Patents

Literature

57results about How to "Guaranteed punching effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

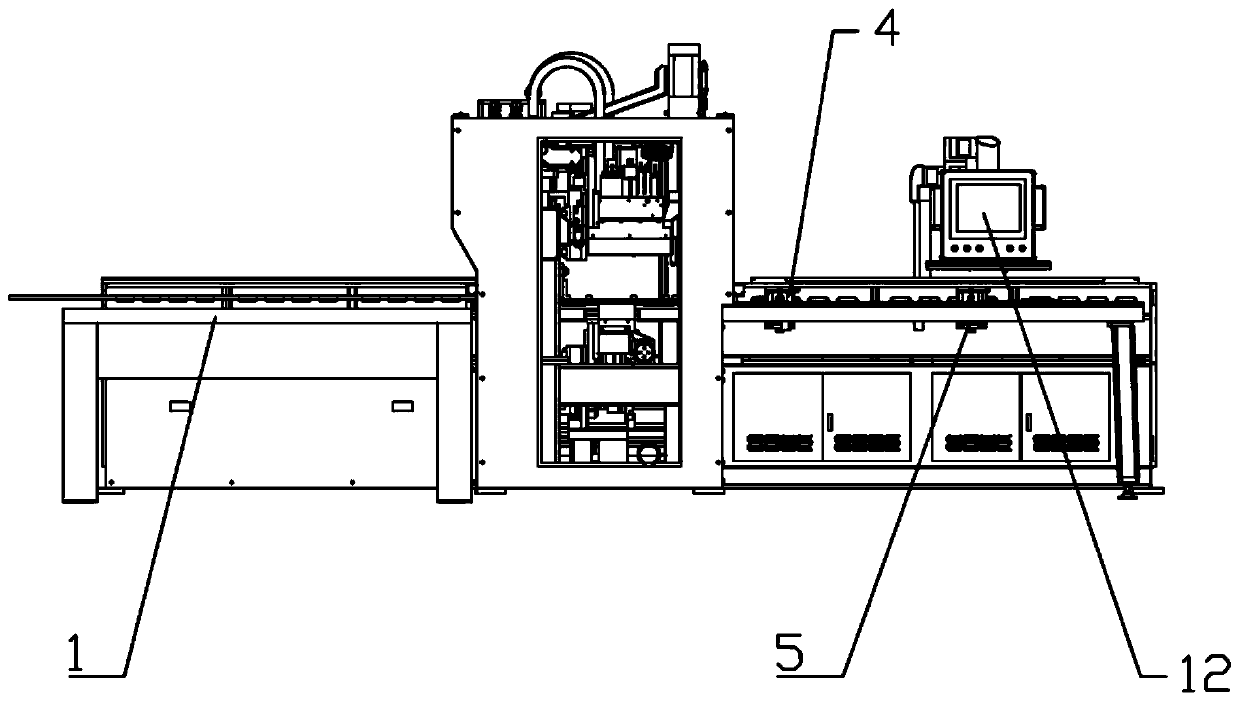

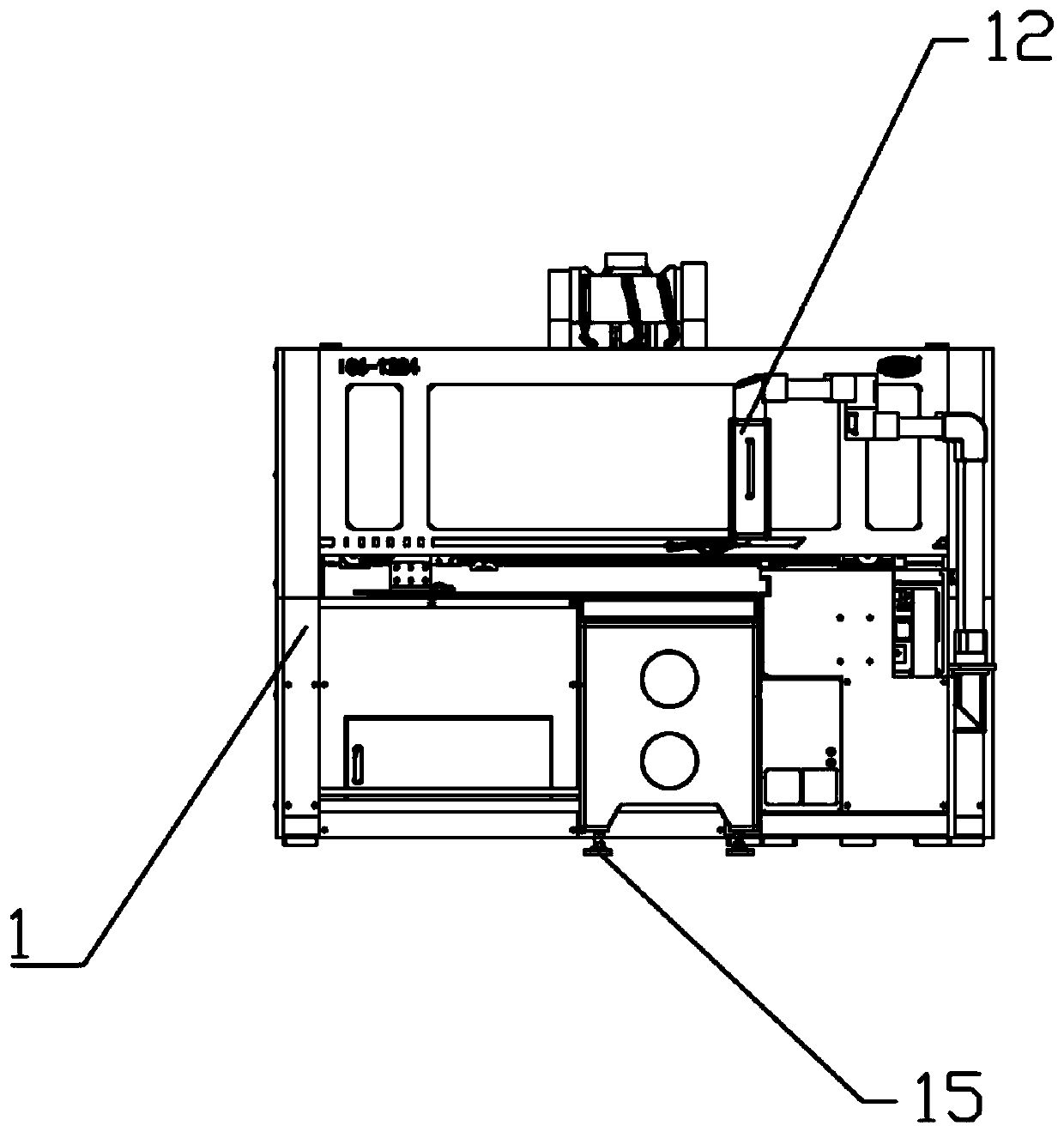

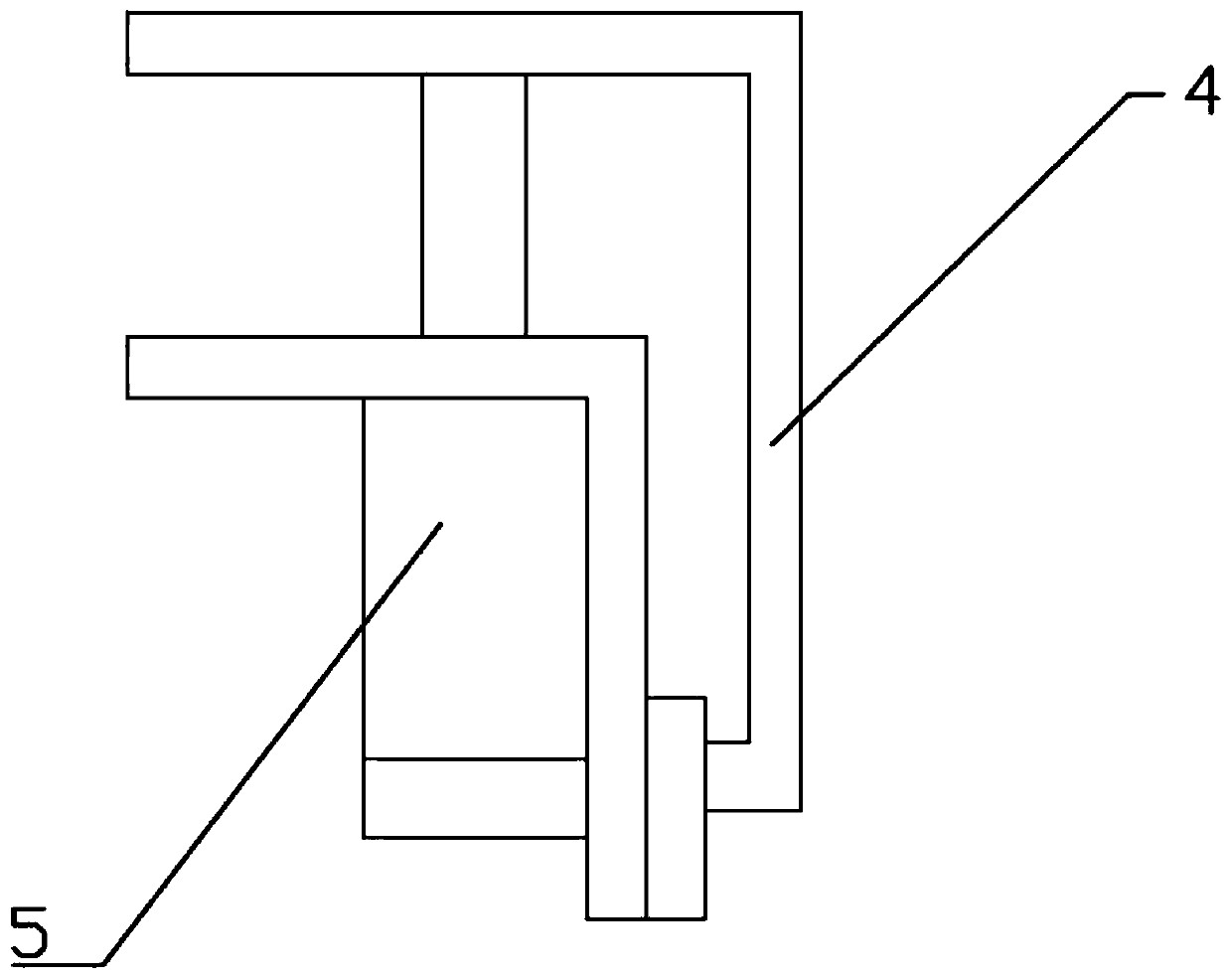

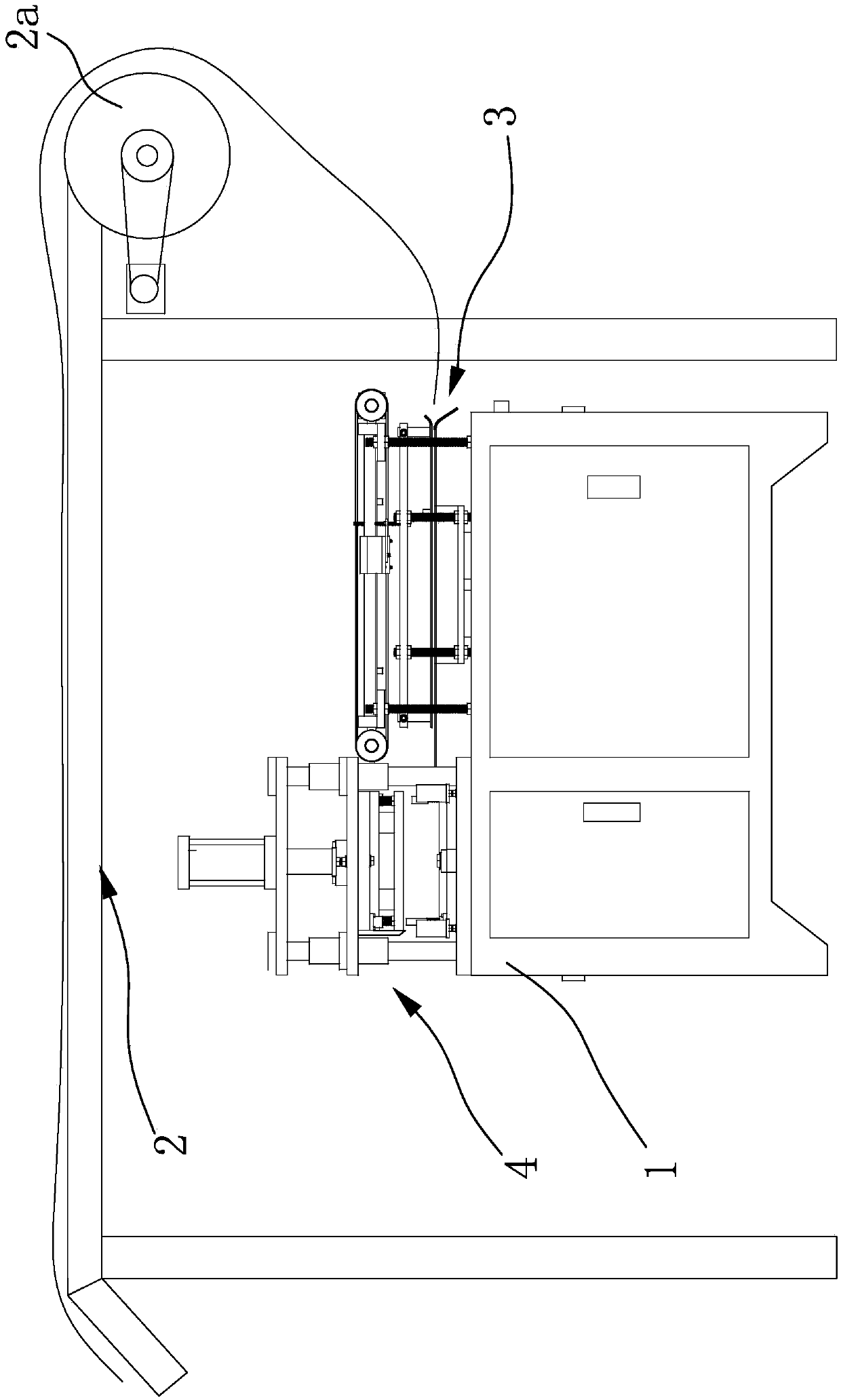

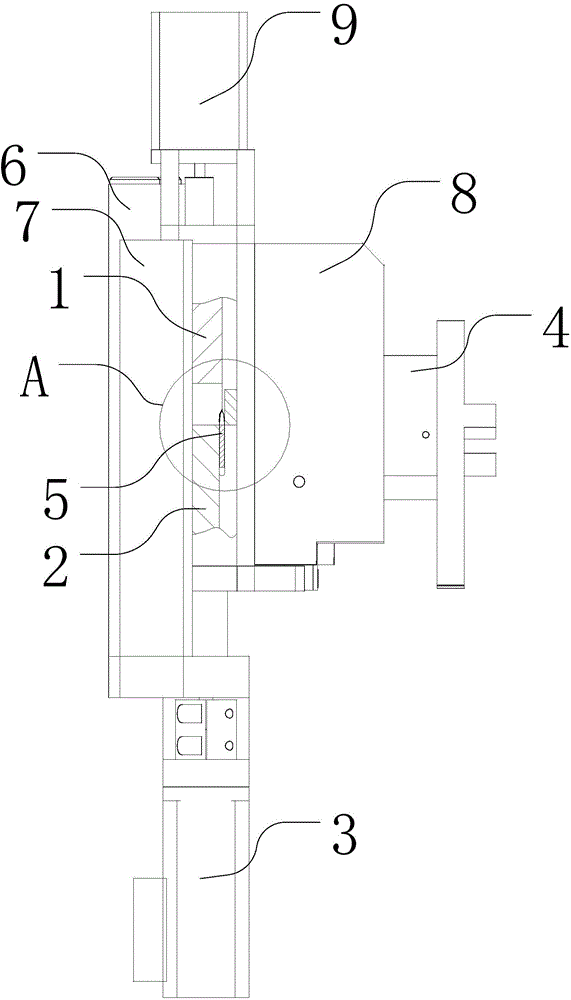

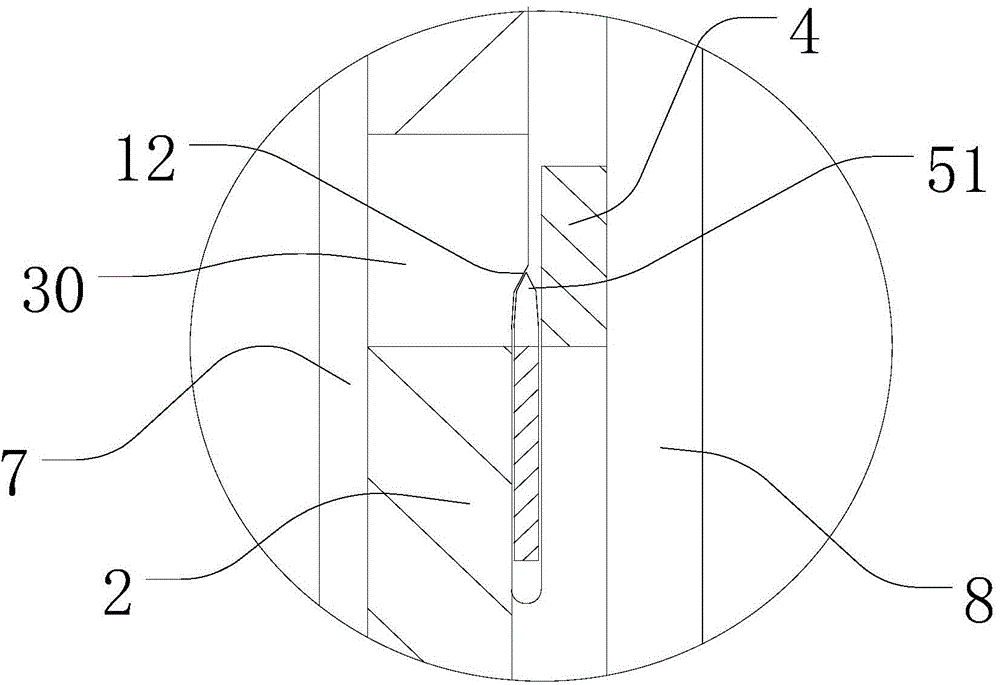

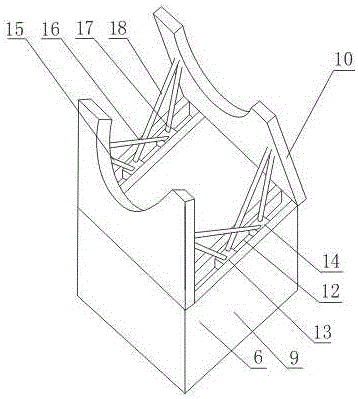

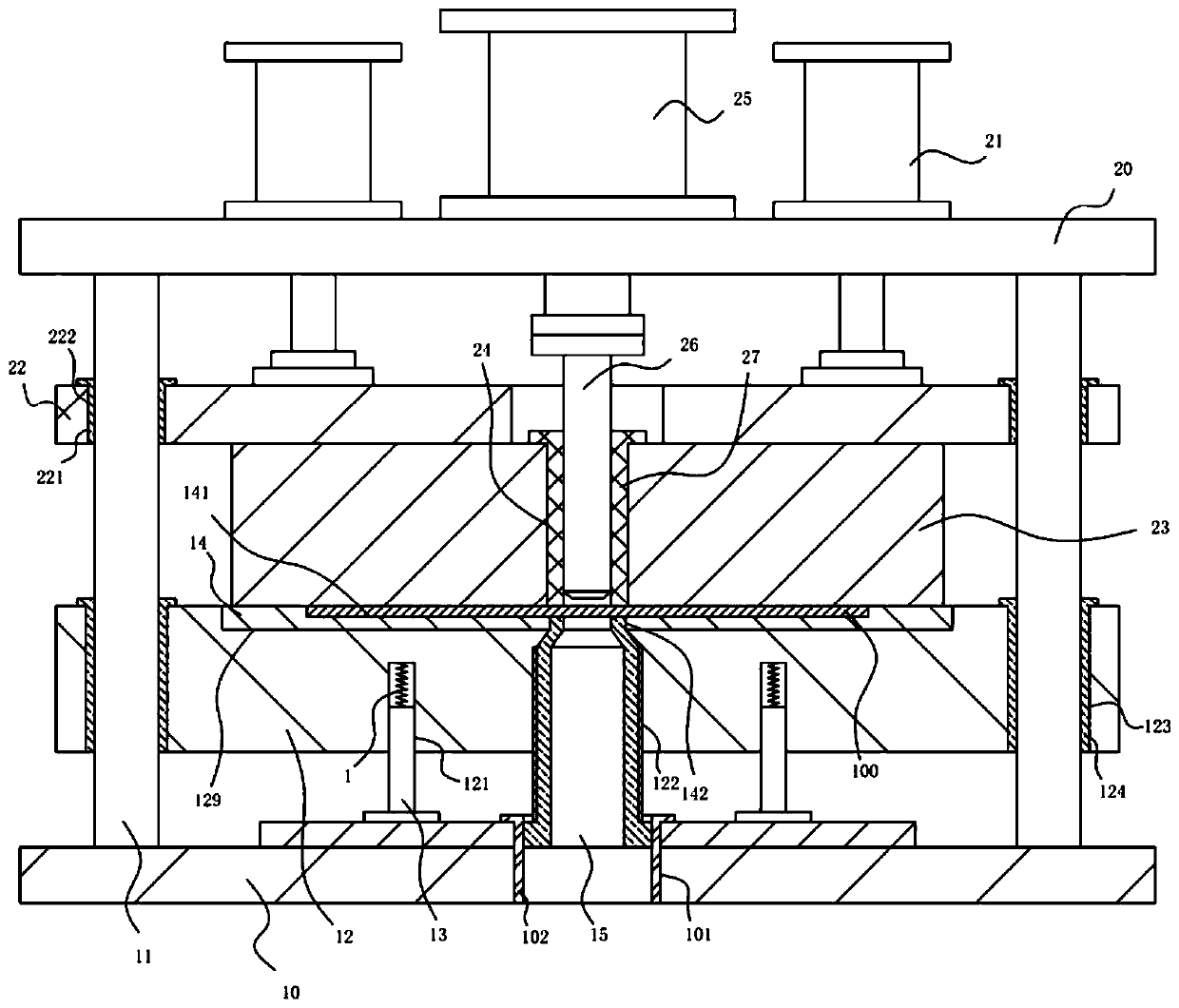

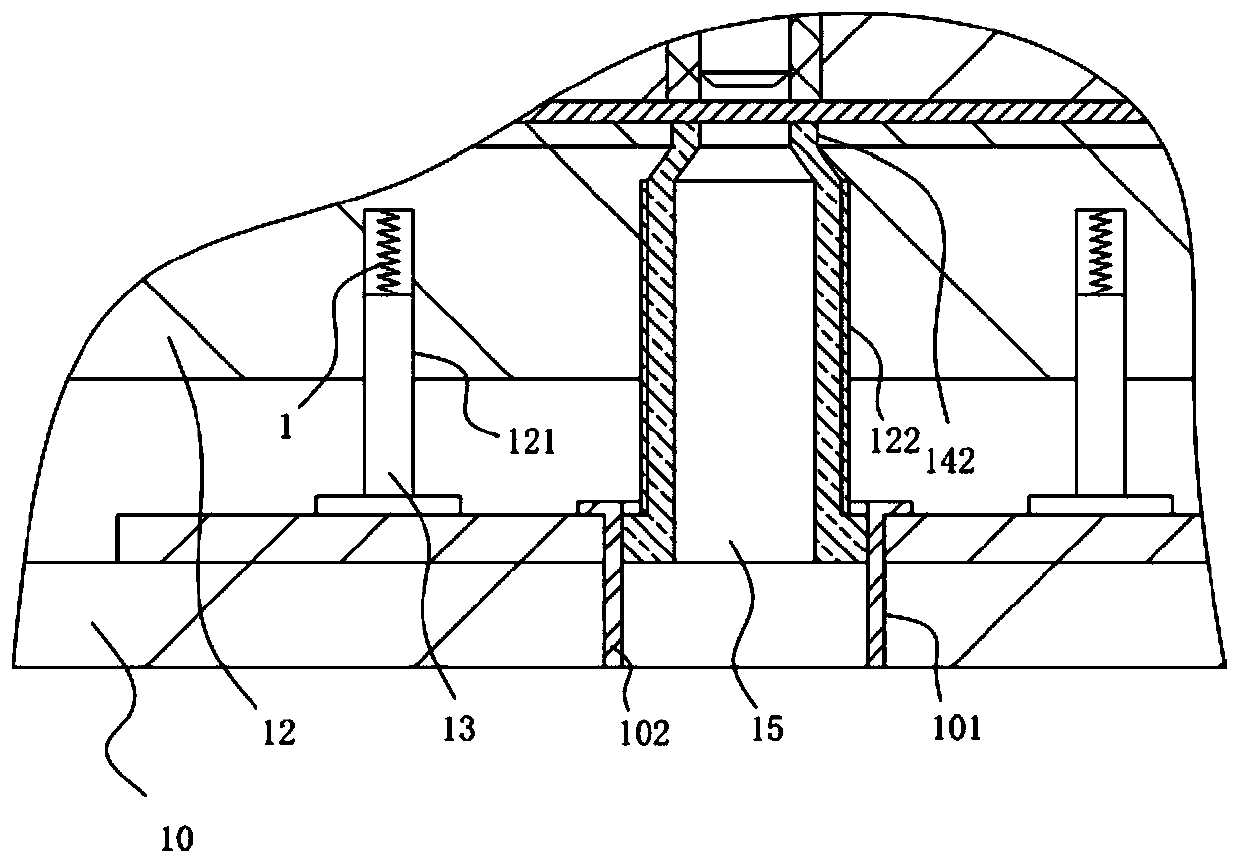

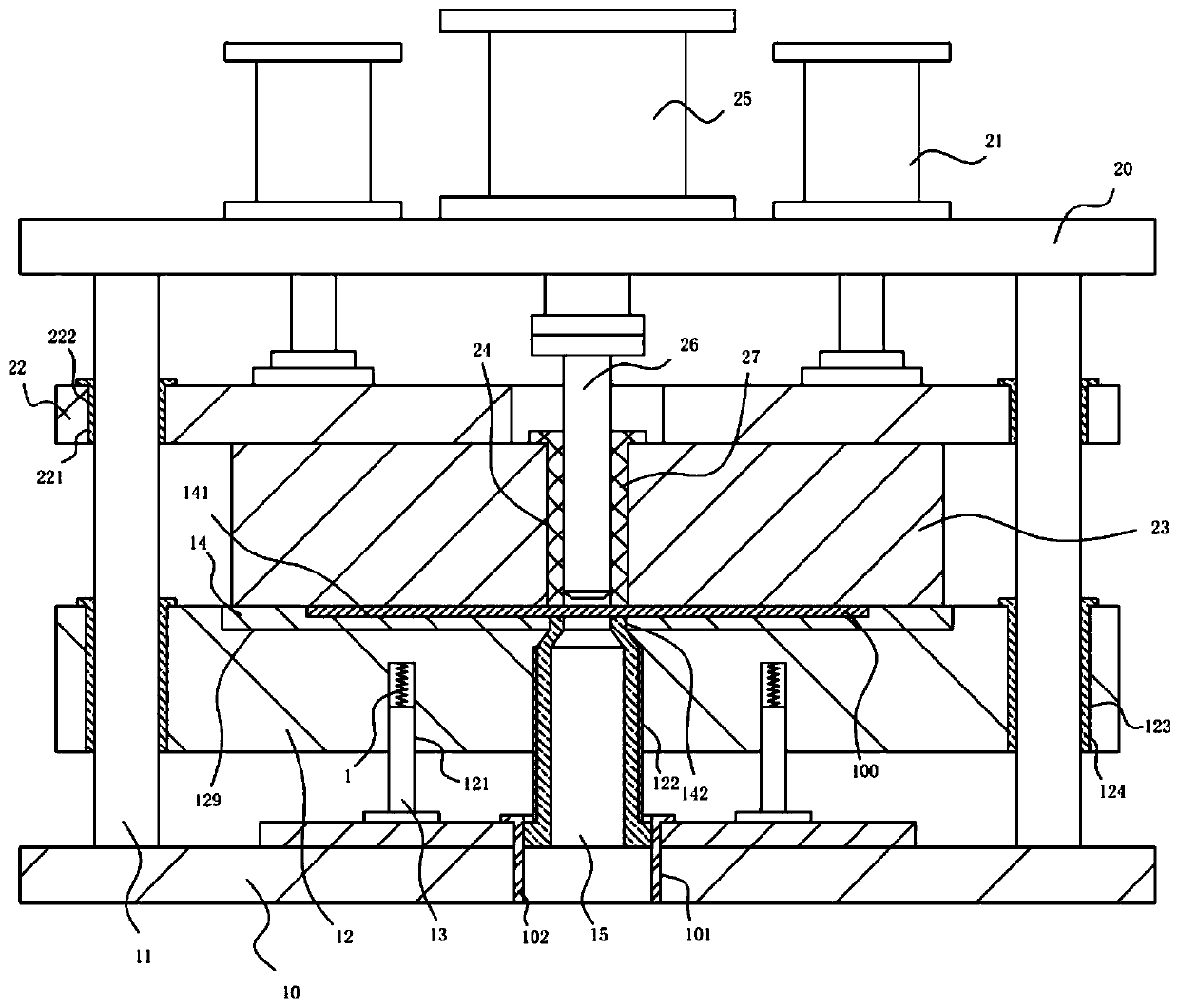

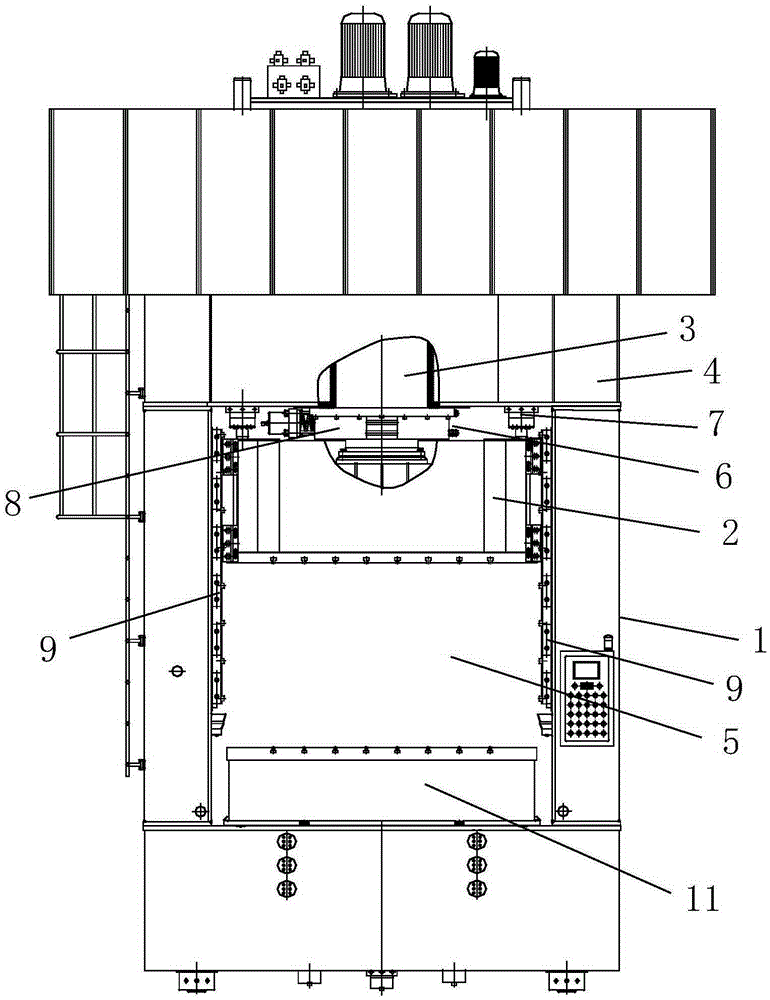

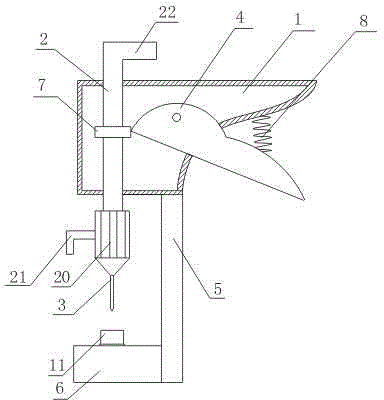

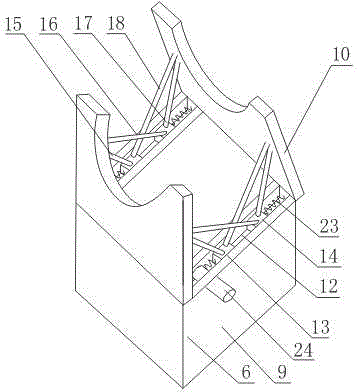

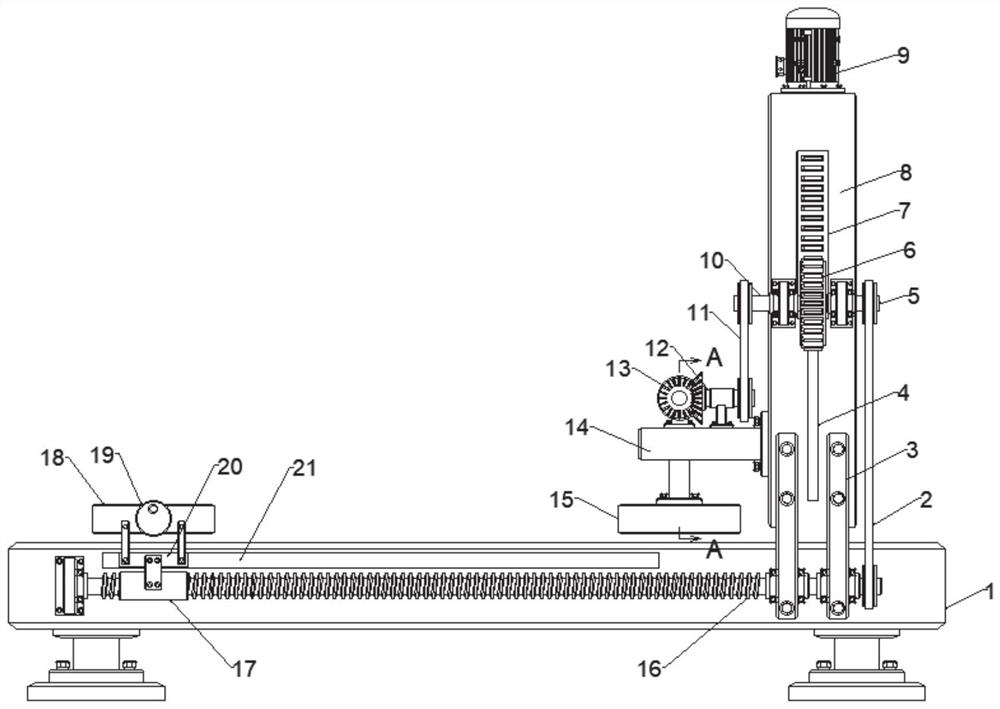

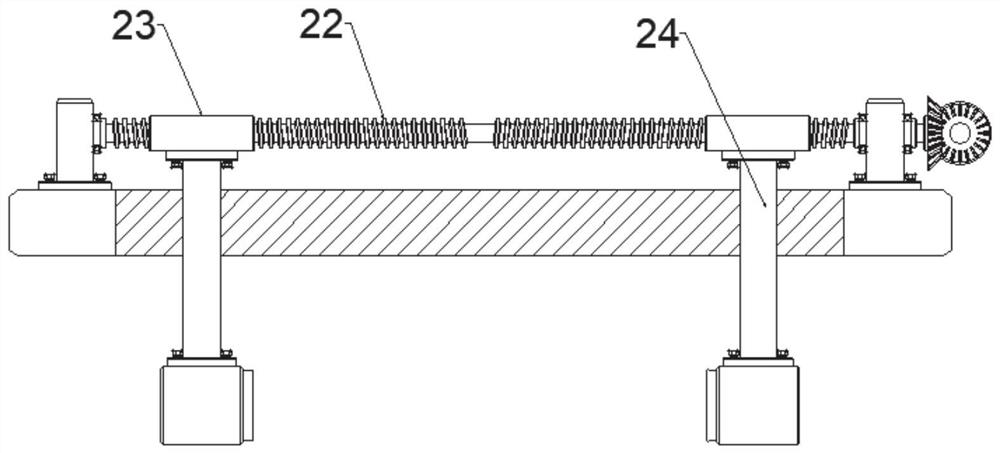

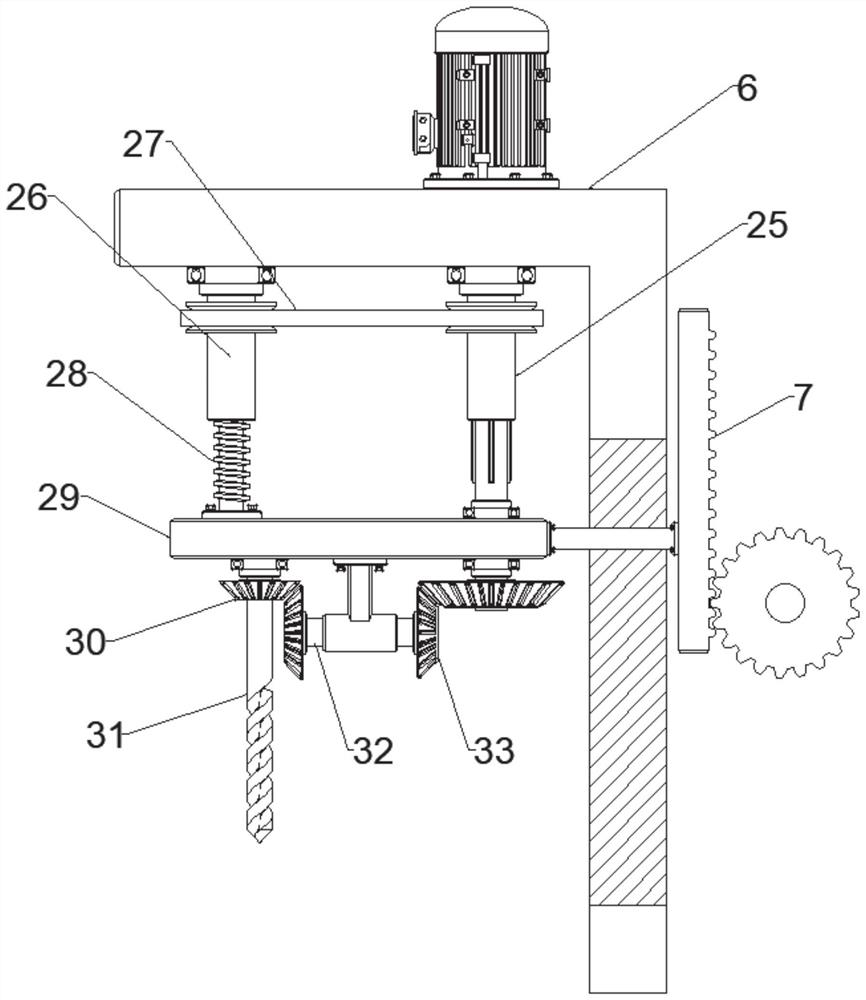

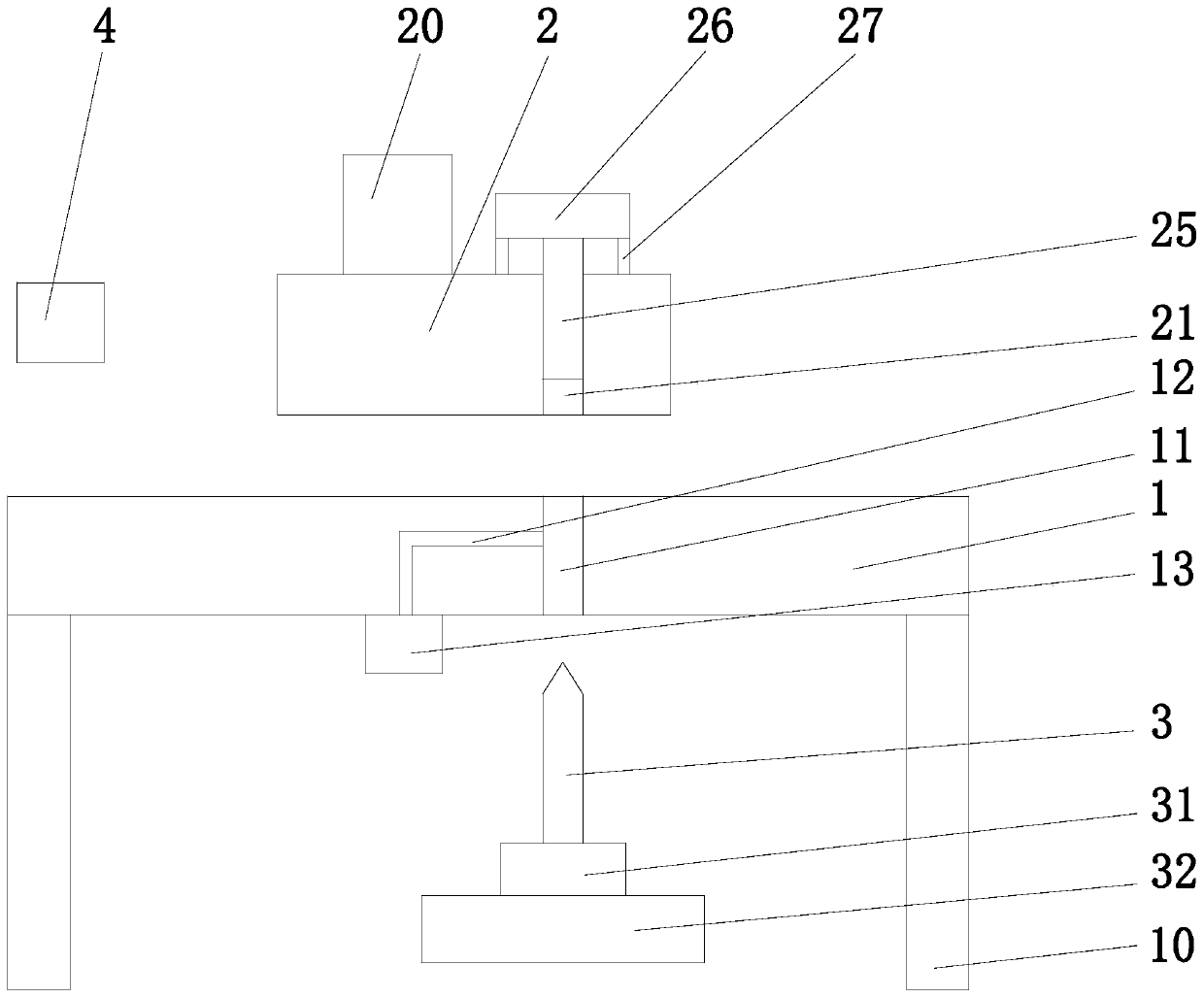

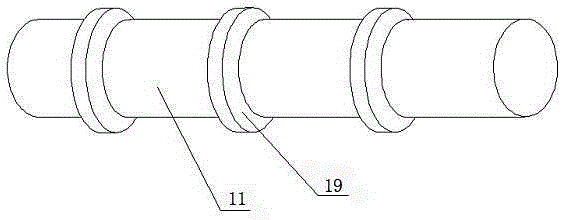

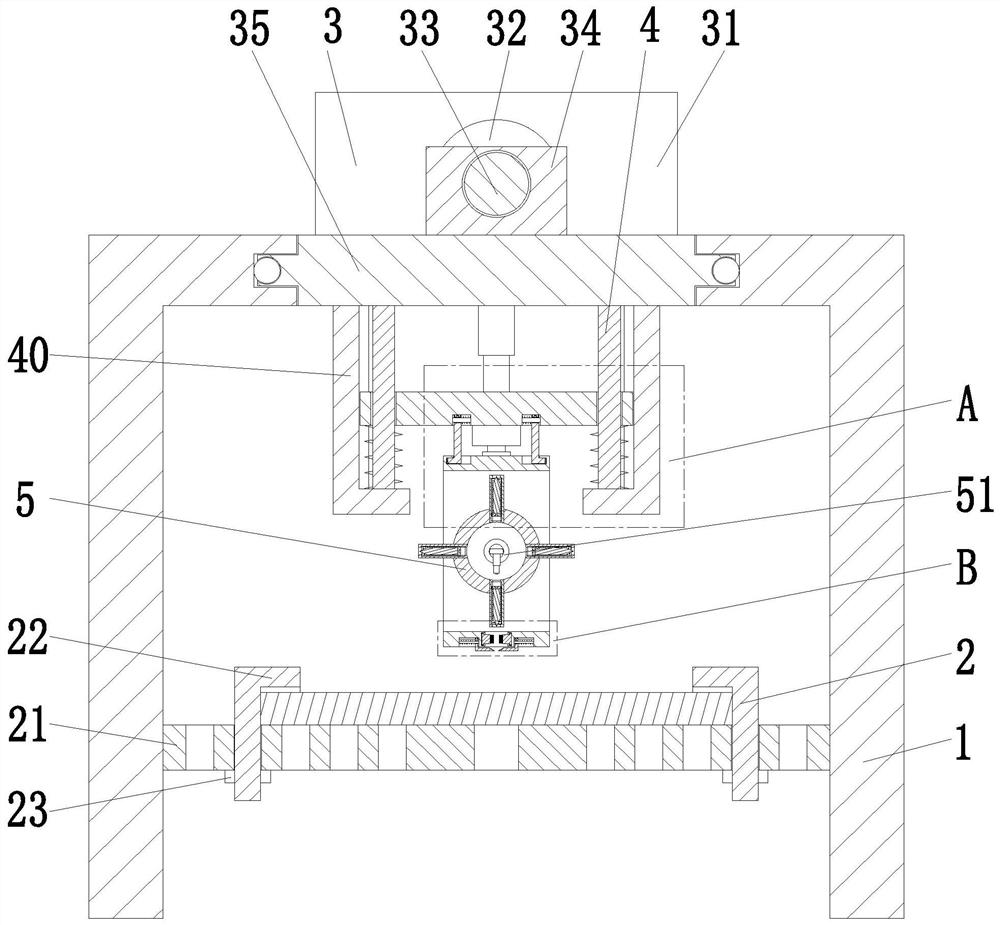

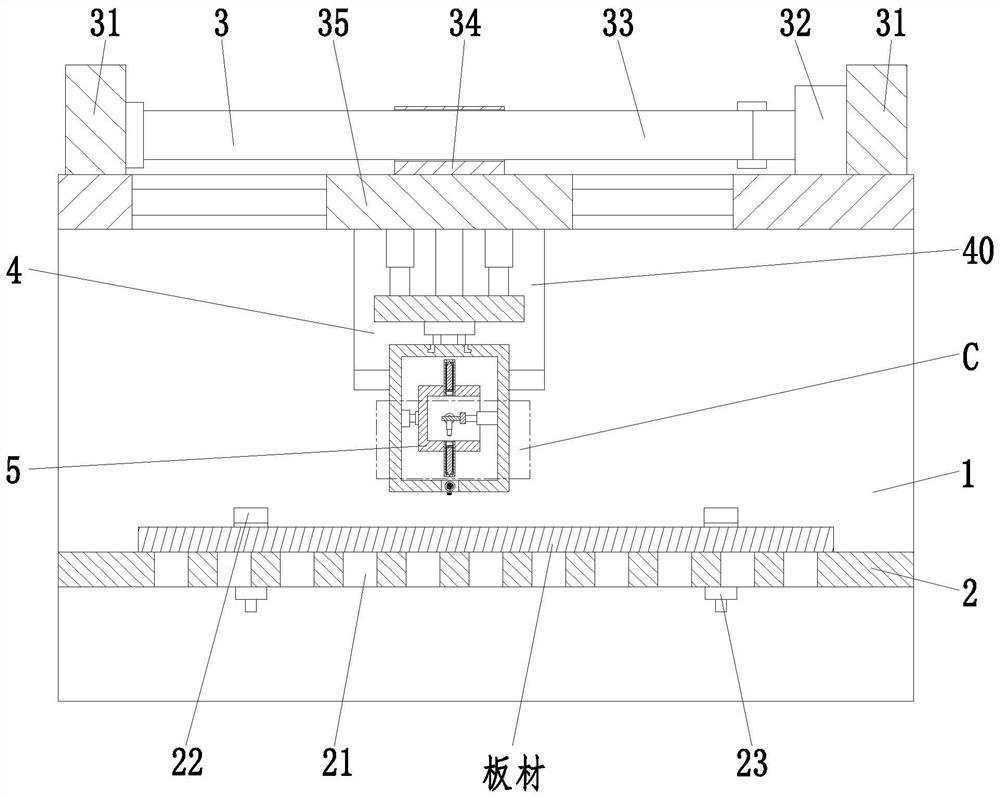

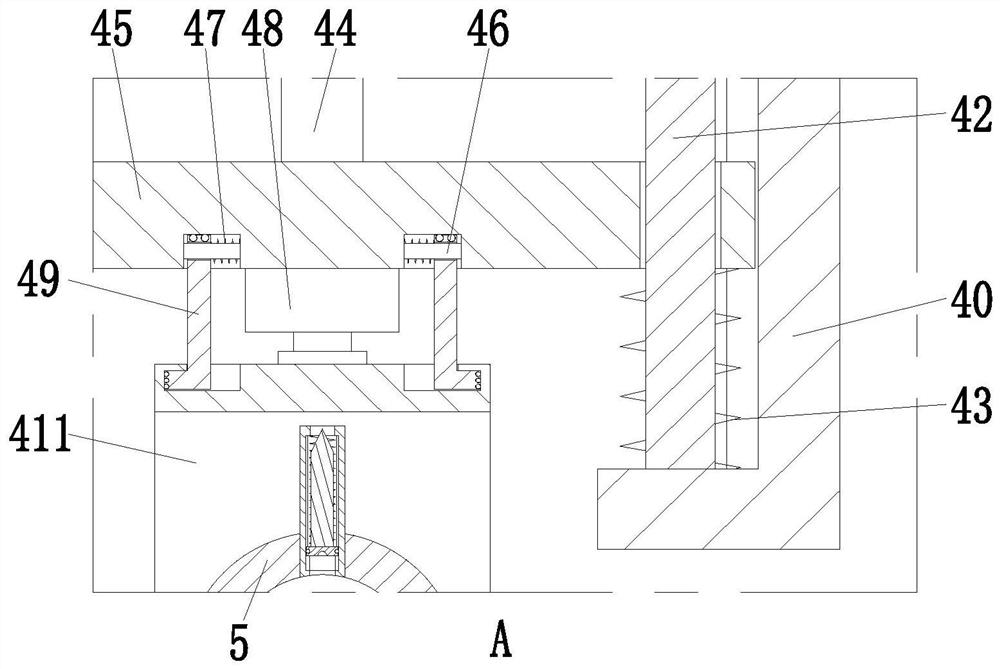

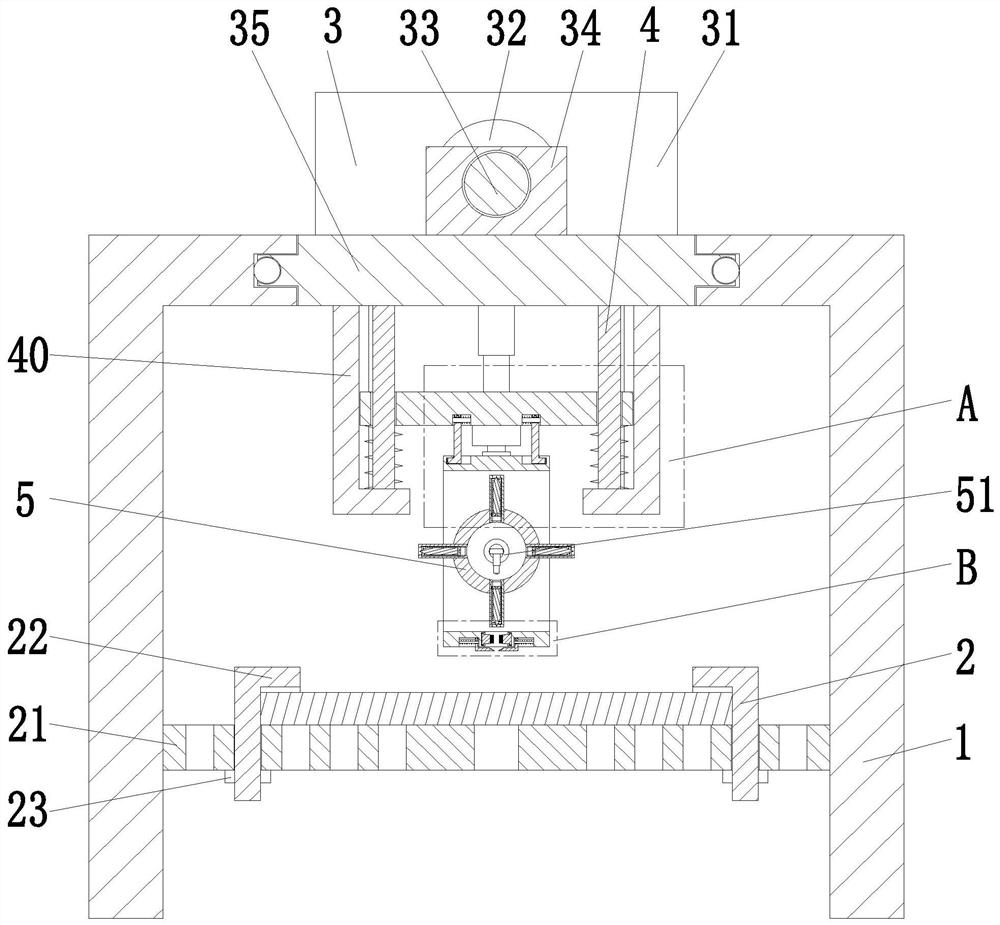

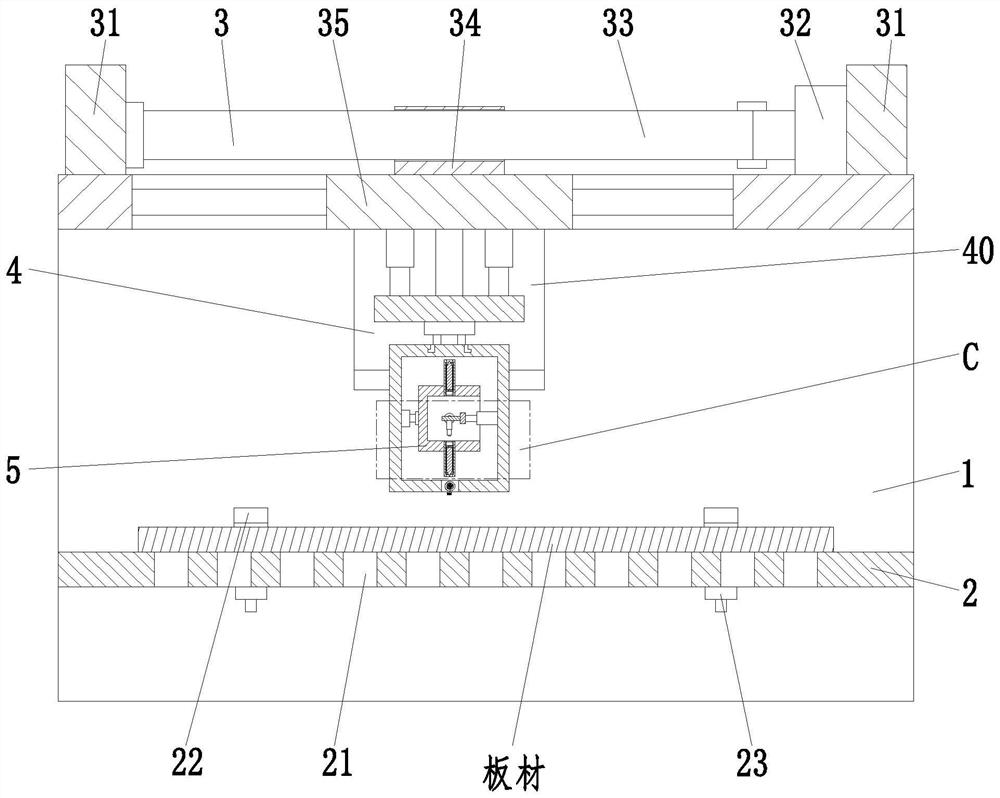

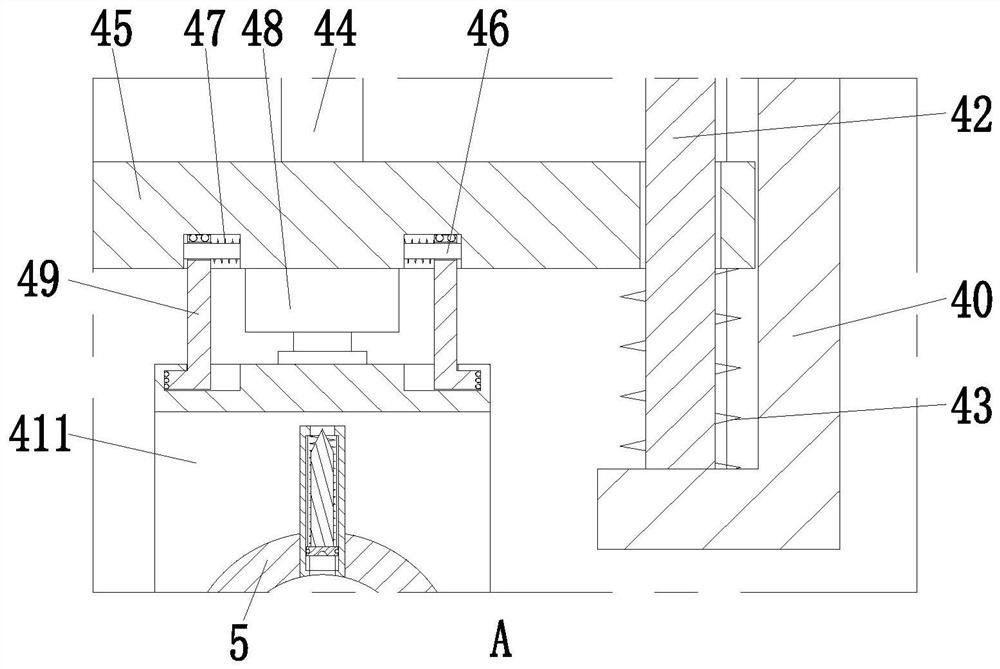

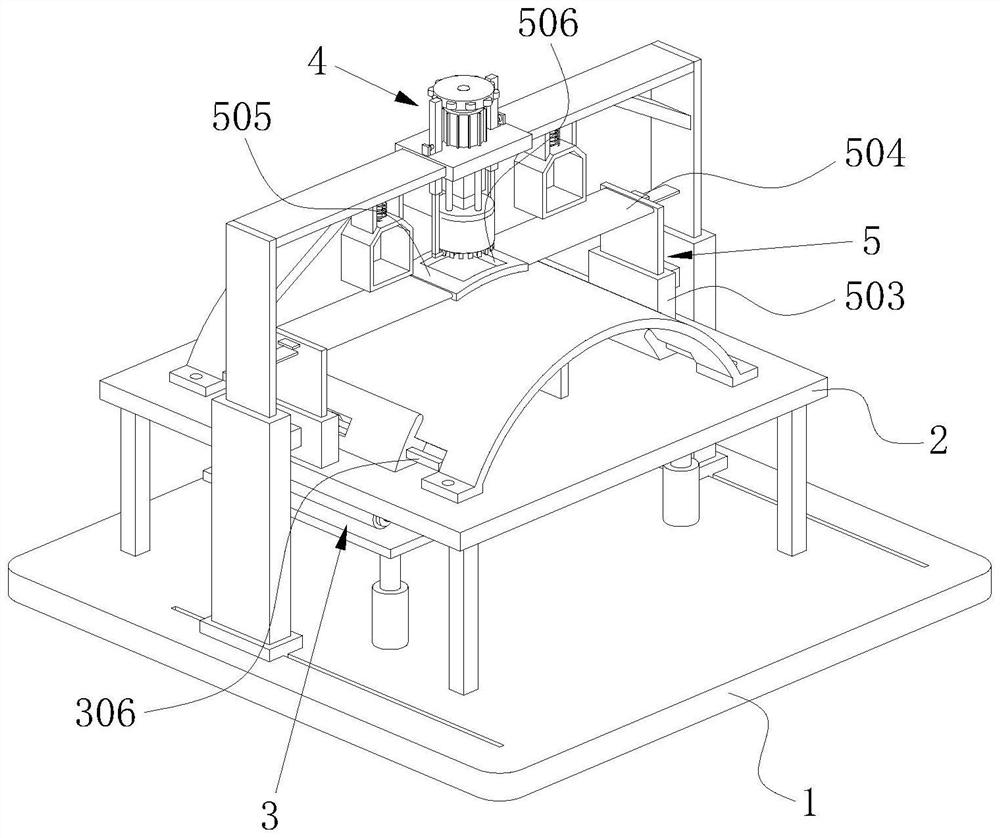

