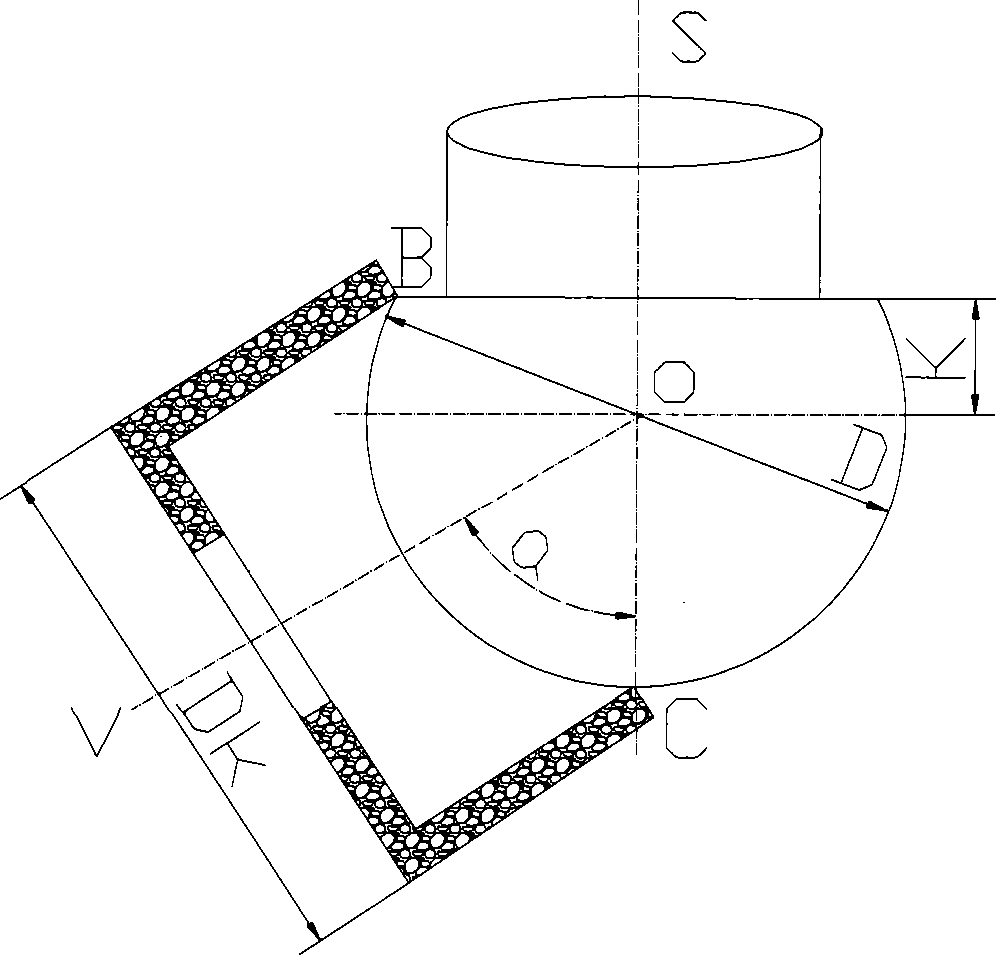

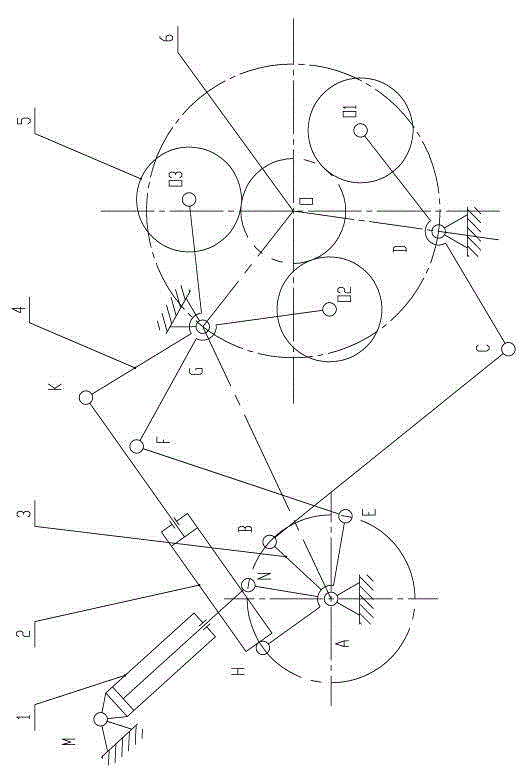

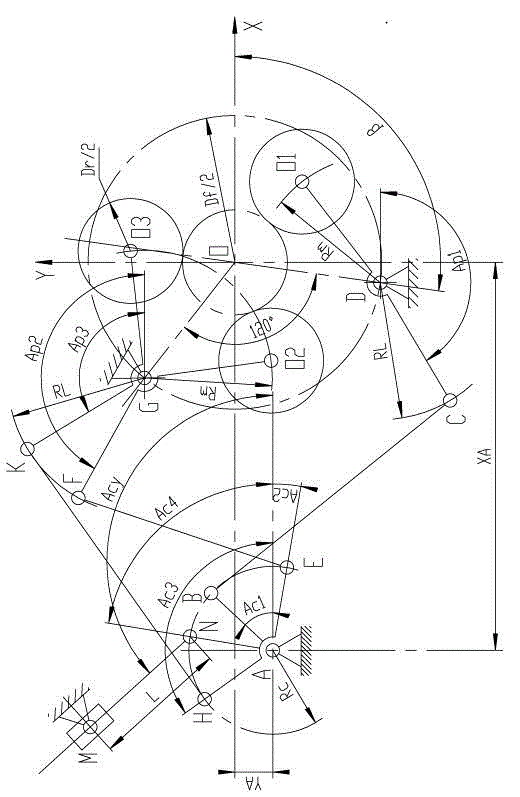

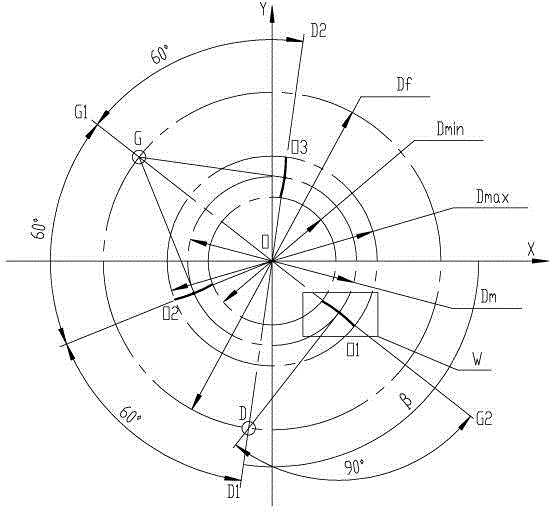

Optimizing design method of three-roller guiding device connecting rod mechanism

InactiveCN104361186AConsistent wearImprove calibration accuracySpecial data processing applicationsHydraulic cylinderWork performance

The invention provides an optimizing design method of a three-roller guiding device connecting rod mechanism. The method is characterized in that the maximum value and the minimum value of opening degree of three guiding rollers, the diameter of the guiding rollers and the travel of a hydraulic cylinder I are used as known conditions, the hinged point position of a rocking bar and the rocking arm length of the guiding rollers are determined according to the principle that the trajectory of the guiding rollers tends to be symmetrical around the rolling center, a hydraulic cylinder II that a piston rod completely penetrates through is regarded as a connecting rod, and the crank hinged point position of the mechanism and the sizes of all the rod pieces are regarded as design variables, so that the travel of the hydraulic cylinder I and the opening degree of the guiding rollers tend to a linear relationship, the operation of tending the inscribed circle center position of the guiding rollers to the rolling center is regarded as an optimizing target, the satisfied condition of the normal working and the good transmission characteristic of the connection rod mechanism are used as a constraint condition, an optimizing design math model is built, a virtual prototype model is built through ADAMS(Automatic Dynamic Analysis of Mechanical Systems), and a main object method is used for completing optimizing and solving, the working performance simulation testing is conducted on the optimized mechanism, and the mechanism parameters are finally determined.

Owner:HUBEI POLYTECHNIC UNIV

Combined grinding ball

The invention discloses a combined grinding ball. The combined grinding ball comprises two hemispherical shells. Each shell comprises a hemispherical alloy abrasion-resistant layer. A hemispherical steel layer is arranged on the inner side of each alloy abrasion-resistant layer. A first extension layer is arranged on the edge of the alloy abrasion-resistant layer in one shell, and a second extension layer is arranged on the edge of the steel layer in the other shell. A first thread is arranged on the first extension layer, and a second thread engaged with the first thread is arranged on the second extension layer. According to the combined grinding ball, the two hemispherical shells are connected through the first thread, the second thread and connecting columns, and thus the two hemispherical shells cannot be separated easily; a lead ball is adopted and can impact the steel layers, so that the grinding ball is made to move irregularly and aimlessly, and accordingly uniform grinding is guaranteed, and the effect is good; through the design of protrusion units, the grinding effect is improved; and the combined grinding ball is simple in structure and low in cost.

Owner:合肥市易远新材料有限公司

Drum brake with cooling function

InactiveCN112032220AImprove braking effectReduce brake failureFluid actuated drum brakesBrake actuating mechanismsControl theoryEmergency brake

The invention relates to the technical field of brake equipment, and discloses a drum brake with a cooling function. The drum brake comprises an axle and a mounting base, wherein the axle penetrates through the mounting base to be fixedly connected with a brake drum, and a brake shoe is hinged to the end face of the mounting base. According to the drum brake with the cooling function, during continuous braking during long downhill, rotation of an adjusting disc drives a compression cylinder to do piston motion, compressed gas enters an external condenser, heat in the brake drum is conveyed tothe external condenser, and the interior of the brake drum is kept in a low-temperature state through the external condenser; and secondly, certain braking capacity is improved under the action of thebrake drum and the compression cylinder, a considerable part of braking force is provided by the compression cylinder when the driving speed of the automobile is adjusted by slightly stepping on thebrake, and the frequency of slightly stepping on the brake is far higher than that of heavily stepping on the emergency brake in daily use, so that the abrasion speed of the brake shoe during daily driving is reduced.

Owner:龚植祥

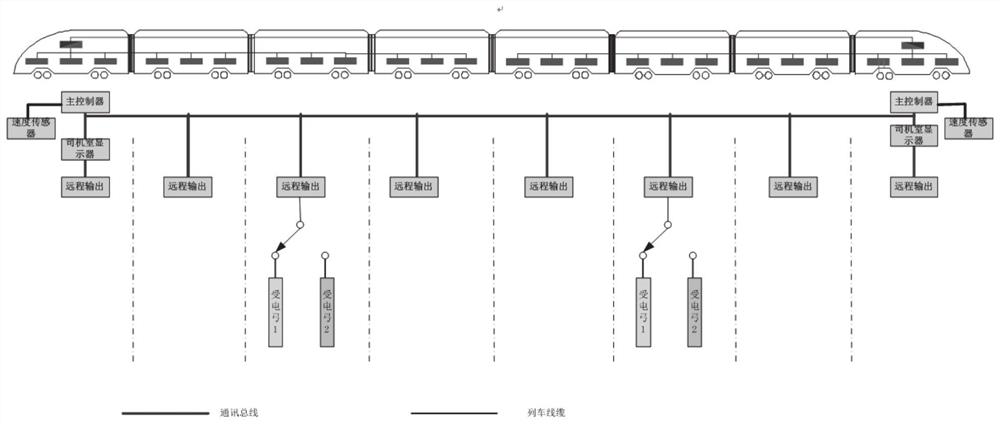

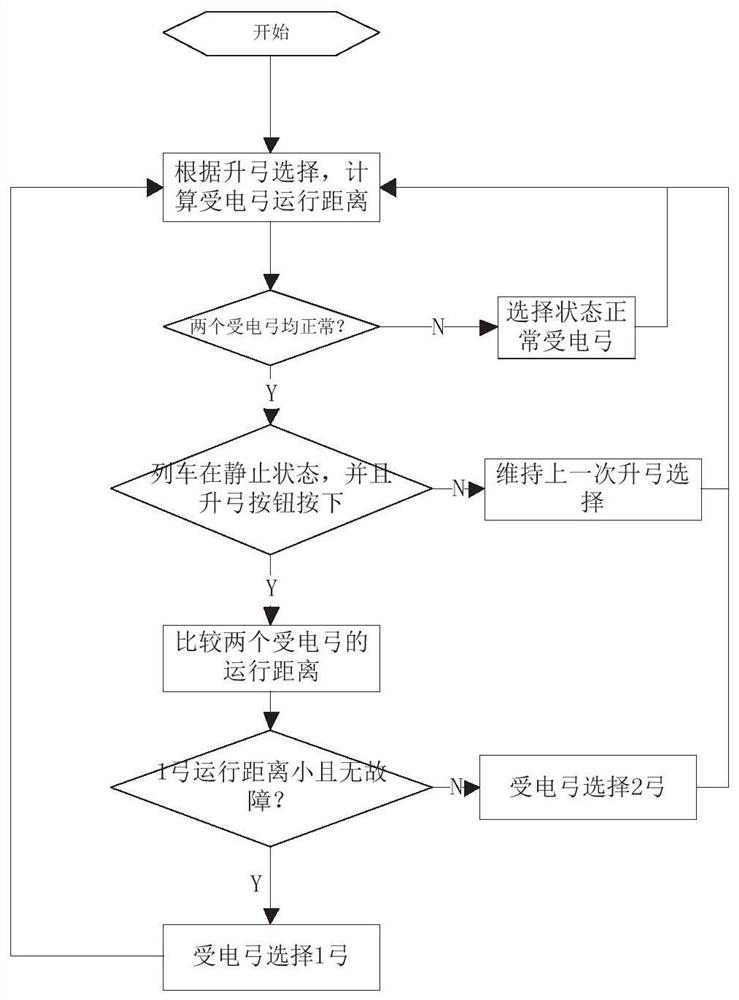

Pantograph pan abrasion intelligent control system and method

ActiveCN112346395AConsistent wearReduce maintenance workloadProgramme controlComputer controlControl engineeringMaster controller

