Patents

Literature

426results about How to "Improve punching efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

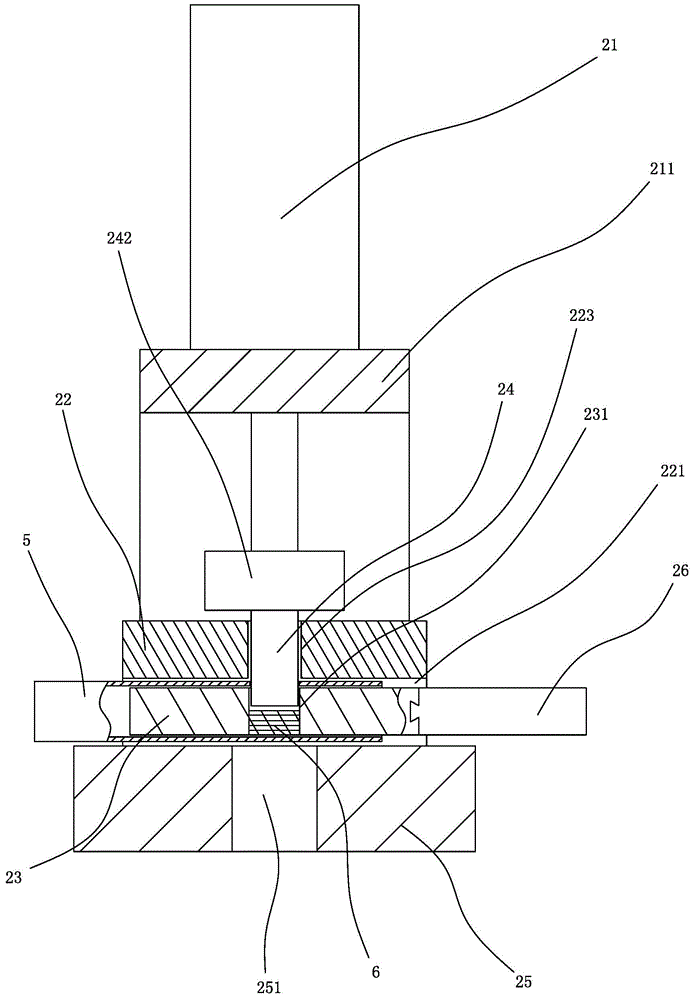

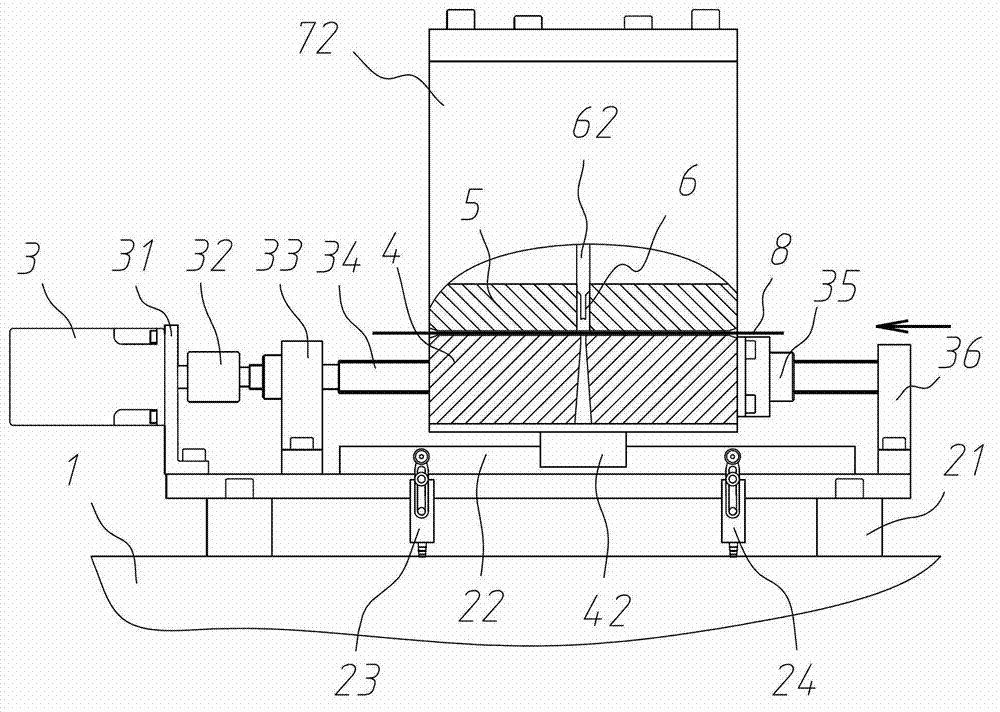

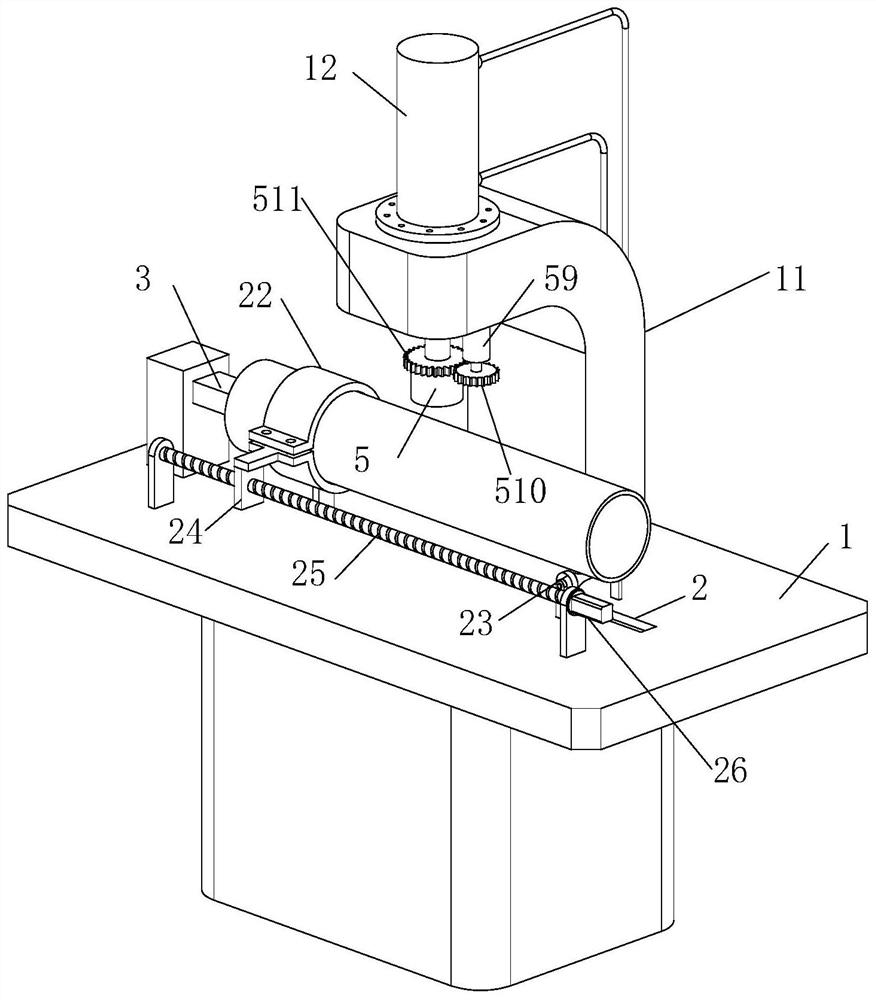

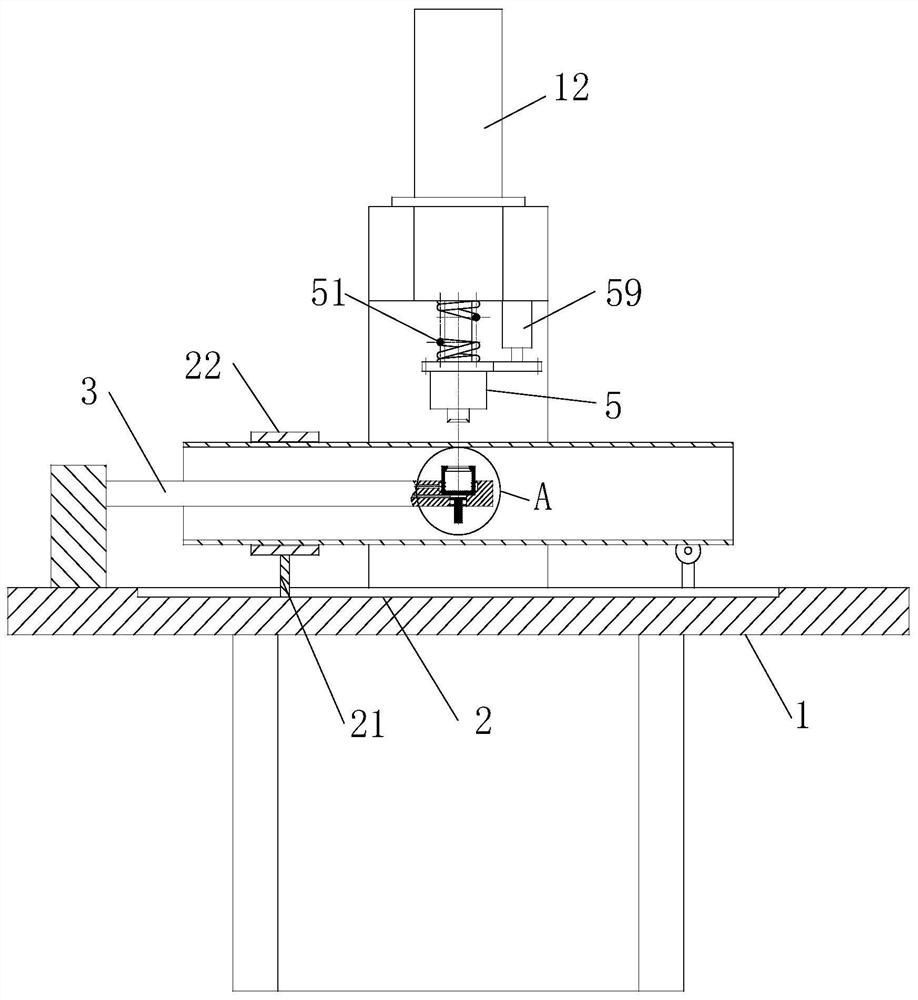

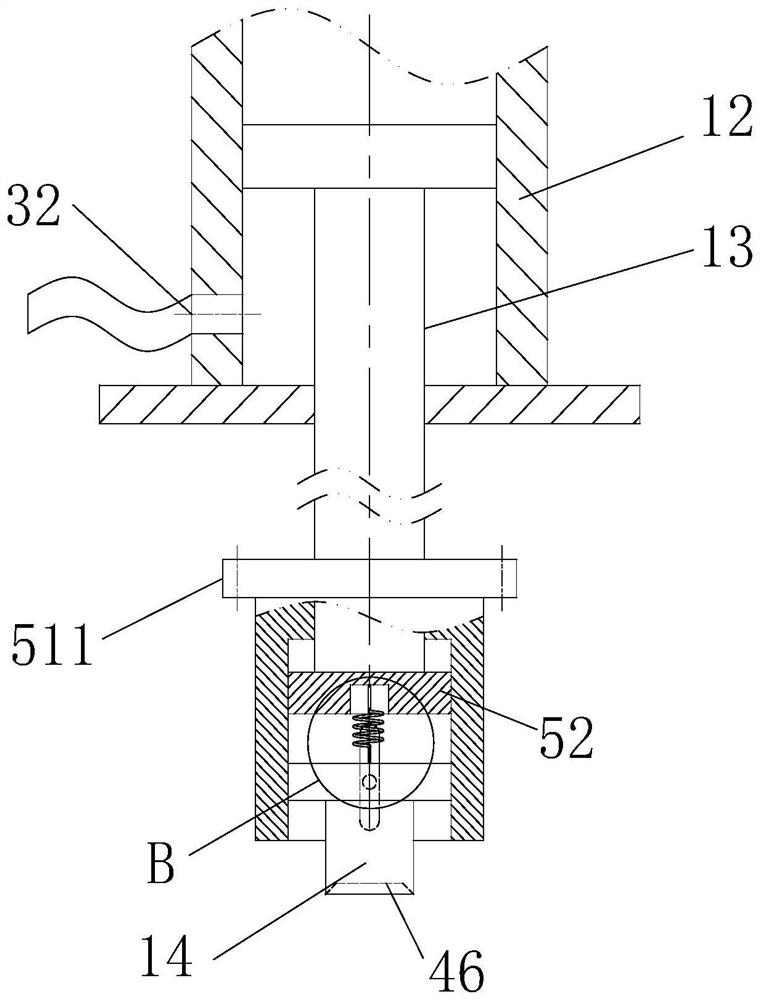

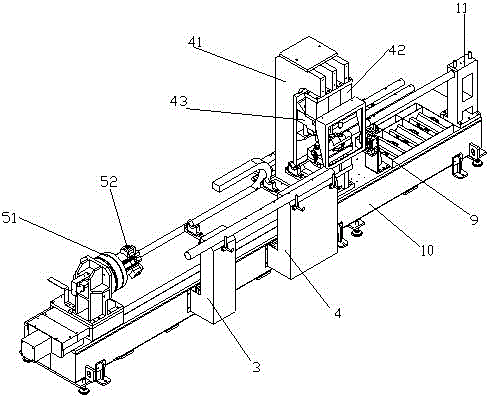

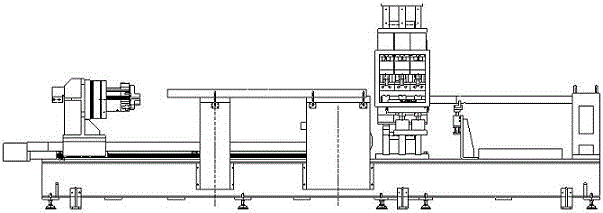

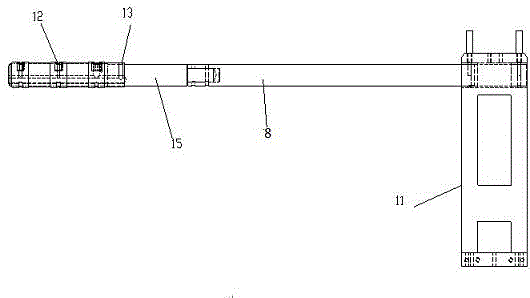

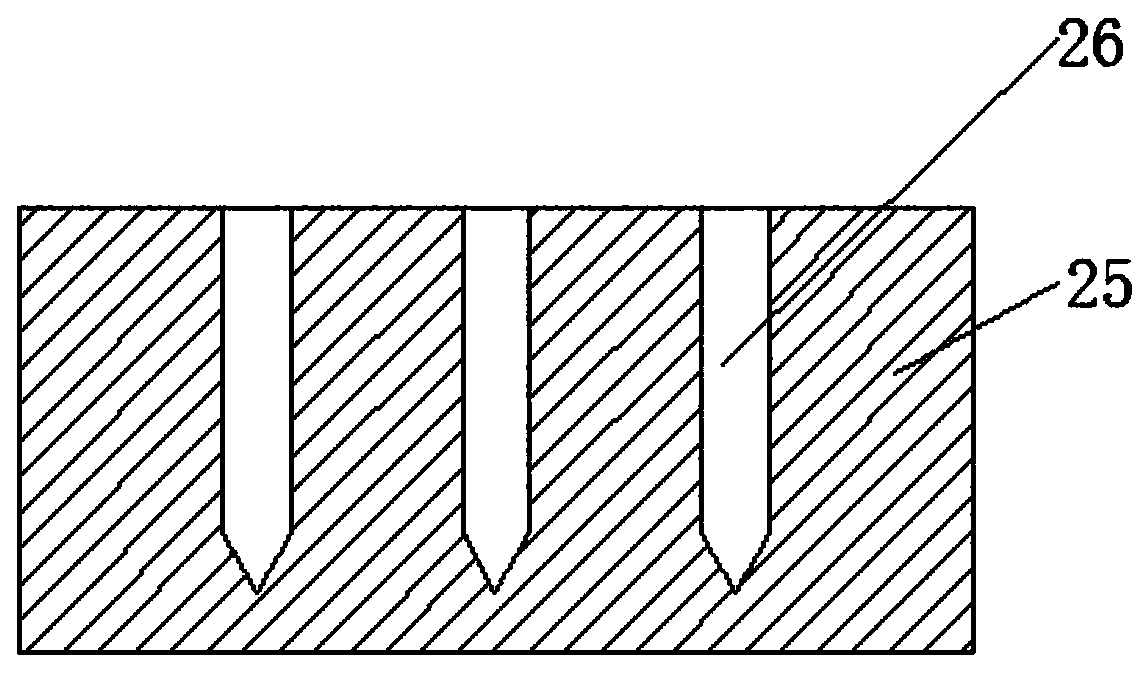

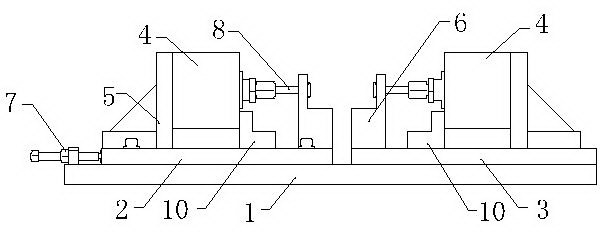

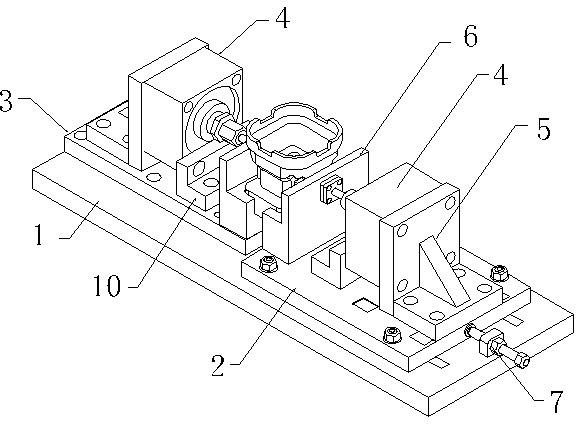

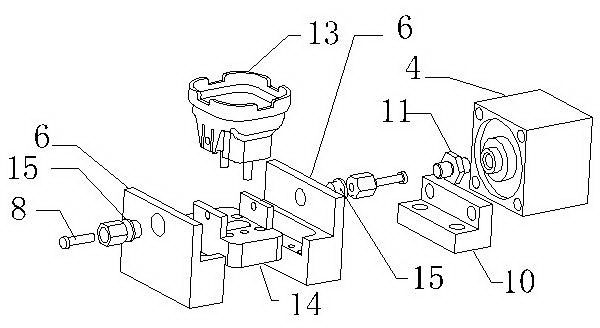

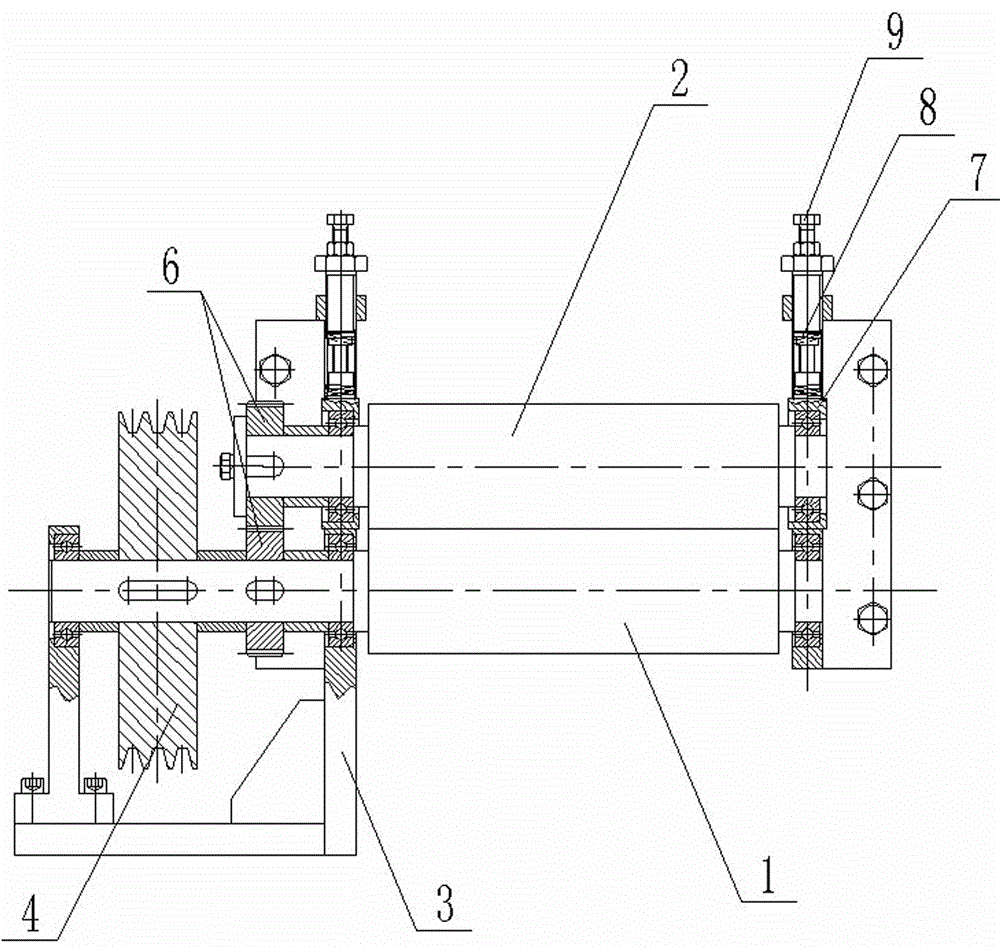

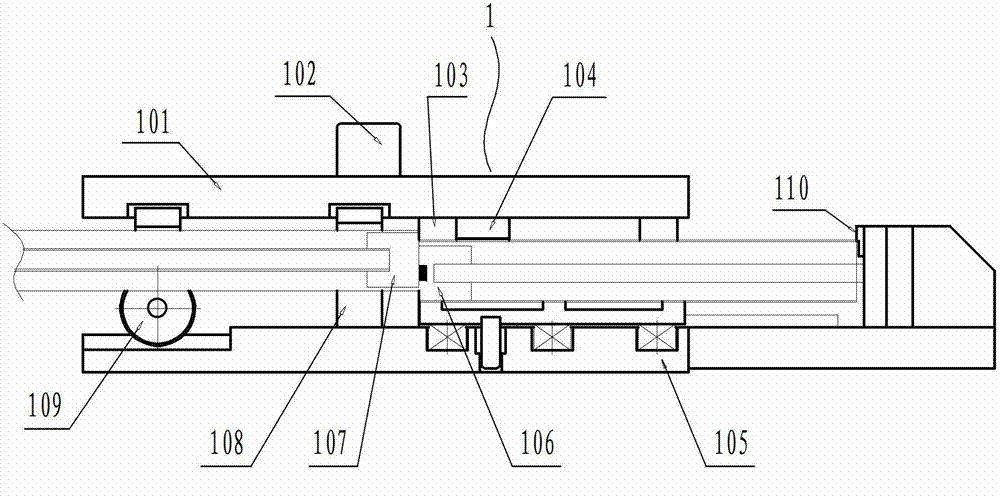

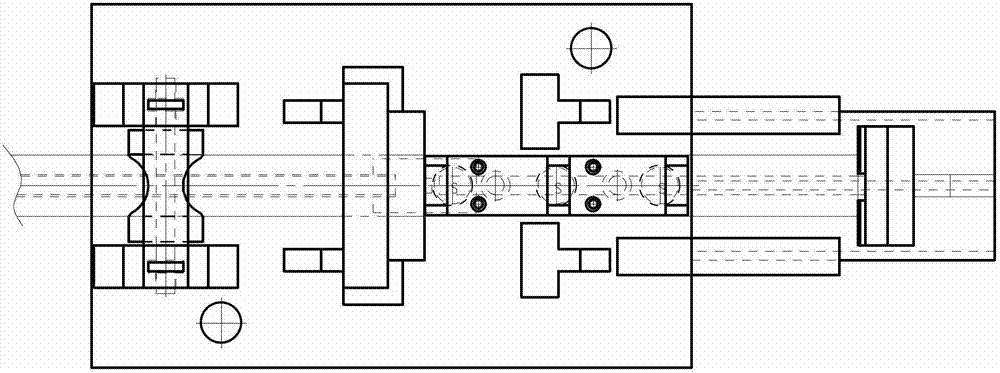

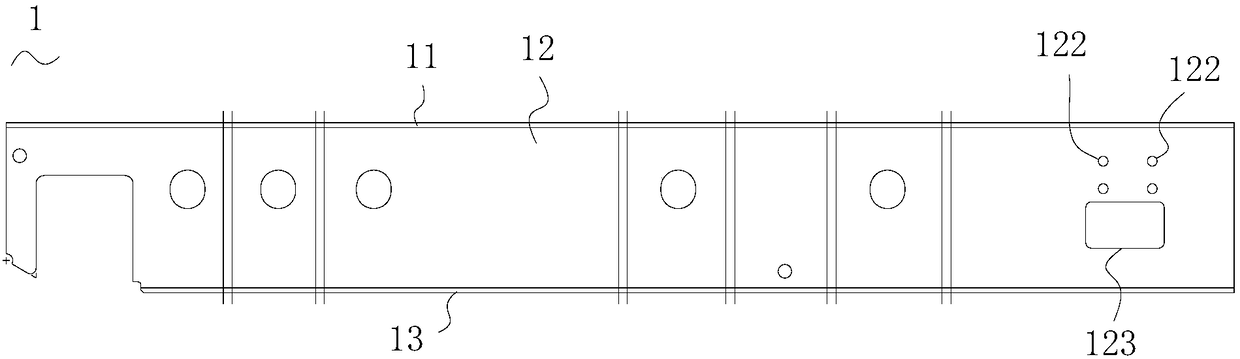

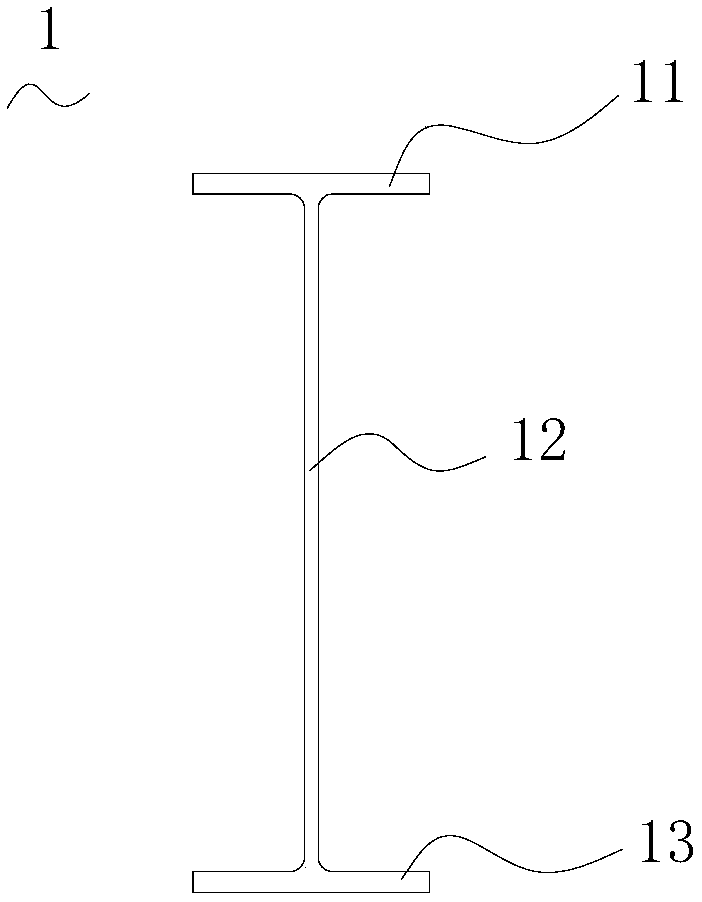

Continuous punching device for linear pipes

ActiveCN104128434ARealize continuous punchingImprove punching efficiencyPerforating toolsMetal-working feeding devicesPunchingLateral extension

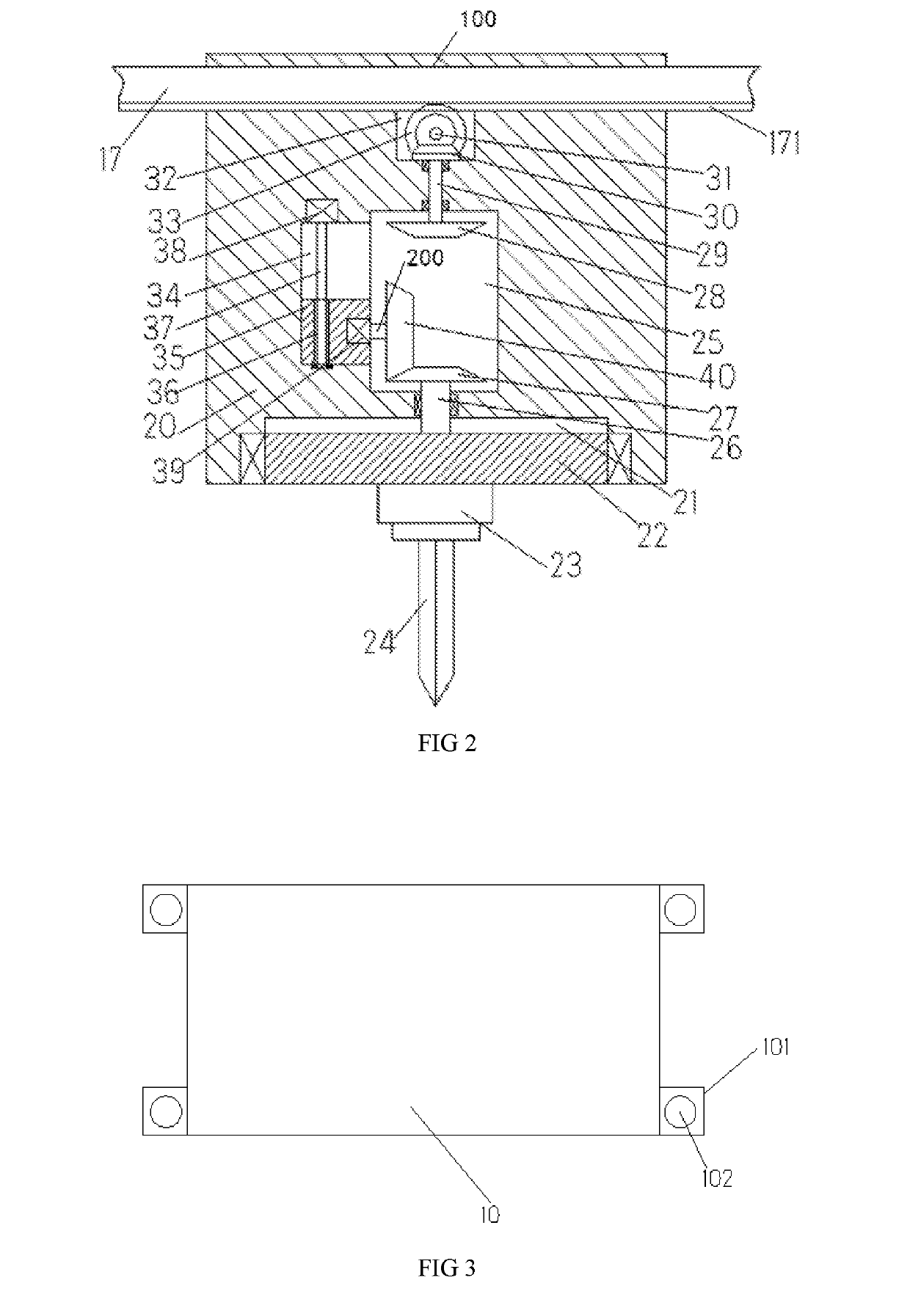

A continuous punching device for linear pipes comprises a base, punching mechanisms, a sliding base, a transverse moving mechanism, clamping mechanisms and a control device, wherein the punching mechanisms are arranged on the base; the sliding base is arranged on the base in a horizontal moving mode in the transverse direction; the transverse moving mechanism drives the sliding base to move in the transverse direction; each clamping mechanism is arranged on the sliding base and used for clamping one end of one linear pipe; the control device is respectively connected with the punching mechanisms and the transverse moving mechanism; each punching mechanism comprises a die holder, a core die and a stamping mechanism; the die holders are arranged on the base, a through hole extending in the transverse direction and allowing one linear pipe to stretch in is formed in the side face of each die holder, a first punched hole communicated with the corresponding through hole is formed in the top face of each die holder, and a discharge hole communicated with the corresponding through hole is formed in the bottom face of each die holder; each core die is arranged in the through hole of the corresponding die holder through a die rod which extends in the transverse direction, and a second punched hole opposite to the first punched hole is formed in each core die; each stamping mechanism comprises a punch which can move up and down relative to the corresponding first punched hole and the corresponding second punched hole and a driving part which can drive the punch to move up and down. The continuous punching device has the advantages of being simple in structure, convenient to operate, high in punching efficiency and the like.

