On-line automobile aluminium alloy hub blank deformation measurement method and measurement device

A technology for aluminum alloy wheels and wheel blanks, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inaccurate measurement of wheel rim deformation, few measurement positions and points, and rare deformation measurement reports, etc., to achieve Improve detection accuracy, improve enterprise production efficiency, reduce the effect of measurement procedures and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content, features and functions of the present invention, an embodiment of the present invention is introduced below, and detailed description is as follows in conjunction with the accompanying drawings.

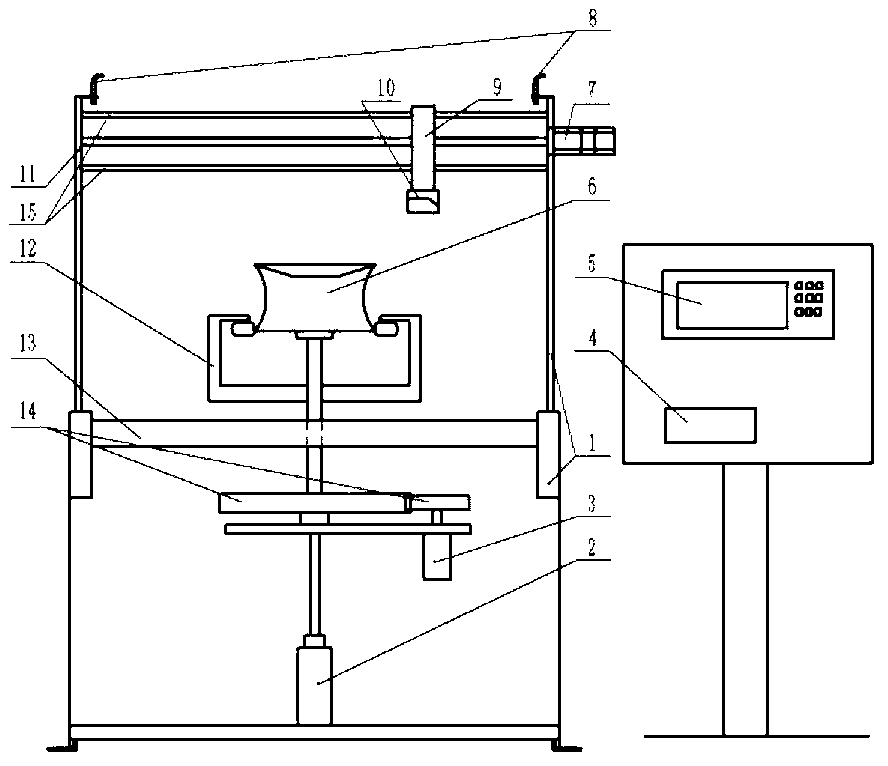

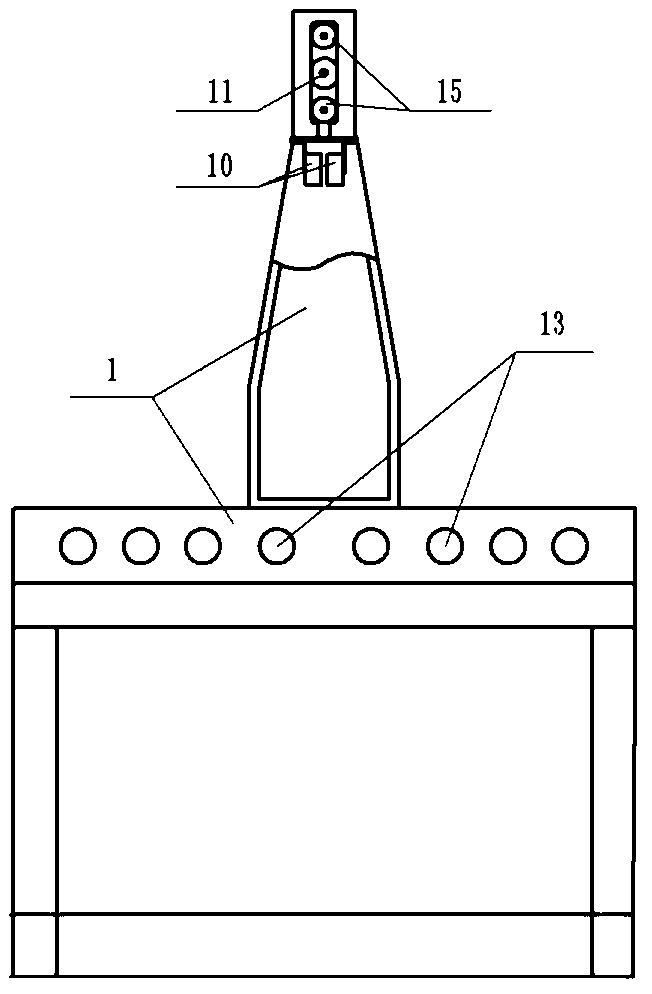

