Manual punching device

A punching device and punching technology, applied in wood stamping, punching machines, metal processing, etc., can solve the problems of high cost, difficulty in meeting small-scale fast punching processing, and low processing efficiency of drilling machines, and achieve low cost and structural Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

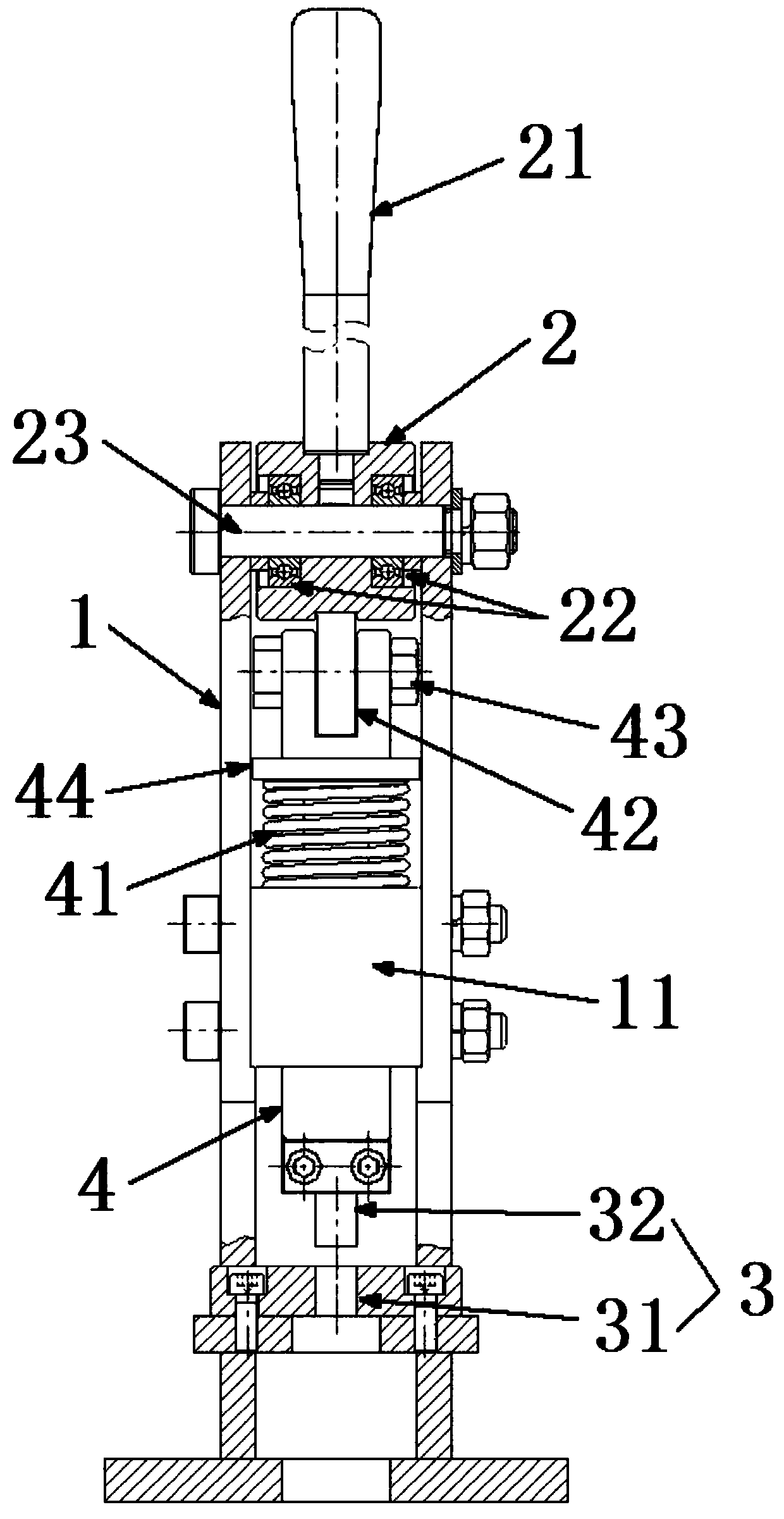

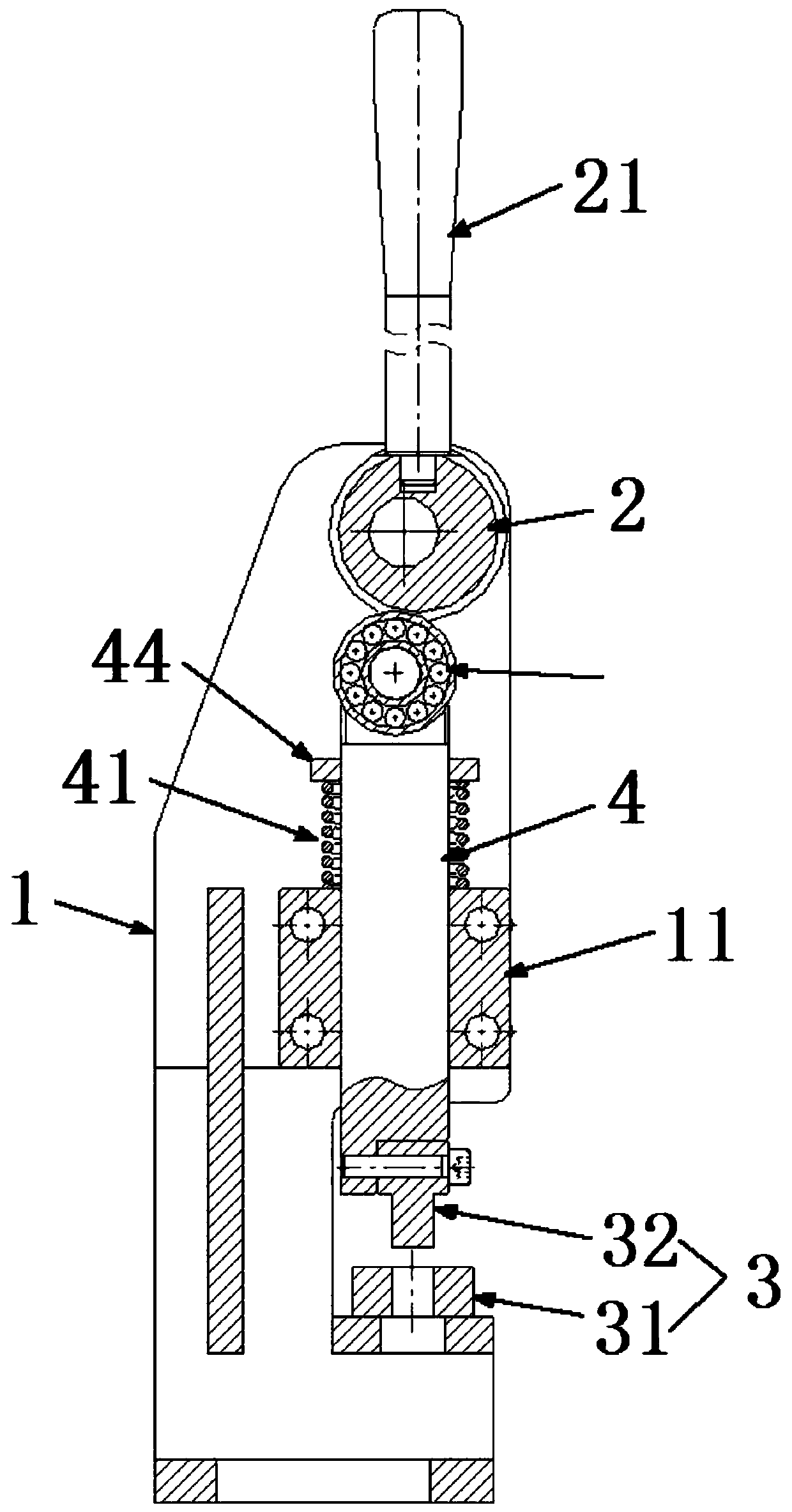

[0057] A manual punching device, comprising:

[0058] Rack 1;

[0059] An eccentric wheel 2 rotatably arranged on the frame 1;

[0060] The die 31 of the punching die 3 arranged at the bottom of the frame 1;

[0061] A telescopic rod 4 arranged in the frame 1, one end of the telescopic rod 4 is provided with a punch 32 of a punching die 3, and the other end is matched with the eccentric wheel 2;

[0062] The telescopic rod 4 is also provided with a return elastic member 41 , and the return elastic member 41 is respectively connected to the telescopic rod 4 and the frame 1 .

[0063] One end of the telescopic rod 4 close to the eccentric wheel 2 is also provided with a first bearing 42 and a first locking rod 43, and the first bearing 42 is fixedly sleeved on the first locking rod 43. The first locking rod 43 is fixedly connected with the telescopic rod 4 . The eccentric wheel 2 is provided with a groove matching the first bearing 42 .

[0064] The eccentric wheel 2 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com