Owner:冠达星股份有限公司

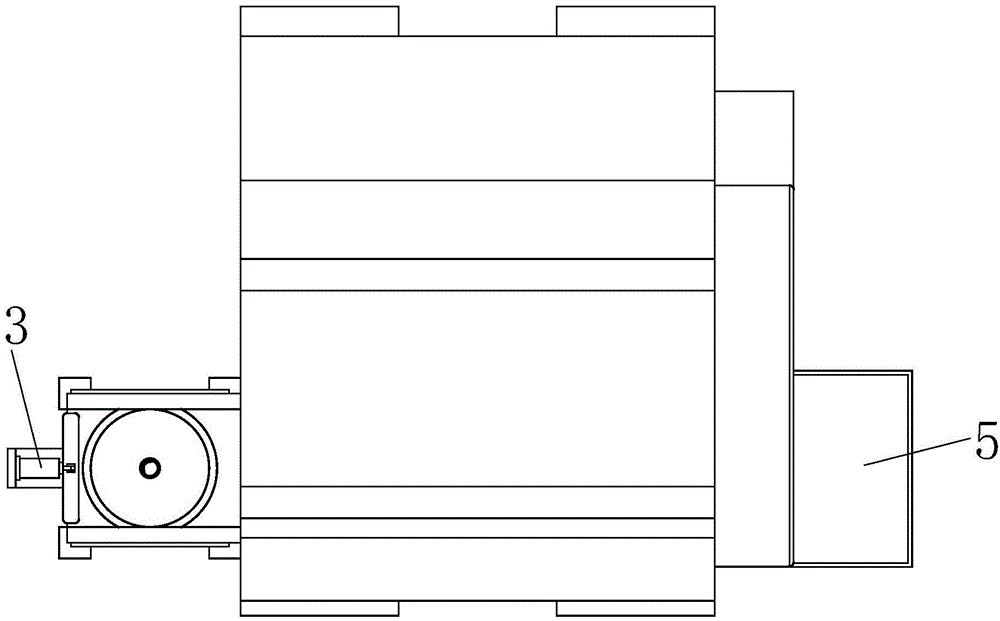

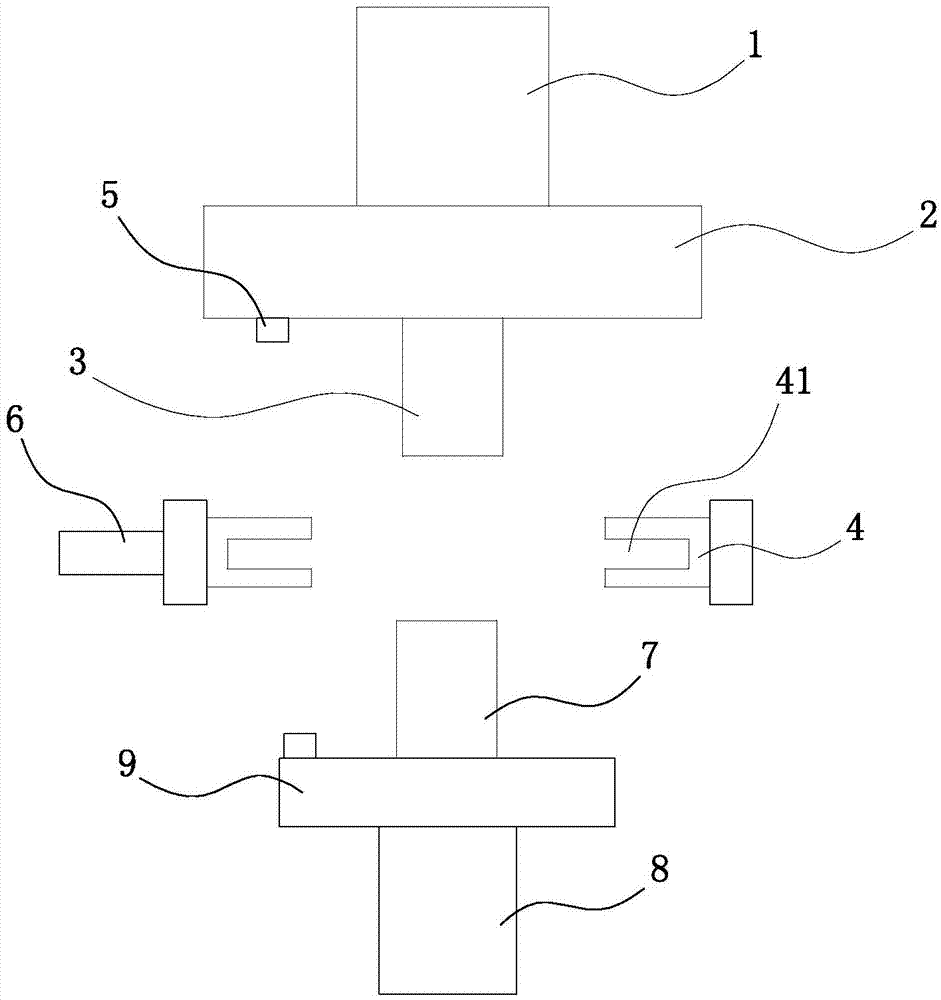

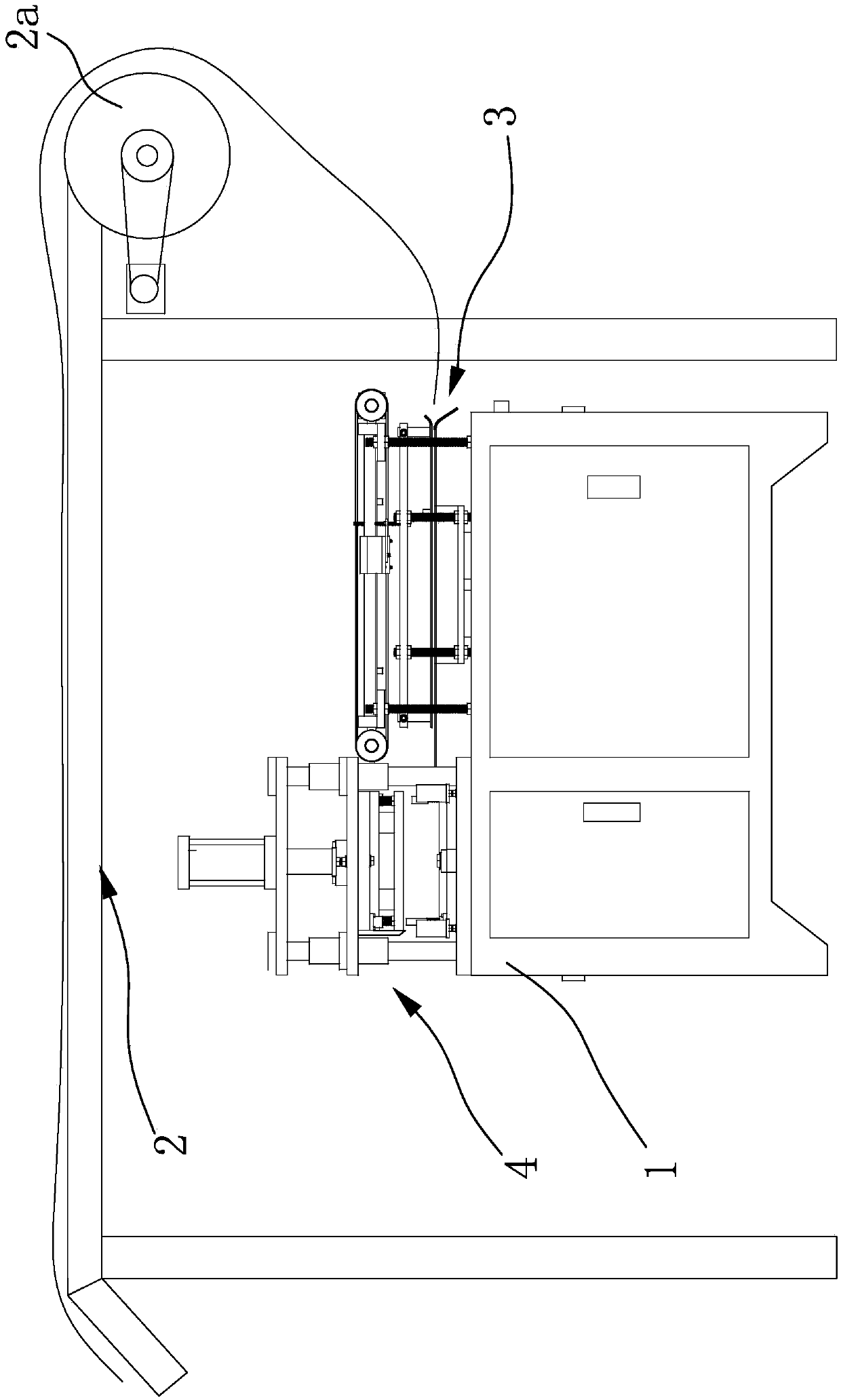

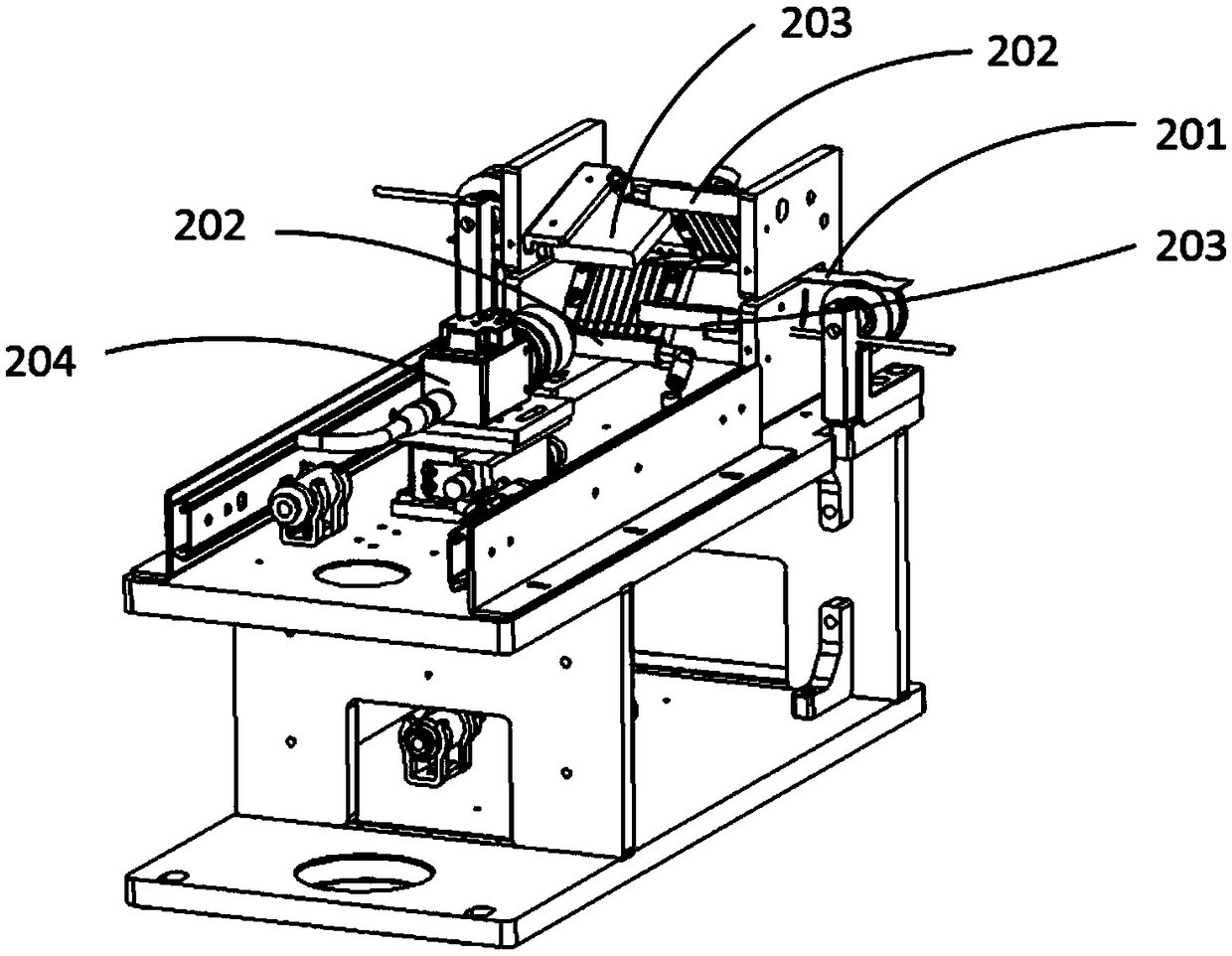

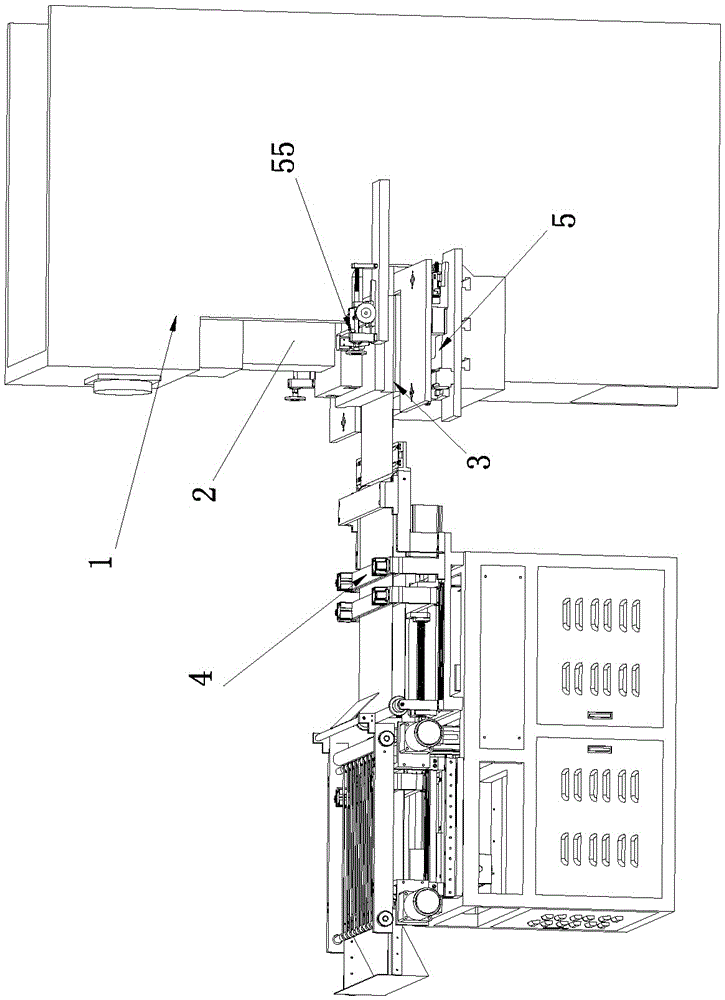

Automatic feeding device, automatic feeding-type punch press and automatic feeding method

InactiveCN103480762AReduce sizeShorten the lengthMetal-working feeding devicesPositioning devicesPunch pressControl system

The invention relates to an automatic feeding-type punch press which comprises automatic feeding devices. The automatic feeding devices are mounted on two sides of a die of the punch press in an alignment manner respectively. Each automatic feeding device comprises a support provided with a worktop on the top face; sliding seats are arranged on screw rod transmission mechanisms mounted on the worktops; feeding sliders are mounted on the sliding seats through guide sliding rails perpendicular to the screw rod transmission mechanisms; plate fixing devices are arranged above the feeding sliders; each feeding slider slides on the corresponding guide sliding rail through two feeding cylinders respectively arranged on two sides of the feeding slider; motors of the automatic feeding devices are controlled by a control system of an electrical control cabinet to drive the screw rod transmission mechanisms to enable the sliding seats to slide, and the feeding cylinders are utilized to control the feeding sliders to slide to complete automatic feeding of plates. The automatic feeding-type punch press is adopted to punch workpieces, the automatic feeding devices are simple in structure, small in occupied space and applicable to processing of various plates, and the die of the punch press is convenient to maintain and easy for workers to operate.

Owner:HANGZHOU KINGNET ELECTROMECHANICAL

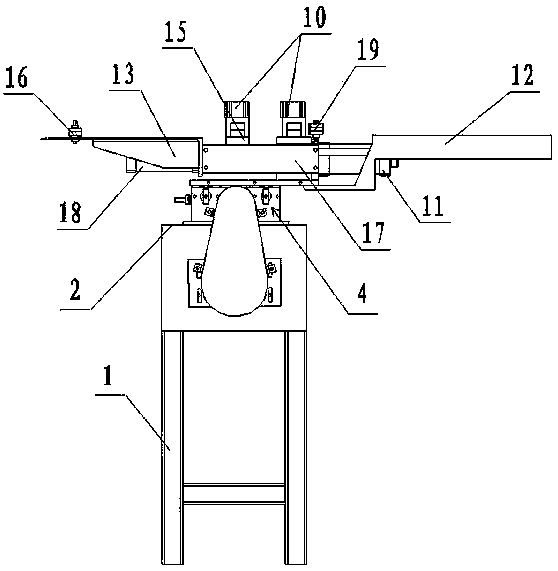

Plastic profile line-following punching machine

InactiveCN103112043AEasy to moveMove preciselyMetal working apparatusPunchingProgrammable logic controller

The invention relates to a plastic profile line-following punching machine. The plastic line-following punching machine comprises a punching die, a base, a line guide rail which is arranged at the upper end of the base and a sliding block which is fixed at the bottom of the die and is matched with the line guide rail, a die driving device, a travel switch, a speed sensor and a programmable logic controller (PLC) system, wherein the die driving device comprises a servo motor, a screw and a coupler, the travel switch is fixed on the base and controls a moving starting point position and a final position of the die, the speed sensor measures a moving distance of a profile online, and the PLC system controls the servo motor to rotate and reverse, controls the rotating speed of the servo motor and drives an air cylinder to act according to the profile moving speed. The plastic profile line-following punching machine can automatically adjust the punching frequency, moving speed and the like of the punching die, and the plastic profile line-following punching machine has the advantages that the precision of the interval between punching holes or grooves is high, punching efficiency is high, punching stability is good, the waste produced is little and the like.

Owner:TONGLING GREAT EXTRUSION TECH

Automatic punching equipment for seamless steel tube

InactiveCN112222287AReduce distortionImprove punching efficiencyPerforating toolsMetal-working feeding devicesPunchingBall screw

The invention belongs to the technical field of automatic equipment, and particularly relates to automatic punching equipment for a seamless steel tube. The automatic punching equipment comprises a machine frame; an oil cylinder is fixedly connected to the top of the machine frame through a vertical rod; a punch is fixedly connected to the bottom of a piston rod of the oil cylinder; a sliding groove is formed in the position, corresponding to the oil cylinder, of the top of the machine frame; a fixing ring is fixedly connected to the top of a sliding block which is connected in the sliding groove in a sliding mode; a support plate is fixedly connected to one side of the fixing ring; a lead screw is connected to the position, corresponding to the support plate, of the machine frame in a rotating mode and is driven by a servo motor to rotate; the lead screw is connected to the support plate through a ball screw nut pair; a supporting rod is fixedly connected to the position, on one sideof the sliding groove, of the machine frame through a support; and a supporting column is arranged at the position, corresponding to the punch, of the supporting rod. According to the automatic punching equipment, the supporting column is inserted into the steel tube to support the punching position of the steel tube, and then deformation of the steel tube in the punching process is reduced.

Owner:温州莜例贸易有限公司

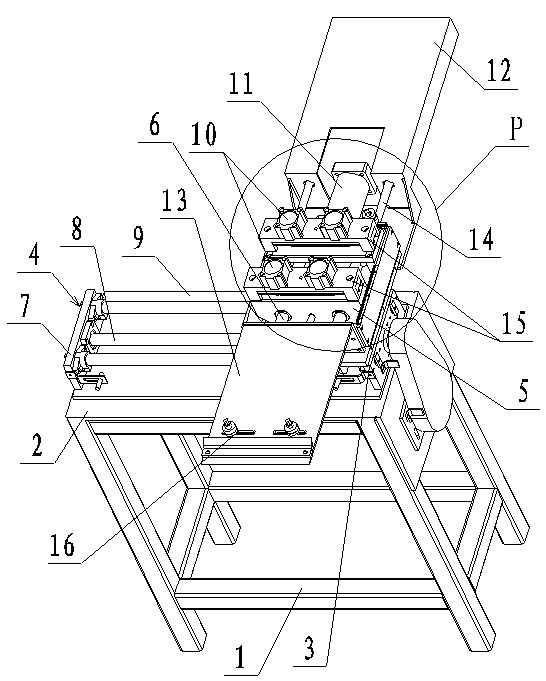

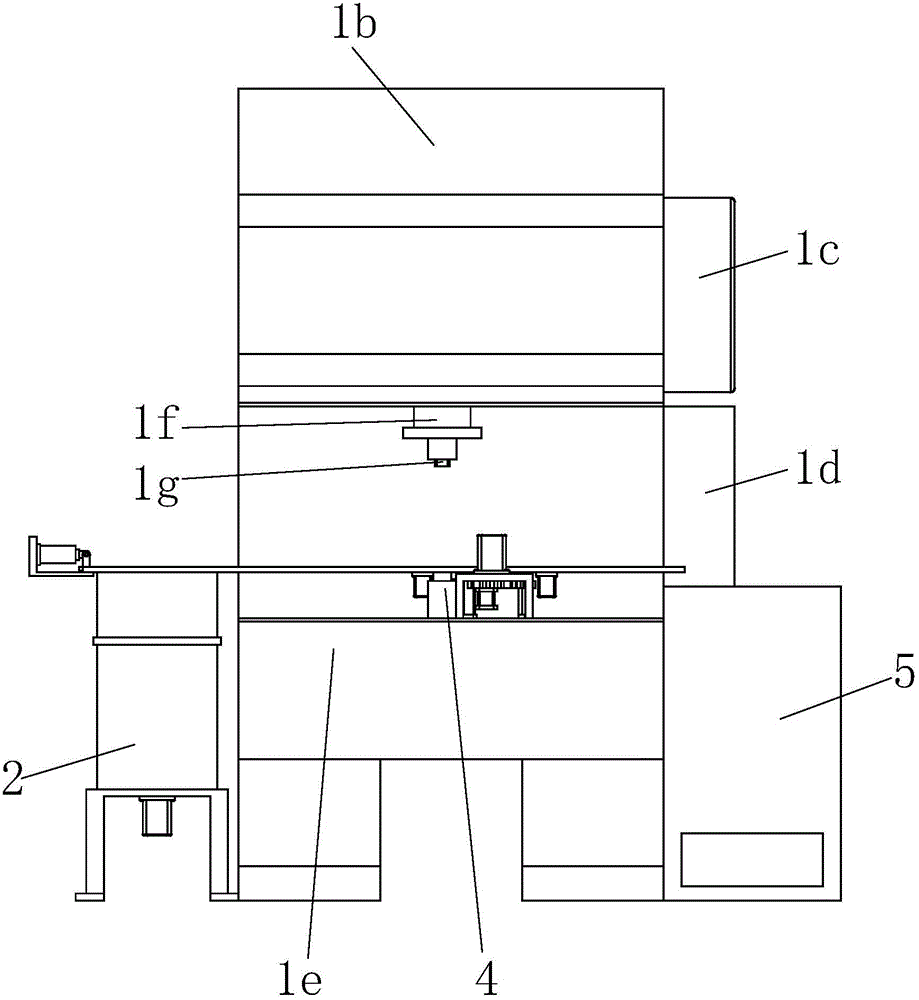

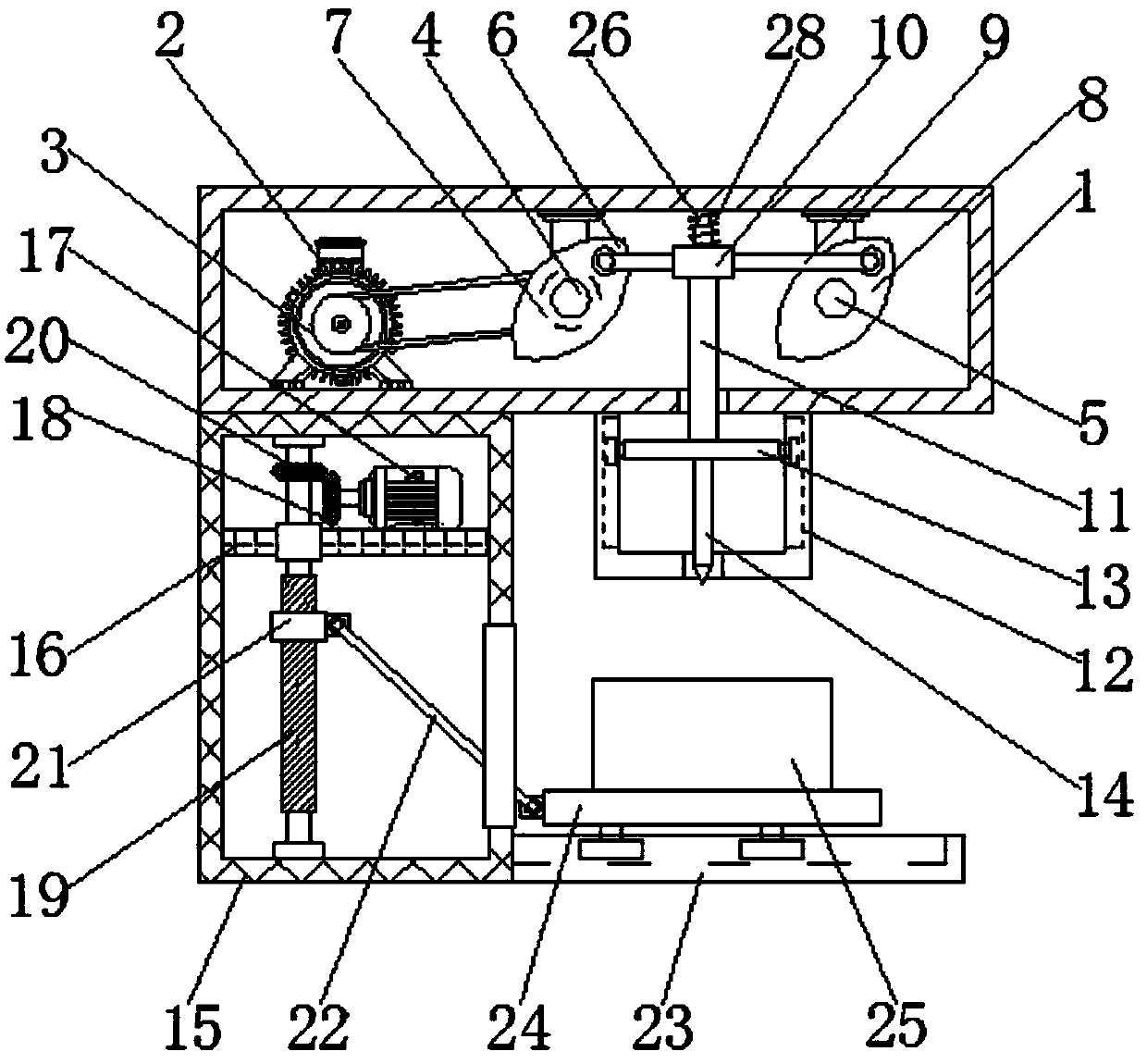

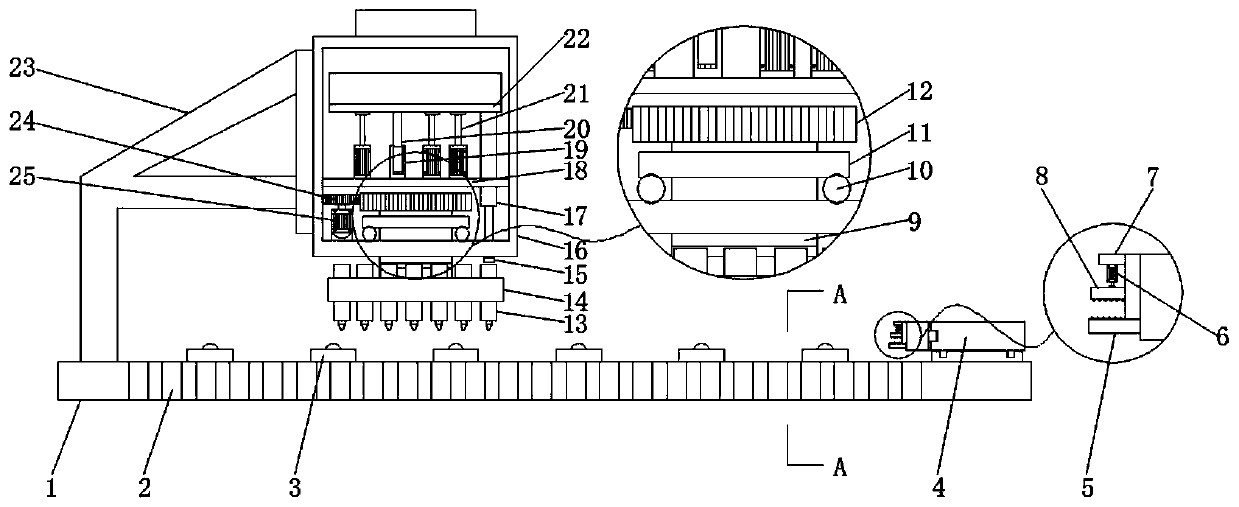

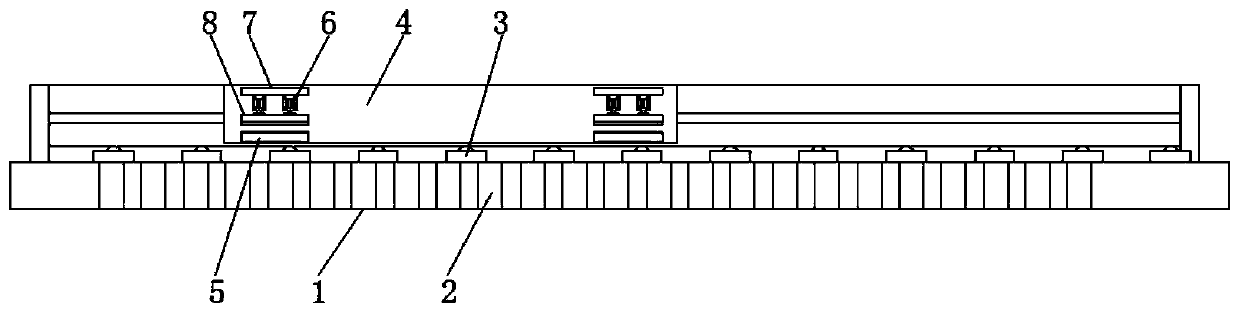

Automatic punching machine tool for disk slices

ActiveCN104624772AImprove punching efficiencyImprove production efficiencyMetal-working feeding devicesPositioning devicesPunchingMachine tool

