Patents

Literature

71results about How to "Continuous cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

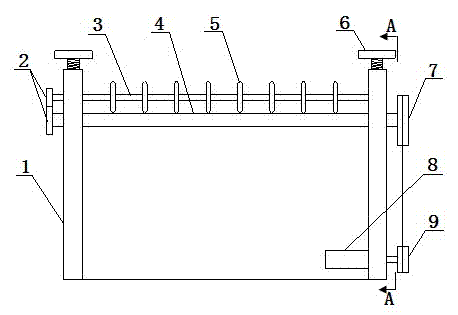

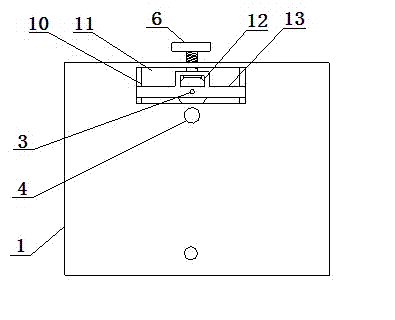

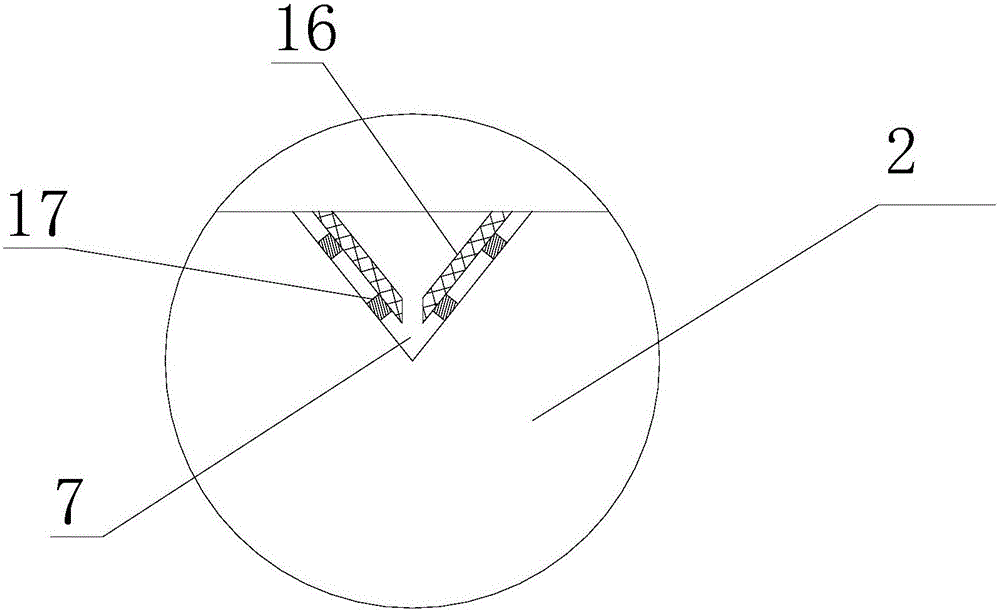

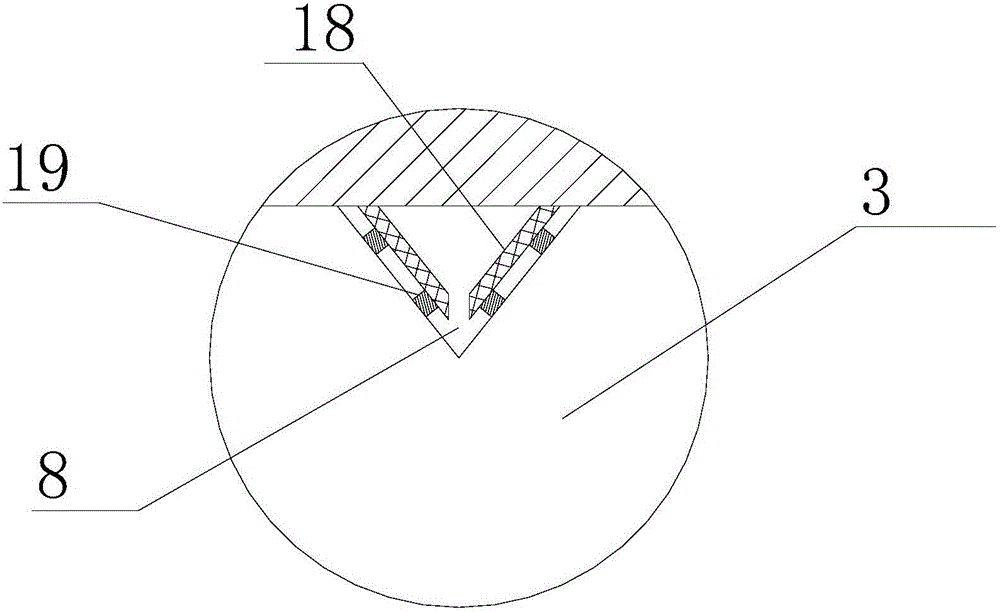

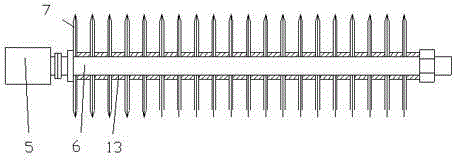

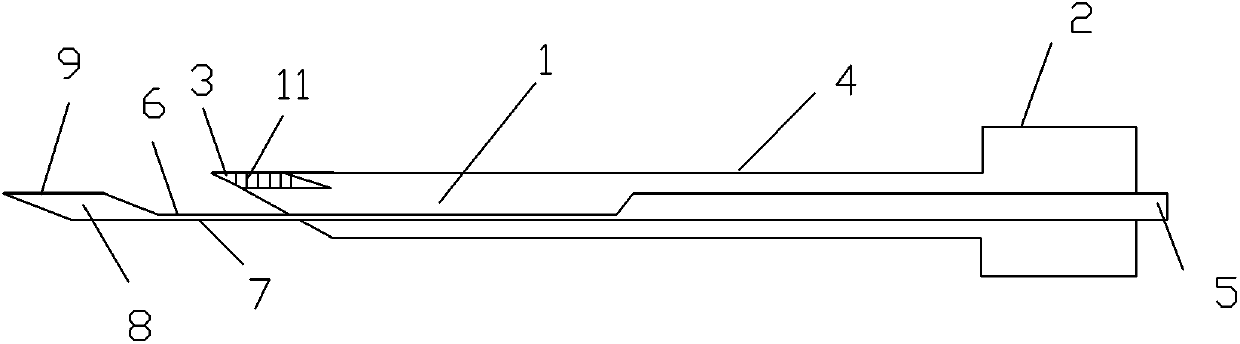

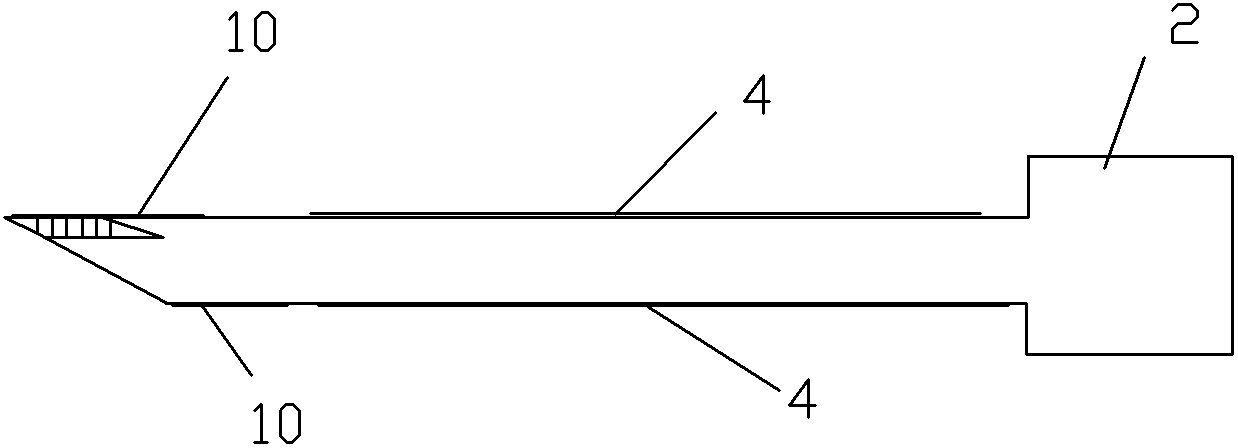

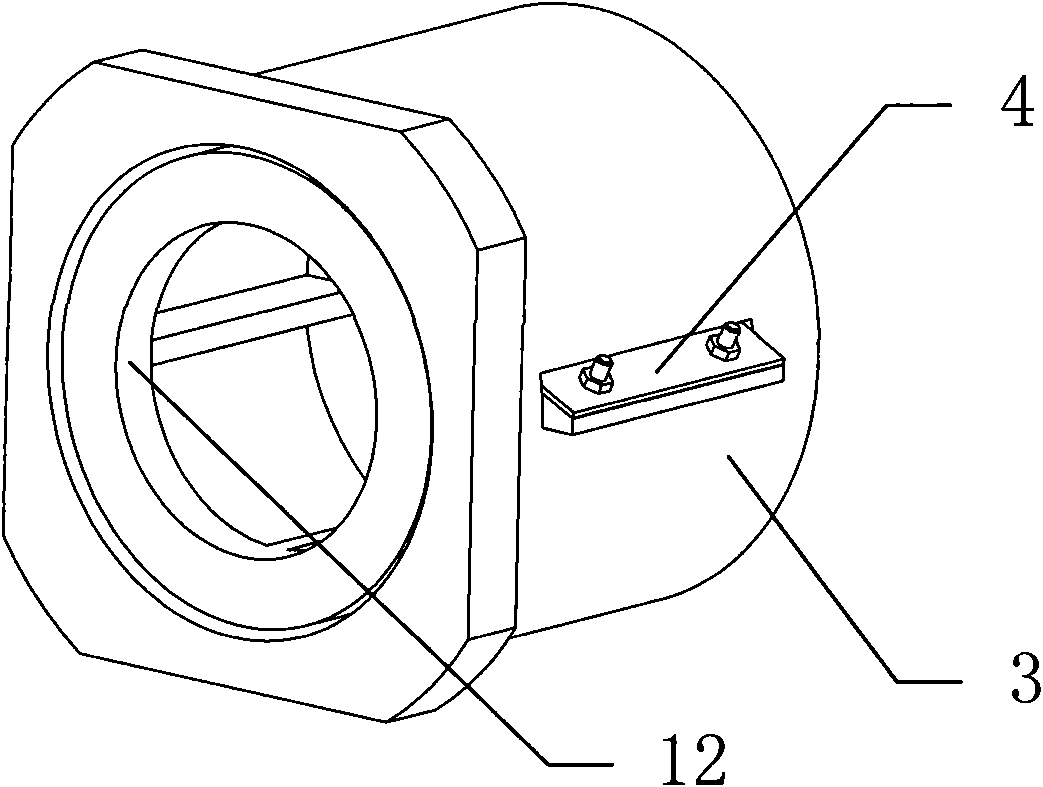

Rubber strip stock cutter

InactiveCN103042552AEnsure equal widthContinuous cuttingMetal working apparatusMotor driveDrive wheel

