Patents

Literature

106results about "Wood punching out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

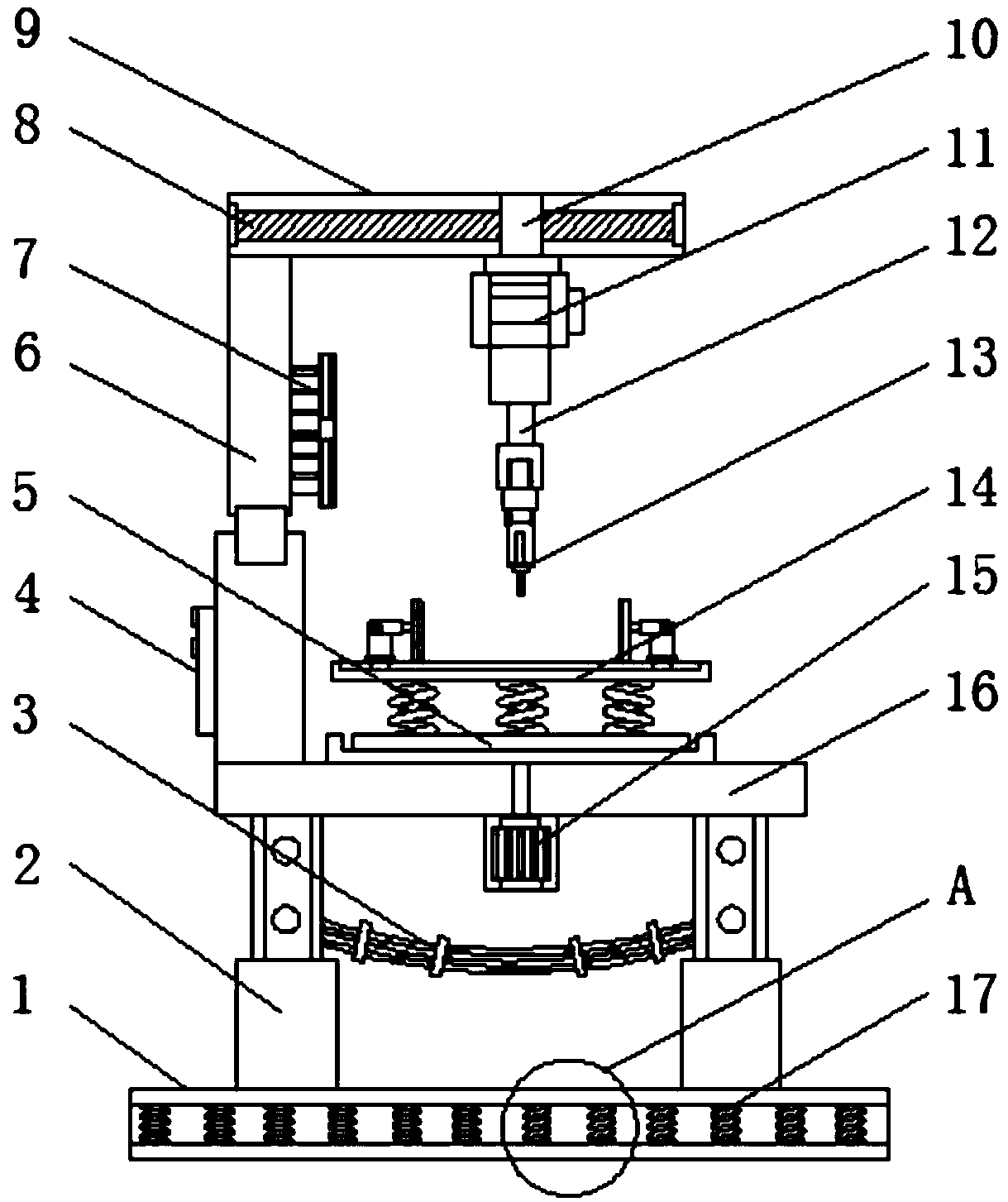

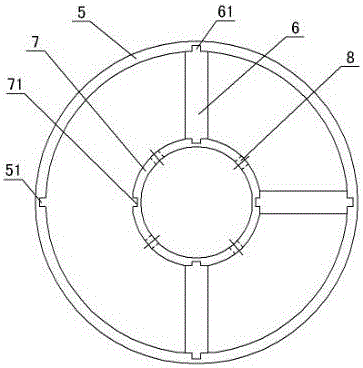

Multi-station door plate punching machine

PendingCN110935785APrevent rotationImprove reliabilityShaping toolsPerforating toolsPunchingGear wheel

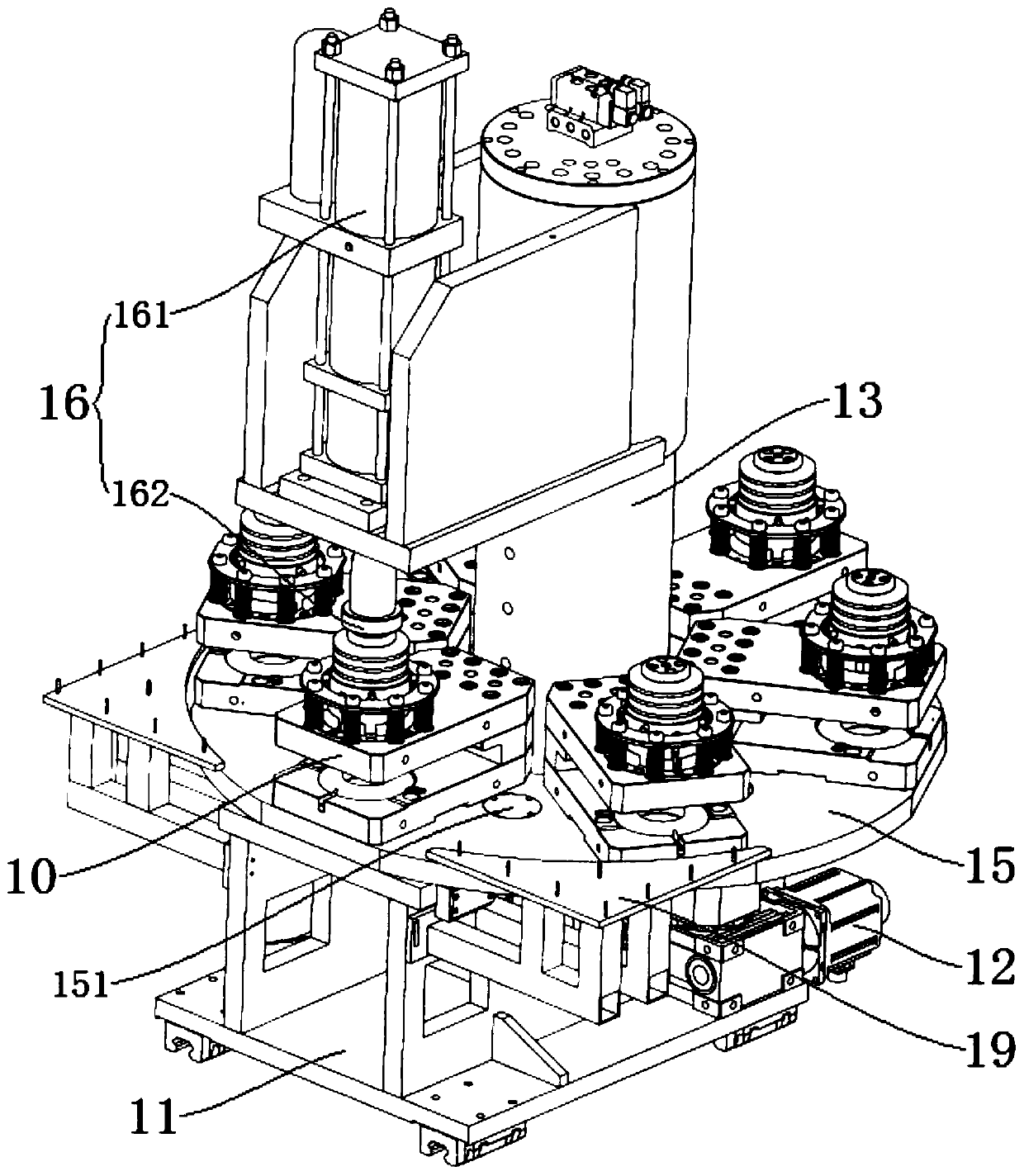

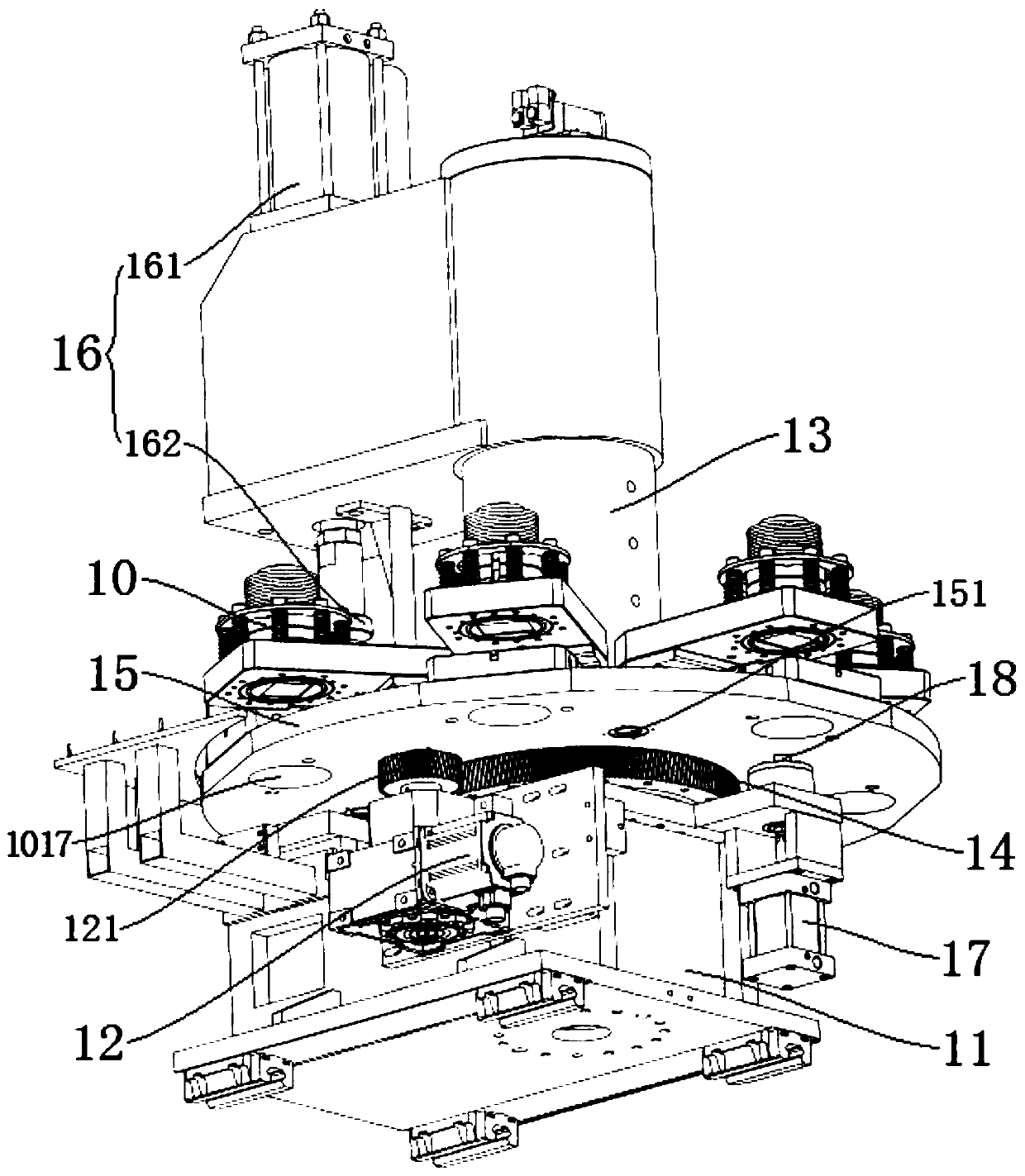

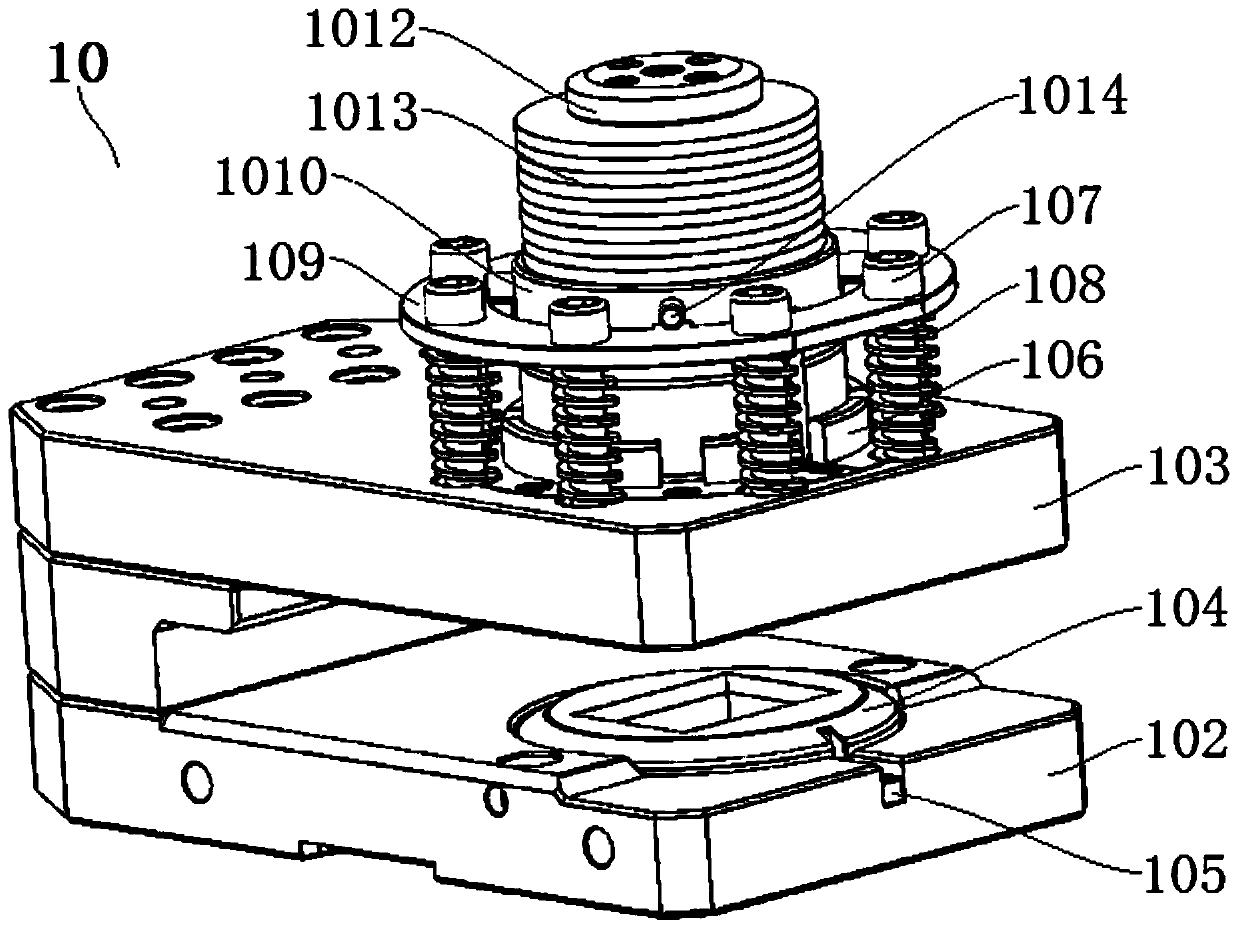

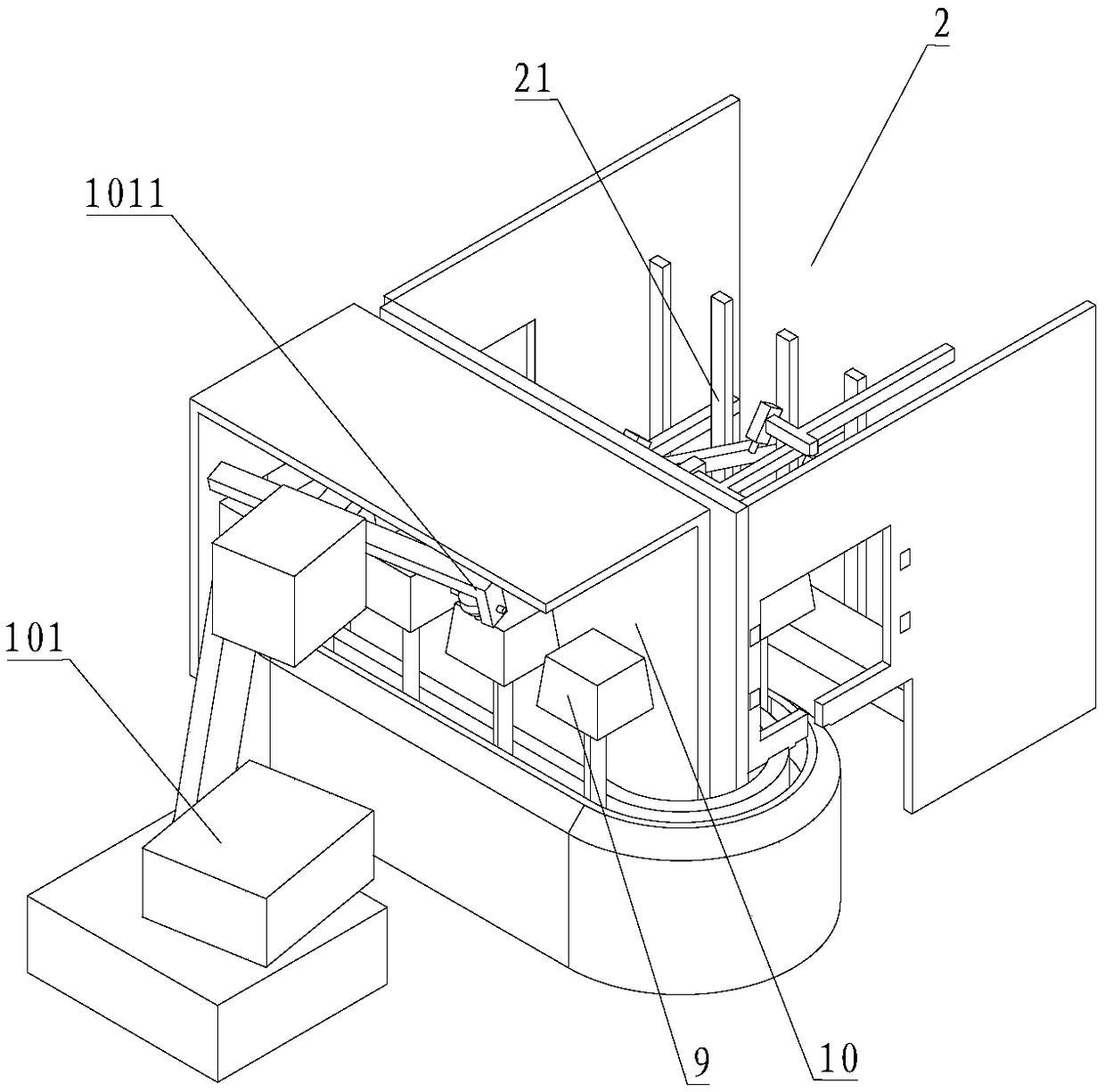

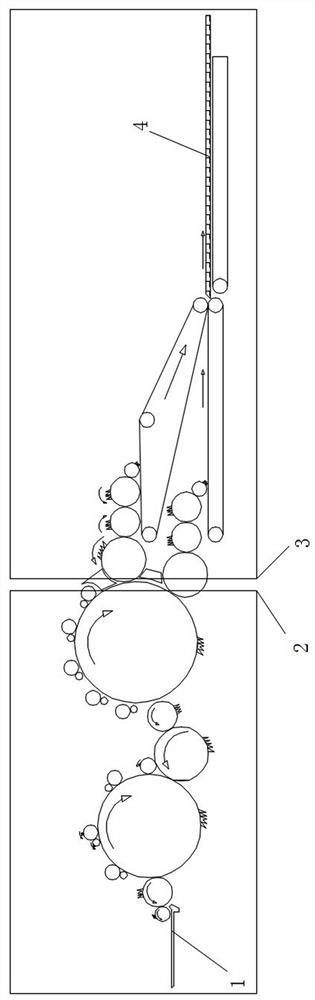

The invention relates to a multi-station door plate punching machine. A pedestal is included. The punching machine is characterized in that the machine includes a supporting column whose lower end portion is fixedly connected with the pedestal, a bearing gear cooperated with a middle portion of the supporting column, an annular rotation disc which is fixedly connected to the bearing gear and is coaxial with the supporting column, and a stamping component fixedly connected to an upper end portion of the supporting column; the door plate punching machine further includes a driving motor fixed tothe pedestal; an output end of the driving motor is fixedly connected with a driving gear, and the driving gear is meshed with the bearing gear; a plurality of door plate punching dies are fixed to the rotation disc; and the stamping component is located above the door plate punching dies and corresponds to the door plate punching dies. The door plate punching dies can be selected according to different requirements, and punching precision, punching efficiency and working reliability can be improved. A door plate can be prevented from being damaged, and integrity of the door plate is guaranteed. Machining and manufacturing are convenient, parts are convenient to install and replace, a service life is long, and cost is low.

Owner:CHONGQING MEXIN MESSON DOORS IND CO LTD

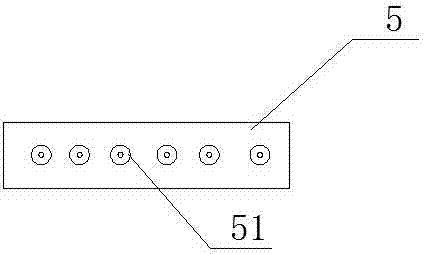

Panel punching device

The invention provides a panel punching device which comprises a worktable and an installation plate, wherein a fixed plate is vertically and upwardly arranged on the worktable, positioning plates are arranged on two sides and opposite side of the worktable connected with the fixed plate, the positioning plates which are made of a lead material are hinged to the worktable, the width of the positioning plates is smaller than the minimum distance from a positioning hole to the edge of each positioning plate, a supporting plate is vertically arranged on the inner side of each fixed plate, an air cylinder is arranged on the supporting plate, the piston rod of the air cylinder passes through the supporting plate and is connected with the installation plate, a plurality of equidistant positioning seats are installed on the installation plate, a punching head is arranged on each positioning seat, a plurality of equidistant positioning holes are formed in one side of the worktable, the positioning holes correspond to the positioning seat, a first storage slot and a second storage slot are arranged in the side wall of the worktable, and the first storage slot is communicated with the positioning holes. According to the device provided by the invention, the installation plate is driven by the air cylinder to move downward to punch the panel, so that the way of previous manual operation is changed. Moreover, the panel needs not to be fixed manually, so that the device is time-saving and labor-saving and high in work efficiency.

Owner:GUANGXI UNIV

Part punching device

InactiveCN108176756AAvoid damage and deformationAvoid scrappingMetal-working feeding devicesMetal working apparatusPunchingTransverse plane

The invention relates to the technical field of machining, and specifically discloses a part punching device. The part punching device comprises a rack and a punching platform, wherein the punching platform is used for bearing a workpiece; the rack is fixedly provided with a telescopic air cylinder; the telescopic air cylinder is internally connected with a first piston in a sliding way; the firstpiston is fixedly connected with a first piston rod; the first piston rod is fixedly connected with a transverse plate; the transverse plate is fixedly connected with a vertical rod and two oblique rods; a vertical central line of the vertical rod is coincided with a vertical central line of the transverse plate; the vertical rod is in threaded connection with a punching tool bit; the two obliquerods are symmetrically arranged along the vertical central line of the transverse plate; each oblique rod is sleeved with a sliding block; the sliding blocks are connected to the rack in the slidingway; grooves are formed in the sliding blocks; the grooves are internally connected with sliding plates in the sliding way; one side of each sliding plate is fixedly connected with a transverse rod, and a spring is fixedly connected between the other side of the sliding plate and the bottom wall of the corresponding groove; the transverse rods are in threaded connection with clamping pieces for clamping the workpiece. The part punching device disclosed by the invention is capable of realizing the punching on parts in different sizes, and an application range of the part punching device is increased.