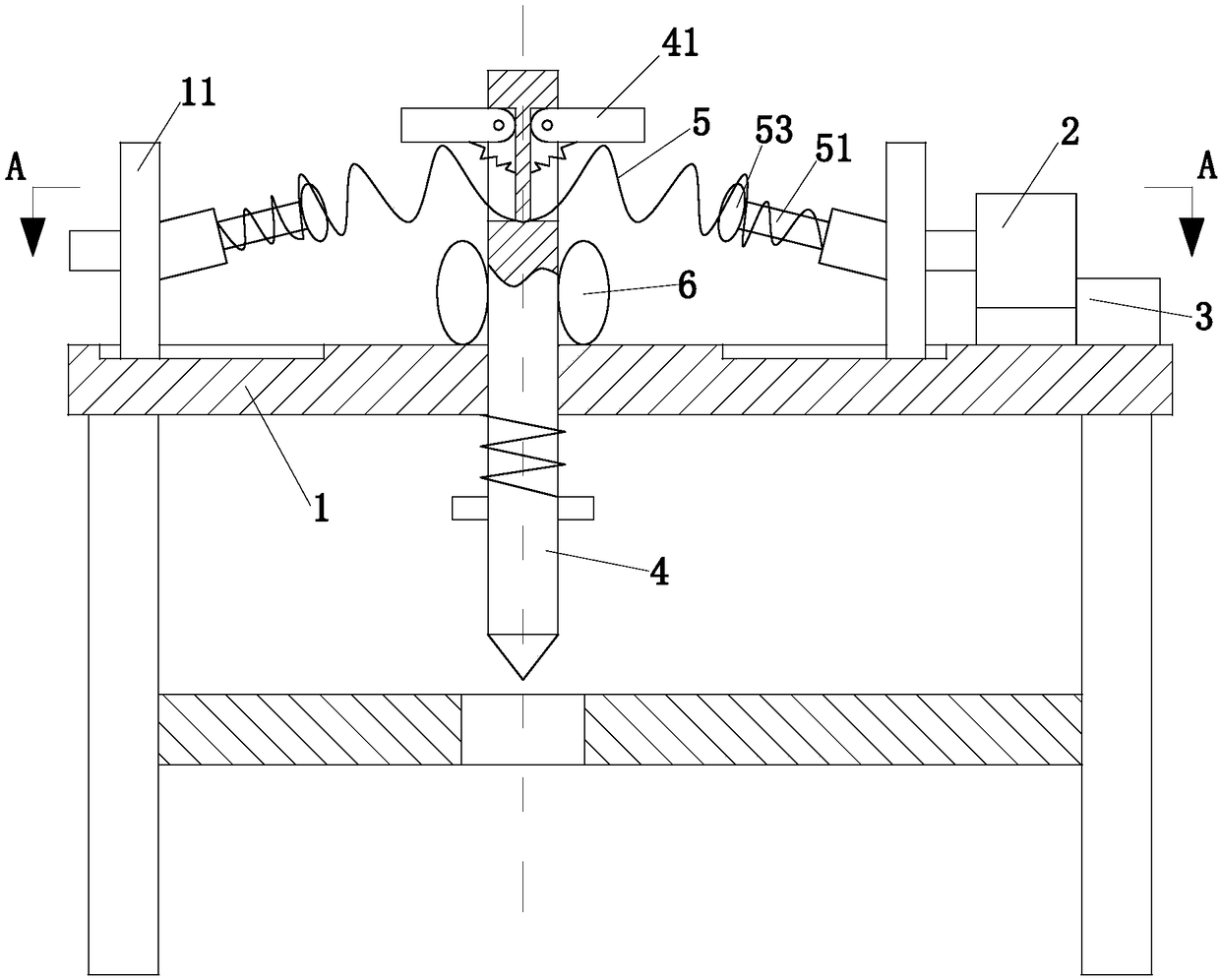

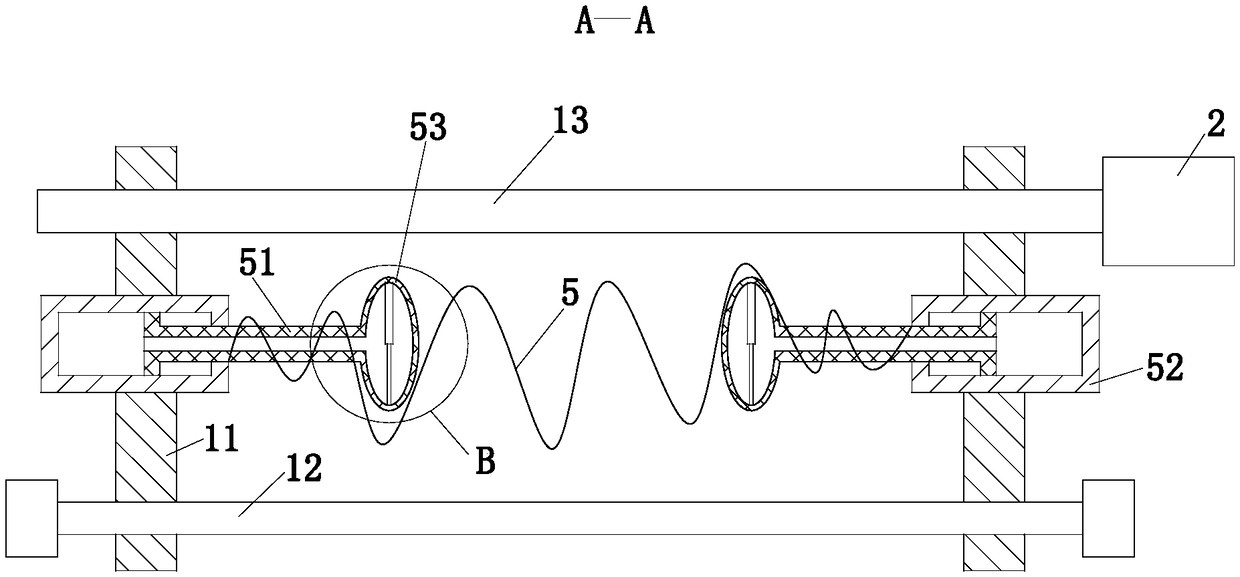

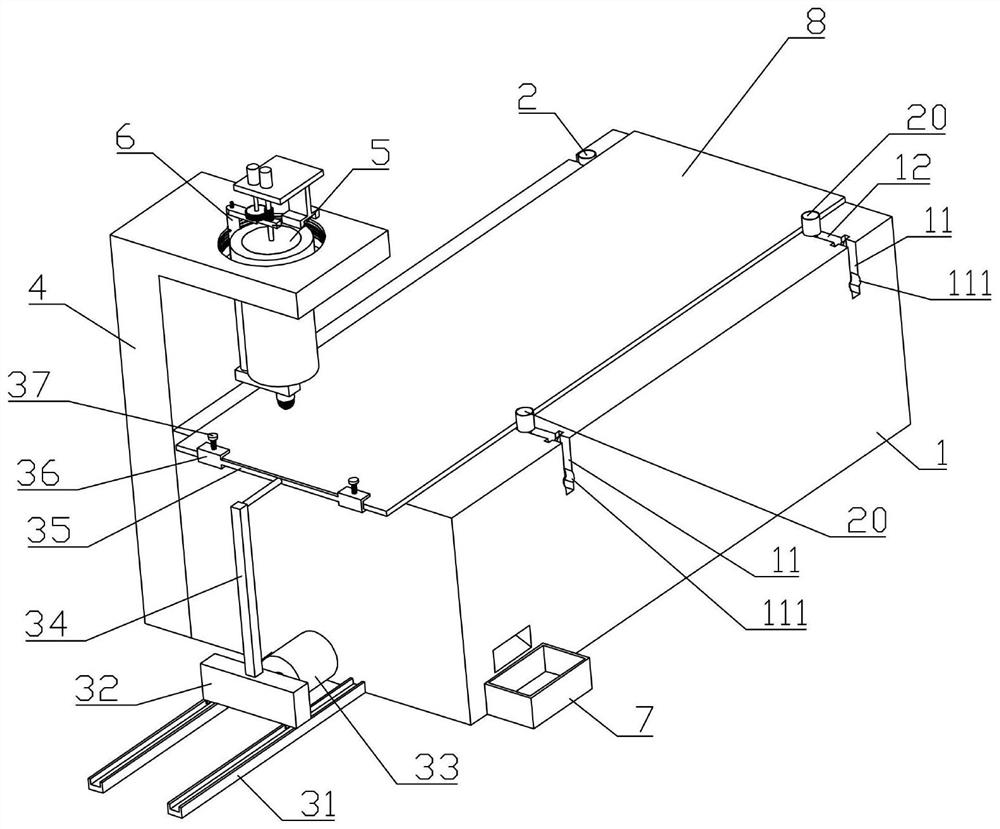

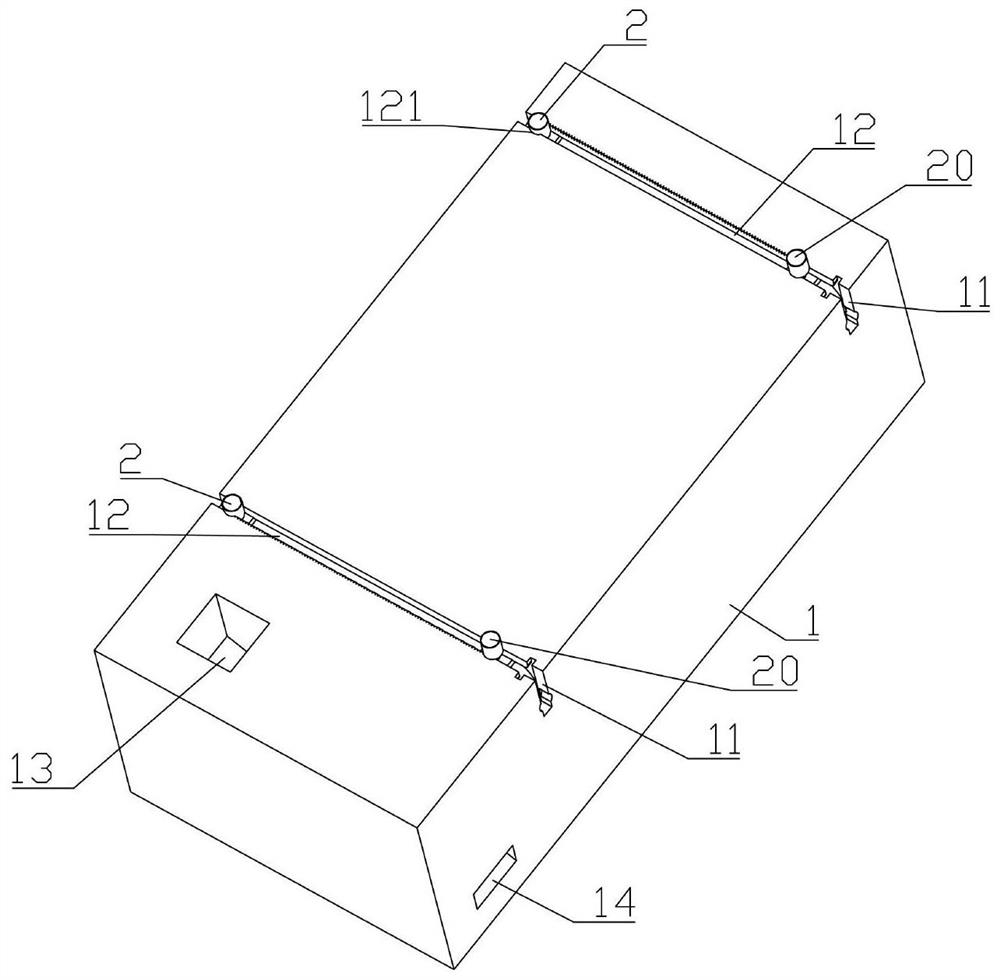

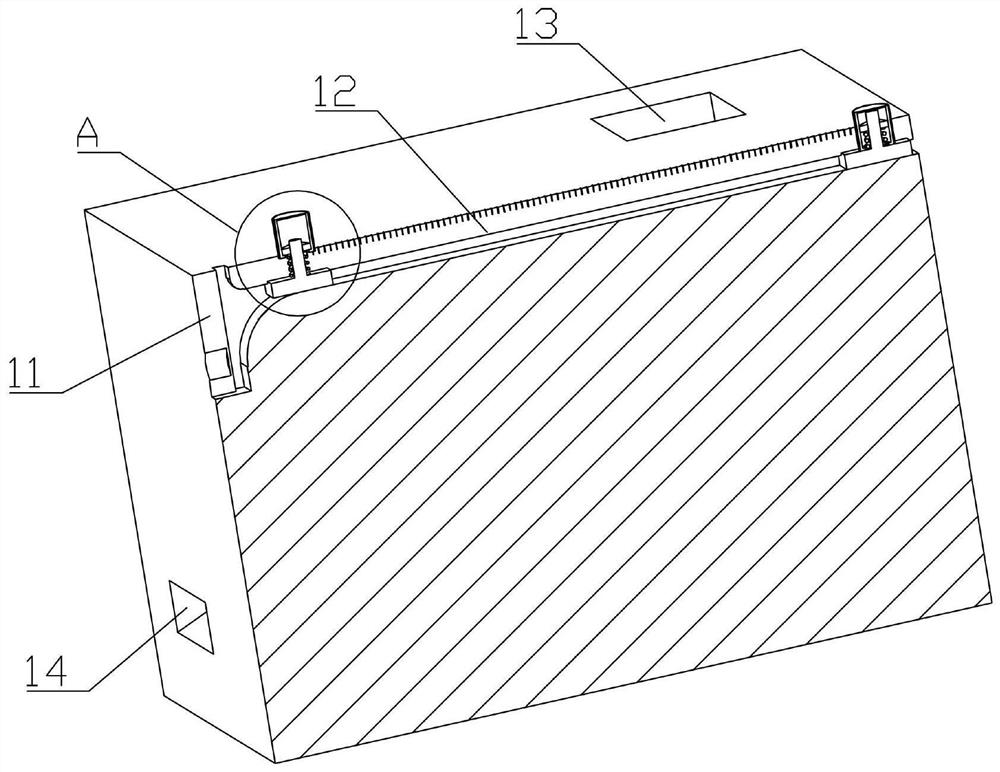

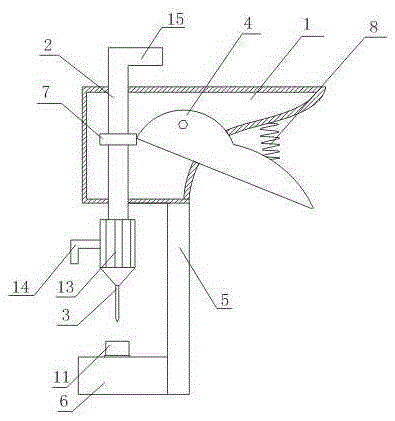

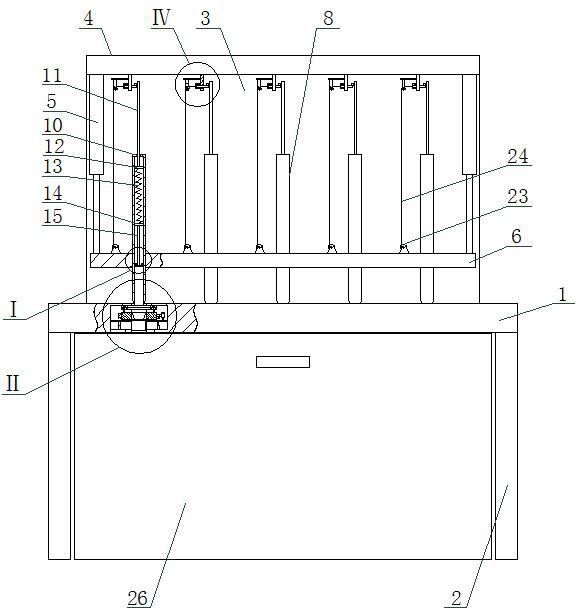

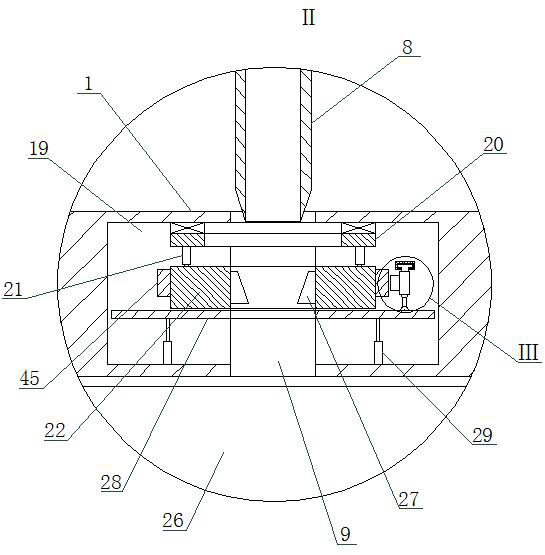

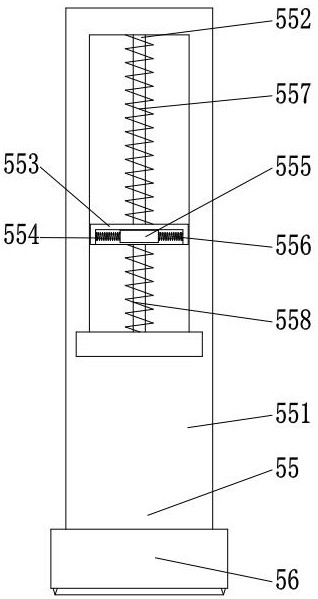

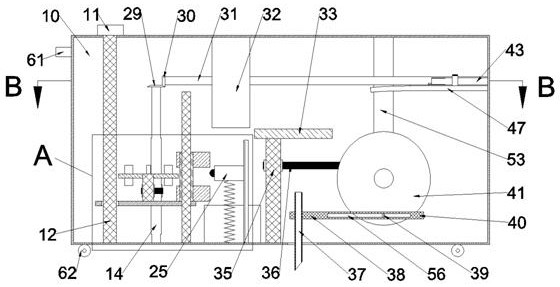

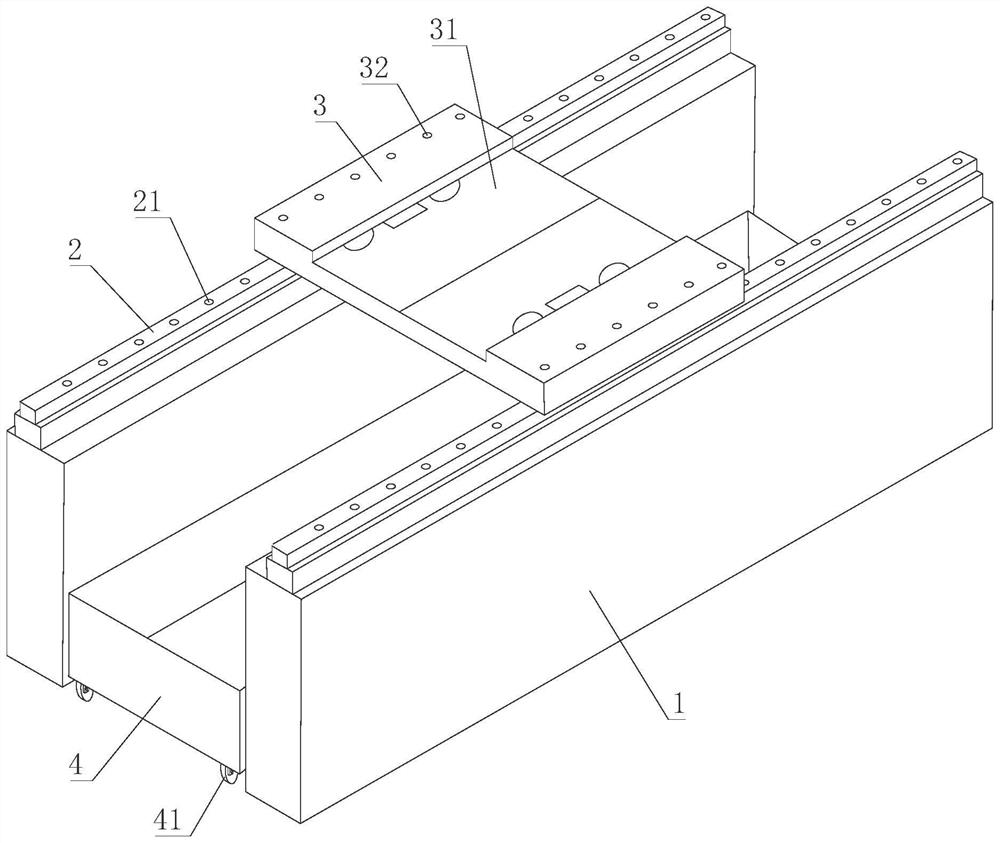

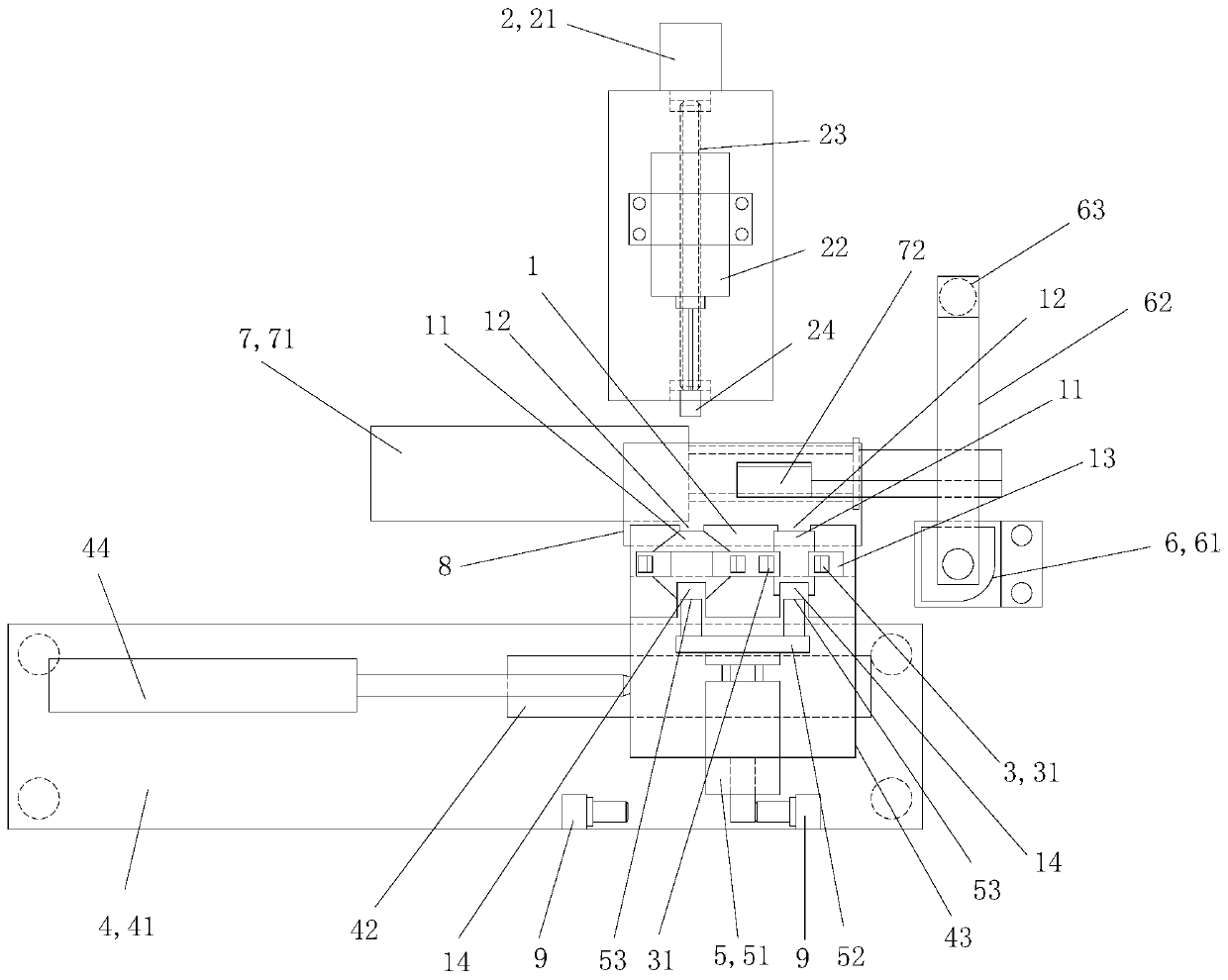

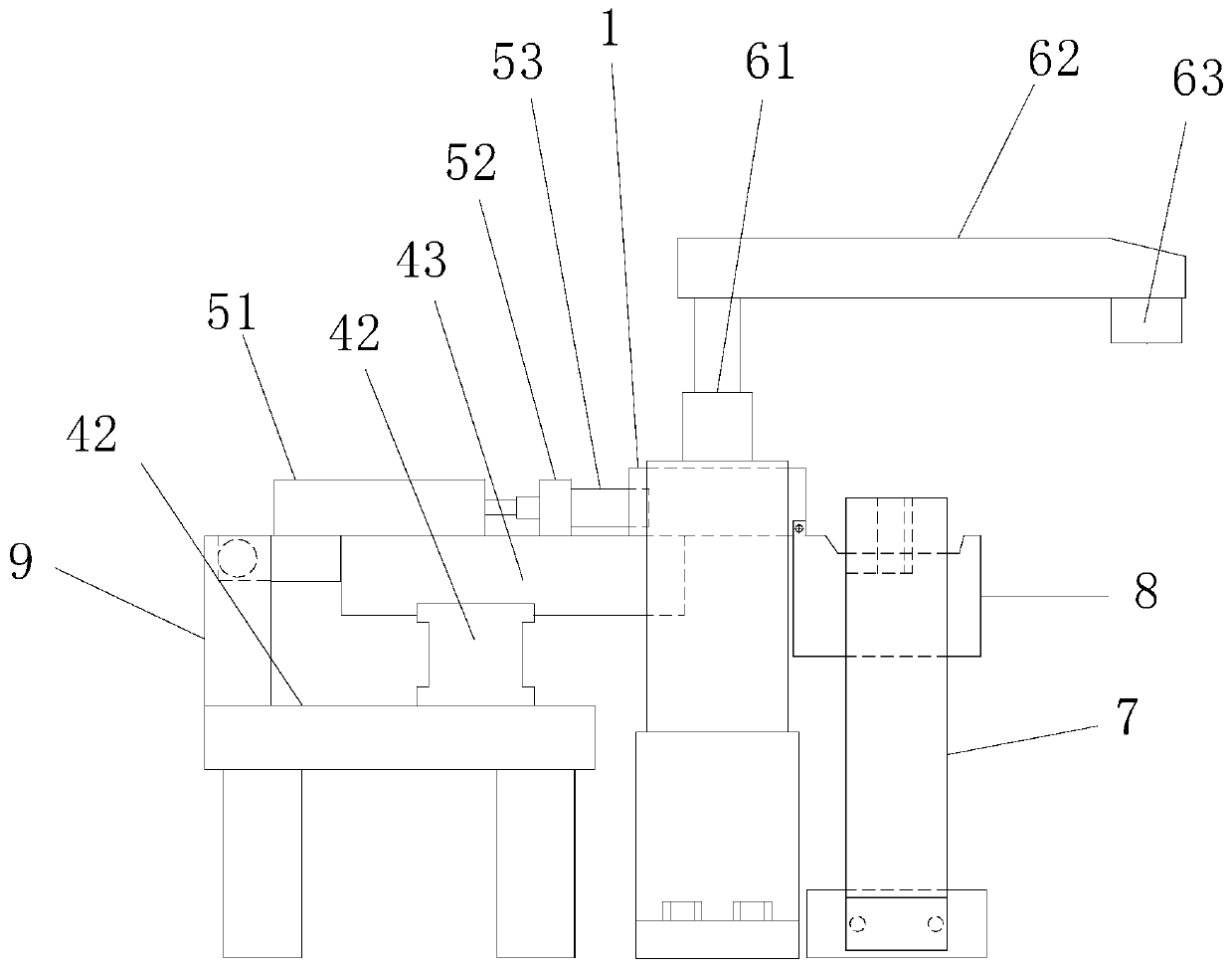

Full-automatic high-efficiency six-sided drill

PendingCN109719805AGuaranteed punching effectImprove drilling efficiencyStationary drilling machinesMulti-purpose machinesElectric machineryDrive motor

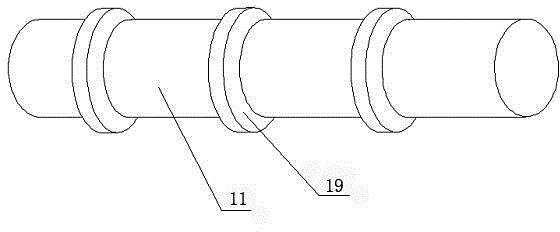

The invention relates to a full-automatic high-efficiency six-sided drill. The full-automatic high-efficiency six-sided drill comprises a lathe bed, wherein a feeding assembly, an executing assembly and a control assembly are arranged on the lathe bed; the feeding assembly is used for conveying a plate to the position of the executing assembly; the executing assembly is used for drilling the plate; the control