Device and method for adjusting roller type punching distance

A technology of adjusting roller and punching, which is applied in the field of plastic processing, can solve the problems of offset of punching position and inaccurate control of plate transfer position, so as to reduce the cost of mold manufacturing, increase product diversification, and realize the effect of automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

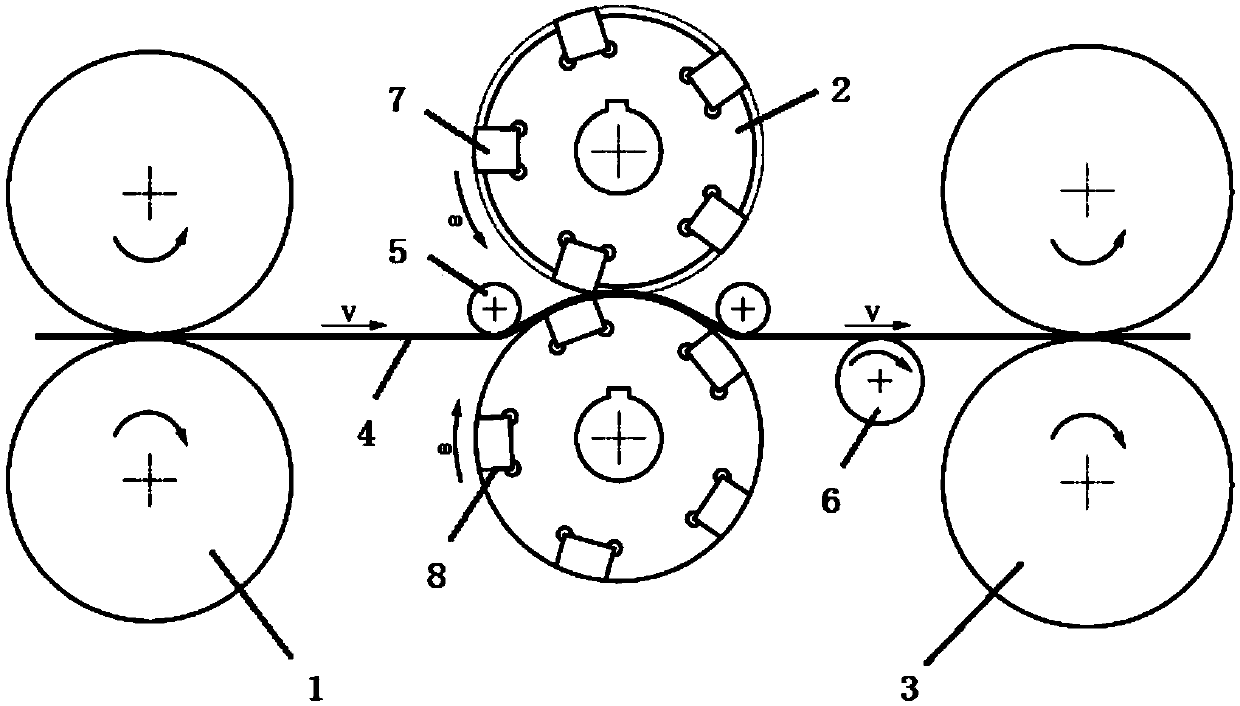

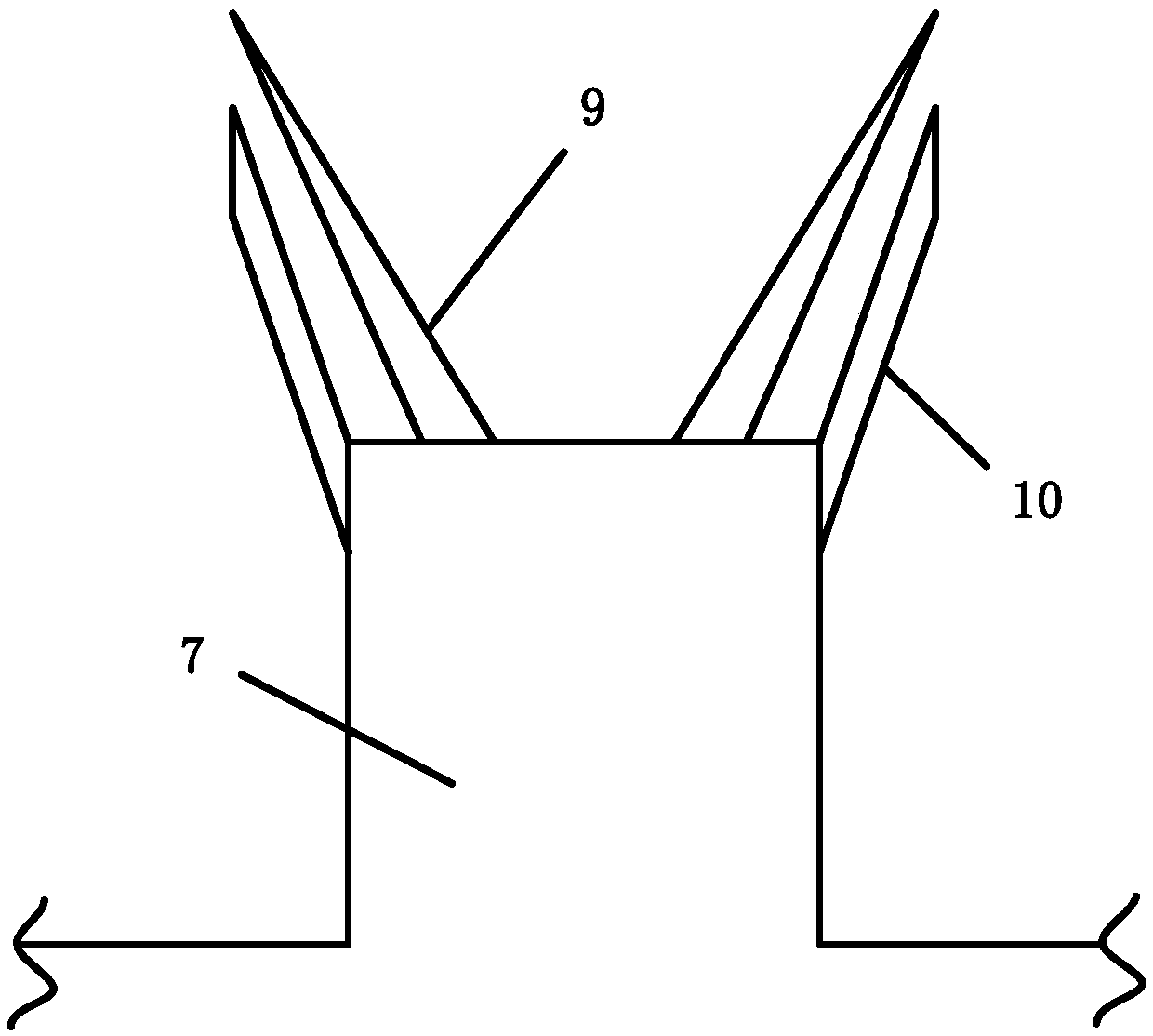

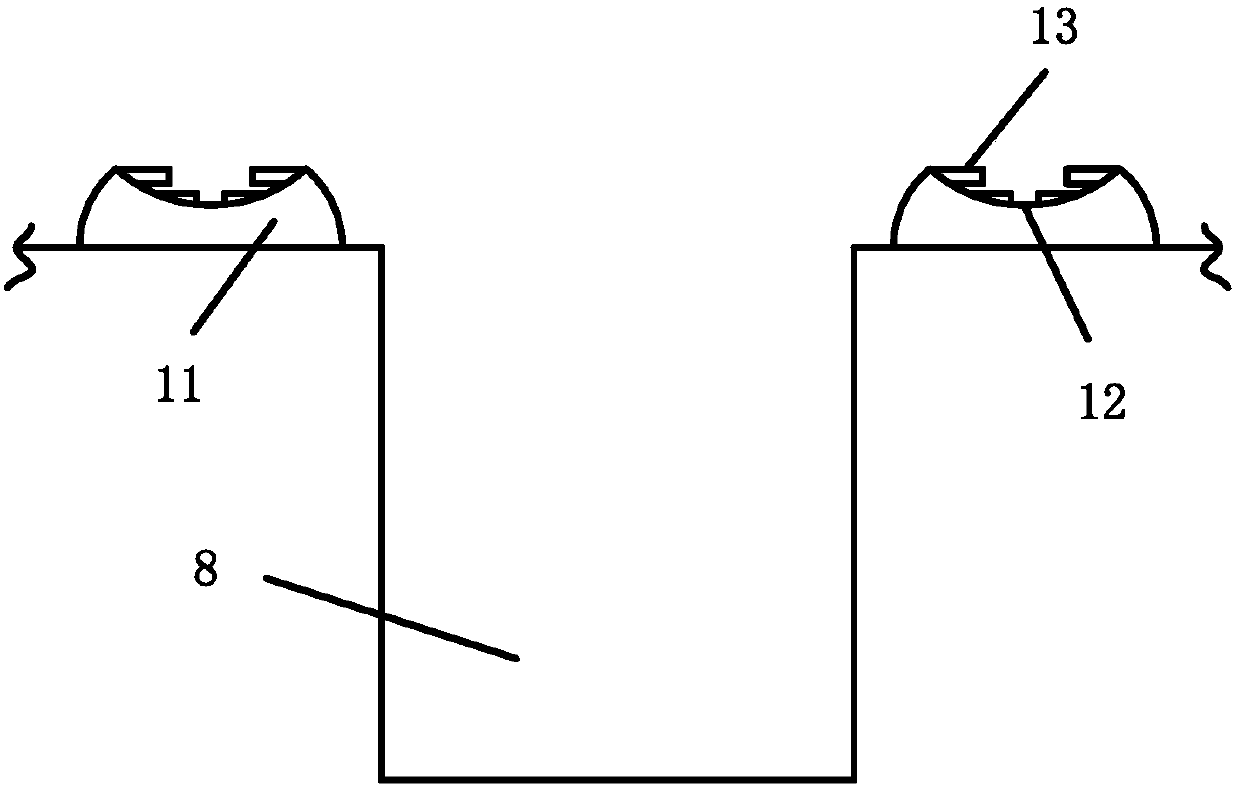

[0027] refer to Figure 1-5 A specific embodiment of the present invention includes two guide rollers 1 that are crimped up and down, two punching rollers 2 that are crimped up and down, two correction rollers 3 that are crimped up and down, and the sheet material 4 passes through the guide rollers in turn. Material pressure roller 1, punching pressure roller 2 and correction pressure roller 3, pressure roller 5 is arranged on both sides of punching pressure roller 2, and speed measuring roller 6 is arranged between punching pressure roller 2 and correction pressure roller 3; The surface of the punching roller 2 positioned above is evenly provided with a punch 7, the surface of the punching roller 2 positioned below is provided with a die 8 corresponding to the punch 7 one by one, and the top of the punch 7 is provided with a cutting strip 9, which is cut The outer edge of the strip 9 is fixed with a rubber outer edge 10, the cutting strip 9 and the rubber outer edge 10 are sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com