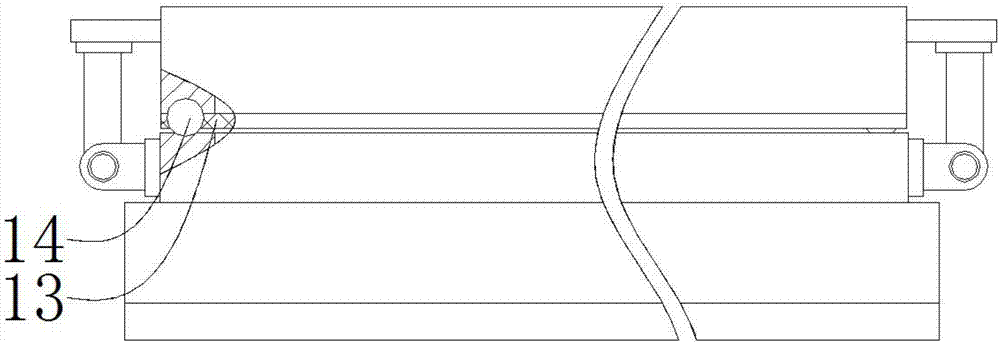

The invention relates to a rubber strip stock cutter. The rubber strip stock cutter is characterized by comprising a frame. A horizontal blade shaft and a horizontal rolling shaft are arranged on the upper portion of the frame sequentially from top to bottom. Two ends of each of the blade shaft and the rolling shaft are rotatably fixed on the frame. A plurality of circular blades, with each having an outer edge, are evenly distributed on the blade shaft. Both ends of each rolling shaft extend out of the frame, while one end meshes with one end of the blade shaft through a gear and a driven wheel is fixed at the other end. A motor is arranged below the rolling shaft on the frame, and an output end of the motor extends out of the frame and corresponds to the drive wheel end of the rolling shaft. A driving wheel is fixed at the output end of the motor. The motor driving wheel is in linkage fit with the rolling shaft driven wheel. By the use of the stock cutter, the cut rubber strips are equal in width, labor waste is avoided, manufacturing cost can be lowered and production efficiency can be improved.