Owner:重庆市璧山区合成机械制造有限公司

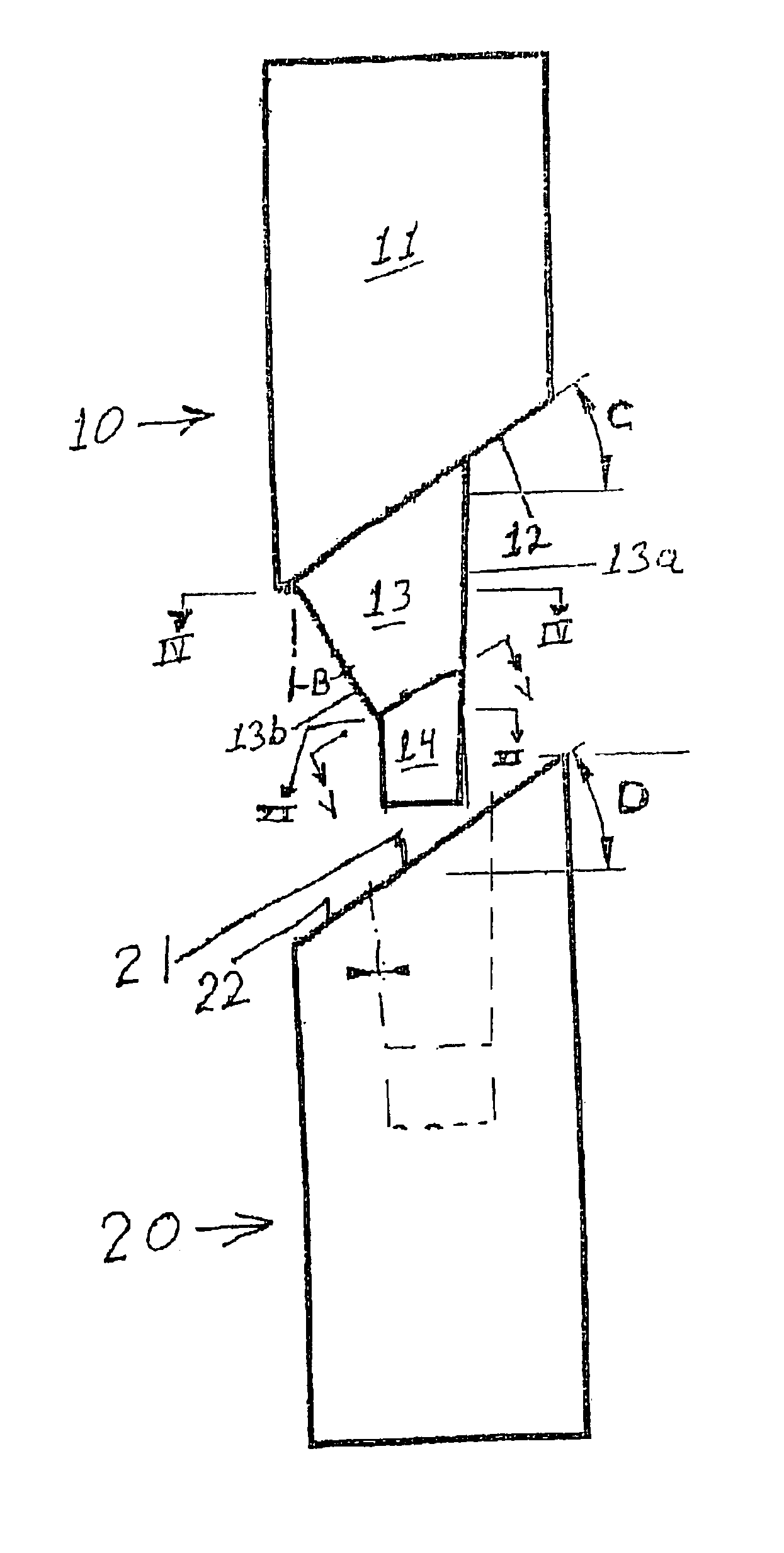

Machine for manufacturing frame of a fan

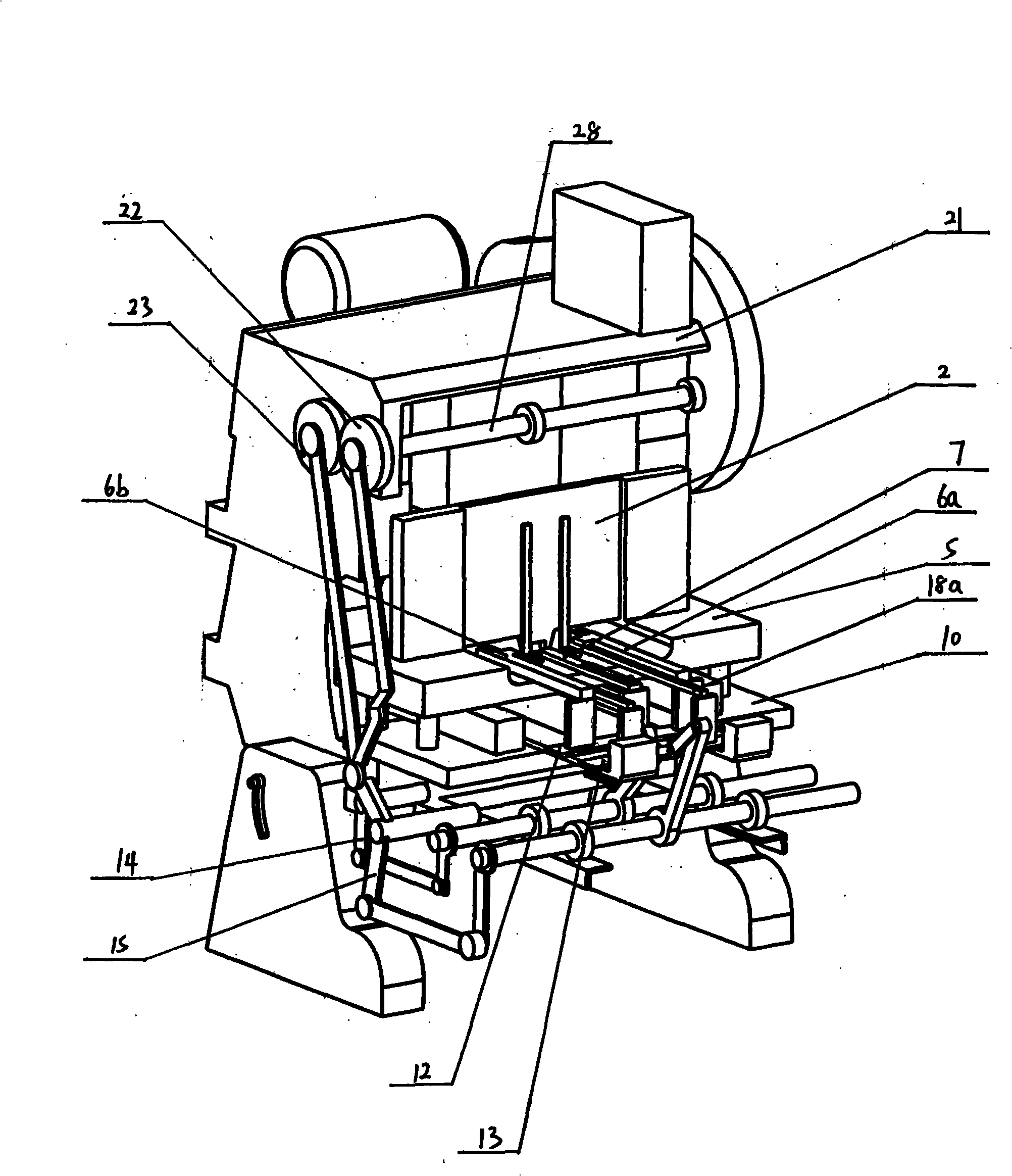

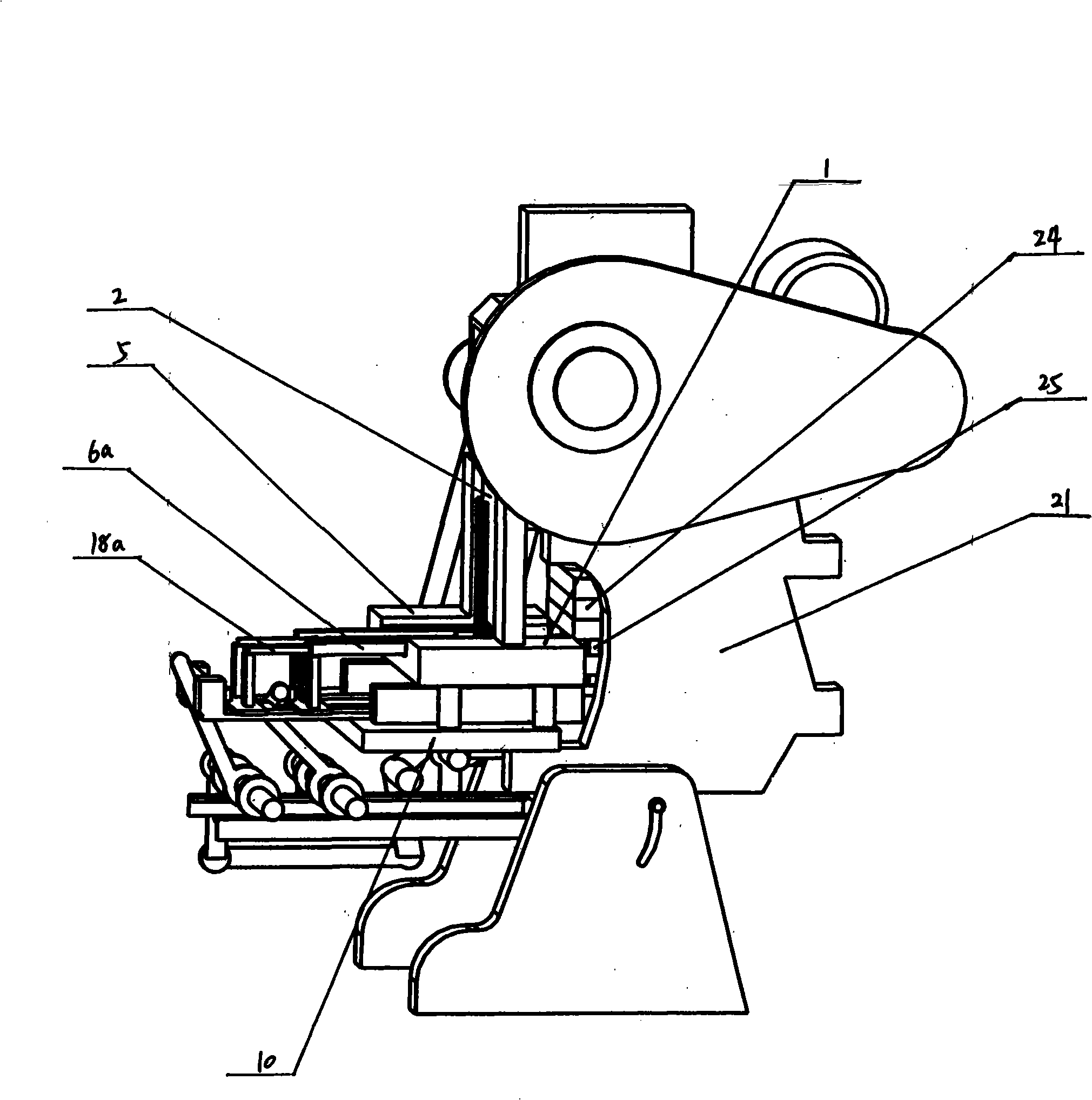

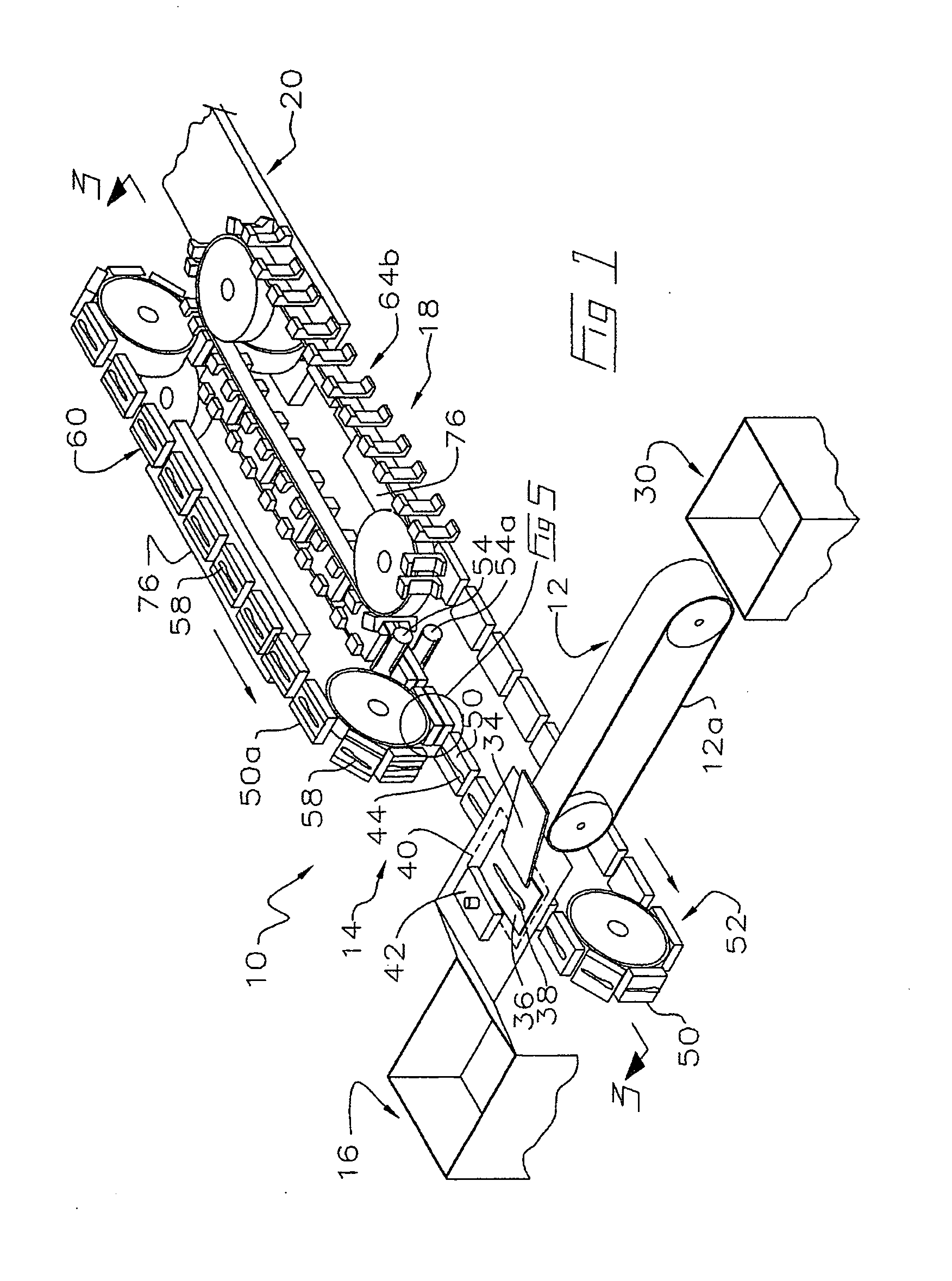

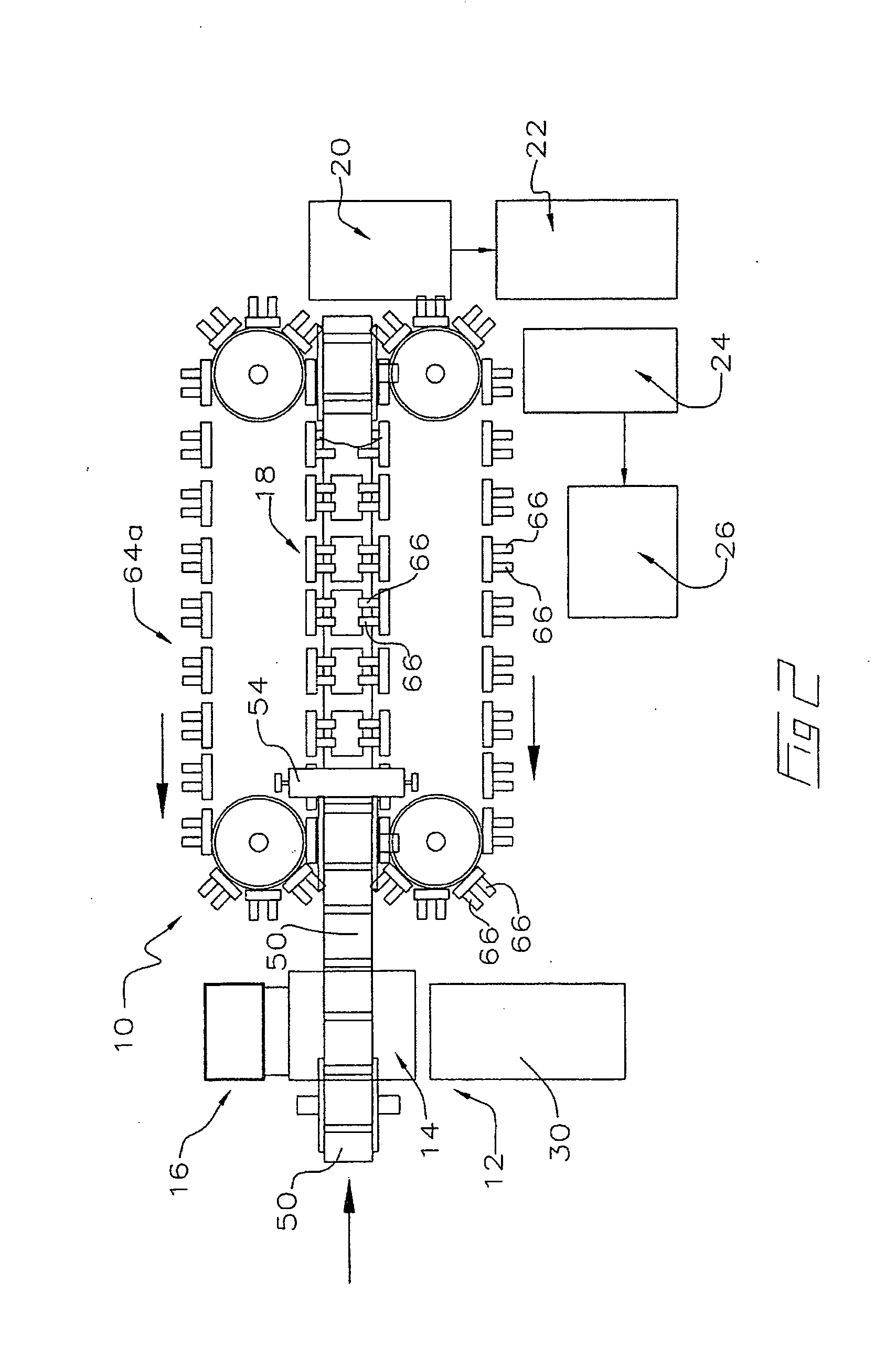

InactiveCN101342717APostural stability and balancePrecise positioningWood compressionWood punching outPunchingEngineering

A fan framework making machine comprises a punch, a machine frame and a base plate which is equipped with a bamboo slice transfer passage; the bamboo slice transfer passage is connected with the punching station of the punch; the punching station is equipped with a female die and a male die, which are used for making fan framework; a slicing mechanism, an intermediate positioning mechanism and a second-grade delivery mechanism are arranged in the bamboo slice transfer passage in turn; the slicing mechanism comprises a storage groove which is arranged above the transfer passage and used for piling bamboo slices; the position of the transfer passage which is over against the opening on the bottom of the storage groove is a slice-falling area; the middle part of the slice-falling area is provided with a first air entry and both sides of the slice-falling area are equipped with side fork which could slide long the bamboo slice transfer passage; the top of the side fork is equipped with a second air entry which is arranged higher than the first air entry; the first air entry and the second air entry are both connected with a negative supply; clearances for the bamboo slices to pass are arranged between the bottom of the storage groove, the bamboo slice transfer passage and the upper surface of the side fork; a central fork which could slide along the bamboo transfer passage aims at the center of the slice-falling area and the central fork and the side fork are both connected with a first reciprocal pushing mechanism.

Owner:夏月明

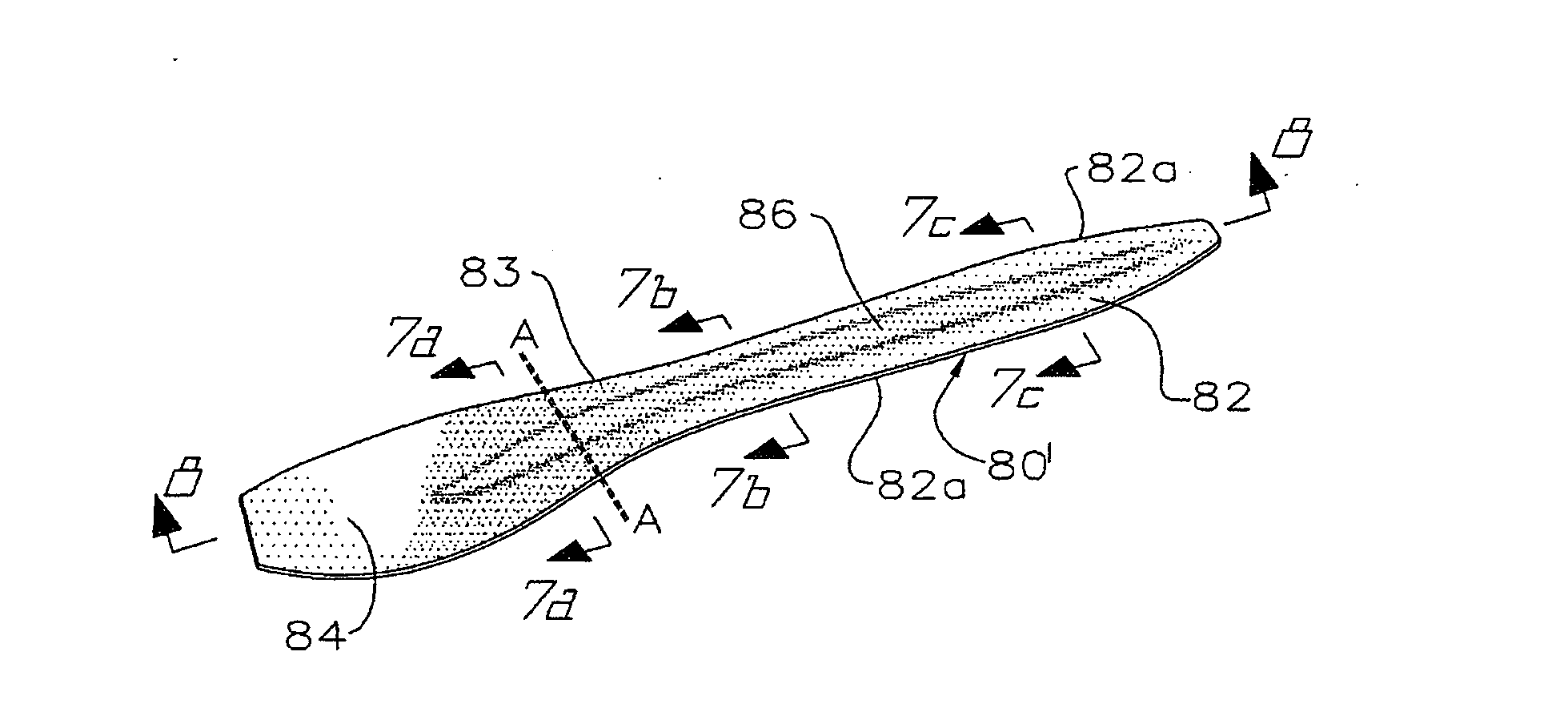

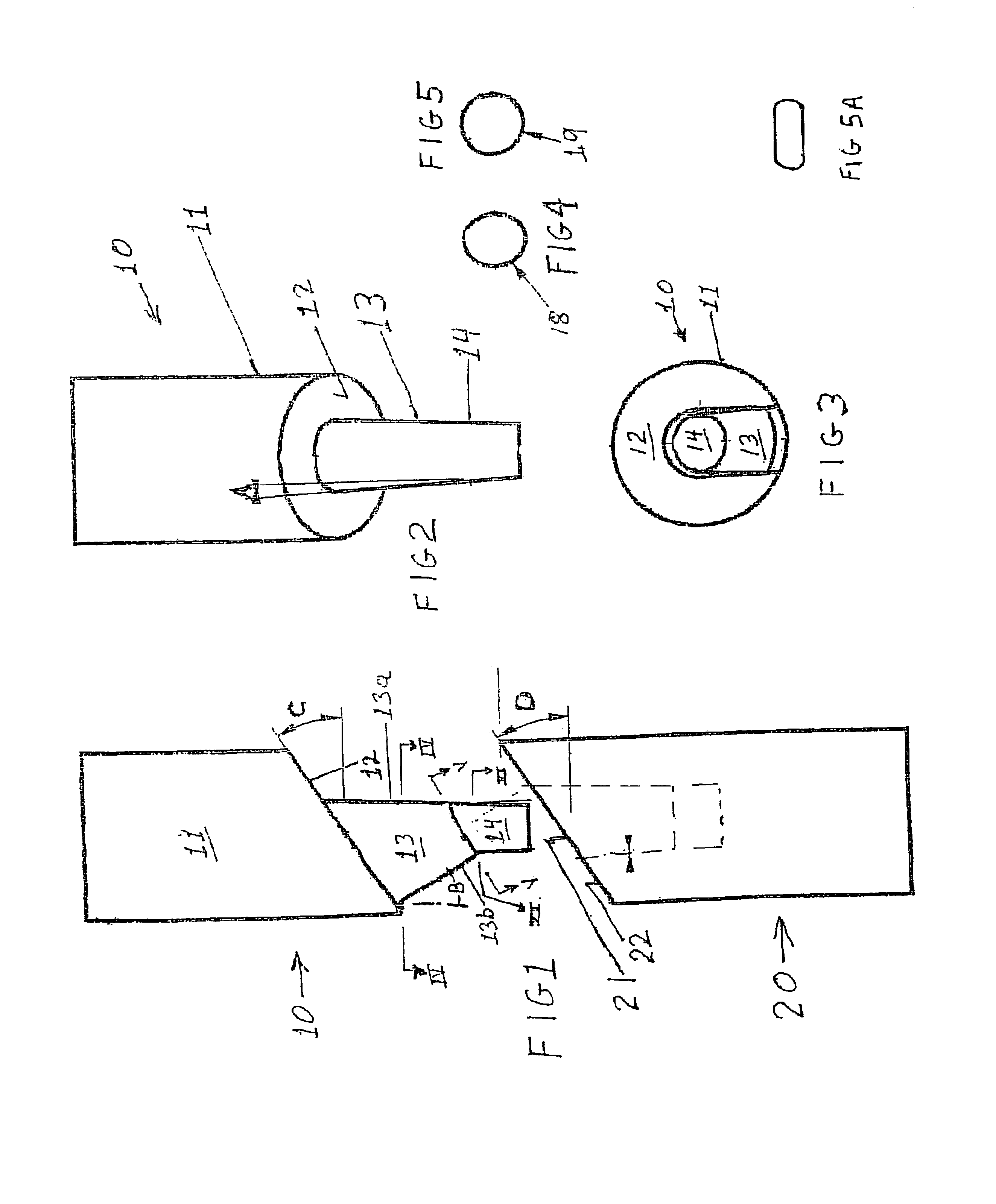

Process of production of disposable wooden cutlery and product thereof

InactiveUS20080178966A1Avoid breakingOther plywood/veneer working apparatusPlywood pressesCutleryEngineering

Owner:SOC COMML SATCO LTDA

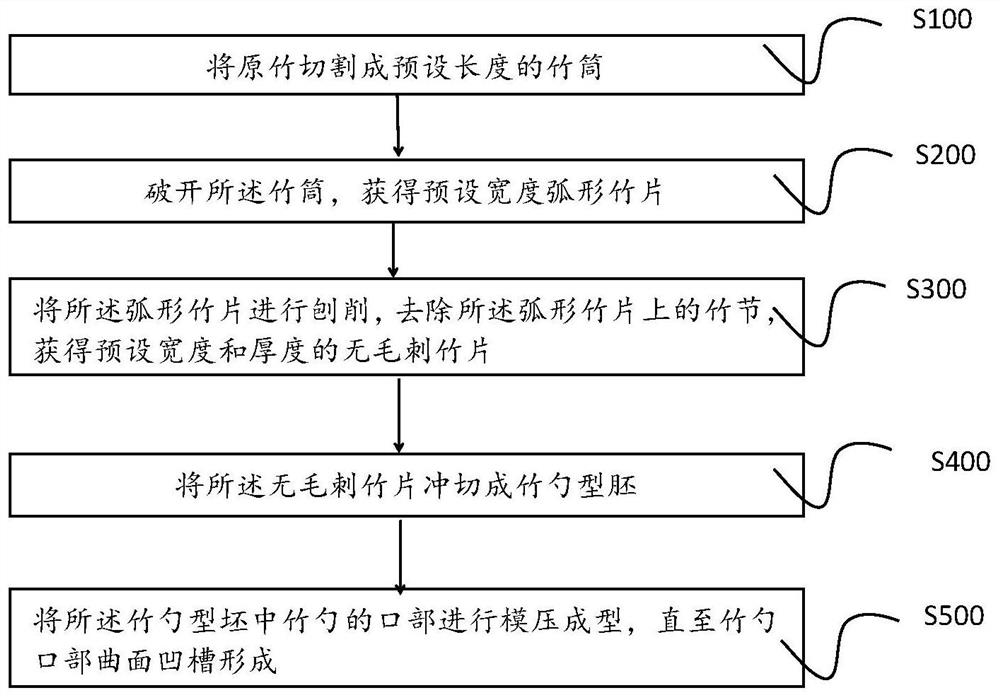

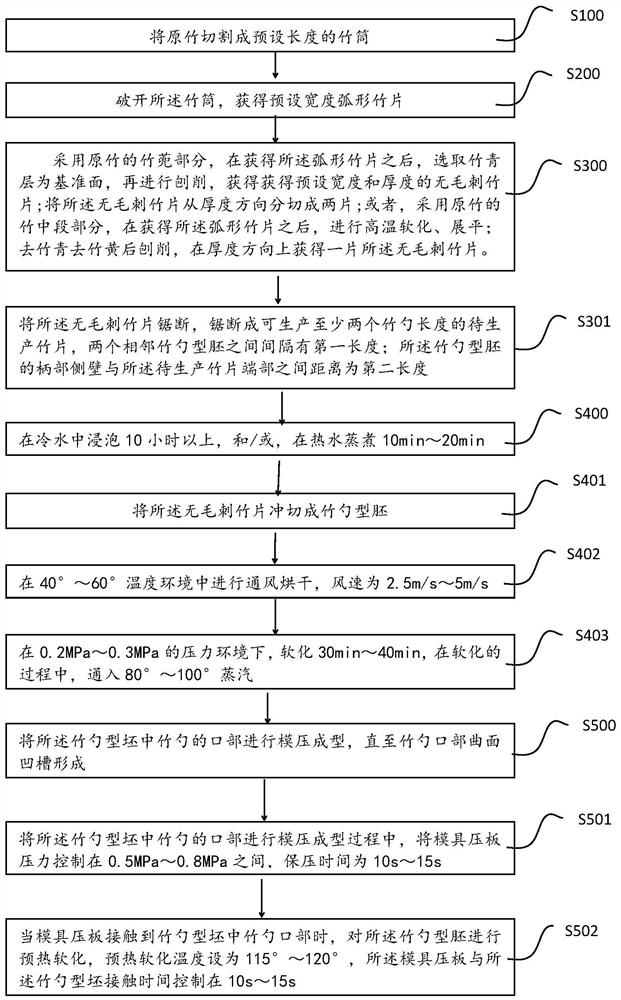

Bamboo spoon tableware processing method

The invention relates to a bamboo spoon tableware processing method. The method adopts raw bamboo as a processing raw material, and comprises the following steps of cutting the raw bamboo into a bamboo tube with a preset length; breaking the bamboo tube to obtain an arc-shaped bamboo chip with a preset width; conducting planing on the arc-shaped bamboo chip, and removing bamboo joints on the arc-shaped bamboo chip to obtain a burr-free bamboo chip with a preset width and thickness; conducting punching on the burr-free bamboo chip to form bamboo spoon-shaped blanks; and carrying out compressionmolding on opening parts of bamboo spoons in the bamboo spoon-shaped blanks until forming curved surface grooves of the opening parts of the bamboo spoons. According to the bamboo spoon tableware processing method, the raw bamboo is adopted for direct production, the economical and environment friendly effects are achieved by replacing plastic with bamboo, and no damage is caused to human bodies.

Owner:HUNAN ACAD OF FORESTRY +3

Strandboard molding having holes at angles of 20 degrees to vertical or more

Mold apparatus for molded wood strand three-dimensionally carved articles of manufacture using at least one hole punch comprised of a base and a funnel shaped hole-defining portion having a funnel angle of 20 degrees or greater to vertical for producing molded holes at angles of 20 degrees or greater to vertical, to facilitate insertion of items such as a T nut within the molded hole in an assembly-line like fashion.