The invention discloses a pantograph pan abrasion intelligent control system and method. The system comprises a speed sensor which is configured to collect the running speed information of a vehicle,and transmit the running speed information to a main controller, a main controller which is configured to calculate the running distance of each pantograph in a vehicle high-voltage unit according tothe received vehicle running speed information, and determine a pantograph which needs to be lifted, and output a pantograph selection signal to a remote output unit, a remote output unit which is configured to send a switching instruction to a switching unit according to the received pantograph selection signal, and the switching unit which is configured to switch a pantograph lifting instructionto the pantograph needing pantograph lifting according to the received switching instruction. According to the pantograph pan abrasion intelligent control system and method of the invention, the intelligent control of the abrasion degree of pantograph pans can be realized, the abrasion degree of the two pantograph pans in the vehicle high-voltage unit is ensured to be consistent, and the overhauland maintenance workload of the vehicle pantograph is reduced.

Owner:CRRC QINGDAO SIFANG CO LTD

Cleaning plate

The invention discloses a cleaning plate. The cleaning plate comprises a rotary plate and an elastic sweeper which is uniformly distributed on the rotary plate in a peripheral direction, wherein the elastic sweeper comprises a cylinder body, a piston rod, a piston, a hairbrush and a pressure spring, the piston is arranged on the piston rod; the piston rod can move back and forth along the inner wall of the cylinder body; the cylinder body is arranged in an inverted manner, namely, the opening of the cylinder faces downwards; the cylinder body comprises an upper cylinder body and a lower cylinder body which are in threaded connection with each other, wherein a ring-shaped bump is arranged on the outer side wall of the upper cylinder body; grains are arranged on the ring-shaped bump part, so that people can rotate the upper cylinder body conveniently; the pressure spring is mounted between the piston and the inner wall of the top of the upper cylinder body; the lower part of the piston rod penetrates through a cylinder lid; the lower end part of the piston rod is detachably connected with the hairbrush. The hairbrush of the cleaning plate can elastically stretch out and draw back according to fluctuation changes of a rod surface, so that abrasion of bristles is relieved, the service life of the hairbrush is prolonged; the upper and the lower cylinder bodies are in threaded connection so as to conveniently regulate the elastic force of the spring; moreover, the threaded connection part is free of interferences of outer dust.

Owner:李丽容

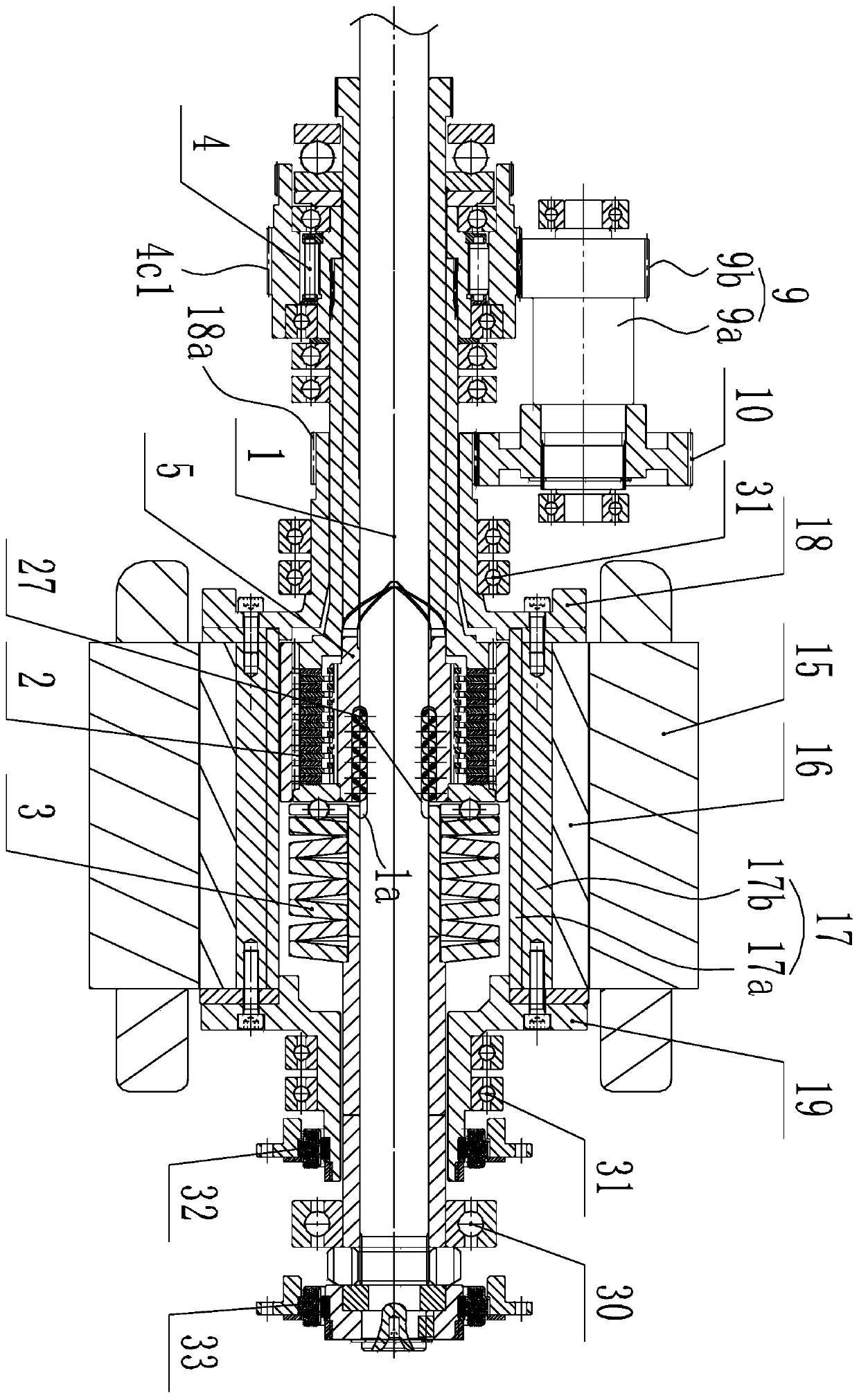

Double-helix double-overrunning integrated intelligent adaptive electric driving front drive system

ActiveCN111016643AReliable cooperationIncrease the number ofElectric propulsion mountingControl devicesDynamic balanceElectric machinery

The invention discloses a double-helix double-overrunning integrated intelligent adaptive electric driving front drive system, which comprises a motor, an adaptive transmission assembly and a front drive power output mechanism, wherein the motor comprises a stator, a rotor and a motor shaft assembly, the motor shaft assembly comprises a motor hollow shaft, a power transmission flange and an outerend mounting flange, the motor hollow shaft is fixed to the inner side of the rotor through the power transmission flange and the outer end mounting flange, and the power transmission flange transmitspower to the front drive power output mechanism through a power output speed reduction assembly and the adaptive transmission assembly in sequence. By the adoption of the technical scheme, the structure is extremely compact, the integration degree is high, the transmission route is short, the transmission efficiency is high, the arrangement of a power mechanism is facilitated, and the influence on dynamic balance of wheels is reduced; through the design of a differential mechanism and related parts, power output of front-engine front-drive layout can be achieved, and the transmission efficiency of the whole transmission axle is high; and through the mounting of the power transmission flange and the outer end mounting flange, the overall balance is better.

Owner:SOUTHWEST UNIVERSITY

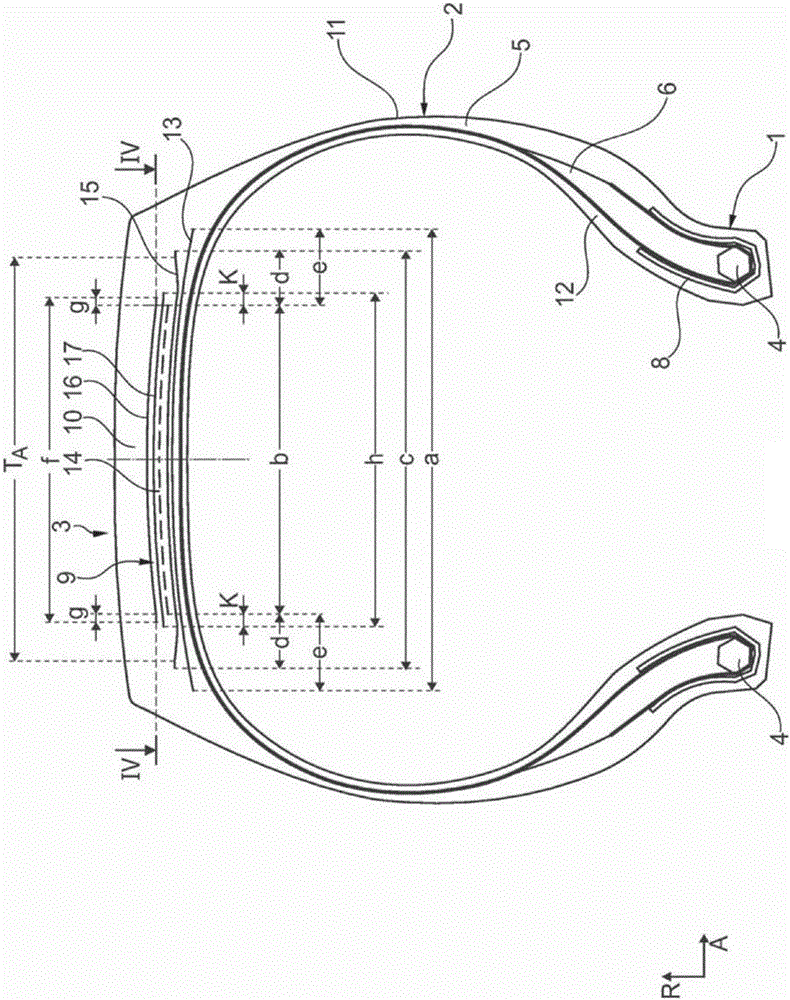

Pneumatic vehicle tire

ActiveCN105829132AIncreased durabilityHigh strengthHeavy duty tyresHeavy duty vehicleEngineeringTread

The invention relates to a pneumatic vehicle tire for utility vehicles having a carcass (5), a belt (9) and a profiled tread (10), wherein the belt (9) consists of at least four belt layers (17, 14, 13, 15), wherein the third belt layer (13) and the fourth belt layer (15) are operative layers, the reinforcements (23, 24) thereof being arranged at an angle to the circumferential direction of 10 DEG - 45 DEG and the reinforcements (25) of the fourth belt layer (15) being arranged at an angle of 10 DEG - 45 DEG, wherein the reinforcements of the third and fourth belt layers (13, 15) are arranged such that they cross one another; the reinforcements (27) of the first belt layer (17) are arranged at an angle of 40 DEG - 75 DEG and the reinforcements (24) of the second belt layer (14) are arranged at an angle of 0 DEG - 5 DEG to the circumferential direction, wherein the reinforcements (23) of the third belt layer (13) and the reinforcements (27) of the first belt layer (17) have the same direction of inclination.