Owner:无锡朴业橡塑有限公司

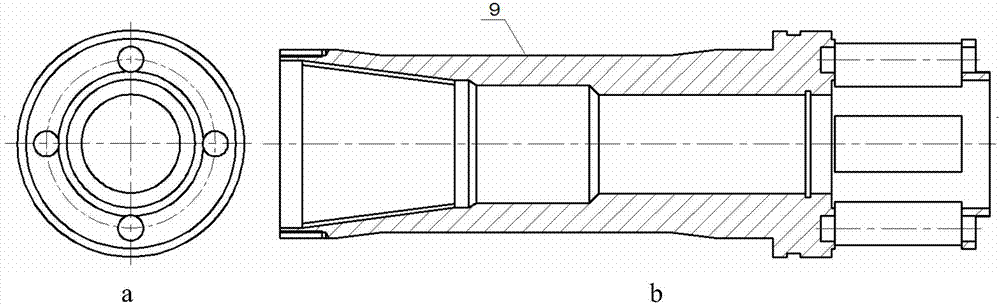

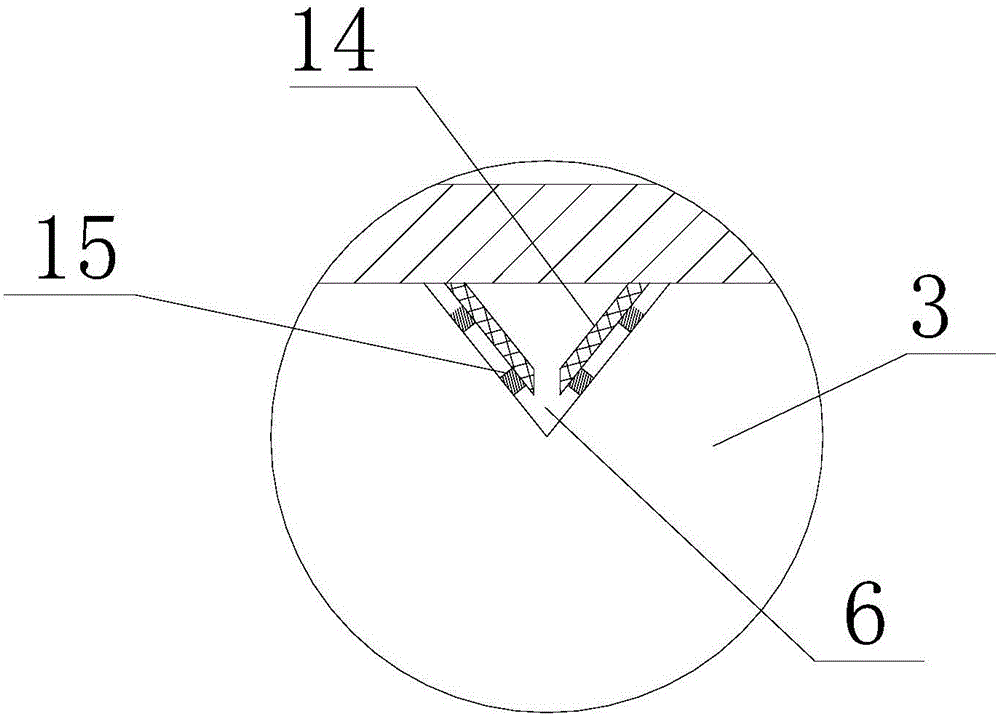

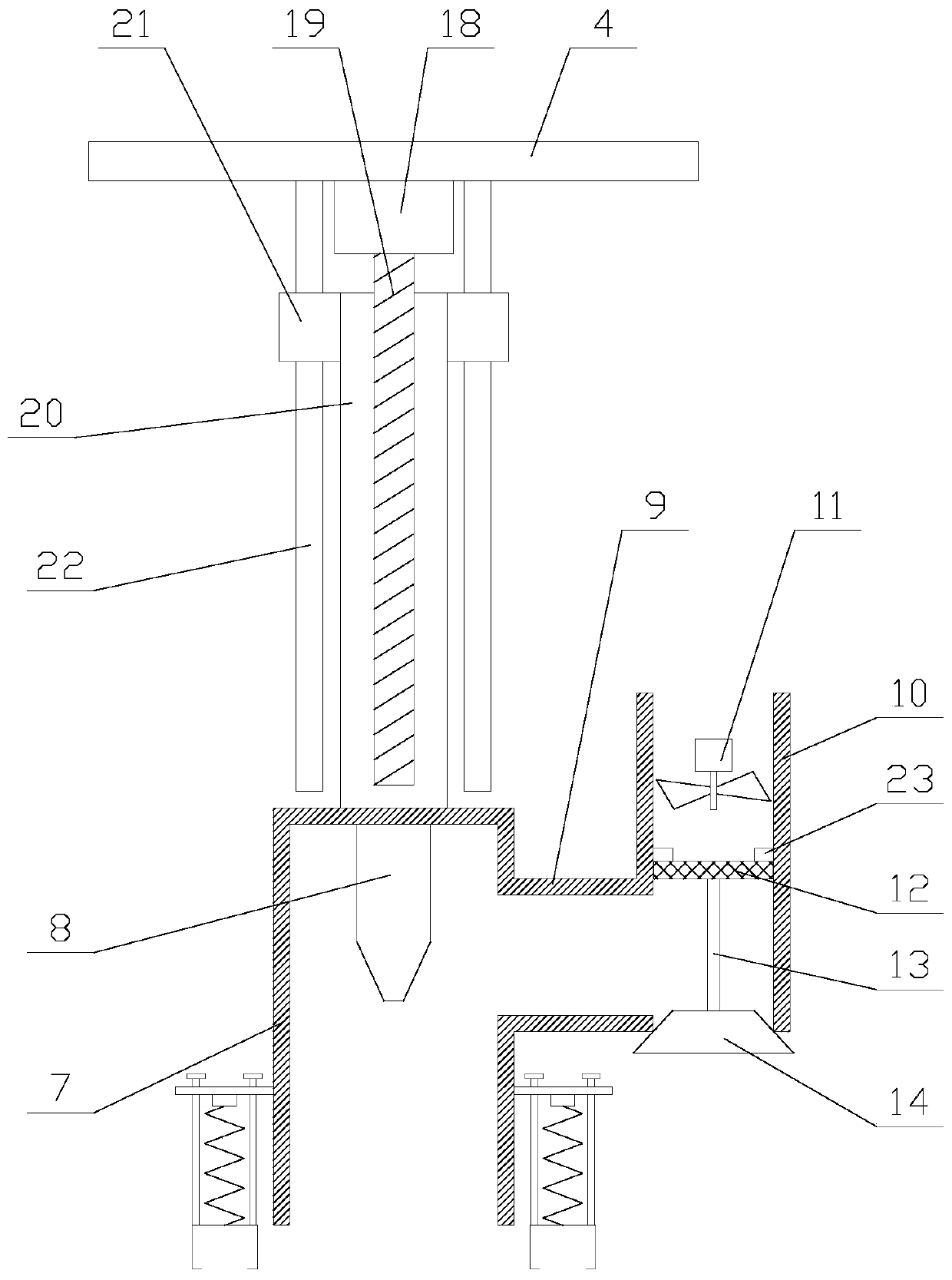

Inertial confinement and induction drilling device with PDC drill bit

ActiveCN107299825ADoes not consume energyPower is not consumed blindlyDrilling rodsBorehole drivesEngineeringSurface pressure

Disclosed is an inertial confinement and induction drilling device with a PDC drill bit. A planetary frame is installed on the outer circumferential surface of an input shaft of the sun wheel in a sleeving mode, and a small sliding bushing is installed on the circumferential surface of the input shaft of the sun wheel in a sleeving mode; four planetary gear shafts are all arranged on the surface of the planetary frame, 8 planetary gears are divided into 2 groups and axially arranged on the planetary gear shafts in a sleeving mode, and one group of planetary gears are close to the drill-collar connecting end of the input shaft of the sun wheel; the end surfaces of the first group of planetary gears are fitted with the inner end surfaces of steps at one end of the input shaft of the sun wheel through end-surface pressure bearings. An output shaft of the planetary frame is installed on the outer circumferential surface of the input shaft of the sun wheel, so that the inner end surface of the output shaft of the planetary frame is fitted with the outer end surface of the planetary frame. The inertial confinement and induction drilling device with the PDC drill bit is completed on the basis of a planetary-wheel reducer structure, and has the advantages that the impact is stable and continuous, the durability is guaranteed, the quality of drilling holes is ensured, and the energy consumption is low.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