The invention relates to an automatic punching machine tool for disk slices. The automatic punching machine tool comprises a machine tool body, an automatic feeding device, a single-piece machining and conveying device, a rotary stamping device and a collection bin. The machine tool body comprises a machine base, a main driving box, a transmission device, a main control box, a workbench, a lifting shaft and a main cutter. The automatic feeding device is arranged on the left side of the workbench. The rotary stamping device is mounted in the middle of the upper end of the workbench. The single-piece machining and conveying device is located between the upper end of the automatic feeding device and the upper end of the rotary stamping device and connected with the automatic feeding device and the rotary stamping device. The collection bin is located on the right side of the workbench and below the right end of the single-piece machining and conveying device. The automatic punching machine tool has the advantages of being reasonable in structural design, high in automation degree and the like, can improve the punching efficiency of the disk slices, saves manpower, guarantees the machining accuracy, shortens time consumed in the process and increases the production benefits of a factory.

Owner:泰州市瑞驰动力机械有限公司

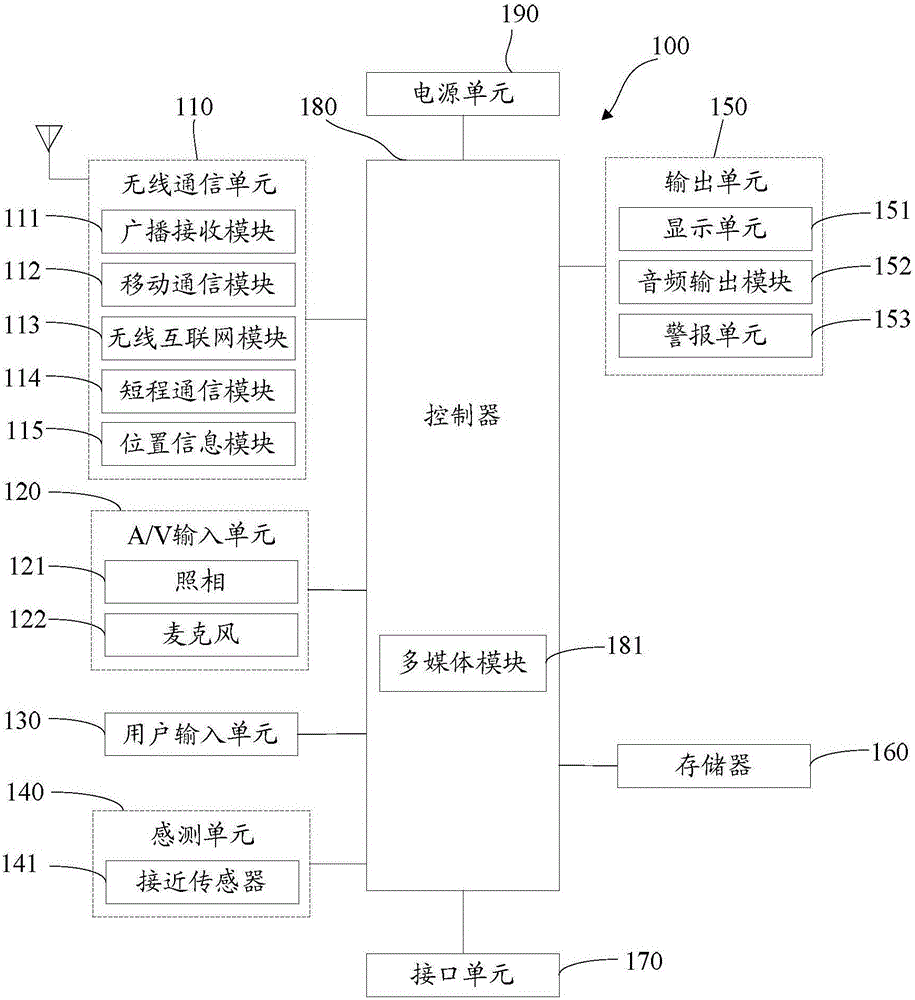

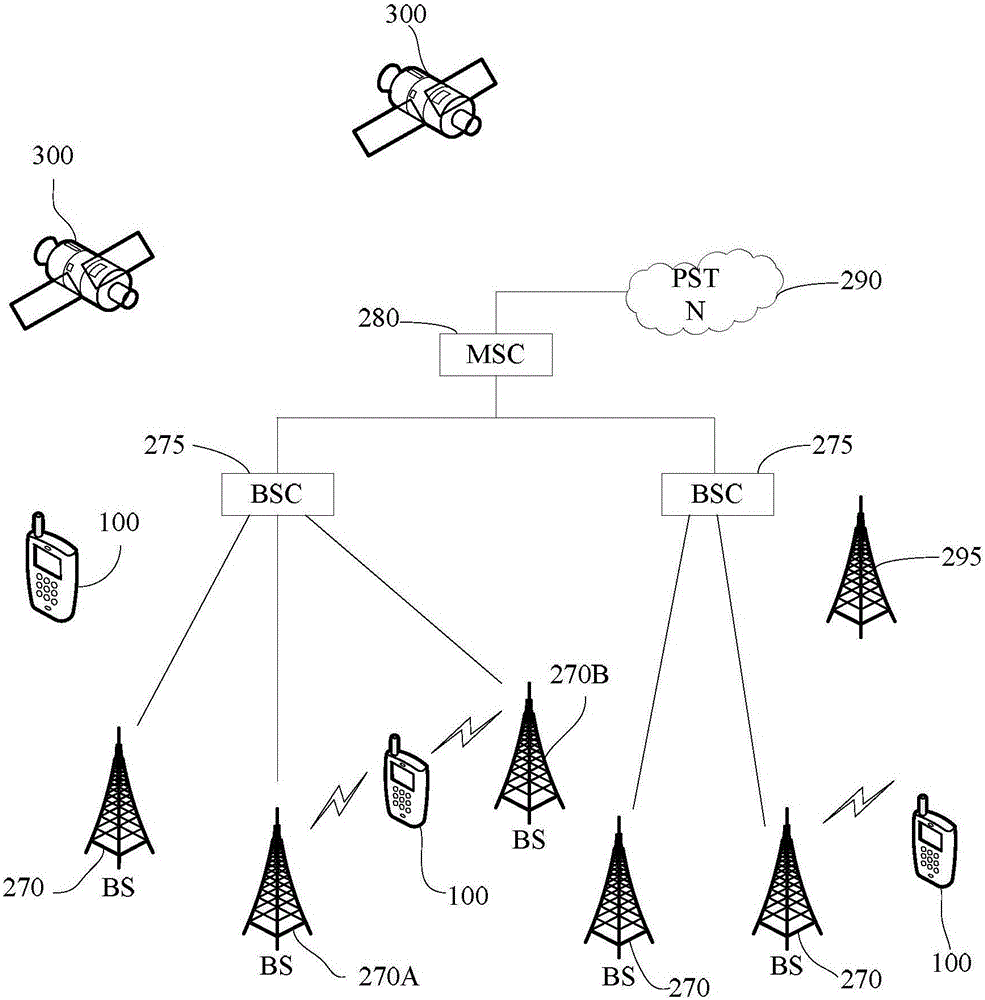

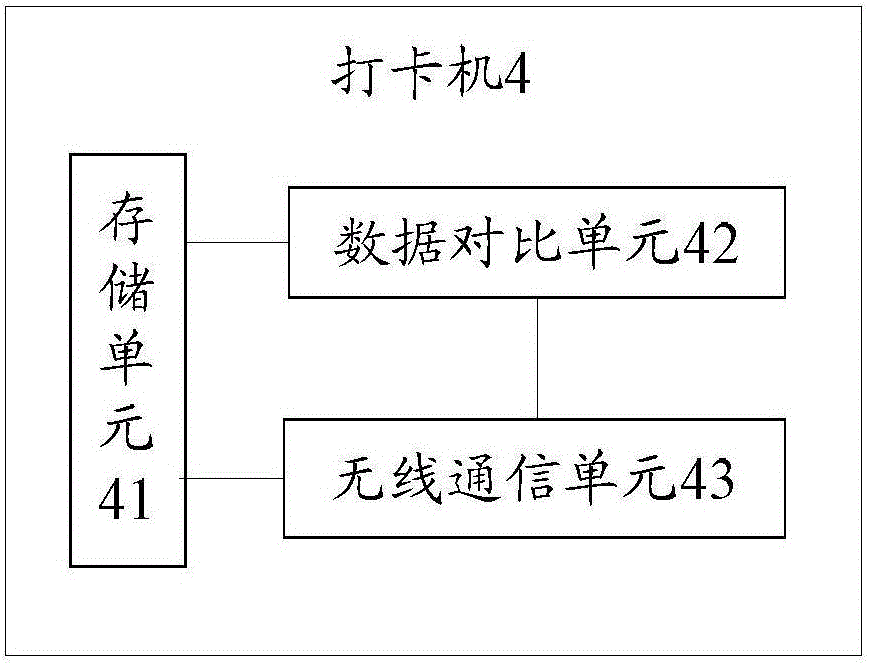

Card punching machine and card punching method

InactiveCN105096400AInhibition of agglomerationImprove punching efficiencyRegistering/indicating time of eventsCommunication unitPunching

The embodiment of the invention discloses a card punching machine. The machine comprises a storage unit, a data comparison unit and a wireless communication unit; the wireless communication unit is used to receive a wireless communication connection request sent by a mobile terminal in a preset scope, is wirelessly connected with the mobile terminal, and also is used to receive first fingerprint information sent by the mobile terminal; the data comparison unit is used to match the first fingerprint information with fingerprint information pre-stored in the storage unit, determine that a first user corresponding to the first fingerprint information successfully punch a card if matching is successful, and record the card punching information of the first user; and the storage unit is used to pre-store the fingerprint information of users and record the card punching information of the users. The embodiment of the invention also discloses a card punching method.

Owner:NUBIA TECHNOLOGY CO LTD

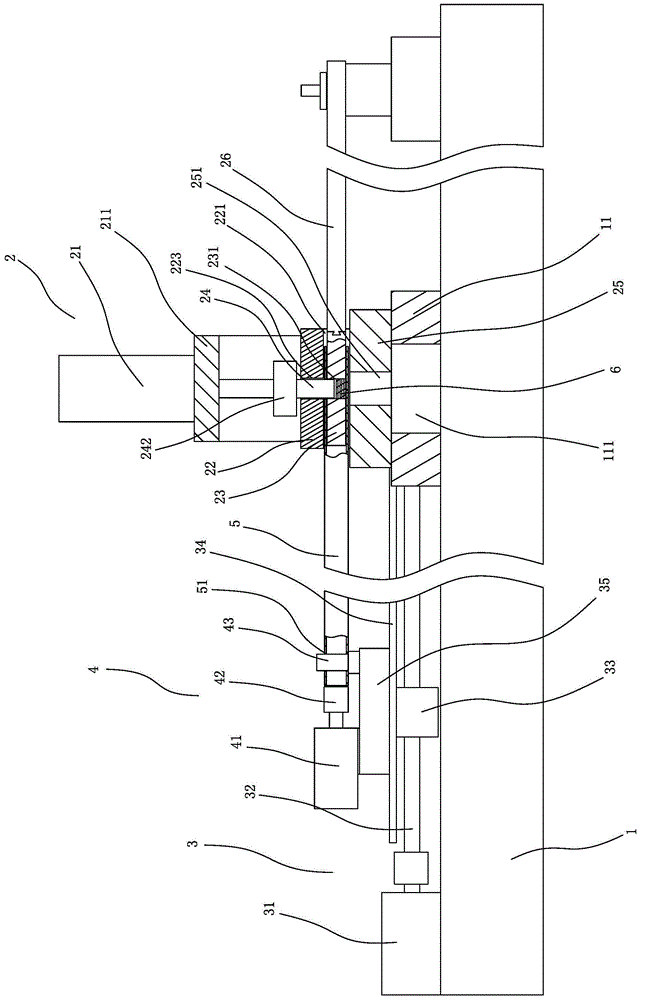

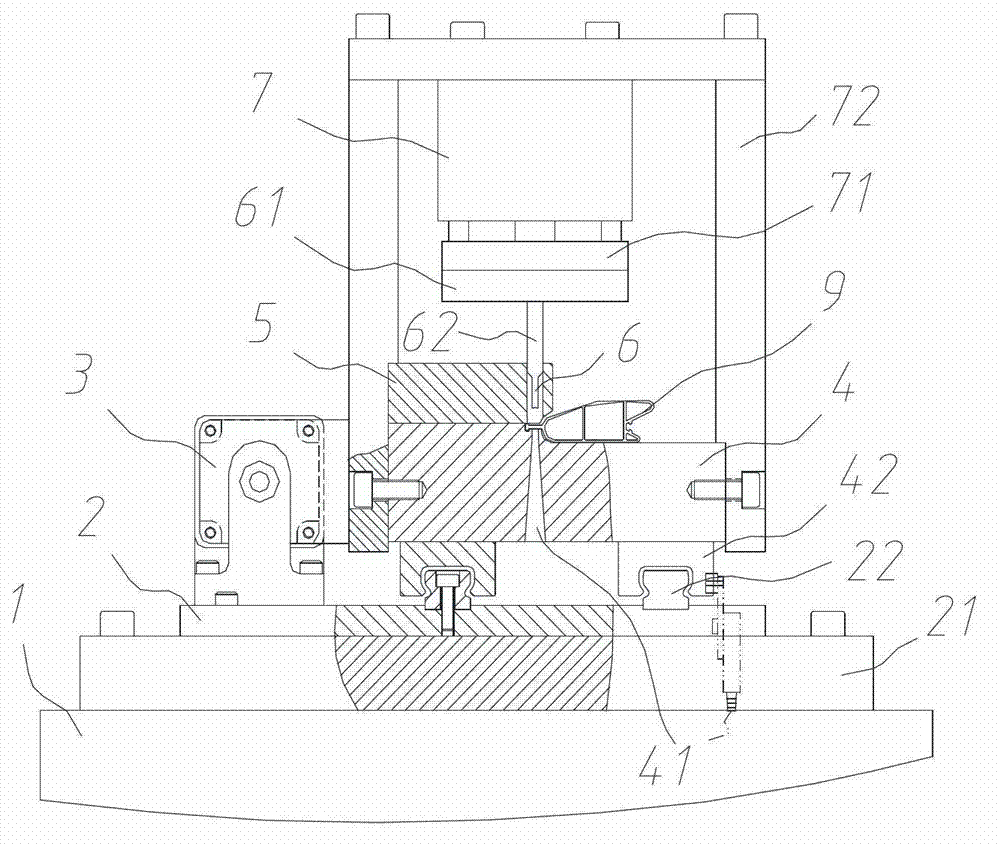

Pipe punching machine

ActiveCN104624779ADischarge in timeImprove punching efficiencyMetal-working feeding devicesStripping-off devicesPunchingUltimate tensile strength

The invention relates to a pipe punching machine. The pipe punching machine comprises a base and an installing base installed on the base, the installing base is provided with a punching device, and the base is provided with a workpiece clamping device and a workpiece lifting device which act in cooperation with the punching device. According to the pipe punching machine, automatic punching without manual intervening can be achieved, the problem that waste is difficult to discharge during punching is solved, the pipe punching precision is improved, the labor intensity of workers is relieved, the production efficiency is high, and the yield is high.

Owner:FOSHAN GOOGOL AUTOMATION TECH

Punching device for electrical equipment manufacturing

InactiveCN107584005AImprove processing efficiencyReduce processing timeMetal working apparatusPunchingElectric machinery

The invention discloses a punching device for electrical equipment manufacturing, and relates to the technical field of electrical equipment. The punching device comprises a top box, a first motor isfixedly connected to the left side of the inner wall of the top box, the surface of a first motor output shaft is sleeved with a first belt pulley, a first rotary shaft and a second rotary shaft are fixedly connected to the top of the inner wall of the top box from left to right in sequence through link rods, a first cam and a second belt pulley are rotatably connected to the surface of the firstrotary shaft from front to back in sequence, the surface of the second belt pulley is in drive connection with the first belt pulley through a belt, the second cam is rotatably connected to the surface of the second rotary shaft, and a connecting rod is rotatably connected to the front of the second cam through the link rod. The punching device for electrical equipment manufacturing achieves the purpose of punching an electrical equipment shell, also drastically simplifies the steps of punching, improves the punching efficiency, therefore improves the overall efficiency of electrical equipmentmachining and saves the machining time of the electrical equipment.

Owner:合肥慕智信息技术有限公司

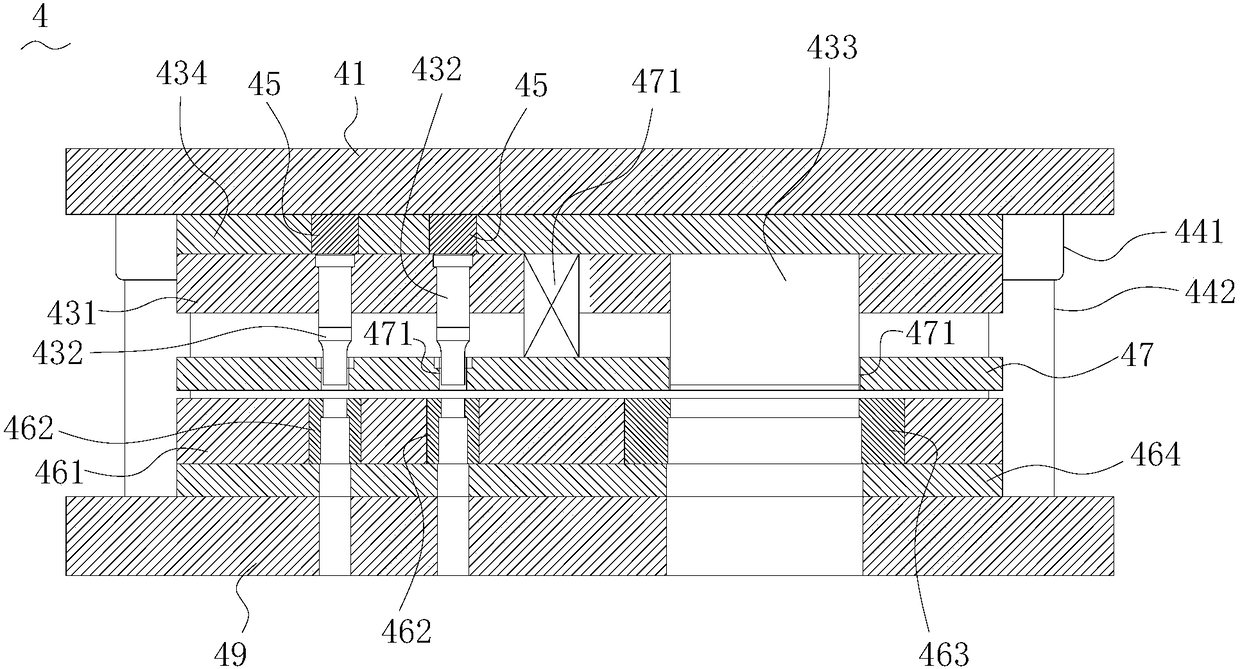

Metal plate two-sided punching device

The invention relates to a metal plate two-sided punching device which comprises an upper punching drive device, an upper die plate and an upper punching head. The metal plate two-sided punching device further comprises a lower punching drive device located below the upper punching head, a lower die plate and a lower punching head. A clamping device is arranged between the upper punching head and the lower punching head. The clamping device comprises clamping blocks symmetrically arranged. The inner side of each clamping block is provided with a clamping groove. The outer side of one clamping block is fixedly connected with an air cylinder. The lower surface of the upper die plate and the upper surface of the lower die plate are respectively provided with one proximity switch. According to the metal plate two-sided punching device, hole machining is achieved by punching the two sides at the same time, thicker plates can be punched, the punching resistance is small and the punching efficiency is high; burrs on the hole edges are avoided in the two-sided punching process, a machined work-piece does not deform, and the quality is high; automatic control is achieved by adopting a controller, the motion is accurate, and the labor intensity is low.