Owner:GFP STRANDWOOD

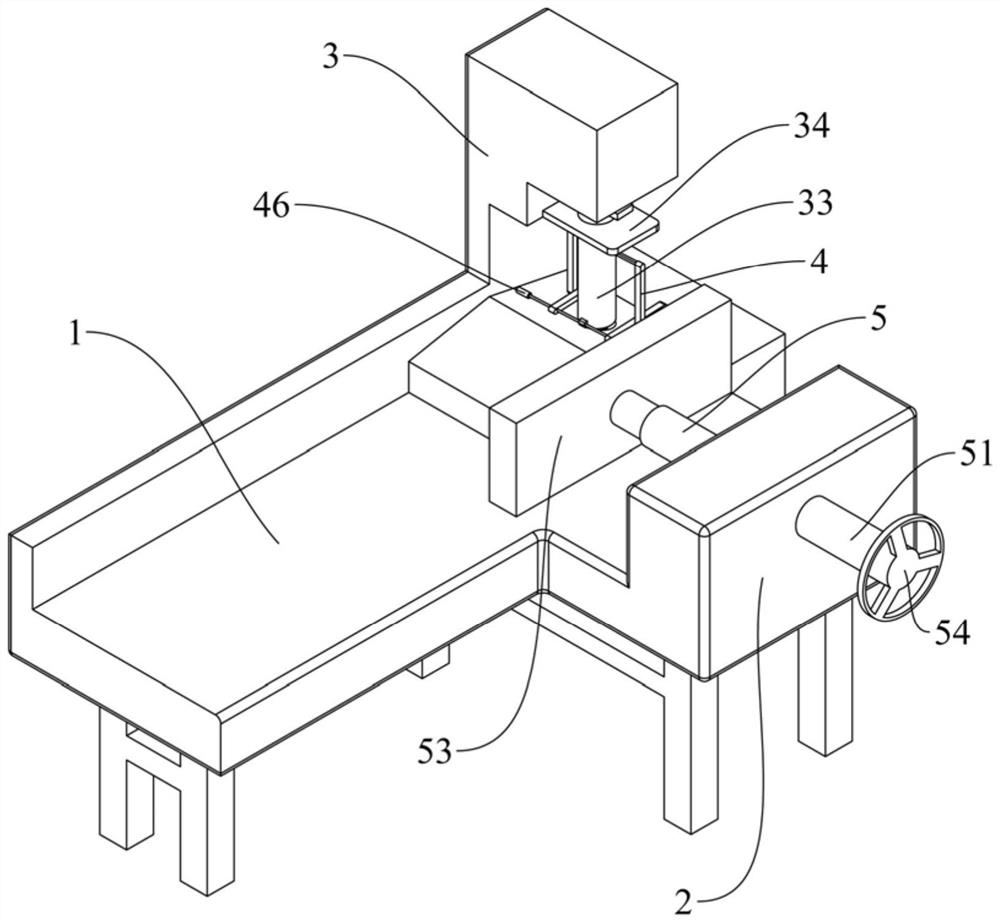

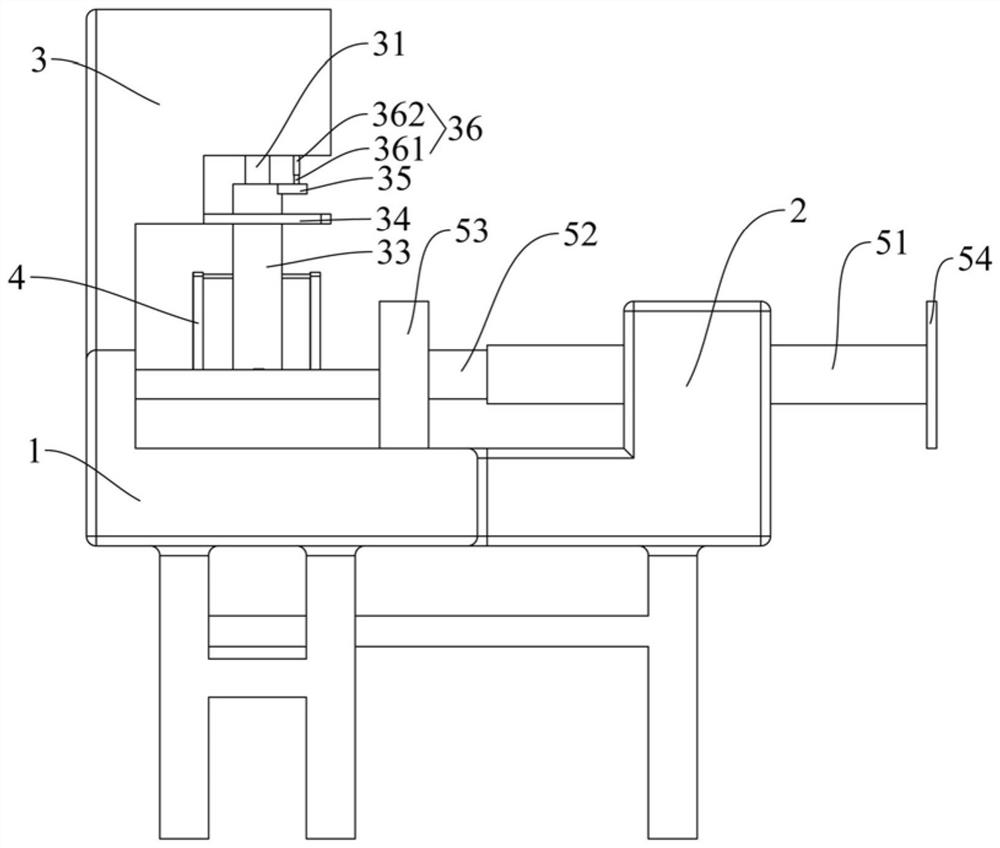

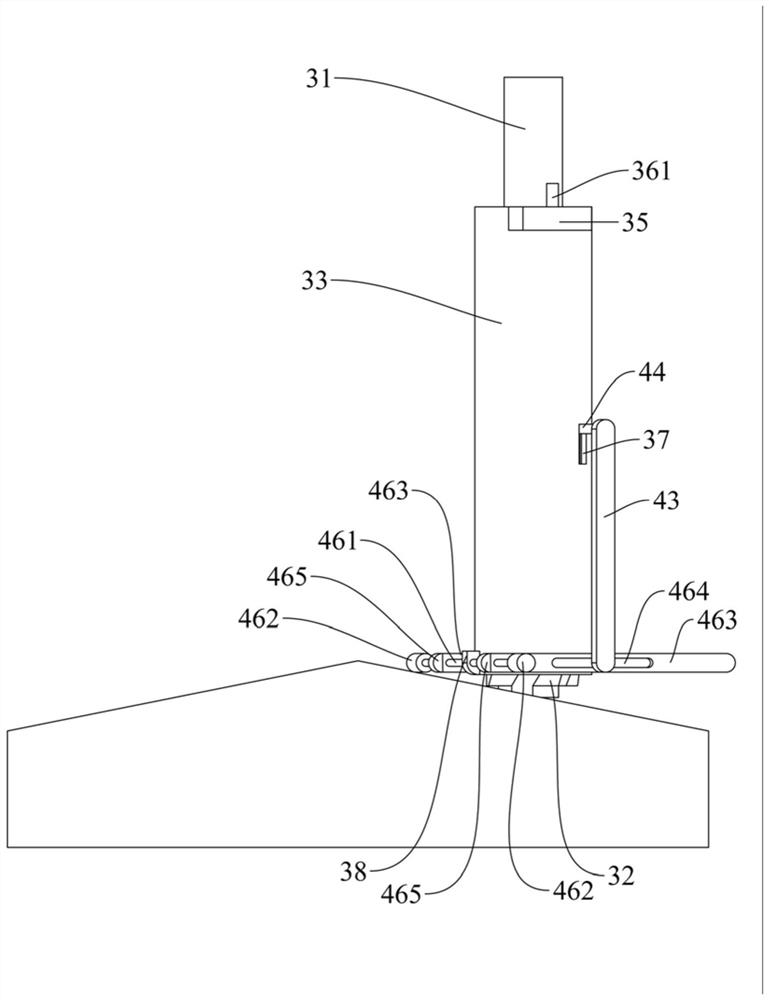

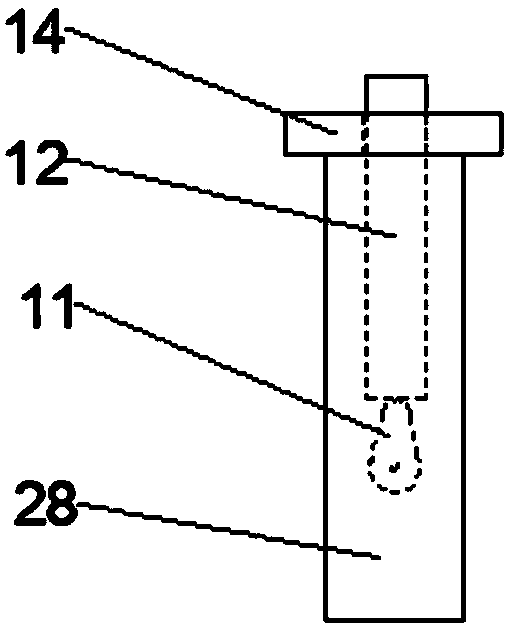

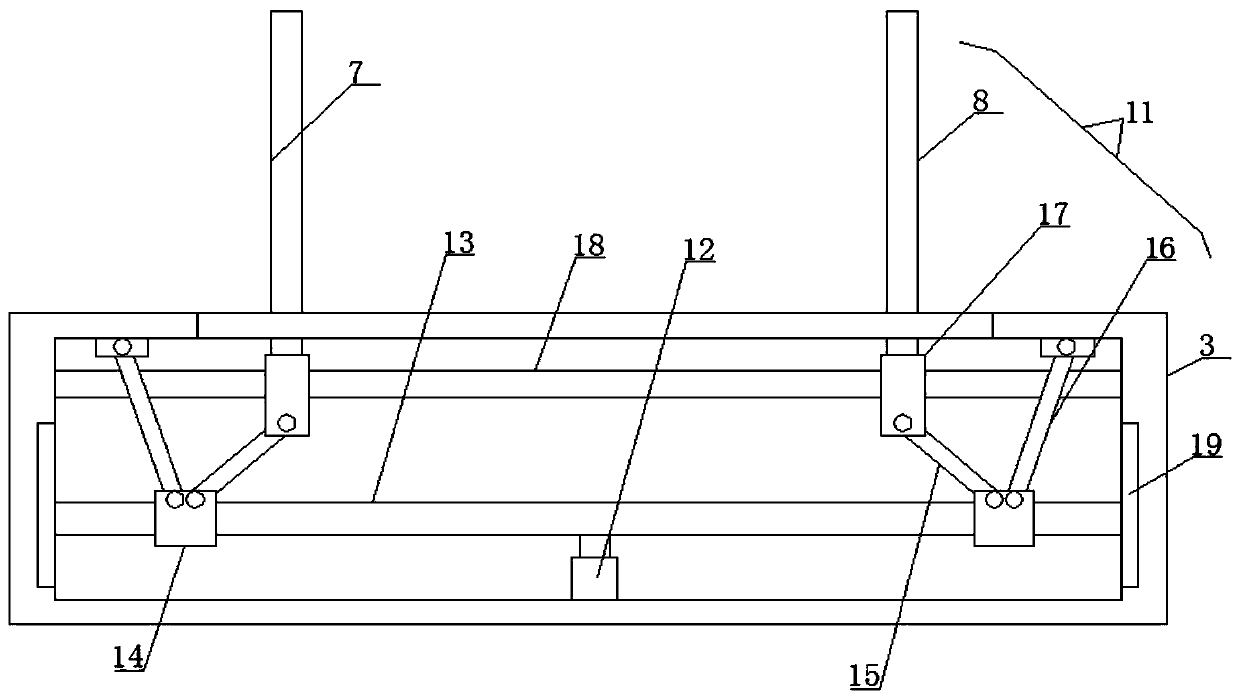

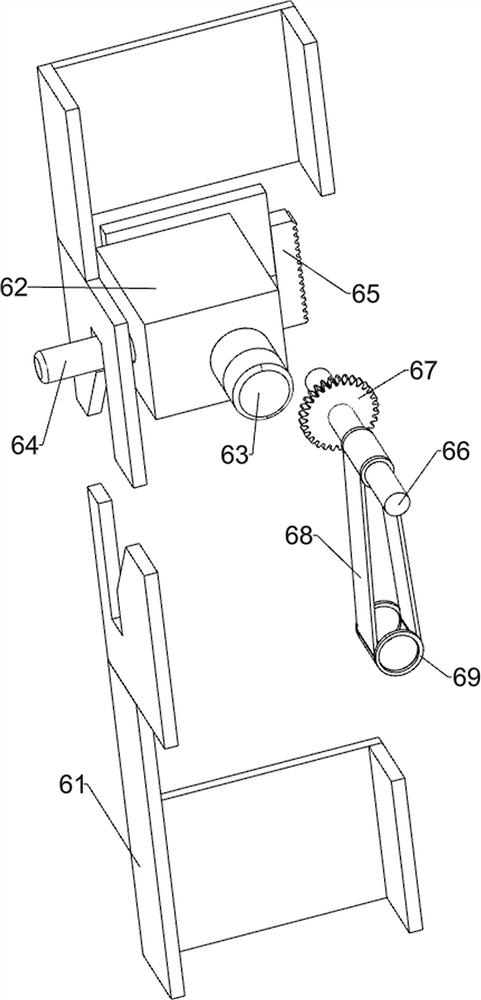

Automatic needle insertion machine for wooden comb

ActiveCN106891410AExtended service lifeImprove assembly efficiencyWood punching outReciprocating motionNeedle insertion

The invention discloses an automatic needle insertion machine for a wooden comb. The automatic needle insertion machine comprises a workbench, a work station, a sliding rail and a machine tool used for performing stamping operation on the work station; one end of the sliding rail is connected with the machine tool; the other end of the sliding rail extends to the side part of the workbench; and the work station can make reciprocating motion on the sliding rail and comprises a sliding sleeve matched with the sliding rail, a connecting part which is connected to the sliding sleeve in an overturning manner, a positioning plate body fixedly arranged on the connecting part, a finished product collection plate body detachably connected with one side of the positioning plate body and a stamping part arranged on the other side of the positioning plate body. Through adoption of the automatic needle insertion machine, traditional manual assembly is abandoned, and automatic stamping operation is adopted to assemble the comb, so that the assembly efficiency of the comb is greatly improved, the firmness of the comb is improved at the same time, and the product performance is more stable.

Owner:浙江景宁华寅工艺品有限公司

Universal robot punching equipment

InactiveCN109013858AEasy to punchAdsorption, collection and cleaning in timePerforating toolsMetal-working feeding devicesPunchingEngineering

Owner:合肥阅辞科技有限公司

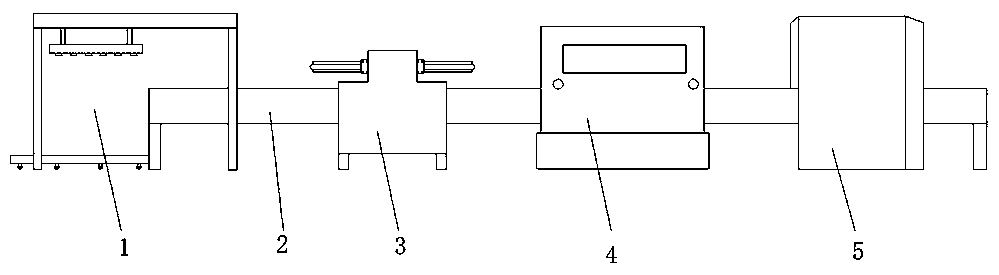

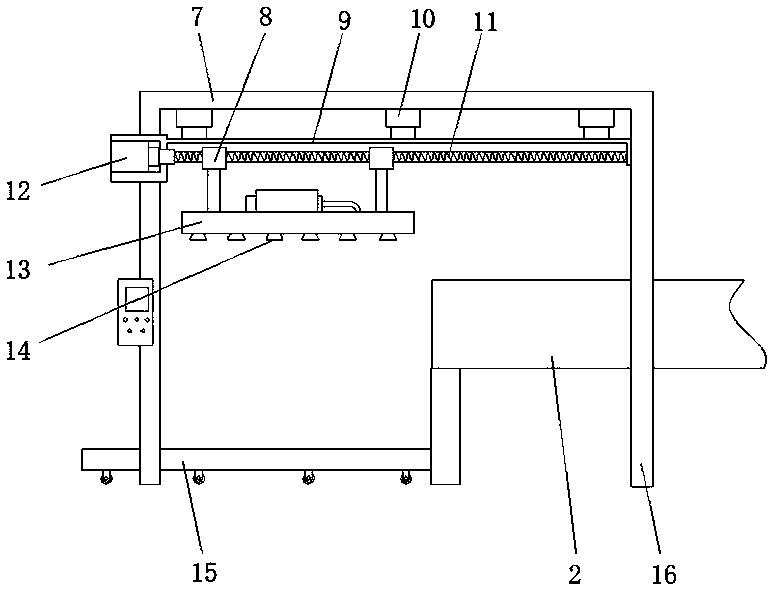

Plate type component production line for intelligent household

InactiveCN110450255AEasy to cutAvoid destructionFeeding devicesCircular sawsProduction lineNumerical control

The invention discloses a plate type component production line for intelligent household. A feeding mechanism, a conveying mechanism, a labeling machine, a cutting device and a wood plate numerical control punching machine are included, wherein the feeding mechanism is arranged on a feeding end of the conveying mechanism; one side of the feeding mechanism is sequentially provided with the labelingmachine, the cutting device and the wood plate numerical control punching machine, and the feeding mechanism comprises a top frame, a movable plate, a hydraulic telescopic rod, a movable piece and asucking disc; and the top end of the movable plate is connected to the top frame through the hydraulic telescopic rod. According to the production line, a main cutting saw wheel and an auxiliary cutting saw wheel set are arranged on the cutting device, the cutting directions of the main cutting saw wheel and the auxiliary cutting saw wheel set are opposite, and the direction of the auxiliary cutting saw wheel set is the same as the running direction of a plate, so that the main cutting saw wheel is prevented from damaging veneer layers on the surface of the plate; and an upper cutting saw wheel and a lower cutting saw wheel of the auxiliary cutting saw wheel set are used for cutting the veneer layers on the two sides of the plate, thereby facilitating cutting of the main cutting saw wheel,and keeping the veneer layers of the plate intact.

Owner:DONGGUAN ZHONGJIN FURNITURE CO LTD

Punching machine with automatic locating function

InactiveCN107584010ASimple structureEasy to useMetal-working feeding devicesMetal working apparatusPunchingPiston

The invention discloses a punching machine with an automatic locating function. The punching machine comprises a punching machine body, an electronic-mechanical box is arranged on the punching machinebody, a driving device is arranged at the upper portion of the interior of the electronic-mechanical box, a pushing shaft is arranged at the lower portion of the driving device, baffles are arrangedat the left and right sides of the electronic-mechanical box, a piston device is arranged at the lower portion of the pushing shaft, a punching rod is arranged at the lower portion of the piston device and internally provided with a rotating shaft, the bottom end of the punching rod is provided with a punching tip, the bottom end of the punching machine body is provided with a worktable, the surface of the worktable is provided with chucks, a PCB is arranged below the chucks, and the worktable is internally provided with a sensor.

