Plate type component production line for intelligent household

A smart home and production line technology, applied in the direction of sawing components, circular saws, wood stamping, etc., can solve the problems of veneer layer damage, sheet surface integrity damage, sheet displacement drilling position, etc., to improve work efficiency, Save labor costs and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

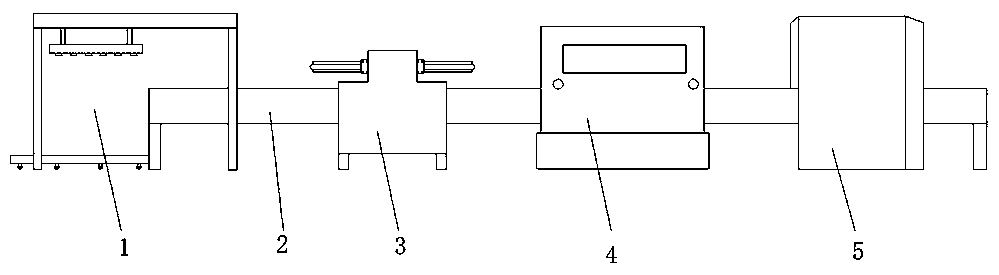

[0028] Such as Figure 1-8 As shown, the present invention provides a technical solution: a production line for panel parts for smart home, including a feeding mechanism 1, a conveying mechanism 2, a labeling machine 3, a cutting device 4 and a plank CNC punching machine 5, the feeding The mechanism 1 is arranged at the feeding end of the conveying mechanism 2, and one side of the feeding mechanism 1 is provided with a labeling machine 3, a cutting device 4 and a wood CNC punching machine 5 in sequence;

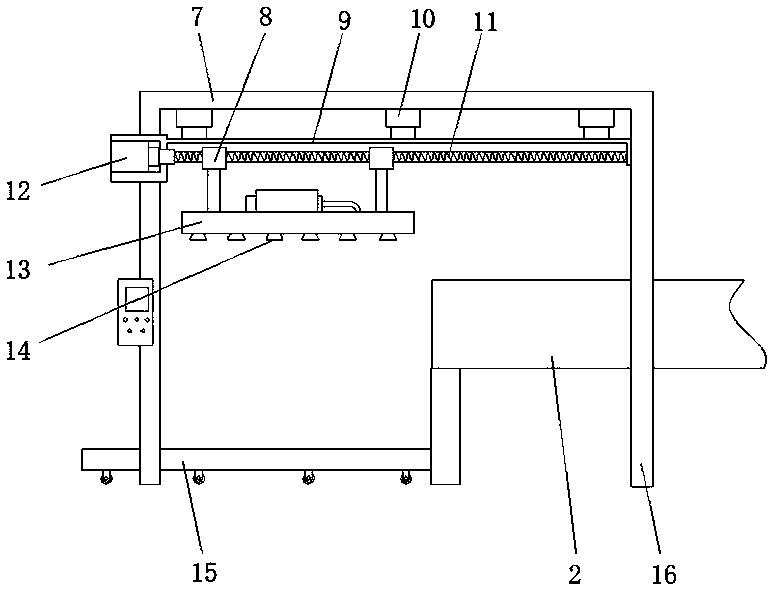

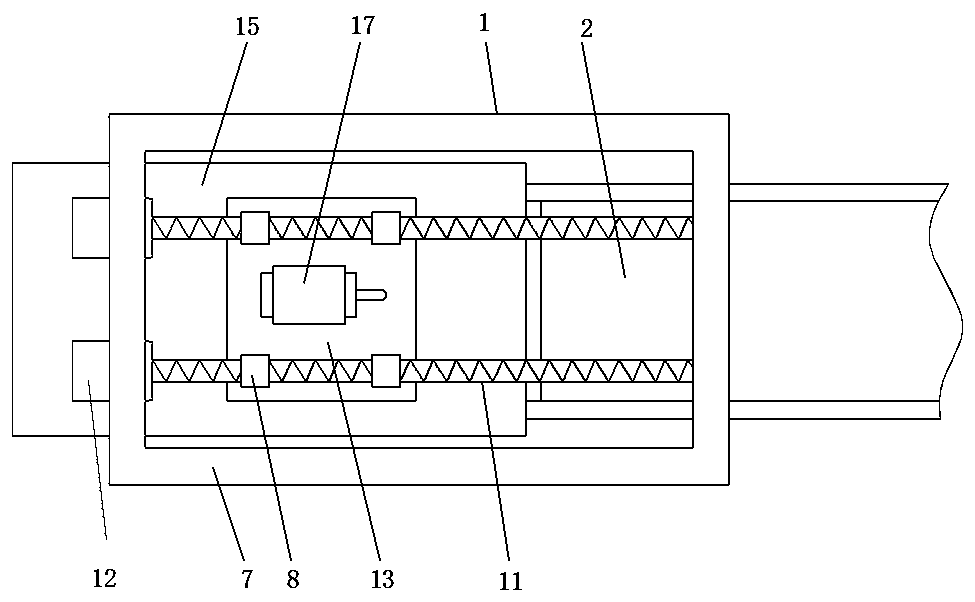

[0029] The feeding mechanism 1 includes a top frame 7, a moving plate 9, a hydraulic telescopic rod 10, a moving part 13 and a suction cup 14, the top of the moving plate 9 is connected to the top frame 7 through a hydraulic telescopic rod 10, and the hydraulic telescopic rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com