Owner:SUZHOU CHENXITE SHEET METAL PROD

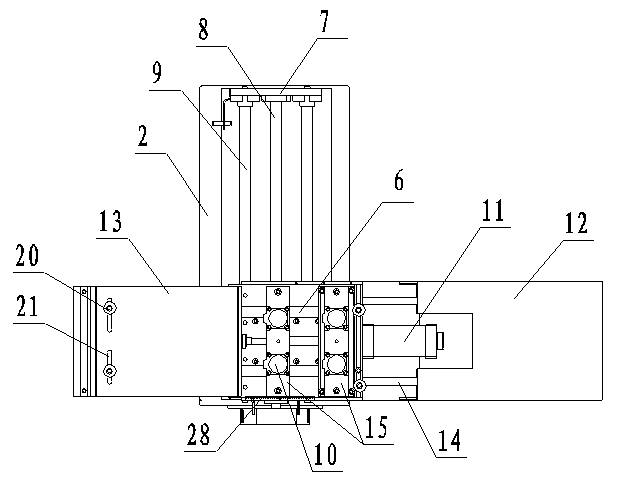

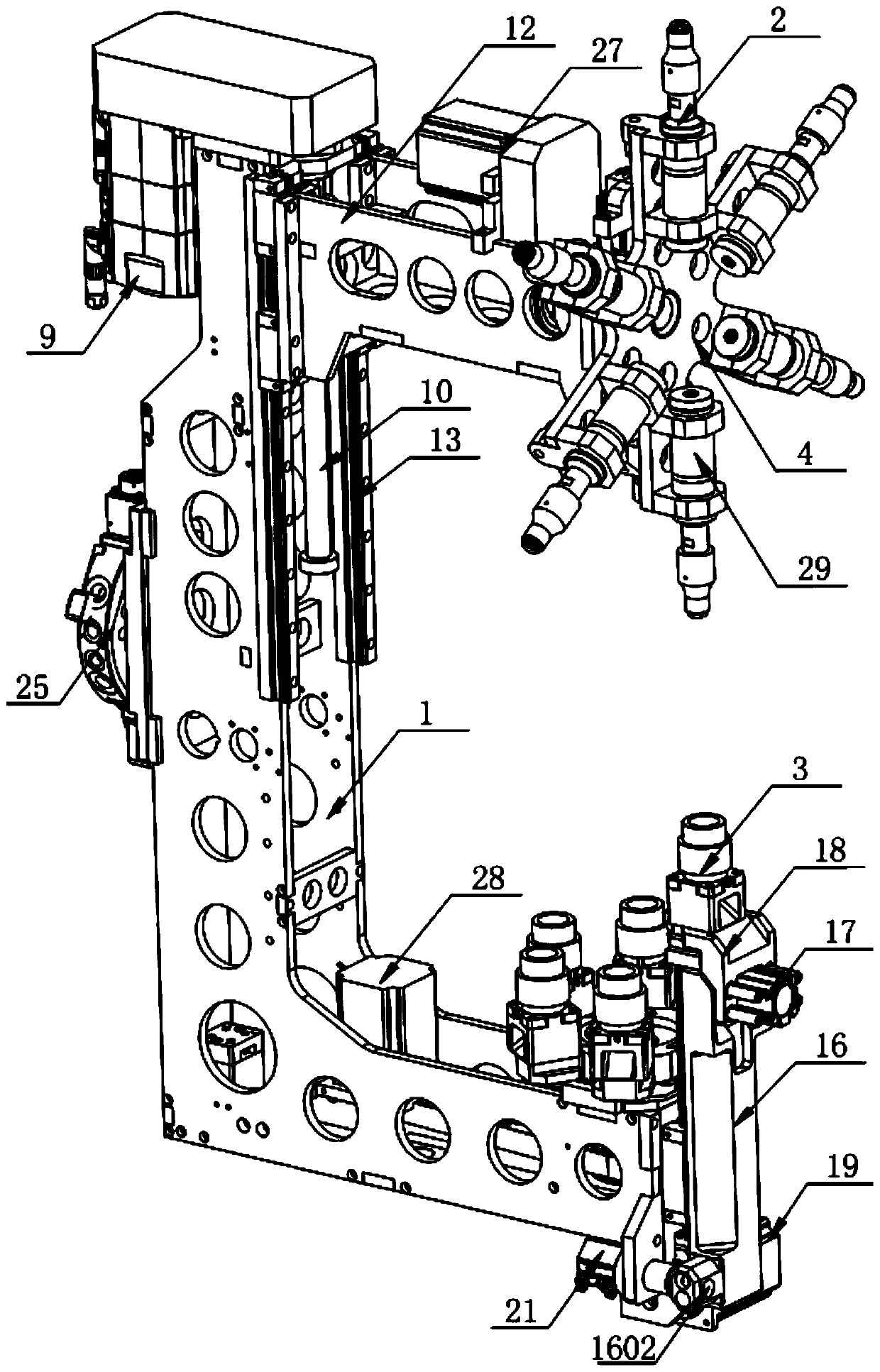

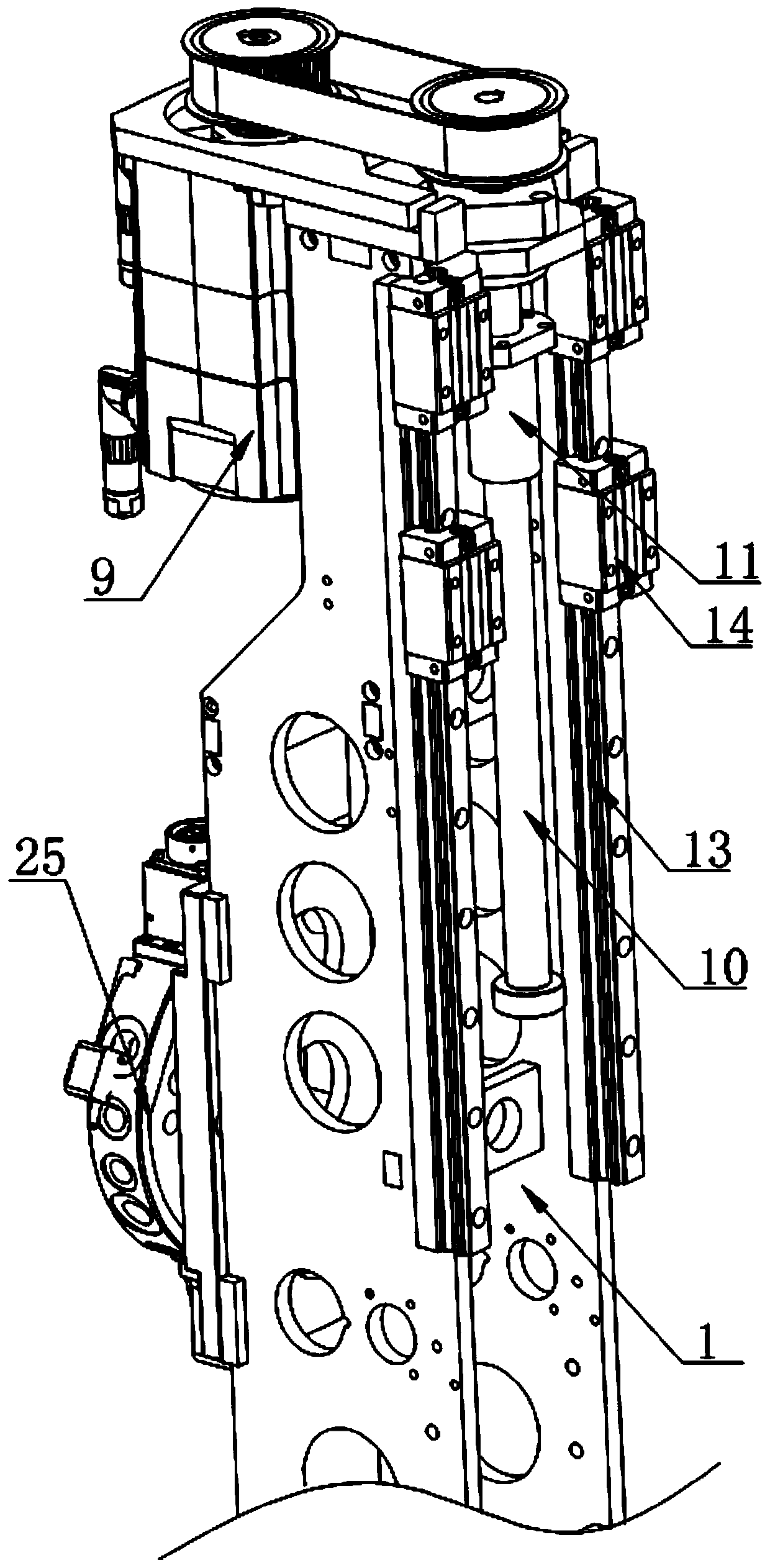

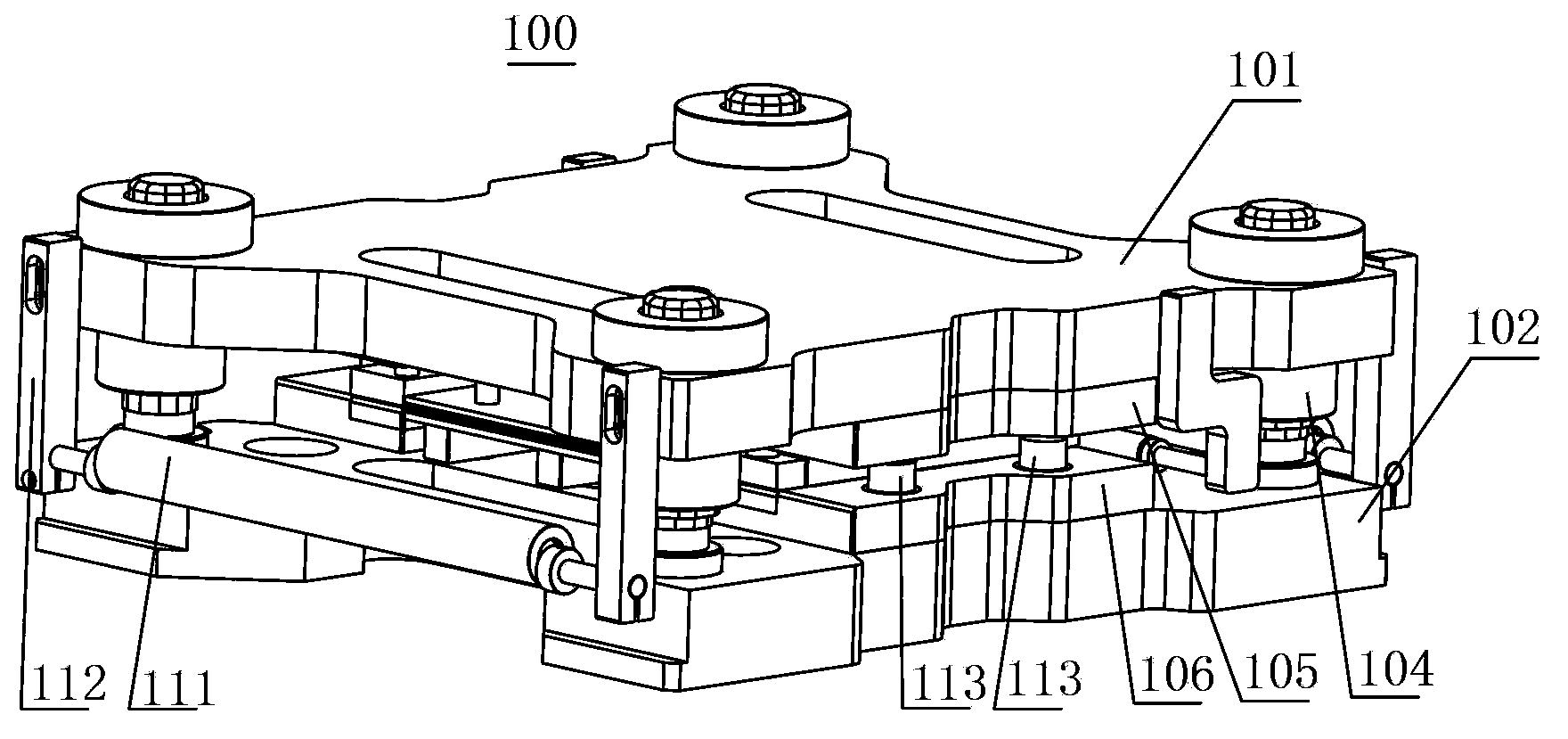

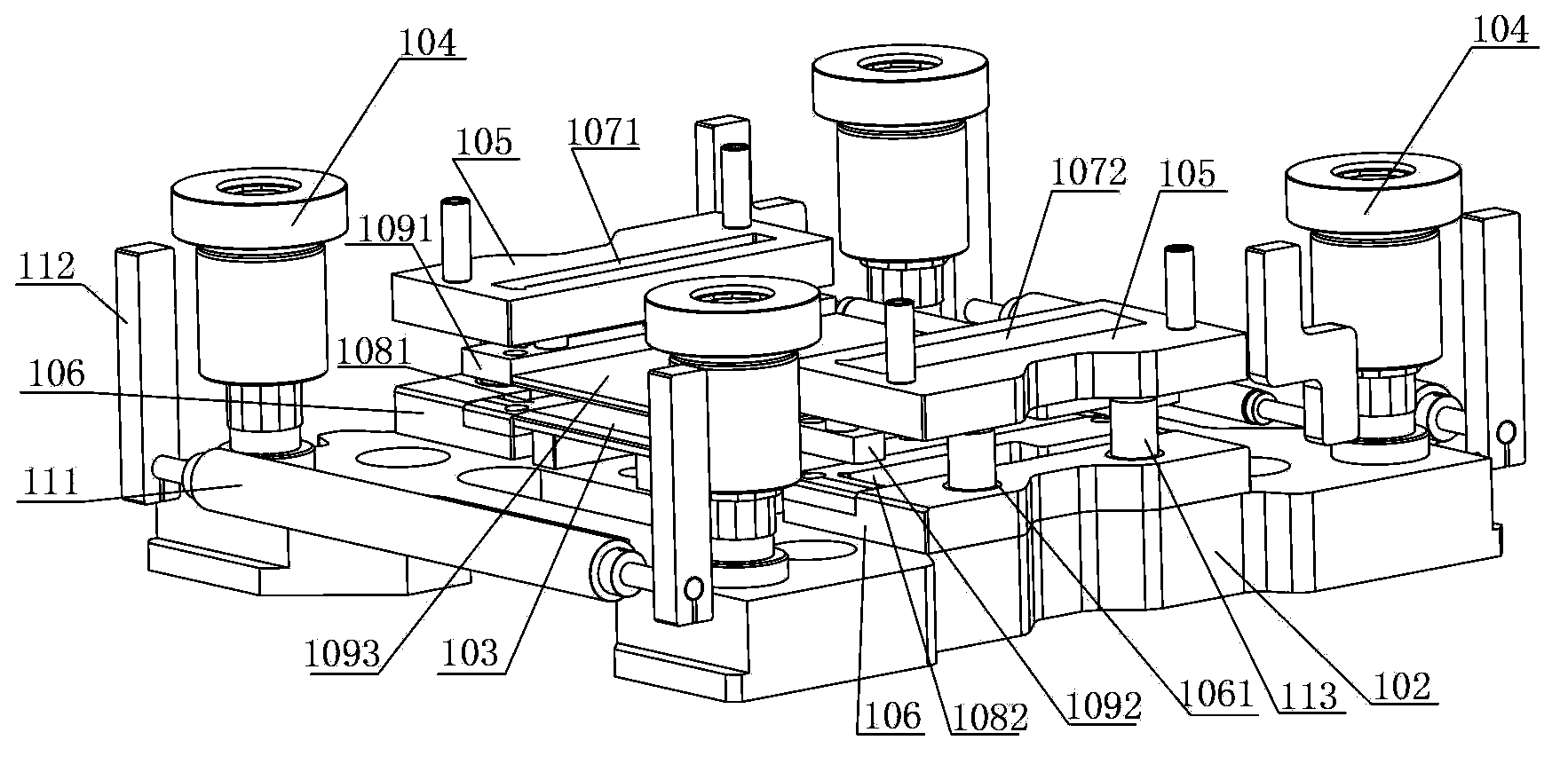

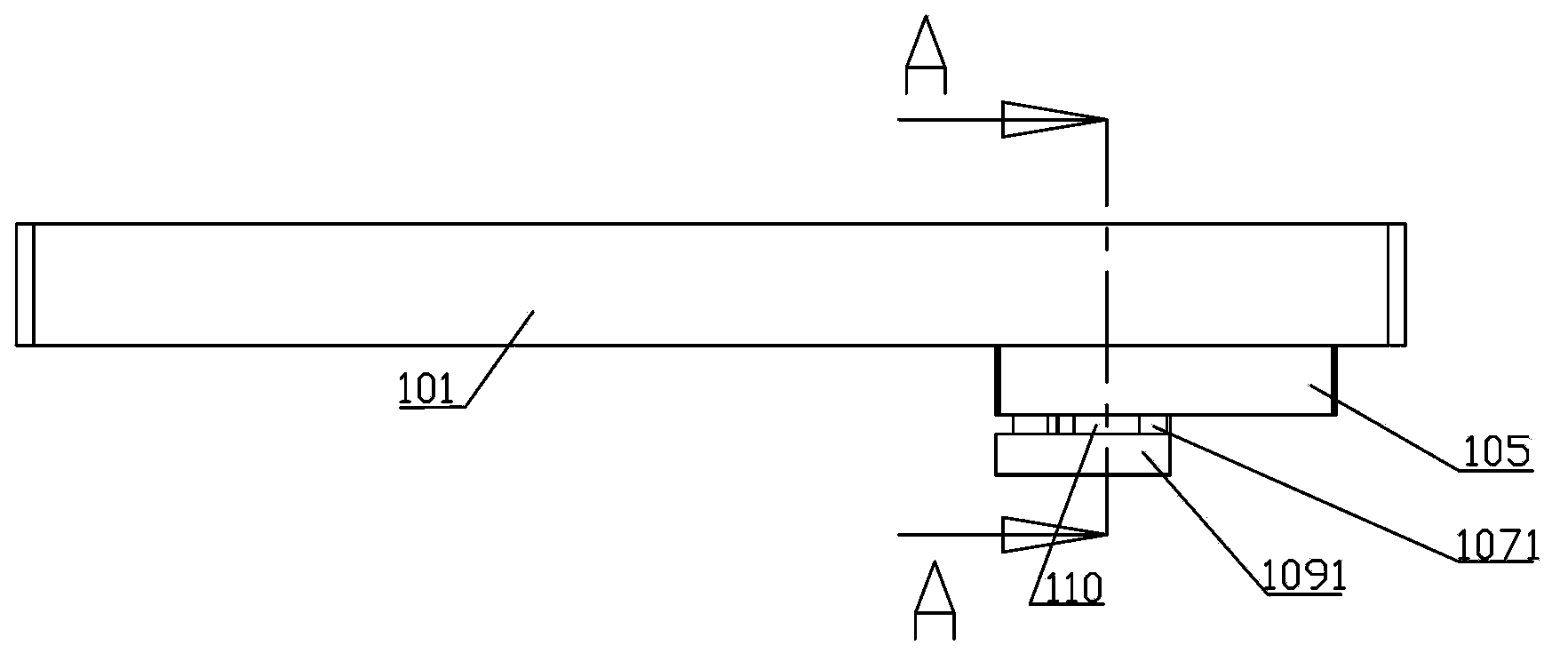

Six-head automatic switching punching module

ActiveCN110918762AMovement is stable and fastReduces problems with docking replacementsPerforating toolsVehicle componentsPunchingRobot hand

The invention provides a six-head automatic switching punching module. The punching module comprises a support body, an upper punching cutter mechanism and a lower punching cutter mechanism, wherein alifting driving mechanism is arranged on the upper part of the support body, the upper punching cutter mechanism is slidably arranged on the lifting driving mechanism, and the lower punching cutter mechanism is arranged on the lower part of the support body and opposite to the upper punching cutter mechanism in position; and during working, the lifting driving mechanism drives the upper punchingcutter mechanism to move downwards, and upper punching cutters on the upper punching cutter mechanism are matched with lower punching cutters on the lower punching cutter mechanism for punching. According to the six-head automatic switching punching module, the upper punching cutter mechanism and the lower punching cutter mechanism are arranged, and six cutters which correspond to one another andare matched and used are arranged on each of the upper punching cutter mechanism and the lower punching cutter mechanism so that cutters can be switched under the motion state of a manipulator, the problem of butt joint replacement of a robot in the production process is reduced, high-precision punching is achieved, and punching efficiency is improved.

Owner:余姚泰速自动化科技有限公司

Blanking device for food box

ActiveCN105500455AImprove processing efficiencyLabor savingMetal working apparatusEngineeringMechanical equipment

The invention provides a blanking device for a food box and belongs to the technical field of mechanical equipment. The technical problem that an existing blanking device for the food box is low in efficiency is solved. The blanking device for the food box comprises a base, an upper die and a lower die, wherein the upper die and the lower die are arranged on the base. The lower surface of the upper die is provided with an inwards-concave containing groove for containing the bottom of the food box, the upper die can reciprocate towards the lower die, and an annular upper cutter is arranged on the groove side of the containing groove. The lower die is fixedly arranged on the base, the upper surface of the lower die is provided with an annular lower cutter opposite to the upper cutter, one side of the lower die is provided with a transfer platform capable of vertically moving, and a push block capable of pushing the food box to the space between the upper die and the lower die is arranged on the transfer platform. The blanking device has the advantages of being high in blanking efficiency and side cutting precision and the like.

Owner:沈正昌

Rubber punching machine

The invention relates to a rubber punching machine, which comprises a base plate provided with a product fixing base and a left punching bottom plate and a right punching bottom plate arranged in opposite. Both the left and right punching bottom plates are provided with punching devices and the product fixing bases. Each punching device comprises a driving member and a punching head. The product fixing base comprises separated bases respectively arranged on the left and right punching bottom plates. The separated bases are provided with punching head holes matched with the punching heads corresponding to the punching head holes on position. At least one of the left and right punching bottom plates is a sliding plate in slip connection with the base plate. One side of the sliding plate is connected with a movable plate adjusting mechanism. The axial leads of the punching heads on the left and right punching bottom plates are superposed. The invention can be used for punching on both sides synchronously without adjusting the positions of the punching heads, thereby improving the punching efficiency.

Owner:泛美汽车零部件(宁波)有限公司

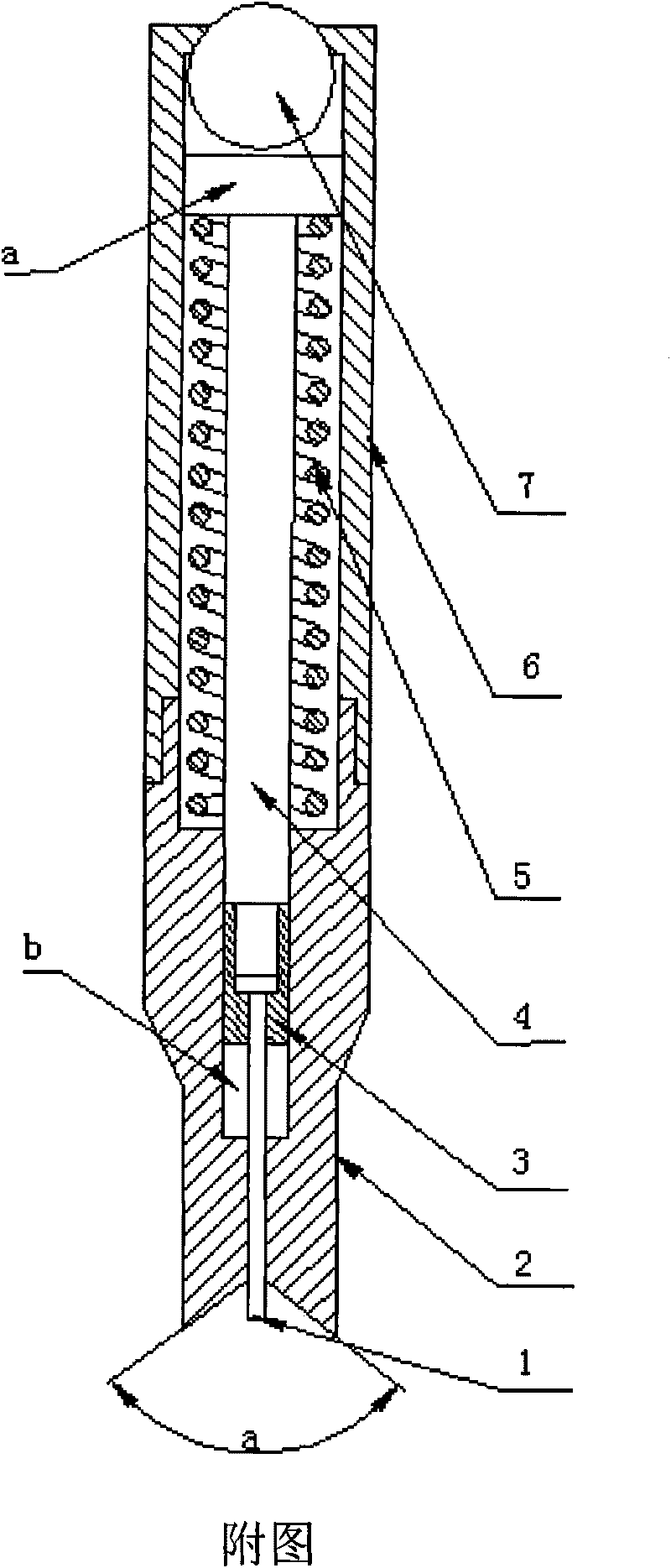

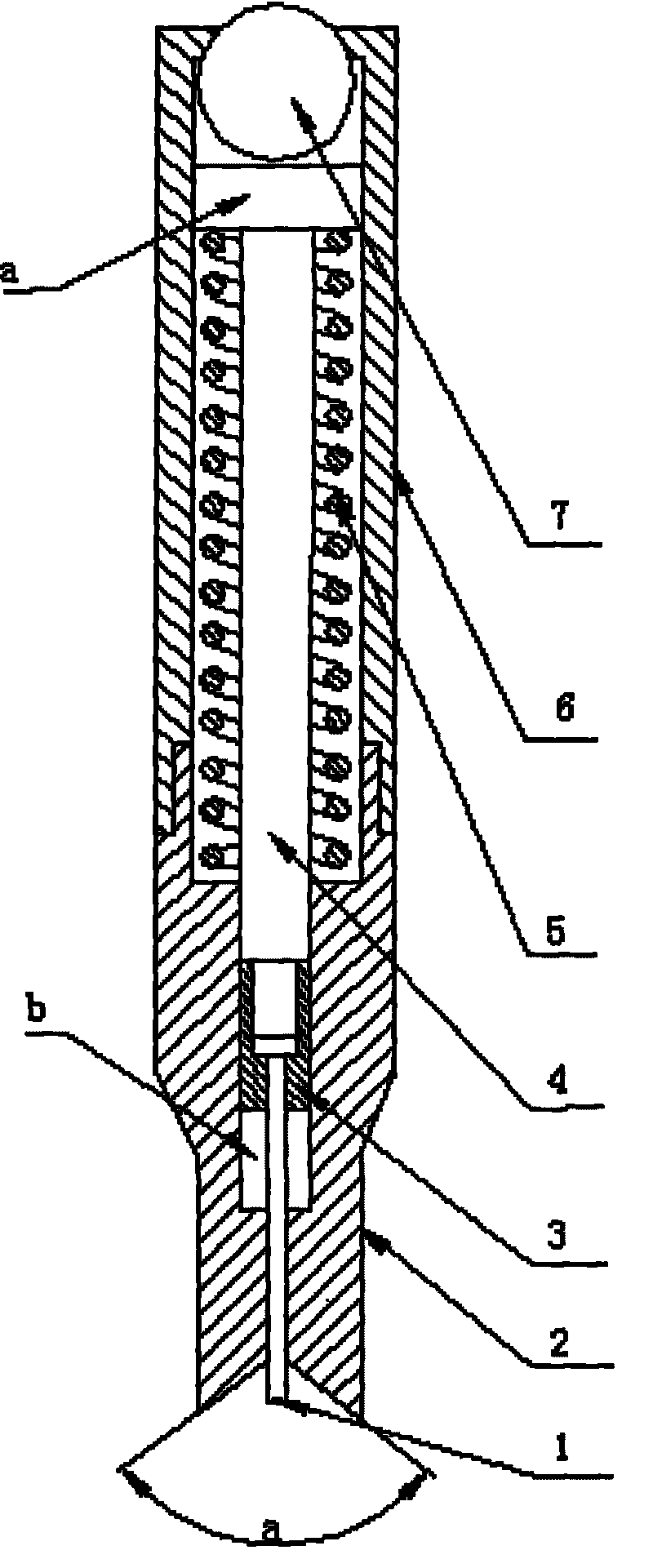

Novel wall tube punching tool

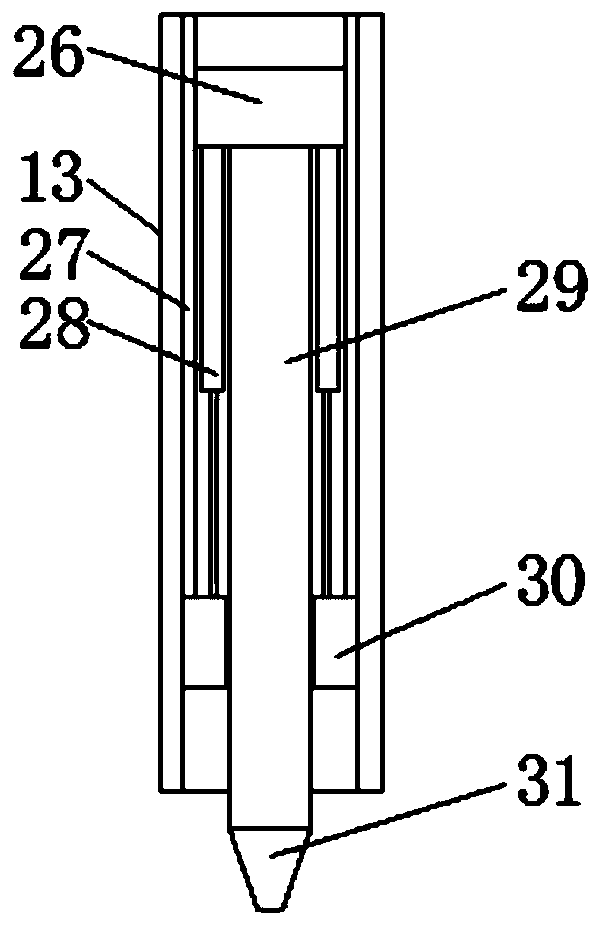

InactiveCN101733323AEasy to useImprove punching efficiencyPerforating toolsMetal working apparatusPunchingSteel ball

The invention relates to a novel wall tube punching tool, a plunger chip is arranged in a hole of a guide column, and external threads at the lower end of a guide rod are screwed in internal threads of the guide column, and a punching needle is tightly fixed; and then a steel ball is arranged in an inner hole of an upper sleeve, and an assembly which integrates the plunger chip, the guide column and the guide rod is arranged, and after a spring is sheathed outside the assembly piece which integrates the plunger chip, the guide column and the guide rod, an upper sleeve and a lower locating sleeve are connected into one body by the internal and external threads; in order to have better guiding function, a proper clearance exists between an outer circle a of the guide rod and an inner hole of the upper sleeve, and a gap exists between the outer circle of the guide column and an inner hole b of the lower locating sleeve; when in use, a V-shaped button of the lower locating sleeve spans at the proper position of the tube wall and is knocked to a steel ball by a hammer, so as to punch a hole, and the punching needle with different diameter can be punched into the corresponding bore diameter.

Owner:杨苏军

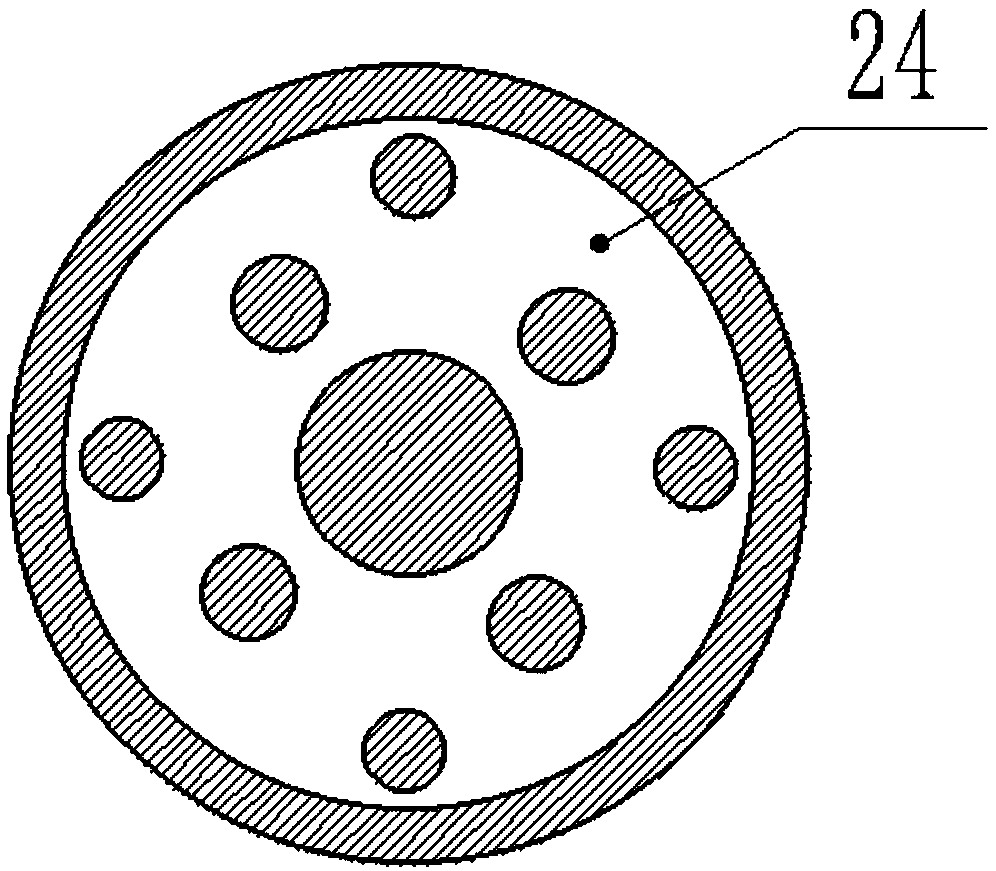

Heat radiation hole punching device of cast aluminum end cover

The invention discloses a heat radiation hole punching device of a cast aluminum end cover. The heat radiation hole punching device comprises a base, a lifting plate, a punching head, a containing table and clamp arms. A cam is fixedly mounted on a connecting shaft. A connecting plate is fixedly mounted between fixed plates located on the left side and the right side. An ejection rod is mounted atthe center position of the connecting plate in a sliding manner, and the punching head is fixedly mounted at the lower end of the ejection rod. The interior of the base is of a hollow structure, anda gear is rotationally mounted at the center position in the base through a rotating shaft. The right side of an upper rack and the left side of a lower rack are fixedly connected with the clamp armscorrespondingly. The position of the punching head is changed, and therefore punching work is carried out on cast aluminum end covers of different end face heights, and universality of the device is greatly improved; a drive motor rotates constantly, and therefore the punching head moves up and down to achieve continuous punching on the cast aluminum end cover; and compared with an existing primary punching device, the situation that primary punching is not achieved in place to cause secondary reworking can be effectively avoided, the punching efficiency is greatly improved, and the situationof secondary reworking is avoided.