assembly is used for controlling the feeding assembly and the executing assembly to perform corresponding actions; the plate is driven to move on a box body through mutual cooperation ofa driving motor, a clamp and a synchronous belt; and the plate is moved to a designated processing position under the control of a computer. Through matching of a lifting assembly and a reinforcing assembly, the drilling position of a drill bit is more accurate, and the drilling effect of the plate is ensured; through the cooperation of a translation assembly and a slotting drill bit, slotting processing is carried out on the plate, and six driving shafts and one auxiliary shaft are mutually matched, so that the drilling processing efficiency of the plate is improved, the processing effect ofthe plate is ensured; and the full-automatic high-efficiency six-sided drill has the advantages of high automation degree, safety and high efficiency.

Owner:山东佳梆数控科技集团有限公司

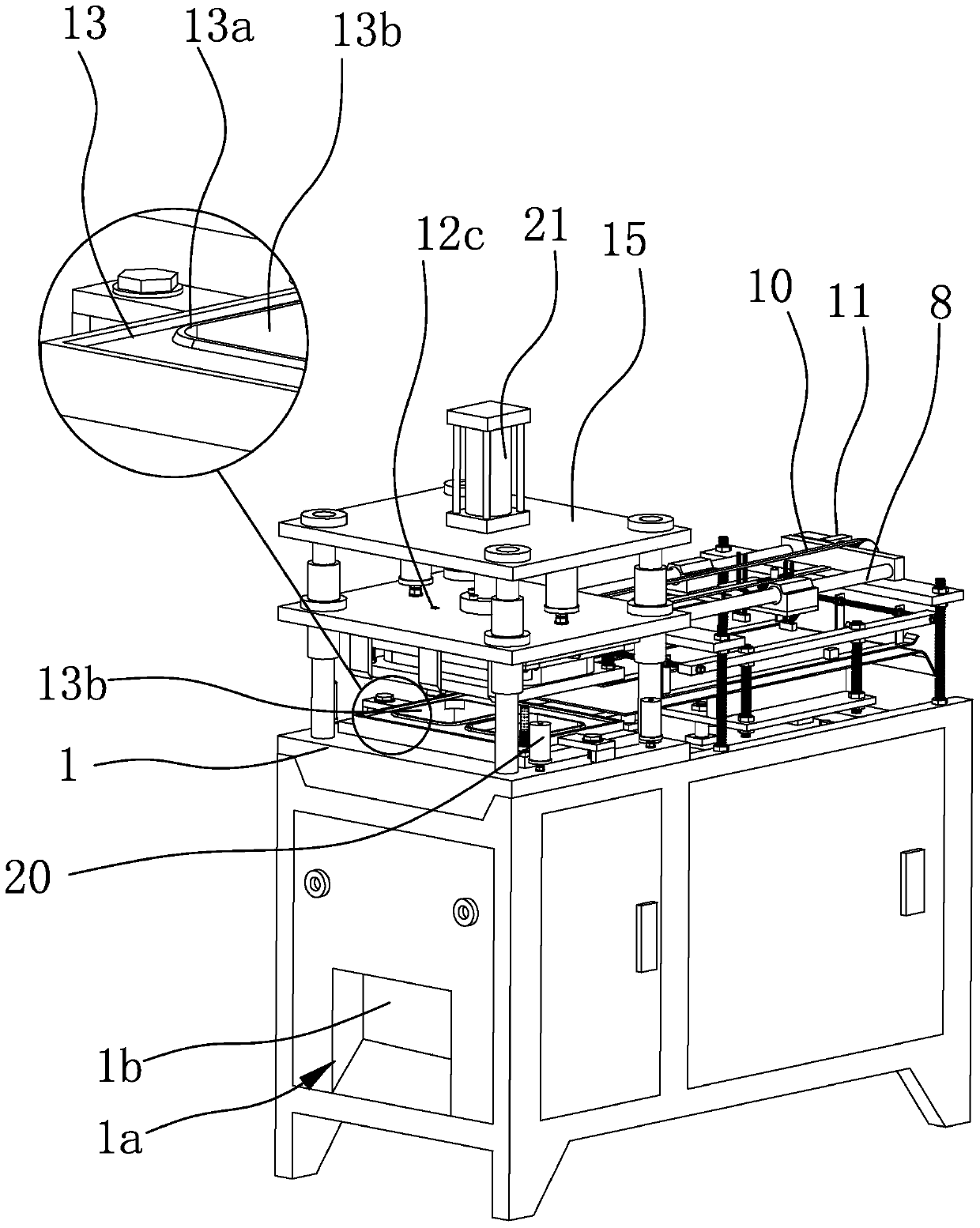

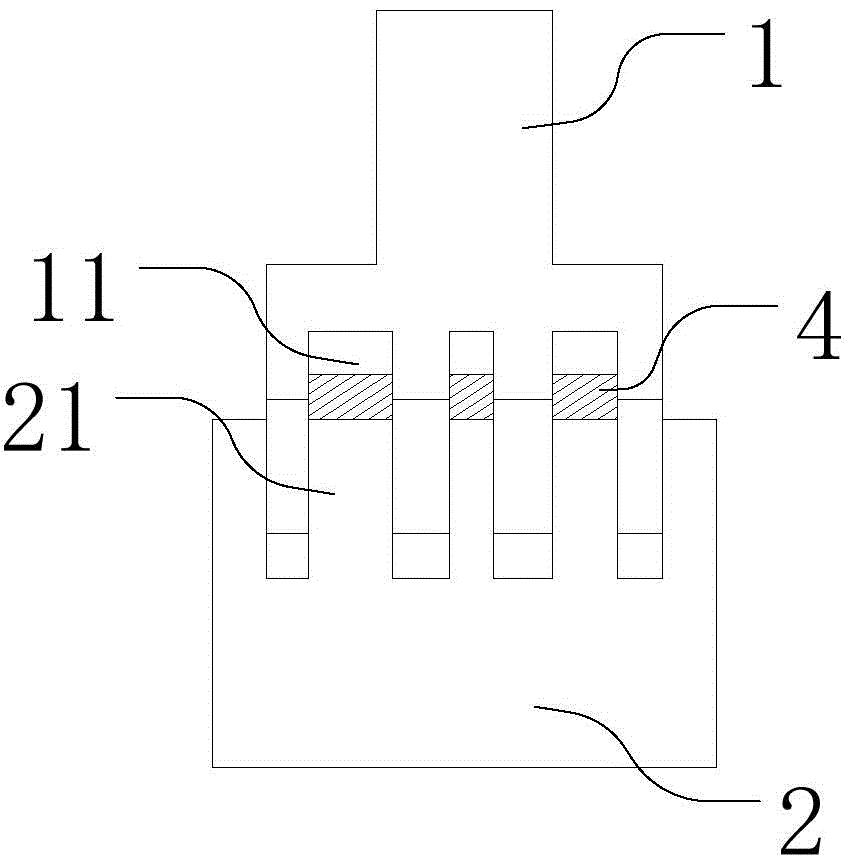

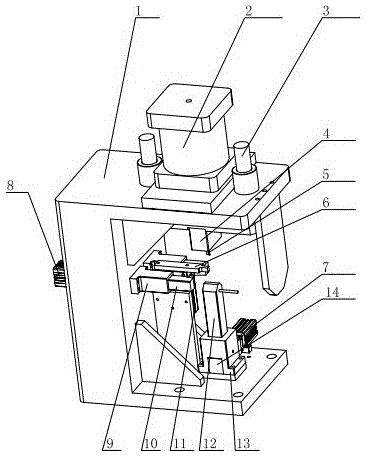

Blanking device for food box

ActiveCN105500455AImprove processing efficiencyLabor savingMetal working apparatusEngineeringMechanical equipment

The invention provides a blanking device for a food box and belongs to the technical field of mechanical equipment. The technical problem that an existing blanking device for the food box is low in efficiency is solved. The blanking device for the food box comprises a base, an upper die and a lower die, wherein the upper die and the lower die are arranged on the base. The lower surface of the upper die is provided with an inwards-concave containing groove for containing the bottom of the food box, the upper die can reciprocate towards the lower die, and an annular upper cutter is arranged on the groove side of the containing groove. The lower die is fixedly arranged on the base, the upper surface of the lower die is provided with an annular lower cutter opposite to the upper cutter, one side of the lower die is provided with a transfer platform capable of vertically moving, and a push block capable of pushing the food box to the space between the upper die and the lower die is arranged on the transfer platform. The blanking device has the advantages of being high in blanking efficiency and side cutting precision and the like.