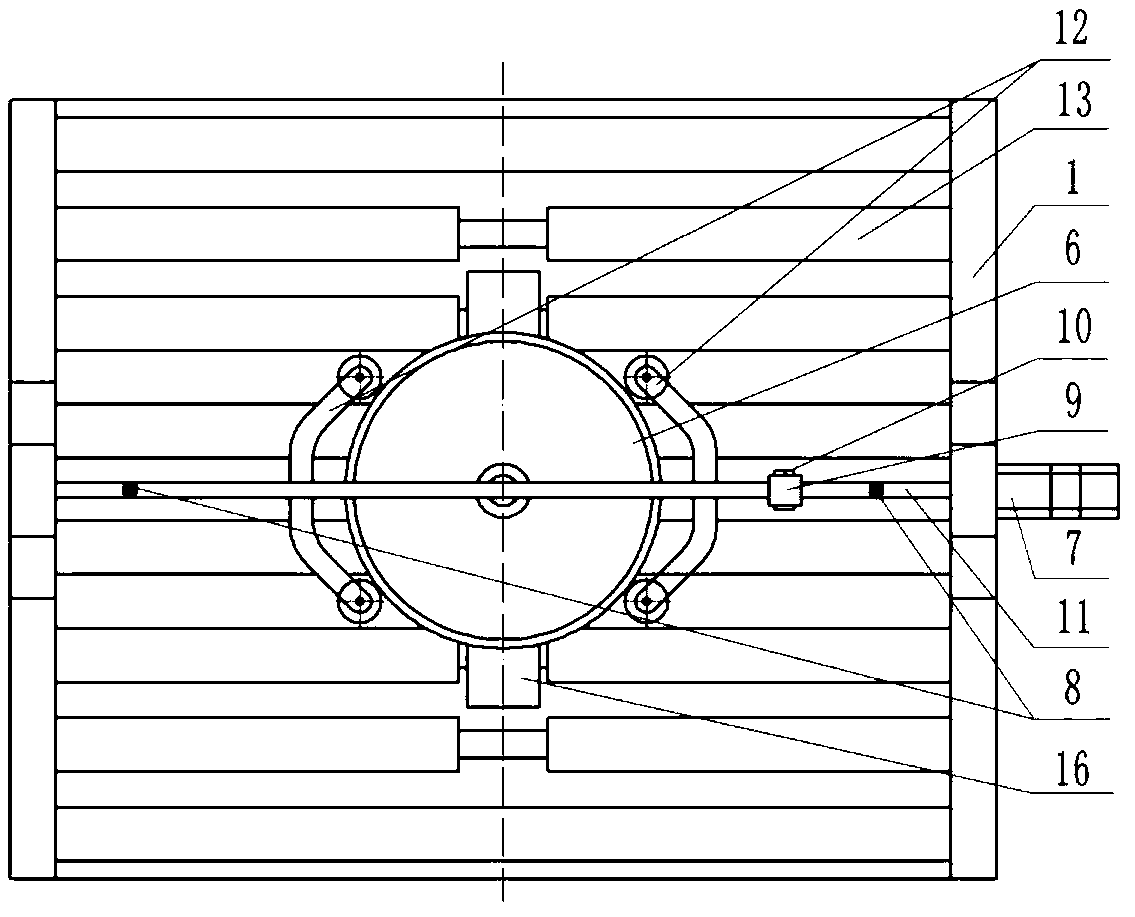

[0027] See Figure 1-6 , the present invention is based on the laser triangulation method of aluminum alloy wheel blank on-line deformation measurement device and its measurement method, the measurement device includes a cylinder 2 installed on the detection table 1, a stepping motor 3, a servo motor 7, a proximity switch 8 , laser fixture 9, laser 10, ball screw 11, pneumatic clamping mechanism 12, roller table 13, gear 14, guide rod 15 and pallet 16, such as figure 1 Shown, wherein, described cylinder 2, gear 14 and supporting plate 16 form cylinder lifting device. The cylinder 2 is arranged at the center of the bottom of the testing table 1, and the cylinder 2 is vertically connected to the supporting plate 16 upwards, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com