Owner:盐城市顺天铸造有限公司

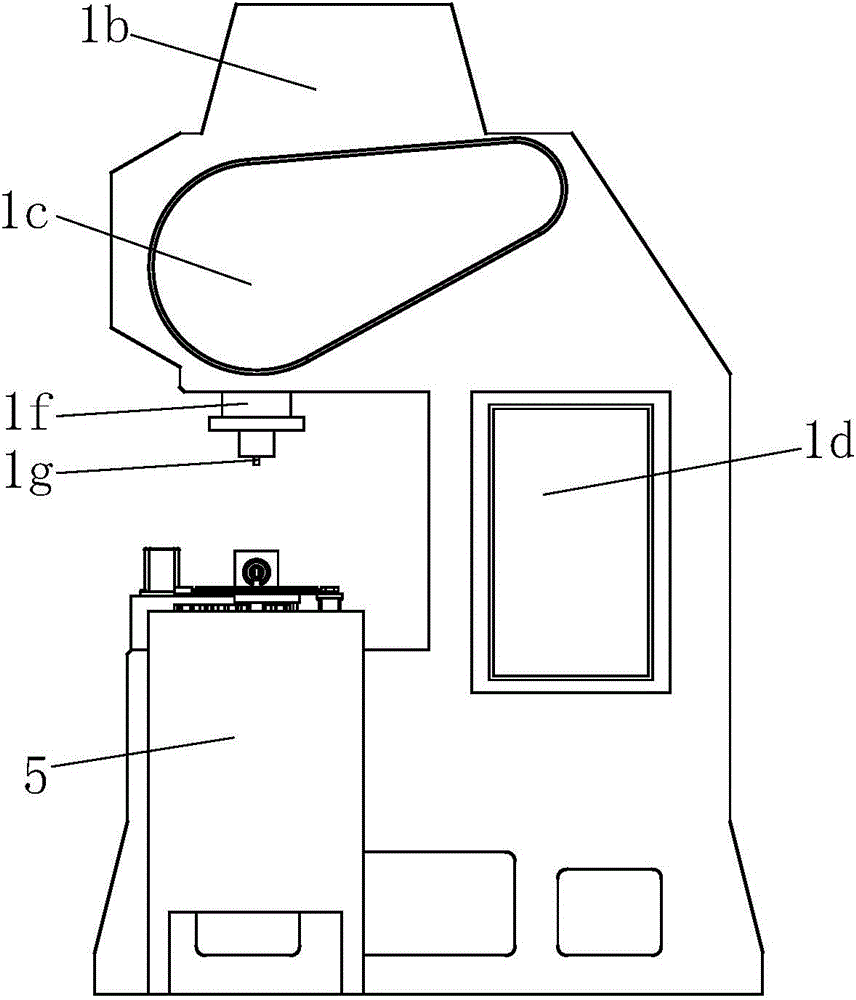

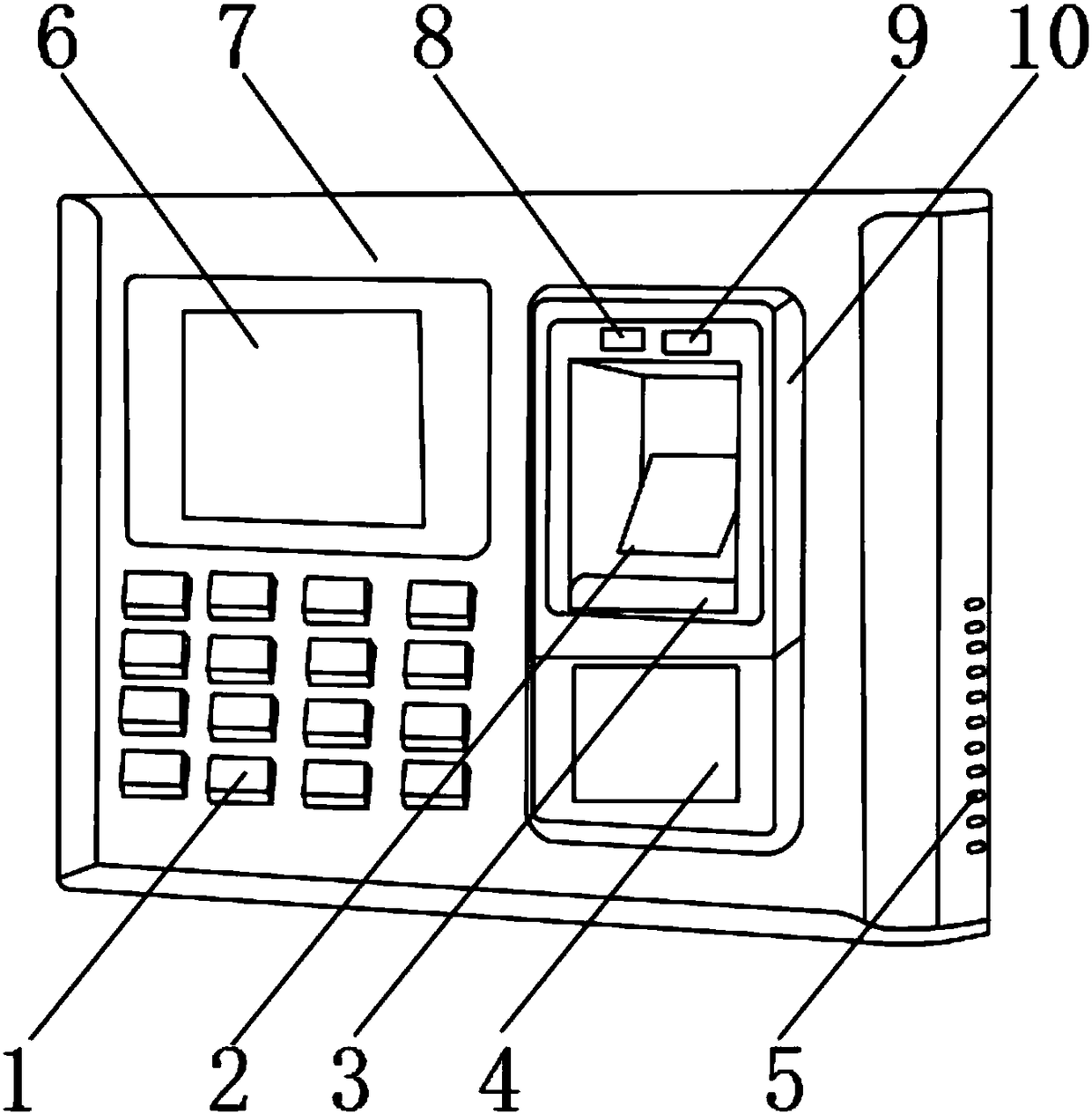

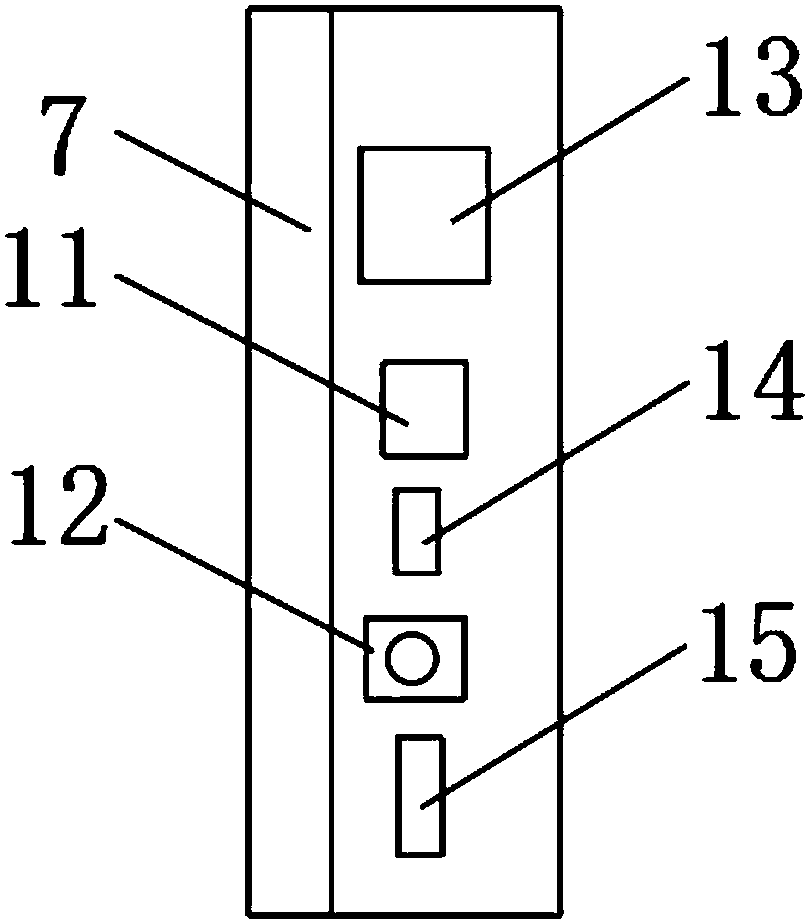

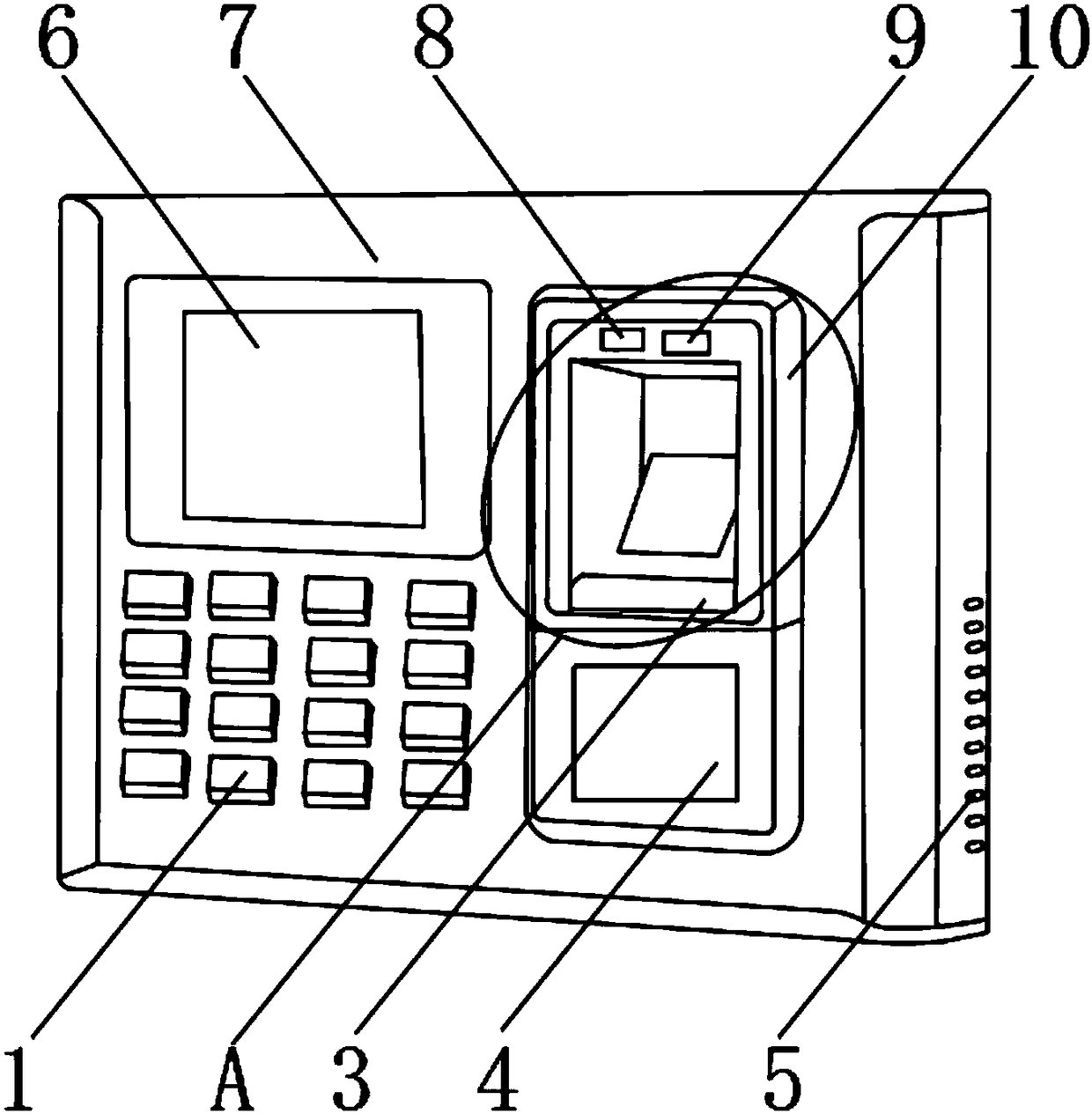

Intelligent fingerprint attendance machine

InactiveCN108198264AImprove punching efficiencySimple structureRegistering/indicating time of eventsMultiple biometrics useComputer visionNetwork interface

The invention discloses an intelligent fingerprint attendance machine which comprises an attendance machine shell and a fingerprint recognition instrument shell. A control keyboard and a display screen are arranged on the outer surface of the front end of the fingerprint recognition instrument shell, the display screen is located above the control keyboard, a network interface, a USB interface anda control interface are fixedly installed on the outer surface of one side of the fingerprint recognition instrument shell, the network interface is arranged above the USB interface, the control interface is arranged below the USB interface, a power interface is arranged below the control interface, and a power switch is arranged below the power interface. The intelligent fingerprint attendance machine is provided with a scanner, a cleaning board and a face recognizer, the contour feature of the upper surface of a finger can be scanned, sweat and dust on a fingerprint recognition instrument panel can be cleaned away, finally, face recognition can be performed when the fingerprint recognition instrument cannot recognize fingerprints, and the better using prospect is brought.

Owner:JIANGSU MARITIME INST

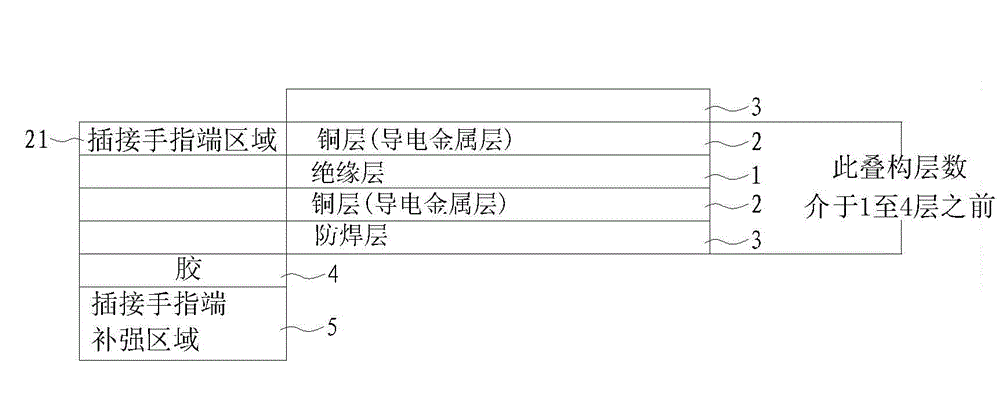

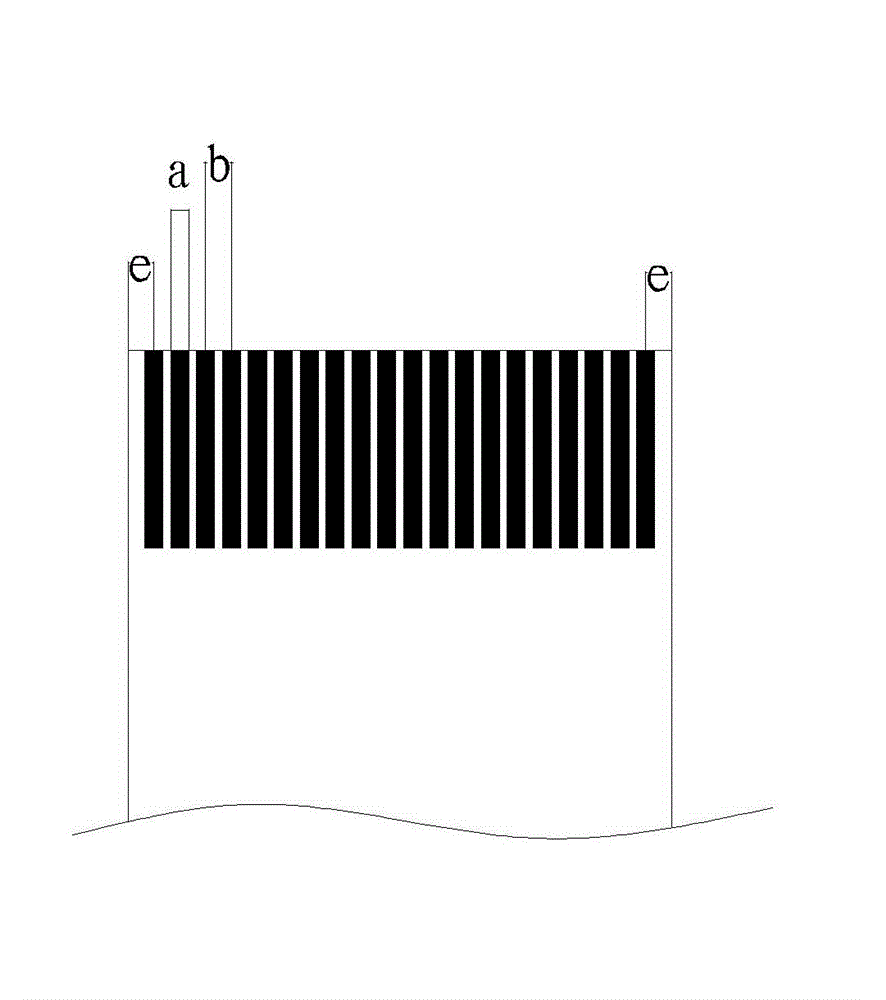

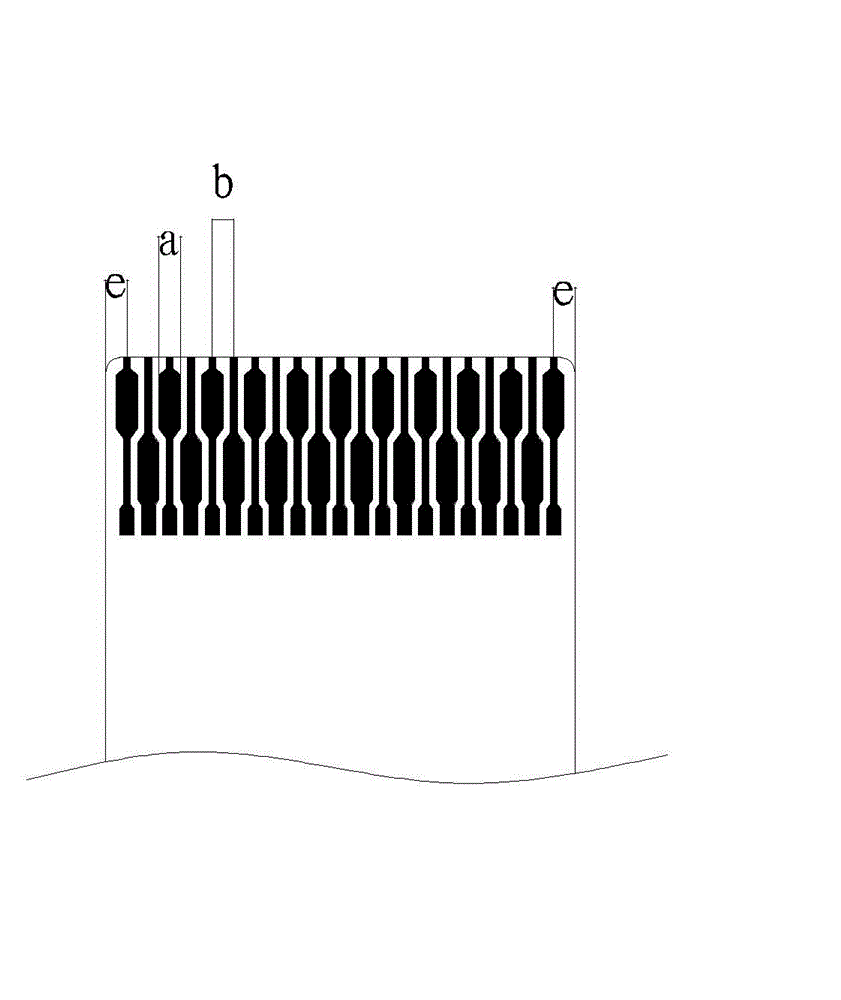

Manufacturing process improvement method for pluggable flexible printed circuit (FPC)

The invention relates to the field of FPC (flexible printed circuit) manufacturing, and relates to a manufacturing process improvement method for a pluggable FPC. The manufacturing process improvement method comprises the manufacturing steps of designing a circuit; forming the circuit; stamping a positioning target; carrying out surface processing and an electrical property test on the circuit; punching the shape of the circuit out; and carrying out detection on a finished product. The manufacturing process improvement method has improvements that in the circuit design, the edges of the shapes of a pluggable finger soldering pan and the FPC are in inward contraction design, a target center of a positioning design target of the pluggable finger soldering pan is stamped to be positioned on a same surface with the pluggable finger soldering pan, and more than two mould positioning holes are adjacent to the pluggable finger soldering pan; in the positioning target stamping, the target center of the positioning target is positioned on the same surface with the pluggable finger soldering pan, and then the positioning target is stamped; and in the shape punching, the punching is carried out twice, wherein the partial shape of the region of the pluggable finger soldering pan is firstly punched, and the partial shape of the other region of the pluggable finger soldering pan is then punched. The manufacturing process improvement method of the pluggable FPC is used for manufacturing pluggable FPCs with favorable pluggable electricity performance.

Owner:厦门爱谱生电子科技有限公司

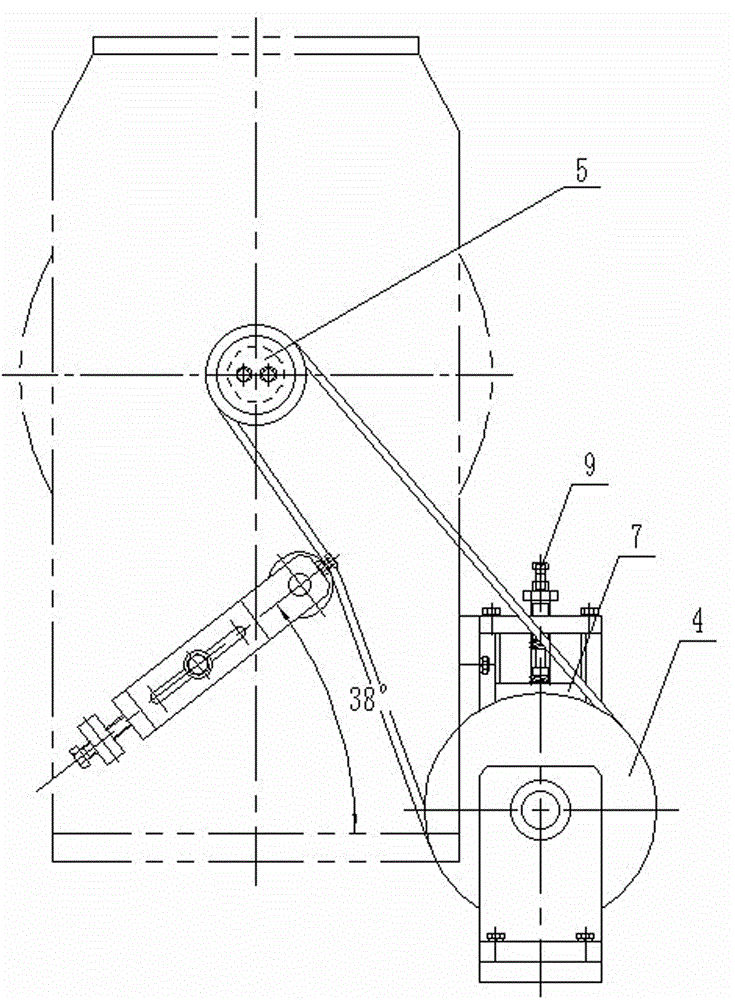

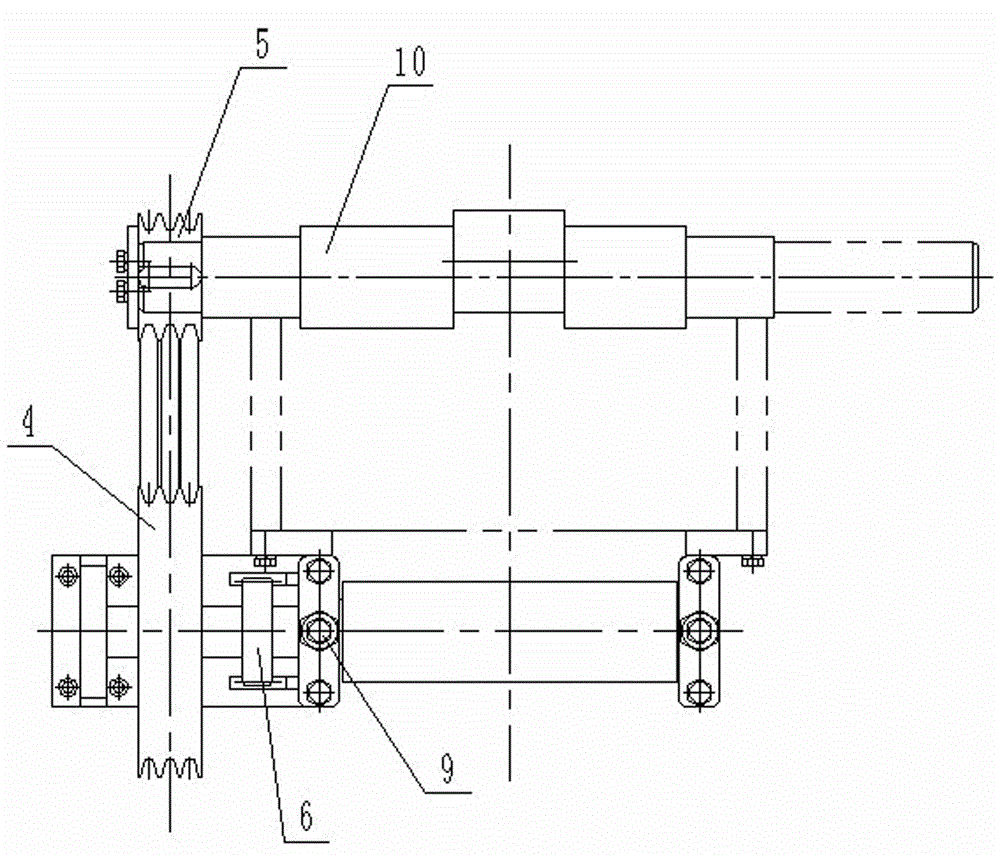

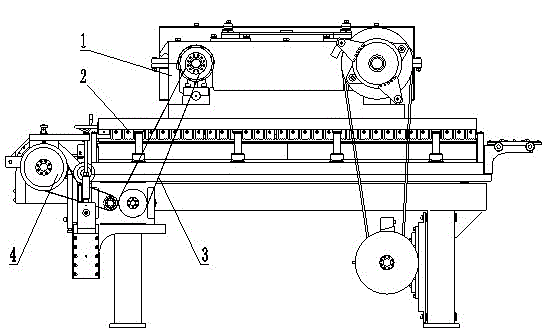

Slipping and continuous feeding device for high speed perforating machine

InactiveCN102974710AImprove transmission efficiencyImprove punching efficiencyMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention relates to a slipping and continuous feeding device for a high-speed perforating machine, which is characterized by comprising a drive roll and a driven roll, wherein the drive roll and the driven roll are arranged up and down in parallel; the drive roll is fixed on a rack by a bearing; one end of the drive roll is connected with a belt pulley; the belt pulley is connected with a driving wheel by a belt; a drive roll shaft as well as a driven roll shaft is provided with a gear; the gear of the drive roll shaft is the same as that of the driven roll shaft; the two gears are in meshed transmission; both sides of the driven roll shaft are respectively matched with two sliding blocks by bearings; the sliding blocks can move up and down and are respectively matched with a vertical guide rail; and the guide rail is fixed on the rack and is provided with a pressure regulation device for pushing the sliding blocks towards the drive roll. According to the invention, a strip is continuously conveyed by the drive roll and the driven roll to enter a stamping die set; an original crank-link mechanism is omitted; at the moment of stamping, slippage between the strip and the drive roll as well as between the strip and the driven roll is stagnated; the slipping resistance can be regulated by the pressure regulation device; and due to combination of continuous feeding and slippage, conveying efficiency is improved, so that integral punching efficiency is improved.

Owner:黑龙江昕泰管业有限公司

Steel plate punching device capable of automatically replacing punch

PendingCN110802161AMove preciselyImprove punching efficiencyShaping toolsMetal-working feeding devicesGear drivePunching

The invention discloses a steel plate punching device capable of automatically replacing a punch. The device comprises a mounting table and a shell. In the device, a rotating shaft, a rotating plate,a sleeve and an ejector rod are utilized, when the punch needs to be replaced, a servo motor drives a driving gear to rotate for a certain number of turns, the driving gear drives a driven gear to rotate for a certain number of turns, and the driven gear drives the rotating shaft to rotate for a certain number of turns, so that the sleeve with different punches is moved to the portion under the ejector rod, a cylinder shrinks, an ejector plate is driven to move downwards quickly, then the ejector rod is driven to move downwards quickly, then a push head is driven to push a sliding block to move downwards, the sliding block moves downwards to drive a guide rod to contract, a punch rod drives the punch to punch a steel plate, a worker controls the rotation angle of the servo motor through aPLC, and then the sleeve with different punches can be switched and rotated to the portion under the push head during work for automatically switching the punches and complete punching. The automationdegree is high, the device is convenient to use, and the punching efficiency is greatly improved.

