Laser processing method of vortex light beam

A laser processing method and vortex beam technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of poor cutting section quality and low processing efficiency, achieve good section quality, low cost, and improve flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

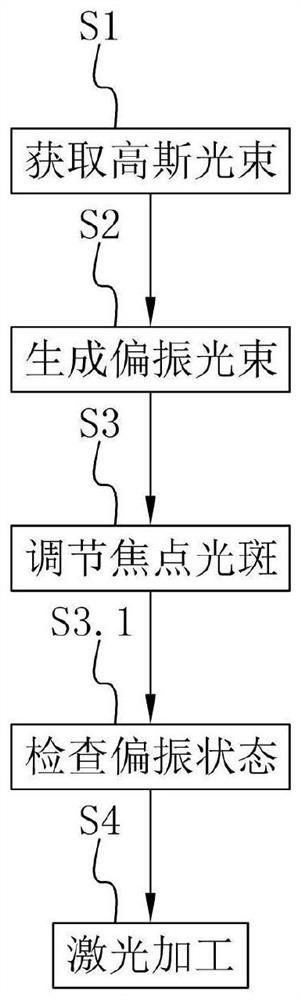

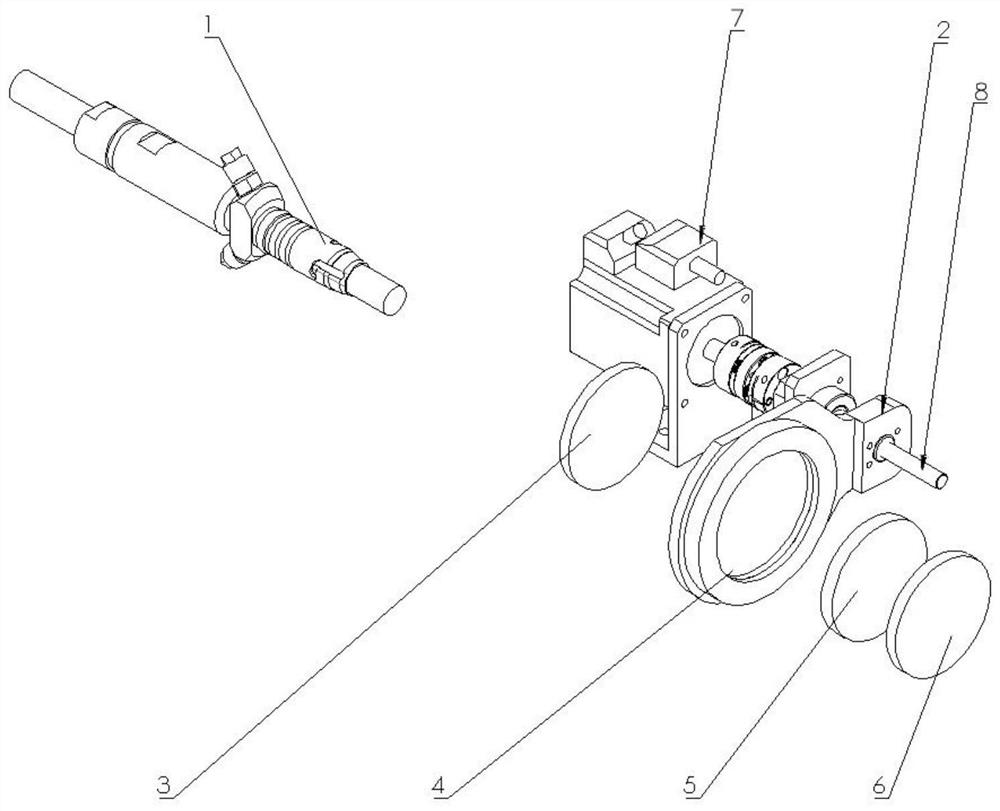

[0056] refer to figure 1 and figure 2 , a laser processing method of a vortex beam, using a laser processing equipment, the laser processing equipment includes a light source element 1, a collimating mirror element 3, a vortex phase plate 4, an axicon mirror 5, a Fourier lens 6 and a control components. The light source element 1 is a light source fiber, and the light source element 1 is used for emitting a Gaussian beam. The light source element 1 , the collimating mirror element 3 , the vortex phase plate 4 , the axicon 5 and the Fourier lens 6 are arranged in sequence along the beam propagation direction. The control assembly includes a motor 7, a lead screw 8 and a mounting seat 2. The output shaft of the motor 7 is fixedly connected to the lead screw 8. The mounting seat 2 is threadedly connected to the lead screw 8 and is used to install the scroll phase plate 4. The mounting seat 2 is connected to the motor 7. Relative translation, so that the motor 7 can drive the ...

Embodiment 2

[0087] A laser processing method of a vortex beam adopts a laser processing equipment, the laser processing equipment comprises a light source element, a collimating mirror element, a vortex phase plate, an axicon mirror, a Fourier lens and a control assembly, and the light source element is used for The Gaussian beam is emitted, the light source element, the collimating mirror element, the vortex phase plate, the axicon mirror and the Fourier lens are arranged in sequence along the beam propagation direction, and the control component is connected with the vortex phase plate and is used to control the passing through the vortex phase plate. the polarization vector of the beam;

[0088] The laser processing method of vortex light speed includes the following steps:

[0089] S1. Obtain a Gaussian beam: the light source element emits a Gaussian beam, and the Gaussian beam passes through the collimator element and then irradiates the vortex phase plate.

[0090] S2. Generate a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com