Owner:沈正昌

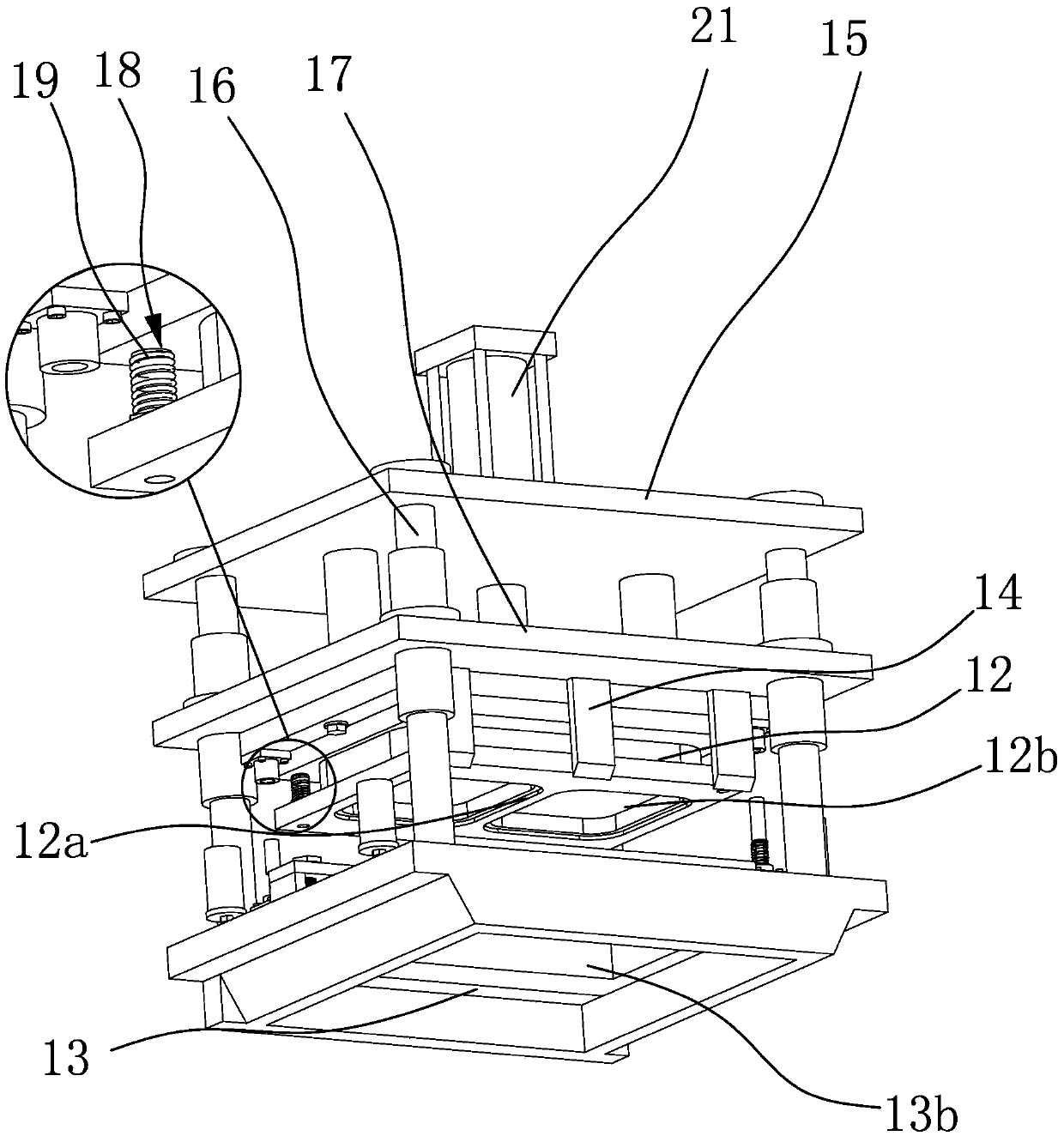

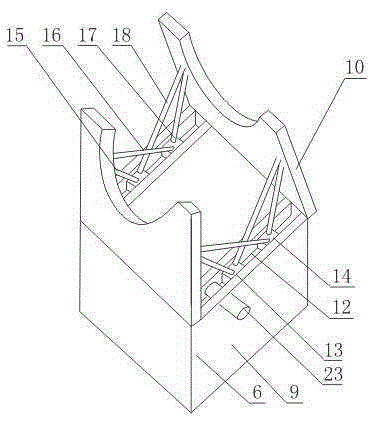

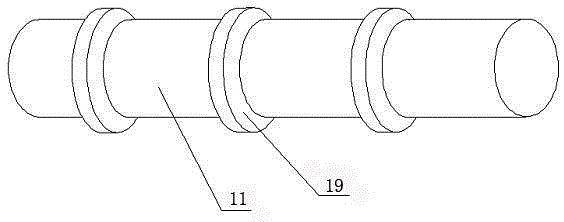

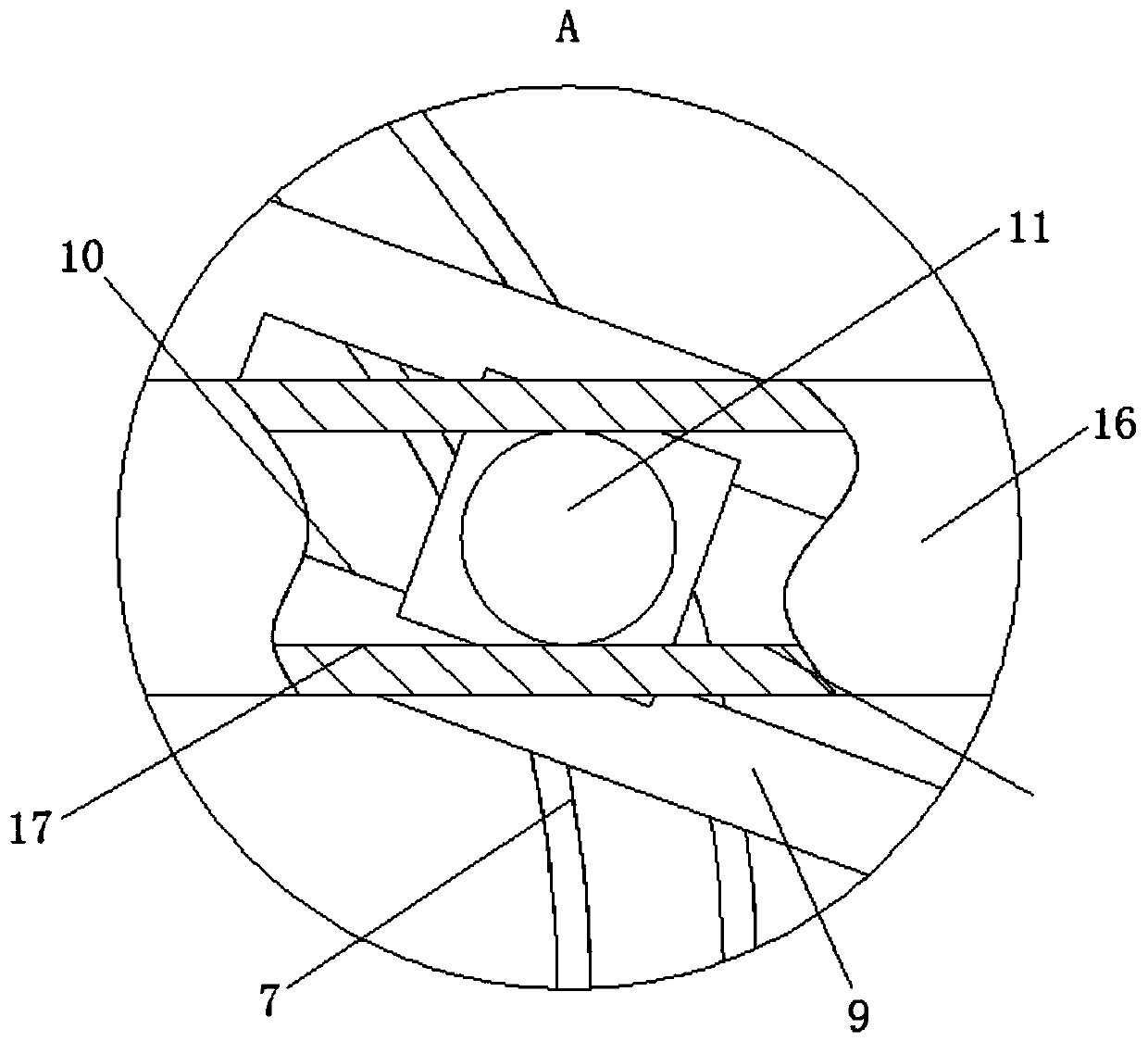

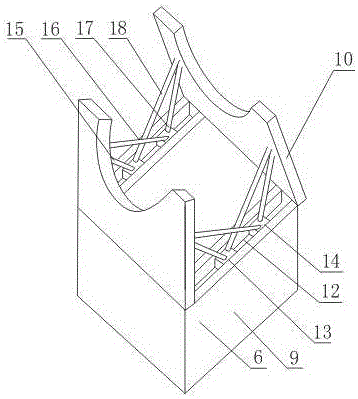

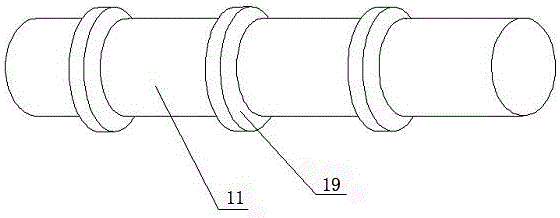

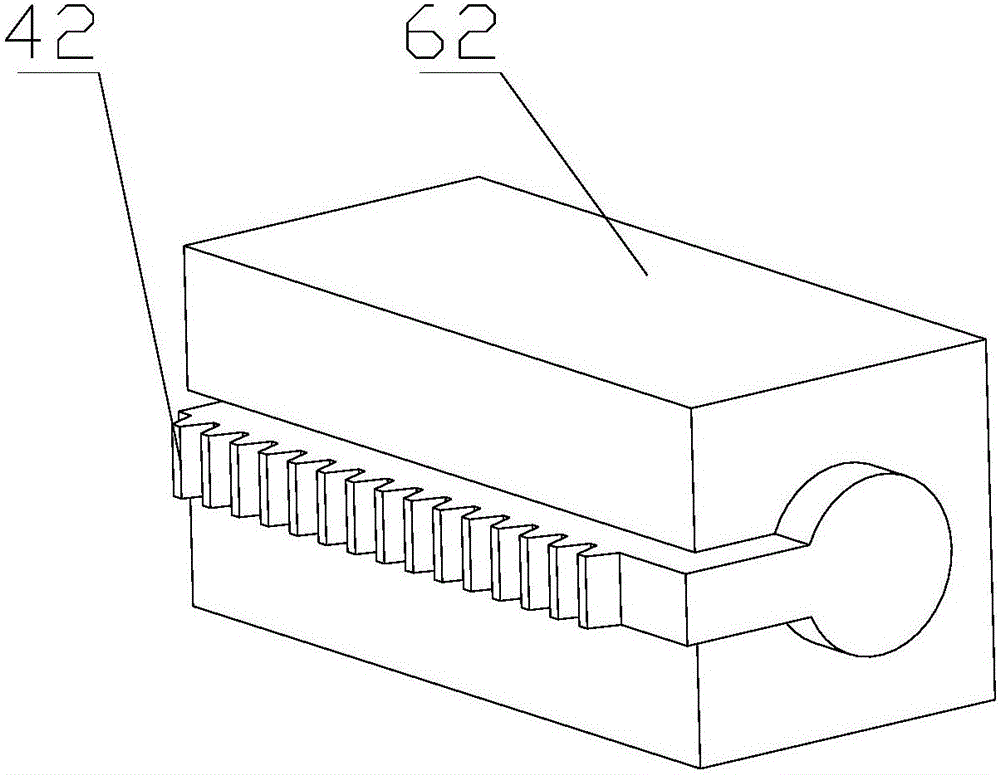

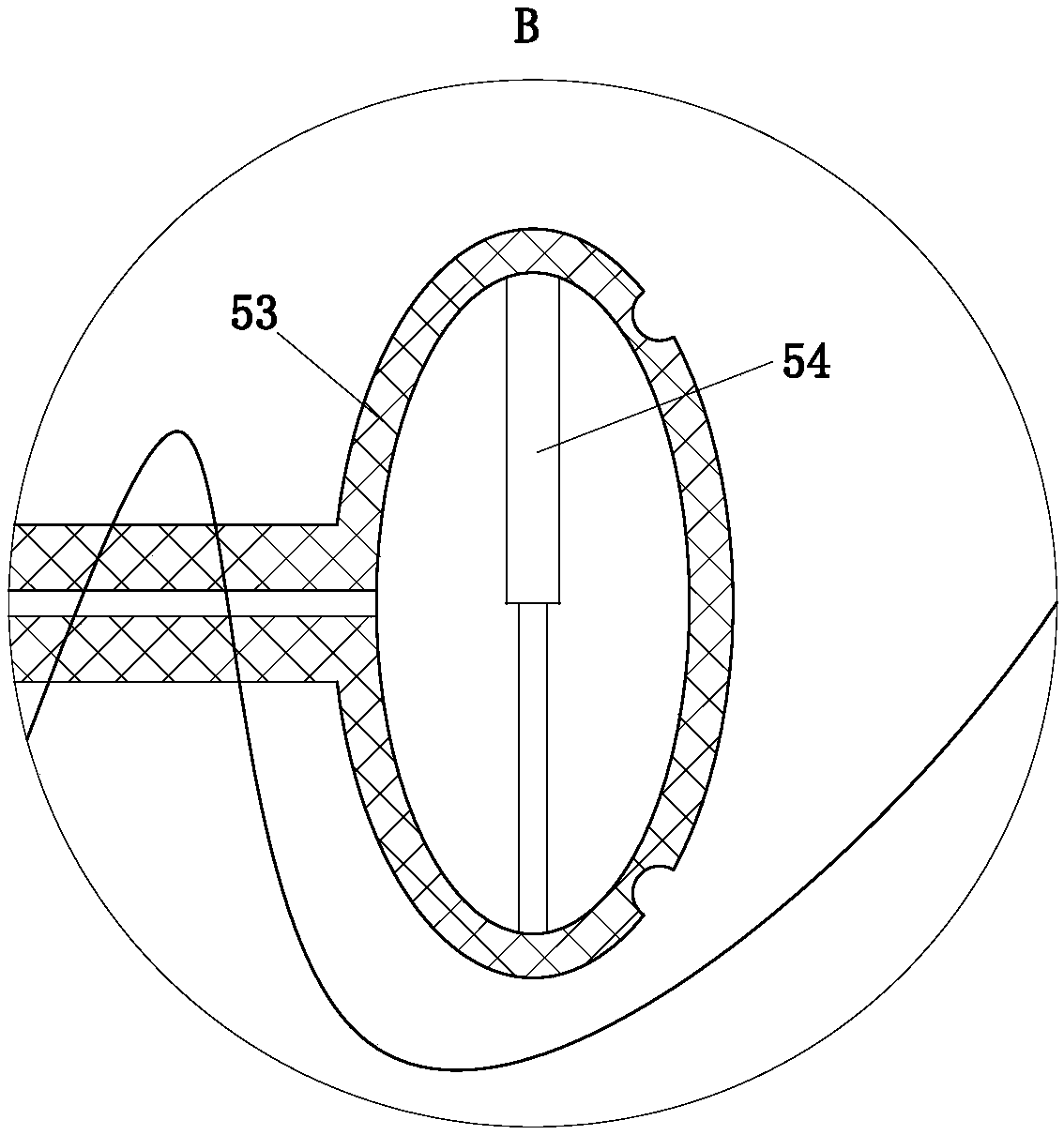

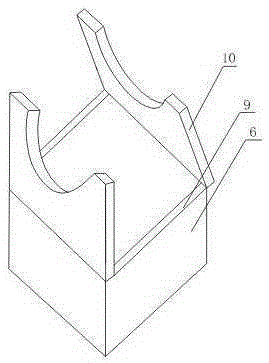

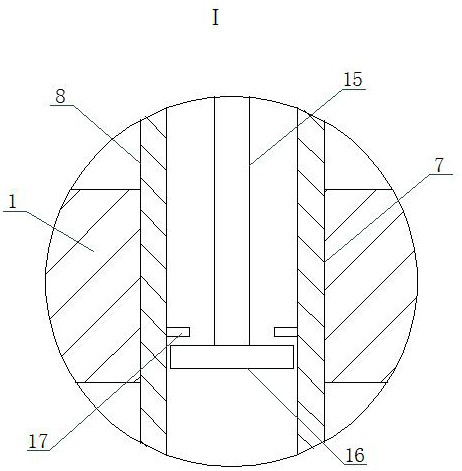

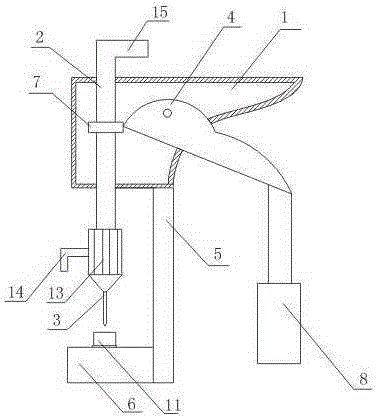

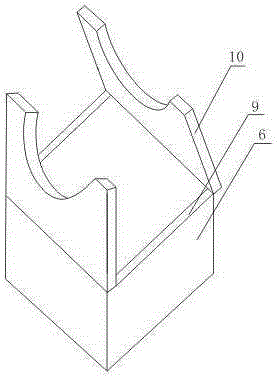

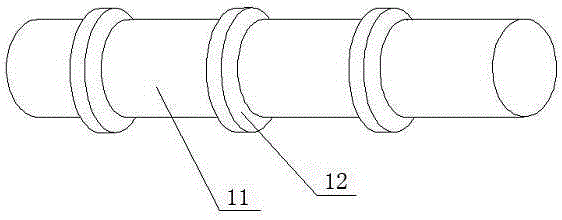

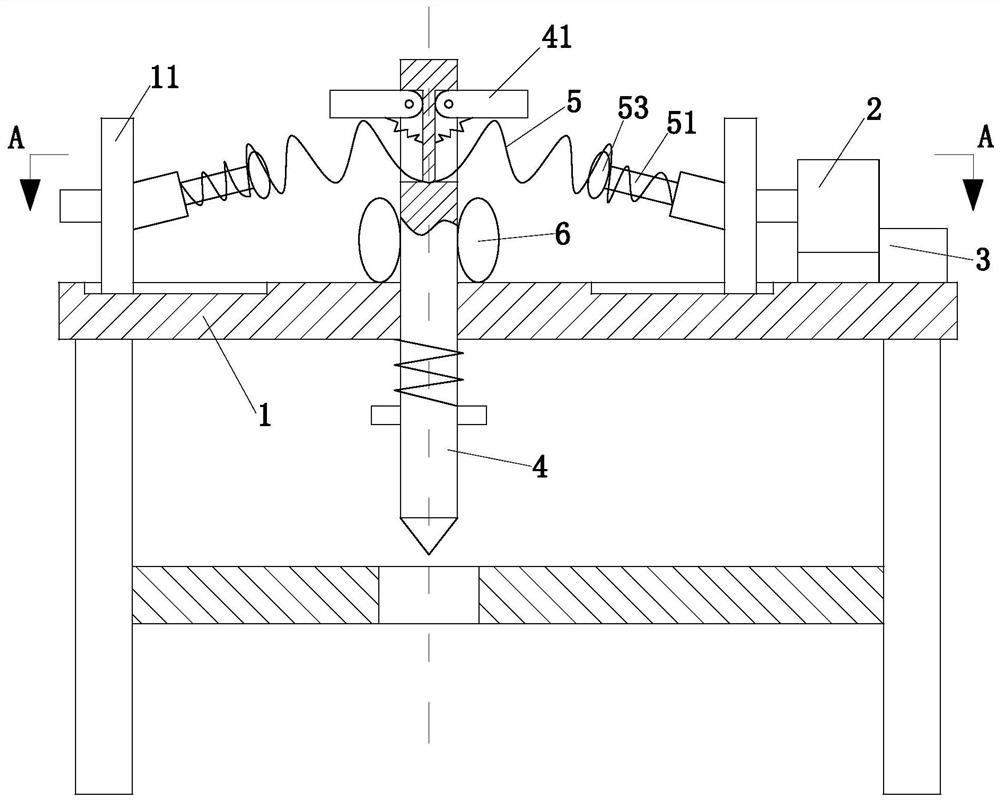

Tooth knife punching die structure for knife bending machine and knife bending machine

ActiveCN104889229AEasy to adjustGuaranteed punching effectOther manufacturing equipments/toolsPunchingEngineering

The invention discloses a tooth knife punching die structure for a knife bending machine and the knife bending machine. The die structure comprises a pillow-position die, a bottom die, a bottom die drive mechanism and a punching male die; and the lower end face of the pillow-position die is provided with groove which penetrates the front and the rear and which matches the punching male die in width, the upper end face of the bottom die is provided with a protruding block which matches the groove in width, the pillow-position die and the bottom die are disposed in an up-down relative manner, the groove and the protruding block are disposed in a matching and sleeving manner to form a die hole matching the punching male die in width, and the bottom die is driven by the bottom die drive mechanism to move in the vertical direction so that the height of the die hole relative to a blade is changed. The pillow-position die and the bottom die are adopted to together form a mother die, the bottom die slides relative to the pillow-position die so that the height of the die hole relative to the blade is adjustable; and the bottom die and the pillow-position die form the die hole adopting a groove-block matching mode, so the blade can be guaranteed to be completely abutted except for at a punching position, tooth knife height adjustments are achieved, and the punching effect is guaranteed at the same time.

Owner:RICHLY TOP CNC EQUIP SHENZHEN CO LTD

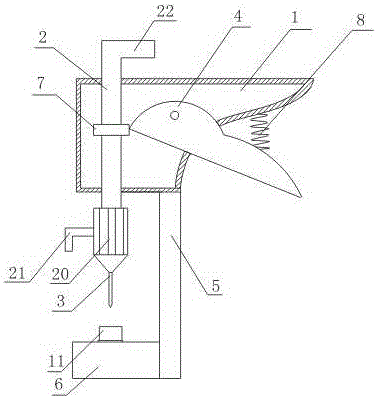

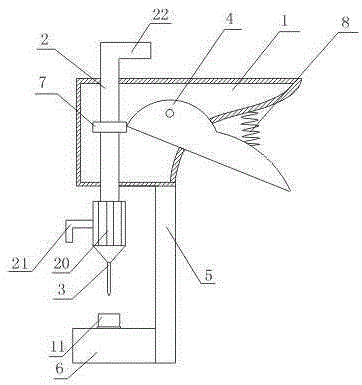

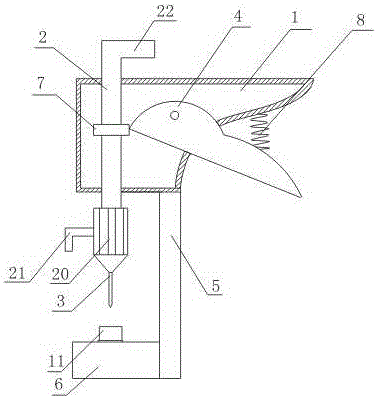

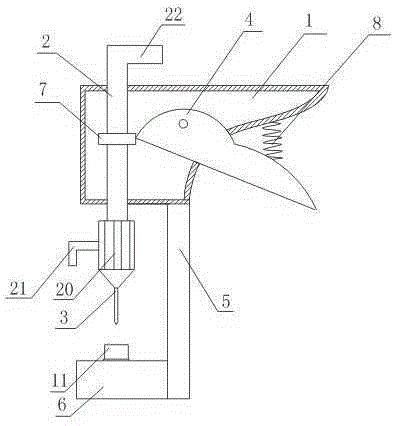

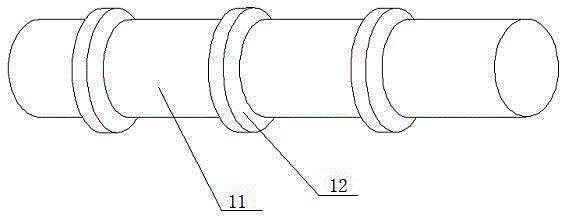

Perforating machine for automatically controlling perforating depth

InactiveCN104998956ASimple structureEasy to operateMetal working apparatusCircular cavityEngineering

The invention discloses a perforating machine for automatically controlling a perforating depth. The perforating machine comprises a fixed handle adopting a cavity structure, slide rods respectively penetrating through openings in the upper and lower end surfaces of the fixed handle and slidingly arranged in the fixed handle, drilling needles arranged at the bottoms of the slide rods, a movable handle hinged to the fixed handle, a support rod fixed at the lower end of the fixed handle, and an adjusting base connected with the support rod, wherein one side of the fixed handle is totally opened. The perforating machine further comprises chucks fixed on the slide rods; and one end of the movable handle is connected with the chucks, and the other end penetrates through an opening in one side of the fixed handle to be positioned outside the fixed handle. The perforating machine further comprises a limiting spring; one end of the limiting spring is connected with the fixed handle, and the other end is connected with the movable handle; the adjusting base comprises a base, and stop covers respectively hinged to the two side edges of the upper surface of the base; semicircular grooves are formed in the side surfaces of the stop covers; and the semicircular grooves formed in the side surfaces of the two stop covers are formed to a circular cavity. The perforating machine further comprises a bottom rod slidingly arranged in the circular cavity. The perforating machine is simple in structure and better in perforating effect.

Owner:CHENGDU LIXIN SCI & TECH

Punching die mechanism with waste-falling protection sleeve

InactiveCN111112447AReduce impactEasy to replace and maintainPerforating toolsPunchingEnvironmental engineering

The invention discloses a punching die mechanism with a waste-falling protection sleeve. The punching die mechanism with the waste-falling protection sleeve comprises a fixed bottom plate of a lower die, wherein a plurality of vertical guide columns are fixed to the side part of the top surface of the fixed bottom plate of the lower die, and an upper fixed plate is fixed to the top surfaces of allthe vertical guide columns; and a lower fixed plate is arranged above the fixed bottom plate of the lower die, all the vertical guide columns are sleeved with the lower fixed plate in an insertion manner, and a plurality of vertical buffer columns are fixed to the side part of the top surface of the fixed bottom plate of the lower die. The punching die mechanism with the waste-falling protectionsleeve is provided with a detachable central screwing sleeve body which is screwed into a central screwing through hole as a protection sleeve for falling of punching wastes, so that the wastes cannotmake contact with the inner sidewall of the central screwing through hole; after the punching die mechanism with the waste-falling protection sleeve is used for a certain time and when the inner sidewall of the central screwing sleeve body is worn, the central screwing sleeve body can be directly detached and replaced, the operation is quite convenient, and the replacement, repair and maintenanceare convenient; and moreover, when an upper die block presses downwards, a buffer effect is realized through buffer springs, and an impact force during the falling of an upper die is reduced, so thatthe punching effect is ensured.

Owner:朱福英

Semi-automatic drilling machine capable of improving drilling quality

The invention discloses a semi-automatic drilling machine capable of improving drilling quality. The machine comprises a fixed handle with a cavity structure, a slide rod respectively inserted through openings on the upper and lower end surfaces of the fixed handle and slidingly arranged in the fixed handle, a drill needle arranged at the bottom of the slide rod, a movable handle hinged to the fixed handle, a support device fixed at the lower end of the fixed handle, and an adjusting base connected with the support rod; and one side of the fixed handle is totally opened. The machine further comprises a chuck fixed on the slide rod; and one end of the movable handle is connected with the chuck, and the other end penetrates through an opening on one side of the fixed handle to position out of the fixed handle. The machine further comprises a limiting spring connected with the fixed handle by one end and connected with the movably handle by the other end; the adjusting base includes a base, and stop covers respectively hinged to two side edges of the upper surface of the base; semicircular grooves are formed in the side surfaces of the stop covers; and the semicircular grooves formed in the side surfaces of the two stop covers form circular cavities. The machine further comprises bottom rods slidingly arranged in the circular cavities. The machine is excellent in punching quality and convenient to use.