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

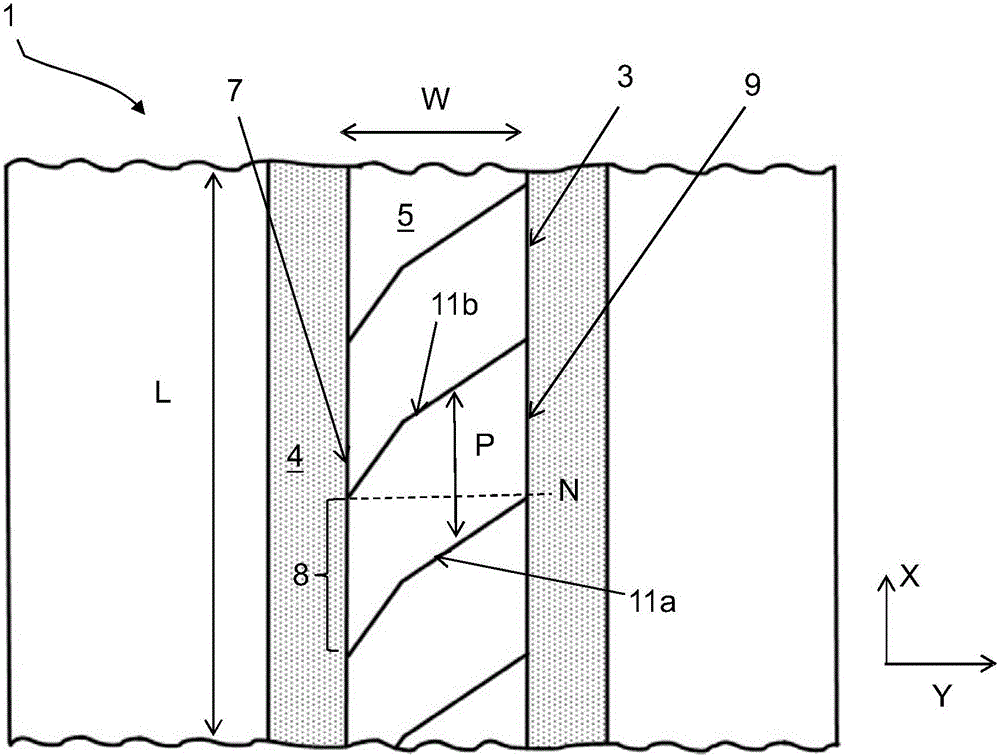

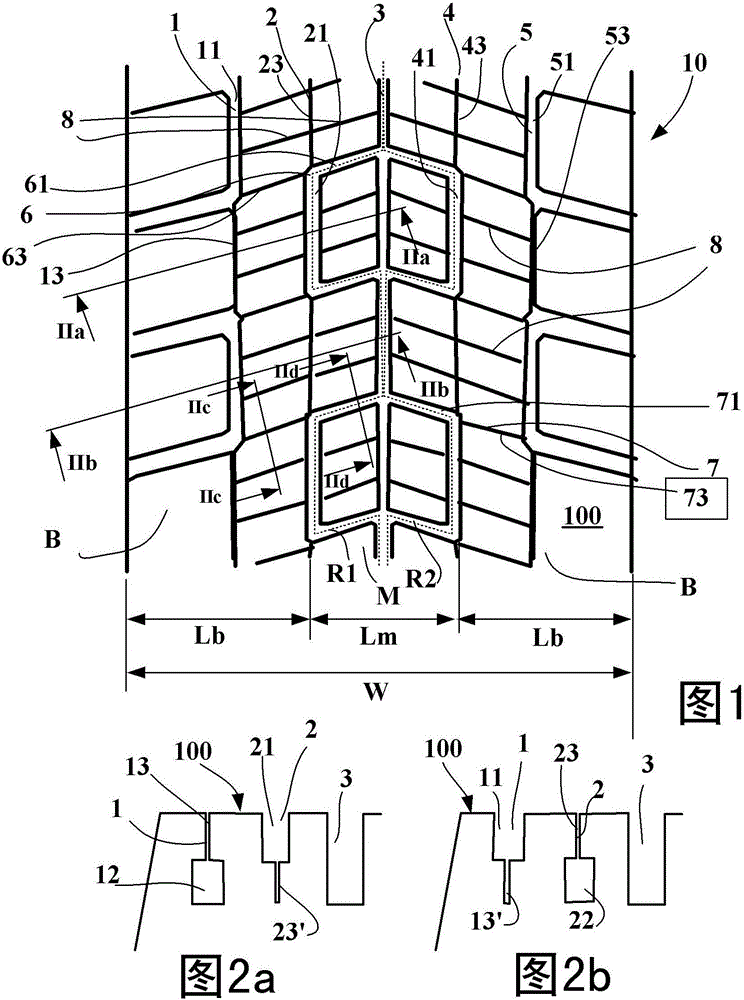

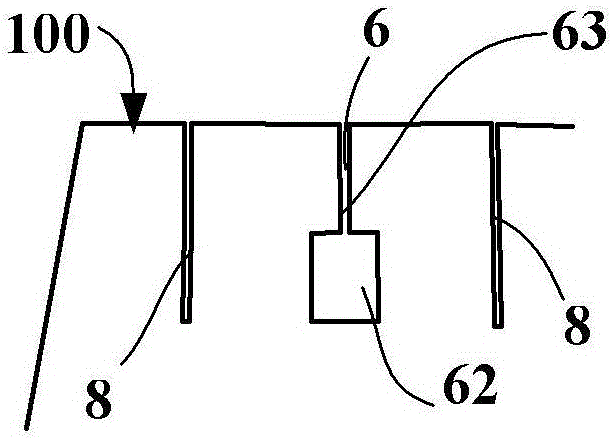

Tread comprising a block having a plurality of sipes

ActiveCN105705347AIncrease widthLimit the risk of splinteringTyre tread bands/patternsRubber materialEngineering

The invention relates to a tyre tread comprising at least one block (3) of rubber material of width W and length L with L>>W. The block extends in a circumferential direction (X) when the tread (1) is mounted on the tyre, the block (3) comprising a contact surface (5) intended to come into contact with the ground and a first lateral wall (7) and a second lateral wall (9) delimiting this contact surface (5). The block (3) further comprises a plurality of sipes (11, 11a, 11b) opening onto the contact surface (5) of the block, each sipe (11) extending over the contact surface (5) in an oblique direction, opening onto the first lateral wall (7) and onto the second lateral wall (9), the sipes of the block being oriented in the same direction. The sipes (11) are spread over the contact surface (5) of the block in such a way that when a sipe (11a) reaches the second lateral wall (9) another sipe (11b) begins from the first lateral wall (7) at the same circumferential level (N) on the block, and each sipe (11) comprises at least two parts.

