Continuous punching device for linear pipes

A technology for punching devices and pipes, applied in the direction of feeding devices, storage devices, positioning devices, etc., can solve the problems of low punching efficiency, complex structure, and inability to realize continuous punching, and achieve the effect of improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

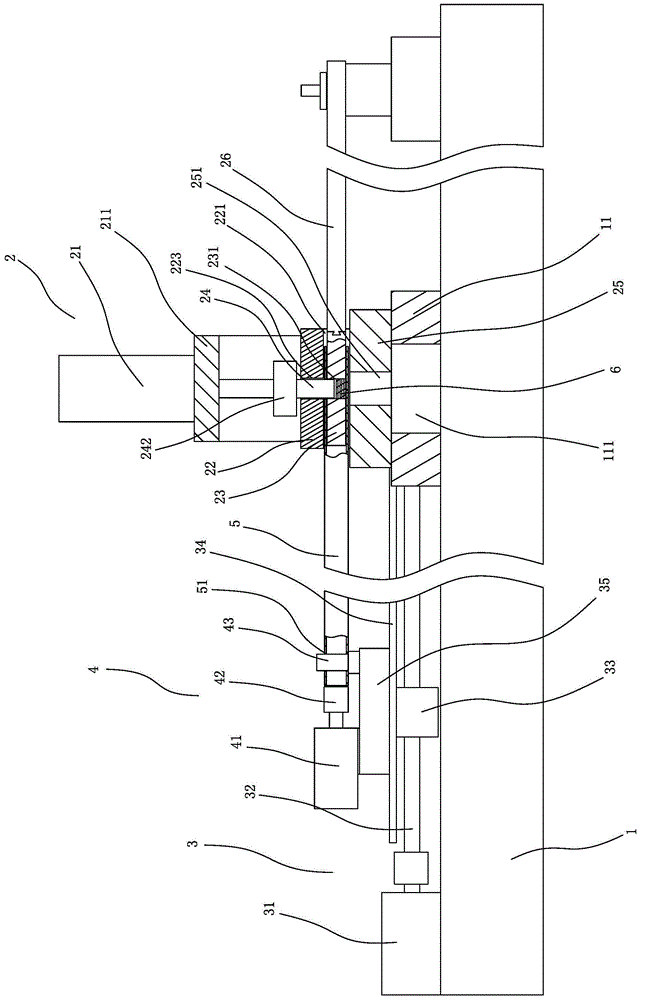

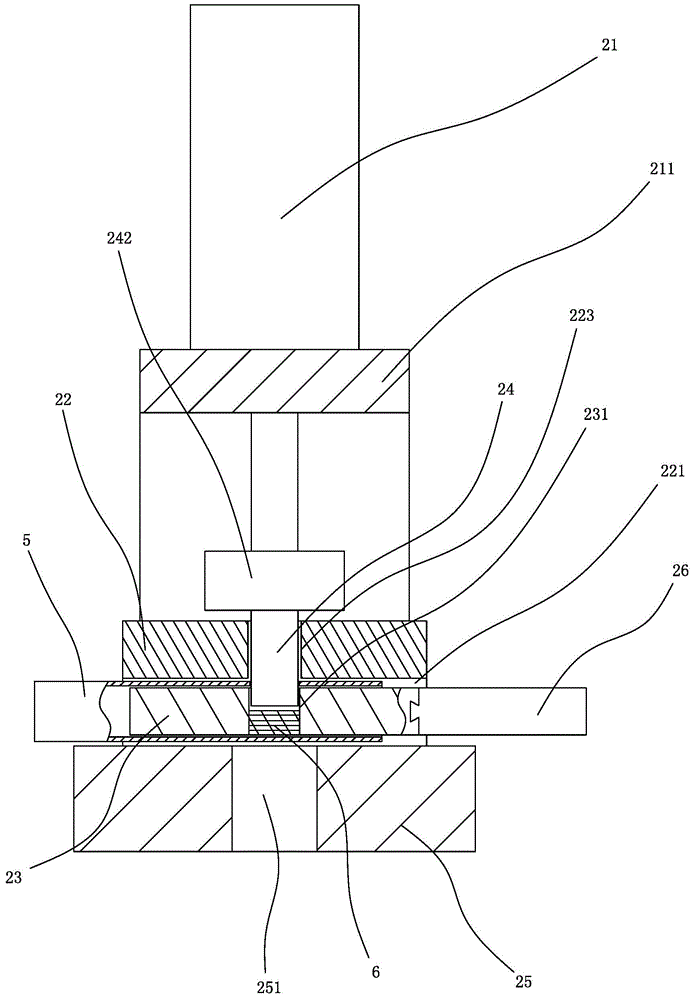

[0020] refer to figure 1 , figure 2 with image 3 As shown, taking a straight pipe with a rectangular cross section as an example, a continuous punching device for a straight pipe includes a base 1, a punching mechanism 2, a sliding seat 35, a lateral movement mechanism 3, a clamping mechanism 4 and a control device, the base 1 is provided with a plurality of punching mechanisms 2 arranged longitudinally at intervals, and the corresponding sliding seat 35 is provided with a plurality of clamping mechanisms 4 arranged longitudinally at intervals. Clamp mechanism 4 is connected, is used for controlling each mechanism to coordinate work.

[0021] The punching mechanism 2 is arranged in the middle of the base 1, including a mold base, a mandrel 23 and a punching mechanism. A through hole 221 extending transversely is formed on the side of the mold base, and a first punching hole 223 communicating with the through hole 221 is formed on the top surface. , the bottom surface is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com