Punching calibration device for outer wall of furnace shell of intermediate frequency furnace

The technology of a calibration device and an intermediate frequency furnace is applied in the field of electric power equipment, which can solve the problems of cutting knife wear, irregular shape of waist hole, material waste, etc., and achieve the effect of reducing material waste, ensuring shape regularity, and ensuring punching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

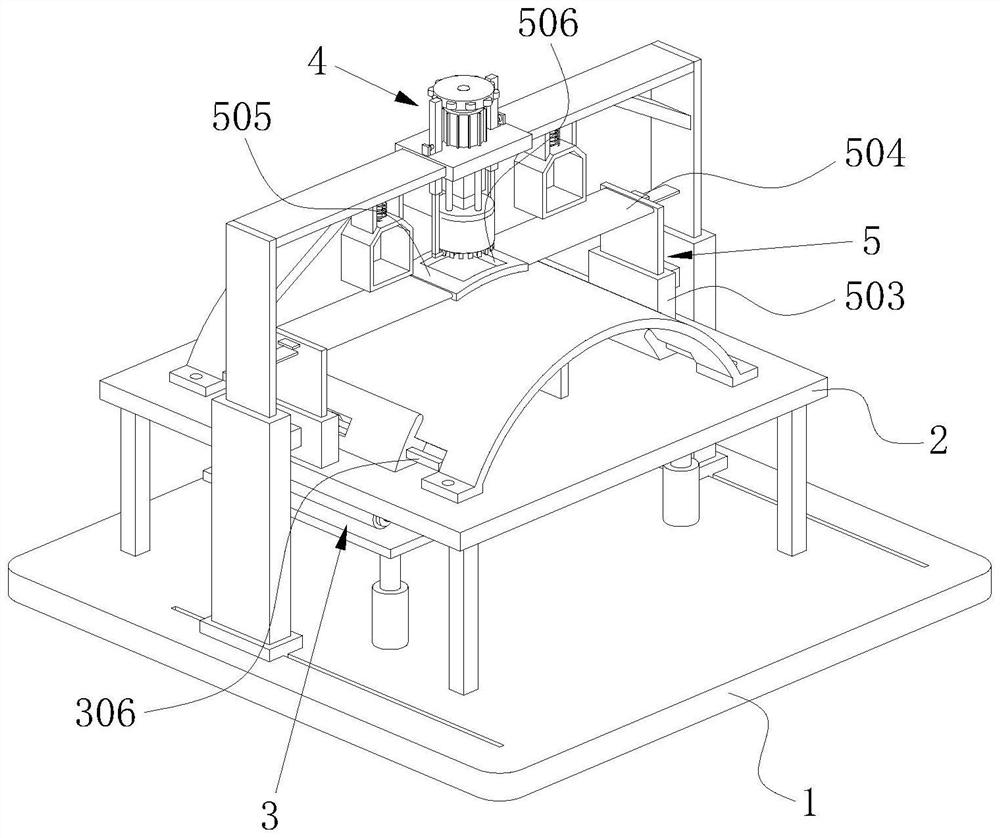

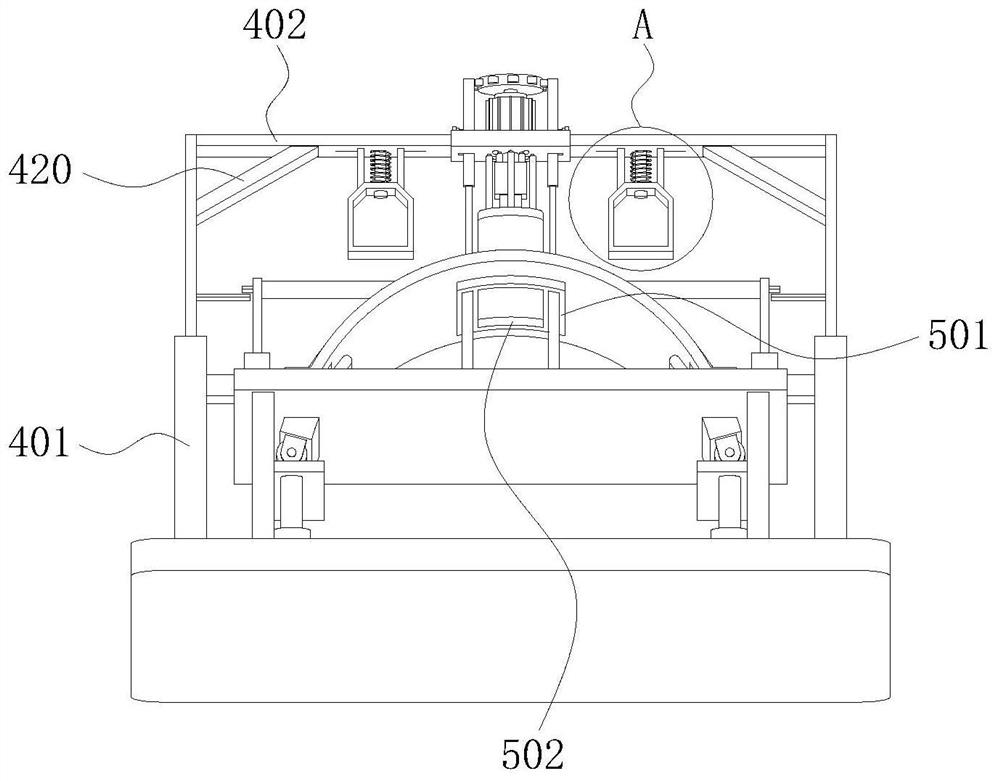

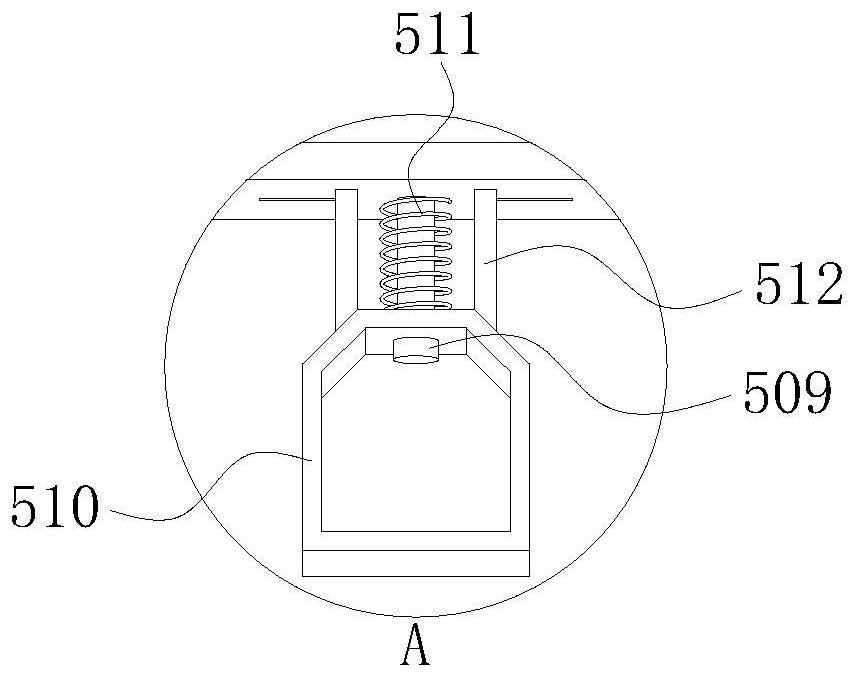

[0025] like figure 1 and Figure 4 As shown, this embodiment provides a drilling calibration device for the outer wall of the intermediate frequency furnace shell, including a horizontal bottom plate 1, the upper surface of the bottom plate 1 is uniformly fixed with support columns, and the top of the evenly arranged support columns is fixed and installed together with A horizontal processing table 2; a clamping mechanism 3 and a punching mechanism 4 are installed on the base plate 1; Through the processing table 2 and slidingly matched with the processing table 2, the top of the arc plate 301 is provided with a clamping groove, and the bottom end of the arc plate 301 is rotated by the bearing frame 302 to install a horizontal roller 303; the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com