Owner:OCIETE DE TECH MICHELIN

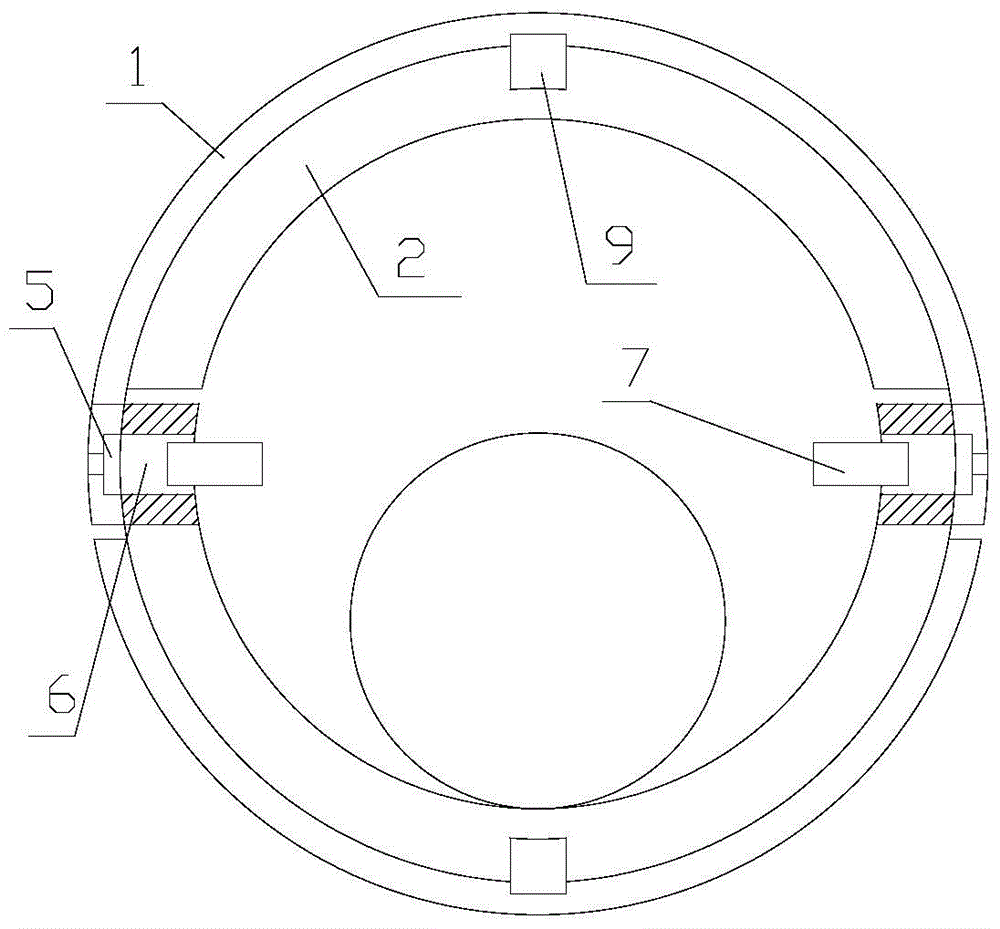

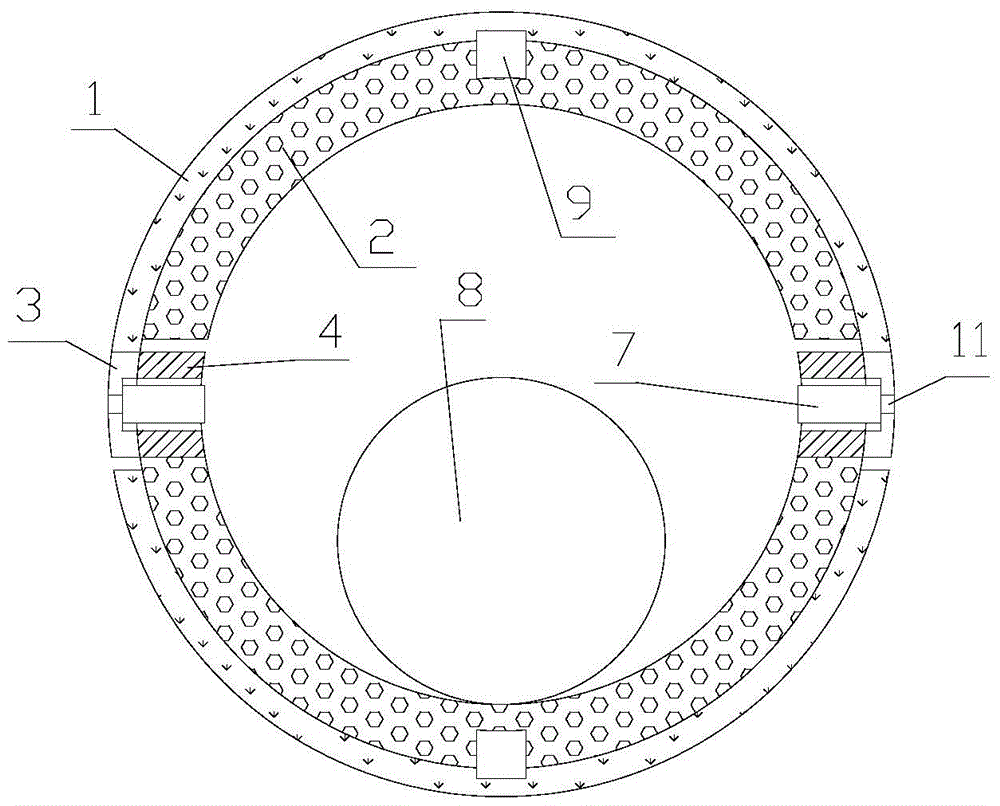

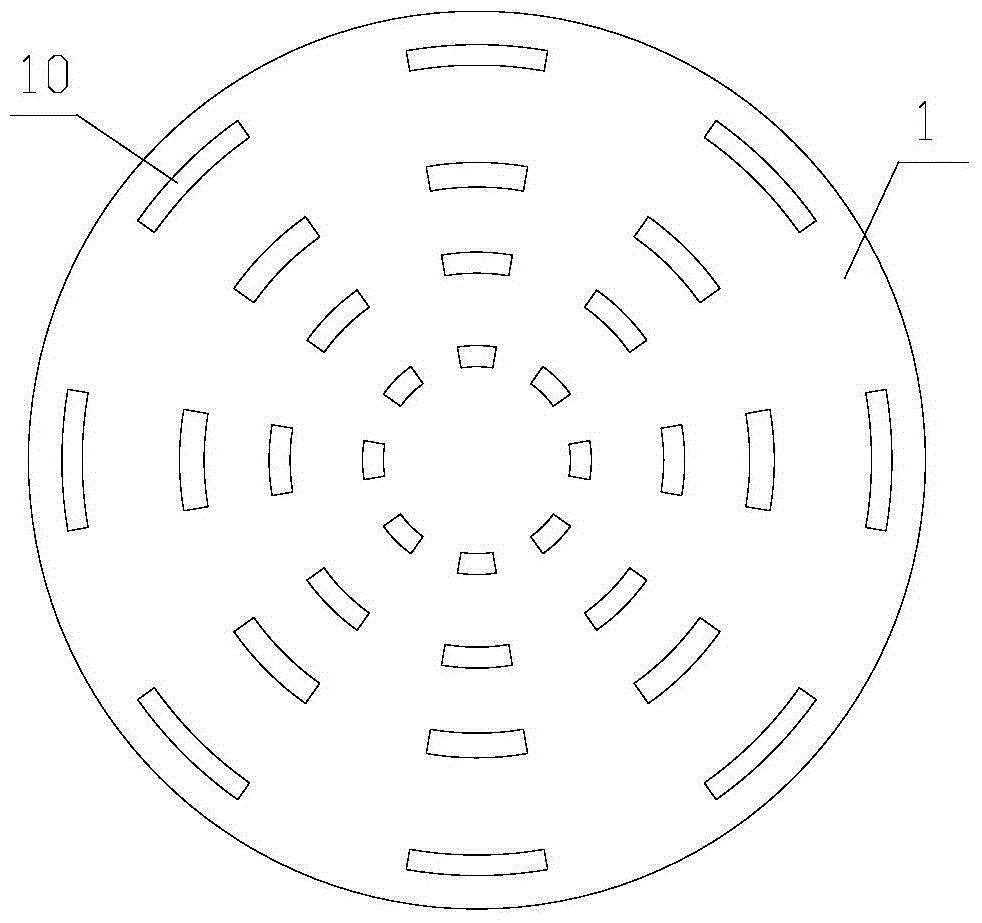

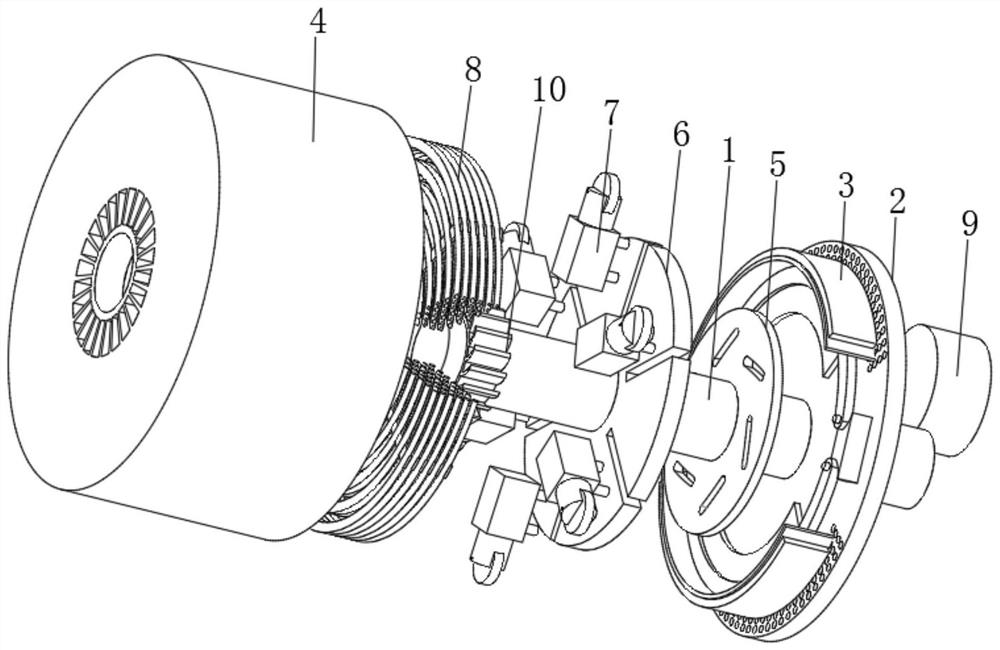

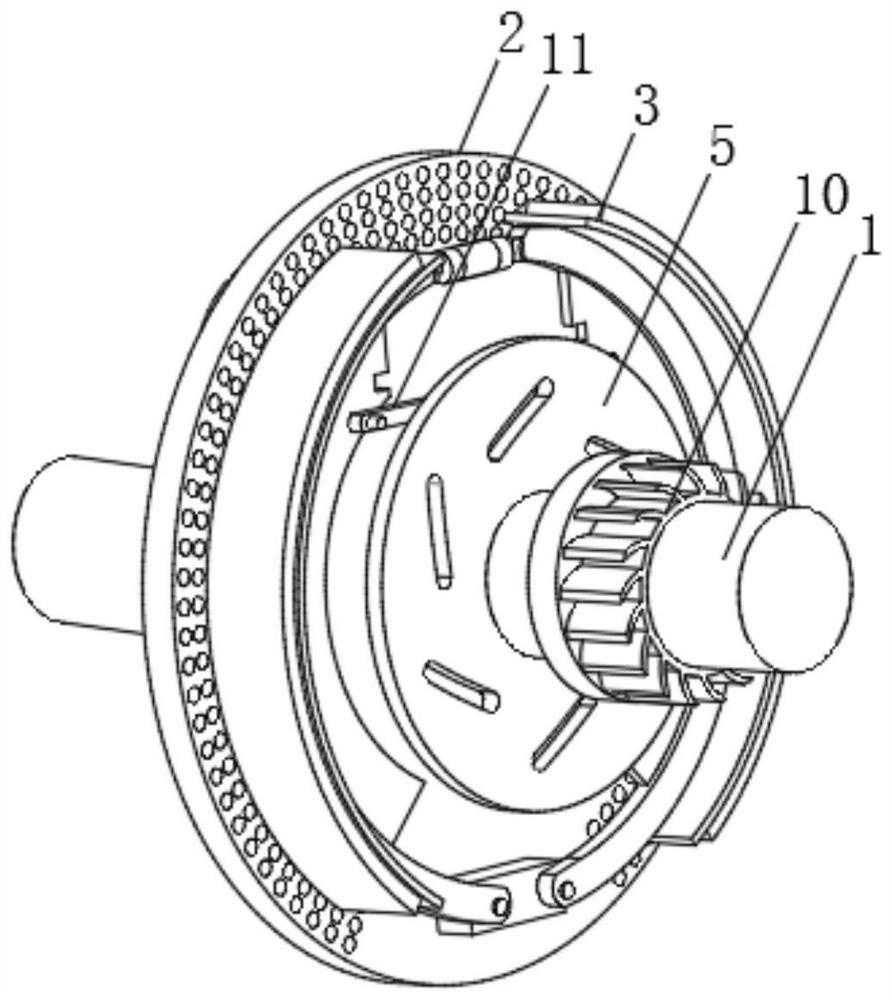

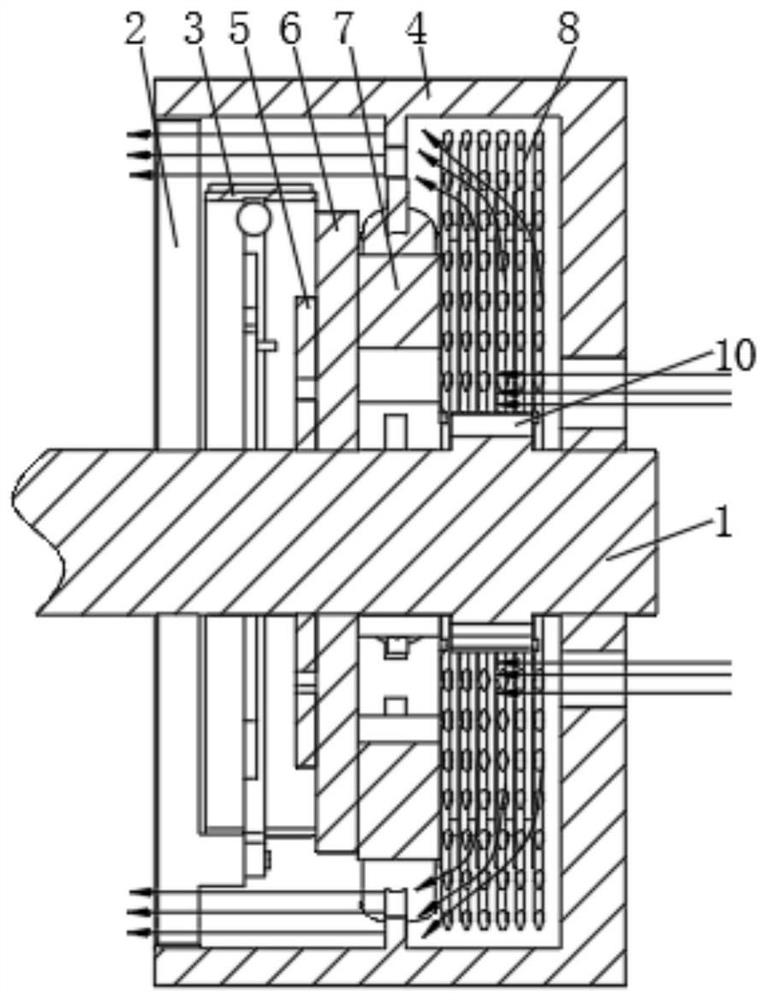

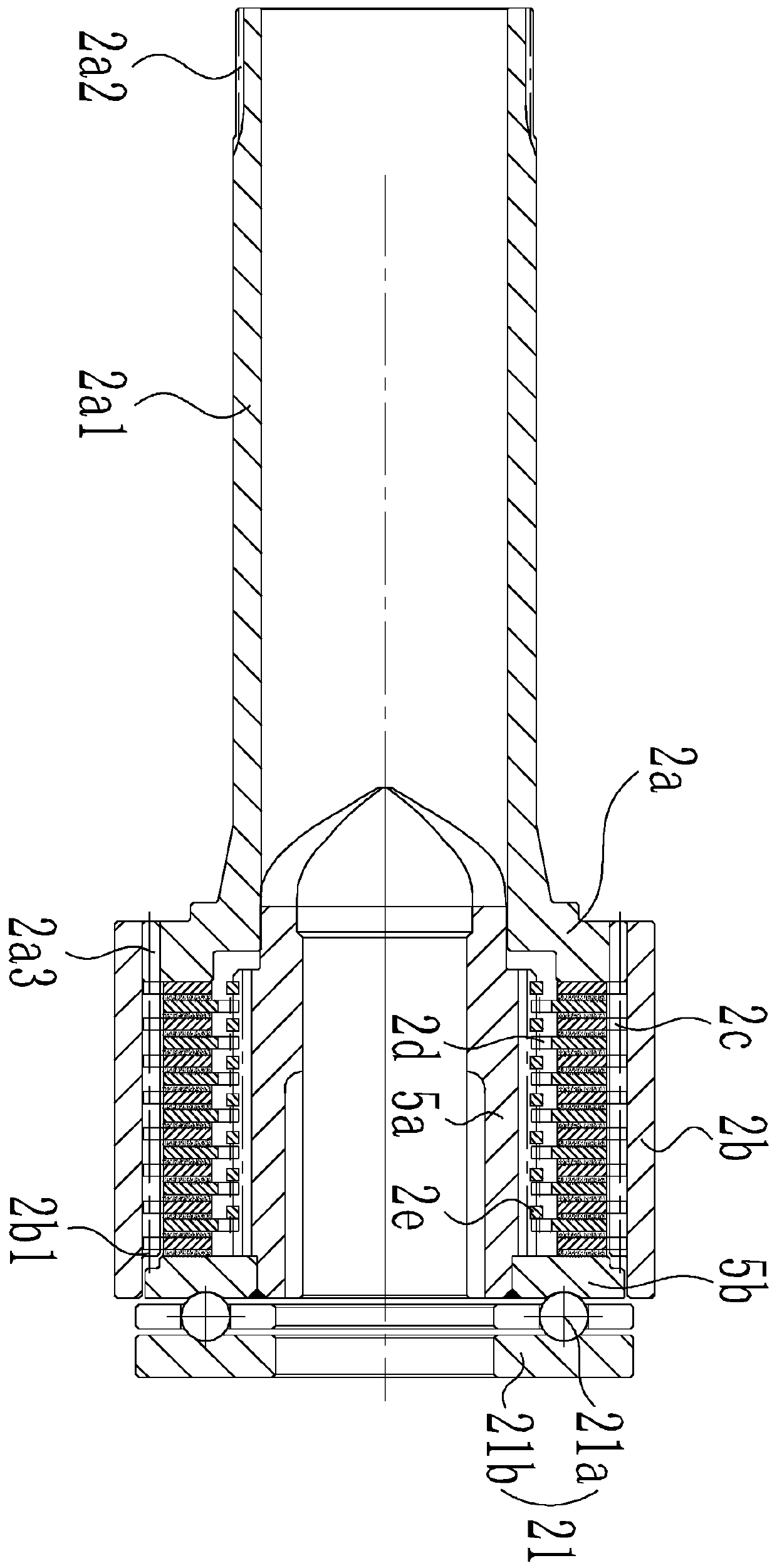

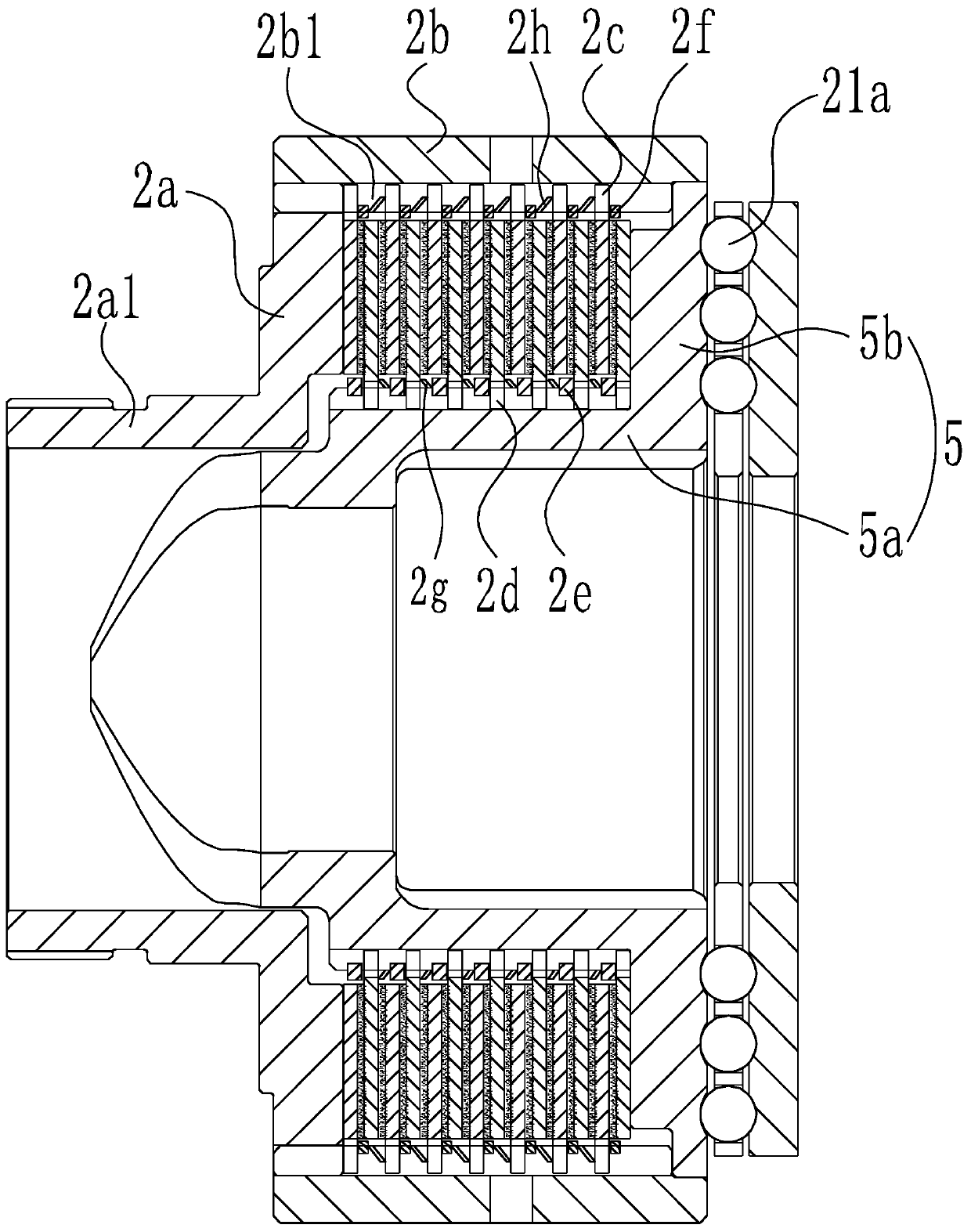

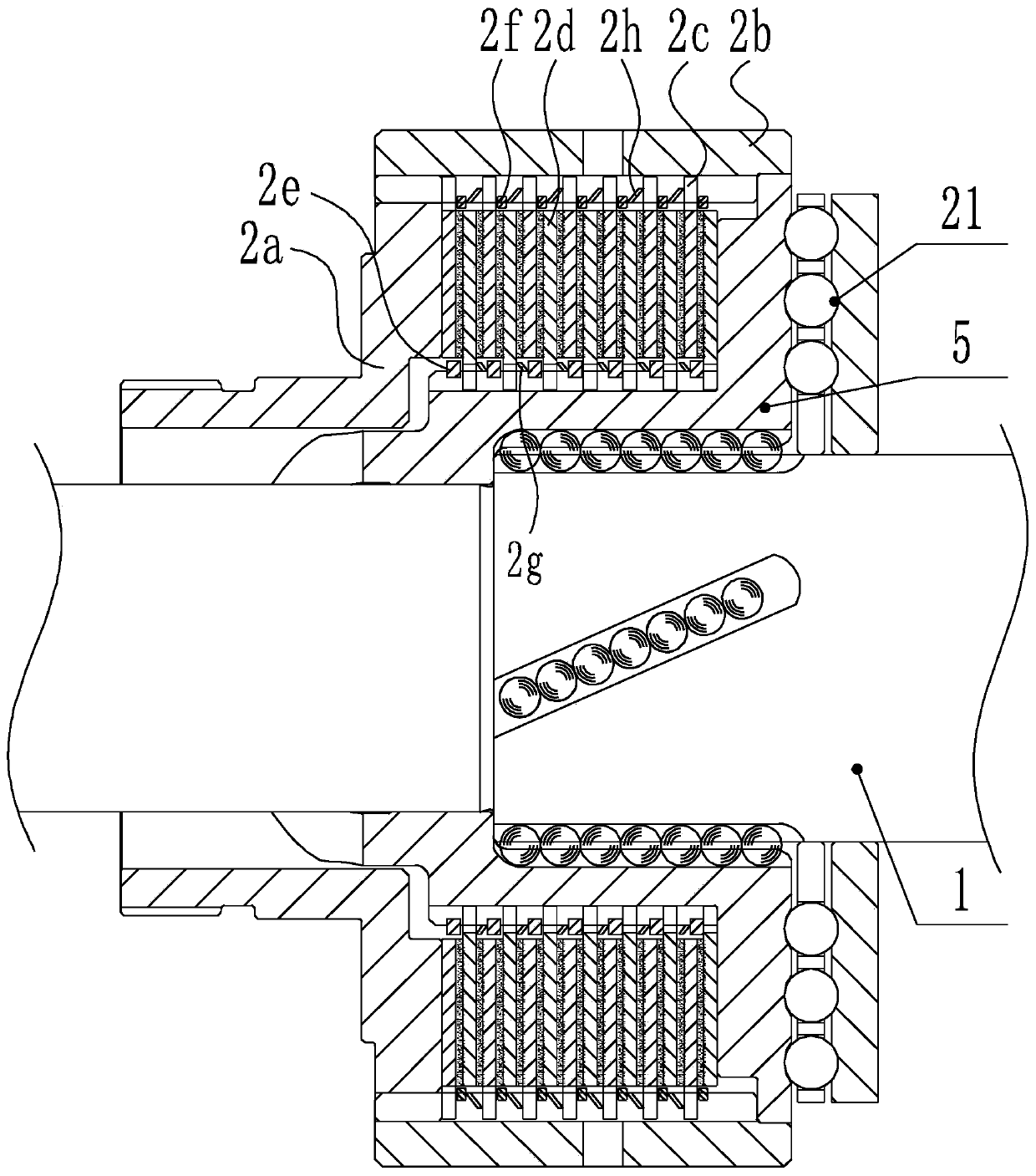

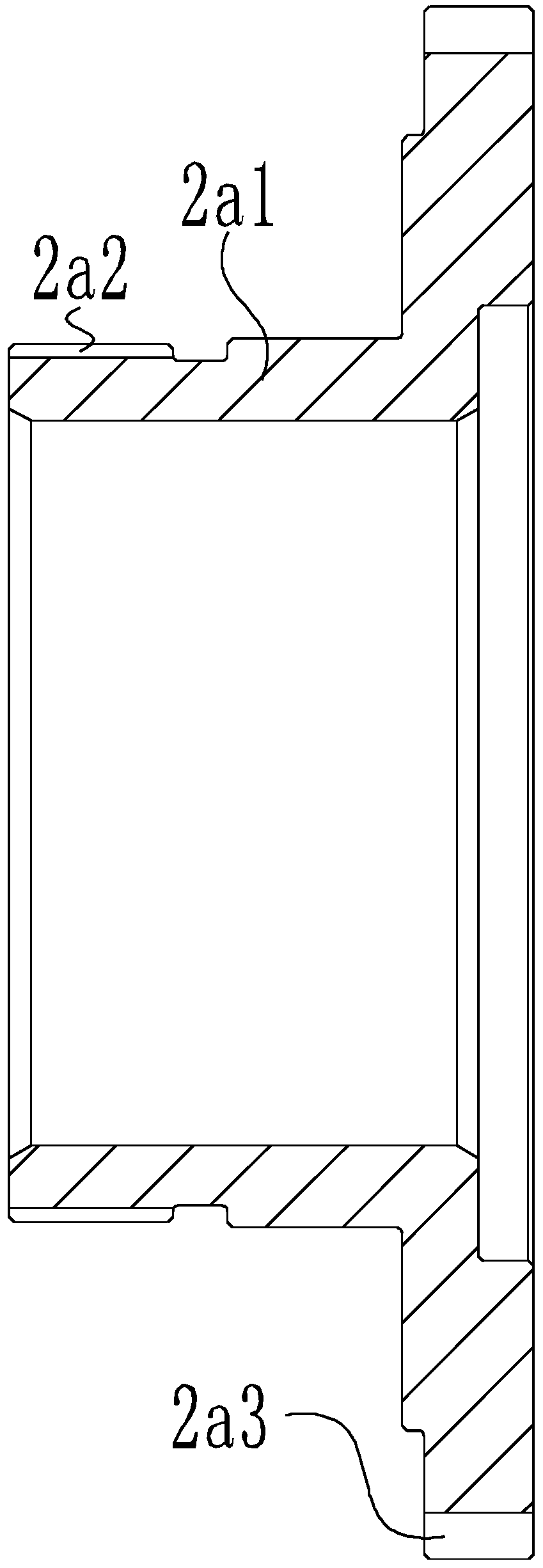

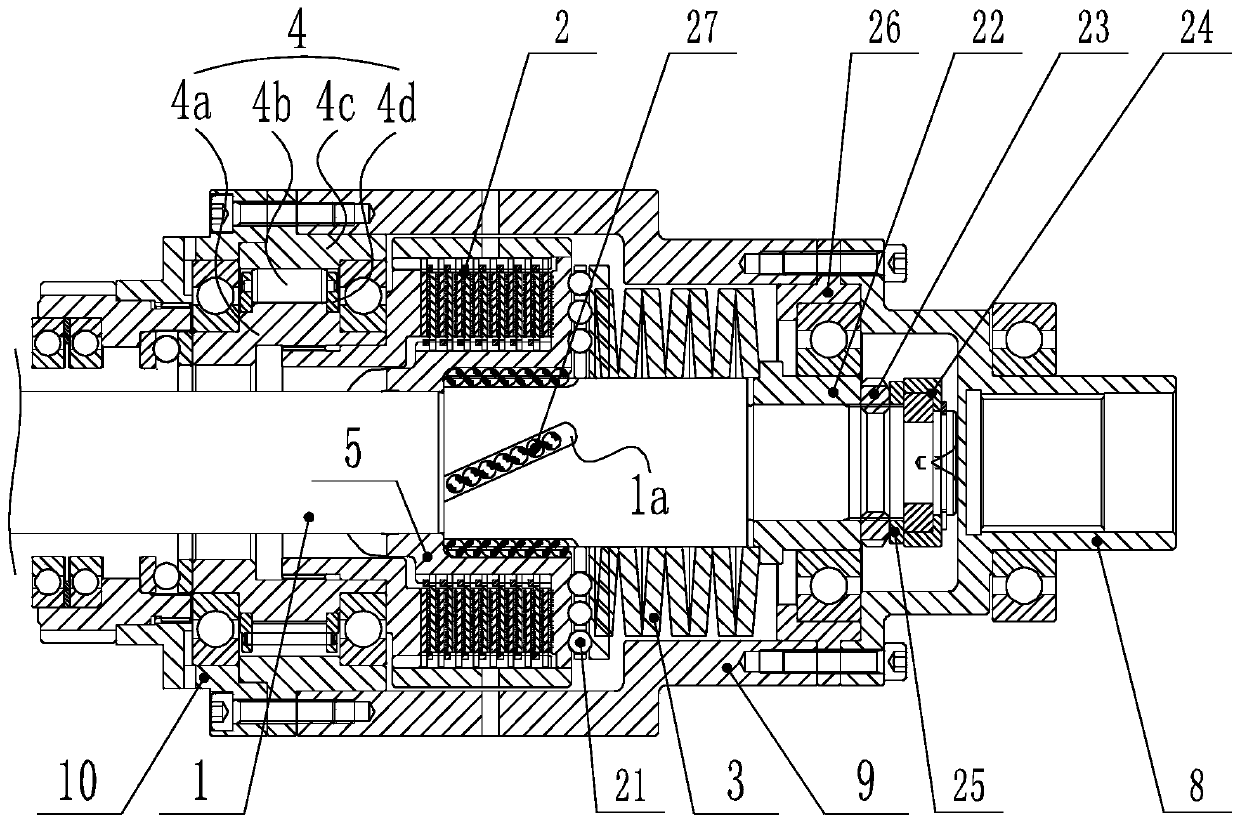

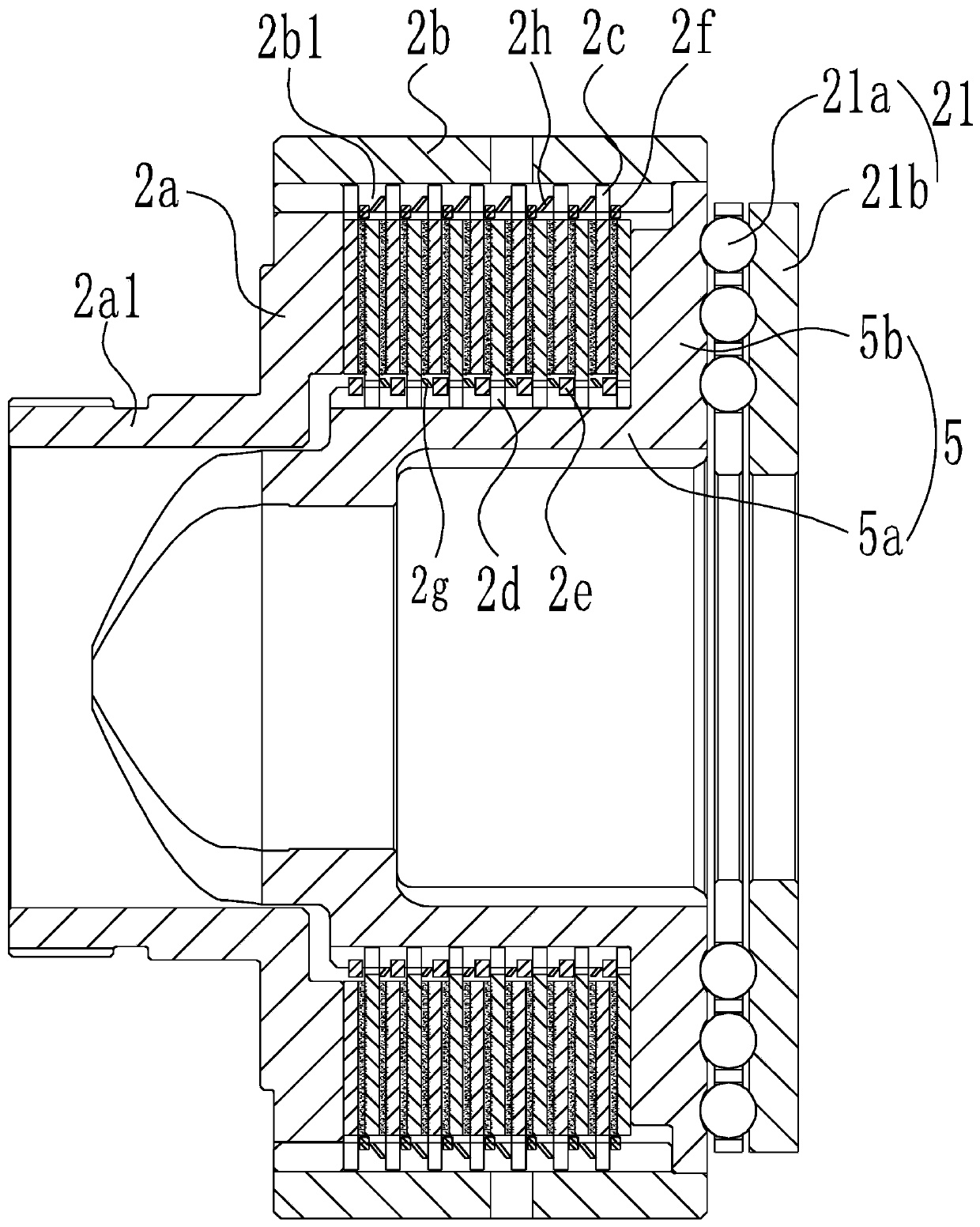

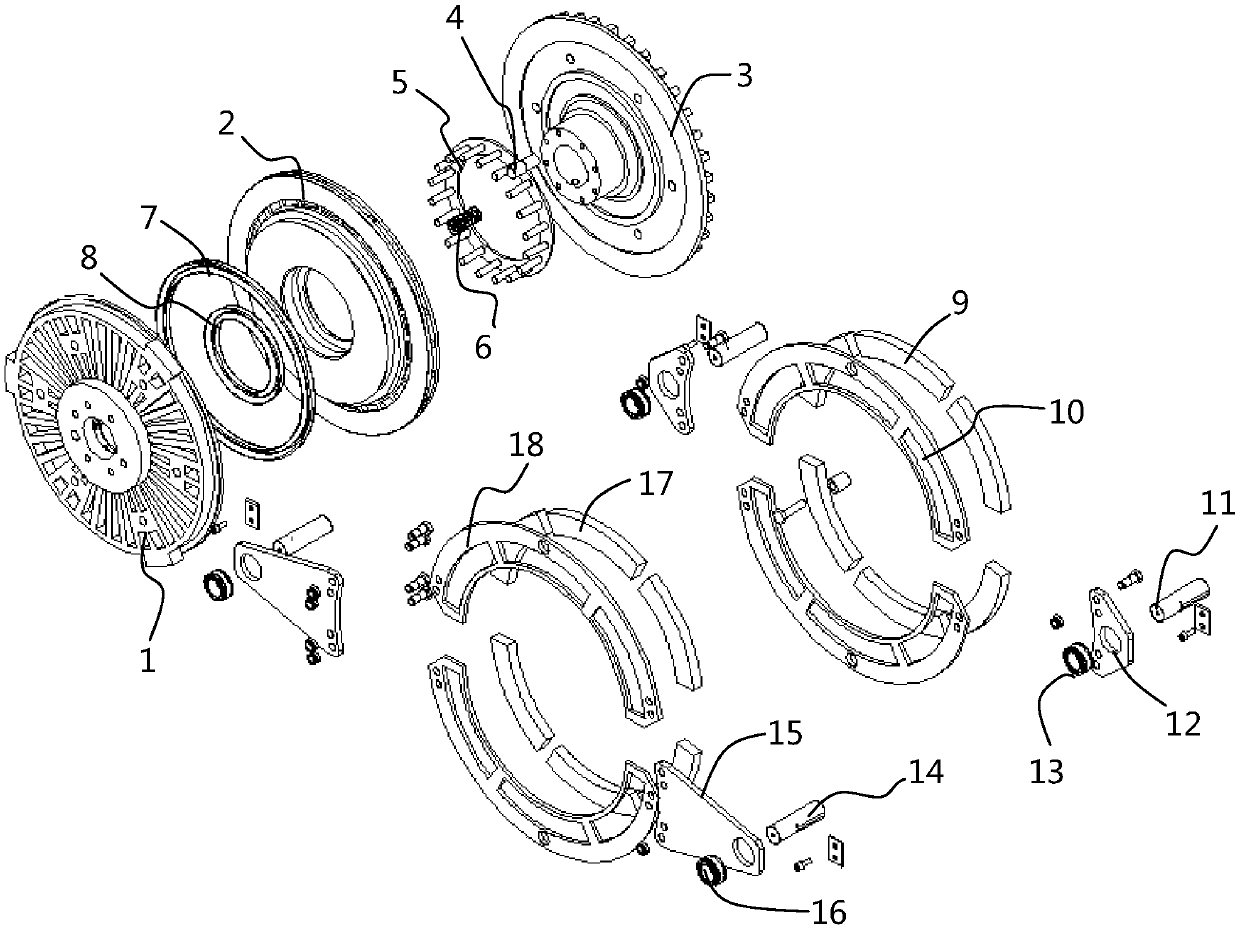

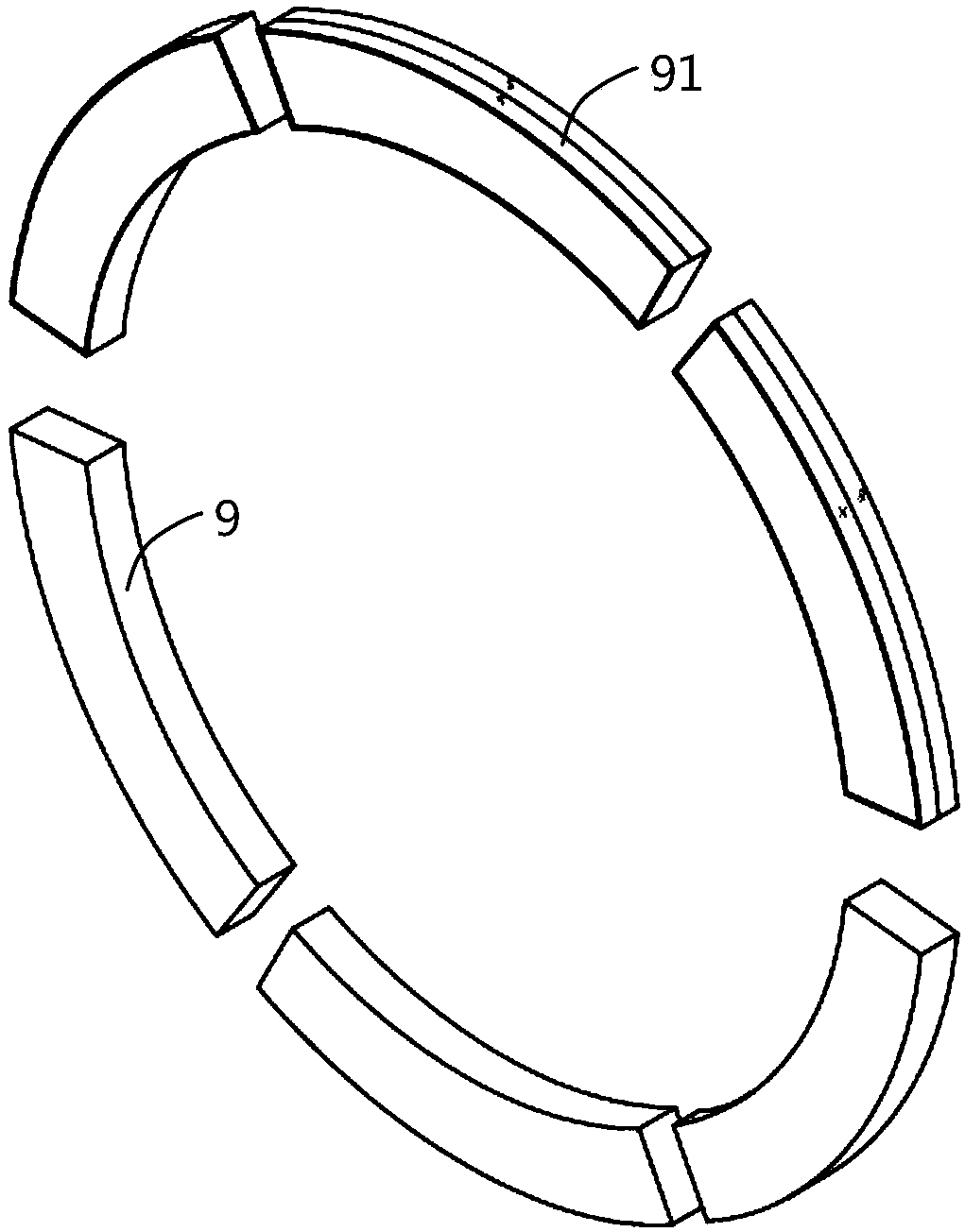

Self-adaptive multi-disc sequenced large torque friction clutch

The invention discloses a self-adaptive multi-disc sequenced large torque friction clutch which comprises a friction disc supporting plate, an inner disc spiral raceway sleeve and a plurality of outerfriction discs and inner friction discs alternately arranged between the friction disc supporting plate and the inner disc spiral raceway sleeve, the outer edge of each outer friction disc is in spline fit to the inner wall of an outer disc spline sleeve, the inner edge of each inner friction disc is in spline fit to the outer wall of an output spiral raceway drum, a plurality of inner disc starting retainer rings are mounted on the outer wall of the output spiral raceway drum in a sleeving manner, and each inner disc starting retainer ring is located on the side, close to a friction disc supporting plate, of each inner friction disc. By adopting the structure, the response speed is improved greatly, so that the quantity of the friction discs can be increased greatly, and therefore, the friction clutch can be applied to a large torque scene. It can be ensured that the inner friction discs and the outer friction discs are separated thoroughly and defects of a conventional multi-disc friction clutch are overcome, so that the wear resistance, stability and reliability of the friction clutch are improved greatly.

