Polishing device for crystal block gluing holes

A technology of crystal and plastic holes, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., which can solve the problems of inconsistent grinding hole positions, sizes and depths, affecting the quality of finished products, and slow speed, etc., to achieve convenience Drilling, reasonable structure design and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

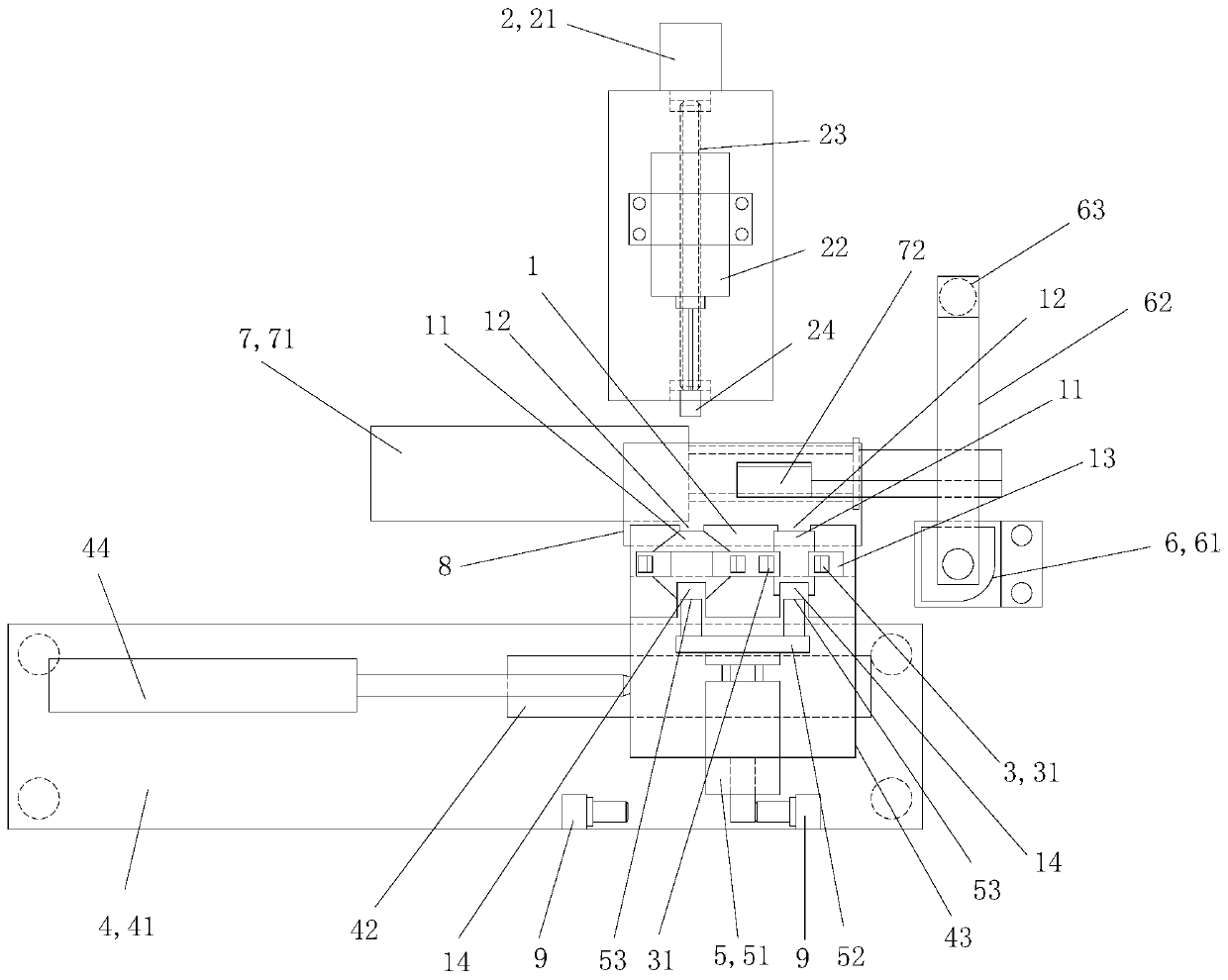

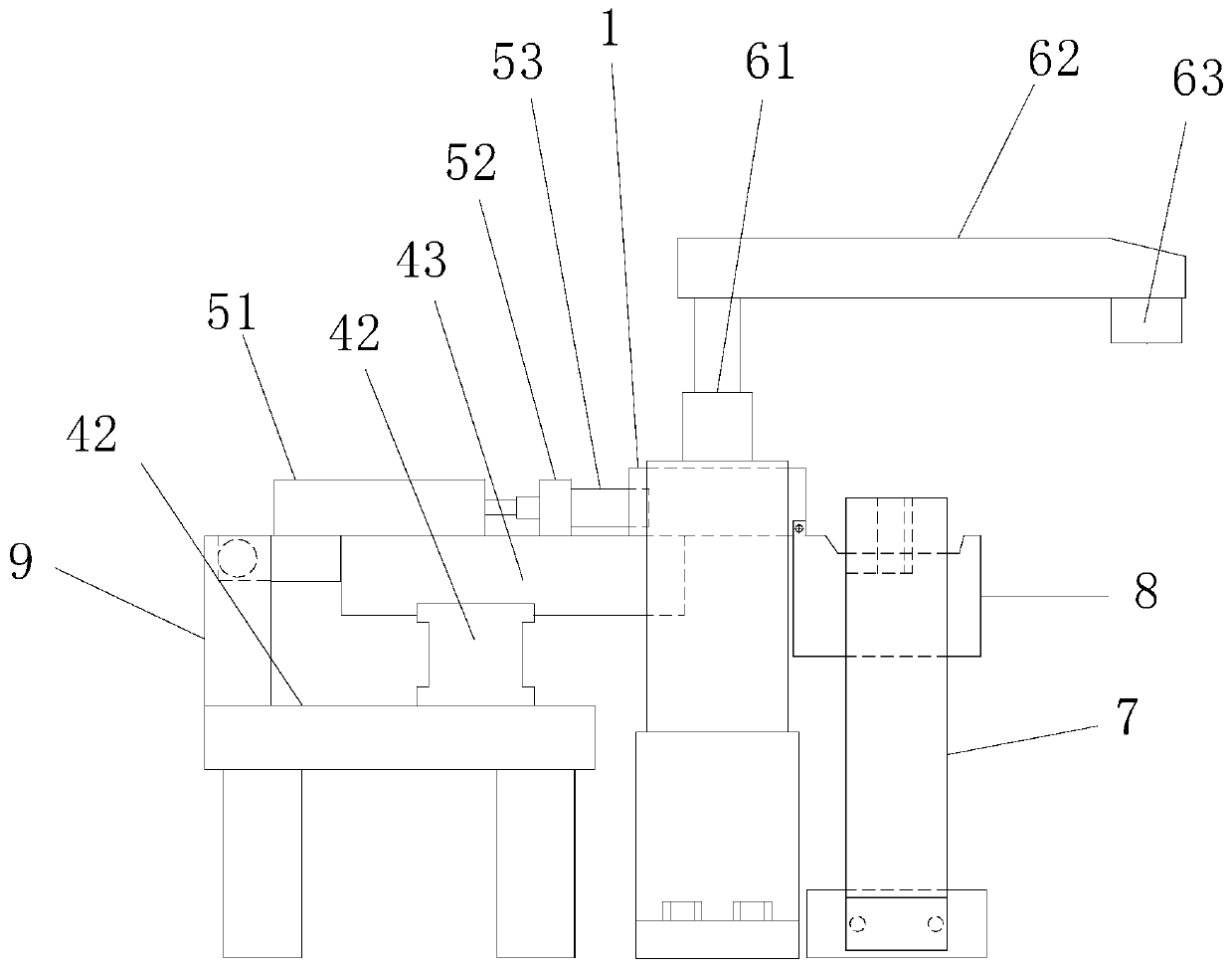

[0036] See figure 1 and figure 2 , The polishing device of the glue hole on the crystal block of the present embodiment includes a base 1, a punching mechanism 2, a clamping mechanism 3, a sliding mechanism 4, a pressing mechanism 5 and a pressing mechanism 6.

[0037] The base 1 is provided with an installation groove 11 for placing a crystal block, and the front side of the base 1 is provided with a guide port 12 communicating with the installation groove 11, and the number of the installation groove 11 is at least one. In this embodiment, The quantity of mounting groove 11 is preferably two, and two mounting grooves 11 are horizontally arranged; The shape of mounting groove 11 is a kind of in triangle, rectangle, circle, hexagon and octagon, in the present embodiment two One of the mounting grooves 11 is octagonal and the other is rectangular.

[0038] The clamping mechanism 3 is used to fix the crystal block in the installation groove 11, and one installation groove 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com