Owner:史军

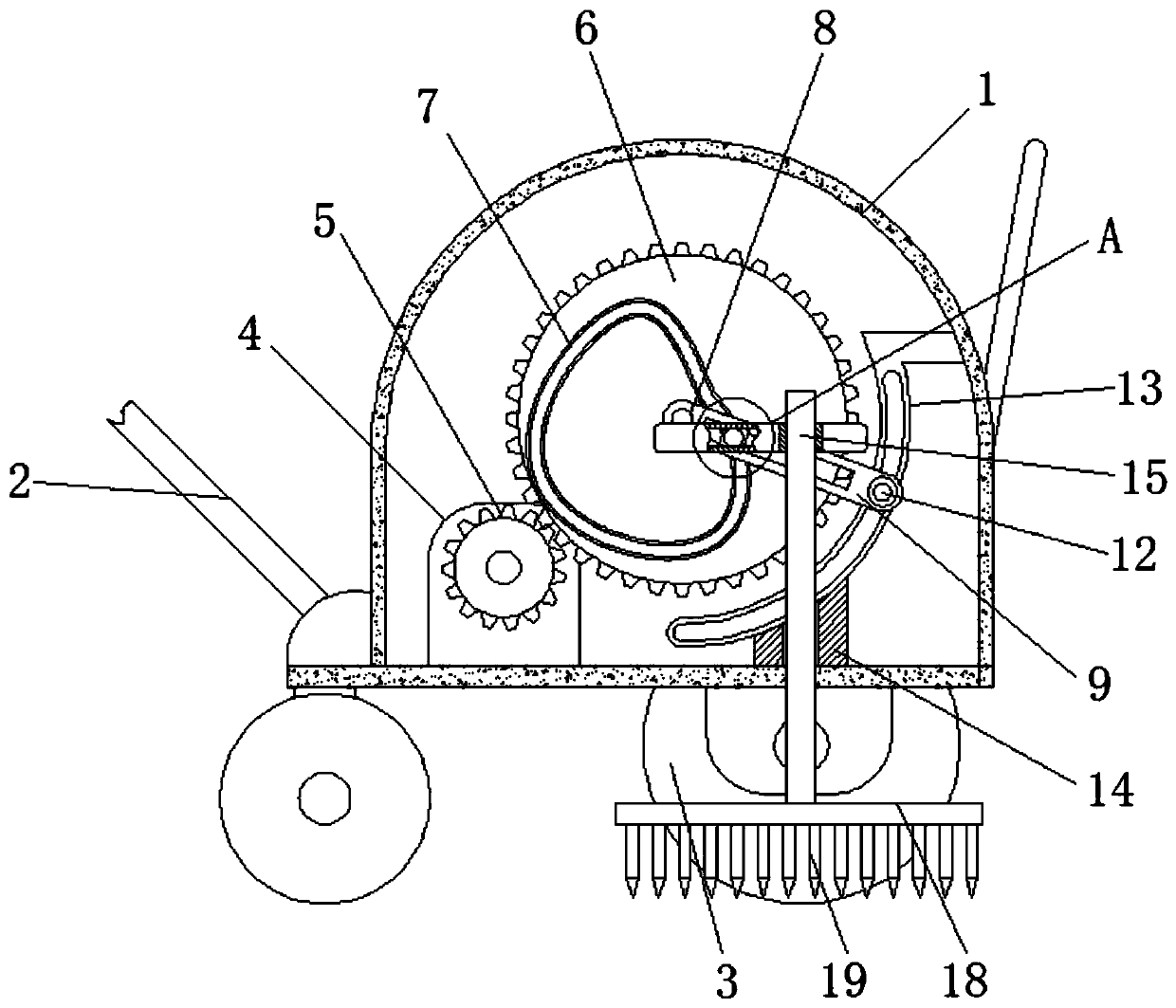

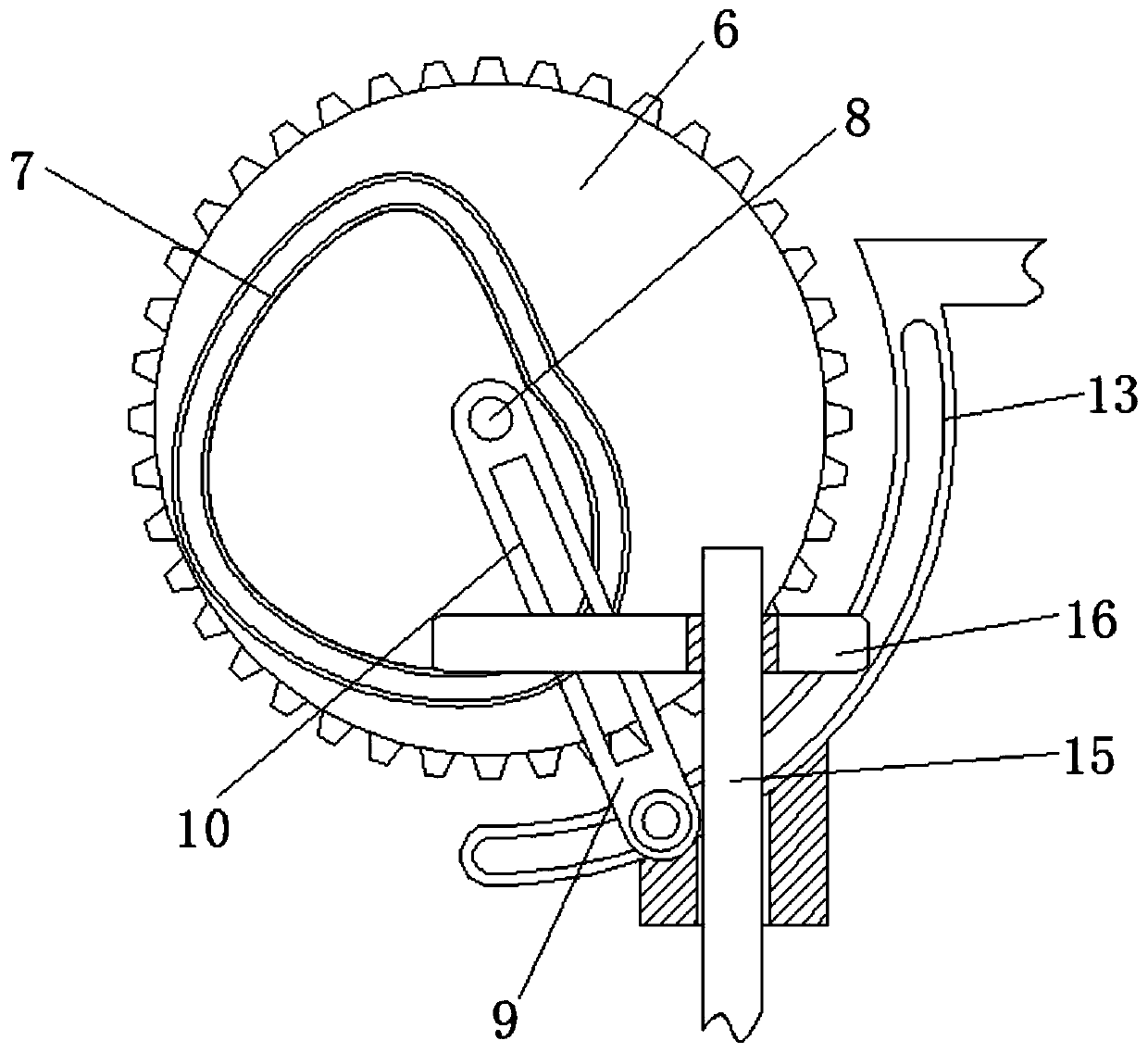

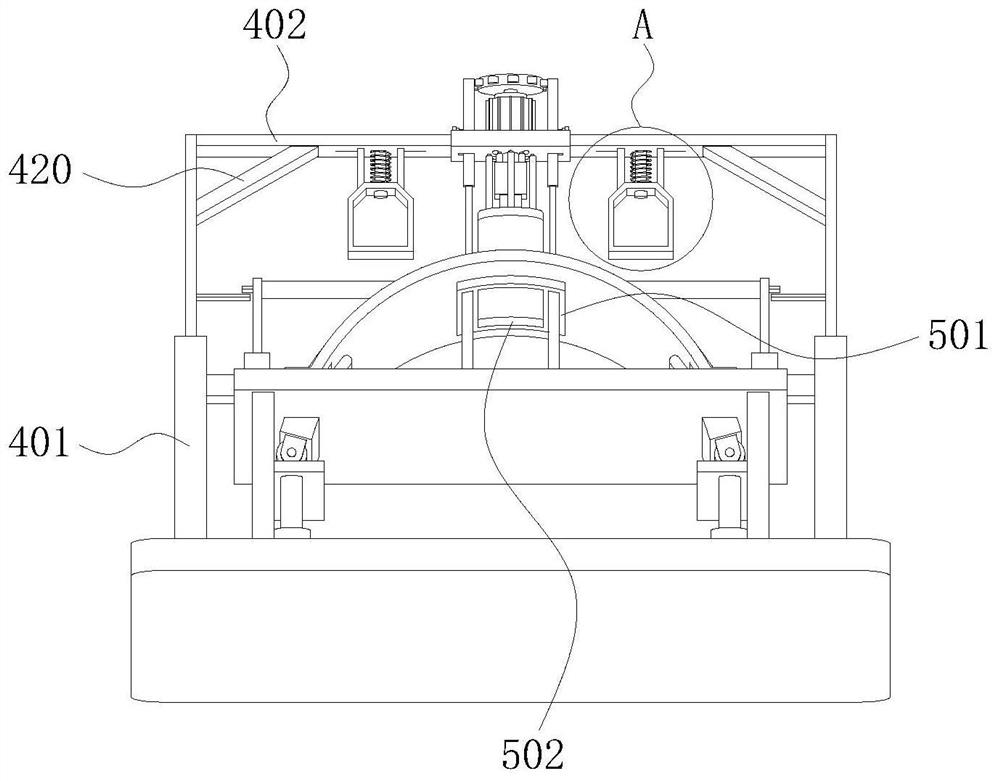

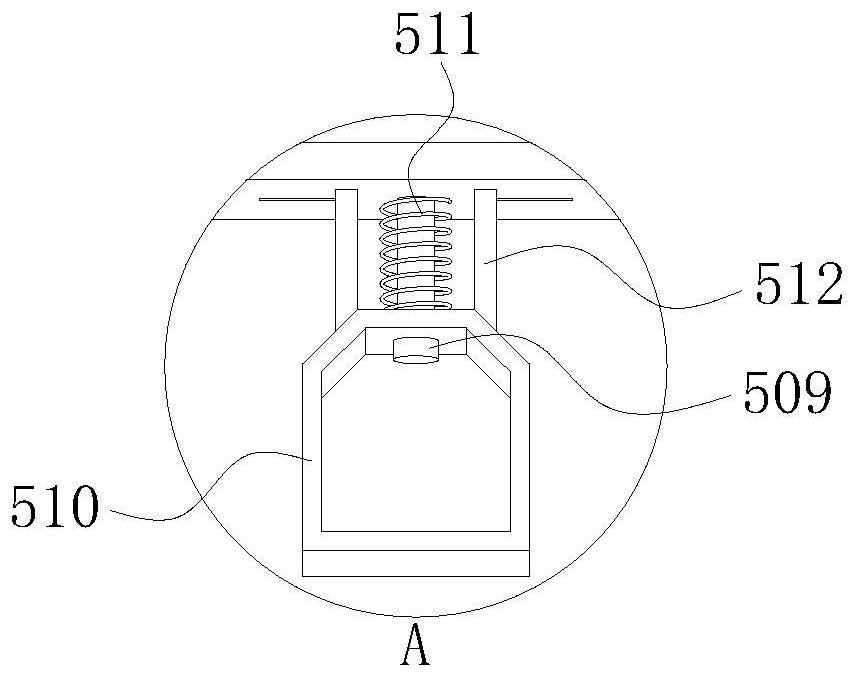

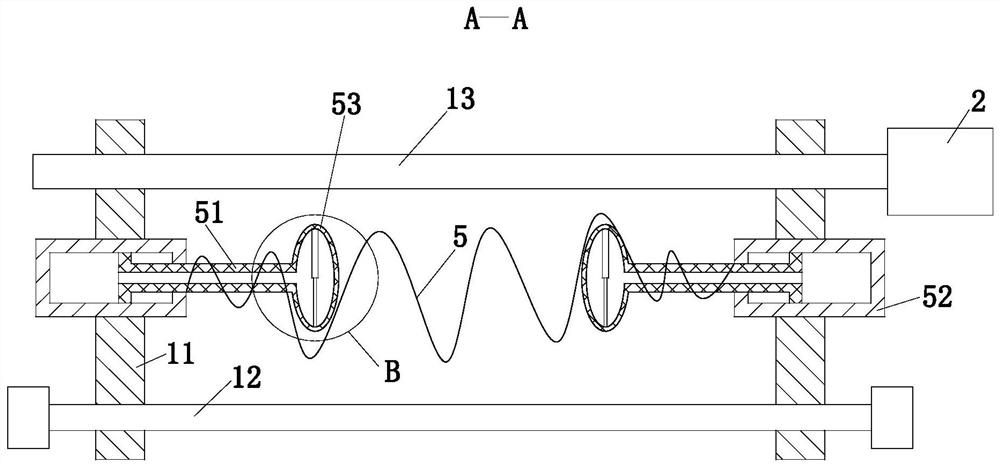

Adjustable lawn aerator based on convex guide rail transmission principle

InactiveCN111201848AGuaranteed punching qualityProtect environmentLawn machinesAgricultural scienceGear wheel

The invention relates to the technical field of environmental protection, and discloses an adjustable lawn aerator based on a convex guide rail transmission principle. The adjustable lawn aerator based on the convex guide rail transmission principle comprises a vehicle body, wherein a handle is fixedly connected outside the vehicle body; wheels are movably connected to the bottom of the vehicle body; a motor is fixedly connected inside the vehicle body; a main gear is fixedly connected outside the motor; a fluted disc is engaged and connected outside the main gear; a guide rail is fixedly connected outside the fluted disc; a connecting shaft is fixedly connected inside the fluted disc; an adjusting rod is movably connected outside the connecting shaft; and a first slide groove is formed inside the adjusting rod. Through the cooperative use of the adjusting rod, a slide block and a transverse rod, the effect of automatically regulating the aeration depth according to different lawns anddifferent soil conditions can be achieved, so that the use range of the device is expanded; the aeration quality of the lawn is ensured, so that the ecological environment of the lawn is protected; and the lawn is enabled to healthily grow.

Owner:ANHUI YINUOQINGCHUN IND DESIGN CO LTD

Quick blanking and drawing two-mode hydraulic machine and working method thereof

A quick blanking and drawing two-mode hydraulic machine comprises a rack. A sliding beam and a pressurization oil cylinder are installed on the rack. The pressurization oil cylinder is vertically installed on an upper beam in a sliding manner, wherein the upper beam is arranged at the top of the rack. The sliding beam is installed in a working cavity in a sliding manner, wherein the working cavity is arranged in the middle of the rack. A plunger rod of the pressurization oil cylinder is connected with the sliding beam. A locking mechanism is installed on the upper beam. A cylinder body of the pressurization oil cylinder is located in the locking mechanism. Stroke return oil cylinders are fixedly arranged on the upper beam. Piston rods of the stroke return oil cylinders are connected with the sliding beam. By the adoption of the quick blanking and drawing two-mode hydraulic machine, the blanking and drawing functions are achieved through hydraulic pressure, the dual purposes are achieved through one machine, equipment investment cost is reduced, and the space occupied by equipment can be saved as well. In the blanking process, the pressurization oil cylinder and the sliding beam fall synchronously, enough blanking inertia can be generated, oil is injected into the pressurization oil cylinder to apply force, and enough pressure can be output by the equipment in the blanking process; and in the oil injection and force applying processes of the pressurization oil cylinder, an oil cavity of the pressurization oil cylinder is basically free of air, the oil pressure in the oil cavity is large due to pumped hydraulic oil, pressure output in the blanking process is further guaranteed, and the blanking effect is guaranteed.

Owner:青岛三维汽车装备有限公司

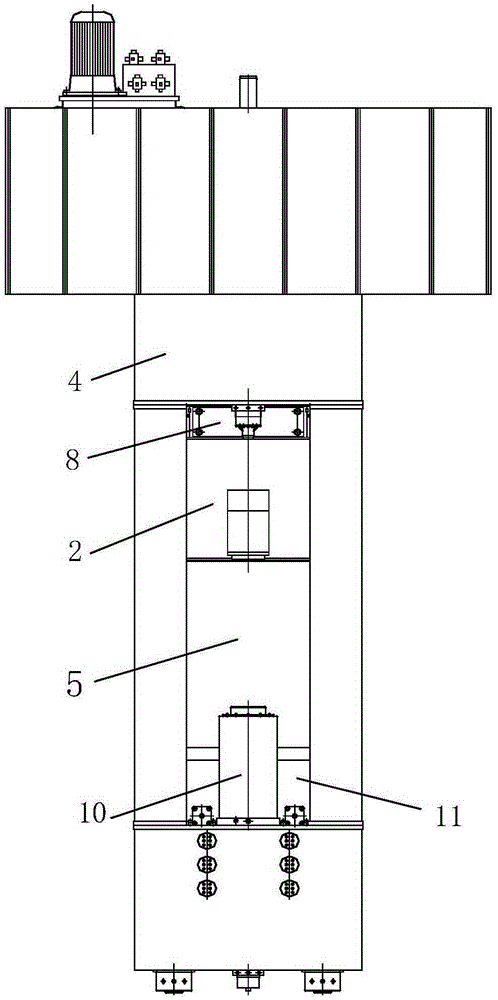

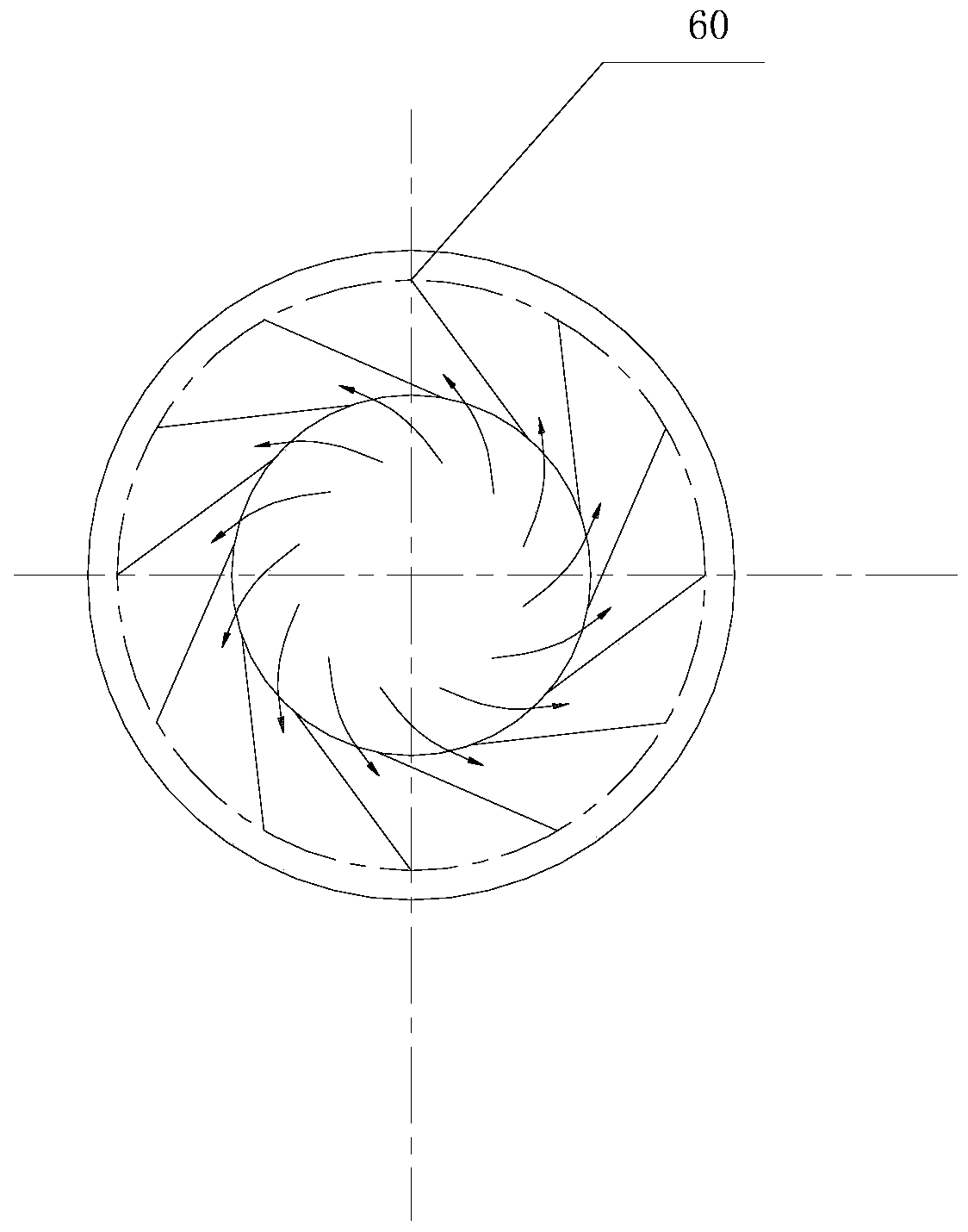

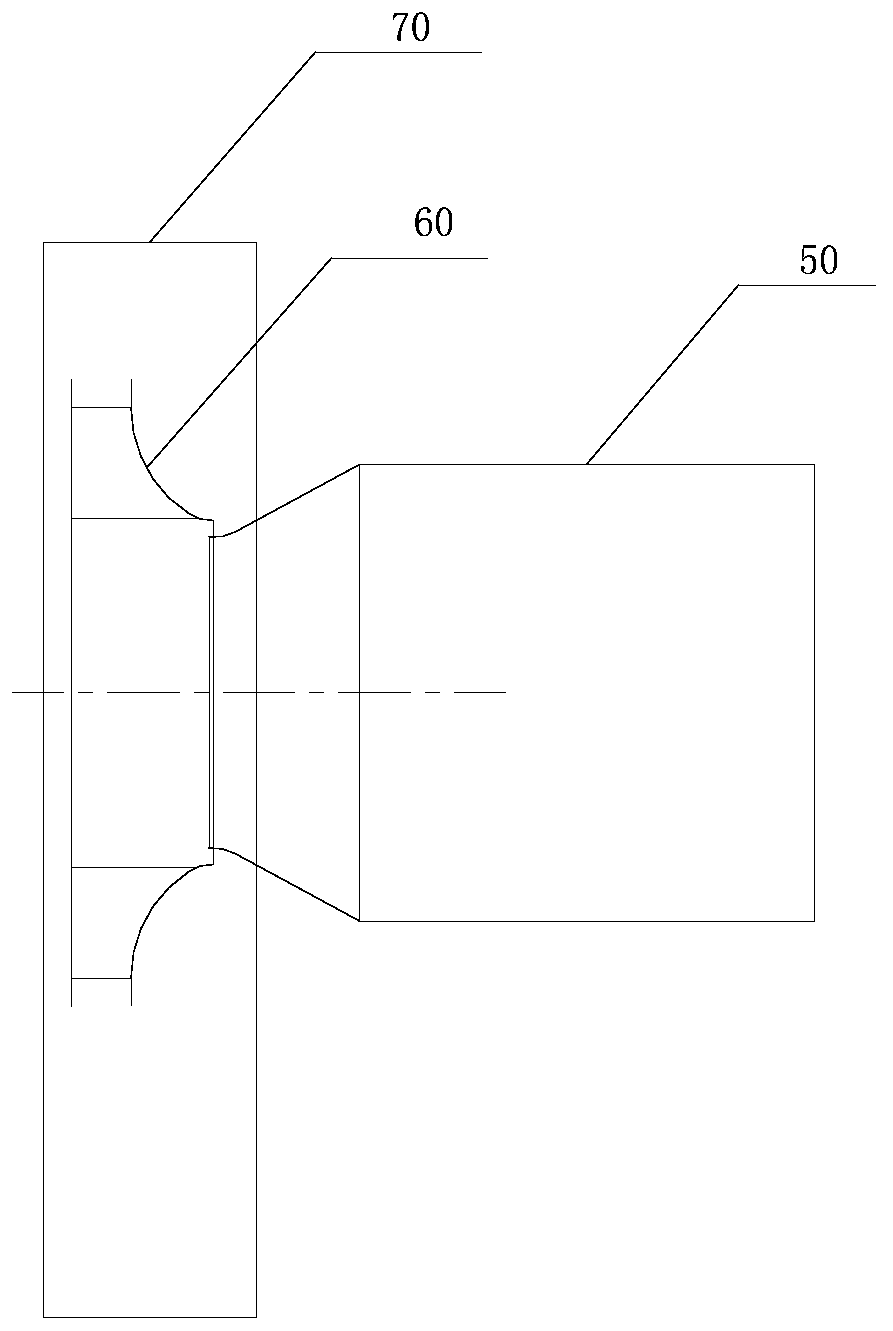

Low flow resistance pre-rotation phase silencer and design method

ActiveCN111271324AImprove aerodynamic performanceUniform and controllable flowPump componentsPumpsImpellerHoneycomb

The invention discloses a low flow resistance pre-rotation phase silencer which comprises an outer barrel and a porous plate arranged in the outer barrel. The porous plate encircles a plurality of runners in the outer barrel, and a space between an inner runner and the outer barrel is filled with a silencing material; the inlet and outlet of the inner runner are staggered. Compared with sheet, honeycomb and labyrinth silencers with messy internal flowing, the runner in the low flow resistance pre-rotation phase silencer is smooth, uniform and controllable in air flow flowing, weak in eddy flowcapacity of air flow and high in flowing efficiency. The pre-rotation air flow angle direction of the air flow is matched with an inlet blade mounting angle in an impeller, so that the pneumatic performance of equipment such as a fan can be improved.