Owner:SOUTHWEST UNIV

Adaptive multi-plate sequencing large-torque friction clutch device with one-way transmission function

The invention discloses an adaptive multi-plate sequencing large-torque friction clutch device with a one-way transmission function. The adaptive multi-plate sequencing large-torque friction clutch device comprises a power input mechanism used for inputting power and a main shaft used for outputting the power, an inner plate spiral raceway sleeve, a friction clutch and an elastic element set are installed on the main shaft in a sleeving mode, the friction clutch comprises a friction plate supporting part arranged on the inner plate spiral raceway sleeve, a plurality of outer friction plates and a plurality of inner friction plates, wherein the outer friction plates and the inner friction plates are alternately arranged between the friction plate supporting part and the inner plate spiral raceway sleeve, all the outer friction plates can slide in the axial direction of the friction plate supporting part, and all the inner friction plates can slide in the axial direction of the inner plate spiral raceway sleeve. According to the scheme, one-way transmission of the power can be achieved, meanwhile the multiple outer friction plates and the multiple inner friction plates which are alternately arranged are utilized, thus born torque is dispersed on each outer friction plate and each inner friction plate, the friction loss is greatly lowered, the defect of poor wear resistance of a traditional disc-type friction clutch is overcome, thus the stability and reliability of the whole device are high, and the service life is long.

Owner:SOUTHWEST UNIVERSITY

Elastic besom with adjustable elasticity

The invention discloses an elastic besom with adjustable elasticity. The elastic besom comprises a cylinder body, a piston rod, a piston, a brush, a pressure spring, a pressing plate and an adjustment bolt, wherein the cylinder body is arranged upside down, namely an opening of the cylinder body is downward; a threaded hole is formed in the rear wall of the cylinder body; the adjustment bolt is arranged in the threaded hole in a penetrating manner; the lower end of the adjustment bolt is propped against the pressing plate; the pressing plate is positioned in the inner cavity of the cylinder body; the piston is arranged on the piston rod; the pressure spring is arranged between the piston and the pressing plate; the lower end part of the piston rod is detachably connected with the brush; the brush of the elastic besom can elastically stretch according to the ups and downs change of a pavement, so that the abrasion to the bristles is alleviated, and the service life of the brush is prolonged; furthermore, the brush can be independently replaced, and the whole cleaning disk does not need to be replaced, so that the cost can be reduced. More importantly, the elasticity of elastic stretching of the elastic besom can be adjusted according to the abrasion degree of each brush, so that the abrasion to the brush can tend to be consistent; meanwhile, the cleaning requirements of different pavements can be met.

Owner:李丽容

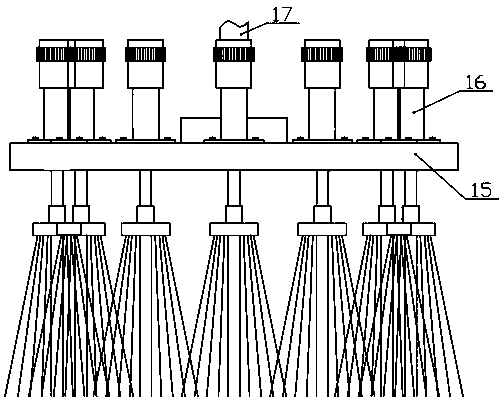

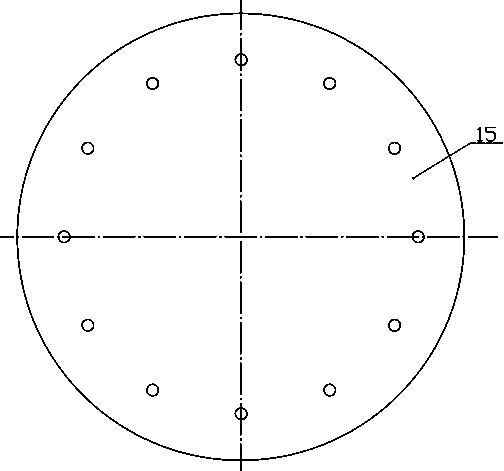

Novel multi-wire sawing machine

ActiveCN104760142AReduce in quantityShorten the lengthWorking accessoriesStone-like material working toolsDrive wheelEngineering

A novel multi-wire sawing machine comprises stand columns, a main cross beam, vertical lifting devices, a drive end rack, a rack cross beam, a tensioning end rack, a driving wheel, guiding wheels, tensioning wheels, two locating wheels, diamond string bead wires and a quarry stone vehicle. The novel multi-wire sawing machine is characterized in that the tensioning wheels are fixed on the rack cross beam and located between the stand columns on the two sides, the driving wheel and the guiding wheels are fixed on the edges of the stand columns on the two sides, and the locating wheels are symmetrically fixed at the two sides of the quarry stone vehicle. According to the novel multi-wire sawing machine, the guiding wheel number is decreased, the cost is lowered, the operation is simplified, the structure is compact, the service life of the string bead wires is prolonged, the stand columns on the two sides are stressed evenly, and the operational stationarity of an overall wheel train system is improved. The novel multi-wire sawing machine has the advantages of being reasonable in stress, simple in structure, high in machining accuracy, stable in work, low in maintenance cost and the like.