Owner:义乌市创伟电器机械有限公司

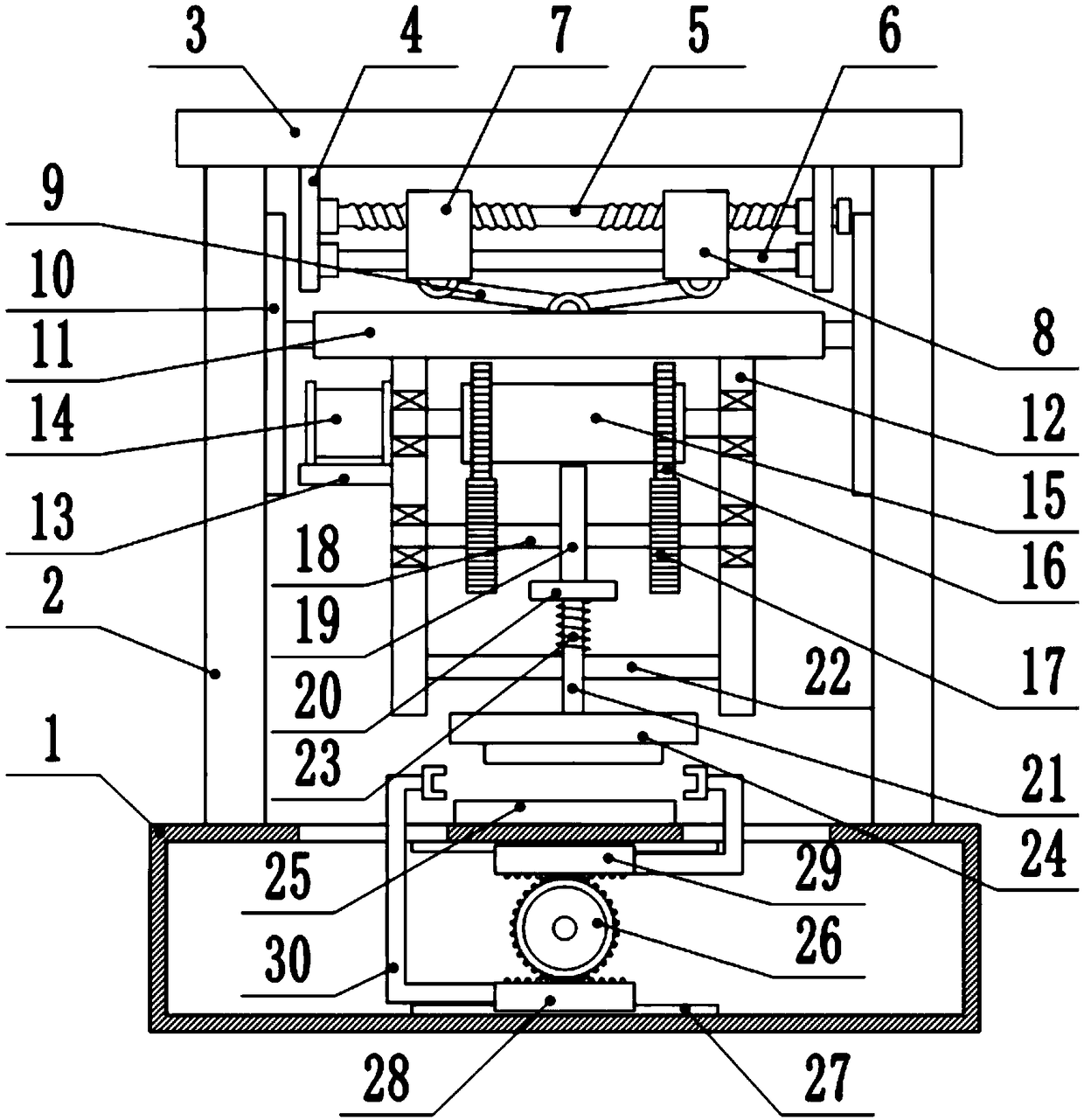

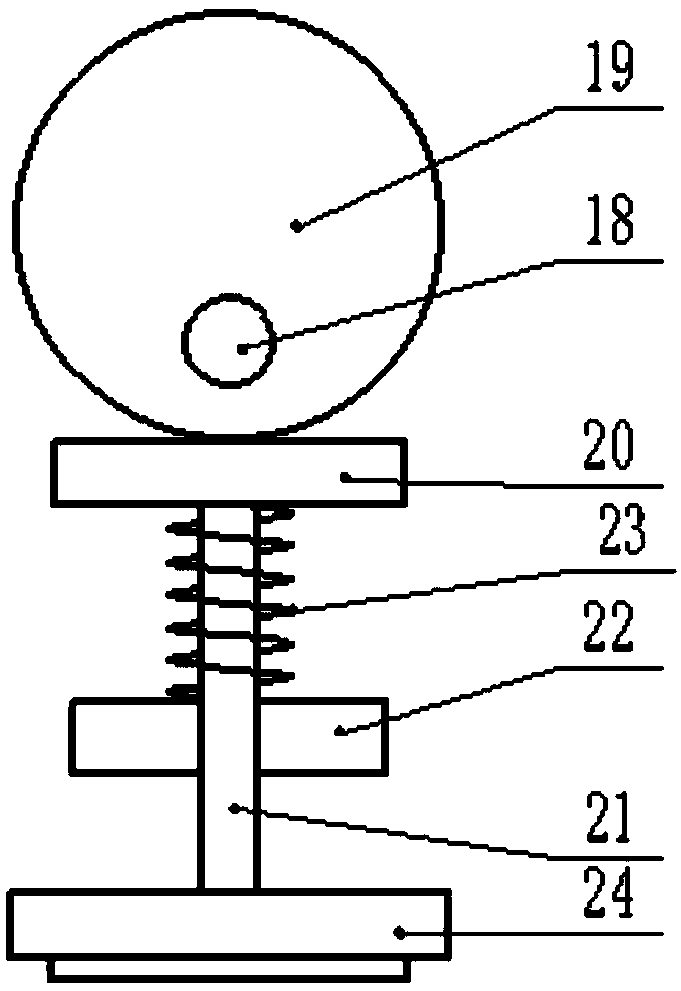

Mailbox Punching Device

InactiveUS20190105796A1Simple structureEasy to useLarge fixed membersMetal working apparatusPunchingGear wheel

The invention discloses a mailbox punching device, comprising a baseplate, two frames which are correspondingly arranged at the two ends of the top of the baseplate, and a box arranged between the two frames on the two ends through a lifting device. The inner bottom of the box is provided with a first steering cavity with a an opening facing downward, and a second steering cavity extends vertically is up and down extended in the box above the first steering cavity. A first sliding groove is connectedly set on the one inner wall of a the second steering cavity, and a steering platform, through bearings, is rotatably mounted in the first steering cavity. A first steering shaft which extends into the second steering cavity, is fixedly arranged on the top of the steering platform, and a first cone pulley bevel gear is fixedly mounted on the first steering shaft in the second steering cavity.

Owner:NANTONG WEIXING TEXTILE TECH CO LTD

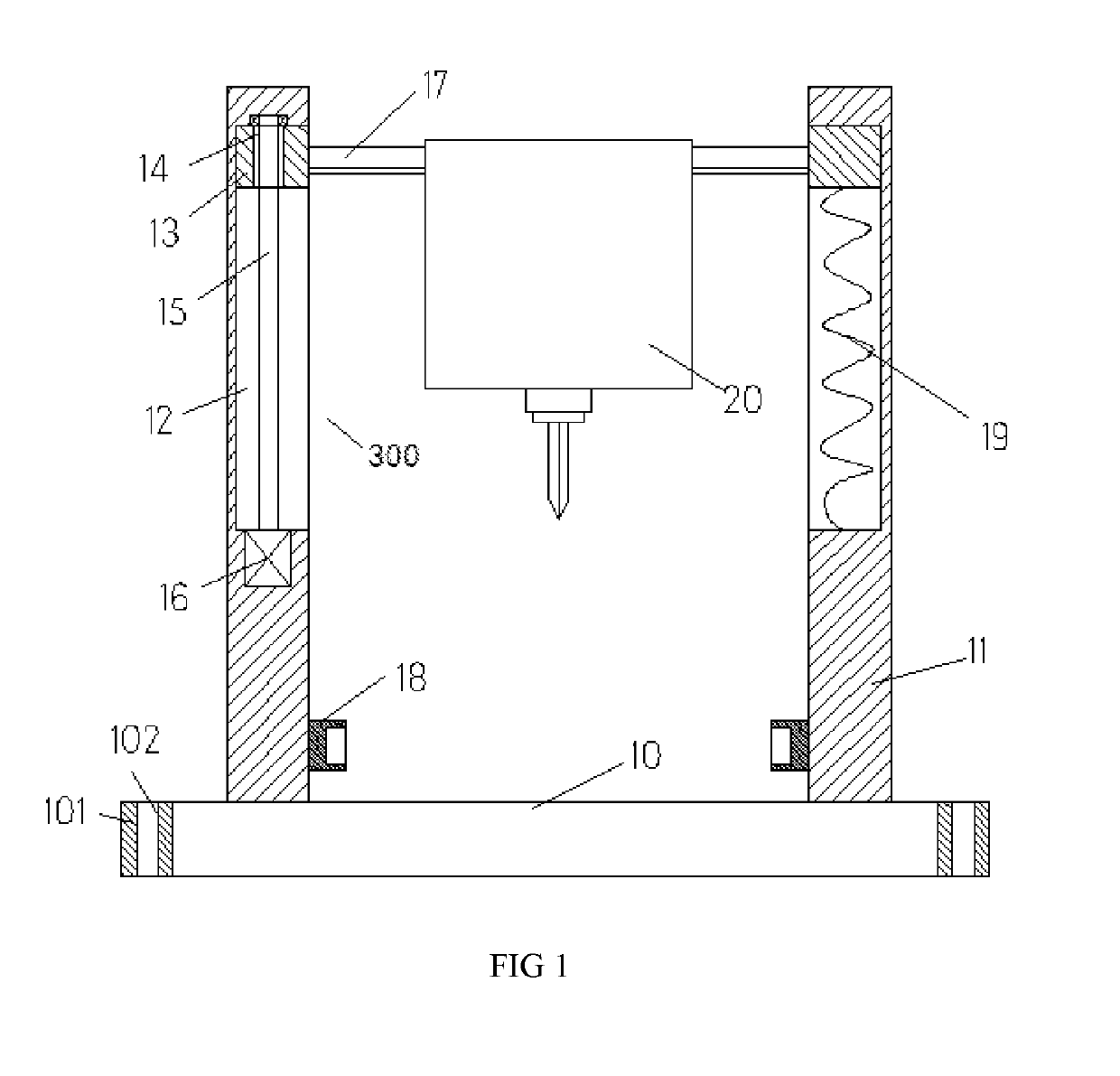

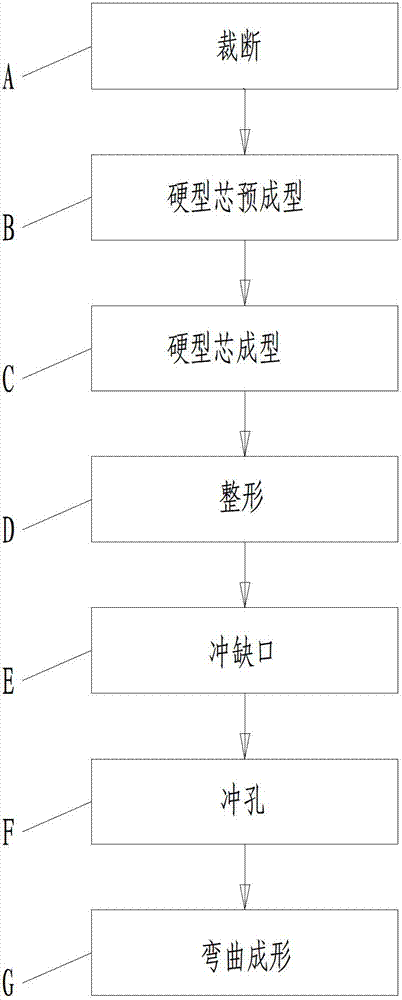

Molding method for trailing arm beam of rear axle bracket assembly of automobile

InactiveCN102921801AIncrease productivityEasy to operateShaping toolsPerforating toolsTrailing armStamping

The invention provides a molding method for a trailing arm beam of a rear axle bracket assembly of an automobile and relates to a production method for auto parts. The method includes the steps of A, cutting: cutting a raw tube into a rough round tube through a cutting die; B, hard core premolding: stamping the rough round tube into a preformed parison tube through a hard core premolding die; C, hard core premolding: stamping the preformed parison tube into a cross-section-variable rectangular hollow tube through the hard core premolding die; D, shaping; E, gap stamping: stamping a gap through a gap stamping die to obtain a cross-section-variable rectangular hollow tube with the gap; F, punching: punching through a punching die to obtain a semi-finished product of the trailing arm beam of the rear axle bracket assembly of the automobile; and G, bend molding: performing bend molding through a molding die to produce a finished product of the trailing arm beam of the rear axle bracket assembly of the automobile. According to the molding method, the production efficiency is high, the production cost is low, and the product quality is stable, so that mass production requirements can be satisfied.

Owner:柳州市昌河模具厂 +1

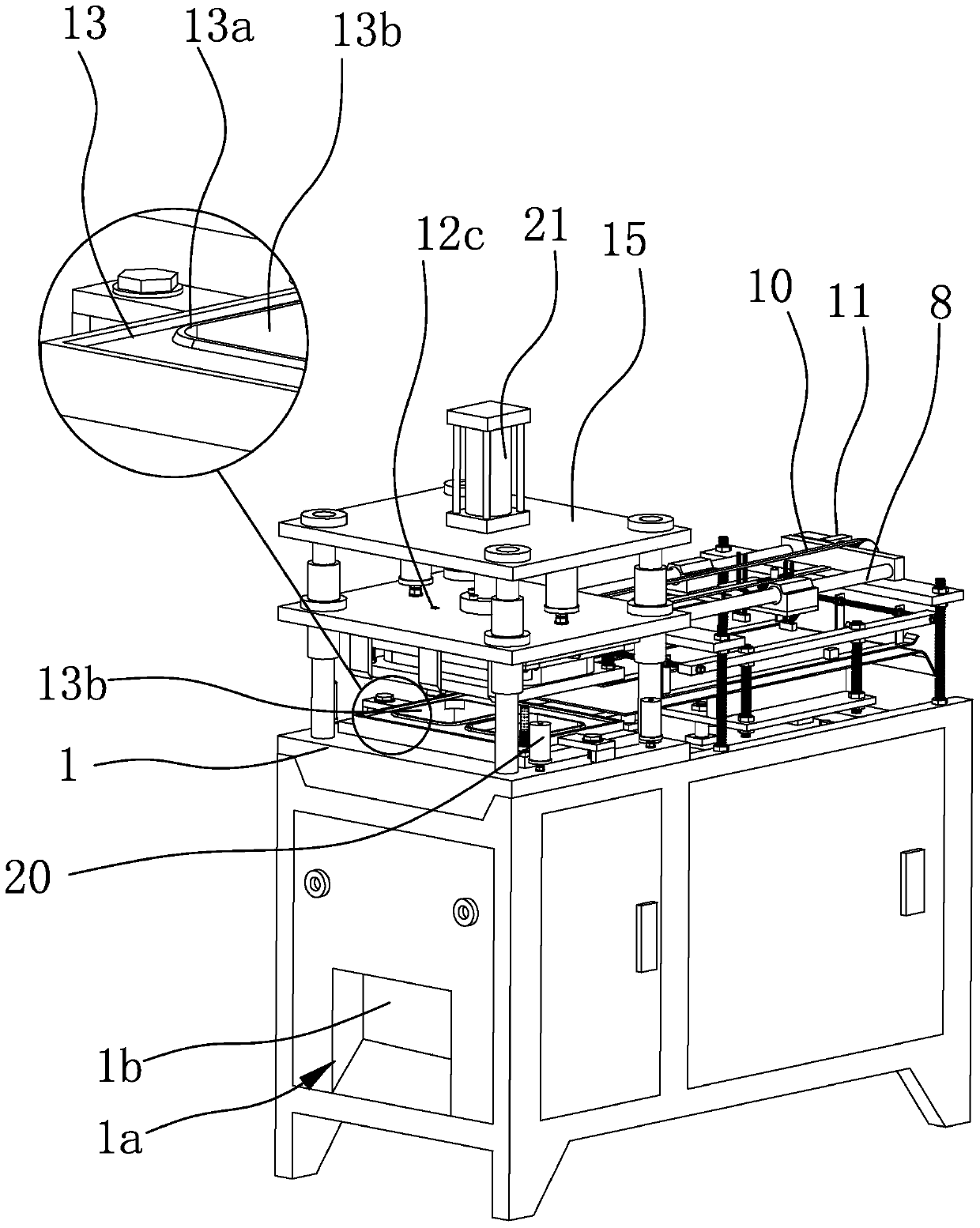

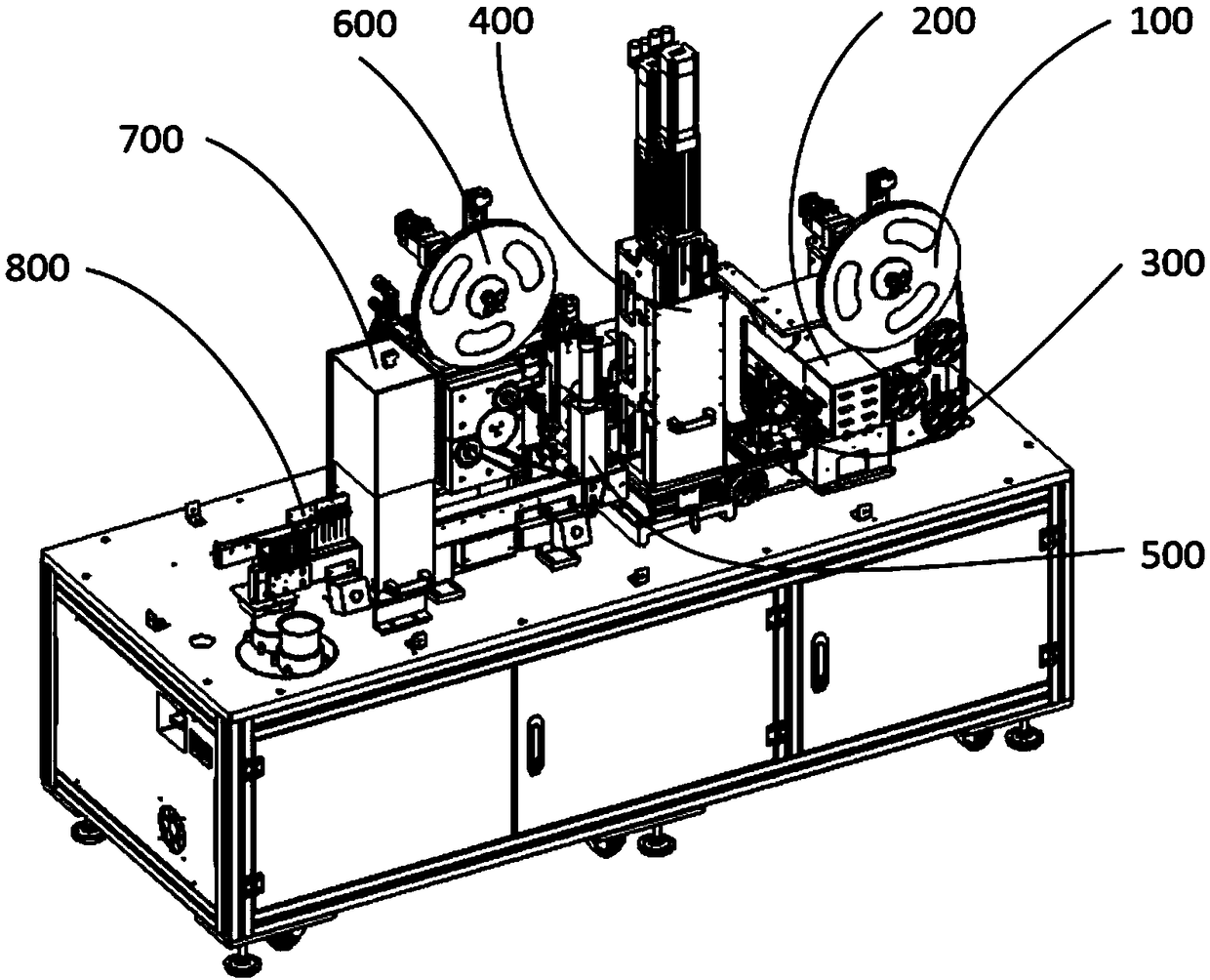

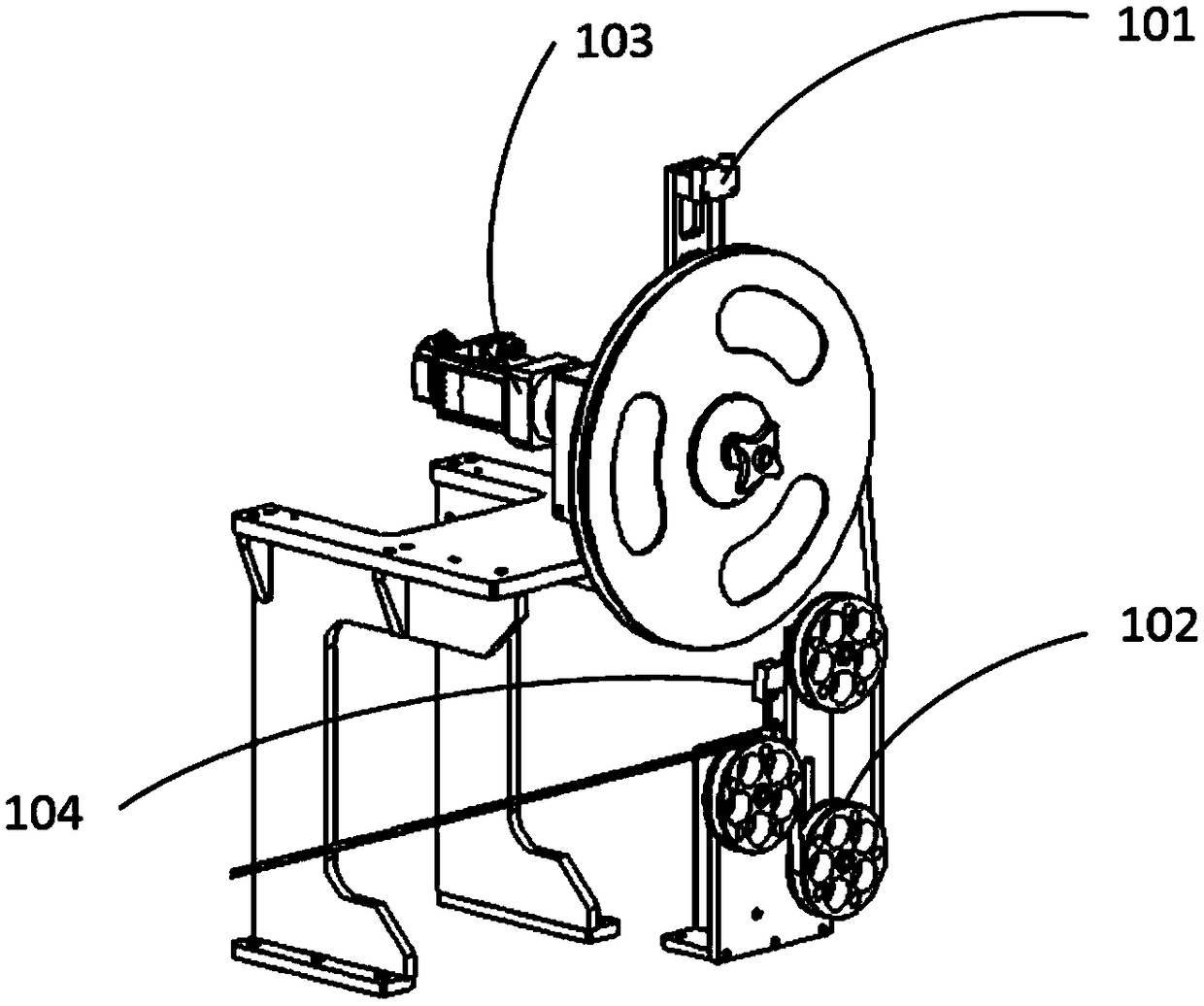

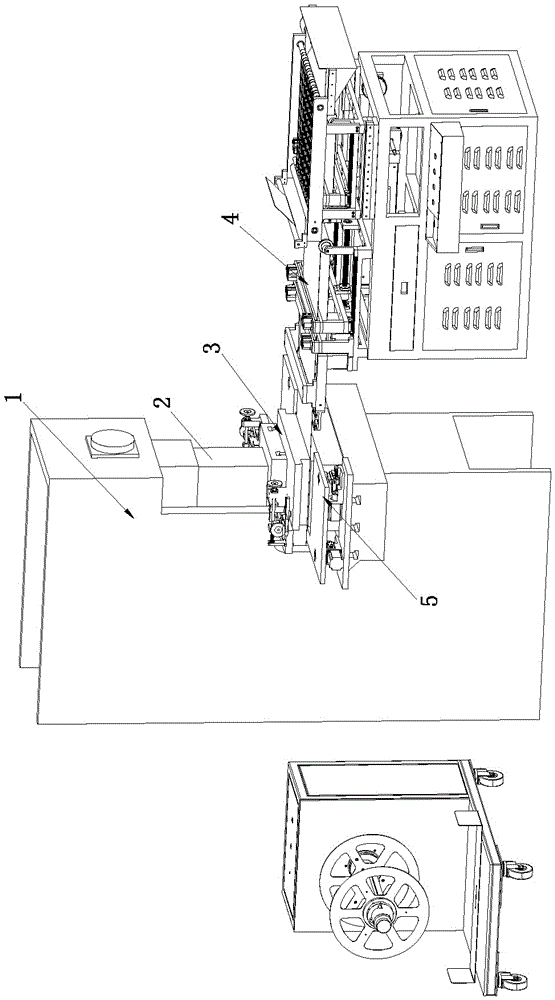

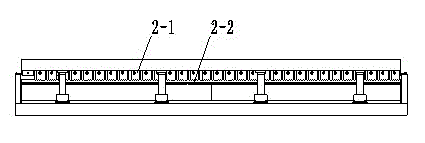

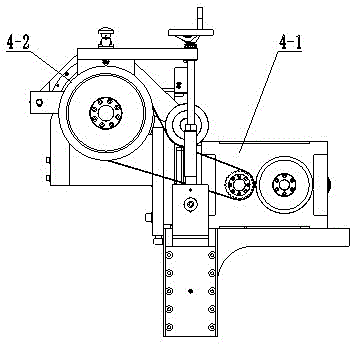

Coil full-automatic punching machine

PendingCN109500202AImprove punching efficiencyImprove detection efficiencyMetal-working feeding devicesMetal working apparatusPunchingTension control

The invention discloses a coil full-automatic punching machine. The punching machine comprises a frame, an unwinding and tension control mechanism, a coil feeding detection mechanism, a coil belt thickness measuring mechanism, a coil belt permeability measuring mechanism, a coil belt continuous punching mechanism, a coil belt feeding and winding mechanism, a punching product online detection mechanism which are sequentially mounted on the frame, and a product punching conveying and collecting mechanism. Compared with the prior art, the coil full-automatic punching machine has the advantages that the production yield is improved and coil punching and detection efficiency is improved.