Owner:张家港奥得森机电设备有限公司

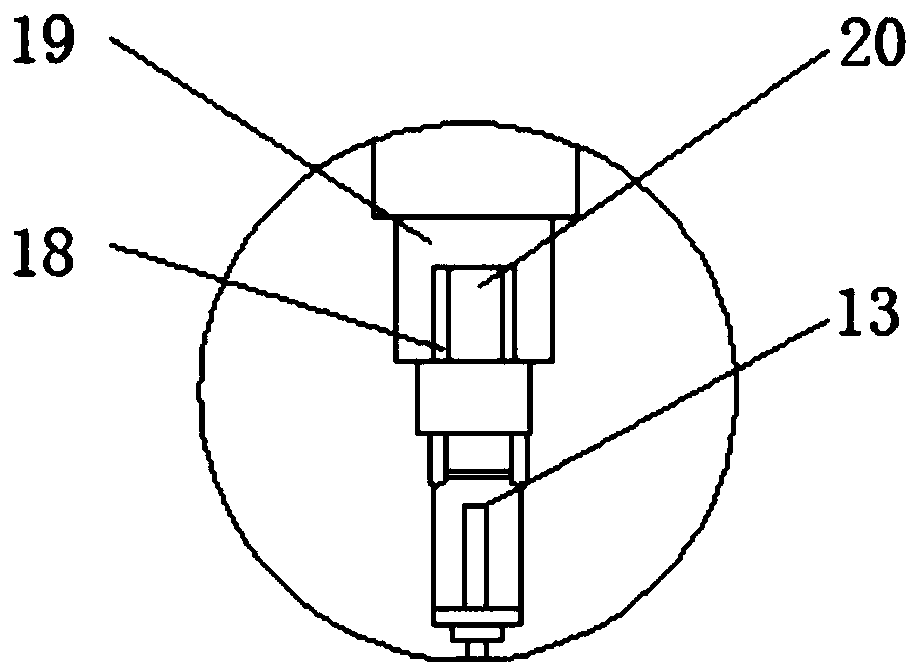

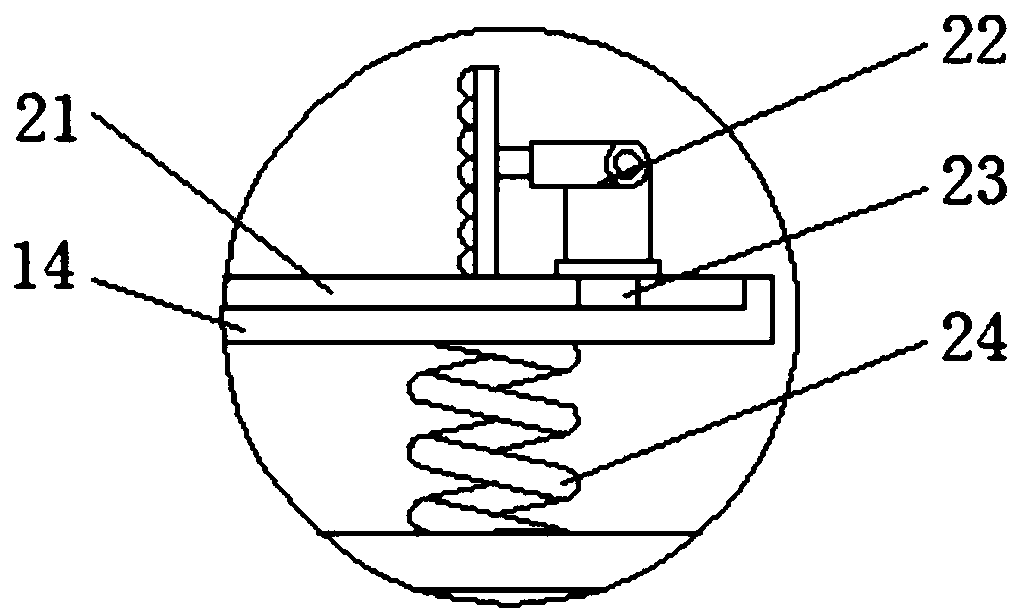

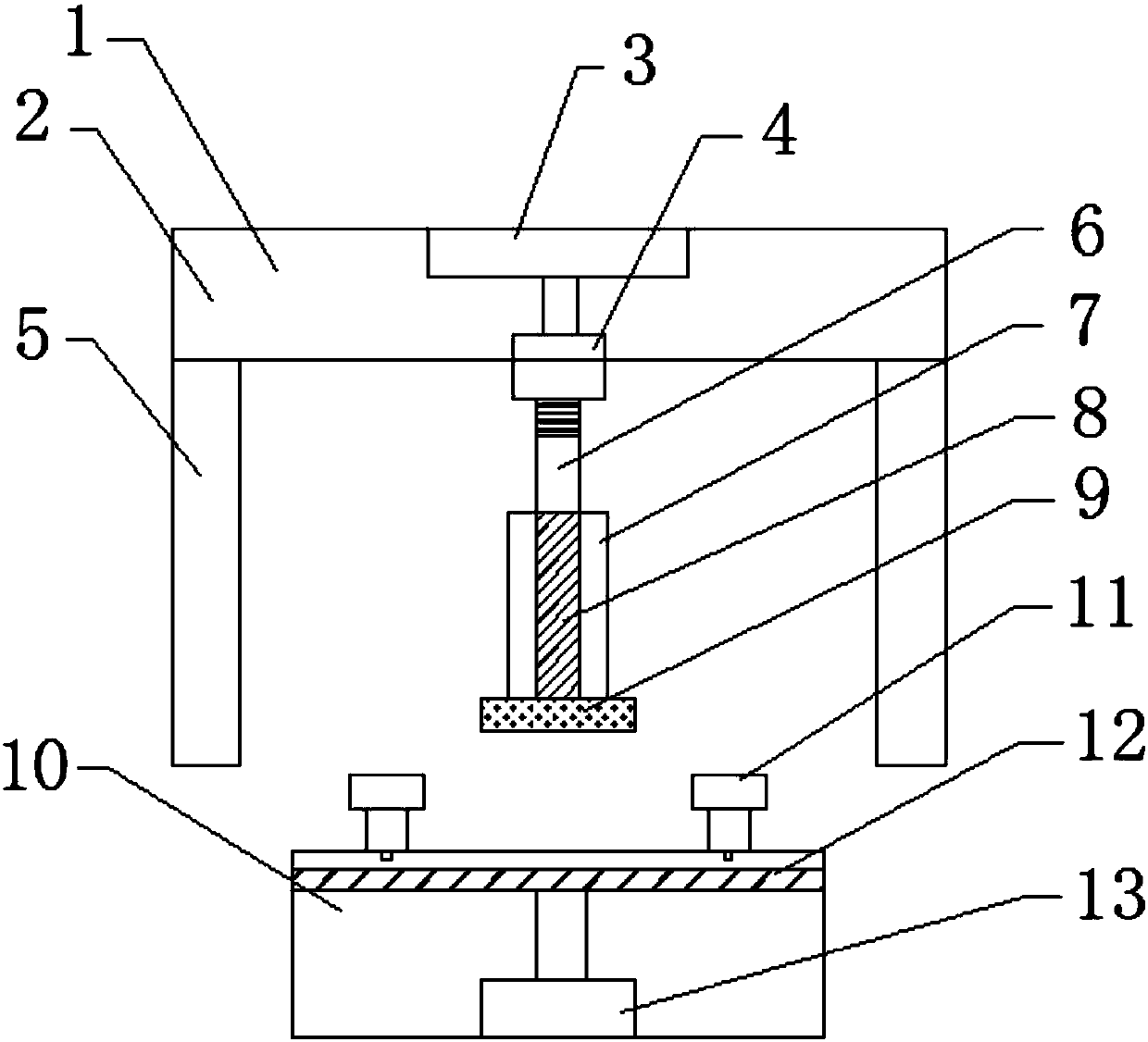

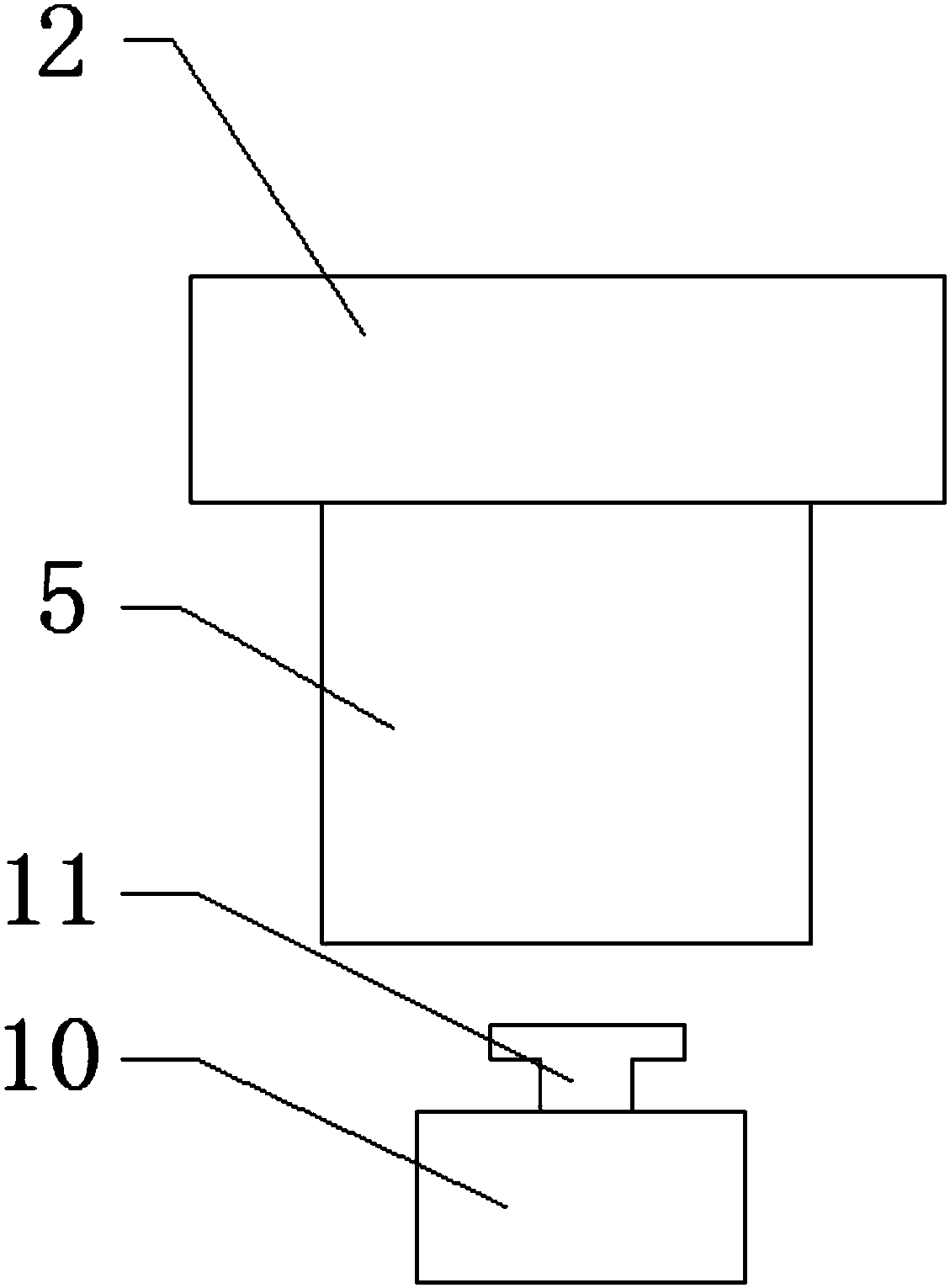

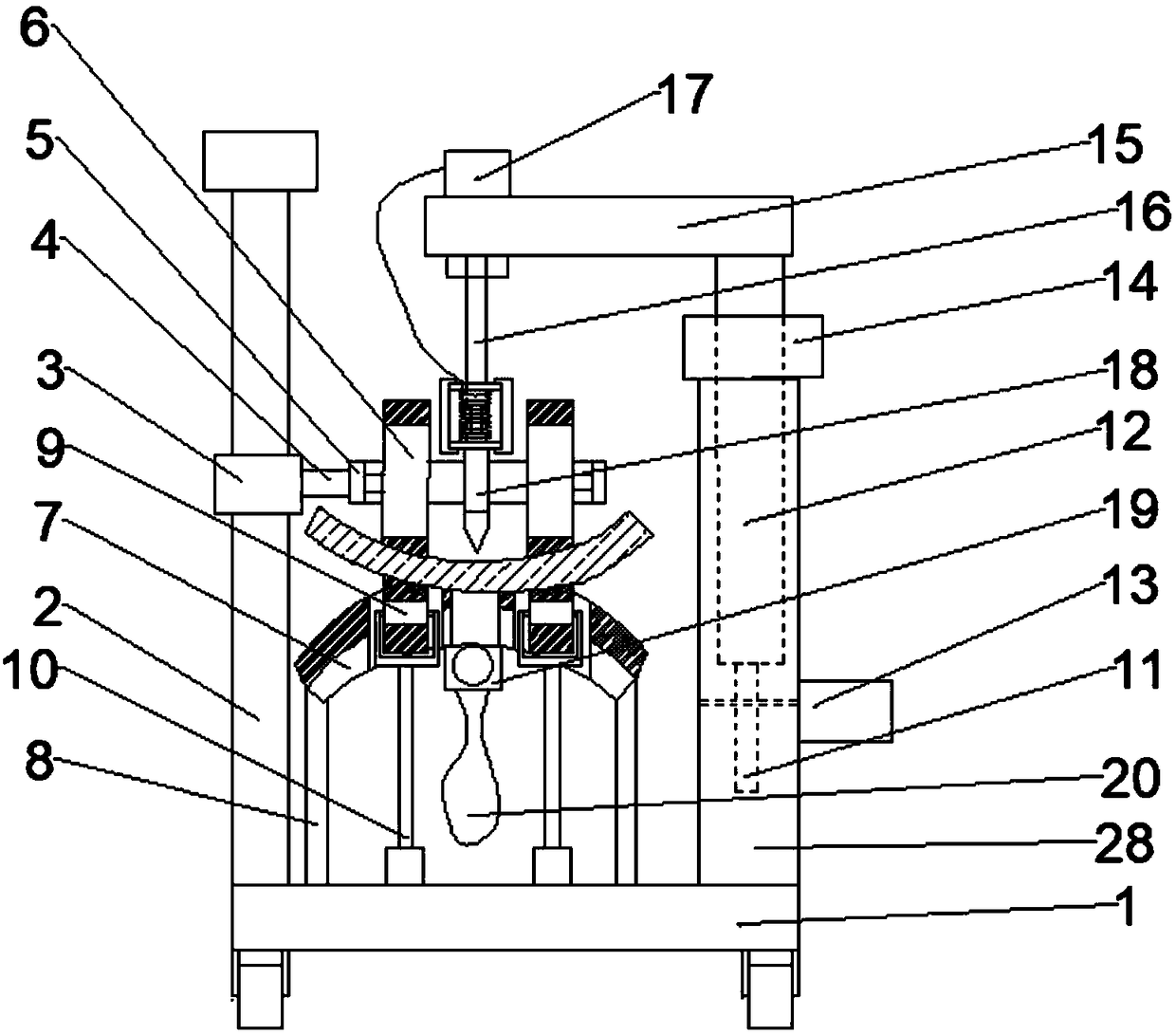

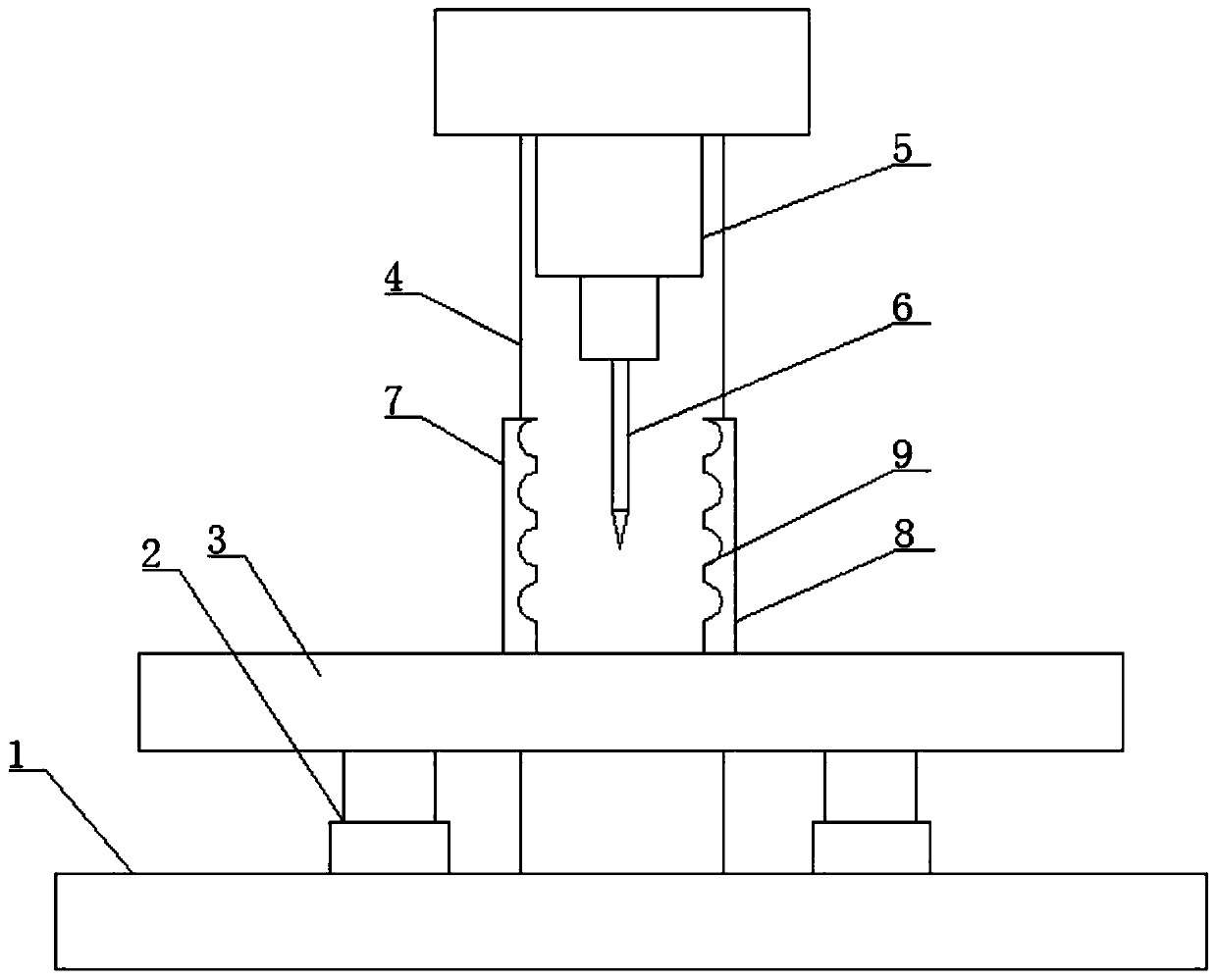

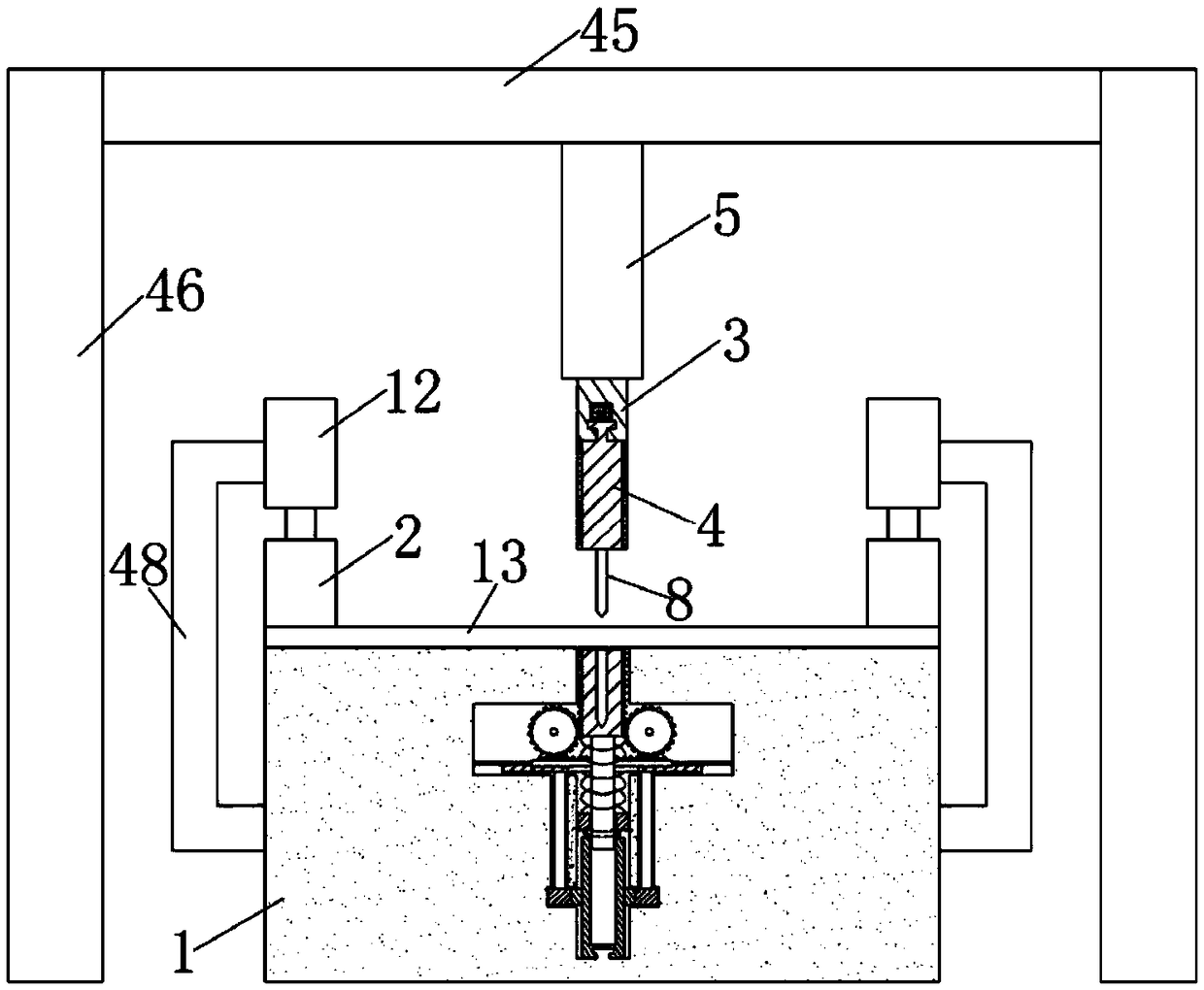

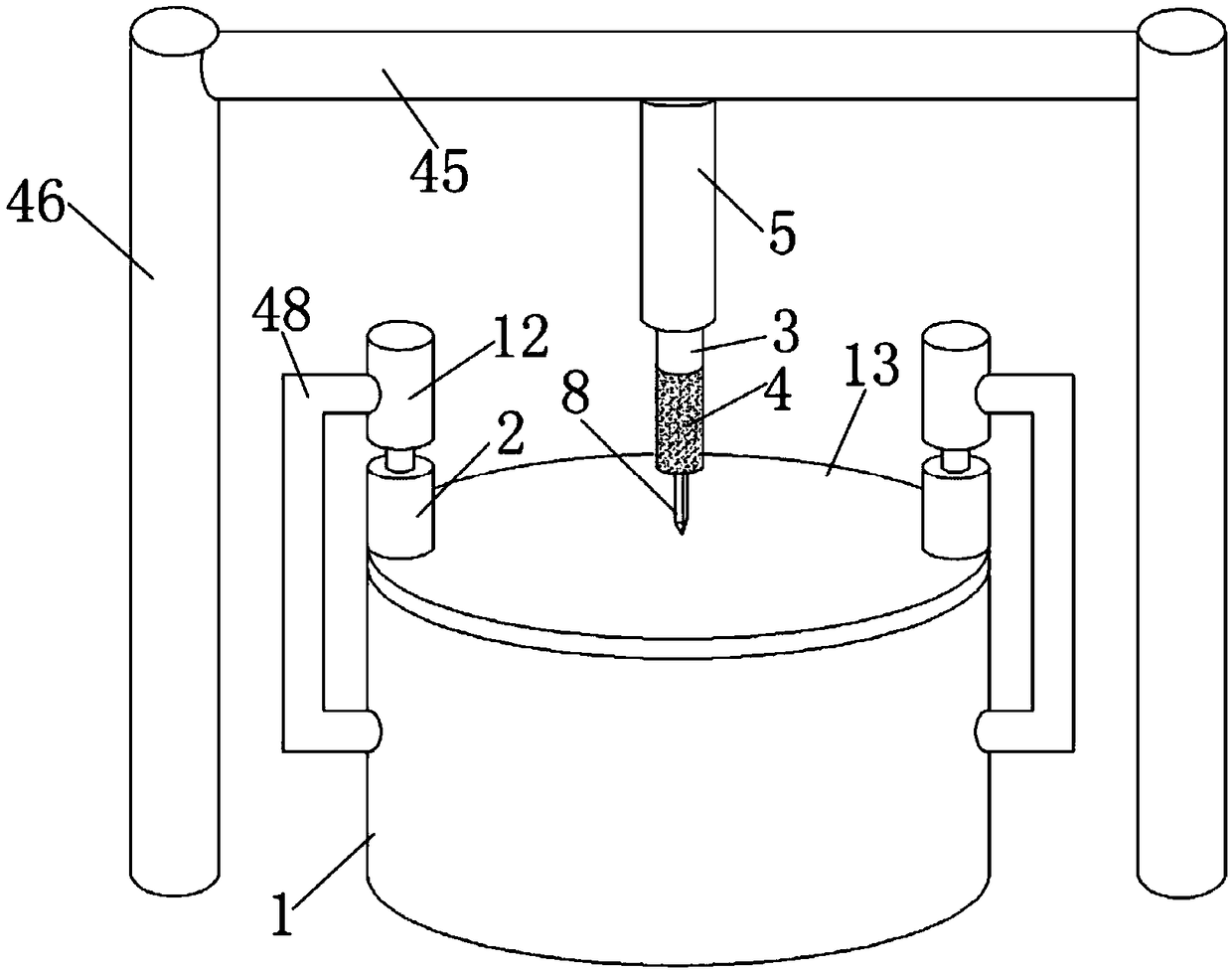

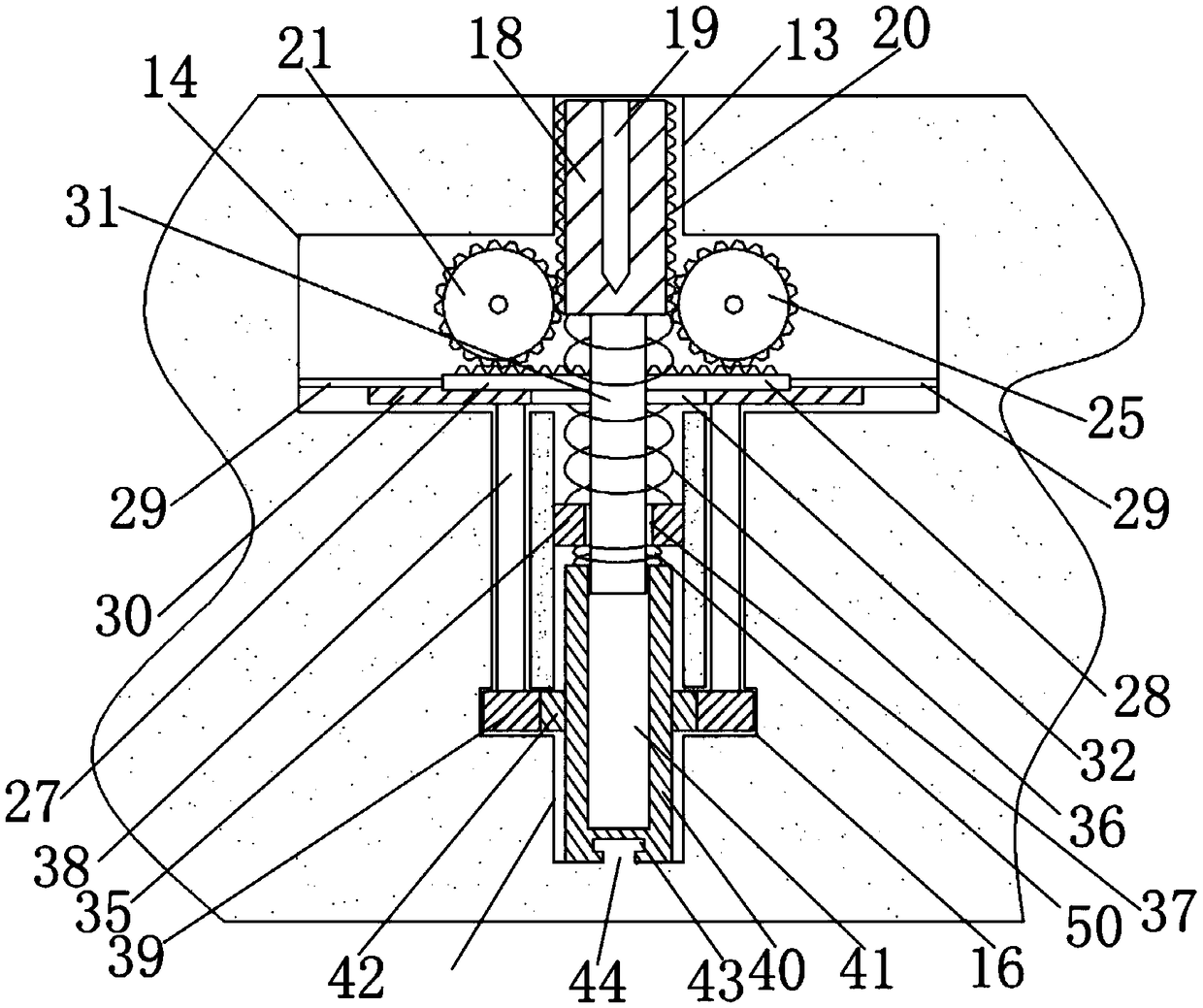

Positioning and punching device for furniture plate production and machining and machining method

ActiveCN114454281AMaximize drilling efficiencyGuaranteed stabilityStationary drilling machinesWood punching outPunchingStructural engineering

The invention relates to the technical field of punching, in particular to a positioning punching device for furniture plate production and machining and a machining method. Comprising a lathe frame and a fixed table. The fixing table is provided with a fastening device used for fastening a to-be-machined plate. A rotating rod extending downwards is further arranged on the supporting table. A drill bit is arranged at the lower end of the rotating rod. A sleeve is coaxially arranged on the outer side of the rotating rod; the supporting table is further provided with a fixing plate extending left and right. The sleeve slidably penetrates through the fixing plate and extends downwards. A supporting plate is arranged outside the upper end of the sleeve, and the upper end face of the supporting plate is fixedly connected with a telescopic rod. The adjusting structure is arranged on the sleeve; the to-be-processed plate is configured to be fastened; and the telescopic rod extends to drive the sleeve to move downwards, so that the adjusting structure gradually deflects and returns to be matched with the inclined surface of the to-be-processed plate in a fitting and positioning manner to keep fastening. The device can adapt to inclined plane drilling machining of different to-be-machined plate gradients, the accuracy of positioning drilling is guaranteed, and the working efficiency and the drilling quality of the device are further improved.

Owner:乐捷家居股份有限公司

Curved plate punching machine

ActiveCN109291190AEasy to fixDistribute pressureDirt cleaningBark-zones/chip/dust/waste removalPunchingEngineering

The invention discloses a curved plate punching machine. The curved plate punching machine comprises a rectangular base, hydraulic lifting rods, a cylindrical support rod, a cylindrical sleeve, a [-shaped bracket, two fixed rollers, a rectangular arch plate, two auxiliary rollers, two Y-shaped support bars, a first motor, a cam, a cam sleeve, a needle rod, a support rod, a second motor, a rotatingrod, a compression spring, a pressure sensor, a second motor control module and a drill bit. A curved plate can be fixed stably, replacement operation of the punching position can be quickly completed, continuous punching is realized, and the efficiency of plate punching is improved; and on the other hand, the pressure of the drill bit on a plate in the punching process is from small to large, the situation that the plate is broken due to sudden high pressure from the drill bit is avoided, the plate punching yield is improved, and energy is saved.

Owner:谢国宁

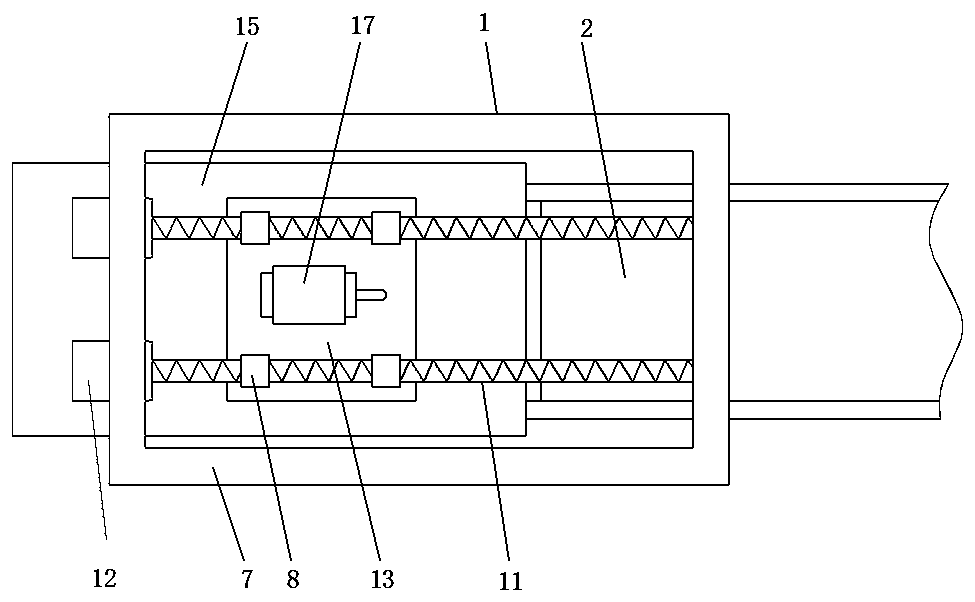

Pin hydraulic punching machine with accurate positioning

InactiveCN111069407AAvoid position deviationSafe feeding and punching processPinsMetal-working feeding devicesElectric machineryStructural engineering

The invention discloses a pin hydraulic punching machine with accurate positioning. The pin hydraulic punching machine comprises a base and telescopic air cylinders which are symmetrically arranged atthe top end of the base, a workbench is arranged at the top ends of the telescopic air cylinders, a vertically-arranged stand column is arranged in the middle of the top end of the base, a driving motor is arranged at the top end of one side of the stand column and located above the workbench, a punching rotating shaft is arranged at the output end of the driving motor, a first clamping plate anda second clamping plate are symmetrically arranged at the positions, which are located on the two sides of the stand column, of the top end of the workbench, and a plurality of evenly-distributed cross-shaped grooves are formed in the sides, which are close to each other, of the first clamping plate and the second clamping plate. The pin hydraulic punching machine with accurate positioning has the beneficial effects that through the cooperative design of the first clamping plate and the second clamping plate, the fact that position deviation between pin bodies in the punching process occurs can be effectively prevented, the pin machining, feeding and punching process can be safer, multiple pins can be punched synchronously, and the pin punching efficiency is improved.

Owner:佛山市三水精诚五金有限公司

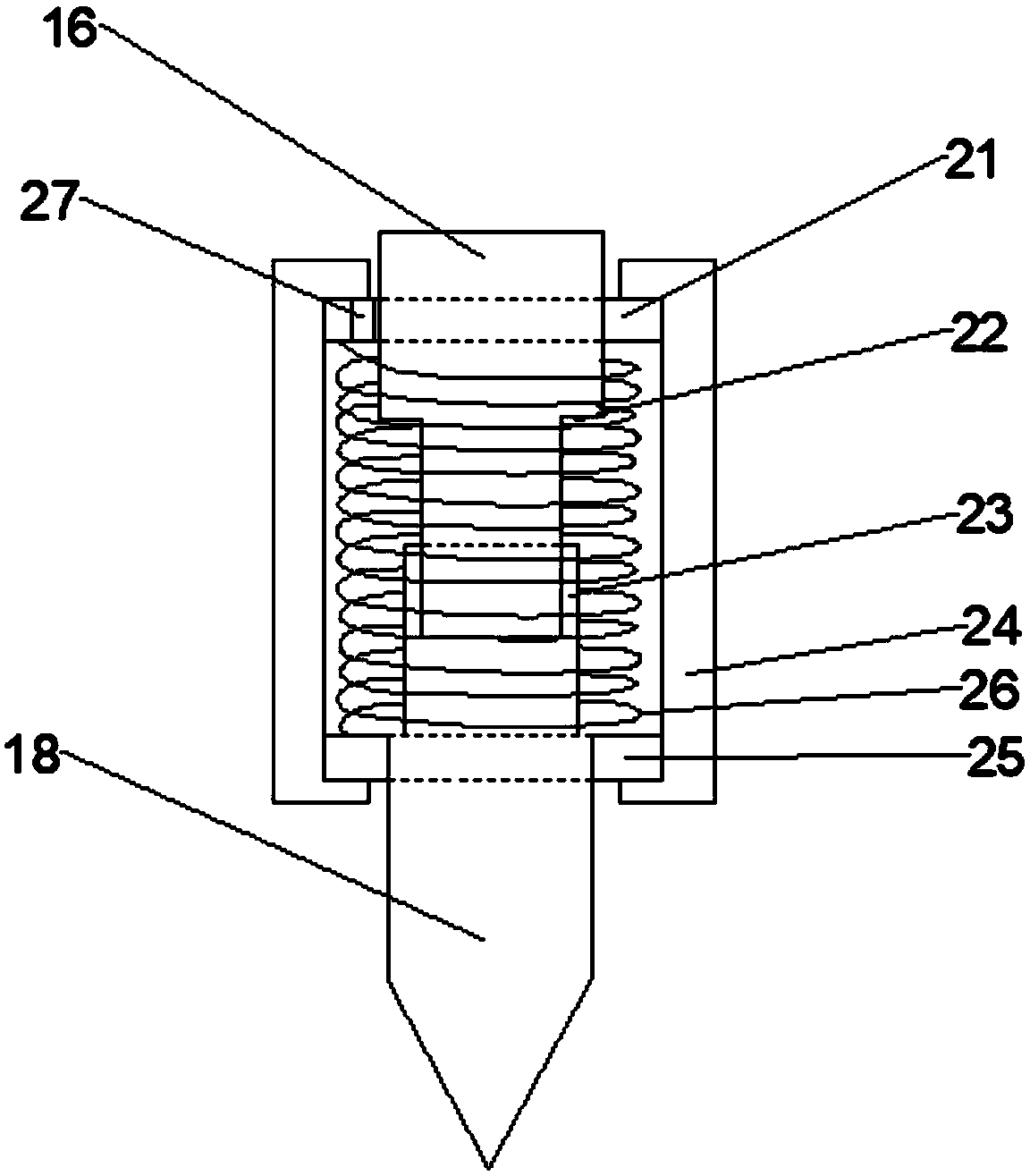

Bamboo frame part punching device and bamboo frame part punching method

ActiveCN110497496AFully warmed upEasy to bendWood compressionCane mechanical workingPunchingEngineering

The invention discloses a bamboo frame part punching device and a bamboo frame part punching method. The bamboo frame part punching device comprises a rack. A die assembly is arranged on the rack andcomprises a die. A preheating plane for pre-heating a to-be-processed bamboo strip is arranged on the die; a plurality of forming areas sinking toward the die are also arranged on the die. The formingareas play a role in setting the bamboo strip. A moving device for moving the bamboo strip is arranged on the preheating plane. A lifting driving device is also arranged on the rack. A pressure headis connected to the lifting driving device, and heating devices are arranged in the die and the pressure head. By arranging the preheating plane on the surface of the die, the bamboo strip can be preheated fully before being punched, so that the bamboo strip can be bended better.