Owner:ZHEJIANG SHANGFENG SPECIAL BLOWER IND CO LTD

Trepanning machining mechanism

InactiveCN104972513ASimple structureEasy to operateMetal working apparatusPunchingStructural engineering

The invention discloses a trepanning machining mechanism. The trepanning machining mechanism comprises a fixed handle of a cavity structure, a sliding rod, a drill point arranged at the bottom of the sliding rod, a movable handle hinged to the fixed handle, a supporting rod fixed to the lower end of the fixed handle and an adjusting base connected with the supporting rod, wherein the sliding rod penetrates through openings in the upper end face and the lower end face of the fixed handle and is arranged in the fixed handle in a sliding mode. According to the trepanning machining mechanism, one end of the movable handle is connected with a clamping disc, the movable handle is hinged to the fixed handle, the movable handle is tightened inwards with force, and the drill point can downwards act on an object to be punched for punching the object. A punching device in the trepanning machining mechanism is simple in structure and easy to operate.

Owner:CHENGDU LIXIN SCI & TECH

Environmental-friendly door plank manufacturing method

ActiveCN113858371AGuaranteed to be locatedPrevent deviationPlywood pressesWood treatment detailsPlankConstruction engineering

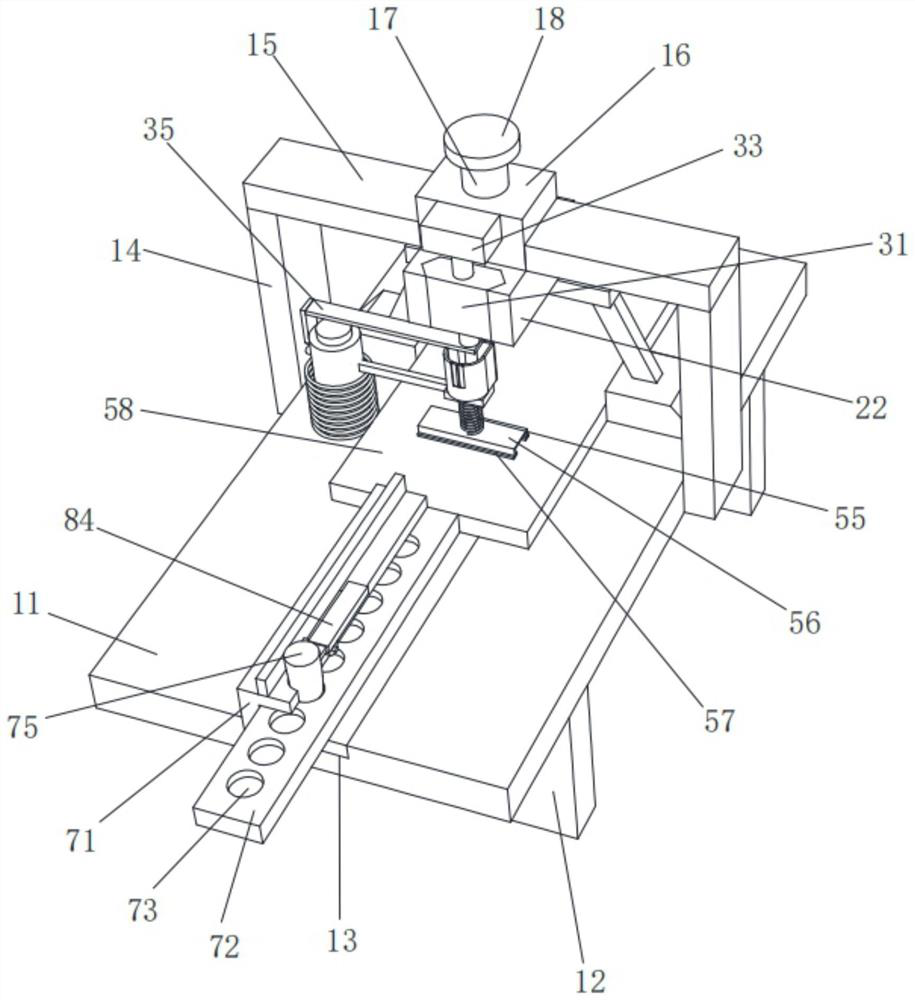

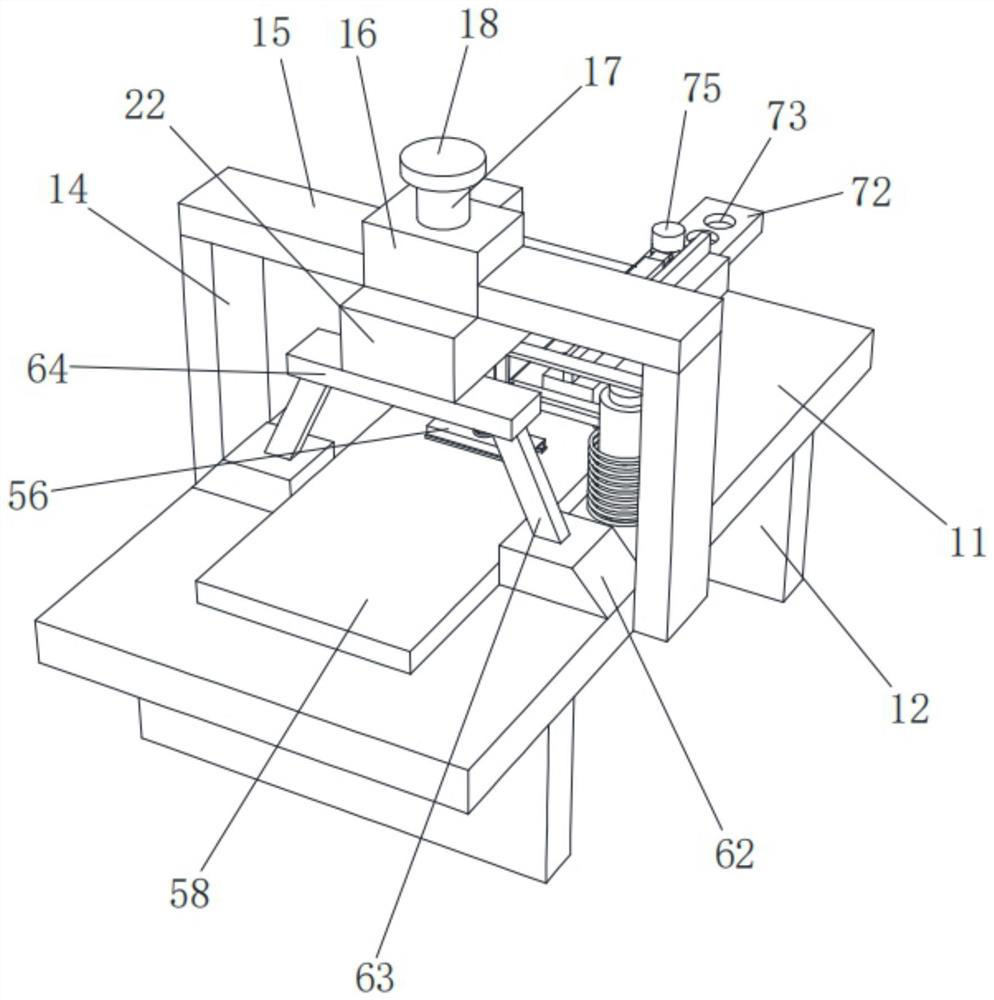

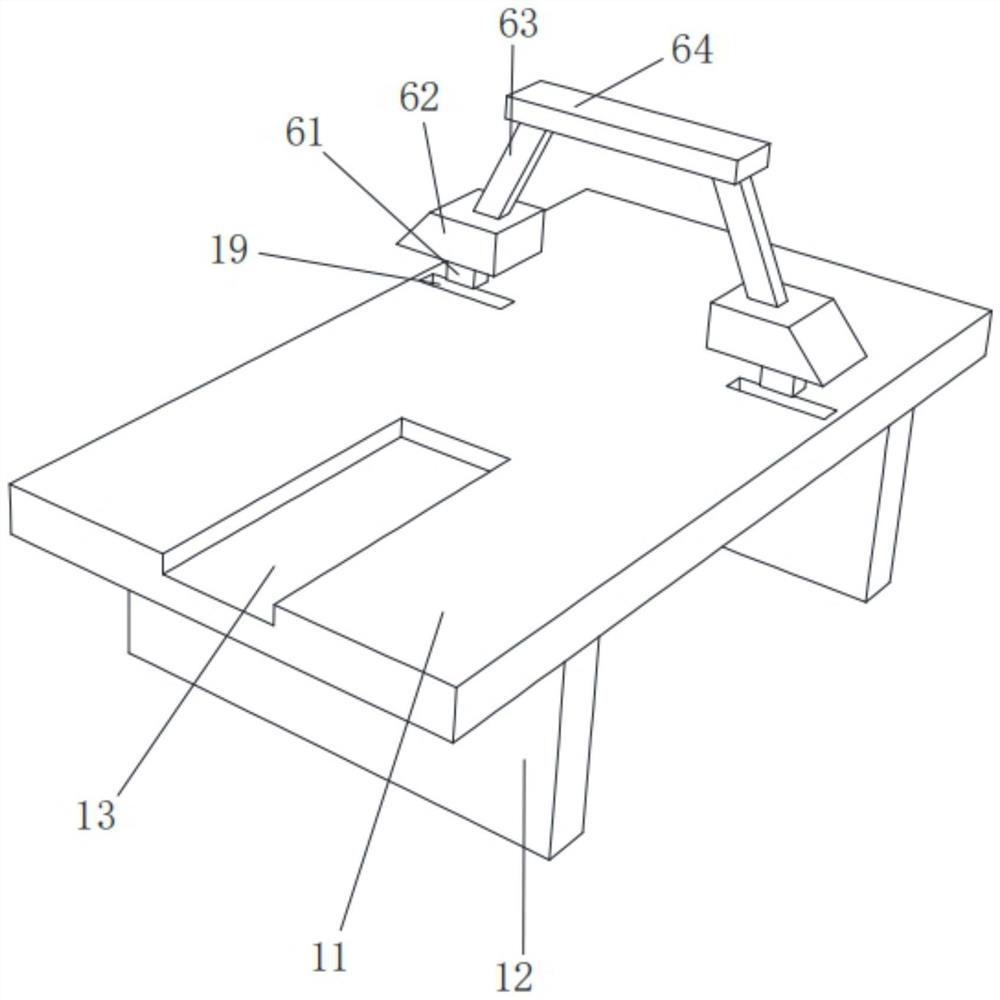

The invention relates to the technical field of environmental-friendly door planks, in particular to an environmental-friendly door plank manufacturing method. The equipment comprises a workbench, supporting legs are fixedly installed at the bottom of the workbench, a rectangular groove is formed in the rear end of the top of the workbench, side plates are symmetrically and fixedly installed on the side walls of the workbench, fixing rods are fixedly installed on the tops of the two side plates, a fixing block is fixedly installed between the two fixing rods, a threaded column is installed in the fixing block in a threaded mode, a nut is fixedly installed at the end of the threaded column, first sliding grooves are symmetrically formed in the end of the workbench, an adjusting mechanism is arranged at the bottom of the threaded column, a lifting mechanism is arranged in the adjusting mechanism, the adjusting mechanism comprises a limiting disc, the limiting disc is fixedly connected with the threaded column, a connecting block is arranged on the surface of the limiting disc in a sleeving manner, a column groove is arranged on the top of the connecting block, and the threaded column is movably arranged in the column groove. According to the equipment, the door planks can be effectively clamped, the displacement of the door planks in the machining process is effectively prevented, the length of the door planks can be adjusted at will, and the equipment is more convenient and faster to use.

Owner:杭州司哲丽科技有限公司

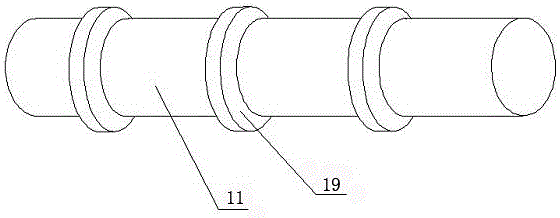

Perforating machine capable of automatically controlling perforating depth

InactiveCN106514777ASimple structureEasy to operateMetal working apparatusAutomatic controlEngineering

The invention provides a perforating machine capable of automatically controlling the perforating depth. The perforating machine capable of automatically controlling the perforating depth comprises a fixed handle of a cavity structure, a sliding rod, a drill pin, a movable handle, a supporting rod and an adjusting seat, wherein the sliding rod penetrates through openings in the upper end face and the lower end face of the fixed handle and is arranged in the fixed handle in a sliding manner, the drill pin is arranged at the bottom of the sliding rod, the movable handle is hinged to the fixed handle, the supporting rod is fixed to the lower end of the fixed handle, and the adjusting seat is connected with the supporting rod. One side of the fixed handle is completely open. The perforating machine capable of automatically controlling the perforating depth further comprises a chuck fixed to the sliding rod. One end of the movable handle is connected with the chuck, and the other end of the movable handle penetrates through the opening in one side of the fixed handle and is located outside the fixed handle. The perforating machine capable of automatically controlling the perforating depth further comprises a limiting spring, wherein one end of the limiting spring is connected with the fixed handle, and the other end of the limiting spring is connected with the movable handle. The adjusting seat comprises a base and stop covers hinged to the two side edges of the upper surface of the base. The side face of each stop cover is provided with a semicircular groove. The semicircular grooves formed in the side faces of the two stop covers constitute a round cavity. The perforating machine capable of automatically controlling the perforating depth further comprises a bottom bar arranged in the round cavity in a sliding manner. The perforating machine capable of automatically controlling the perforating depth is simple in structure and excellent in perforating effect.

Owner:刘海峰

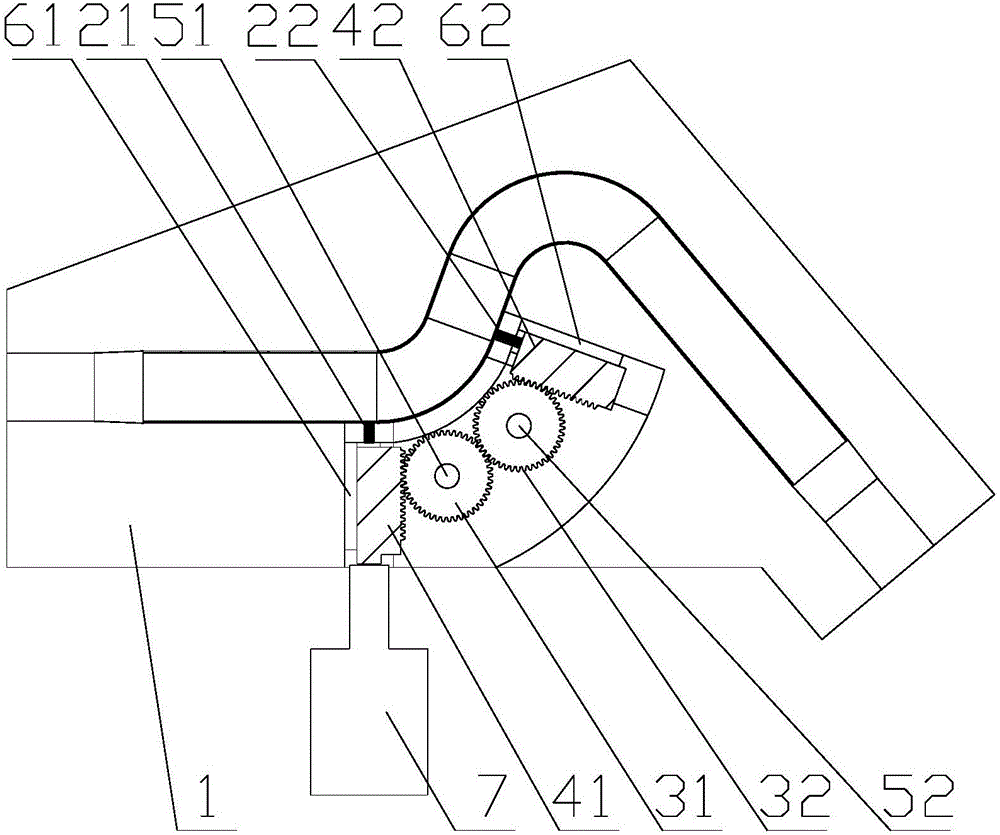

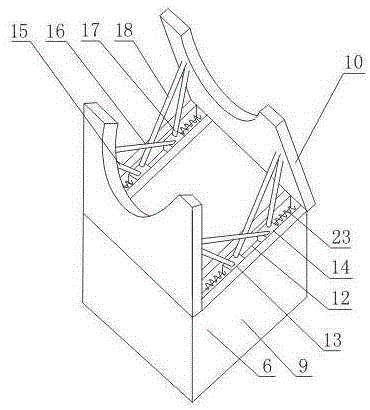

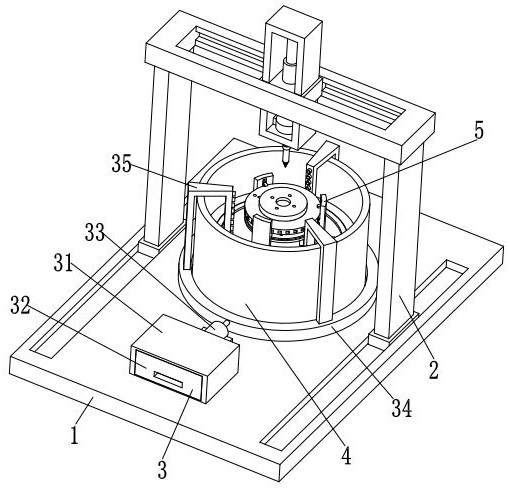

Surface fixed-distance punching device for processing of wood board

The invention relates to a surface fixed-distance punching device for processing of a wood board. The surface fixed-distance punching device for processing of the wood board comprises a workbench and a bearing frame fixed to the workbench through a mounting frame, a drill bit is arranged at one side, facing the workbench, of the bearing frame, the drill bit is connected with a driving mechanism mounted on the bearing frame, the workbench is further provided with a clamping mechanism, the clamping mechanism is connected with a horizontal conveying mechanism mounted on the workbench, the horizontal conveying mechanism is rotatably connected with a first driving rod rotatably mounted on the bearing frame through a first driving belt, the first driving rod is matched with a gear fixed to a second driving rod rotatably connected with the bearing frame through a ratchet mechanism, the gear is matched with a rack plate which slides on the bearing frame and is connected with the driving mechanism, the device further comprises an auxiliary clamping mechanism, and the auxiliary clamping mechanism is mounted on the bearing frame and connected with the second driving rod.

Owner:湖南省石城竹木制品有限公司

Perforating device for laser thermoprint bend-resistant clothing hangtag

InactiveCN110181597ANot easy to burrGuaranteed punching effectPolishing machinesMetal working apparatusDeckleEngineering

The invention discloses a perforating device for laser thermoprint bend-resistant clothing hangtag. The perforating device comprises a perforating table, a pressing plate, a perforating rod, a first pressing device, a second pressing device, a lifting device, a polishing rod and a control device. The pressing plate is arranged above the perforating table. The pressing plate is connected with the first pressing device. A through hole in vertical arrangement is formed in the pressing plate. The perforating rod is inserted inside the first through hole. The perforating rod is connected with the second pressing device. The second pressing device is fixed to the pressing plate. The second through hole in vertical arrangement is formed in the perforating table. The second through hole penetratesthe upper end and the lower end of the perforating table. The second through hole is located over the first through hole. The polishing rod in vertical arrangement is arranged below the second through hole. The polishing rod is connected with a motor. The motor is connected with a lifting device. By means of the cooperation of the first through hole, the second through hole and the polishing rod,perforated holes can be effectively polished; deckle edge is not likely to generate; perforating efficiency is guaranteed.

Owner:HAIYAN HUAGANG PRINTING CO LTD

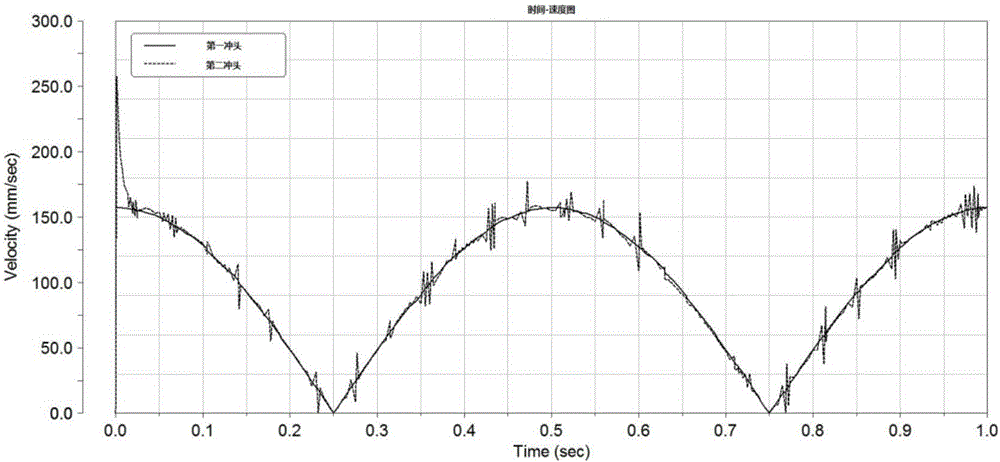

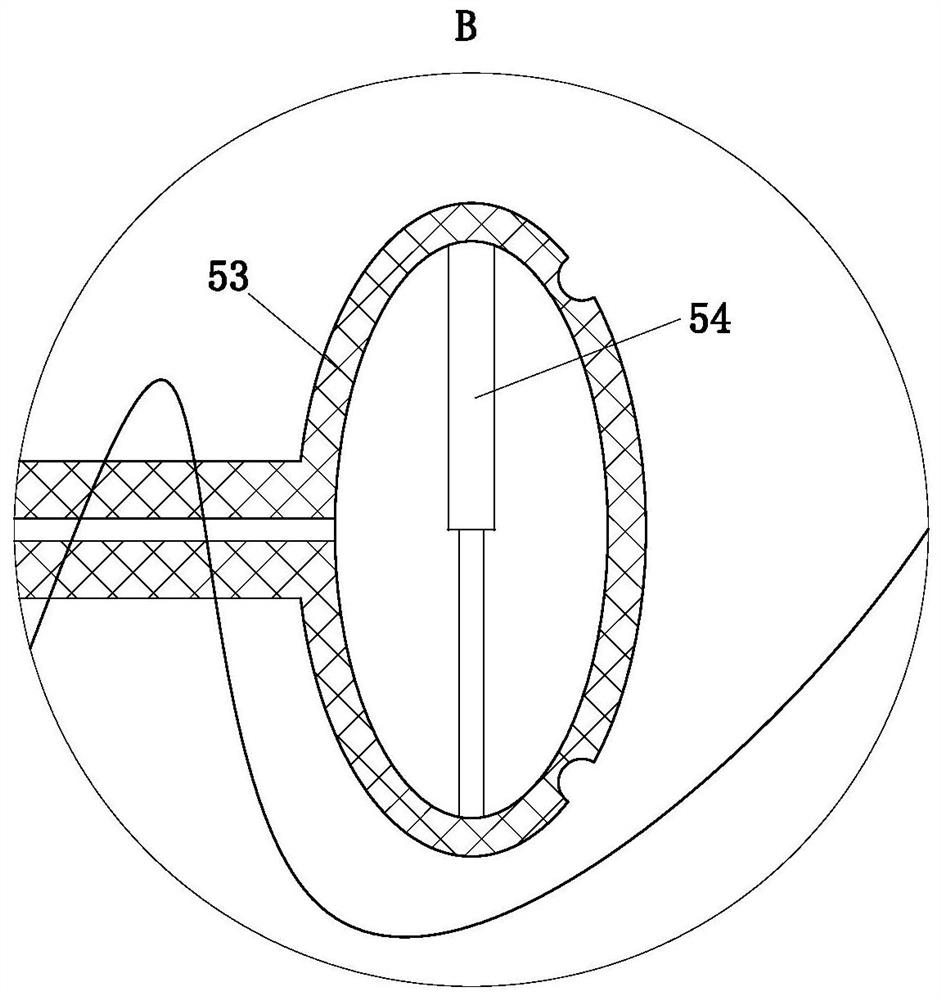

Synchronous punching device in internal high-pressure forming mold

ActiveCN106734724AGuaranteed punching effectGuaranteed synchronicityPerforating toolsVehicle componentsPunchingPipe fitting

The invention discloses a synchronous punching device in an internal high-pressure forming mold. After a pipe fitting to be molded is molded through the internal high-pressure forming mold, a pipe wall in a mold cavity is synchronously punched through a first punch and a second punch; high-pressure liquid in the pipe fitting is used for supporting to guarantee the punching effect; further, the first punch and the second punch are in engaged transmission through gears; on the one hand, the gear transmission guarantees the speed and the displacement transmission synchronism, so that the transmission reliability and the machining precision are improved; and on the other hand, because of angle flexibility of gear engagement, different positions on different planes can be synchronously punched, and the use flexibility is excellent and not limited by the use environment.