Owner:东莞市智立方自动化设备有限公司

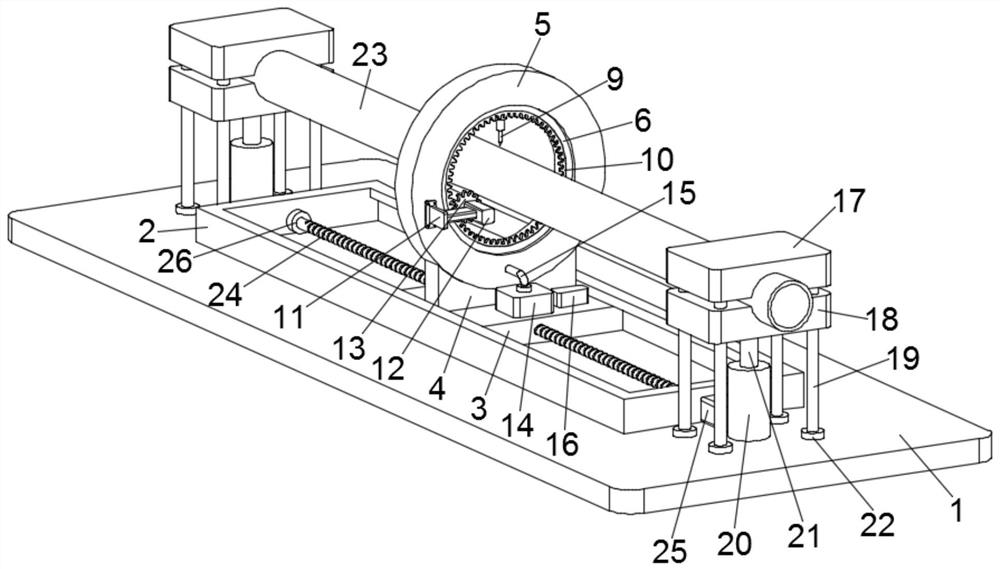

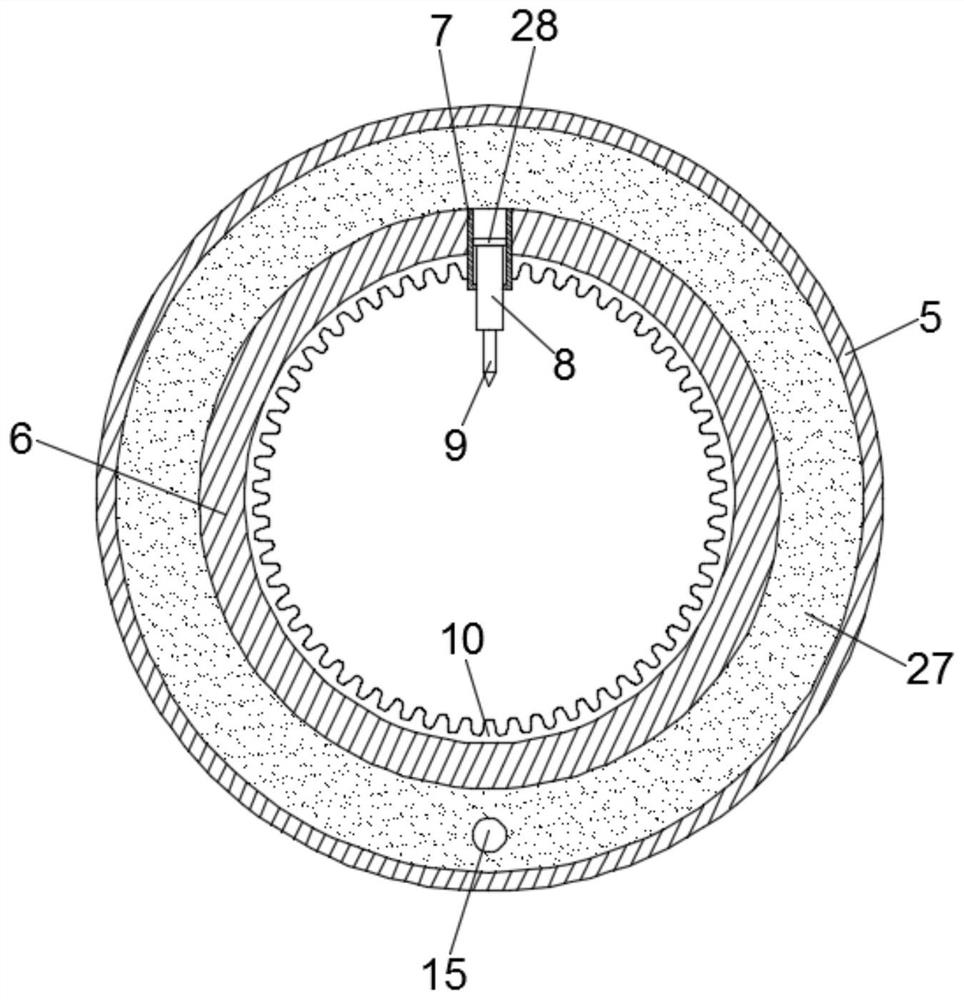

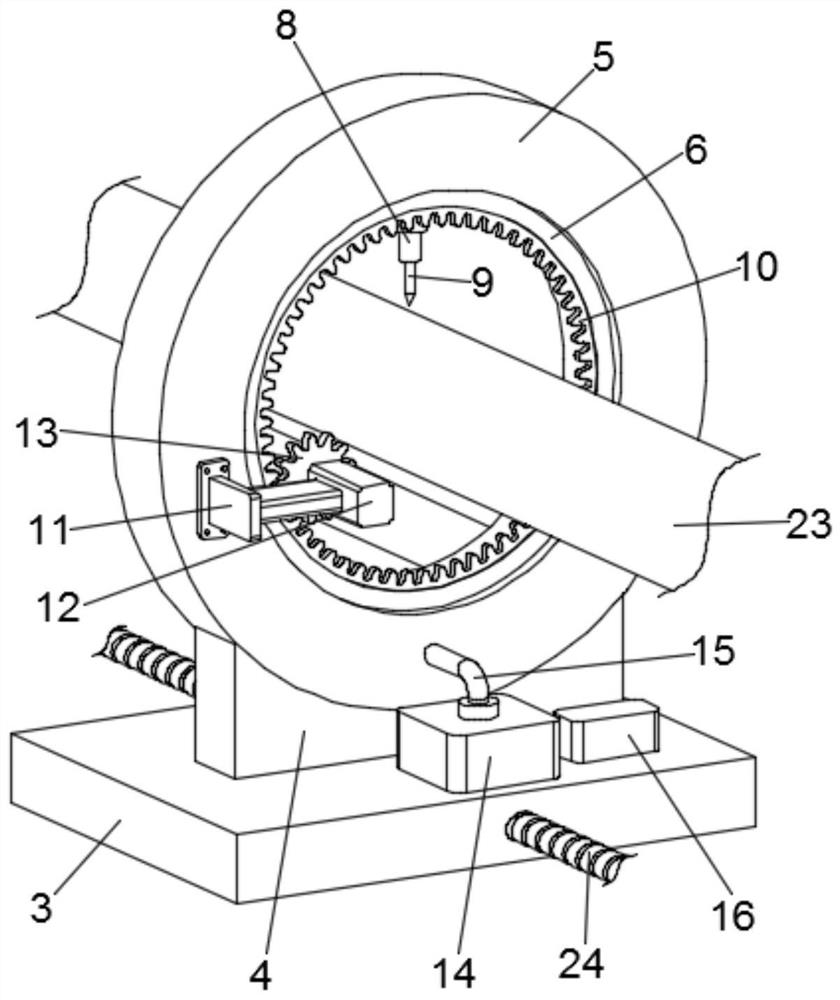

Steel pipe punching device for building construction

The invention discloses a steel pipe punching device for building construction. The steel pipe punching device comprises a base, a sliding rail is installed on the base, a ring sleeve is installed inthe sliding rail in a sliding mode, an annular cavity is formed in the ring sleeve, a rotating ring is rotationally clamped on the inner side of the ring sleeve, a sleeve is fixedly installed on the rotating ring, a telescopic ejector rod is movably sleeved with the sleeve, a punch is installed at the extending tail end of the telescopic ejector rod, and a hydraulic device communicating with the annular cavity is installed on a sliding block; a rotating motor is installed on the outer wall of the ring sleeve, a gear is rotationally installed at the output end of the rotating motor, a gear ringis arranged on the inner wall of the rotating ring, and a controller is installed on the sliding block; and a transverse moving mechanism is arranged on the sliding rail, and clamping assemblies arearranged at the two ends of the sliding rail. According to the steel pipe punching device for building construction, a steel pipe is clamped and fixed through the clamping assemblies, the ring sleeveis driven by the transverse moving mechanism to move transversely along the steel pipe, and meanwhile, the punch can rotate around the circumferential direction of the steel pipe to any angle, and therefore punching operation of the steel pipe at different positions and angles is achieved, adjustment is convenient and flexible, the punching precision is high, and the punching efficiency is improved.

Owner:潘帅

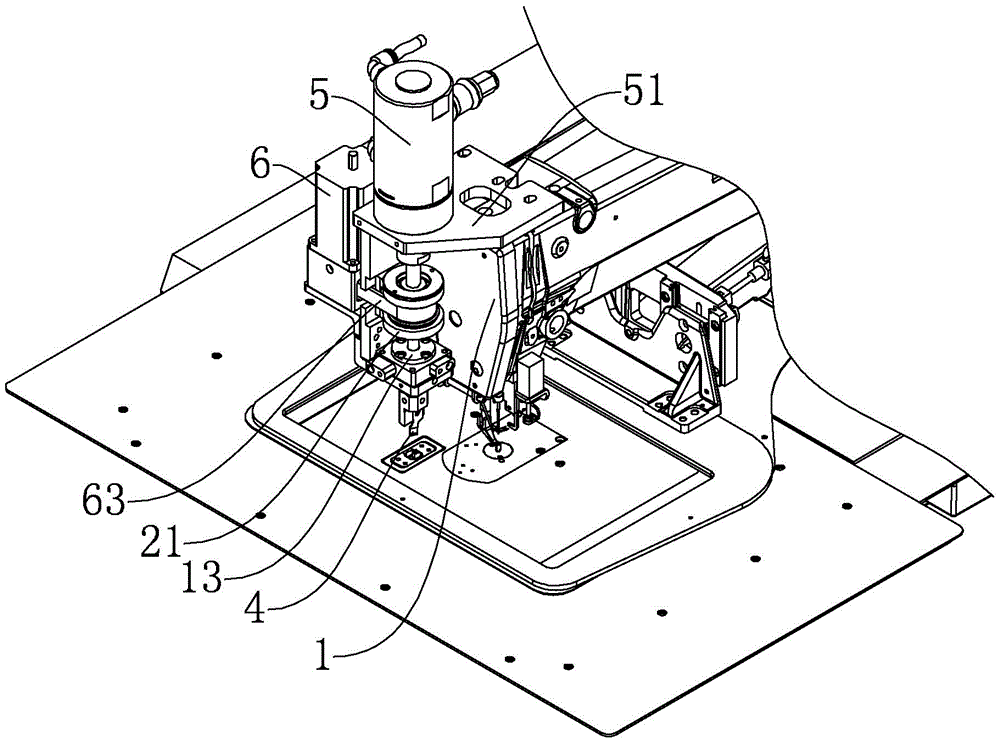

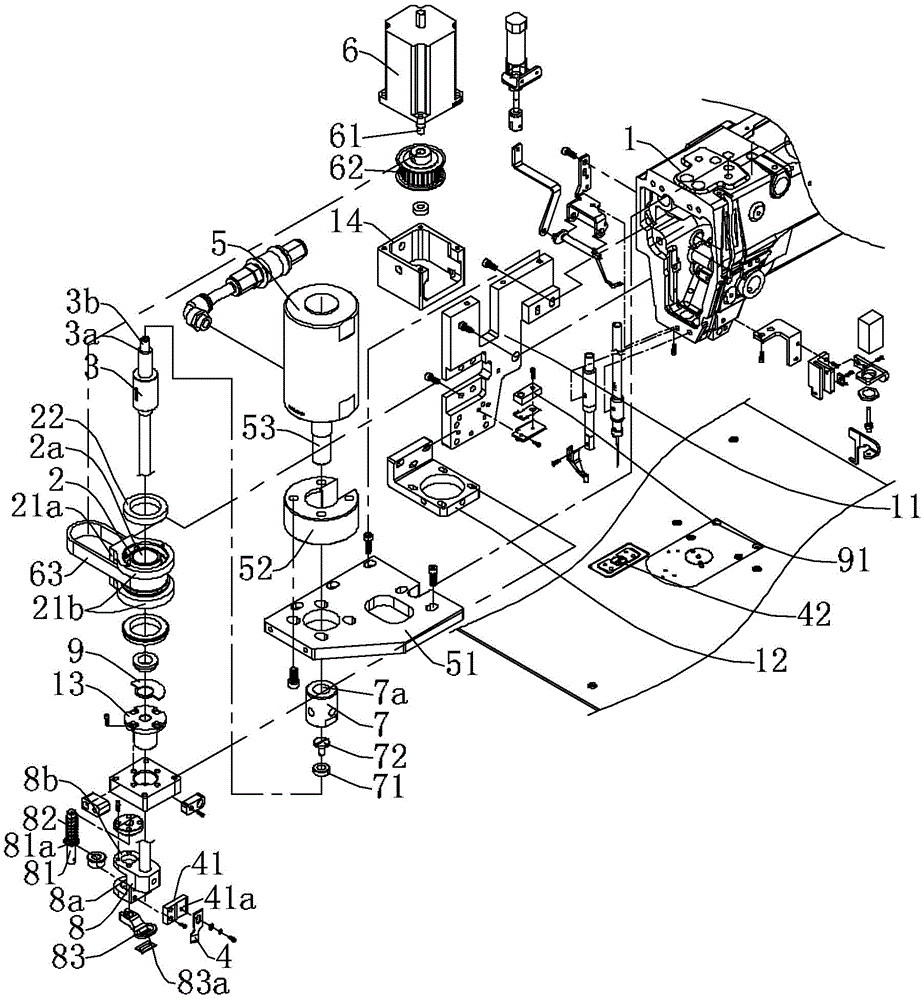

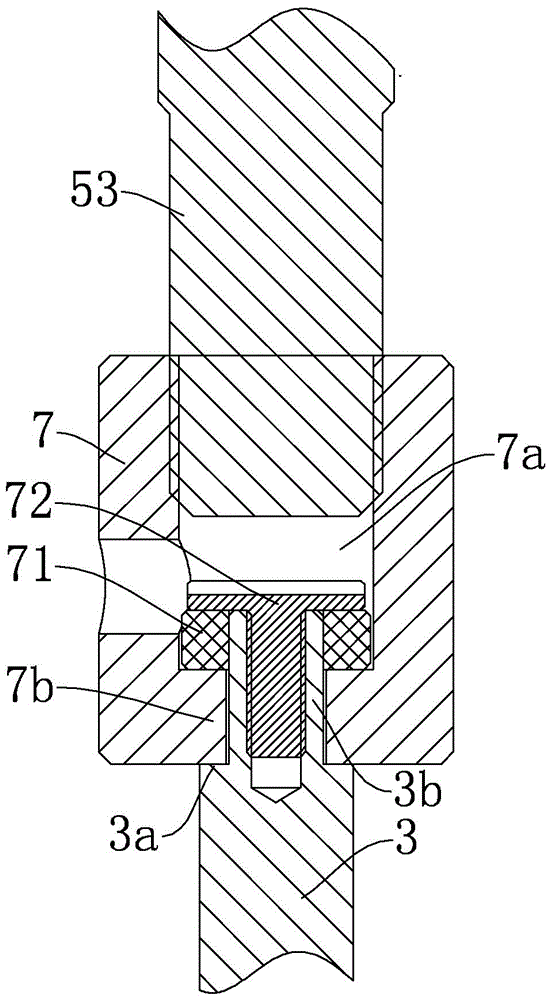

Rotary sewing material punching machine

The invention discloses a rotary sewing material punching machine which comprises a sewing machine head. A rotatable driven wheel and a motor for driving the driven wheel to rotate through a transmission mechanism are installed on one side of the sewing machine head. A spline shaft sleeve is arranged at the axis of the driven wheel. A spline transmission shaft capable of moving axially is arranged in the spline shaft sleeve. A punching cylinder for driving the spline transmission shaft to axially move is arranged at the upper end of the spline transmission shaft. A punch is connected with the lower end of the spline transmission shaft. The rotary sewing material punching machine has a punching function and a sewing function; by controlling the rotating angle of the motor, the rotating angle of the punch can be adjusted, and therefore the angle of the punch is automatically adjusted, and the punch efficiency of sewing material is improved.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

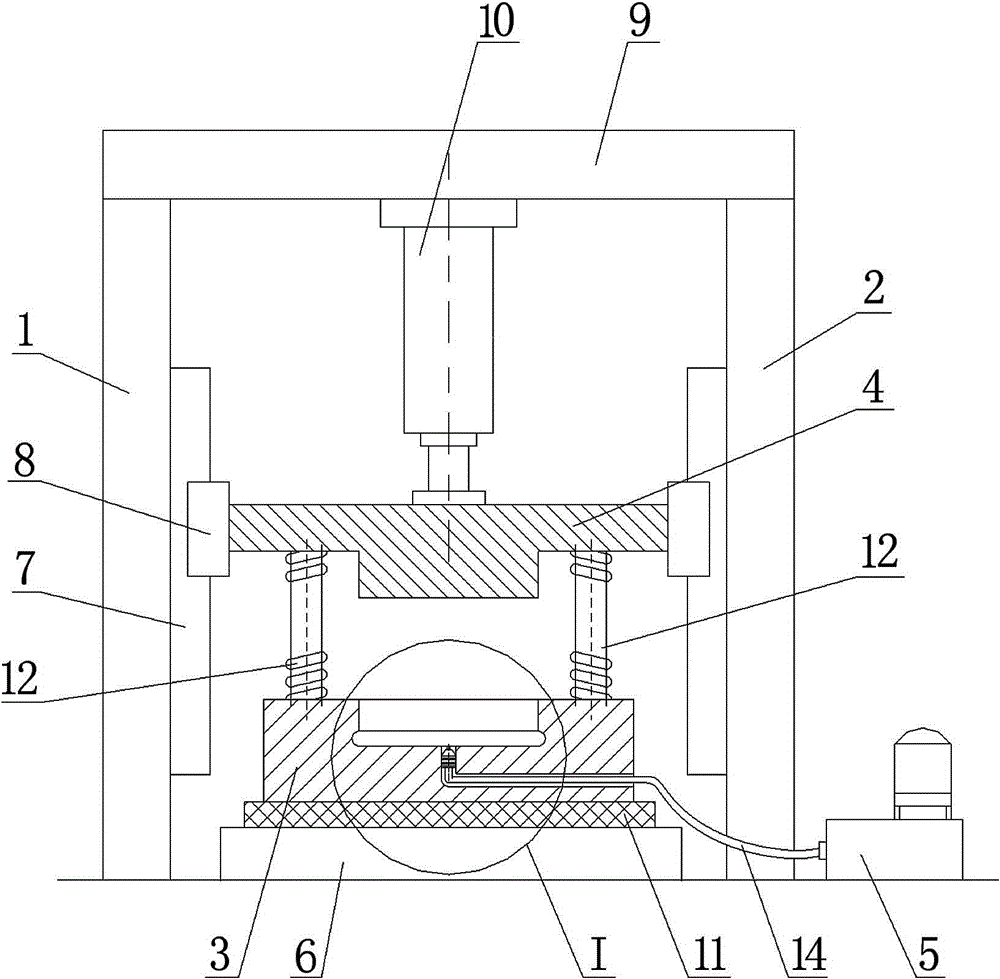

Alignment punch press system

ActiveCN105538410ARealize automatic alignmentReduce labor costsMetal working apparatusPunch pressFlexible circuits

The invention relates to the technical field of flexible circuit board production equipment, in particular to an alignment punch press system. The system comprises a punching device and a four-axis automatic alignment platform, wherein the punching device is provided with a puncher pin for punching, the four-axis automatic alignment platform comprises a bottom plate, a CCD camera assembly, a computer control assembly and an operation table used for adjusting material positions, the bottom plate is arranged on the punching device, a punching station is arranged between the puncher pin and the operation table, four groups of X-Y-theta alignment units used for driving the operation table to achieve X-Y-axis horizontal movement and rotation are arranged between the bottom plate and the operation table, the four groups of X-Y-theta alignment units are distributed on the bottom plate in a rectangular shape, rotary shafts of the four groups of X-Y-theta alignment units are rotationally connected with the operation table, the CCD camera assembly and at least three groups of X-Y-theta alignment units are connected with the computer control assembly through electric signals, and the CCD camera assembly shoots materials on the operation table. The punch press system is high in alignment efficiency and accuracy and improves punching quality and punching efficiency.

Owner:SHENZHEN VILITY AUTOMATION EQUIP

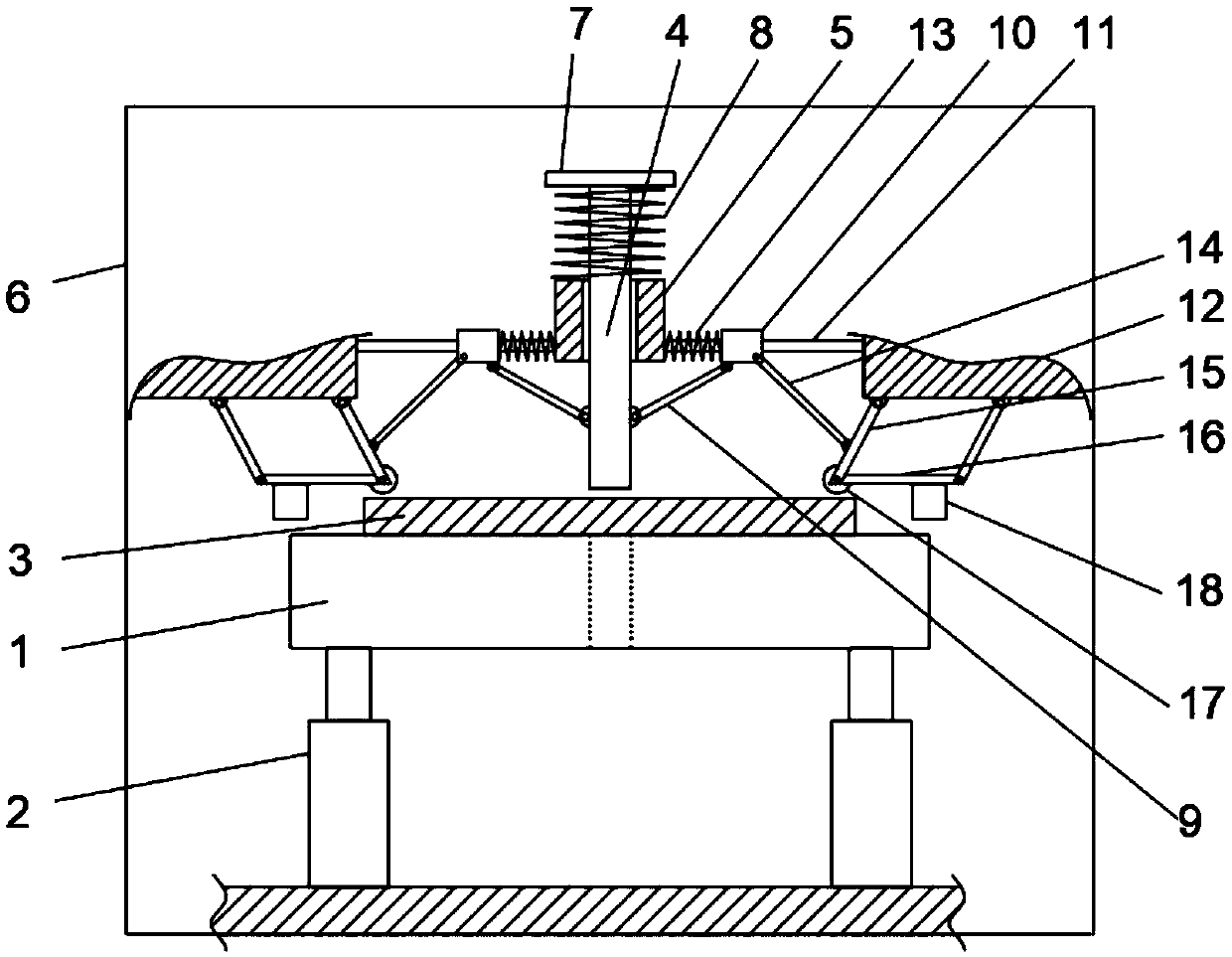

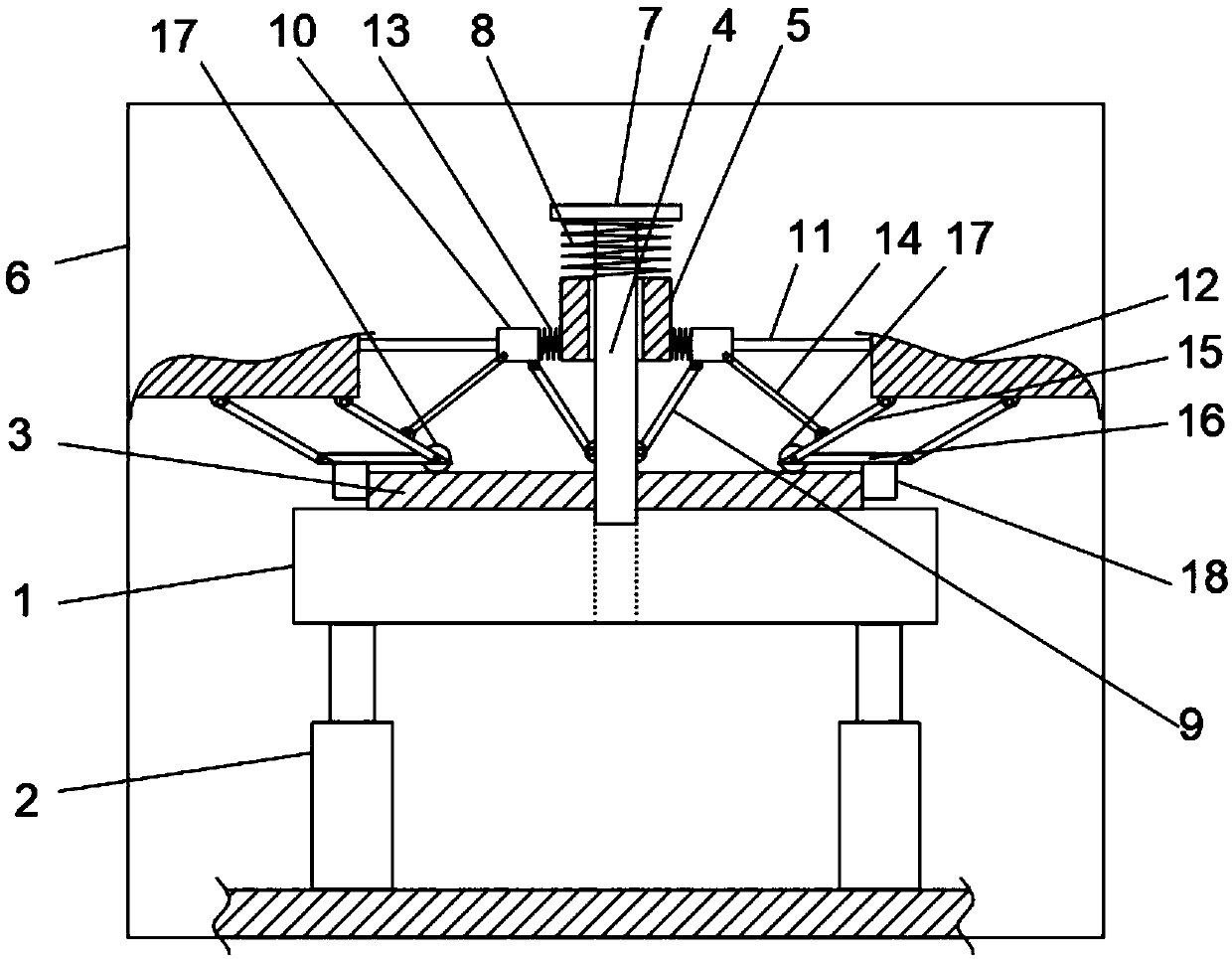

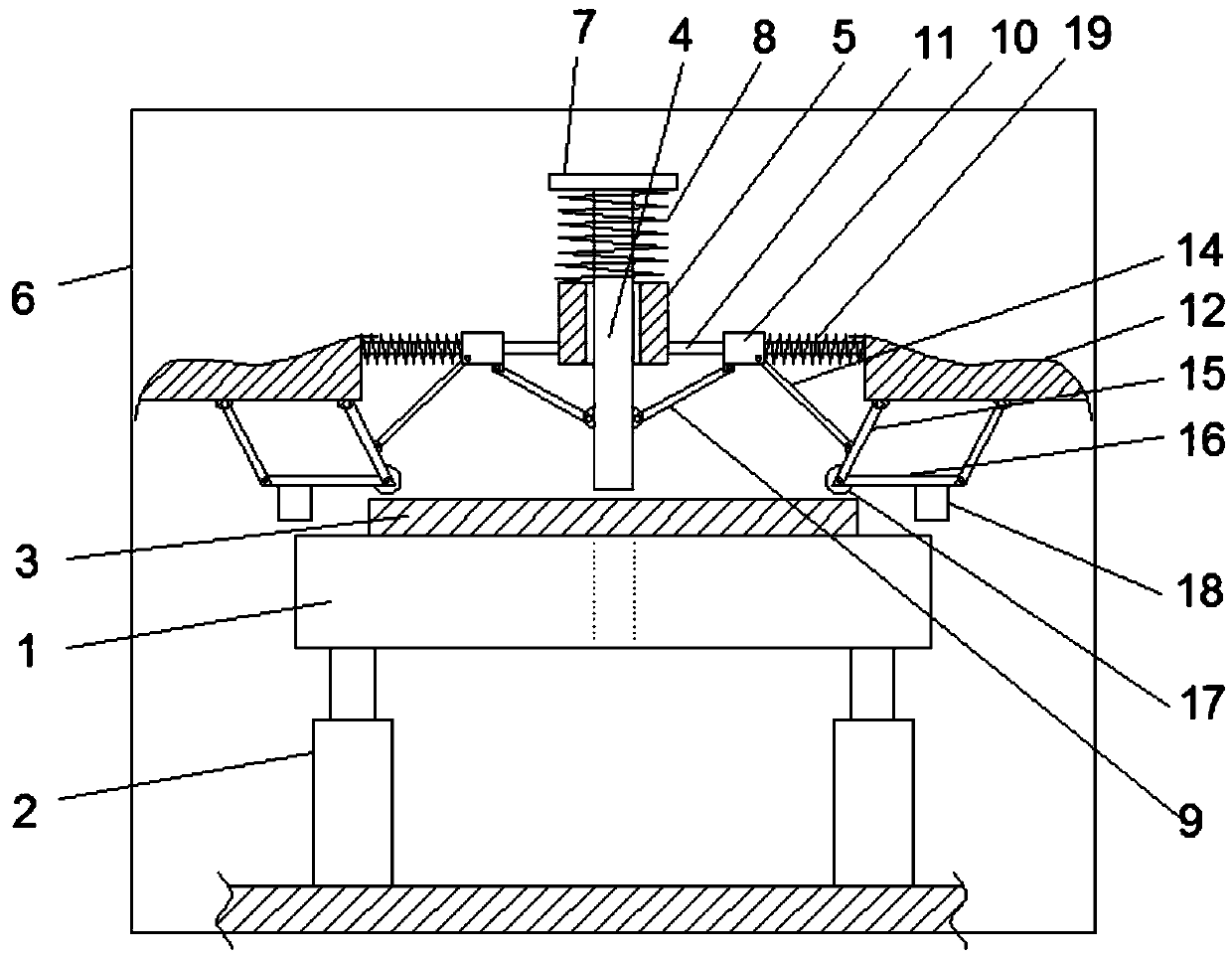

Self-pressing type hole punching device and punching method

InactiveCN108672547AIngenious and reasonable structureGuaranteed punching qualityPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a self-pressing type hole punching device and a punching method. The self-pressing type hole punching device comprises a lifting workbench for bearing a punched part, a hole punching rod for punching the punched part, a locating device for clamping and locating the punched part, and a linkage device for linking the punched part and the locating device. The hole punching rod, the locating device and the linkage device are all located above the workbench, the locating device is located at the circumferential position of the hole punching rod, and the linkage device is connected with the hole punching rod and the locating device. According to the self-pressing type hole punching device and the punching method, the hole punching rod and the locating device can achieve linkage, and hole punching efficiency is improved.