Owner:ZHEJIANG SANJIAN IND & TRADE

Oak plug manufacturing device

InactiveCN112045790ARealize automatic interval feedingContinuous cuttingSievingScreeningMechanical engineeringIndustrial engineering

The invention relates to a manufacturing device, in particular to an oak plug manufacturing device. The oak plug manufacturing device is safe, reliable and high in yield. The oak plug manufacturing device comprises a base, wherein mounting plates are arranged at the two sides of the bent position of the top of the base; a mounting table, which is arranged at the side, away from the mounting plates, of the top of the base; a fetching device, which is arranged at the top of the mounting table; and a feeding device, which is arranged between the two mounting plates. According to the device, automatic and alternate feeding of oak is realized, the oak can be continuously cut through cooperation of the fetching device and the feeding device, the hands of a worker can keep away from a cylindricalknife under the action of a sliding ejector rod and a conveying belt, the safety of the device is enhanced, and the personal safety of the worker is protected.

Owner:王八生

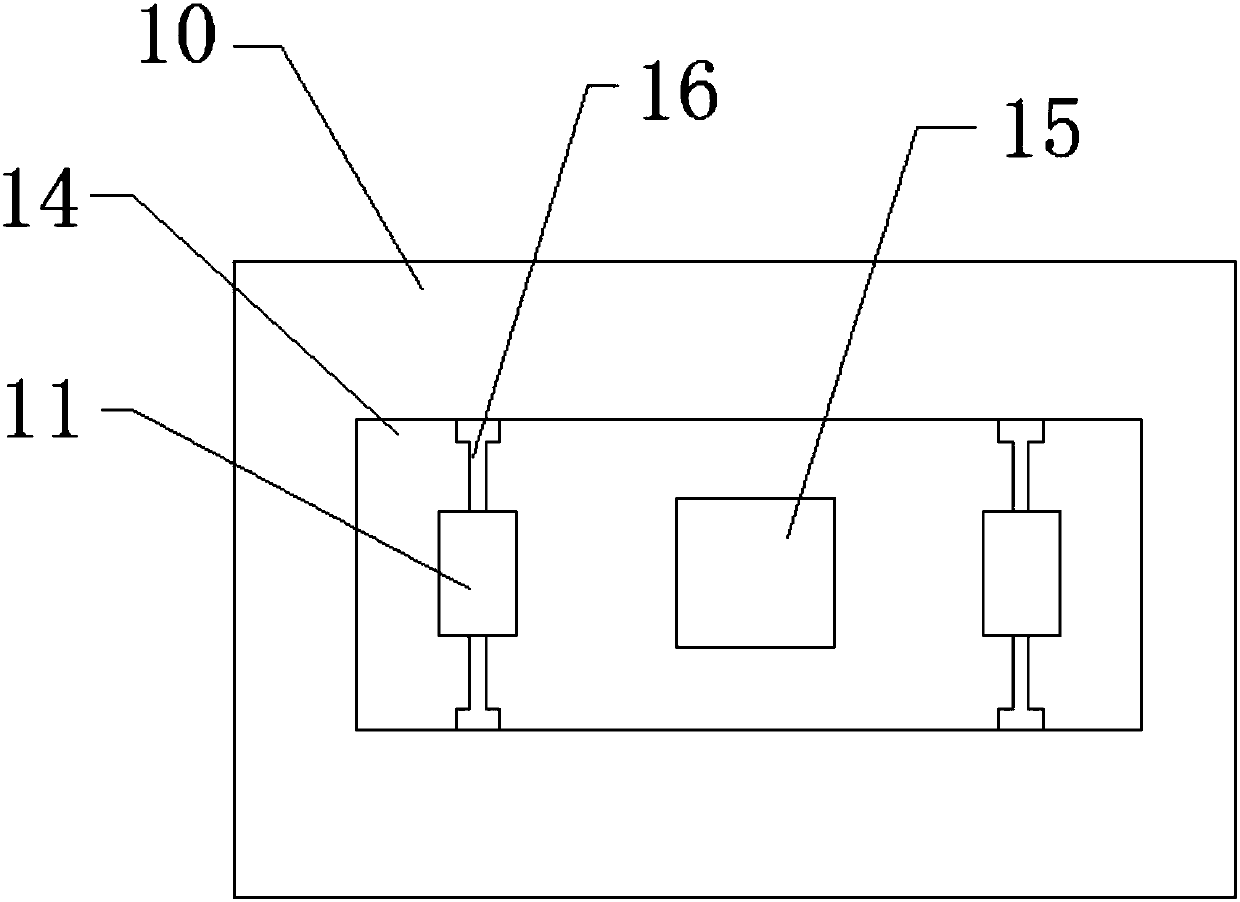

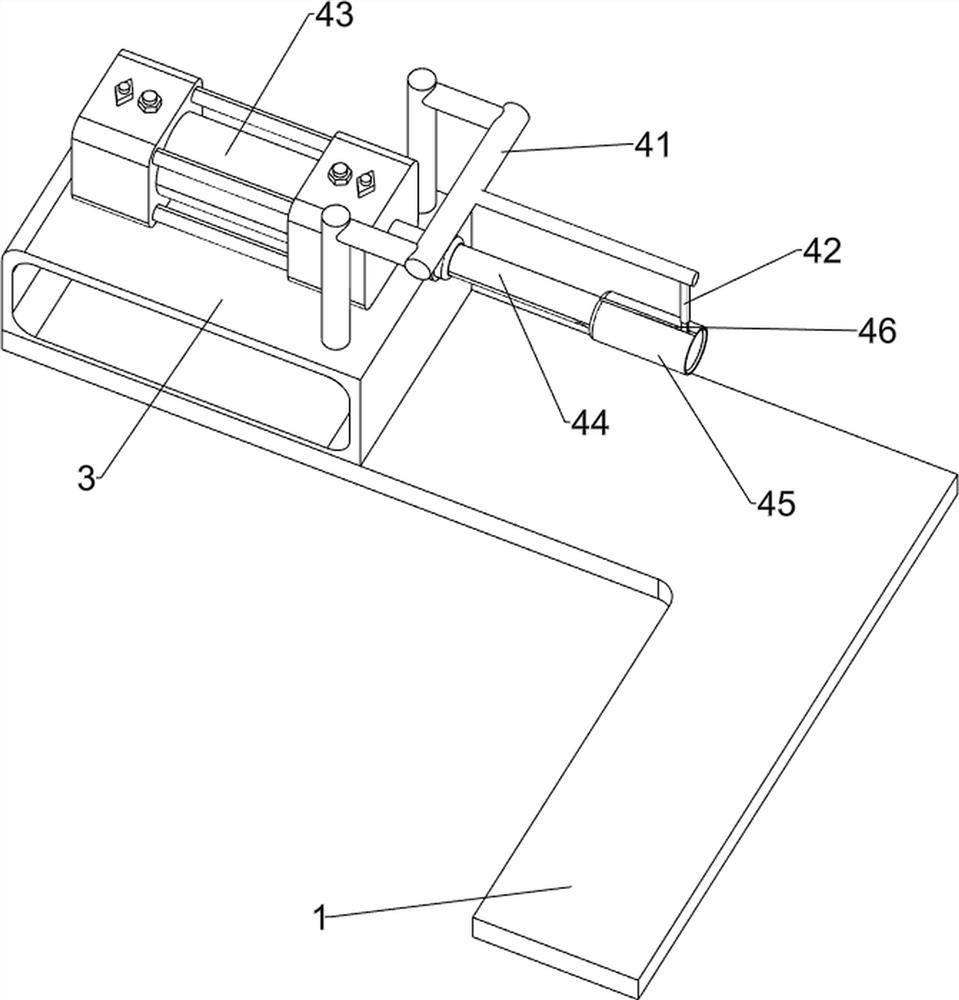

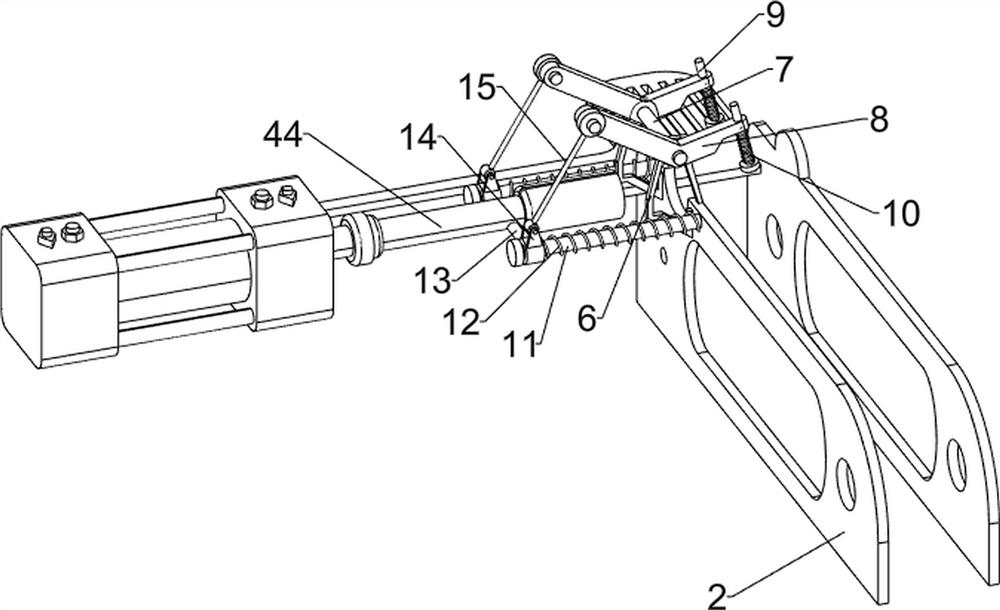

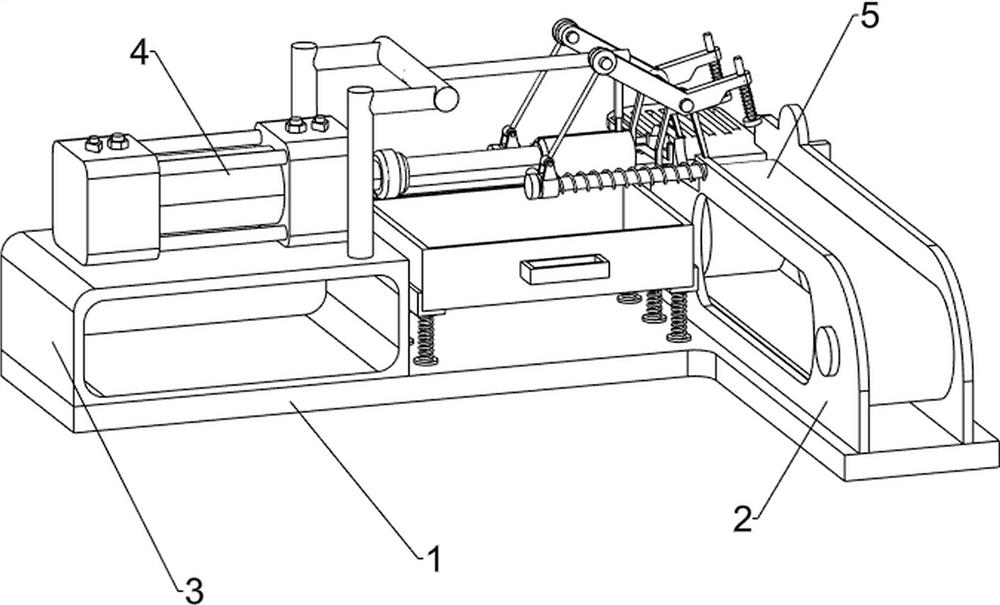

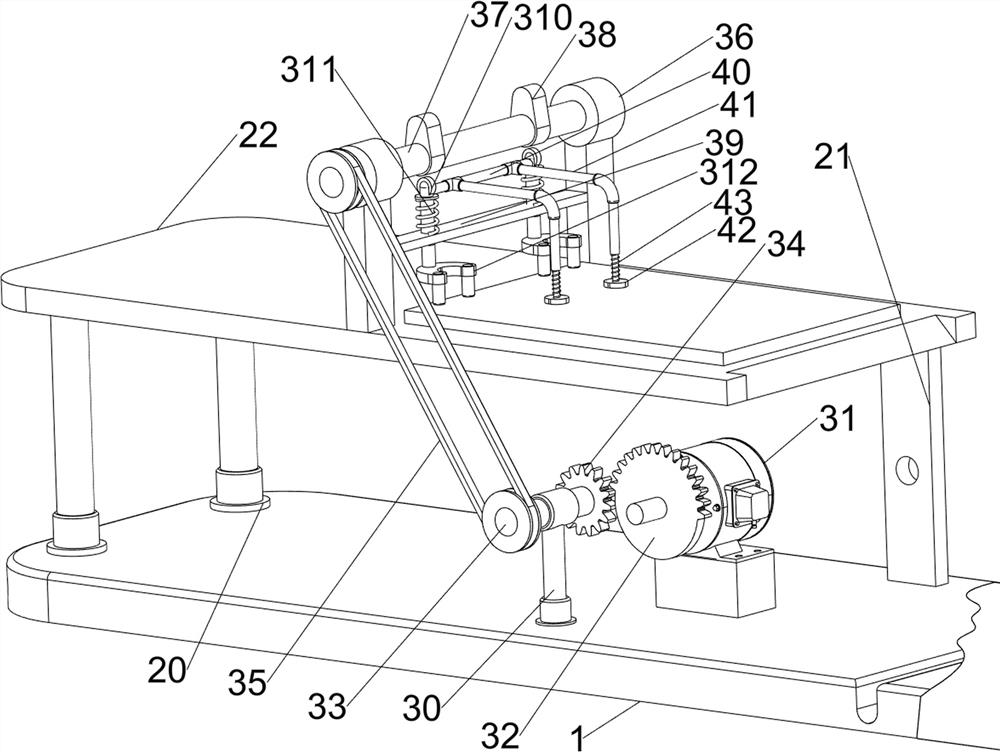

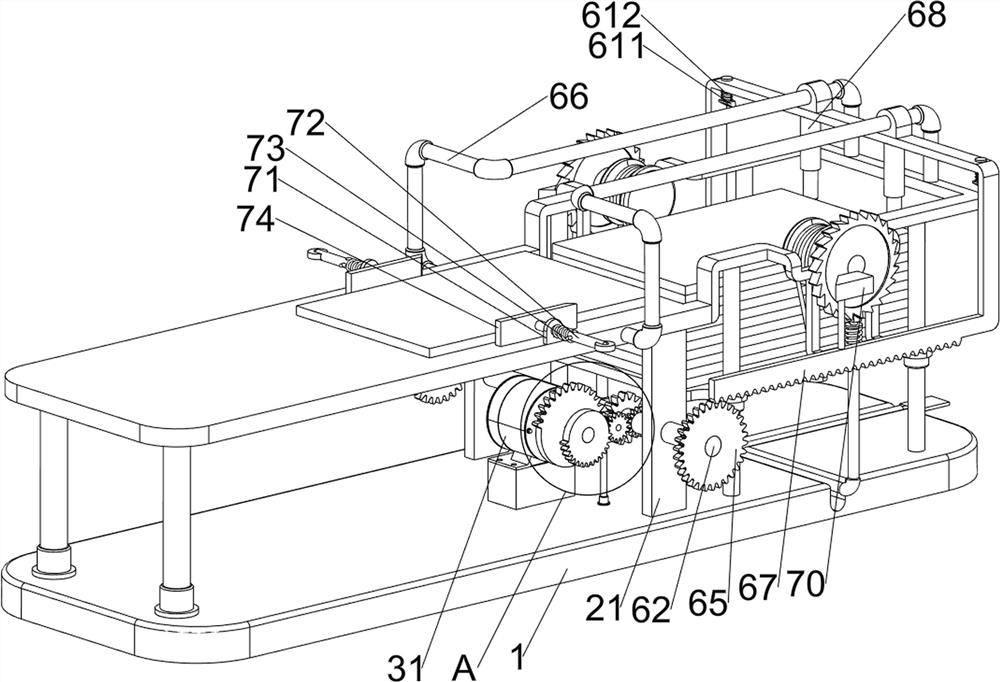

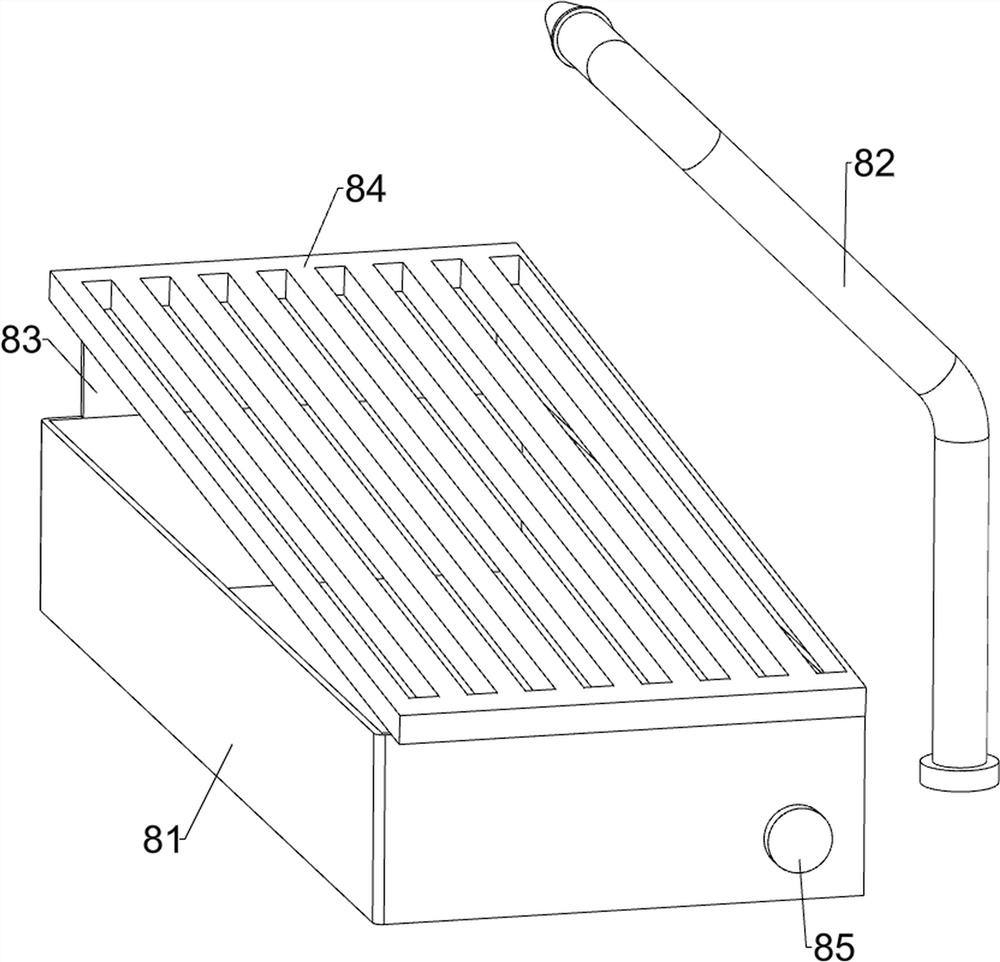

Stamping type wood composite board punching device

ActiveCN112809870AConvenient punching workSave human effortWood punching outPunchingStructural engineering

The invention relates to a punching device, in particular to a stamping type wood composite board punching device. According to the stamping type wood composite board punching device, manual drilling work is not needed. The stamping type wood composite board punching device comprises a bottom plate and a punching mechanism, and a supporting mechanism is arranged at the top of the bottom plate; and the punching mechanism is arranged on the supporting mechanism. Through the arrangement of the supporting mechanism and the punching mechanism, under the cooperation of workers, punching work can be continuously conducted on a composite board; a fixing mechanism is arranged to clamp the composite board during punching work, so that punching work is more convenient; and through cooperation of a feeding mechanism and a pushing mechanism, automatic feeding work of the composite board can be completed, and manpower is further saved.

Owner:山东久乐福木业有限公司

Medal template manufacturing process

InactiveCN104002346AIncrease productivityPunching edge smoothingWood compressionWood punching outIndustrial engineeringHot press

The invention discloses a medal template manufacturing process. The medal template manufacturing process solves the problems of low manufacturing efficiency, high manufacturing costs, influence on the health of operators and high sheet scrap rate of medal template manufacturing processes in the prior art. The medal template manufacturing process includes the steps of (1), stamping a density board into a sheet in a required size in accordance with the specification of a medal to obtain a surface board; (2), digesting and drying the surface board and pasting grainy paper to one side of the surface board; (3), placing the surface board pasted with the grainy paper in a hot pressing mould for hot pressing for further obtaining the surface board with embossed pattern formed on the side pasted with the grainy paper; (4), stamping another density board into a sheet identical to the finished surface board in shape and stamping support mounting holes in the sheet to obtain a back board; (5), pasting grainy paper on one side of the back board, the surface board and the back board are fitted with both of the sides pasted with the grainy paper facing outwards, and performing injection molding binding on the surface board and the back board to obtain a medal template. The medal template manufacturing process has the advantages of being simple in manufacturing process and capable of greatly improving the manufacturing efficiency and the like.

Owner:白植平

Processing method of bamboo shoot sheath circular tea tray

ActiveCN107116657AMeet the needs of material and cultural lifeHigh economic valueWood compressionPlant material mechanical workingAdhesive beltAdhesive

The invention discloses a processing method of a bamboo shoot sheath circular tea tray. The processing method comprises the steps of firstly, selecting naturally shedding bamboo shoot sheaths, airing the bamboo shoot sheaths, stewing the aired bamboo shoot sheaths in boiling water to be softened, after flattening and shaping, putting the bamboo shoot sheaths into a roller to be rolled, removing thin burrs growing on the surfaces of the bamboo shoot sheaths, and manufacturing the bamboo shoot sheaths into triangular bamboo shoot sheath sheets through stamping of a punch; secondly, neatly placing the eight triangular bamboo shoot sheath sheets, and gluing a splicing joint of the two adjacent triangular bamboo shoot sheath sheets with a punched adhesive tape which is dipped in water, so as to obtain a circular bamboo shoot sheath spliced sheet; again, purchasing impregnation transparent wear resistant paper and formaldehyde-free soybean glue, adding an isocyanic acid tallow adhesive, after uniform mixing, brushing a mixture on the two surfaces of the circular bamboo shoot sheath spliced sheet adopted as a rubber plate, and carrying out assembly according to the specified requirement; and finally, brushing a release agent in a tea tray mold, putting the assembled circular bamboo shoot sheath spliced sheet in the tea tray mold, starting a hot press for hot pressing to obtain a bamboo shoot sheath circular tea tray blank, rounding the bamboo shoot sheath circular tea tray blank through a grinding machine, brushing boiled oil on the rounded bamboo shoot sheath circular tea tray blank, and airing to obtain the bamboo shoot sheath circular tea tray. According to the processing method, economic value of phyllostachys edulis can be greatly improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Decorative plate punching and polishing integrated machine based on stroke energy utilization

The invention designs a solid-punch-type punching and polishing machine. Remaining stroke energy of a spacing punch is utilized to be converted into rotating force of a sand surface polished layer topolish the inner wall of a circle center hole, so that punching and polishing of the hole inner wall are completed in the same device and even in the same stroke, the working procedure is greatly saved, the energy utilization rate is increased, the occupied area of the machine is decreased, external polishing power does not need to be used, the integration level is greatly improved, and the greateffects are obtained in actual use.

Owner:安徽省行千里知识产权服务有限公司

Preparation method of embossed decorative board for wooden art crafts

InactiveCN109623989AClear textureImprove the decorative effectWood compressionOrnamental structuresPunchingEngineering

The invention discloses a preparation method of an embossed decorative board for wooden art crafts, and relates to the technical field of board embossing. The method comprises the following steps thatS1, a pattern is engraved on a mold by an engraving and milling machine according to a mold file; S2, the mold is assembled on a punching machine; S3, a board is placed on a working table top of thepunching machine; S4, the punching machine presses the mold downwards onto the board, and the pattern with clear textures is embossed. According to the preparation method, various embossed textures are pressed onto the ordinary board by the mold, the textures of the pressed board are clear, the great decorative effect is achieved, the machining process is simple and more convenient, the machiningtime is short, and the production efficiency is high.

Owner:FUZHOU CHANGCHUNTENG HOME FURNISHING MFG

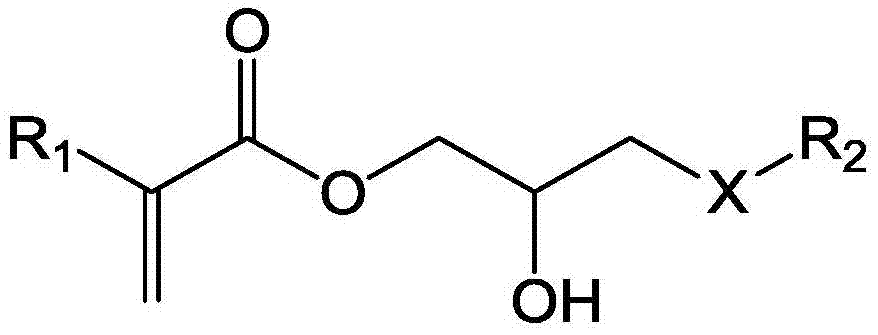

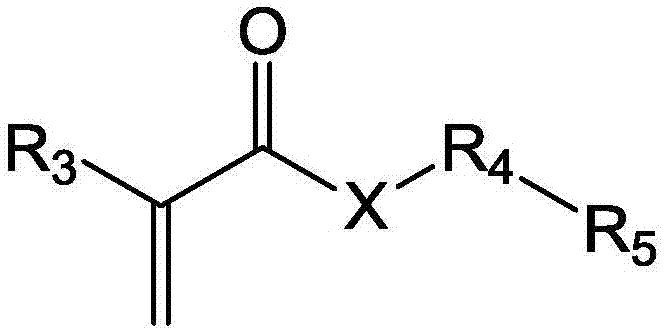

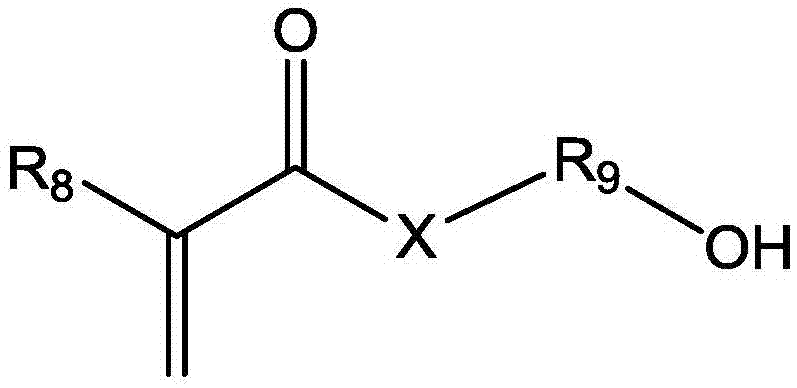

Adhesive composition and composite polarizing plate using same

InactiveCN105452407AImprove heat resistanceExcellent heat and humidity resistanceOther plywood/veneer working apparatusFilm/foil adhesivesHeat resistancePolarizer

The present invention relates to an adhesive composition and a composite polarizing plate using same, more specifically to an adhesive composition and a composite polarizing plate using same, in which the adhesive composition comprises: a photopolymerizable compound containing acrylic monomers having a hydroxyl or carboxyl group, and 6-18 carbon aromatic rings; and a photopolymerization initiator, thereby markedly improving the adhesiveness between a polarizer and a patterned retardation layer when utilized in producing a composite polarizing plate by adhering the polarizer and patterned retardation layer, and contributing to improving heat resistance and moist heat resistance, as well as to imparting a superb three-dimensional effect.