Owner:福建天石源科技股份有限公司

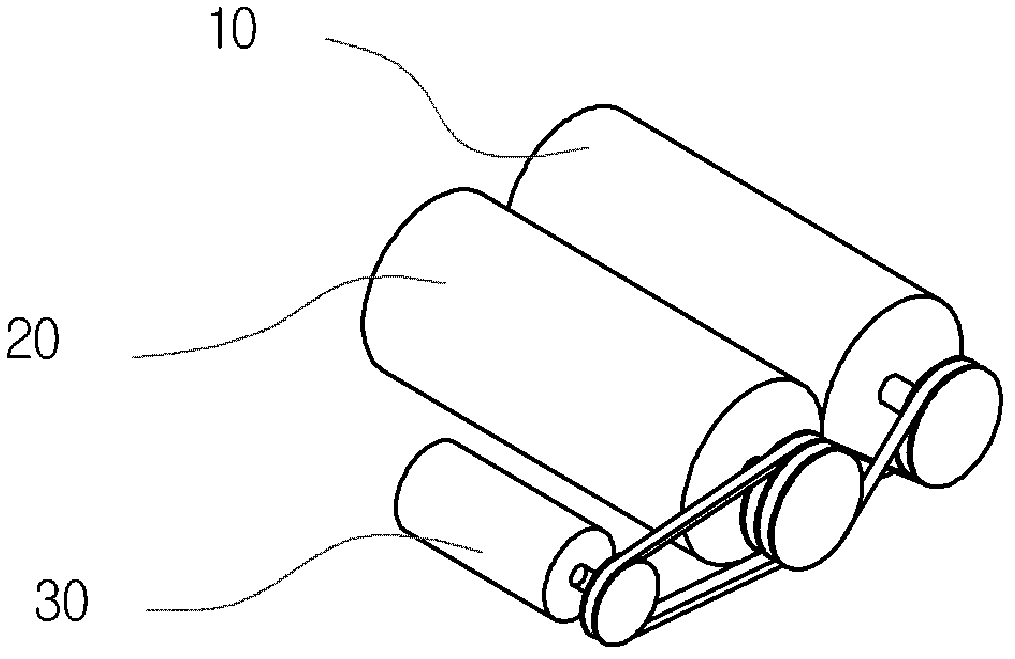

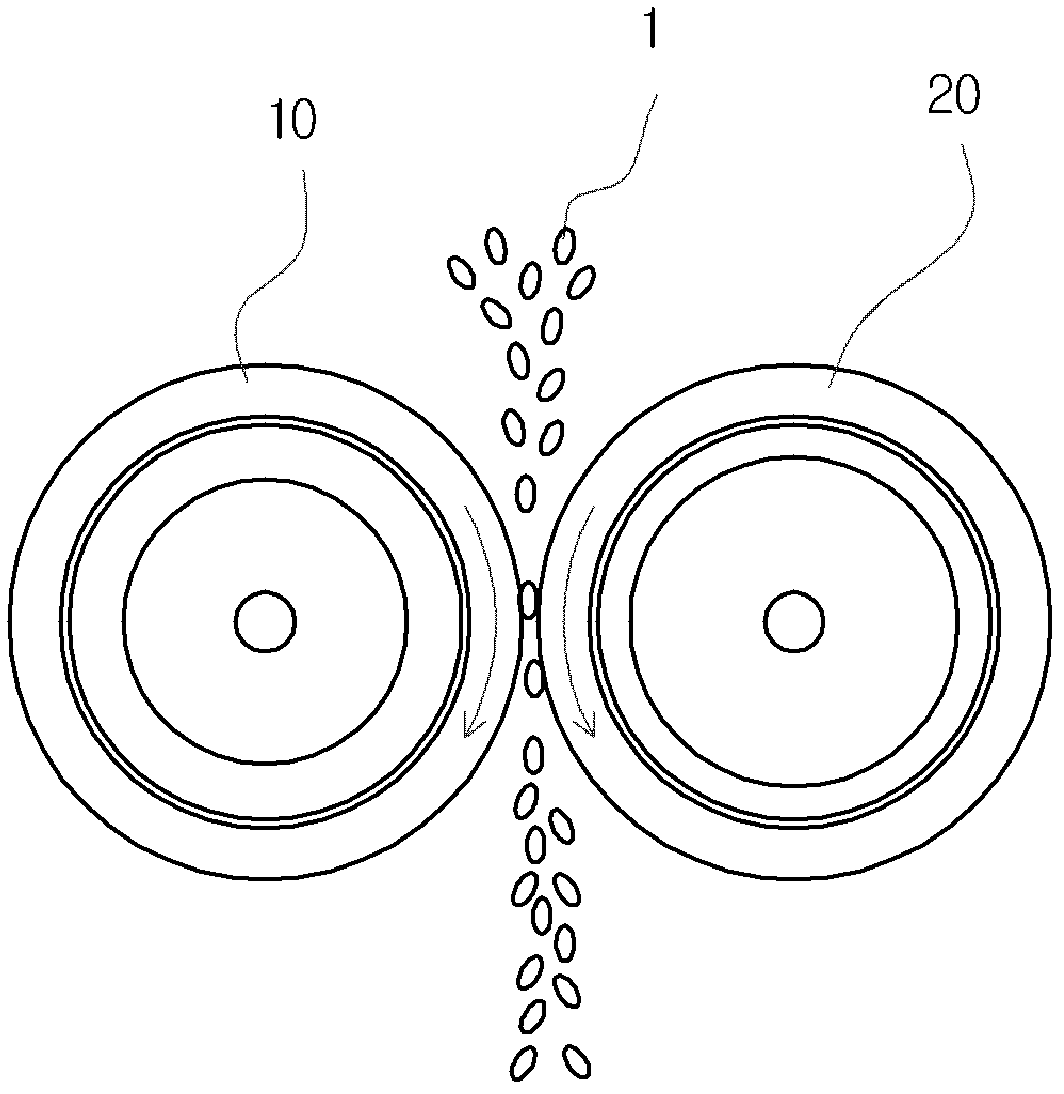

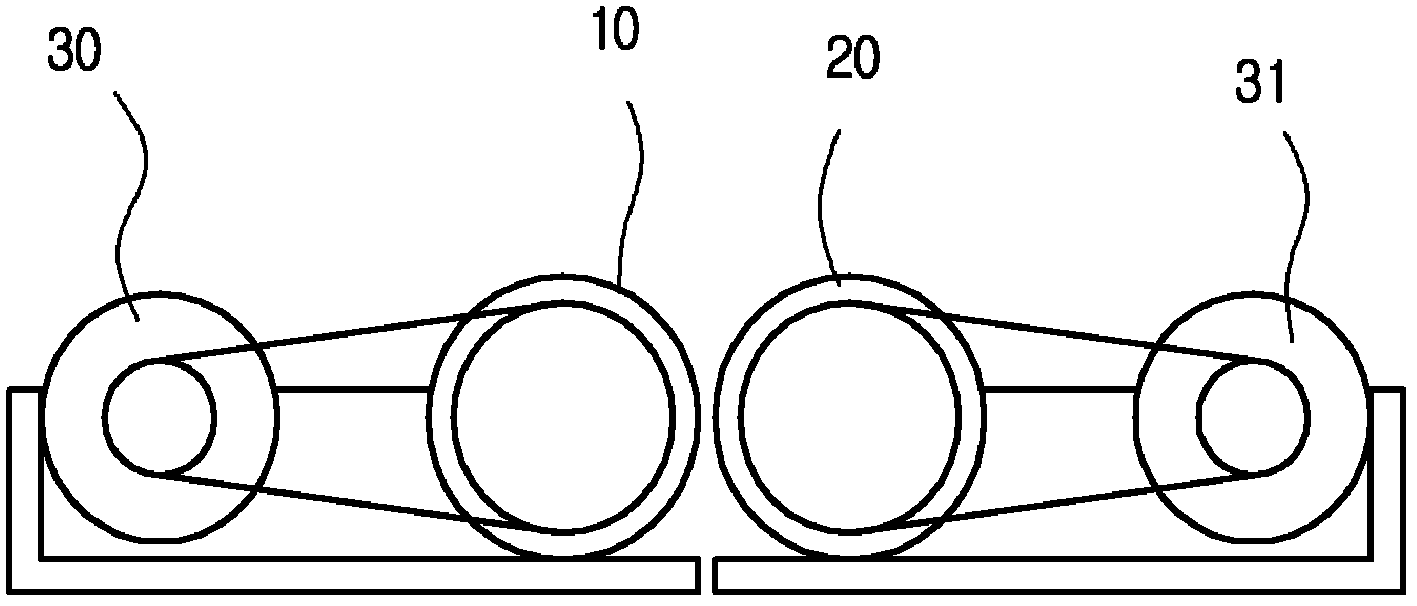

Peeling rollers of hulling machine and driving method thereof

InactiveCN102614953AConsistent wearExtended use timeGrain huskingGrain polishingEngineeringMechanical engineering

The invention provides a hulling machine for peeling paddy rice through a pair of peeling rollers rotating at different speeds, and particularly relates to peeling rollers of the hulling machine and a driving method thereof. Each peeling roller is partitioned into two parts of different diameters in a length direction respectively; and after the peeling roller of a smaller diameter on one side and the peeling roller of a larger diameter on one side in the pair of peeling rollers are arranged oppositely, and the peeling rollers rotate at the same rotating speed, so that peeling is realized. The peeling rollers are constructed in a way that: in the hulling machine in which the pair of peeling rollers are arranged oppositely and rotate at different rotating speeds respectively, each peeling roller is partitioned into two parts in the length direction, the diameter of one side is smaller than that of the other side, a part of the peeling roller on a smaller-diameter side and a part on a larger-diameter side are arranged oppositely, and a larger-diameter part and a smaller-diameter part are arranged oppositely.

Owner:崔在天

Combined pneumatic dry-type friction clutch brake for forging machine

PendingCN108679127AConsistent wearMove quicklyBraking discsBrake actuating mechanismsMagnetic polesClutch

The invention discloses a combined pneumatic dry-type friction clutch brake for a forging machine, and belongs to the technical field of clutches. The combined pneumatic dry-type friction clutch brakecomprises a clutch disc, first friction blocks, a brake disc and second friction blocks; a plurality of strip-shaped through holes are formed in the disc face of the clutch disc in the circumferential direction, first fixed magnetic pole pieces comprising N poles and S poles are arranged around the strip-shaped through holes, first movable magnetic pole pieces with opposite N poles and S poles are arranged around the first friction blocks, and the first friction blocks are arranged in the strip-shaped through holes in a clearance fit mode; and a plurality of strip-shaped through holes are formed in the disc face of the brake disc in the circumferential direction, second fixed magnetic pole pieces comprising N poles and S poles are arranged around the strip-shaped through holes, second movable magnetic pole pieces with opposite N poles and S poles are arranged around the second friction blocks, and the second friction blocks are arranged in the strip-shaped through holes in a clearancefit mode. Therefore, the first friction blocks and the second friction blocks can move towards one side quickly and basically synchronously, and it is ensured that abrasion of the friction blocks isconsistent.

Owner:ANHUI LIYUAN NUMERICAL CONTROL CUTTING TOOL & PATTERNS MFG

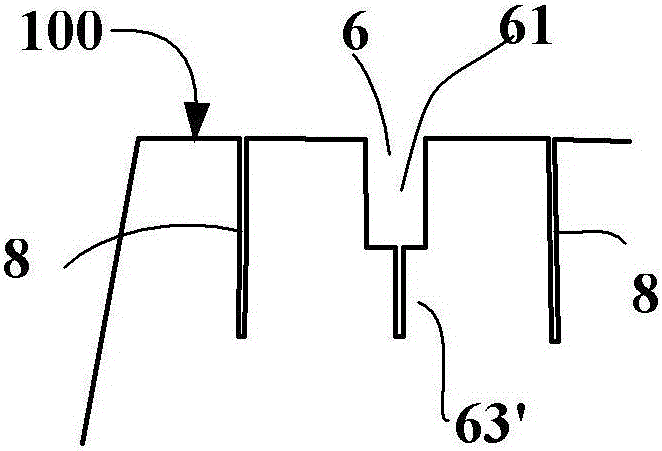

Evolving tread for a tyre

ActiveCN105793068AImprove drainage capacitySatisfactory drainageTyre tread bands/patternsEngineeringMechanical engineering

Tread (10) for heavy goods vehicle tyre comprising, over a first axial part (M) a groove (2, 4) that is wavy in the thickness and continuous in a first direction, and grooves (6, 7) that are wavy in the thickness and continuous in a second direction and connected to a groove (2, 4) that is wavy in the first direction and, over a second axial part (B) of the tread a groove (1, 5) that is wavy in the thickness and continuous in a third direction and grooves (6, 7) that are wavy in the thickness and continuous in a fourth direction and connected to a groove (1, 5) that is wavy in the third direction, this tread being such that, when new, the parts that are open onto the tread surface in the first axial part (M) are connected to one another to form a continuous surface network and in that the parts that are open onto the tread surface in the second axial part (B) are discontinuous with one another and, once a partial wear state has been crossed, the parts that are open onto a new tread surface (100') in the second axial part (B) are connected to one another to form a continuous surface network and in that the parts that are open onto the new tread surface (100') in the first axial part (M) are discontinuous with one another.

Owner:OCIETE DE TECH MICHELIN

Pneumatic vehicle tyre

ActiveCN105829131AReduced and even wearUniform wearHeavy duty tyresHeavy duty vehiclePulp and paper industryTread

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

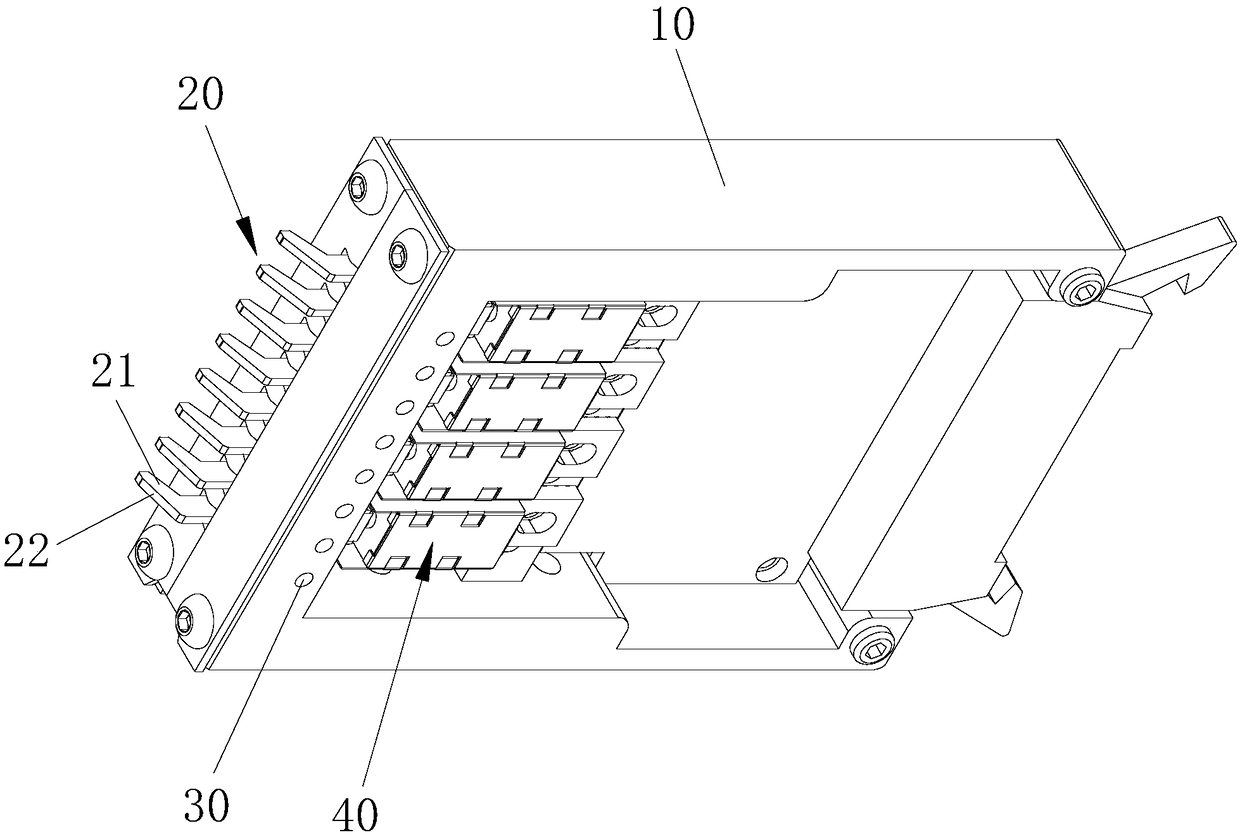

Pin selecting piece group of pin selector

ActiveCN108265383AShorter friction contact travelExtended service lifeWeft knittingTool bitAcute angle

The invention relates to a pin selecting piece group of a pin selector. The pin selecting piece group comprises a plurality of pin selecting pieces which are connected onto a shell of the pin selectorin a swinging manner and correspond to striking pins projecting out of a pattern bit, axis of oscillation of the plurality of pin selecting pieces are parallel to one another and stay on a same plane, each pin selecting piece is provided with a tool bit extending out of the pin selector shell, the tool bit is provided with an oblique surface, and the oblique surface can contact the striking pinscorresponding to the tool bit on the pattern bit in a sliding manner. The oblique surface forms an acute angle alpha with the length direction of the pin selecting piece, and the angle alpha corresponding to the oblique surface of the pin selecting piece is gradually increased according to a sequence from top to bottom. The oblique surface on the tool bit of the pin selecting piece has different oblique angles according to different positions, so that a friction contact distance between the original tool bit and the pattern bit is shortened, the friction force between the original tool bit andthe pattern bit is also reduced, the problem in the prior art that the striking pin is severely abraded on the pattern bit is solved, and the service life of the pattern bit is prolonged.

Owner:CHANGSHU CHANGRUN INTELLIGENT TECH

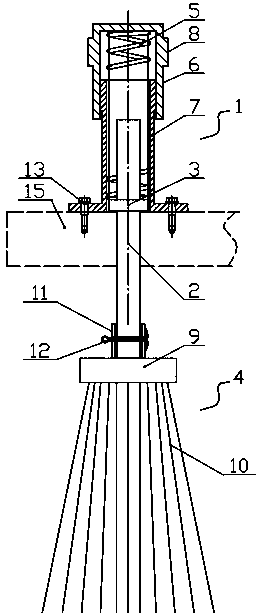

Punching calibration device for outer wall of furnace shell of intermediate frequency furnace

PendingCN114130888AConsistent wearGuaranteed punching effectMetal-working feeding devicesGrinding machinesPunchingIntermediate frequency

The invention belongs to the technical field of power equipment, and particularly relates to a punching calibration device for the outer wall of a furnace shell of an intermediate frequency furnace, the punching calibration device comprises a horizontal bottom plate, supporting columns are uniformly and fixedly mounted on the upper surface of the bottom plate, and a horizontal machining table is jointly and fixedly mounted at the tops of the uniformly arranged supporting columns; a clamping mechanism and a punching mechanism are mounted on the bottom plate; when the outer wall of the furnace shell of the intermediate frequency furnace is punched through the punching device, it is guaranteed that the abrasion degrees of all the cutting blocks are consistent, and therefore material waste is reduced; and after trepanning is finished, the grinding wheel horizontally moves in the rotating state to calibrate the two side walls of the kidney-shaped hole, it is guaranteed that the two side walls of the kidney-shaped groove are flush, and it is further guaranteed that the shape of the kidney-shaped hole is regular.

Owner:泰州市科健电炉电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com