Owner:陈嘉亮

Punching and molding die and punching and molding method of workpieces

PendingCN109127876AImprove punching efficiencyAchieve integrationShaping toolsPerforating toolsPunchingEngineering

The invention discloses a punching and molding die and a punching and molding method of workpieces. The punching and molding die comprises a concave die component, a convex die component and at leastone insertion plate, wherein the concave die component comprises a plurality of concave dies embedded in a concave die fixing plate; the convex die component comprises a plurality of convex dies mounted in a convex die fixing plate; at least one convex die is a switchable convex die and is slidably mounted in a convex die switching hole; at least one insertion plate cushion is arranged at the topend of the switchable convex die; the insertion plate is inserted in an insertion groove; the insertion groove is communicated with the convex die switching hole. The punching and molding method is characterized by arranging the insertion plate which can be pulled out and inserted at the top end of at least one convex die used for punching or molding, selectively pulling and inserting the insertion plate so as to repeatedly and continuously punch or mold the workpieces. The punching and molding die and the method thereof are capable of rapidly switching, punching or molding a plurality of holes in close distance or multiple groups of irregularly-distributed and equidistant or non-equidistant combined holes on a die, so that the punching and molding efficiency can be improved.

Owner:东莞中集专用车有限公司

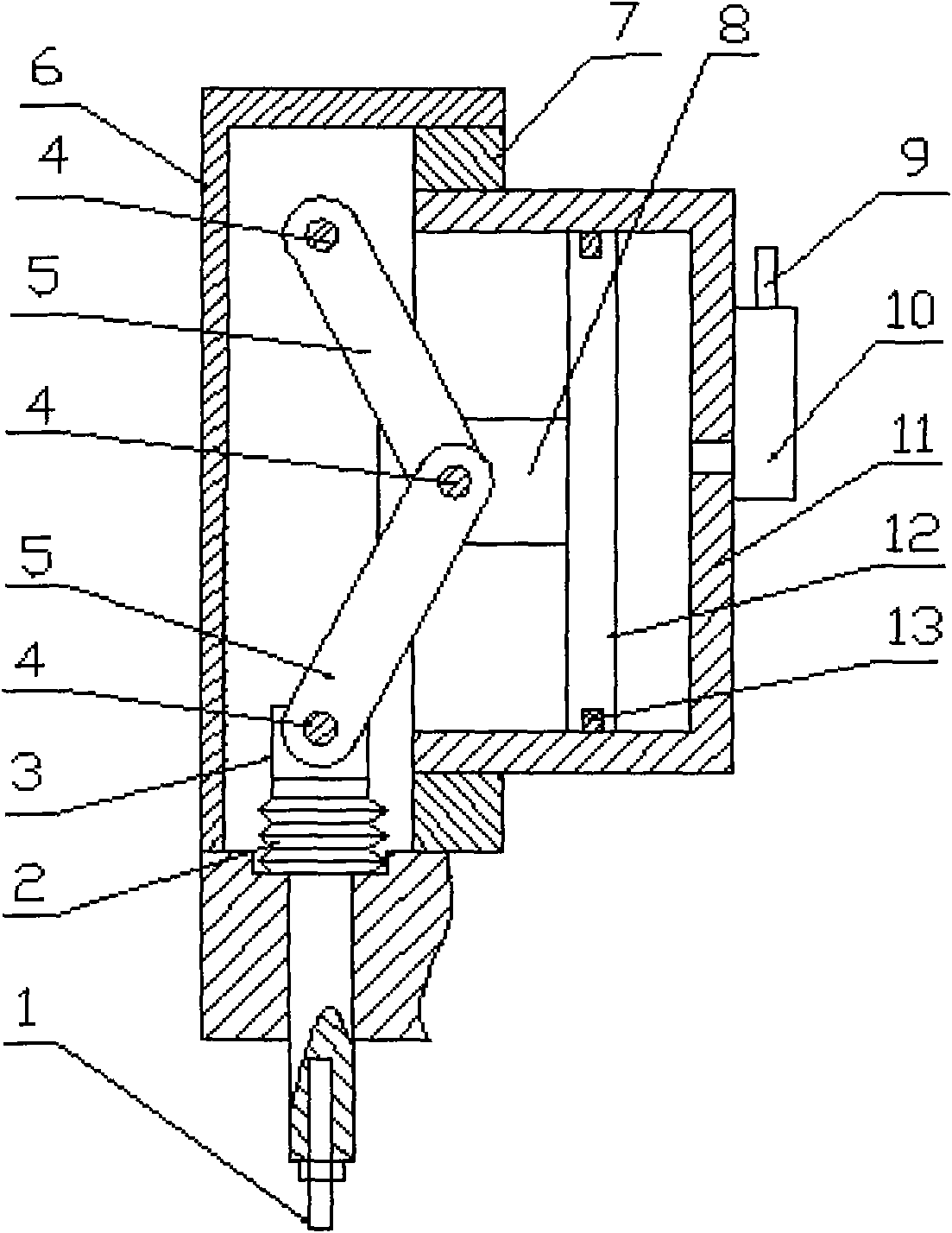

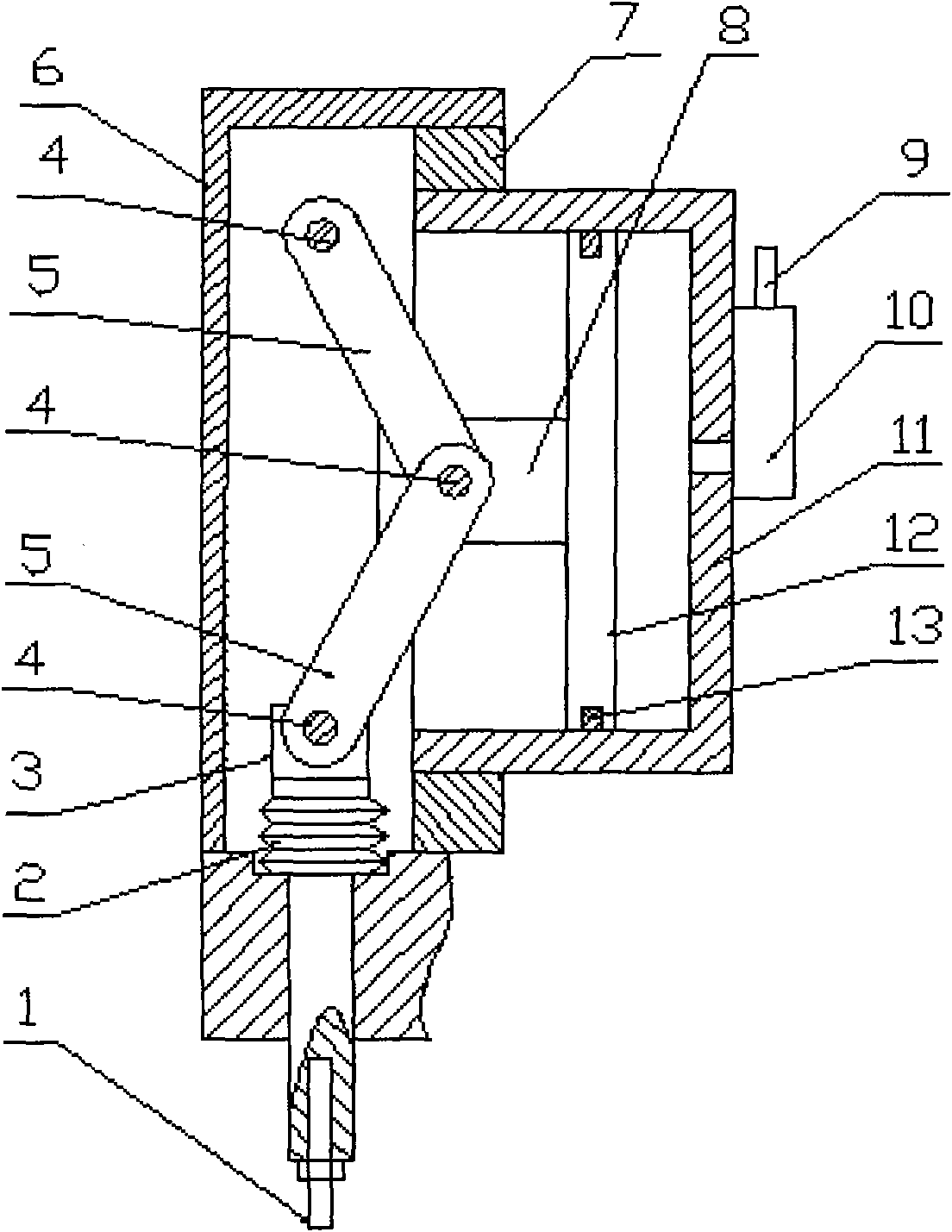

Novel pneumatic punching machine

The invention relates to a novel pneumatic punching machine. The novel pneumatic punching machine is characterized in that a punch head is exactly arranged on a bracket after adequate quantity and specifications of butterfly springs are arranged on the punch head; two sections of connecting rods are exactly articulated with the bracket and the punch head through pin shafts; a flange sleeve is arranged on the bracket; a cylinder assembly comprising a piston rod, a piston, a cylinder and a seal ring is arranged on the flange sleeve; the two sections of connecting rods are exactly articulated with the piston rod by adopting pin shafts, a rapid release valve is arranged on a cylinder body or other appropriate positions of the cylinder, an air inlet connector is arranged on the rapid release valve, and a drill bit is arranged on the punch head.

Owner:吴远东

Manufacturing device of mesh grid of lead-acid storage battery

ActiveCN102873182AGuaranteed accuracyPlay a positioning roleElectrode carriers/collectorsMesh gridEngineering

The invention provides a manufacturing device of a mesh grid of a lead-acid storage battery and achieves production of mesh grids of lead-acid storage batteries. The manufacturing device comprises a punch, a wire drawing die and a stepping feed mechanism. The wire drawing die is mounted on the punch and comprises an upper die and a lower die. The upper die comprises a die holder and a set of punching blades symmetrically arranged on two sides of the die holder. The punching blades are arranged in a step manner along the two sides of the die holder, wherein each punching blade is provided with a set of punching teeth and a correction tooth which is located at the front end of the feeding direction of the punching blade. Non-chip forming of the mesh grid is achieved, precision in size of the mesh grid is guaranteed effectively, and production efficiency of the mesh grid is improved.

Owner:BAODING GOLDEN SUNLIGHT POWER EQUIP TECH

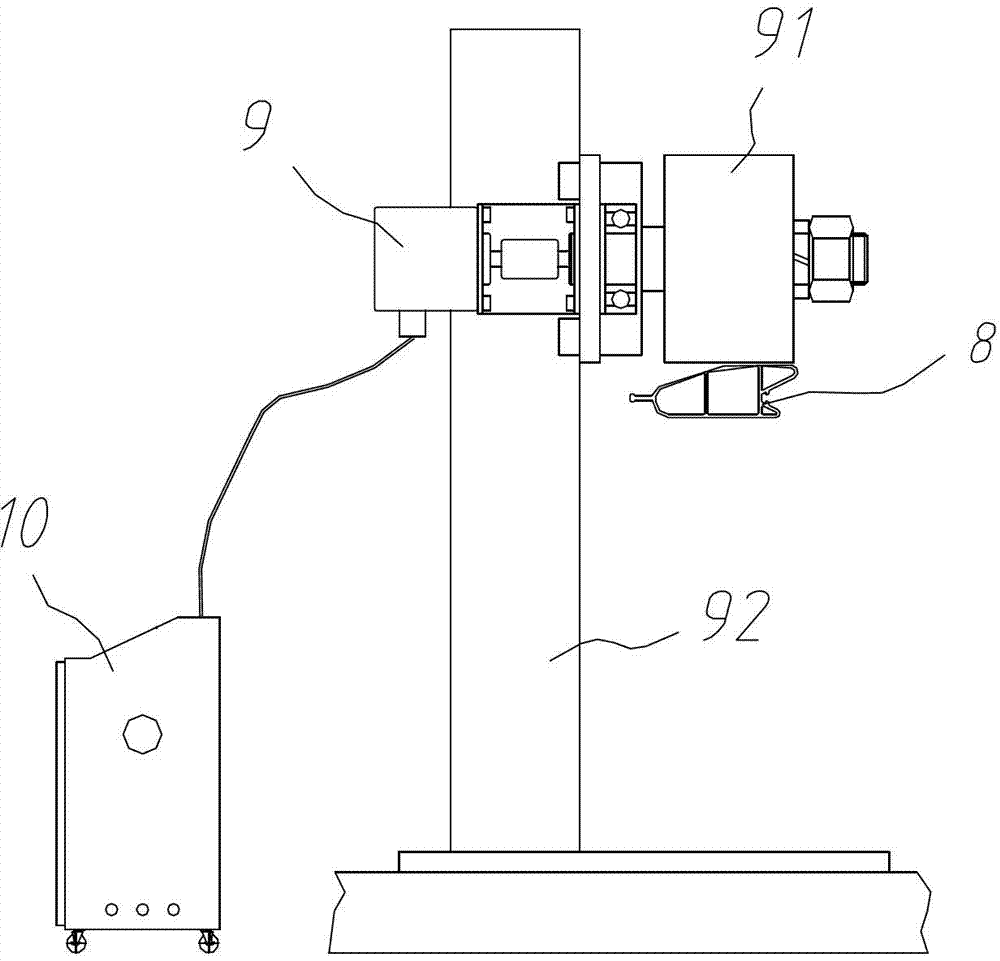

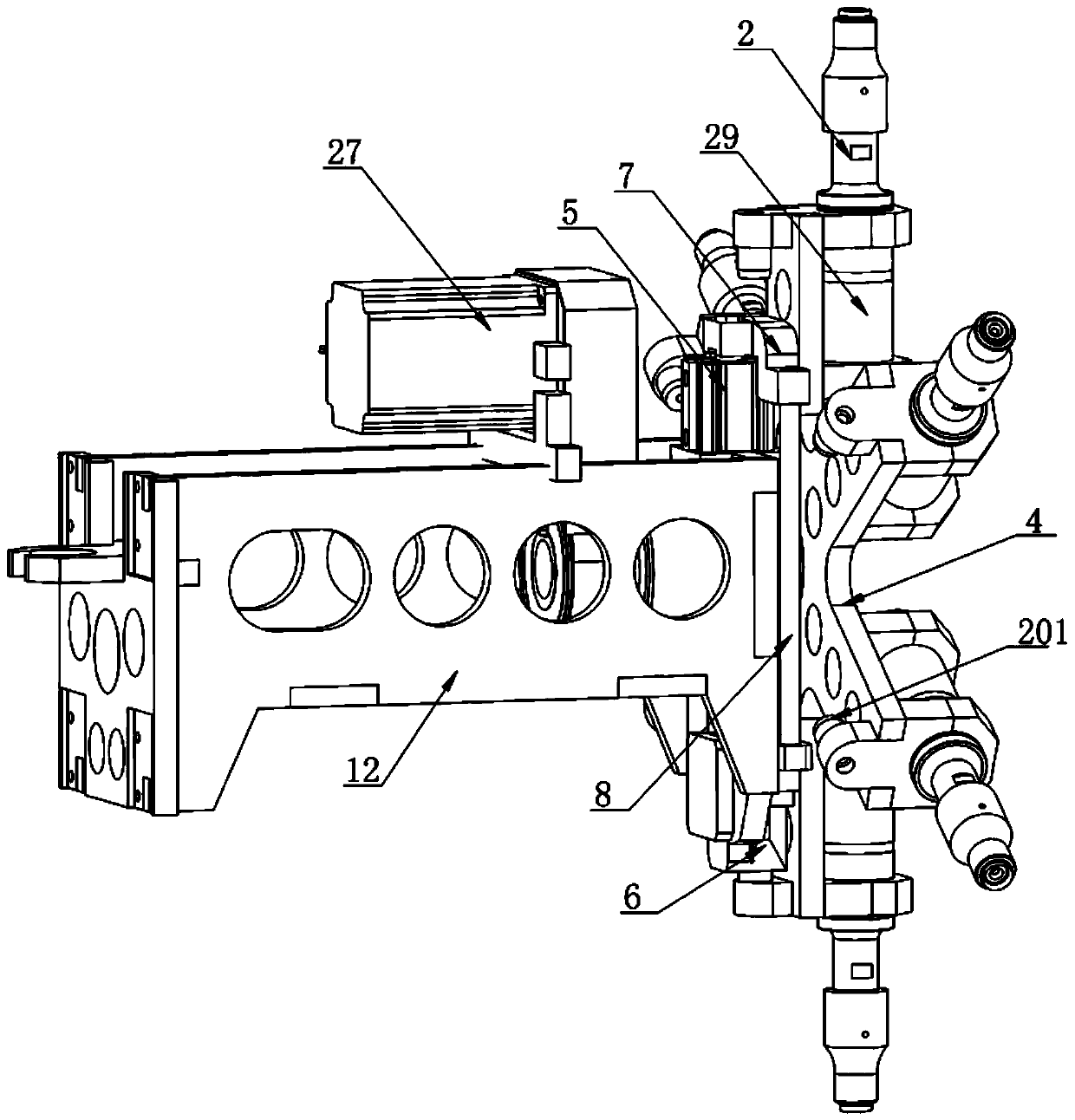

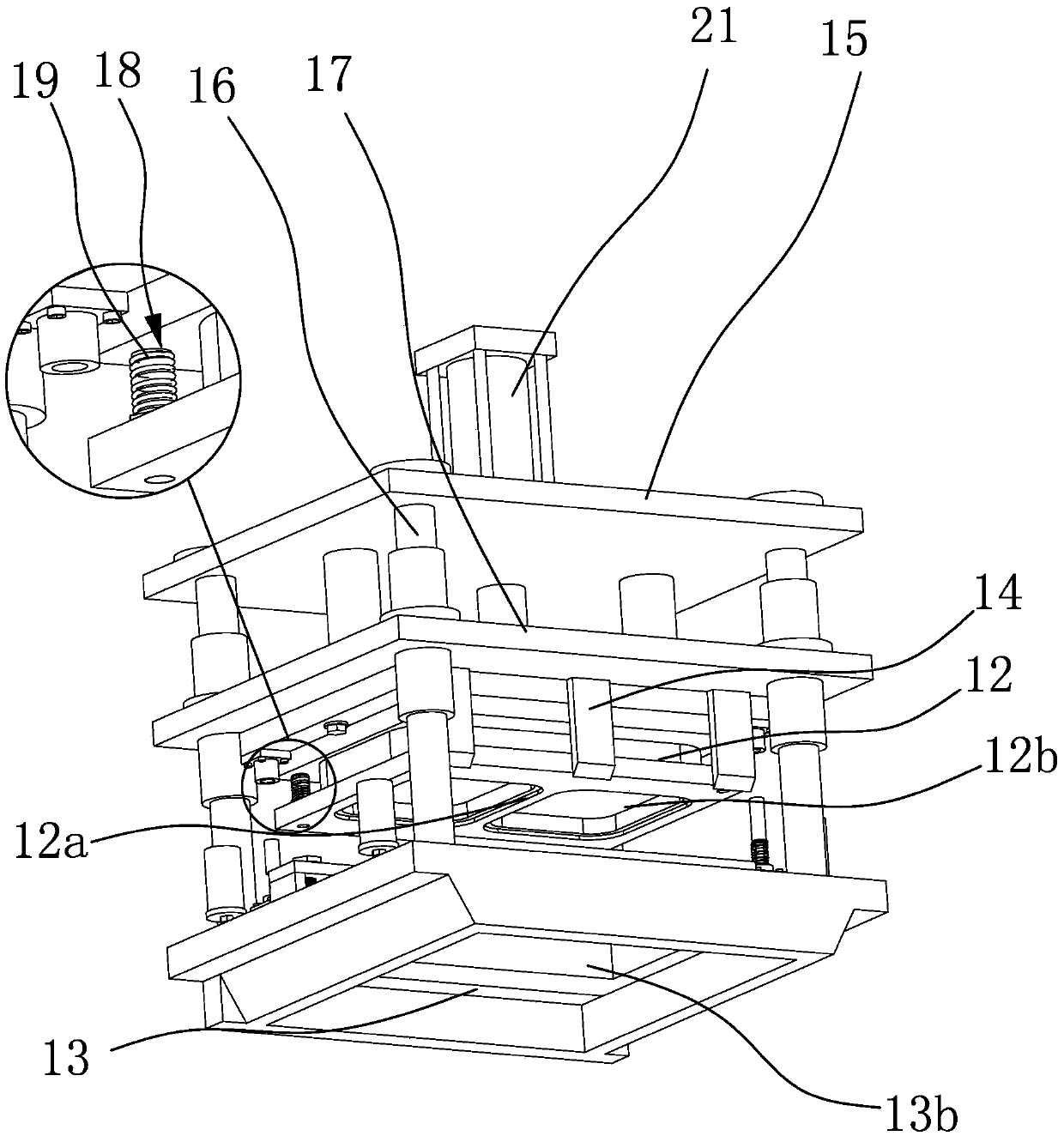

Pole piece punching mechanism and pole piece manufacturing device

ActiveCN103367698AShort strokeGuaranteed to affect punching accuracyElectrode manufacturing processesPunchingRight convex

The invention discloses a pole piece punching mechanism and a pole piece manufacturing device. The pole piece punching mechanism comprises a punching driving mechanism, an upper fixed plate, a lower fixed plate, a supporting platform, an external guide post, an upper template, a lower template, convex molds, concave molds, pressure plates and elastic parts, wherein the elastic part is arranged between the upper fixed plate and the pressure plate so as to apply downward elastic acting force to the pressure plate; the convex molds comprise a left convex mold and a right convex mold; the concave molds comprise a left concave mold and a right concave mold; the pressure plates comprise a left pressure plate, a right pressure plate and a middle pressure plate; the elastic parts comprise a left elastic part, a right elastic part and a middle elastic part. When at a mold opening state, the lower surfaces of the left and the right pressure plate are lower than those of the left and the right convex mold, and the height difference of the lower surfaces of the left and the right pressure plate and the lower surfaces of the left and the right convex mold is between 0.05mm and 0.1mm; the lower surface of the middle pressure plate is lower than the lower surfaces of the left and the right pressure plate, and the height difference of the lower surface of the middle pressure plate and the lower surfaces of the left and the right pressure plate is smaller than 1mm. The pole piece punching mechanism has the advantages of high punching efficiency, high precision and little burring.

Owner:SHENZHEN YINGHE TECH

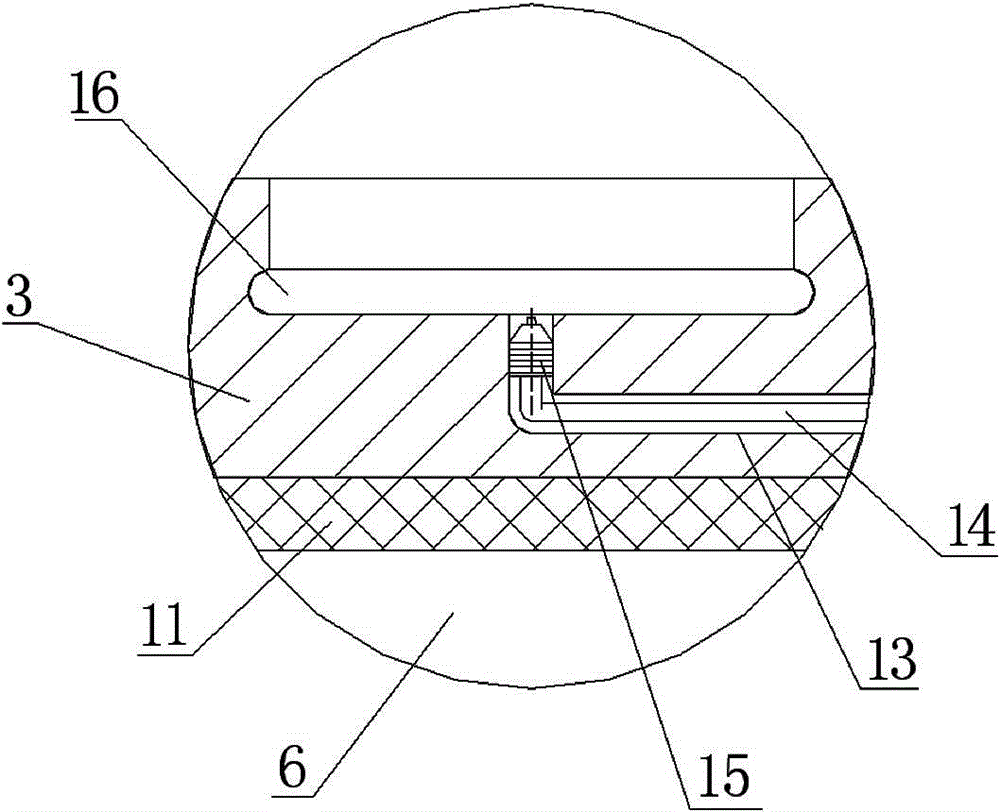

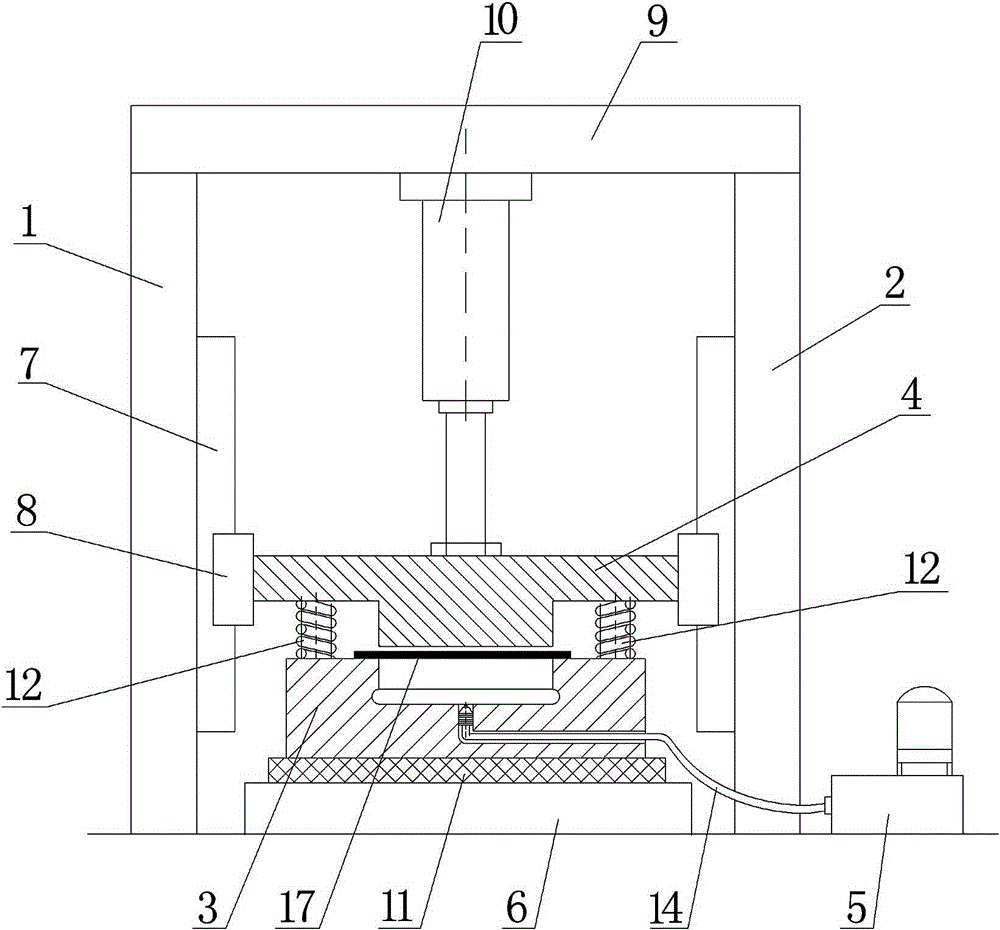

Novel punching die for easy-to-tear films on polypropylene infusion bags

ActiveCN105171844ACompact structureHigh punching precisionMetal working apparatusPunchingPolypropylene

The invention discloses a novel punching die for easy-to-tear films on polypropylene infusion bags. The punching die comprises a vertical column I (1), a vertical column II (2), a female die (3), a male die (4), a constant-pressure air source (5), and a workbench (6) arranged between the vertical column I (1) and the vertical column II (2). An air cylinder (10) is fixedly installed on the bottom surface of a supporting beam (9). The action end of a piston rod of the air cylinder (10) is provided with the male die (4). The left end and the right end of the male die (4) are fixed to two sliding blocks (8) respectively. An air inflow pipe (14) and an air nozzle (15) are arranged in an L-shaped channel (13). One end of the air inflow pipe (14) is connected with the air nozzle (15). The other end of the air inflow pipe (14) is connected with the output end of the constant-pressure air source (5). An annular groove (16) for collecting powdered scraps of the easy-to-tear films is formed in the inner wall of a groove of the female die (3). The punching die has the beneficial effects that punching accuracy is high, safety and reliability are achieved, the easy-to-tear films are convenient to take out, and punching efficiency is improved.

Owner:SICHUAN KELUN PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com