Owner:DONGWOO FINE CHEM CO LTD

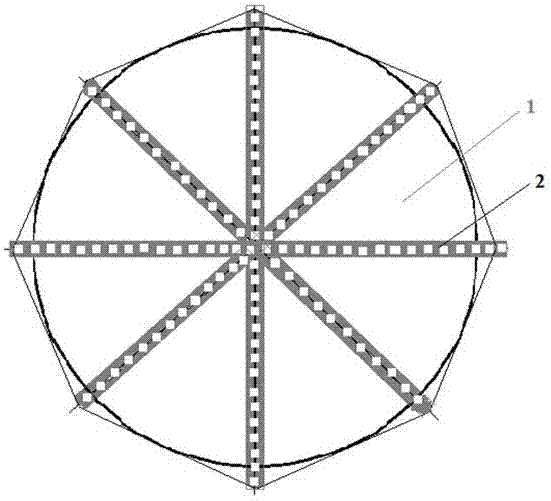

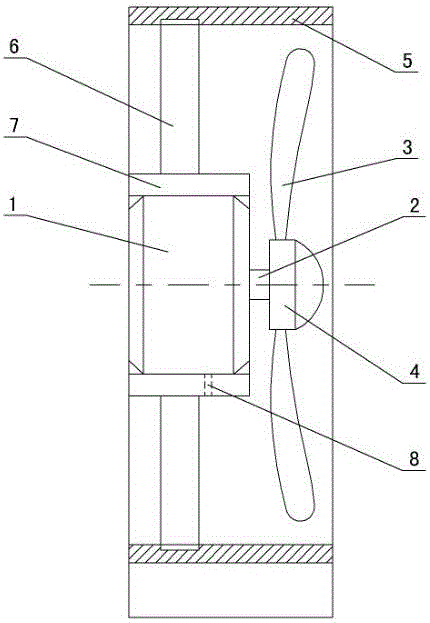

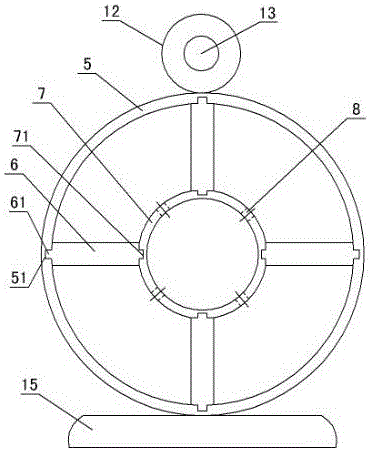

Method of manufacturing wooden-support miniature electric fan

A method of manufacturing a wooden-support miniature electric fan comprising a motor, blades and a support is characterized by including the steps of manufacturing an outer fixing frame, manufacturing an inner fixing ring, manufacturing a support rod, manufacturing fan blades, manufacturing blade fixing rings, manufacturing a blade enclosure, and mounting and forming; the support of the whole electric fan is made of natural wood, has wood texture, is robust and elegant and highly interesting, may act as a crafts for placement, and is deeply popular with people; all wood material is subjected to anti-cracking and anti-shrinking treatment, and long life is provided.

Owner:邱禹迪

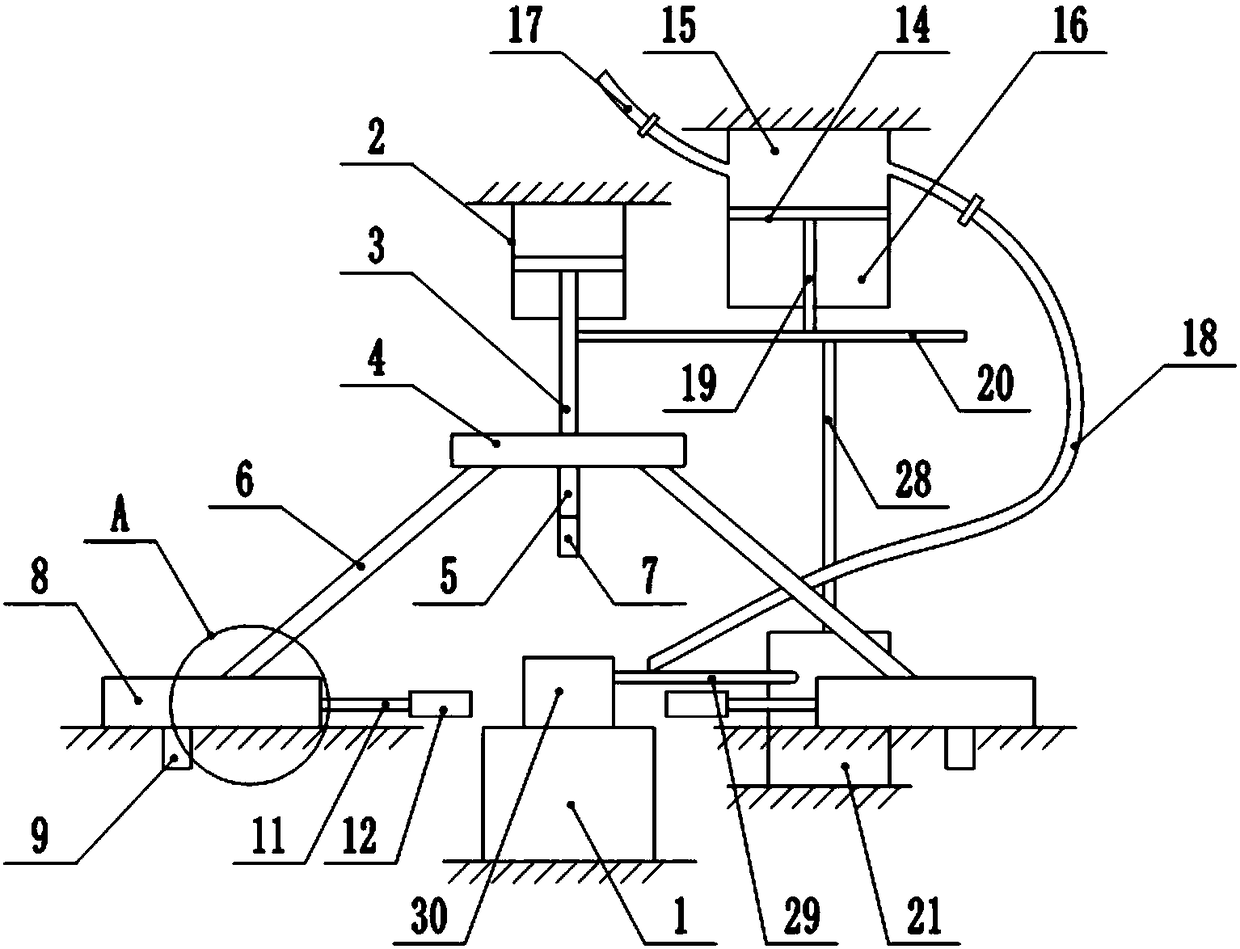

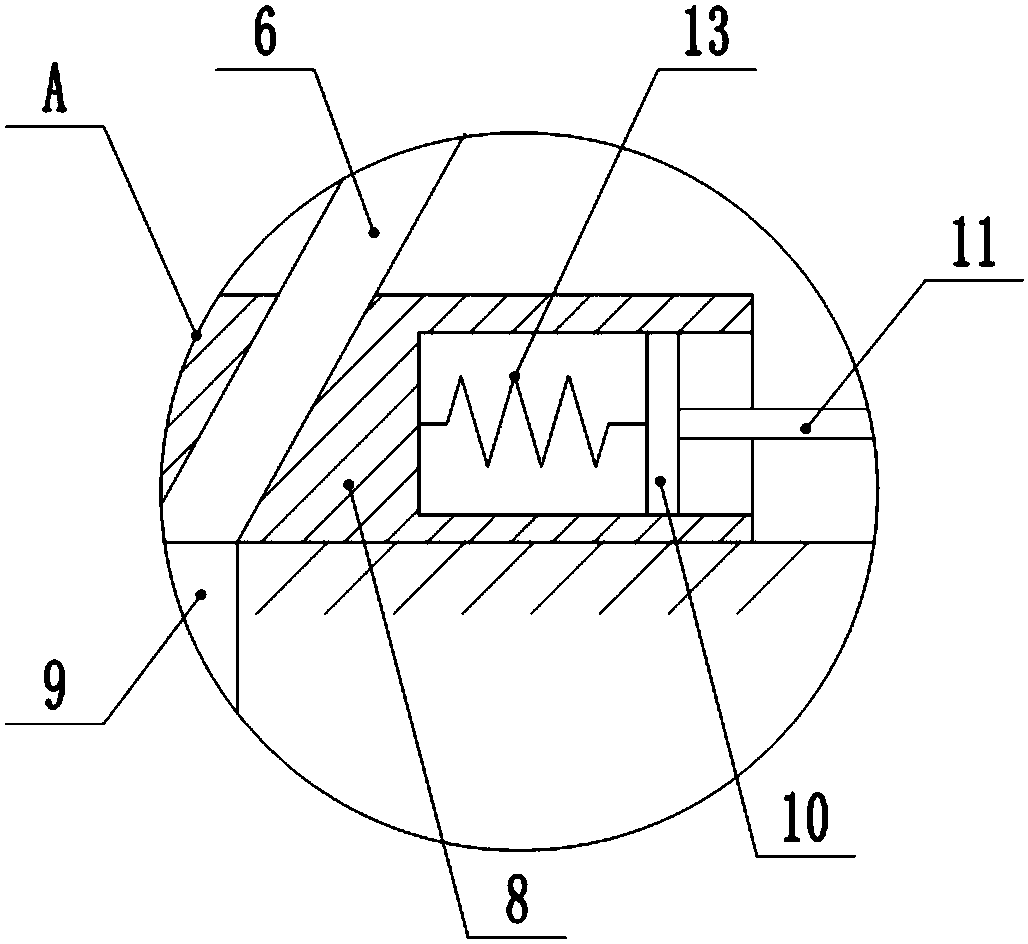

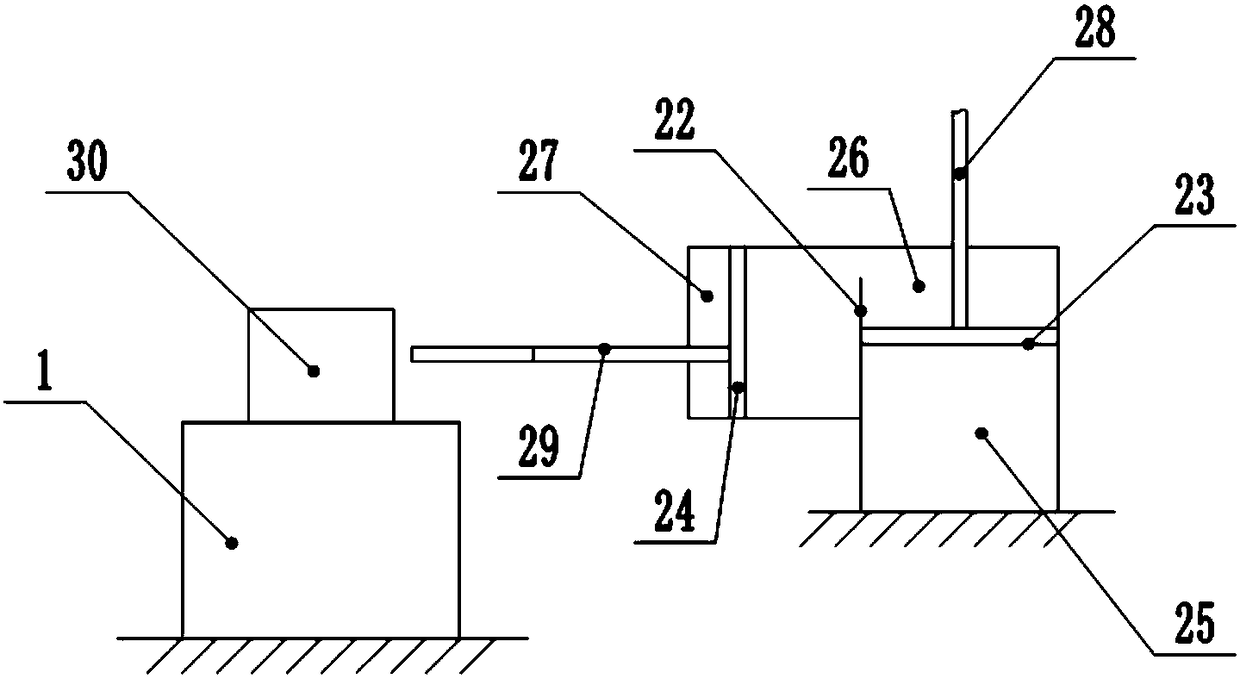

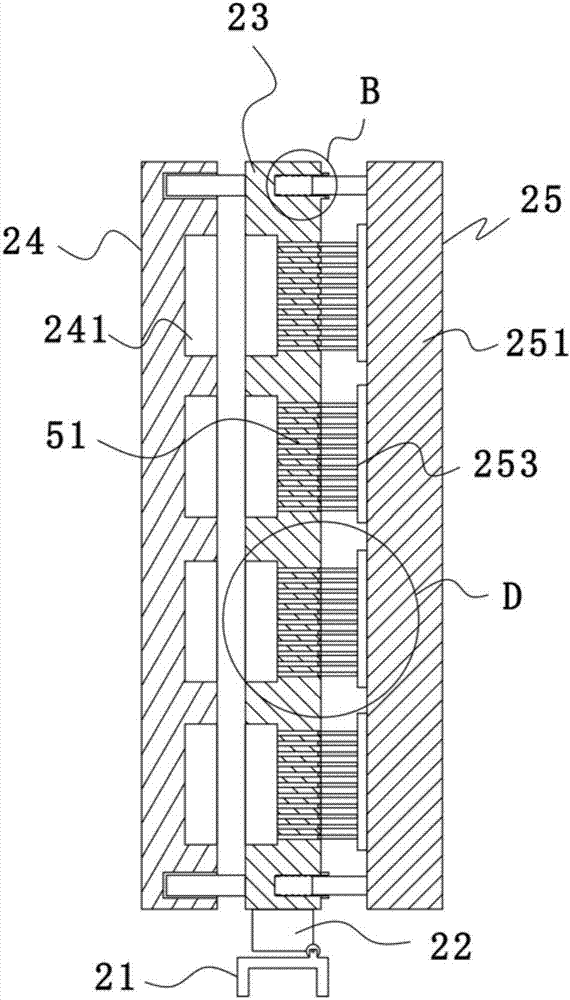

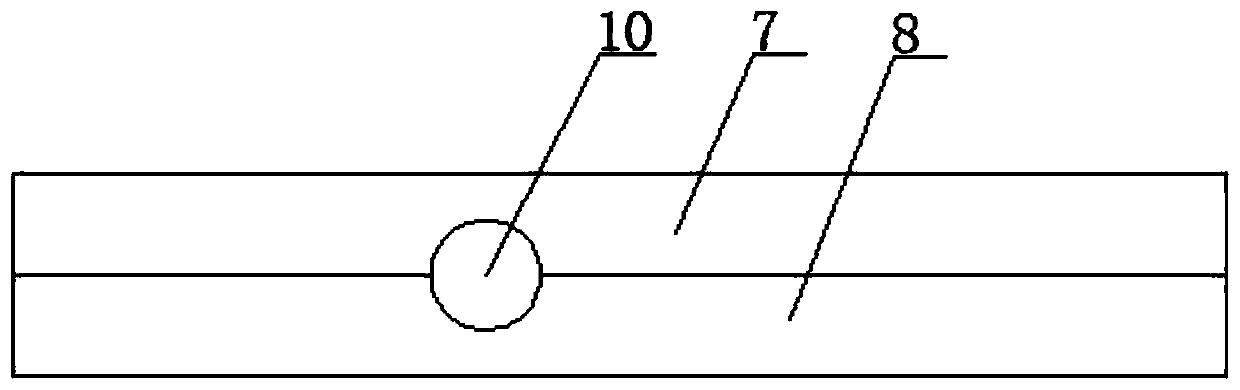

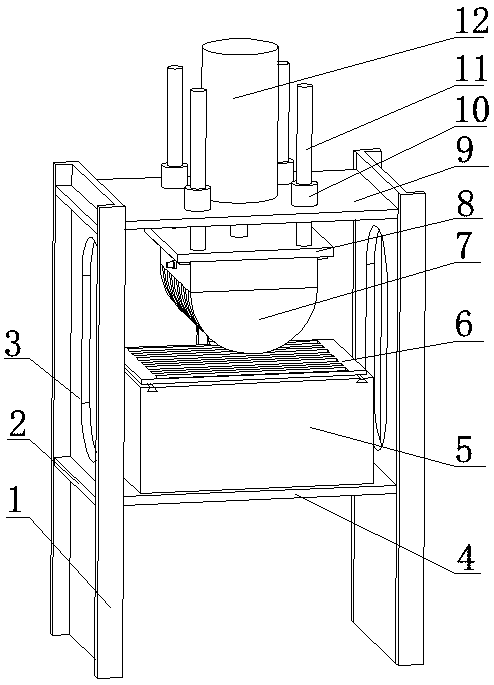

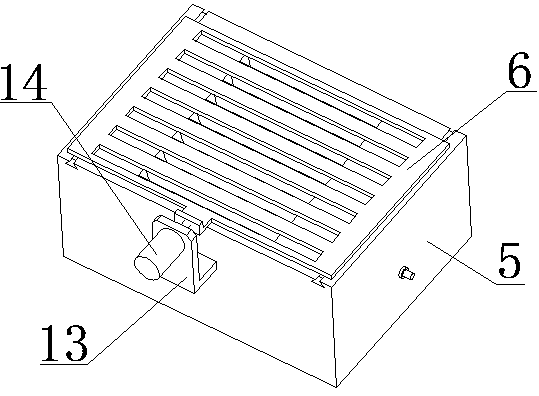

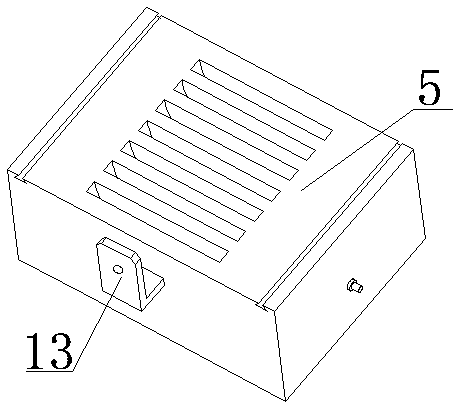

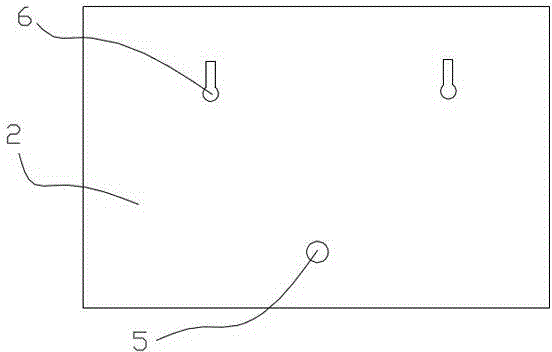

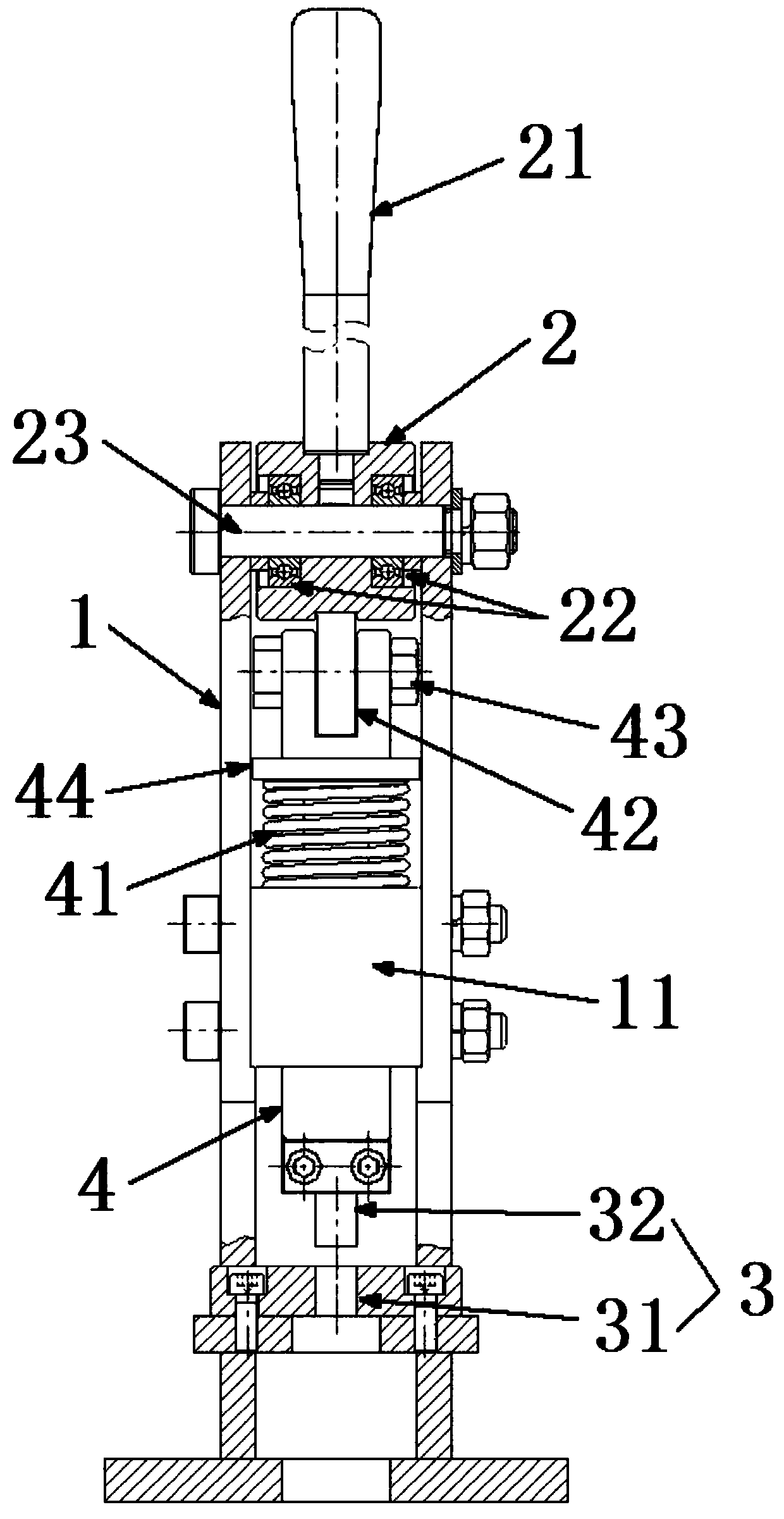

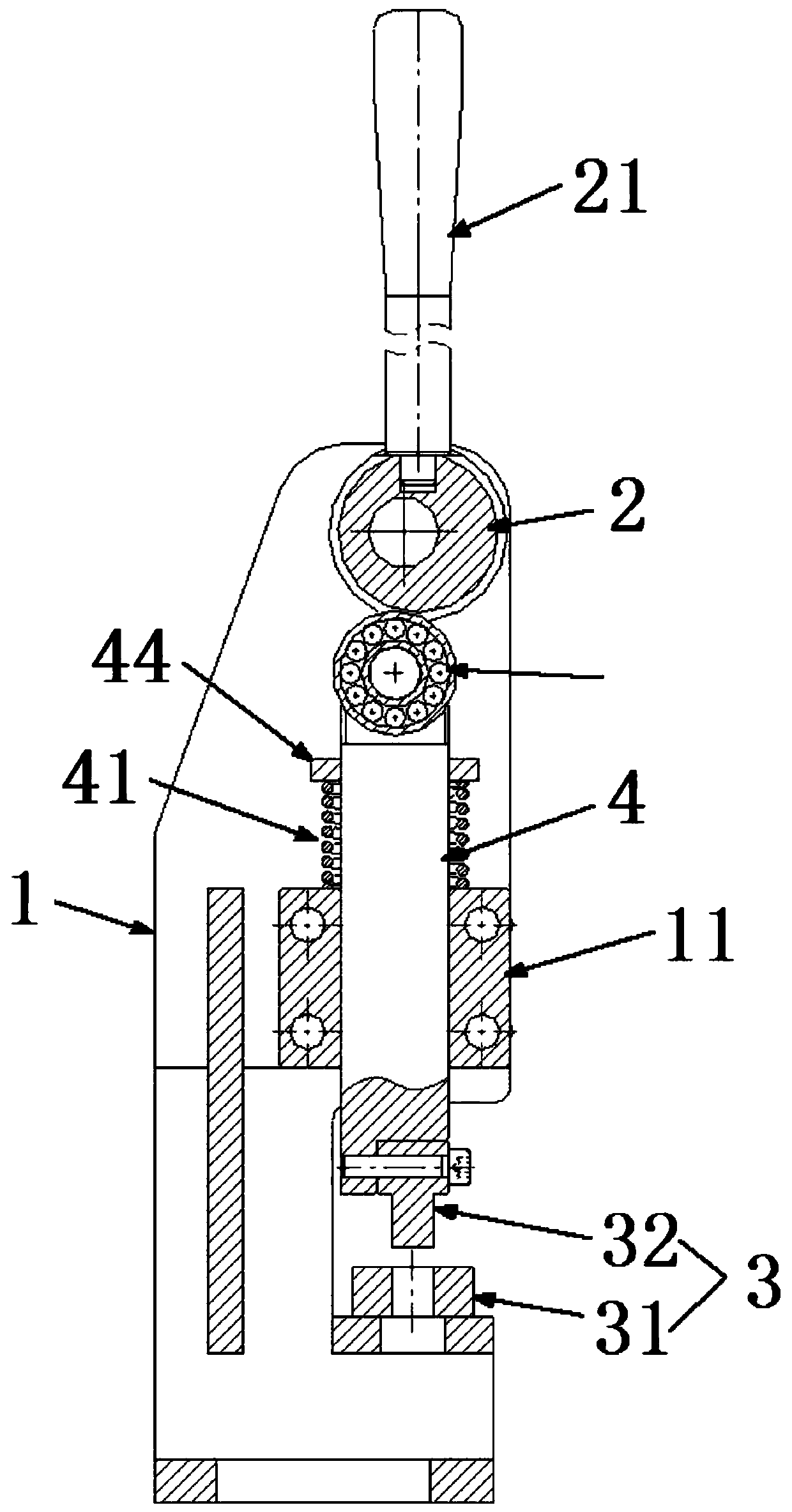

Manual punching device

InactiveCN110884185ASimple structureEasy to usePress ramMetal working apparatusPunchingWorking environment

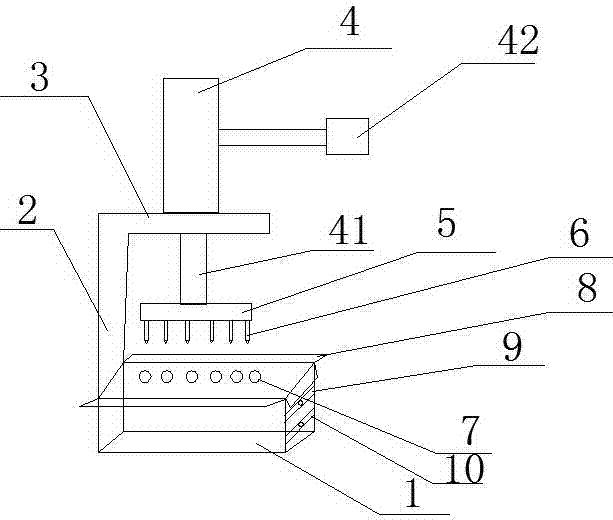

The invention discloses a manual punching device. The manual punching device comprises a rack (1); an eccentric wheel (2) which is rotatably arranged on the rack (1); a female die (31) of a punching die (3) which is arranged at the bottom of the rack (1); a telescopic rod (4) which is arranged in the rack (1), wherein a male die (32) of the punching die (3) is arranged at one end of the telescopicrod (4), and the other end of the telescopic rod (4) is matched with the eccentric wheel (2); the telescopic rod (4) is further provided with a return elastic part (41), and the return elastic part (41) is connected with the telescopic rod (4) and the rack (1). The manual punching device is simple in structure, small, exquisite, flexible, convenient to use, low in cost, high in efficiency, capable of being moved to any position to be used, capable of adapting to various working environments, capable of meeting various hole machining requirements for punching, chambering, hole repairing and the like and wide in application range.