Owner:BAOLONG ANHUI AUTO PARTS

Lever drilling device

InactiveCN106514776ASimple structureEasy to operateMetal working apparatusCircular cavityElectrical and Electronics engineering

The invention discloses a lever drilling device. The lever drilling device comprises a fixed handle with a cavity structure, a slide rod slidingly arranged in the fixed handle by respectively penetrating through openings on the upper and lower end surfaces of the fixed handle, a drilling needle arranged at the bottom of the slide rod, a movable handle hinged to the fixed handle, a support rod fixed at the lower end of the fixed handle, and an adjusting base connected with the support rod; and one side of the fixed handle is totally opened. The lever drilling device further comprises a chuck fixed on the slide rod; and one end of the movable handle is connected with the chuck, and the other end penetrates through the opening on one side of the fixed handle and is positioned out of the fixed handle. The lever drilling device further comprises a limiting spring connected with the fixed handle by one end and connected with the movable handle at the other end; the adjusting base includes a base, and stop covers respectively hinged to two side edges of the upper surface of the base; semicircular grooves are formed in the side surfaces of the stop covers; and the semicircular grooves formed in the side surfaces of the two stop covers form a circular cavity. The lever drilling device further comprises a bottom rod slidingly arranged in the circular cavity. The lever drilling device is simple in structure and better in punching effect.

Owner:胡峻源

Automatic cleaning equipment for CNC machine tools

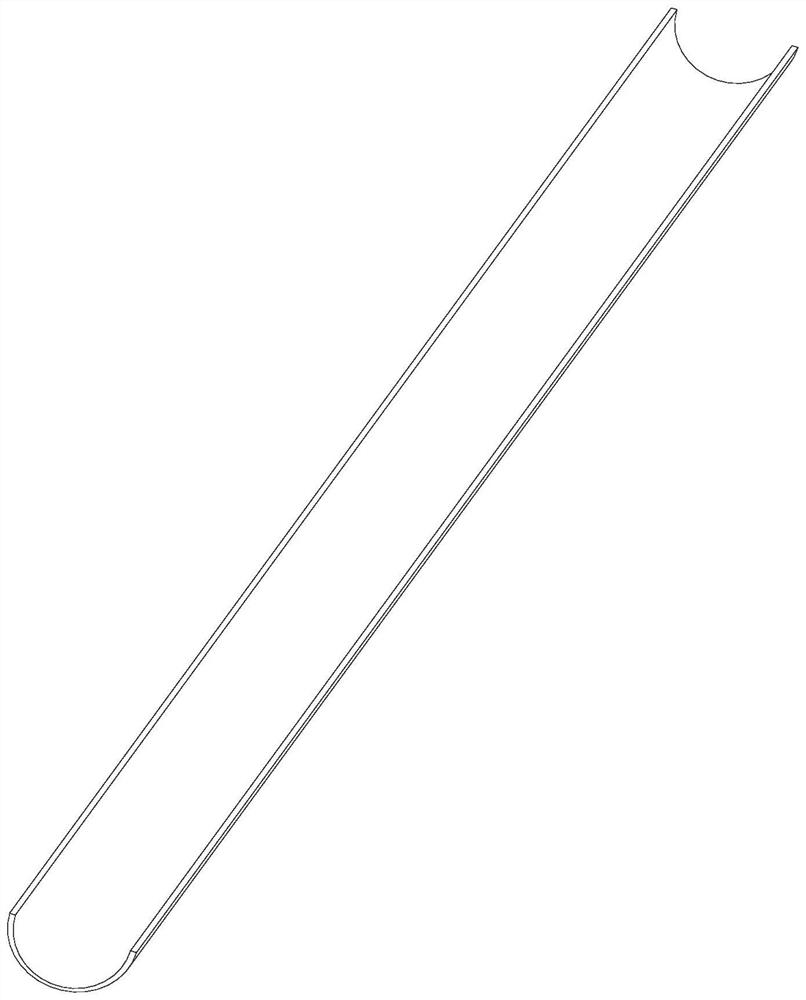

ActiveCN112893930BGuaranteed stabilityUniform hole arcFeeding apparatusBoring/drilling componentsNumerical controlProcess engineering

The invention provides an automatic cleaning device for a CNC machine tool, including a U-shaped frame, a fixing unit, an adjustment unit, a limit unit and an execution unit; A large amount of iron filings are produced, and if the iron filings generated during the drilling process are not cleaned up in time, the drill bit will wear out quickly and the service life of the drill bit will be reduced; the processed drill bit needs to be replaced frequently, and the current drill bit is used for drilling the plate. During the process, it is easy to make the drilling holes on the plate prone to deflection, thereby affecting the processing quality of the plate, and the cutting tool size inside the current CNC machine tool is fixed, and it is difficult to improve the applicability of its work.

Owner:DEZHOU TAISHUO MACHINERY

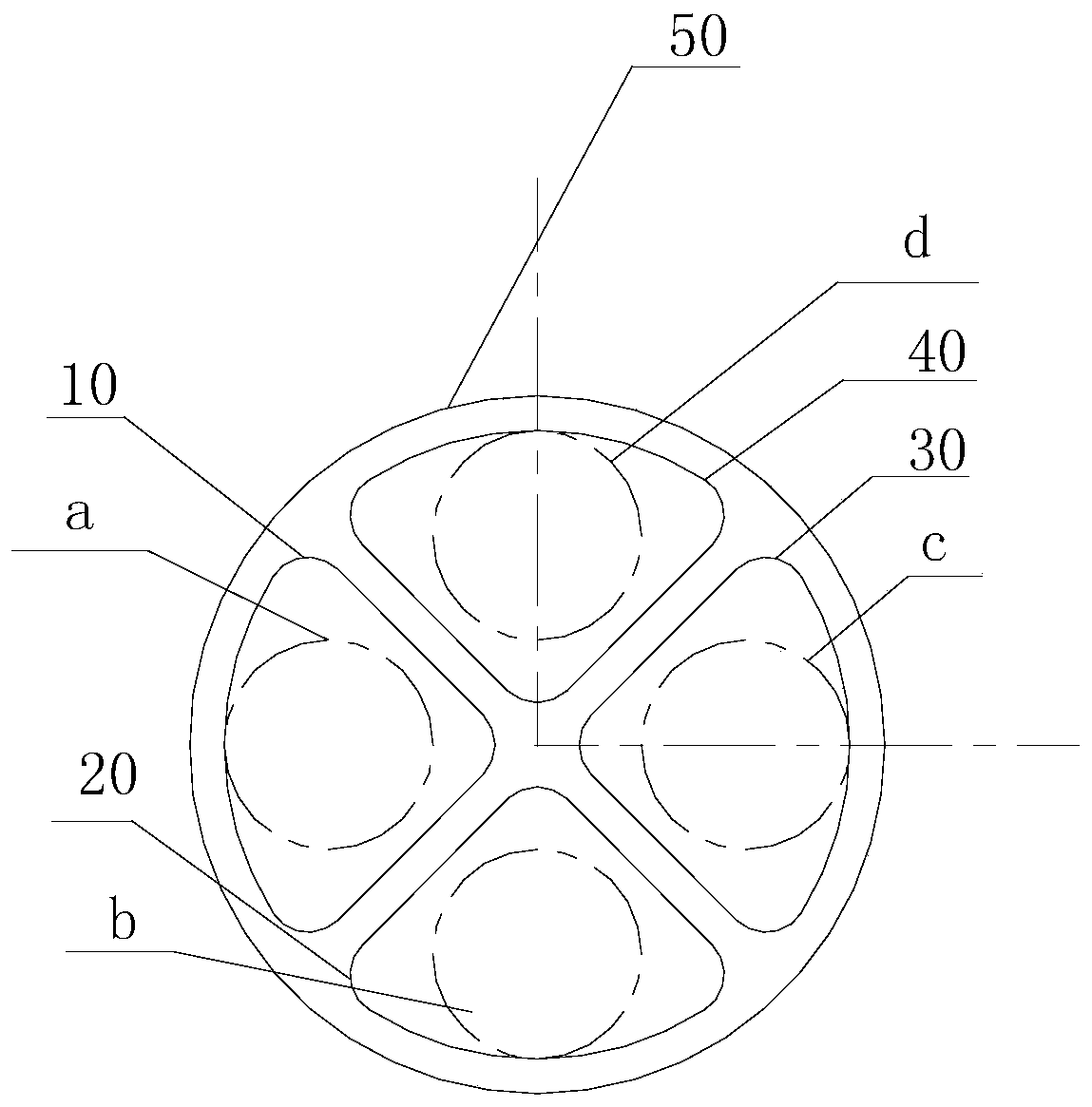

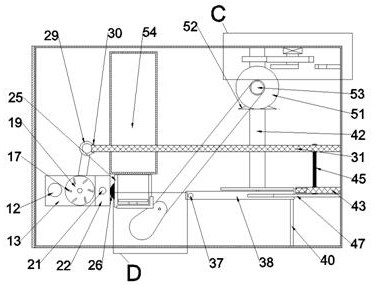

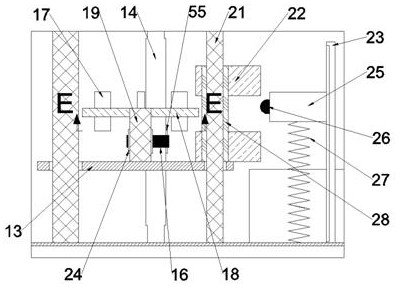

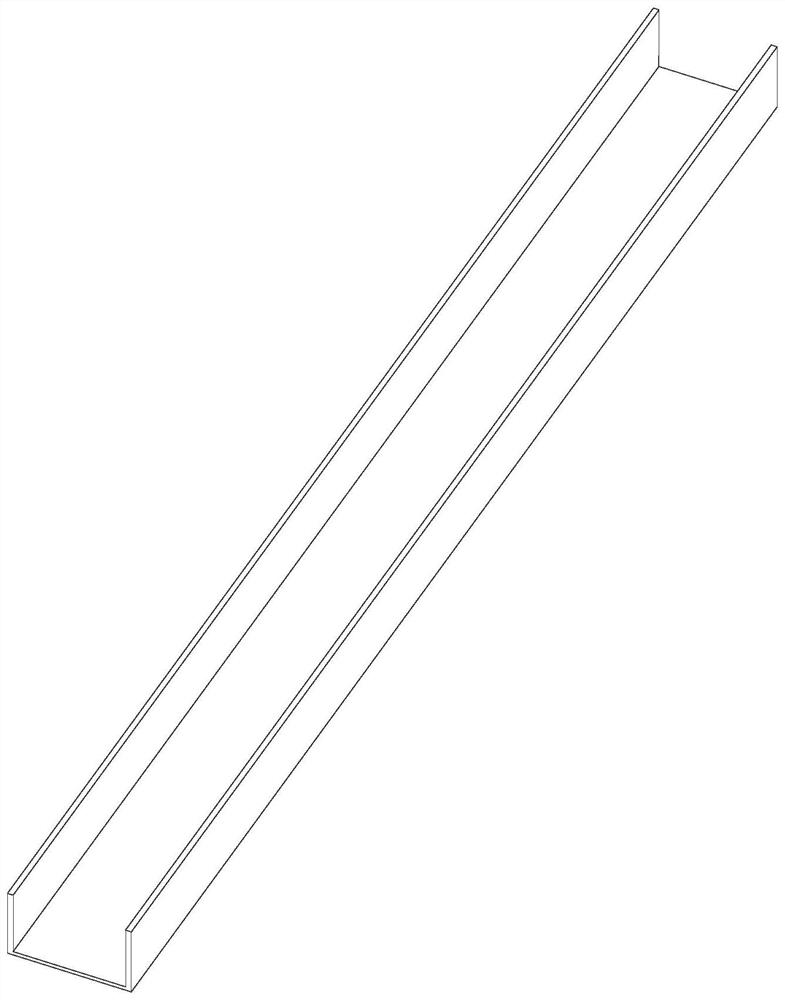

Automatic cleaning equipment for numerical control machine tool

ActiveCN112893930AGuaranteed stabilityUniform hole arcFeeding apparatusBoring/drilling componentsNumerical controlExecution unit

The invention provides automatic cleaning equipment for a numerical control machine tool. The automatic cleaning equipment comprises a U-shaped frame, a fixing unit, an adjusting unit, a limiting unit and an executing unit. The problems that in the working process of an existing numerical control machine tool, a large amount of scrap iron is generated when a plate is machined and drilled, a drill bit is rapidly abraded due to the fact that the scrap iron generated in the machining and drilling process is not cleared away in time, the service life of the drill bit is shortened, and the drilling bit for machining needs to be frequently replaced are solved, the problem that the machining quality of the plate is affected due to the fact that when the existing drilling bit is used for drilling the plate, a drilled hole in the plate is prone to deflection is solved, and the problem that the size of a cutting tool in the existing numerical control machine tool is fixed, and the working applicability of the cutting tool is difficult to improve is solved.

Owner:DEZHOU TAISHUO MACHINERY

Punching calibration device for outer wall of furnace shell of intermediate frequency furnace

PendingCN114130888AConsistent wearGuaranteed punching effectMetal-working feeding devicesGrinding machinesPunchingIntermediate frequency

The invention belongs to the technical field of power equipment, and particularly relates to a punching calibration device for the outer wall of a furnace shell of an intermediate frequency furnace, the punching calibration device comprises a horizontal bottom plate, supporting columns are uniformly and fixedly mounted on the upper surface of the bottom plate, and a horizontal machining table is jointly and fixedly mounted at the tops of the uniformly arranged supporting columns; a clamping mechanism and a punching mechanism are mounted on the bottom plate; when the outer wall of the furnace shell of the intermediate frequency furnace is punched through the punching device, it is guaranteed that the abrasion degrees of all the cutting blocks are consistent, and therefore material waste is reduced; and after trepanning is finished, the grinding wheel horizontally moves in the rotating state to calibrate the two side walls of the kidney-shaped hole, it is guaranteed that the two side walls of the kidney-shaped groove are flush, and it is further guaranteed that the shape of the kidney-shaped hole is regular.

Owner:泰州市科健电炉电器有限公司

Film piercing equipment

ActiveCN109262730AMeet processing needsReduce energy consumptionNon-rotating vibration suppressionMetal working apparatusSlide plateEngineering

The invention belongs to the technical field of film piercing equipment, and particularly relates to film piercing equipment. The film piercing equipment comprises a support, a motor, a controller, sliding plates, a punch, a clamping block, a first spring, a guide rod, a lead screw and a controller, wherein a first air bag is arranged between the support and the clamping block; rubber bars are arranged at the two ends of the axis of the first spring; an inclined angle is formed between each rubber bar and the plane of the support; the rubber bars penetrate through the axis of the first springto erect up the first spring; a cylinder is arranged on each of the two sliding plates; each cylinder is fixed on the corresponding sliding plate; a telescopic rod is arranged in a second air bag; thetwo ends of the telescopic rod are fixed on the inner wall of the second air bag; two clamping grooves are formed in the outer wall of the second air bag; and the two clamping grooves are symmetrically formed in the upper end and the lower end of the second air bag. By a simple transmission structure, energy consumption for running of the equipment is reduced; and due to discontinuous working travels, the requirement for processing of scattered raw materials is met.

Owner:SHANDONG SENBOSITE PLASTIC TECH CO LTD

Perforating device for aluminum alloy plate machining

ActiveCN112705947AAvoid polishing processReduce labor intensityFeeding apparatusOther manufacturing equipments/toolsEngineeringWorkbench

The invention belongs to the technical field of aluminum alloy plate machining, and particularly relates to a perforating device for aluminum alloy plate machining. The device comprises a workbench, wherein two first sliding grooves are formed in the workbench, the two first sliding grooves are separately positioned on two sides of the workbench, a second sliding groove is formed at the first sliding groove on one side of the workbench, first limiting pieces are slidably mounted at the ends of the first sliding grooves and on the workbench, a second limiting piece is slidably mounted at the end of the second sliding groove, a moving assembly is mounted on one side of the workbench, the moving assembly is fixedly connected to one side of an aluminum alloy plate, a perforating mechanism is fixedly mounted on one side of the workbench, the perforating mechanism corresponds to the edge of one side of the aluminum alloy plate and comprises a fixing frame, a polishing assembly and a perforating assembly, and the problems that according to an existing perforating device, due to structural defects, subsequent procedures are increased, labor intensity is increased, and a perforating direction deviates are solved.

Owner:重庆新久融科技有限公司

Adjustable mechanical tool used for drilling

InactiveCN106553232ASimple structureEasy to operateMetal working apparatusEngineeringCircular cavity

The invention provides an adjustable mechanical tool used for drilling. The adjustable mechanical tool comprises a fixed handle in a cavity structure, a slide rod which runs through openings in upper and lower end faces of the fixed handle and is slidably arranged in the fixed handle, a drill bit which is arranged at the bottom of the slide rod, a movable handle which is hinged with the fixed handle, a support rod which is fixed on the lower end of the fixed handle, and an adjusting seat which is connected with the support rod. One side of the fixed handle is fully open. The adjustable mechanical tool further comprises a chuck which is fixed with the slide rod. One end of the movable handle is connected with the chuck. The other end runs through the opening in one side of the fixed handle, and is located outside the fixed handle. The adjustable mechanical tool further comprises a limit spring. One end of the limit spring is connected with the fixed handle, and the other end is connected with the movable handle. The adjusting seat comprises a base and baffle covers which are hinged with both sides of the upper surface of the base. The side of each baffle cover is provided with a semi-circular groove. Semi-circular grooves in the sides of two baffle covers form a circular cavity. The adjustable mechanical tool further comprises a bottom rod which is slidably arranged in the circular cavity. The drilling device provided by the invention has the advantages of simple structure and easy operation.

Owner:史军

An automatic test paper binding device

An automated complete book binding device for test papers, including a workbench, the four corners of the bottom of the workbench are respectively fixed with table legs, the rear of the top of the workbench is fixedly connected to a vertical board, the upper part of the front of the vertical board is fixedly connected to the back of a horizontal board, and the bottom of the horizontal board The two sides of the two sides are respectively fixedly connected to the upper end of the electric push rod, and the lower end of the electric push rod is fixedly connected to the top surface of the horizontal plate. A row of several first through holes is opened on the top surface of the horizontal plate, and the bottom surface of the first through hole is respectively fixed and installed. Open vertical cylinder, the lower end of the vertical cylinder is an annular knife edge, and the front side of the top surface of the workbench is provided with several second through holes, and the grinding device capable of grinding the bottom of the corresponding vertical cylinder is provided in the second through holes. When the device is punching holes, it can realize the automatic cleaning of the vertical tube, and discharge the paper scraps in the vertical tube out of the vertical tube, which is convenient for the user to clean and collect the paper scraps, avoids the blockage of the vertical tube, and improves the reliability of the vertical tube. To ensure the punching effect of the vertical cylinder.

Owner:咸阳天裕印务有限公司

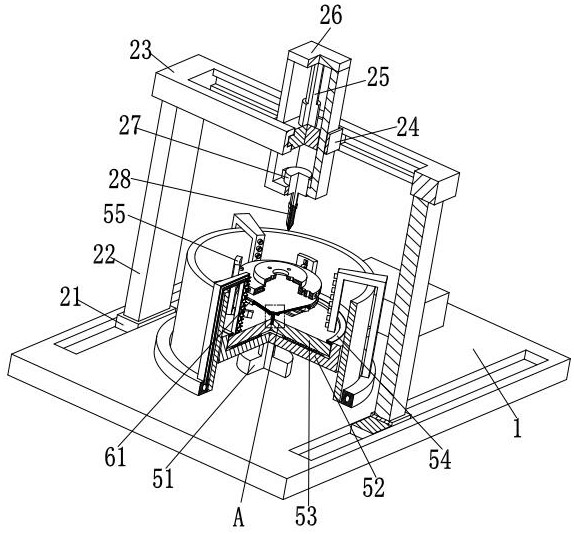

Automated drilling and processing equipment for automobile brake disc manufacturing

ActiveCN113263205BAvoid scratchesQuality assuranceAutomatic control devicesFeeding apparatusBrakeCollector device

The invention relates to the technical field of brake disc processing; in particular, it relates to an automatic drilling and processing equipment for manufacturing automobile brake discs, including a base plate, a drilling device, an adsorption device, a limit sleeve, a fixing device and a material collecting device; During the hole processing in the middle of the brake disc, it is difficult to fix the brake discs with different diameters, and the brake disc is prone to shaking during the process of drilling the brake disc, and the waste debris generated during the drilling process on the surface of the brake disc is scattered. It is difficult to clean on the ground, the efficiency of manual cleaning is low, and the debris is easy to cause scratches on the surface of the brake disc and other problems.

Owner:江苏特塑新能源科技有限公司

Combined pressure hole equipment

InactiveCN106553235ASimple structureEasy to operateMetal working apparatusMechanical engineeringHydraulic pressure

The invention provides combined pressure hole equipment. The combined pressure hole equipment comprises a fixed handle of a cavity structure, a sliding rod which penetrates an upper end face opening and a lower end face opening of the fixed handle and is slidably arranged in the fixed handle, a perforating needle arranged at the bottom of the sliding rod, a movable handle hinged to the fixed handle, a supporting rod fixed to the lower end of the fixed handle and an adjusting seat connected with the supporting rod. One side of the fixed handle is completely open. The combined pressure hole equipment further comprises a clamping disc fixed to the sliding rod. One end of the movable handle is connected with the clamping disc, and the other end of the movable handle penetrates the opening in one side of the fixed handle and is located outside the fixed handle. The combined pressure hole equipment further comprises a hydraulic device fixed to the other end of the movable handle. According to the combined pressure hole equipment, the movable handle is hinged to the fixed handle, one end of the movable handle is connected with the clamping disc, the movable handle is driven by the hydraulic device to move up and down, and a perforating needle acts on a substance to be perforated and perforates holes in the substance. The combined pressure hole equipment is simple in structure and easy to operate.

Owner:史军

Lawn perforating machine capable of automatically adjusting perforating depth according to soil compactness

InactiveCN112930723AAvoid dehydration and droughtAvoid destructionLawn machinesAgricultural engineeringSoil texture

The embodiment of the invention discloses a lawn perforating machine capable of automatically adjusting the perforating depth according to the soil compactness. The lawn perforating machine capable of automatically adjusting the perforating depth according to the soil compactness comprises a perforating vehicle box body, a perforating and soil unloading mechanism located in the perforating vehicle box body, a stroke judging mechanism located on the rear side of the perforating and soil unloading mechanism, a transferring mechanism located on the left side of the perforating and soil unloading mechanism, a weight judging mechanism located on the left side of the transferring mechanism and a trigger adjusting mechanism located on the left side of the weight judging mechanism. By rotating an adjusting switch to change the position of an adjusting electromagnet, the adjusting requirement for the perforating depth of soil of different soil textures can be met, meanwhile, the soil compactness is judged according to the quality of a soil core obtained after perforating is completed, then the perforating depth of the next time is adjusted, and therefore the perforating effect is guaranteed.

Owner:深圳市虹均愁实业有限公司

Intelligent profile rolling assembly line

The invention belongs to the technical field of profile machining, and particularly relates to an intelligent profile rolling assembly line which comprises a control system, an unwinding mechanism, a straightening mechanism, a blanking system, a rolling forming mechanism and a cutting mechanism. The blanking system comprises two supporting seats arranged in parallel, lower die mounting beams arranged on the supporting seats, blanking lower dies mounted on the two lower die mounting beams and a blanking driving mechanism arranged above the blanking lower dies, and the output end of the blanking driving mechanism is connected with a blanking upper die matched with the blanking lower dies; the blanking driving mechanism is connected with the control system, and the control system automatically controls the blanking driving mechanism to move up and down according to system signals. The problems that an existing profile rolling assembly line is limited in application range, single in profile product capable of being produced and high in production cost are solved.

Owner:江苏亚龙汽车有限公司

Polishing device for crystal block gluing holes

The invention discloses a polishing device for crystal block gluing holes. The polishing device comprises a base, a punching mechanism and a clamping mechanism; the base is provided with a mounting groove for placing crystal blocks; a guide port communicating with the mounting groove is formed in one side surface of the base; the clamping mechanism is used for fixing the crystal blocks in the mounting groove; and the punching mechanism is positioned on one side of the base and aligned to the mounting groove. The polishing device has the characteristics of high speed, high efficiency and high product quality.

Owner:江苏长江智能制造研究院有限责任公司 +1

An automatic notching device for lock body processing equipment

Owner:垫江县和欣钢质门有限公司

film punching device

ActiveCN109262730BMeet processing needsReduce energy consumptionNon-rotating vibration suppressionMetal working apparatusPunchingElectric machinery

The invention belongs to the technical field of film piercing equipment, and particularly relates to film piercing equipment. The film piercing equipment comprises a support, a motor, a controller, sliding plates, a punch, a clamping block, a first spring, a guide rod, a lead screw and a controller, wherein a first air bag is arranged between the support and the clamping block; rubber bars are arranged at the two ends of the axis of the first spring; an inclined angle is formed between each rubber bar and the plane of the support; the rubber bars penetrate through the axis of the first springto erect up the first spring; a cylinder is arranged on each of the two sliding plates; each cylinder is fixed on the corresponding sliding plate; a telescopic rod is arranged in a second air bag; thetwo ends of the telescopic rod are fixed on the inner wall of the second air bag; two clamping grooves are formed in the outer wall of the second air bag; and the two clamping grooves are symmetrically formed in the upper end and the lower end of the second air bag. By a simple transmission structure, energy consumption for running of the equipment is reduced; and due to discontinuous working travels, the requirement for processing of scattered raw materials is met.

Owner:SHANDONG SENBOSITE PLASTIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com