Owner:HUNAN NONGGUANG AGRI EQUIP CO LTD

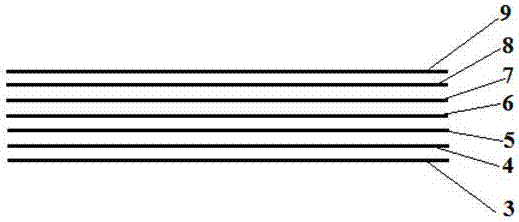

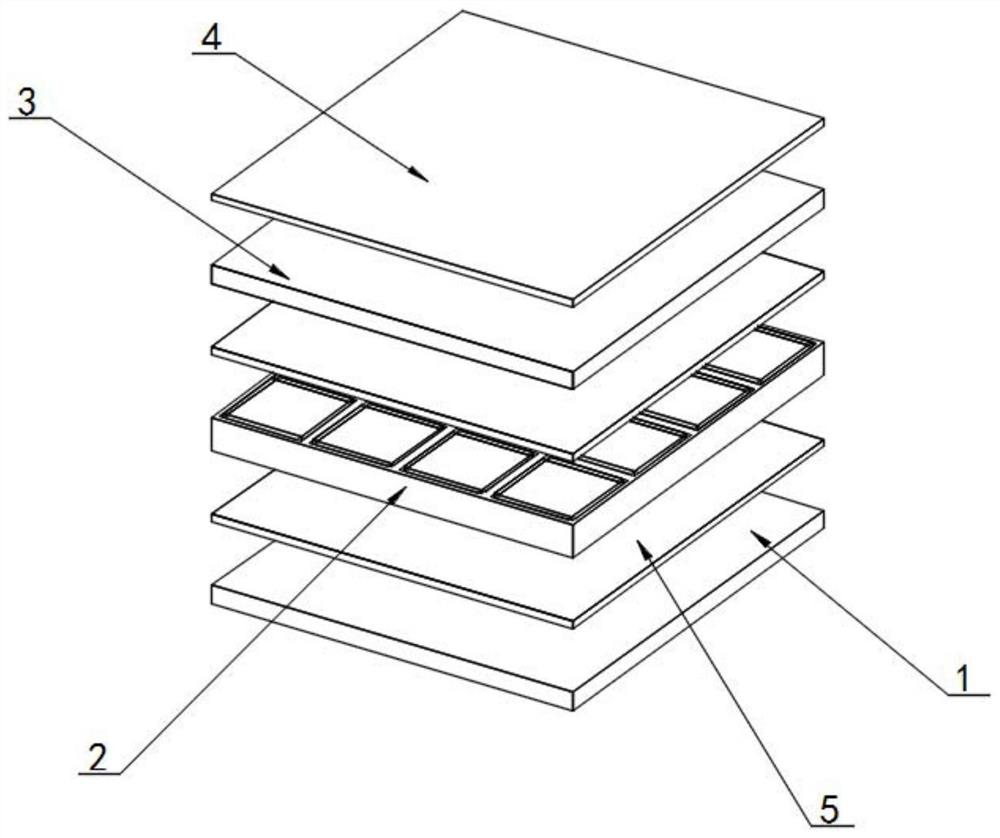

Environment-friendly formaldehyde-free flame-retardant plywood and preparation process thereof

ActiveCN113977710AImprove flame retardant performanceFirmly connectedWood compressionLaminationWood veneerSingle plate

The invention relates to the technical field of plywood, and discloses environment-friendly formaldehyde-free flame-retardant plywood, which comprises a lower-layer wood veneer, wherein a plywood layer is arranged at the top of the lower-layer wood veneer, an upper-layer wood veneer is arranged at the top of the plywood layer, an outer film aluminum foil layer is arranged at the top of the upper-layer wood veneer, adhesive film layers are sprayed between the plywood layer and the lower-layer wood veneer and between the plywood layer and the upper-layer wood veneer, filler grids are uniformly distributed in the plywood layer, and fireproof film bags are adhered to the inner walls of the filler grids. According to the invention, fireproof film bags are attached to the inner side of filler grids on a plywood layer, the filler grids are filled with gluing filler blocks to form a plywood interlayer, when the plywood is burned, the fireproof film bags are damaged, fire-fighting dust blocks are thermally decomposed to generate fire-fighting dust, and pressure bubble particles on the surface of the fireproof film bags explode, so that the dust is dispersed, open fire on the plywood is extinguished, and the flame retardant effect of the plywood is improved.

Owner:TAOJIANG HONGSEN WOOD IND

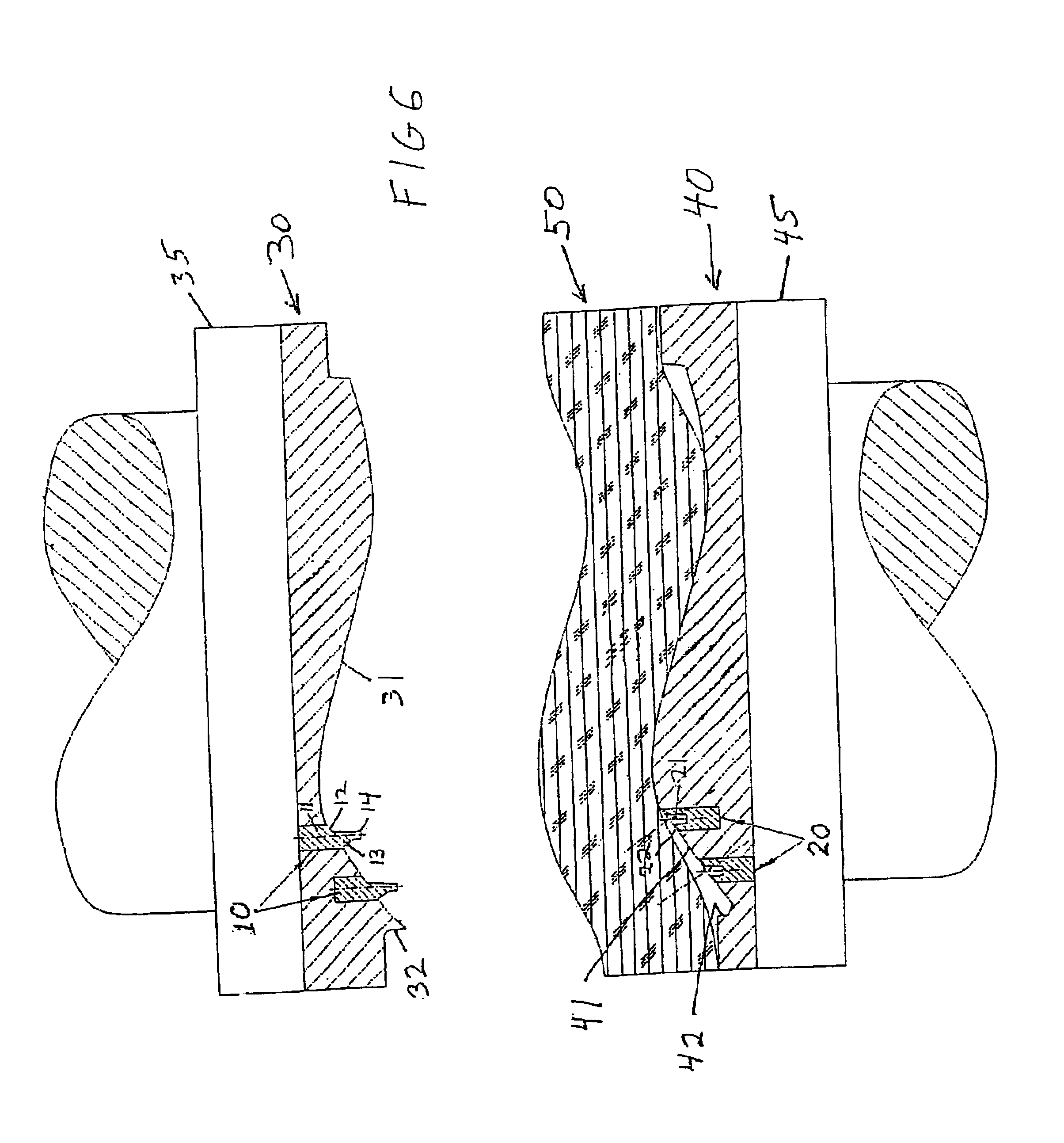

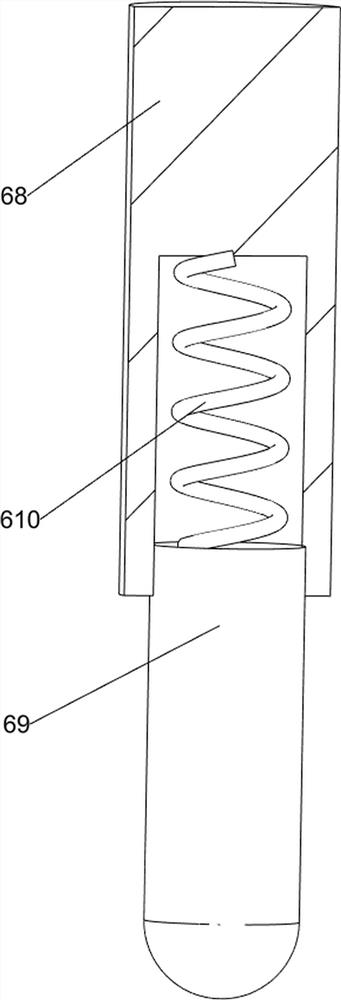

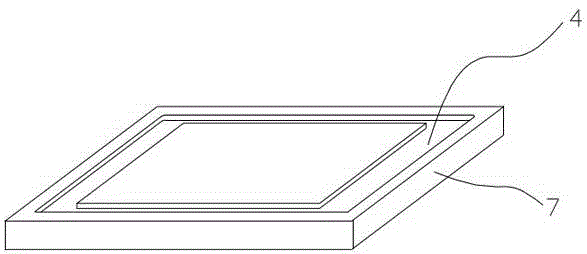

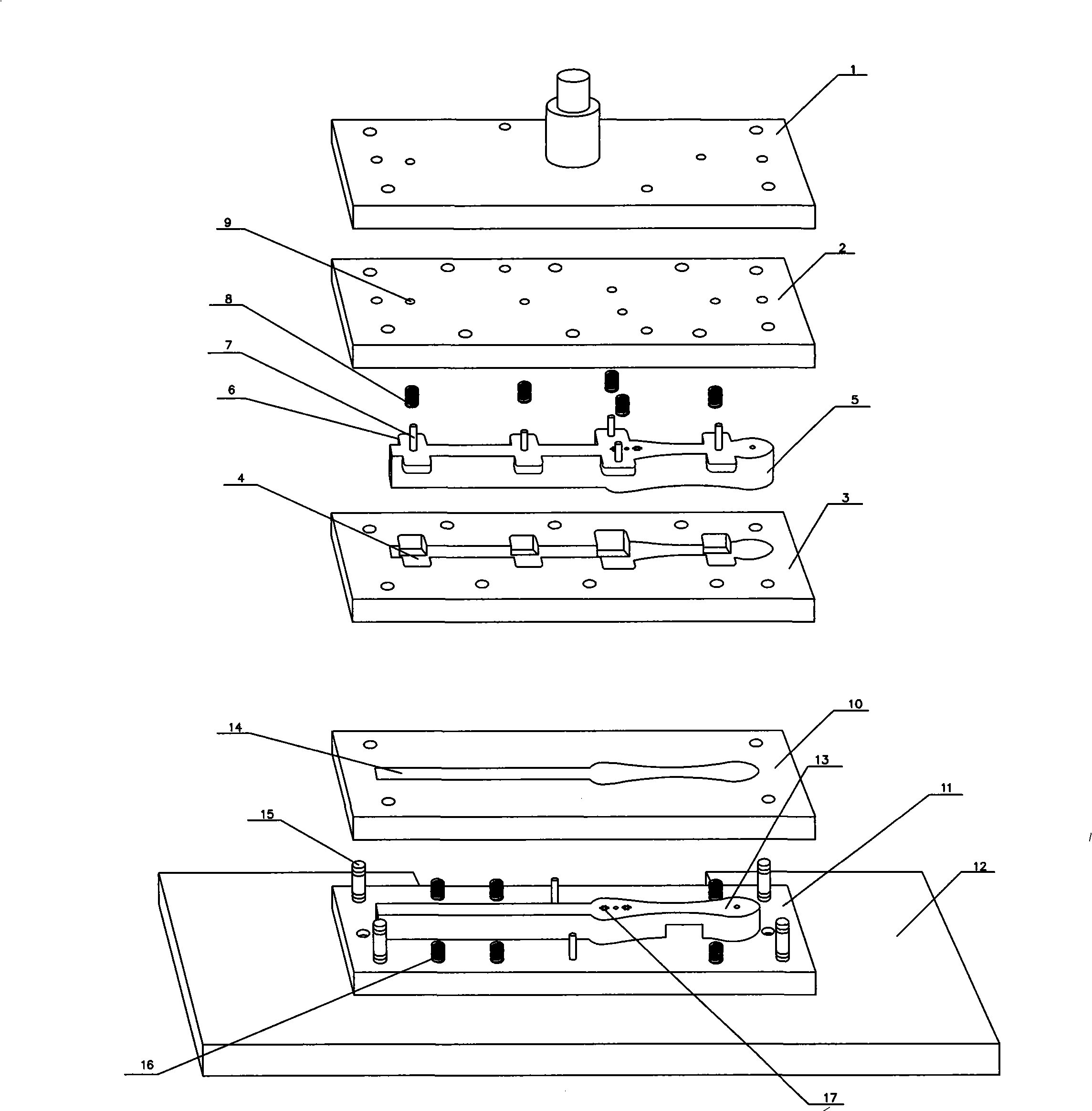

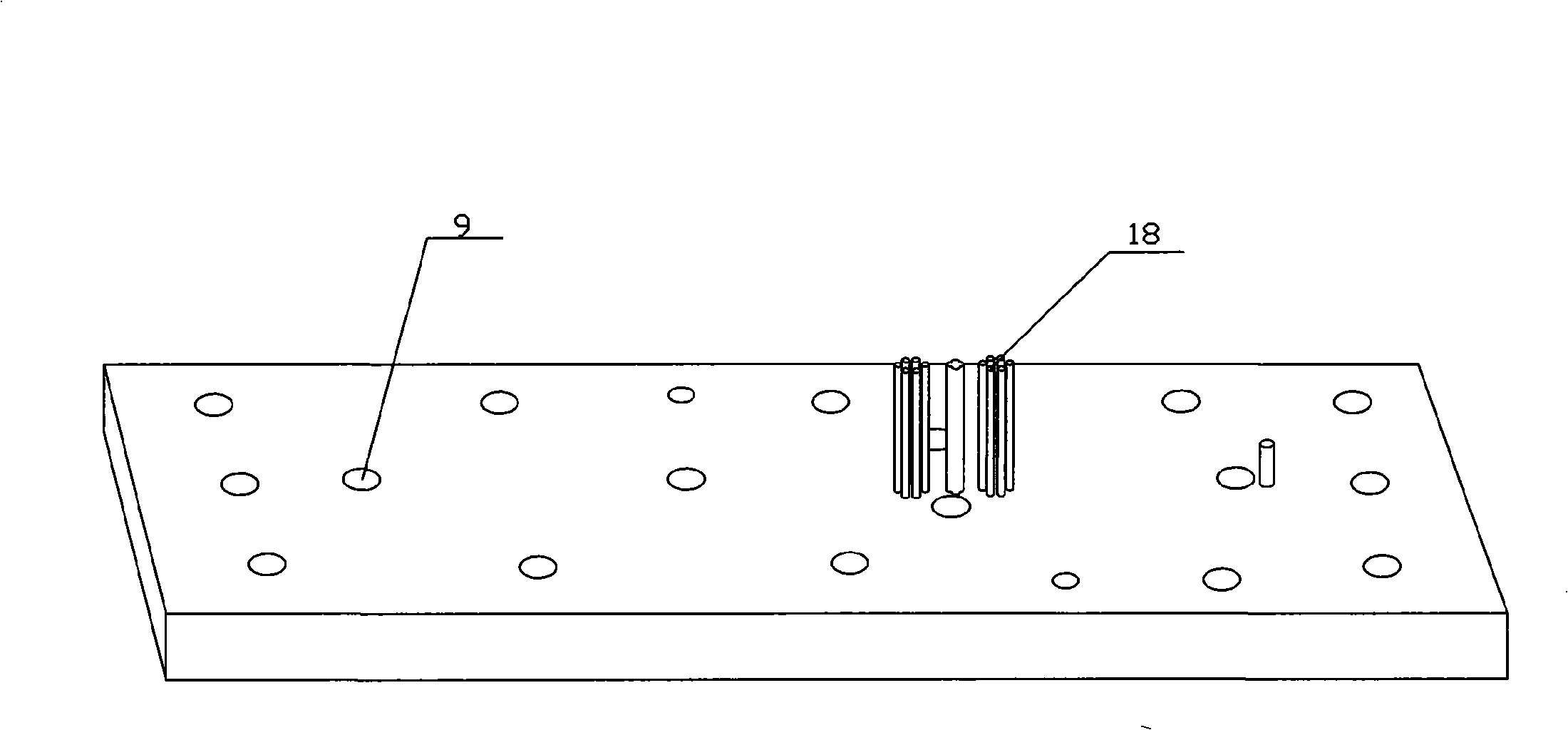

Mount press forming mold

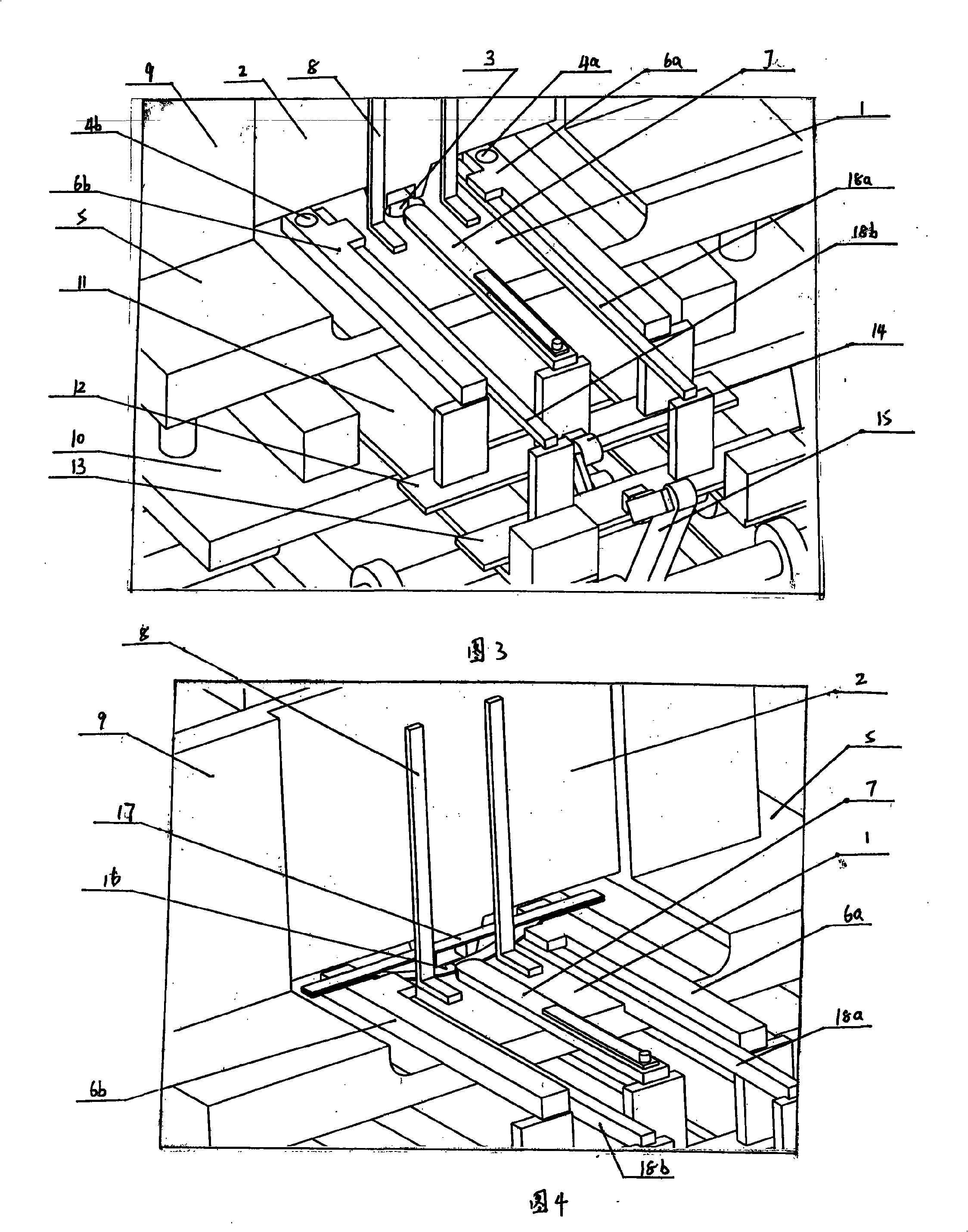

InactiveCN101352864AImprove forming qualityForming quality is beautifulWood compressionWood punching outEngineering

The invention relates to a fan framework stamping mold, comprising a male mold and a female mold, the male mold consists of an upper mold seat, an upper-middle seat and an upper panel that are superposed sequentially from up to down. The upper mold seat is connected with the upper-middle seat by pins, the upper-middle seat is connected with the upper panel by pins, the upper panel is opened with a through hole, the shape of which matches with an upper mold core that is arranged in the upper panel in a sliding way, the upper mold core is provided with a stopper that prevents the upper mold core from separating from the upper panel, the top of the upper mold core is provided with a pin column that goes through the guide hole of the upper-middle seat, and a spring that is sheathed on the pin column supports the upper mold core on the upper panel closely; the female mold consists of a lower panel, a lower middle seat and a lower mold seat that are superposed sequentially from up to down, a lower mold core is fixedly connected on the lower panel, the lower middle seat is fixedly connected on the lower mold seat, the lower panel is opened with a through hole, the shape of which matches with the lower mold core that is sheathed in the through hole, the lower panel is sheathed on the pin column in the lower middle seat, and a closely supporting spring is arranged between the lower middle seat and the lower panel.

Owner:夏月明

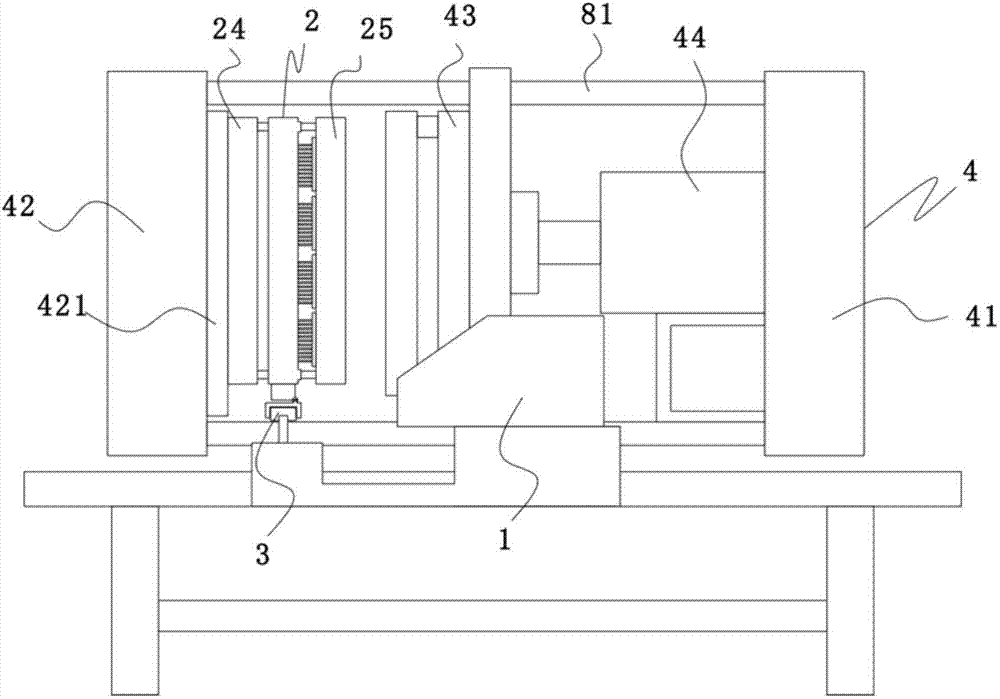

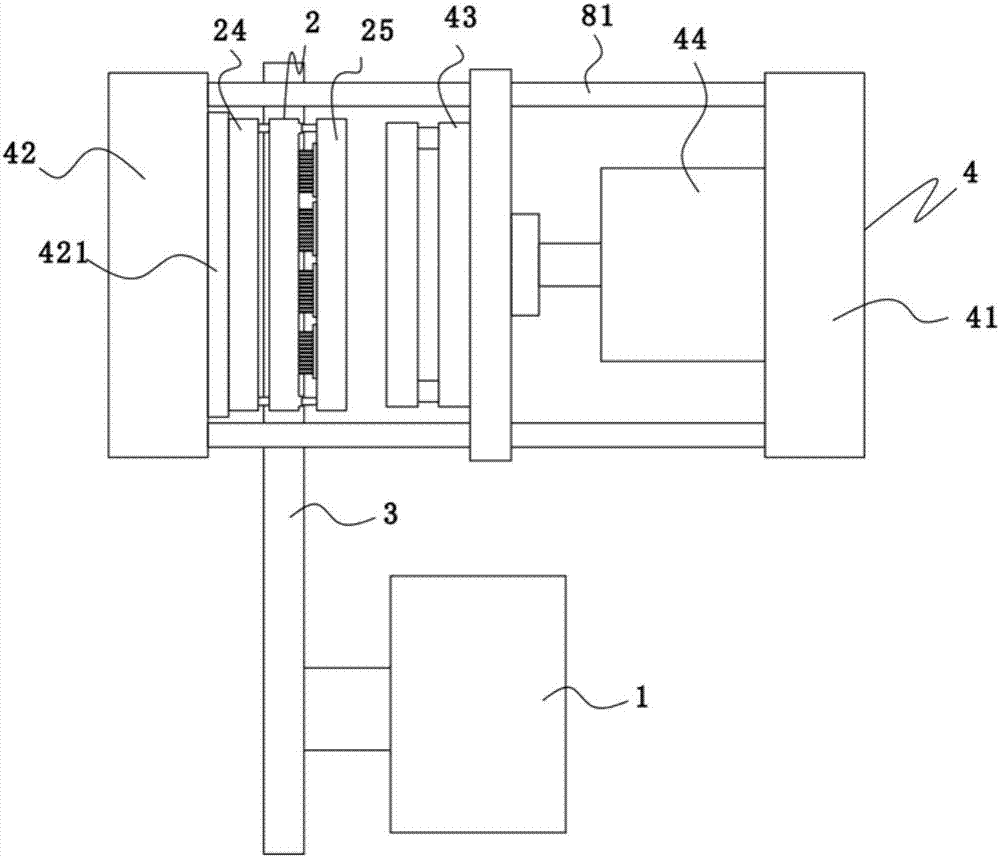

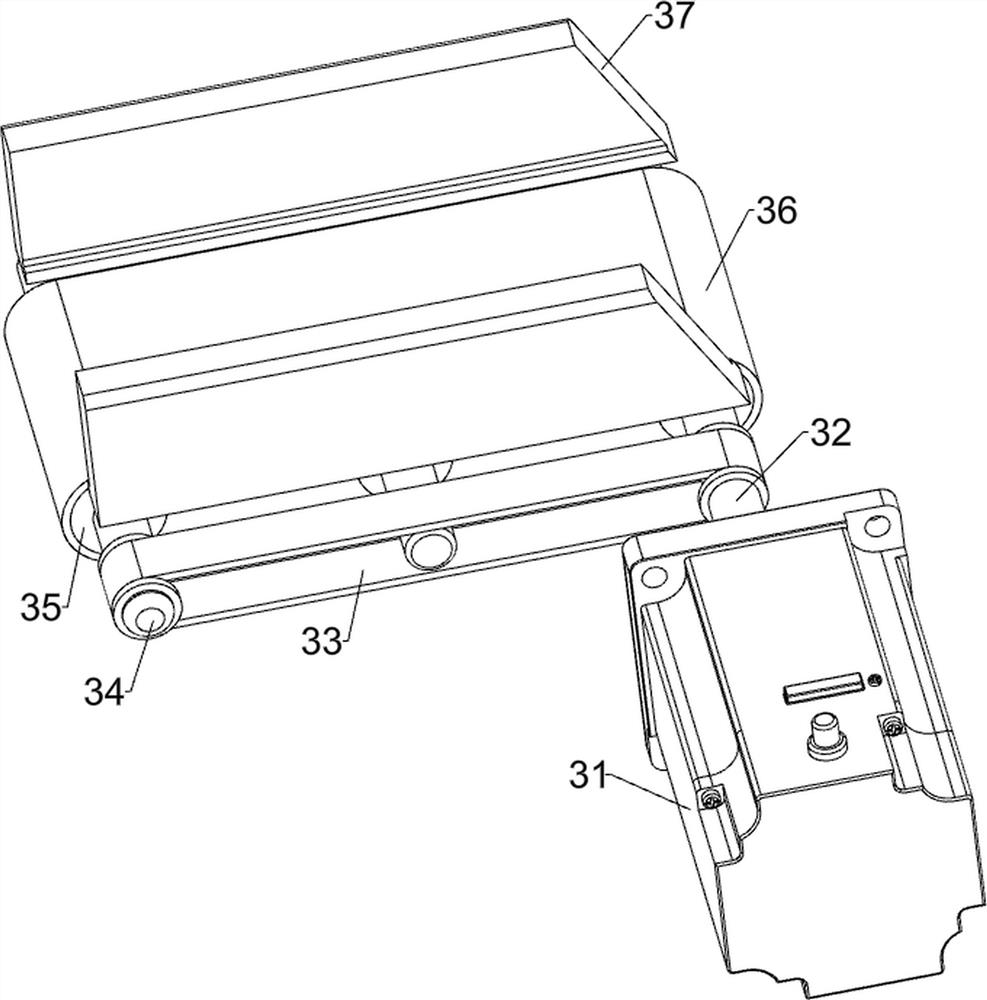

Plate punching equipment for intelligent manufacturing

The invention relates to plate punching equipment, in particular to plate punching equipment for intelligent manufacturing. According to the plate punching equipment for intelligent manufacturing, the punching quality is good, the punching position is fixed, and wood chips can be cleaned. The plate punching equipment for intelligent manufacturing comprises a base, supporting frames, a driving transportation mechanism and a stamping and punching mechanism, wherein the base is used for installing the whole equipment, the multiple supporting frames are arranged at the top of the base, the driving transportation mechanism is arranged in the middle of the top of the base, and the stamping and punching mechanism is arranged on one side of the top of the base. Through cooperation of a vertical plate, a stabilizing column and a first spring, a buffering plate drives a lower pressing block to move downwards, and the lower pressing block makes contact with a sliding plate and drives the vertical plate to slide downwards, so that plates on a conveying belt are blocked; meanwhile, the stabilizing column abuts against a punching table, so that the situation that the punching table shakes left and right in the punching process is prevented.

Owner:山东民创重工科技有限公司

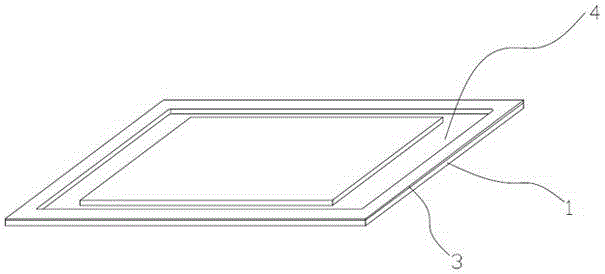

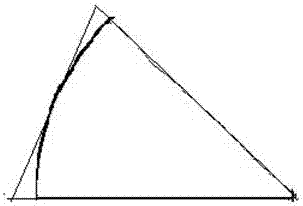

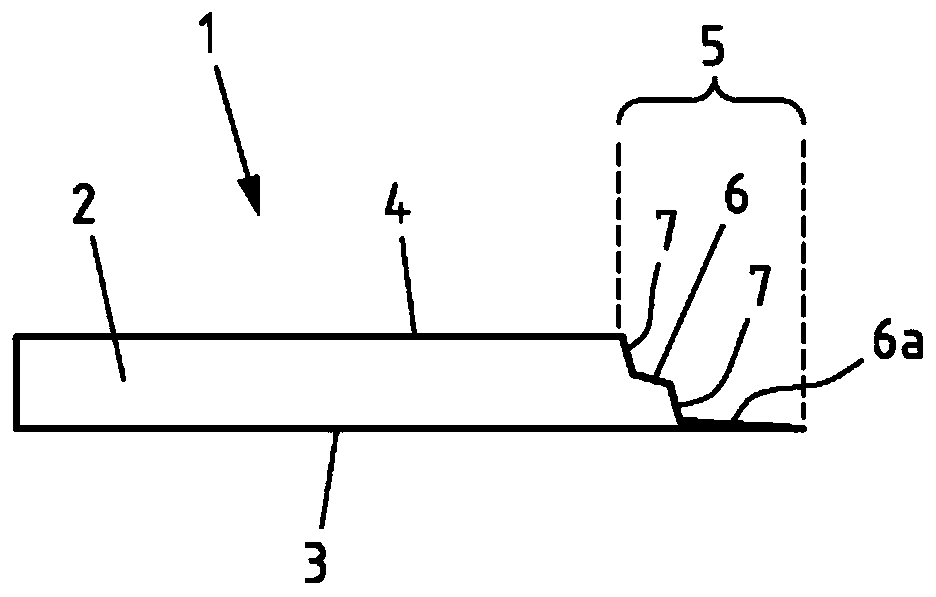

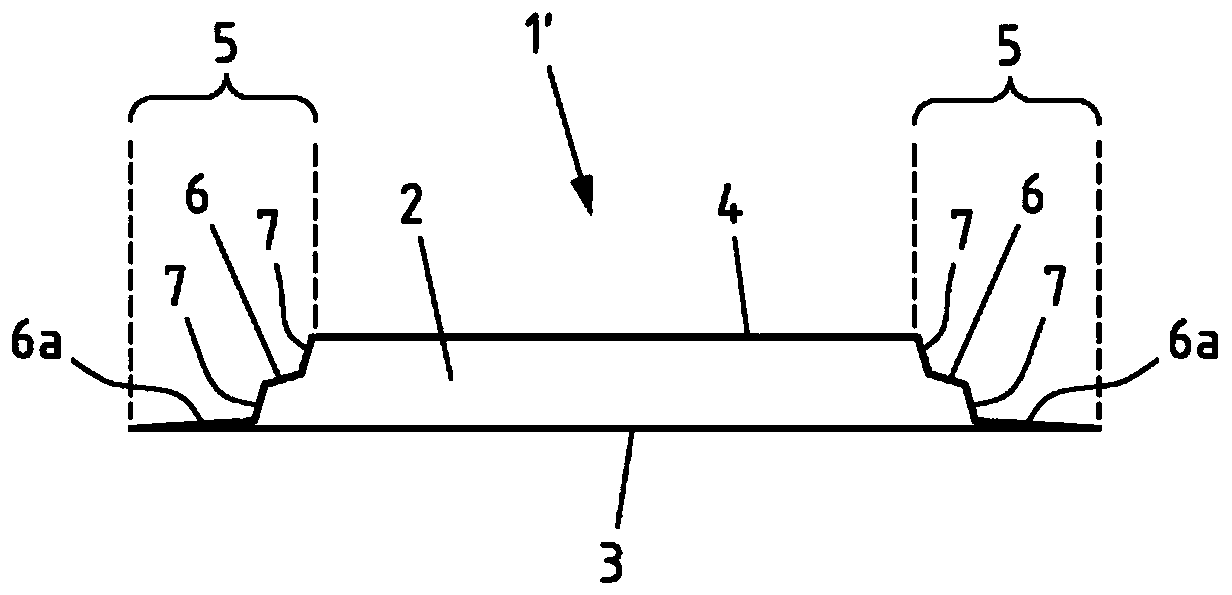

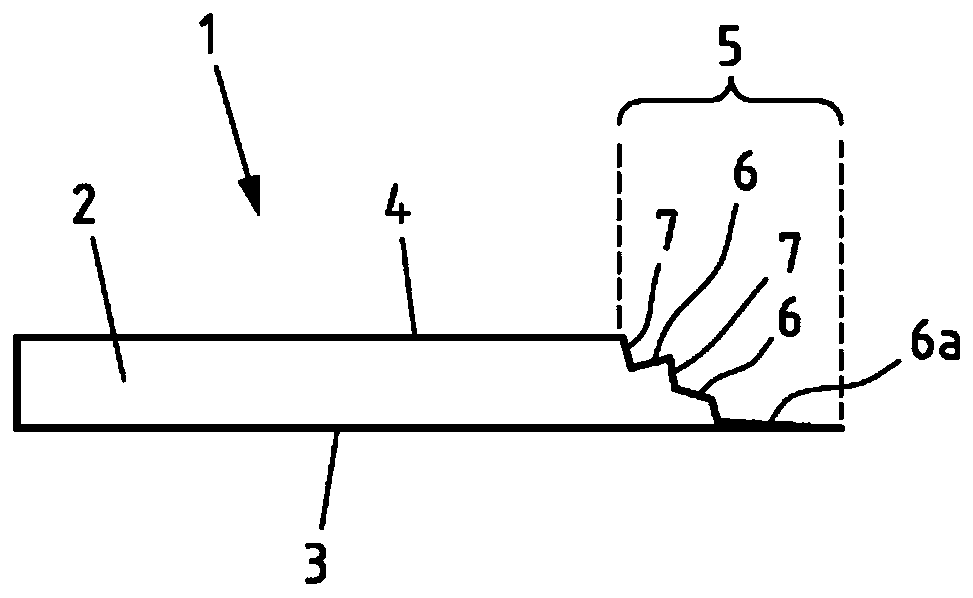

Edge strip and method for production thereof

ActiveCN111587078AOther plywood/veneer working apparatusWood compressionStructural engineeringTwo step

The invention relates to an edge strip (1, 1') for pieces of furniture, comprising a main body (2), which has a lower face (3), which can be laid against a piece of furniture, and an upper face (4), which faces away from the lower face (3), the upper face (4) having at least one transition portion (5) dropping toward a border of the main body (2). The aim of the invention is to enable a better visual impression of the edge strip (1, 1') in the transition portion. This aim is achieved, according to the invention, in that the transition portion (5) drops to the border of the main body (2) in a stepped shape, wherein the transition portion (5) has at least two steps each having an upper surface (6, 6a) and a border-side surface (7), and the upper surfaces (6, 6a) are oriented independently ofone another relative to the lower face (3) in such a way that the smallest angles of the upper surfaces (6, 6a) relative to the lower face (3) are on average -45 degrees to 75 degrees, in particular-45 degrees bis 45 degrees, and the border-side surfaces (7) are inclined independently of one another relative to the lower face (3) in such a way that the smallest angles of the border-side surfaces(7) relative to the lower face (3) are on average 20 degrees to less than 90 degrees, in particular 46 degrees to less than 90 degrees, in particular up to 80 degrees.

Owner:FRITZ EGGER GMBH & CO OG

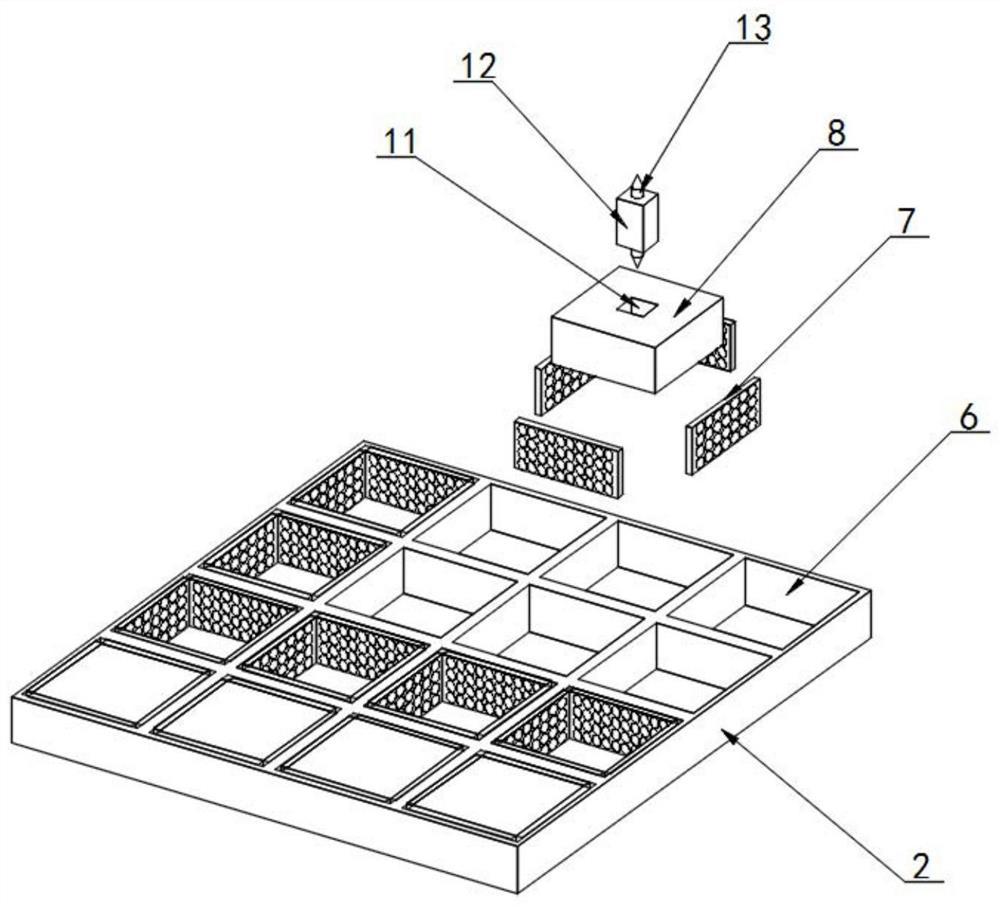

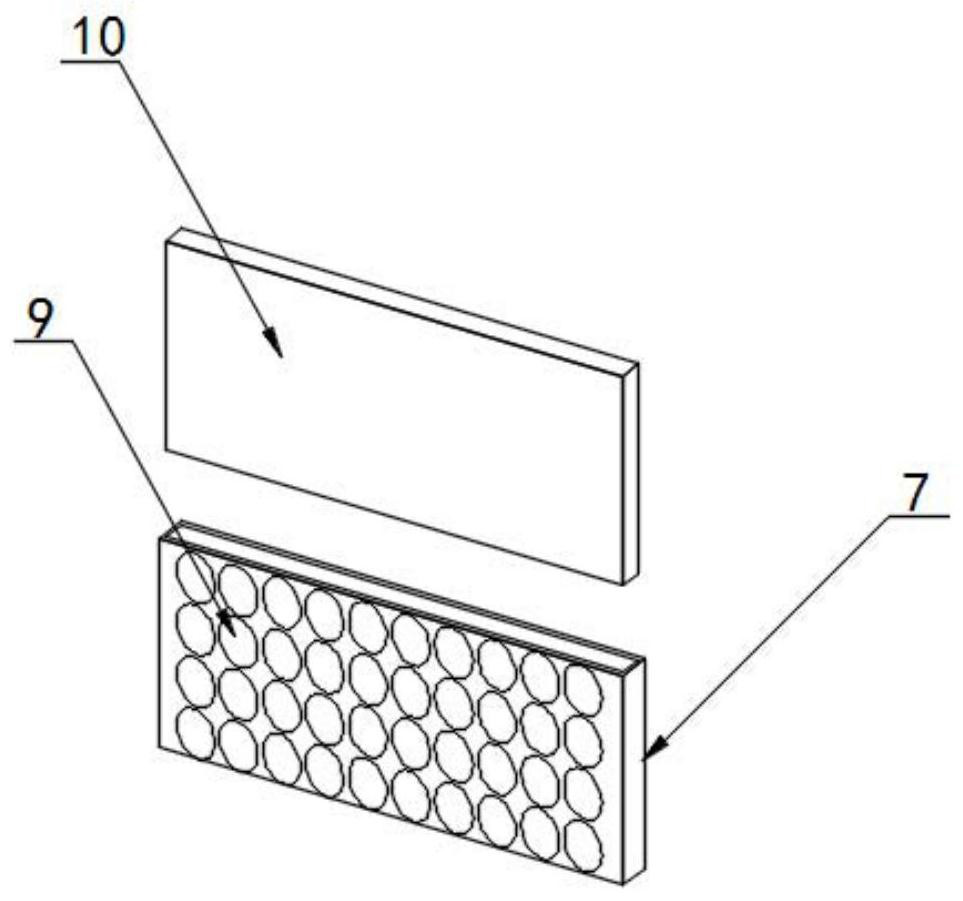

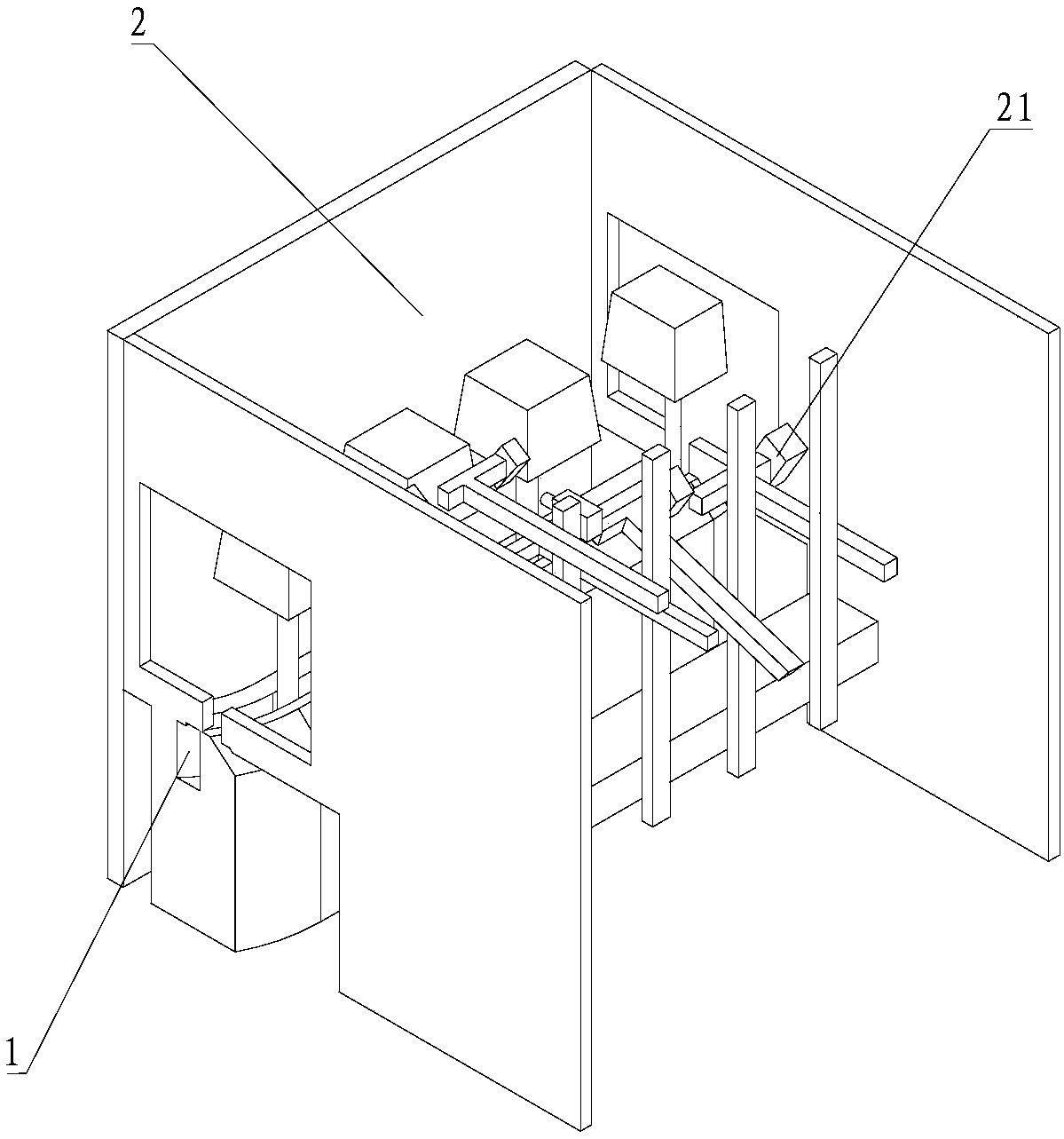

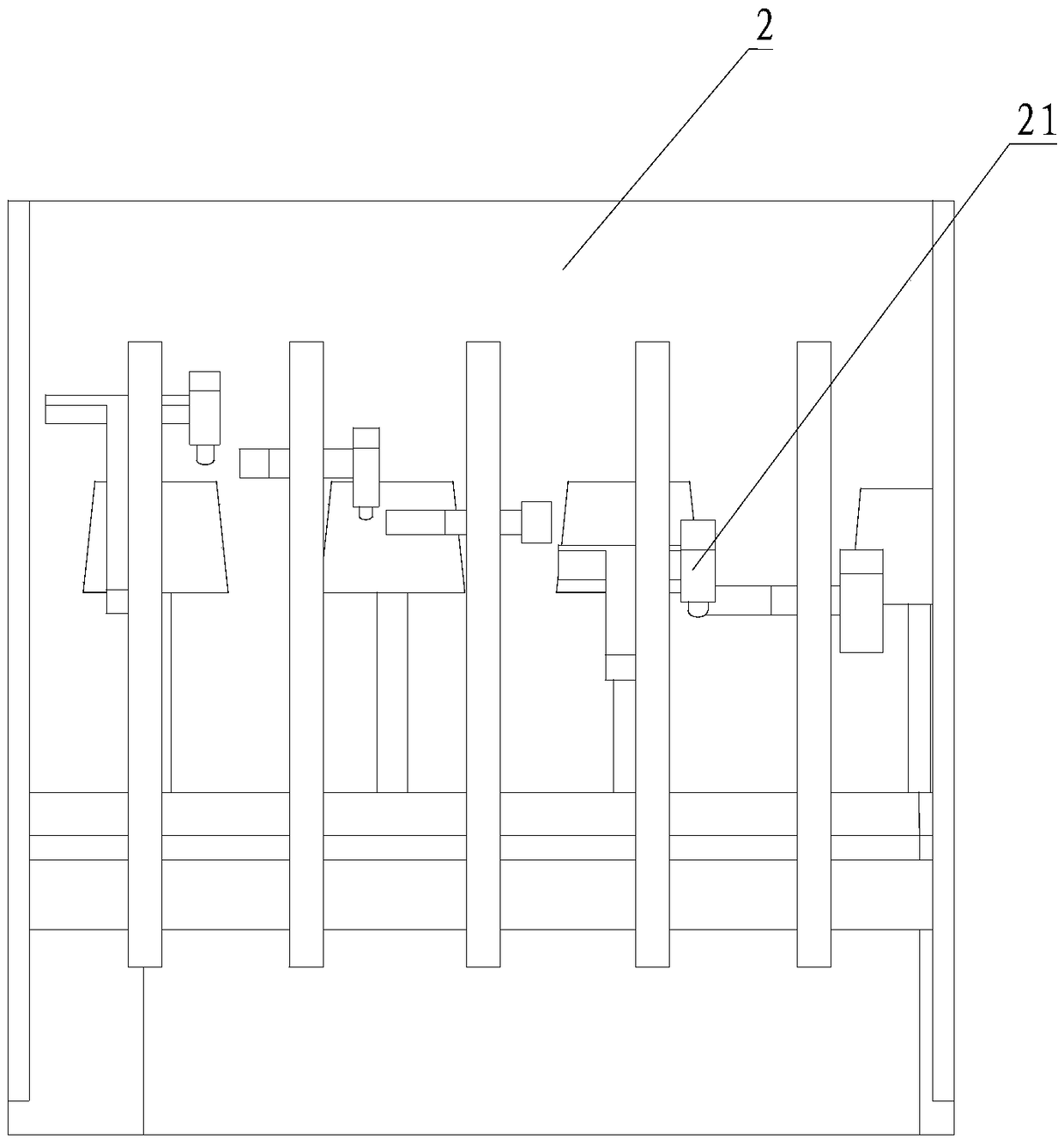

Multi-station continuous stamping automatic assembly line mechanism

ActiveCN109318332AImprove uniformityImprove dust removal effectWood compressionCane mechanical workingEngineeringAssembly line

The invention relates to the technical field of mechanical design, in particular to a multi-station continuous stamping automatic assembly line mechanism. A supporting frame rotates positively or reversely along with motion of a conveying chain, in the process of passing through a stamping chamber, multiple stamping guns are distributed in sequence in one direction, the horizontal heights of the stamping guns are gradually reduced in the direction, multi-station continuous stamping can be achieved, the dust removal effect can be improved, the subsequent powder spraying uniformity is improved,the air outlet direction of the stamping guns is perpendicular to the surface of a bamboo product to be subjected to powder spraying, wind generated by the stamping guns reaches the maximum value whenreaching the surface of the bamboo product to be subjected to powder spraying, wind losses can be effectively reduced, and the dust removal effect is improved.

Owner:福建迈拓钢竹家居用品有限公司

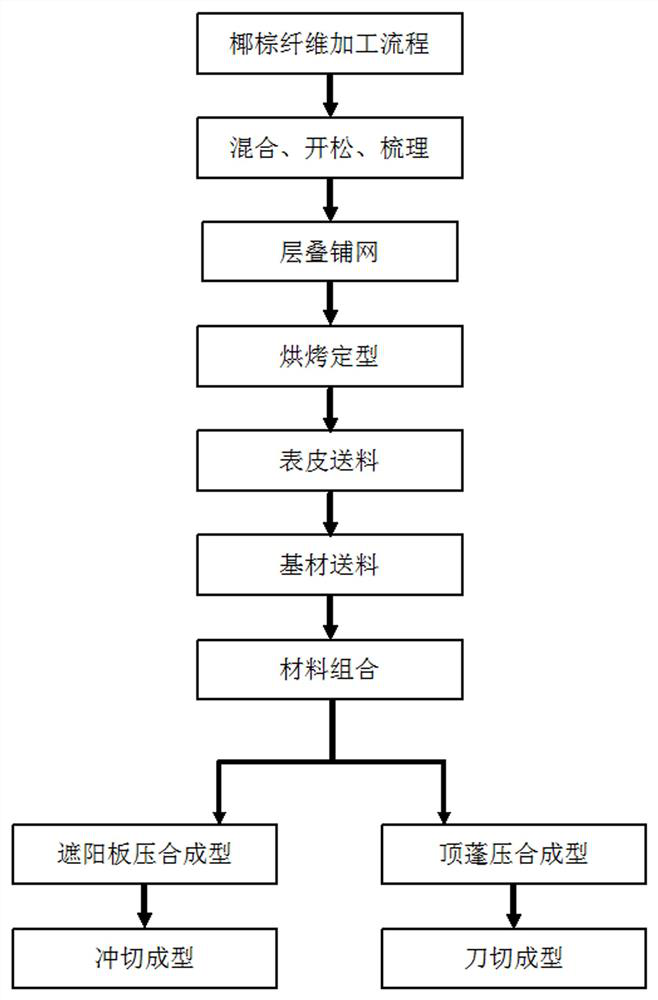

Plant fiber sun visor and manufacturing process thereof

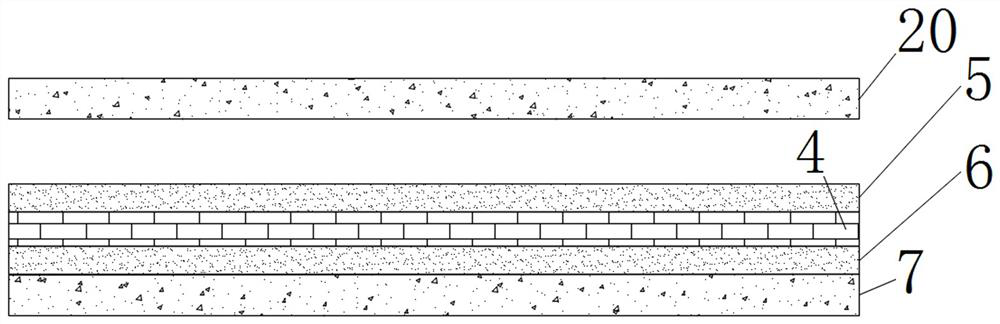

PendingCN112692953AImprove rigidityImprove temperature resistanceLamination ancillary operationsSynthetic resin layered productsGlass fiberPlant fibre

The invention relates to a plant fiber sun visor and a manufacturing process thereof. The plant fiber sun visor comprises a fabric layer and a coconut fiber filament base material which are arranged from top to bottom, the fabric layer and the coconut fiber filament base material are subjected to hot press molding, and the coconut fiber filament base material is formed by hot press molding of an adhesive film, a mixed fiber layer, an adhesive film and non-woven fabric which are arranged from top to bottom. The mixed fiber layer is formed by mixing coconut fibers and polypropylene fibers according to the ratio of 55%-65%: 45%-35%, and conducting opening, carding, stacking and lapping, and rolling, heating and shaping, a coconut fiber and PP material combined plate is adopted for replacing an existing glass fiber material plate, the design is reasonable, the formed sun visor and ceiling have high rigidity and temperature resistance, waste can be recycled, and is easy to decompose, and the sun visor has the effects of high toughness, low VOC (Volatile Organic Compounds), bacterium resistance and moisture resistance, and is environmentally friendly and healthy.

Owner:FUZHOU LIANHONG MOTOR PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com