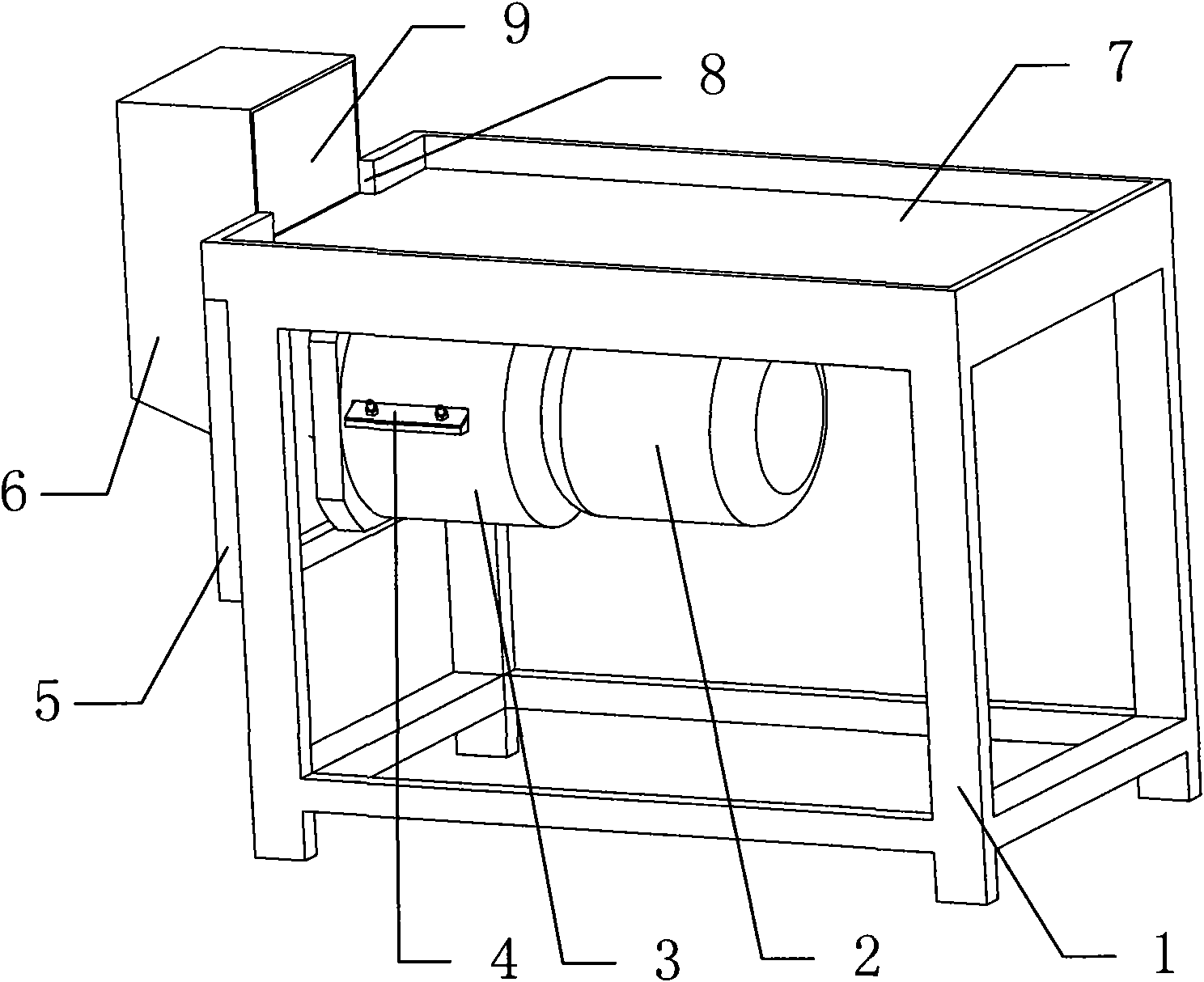

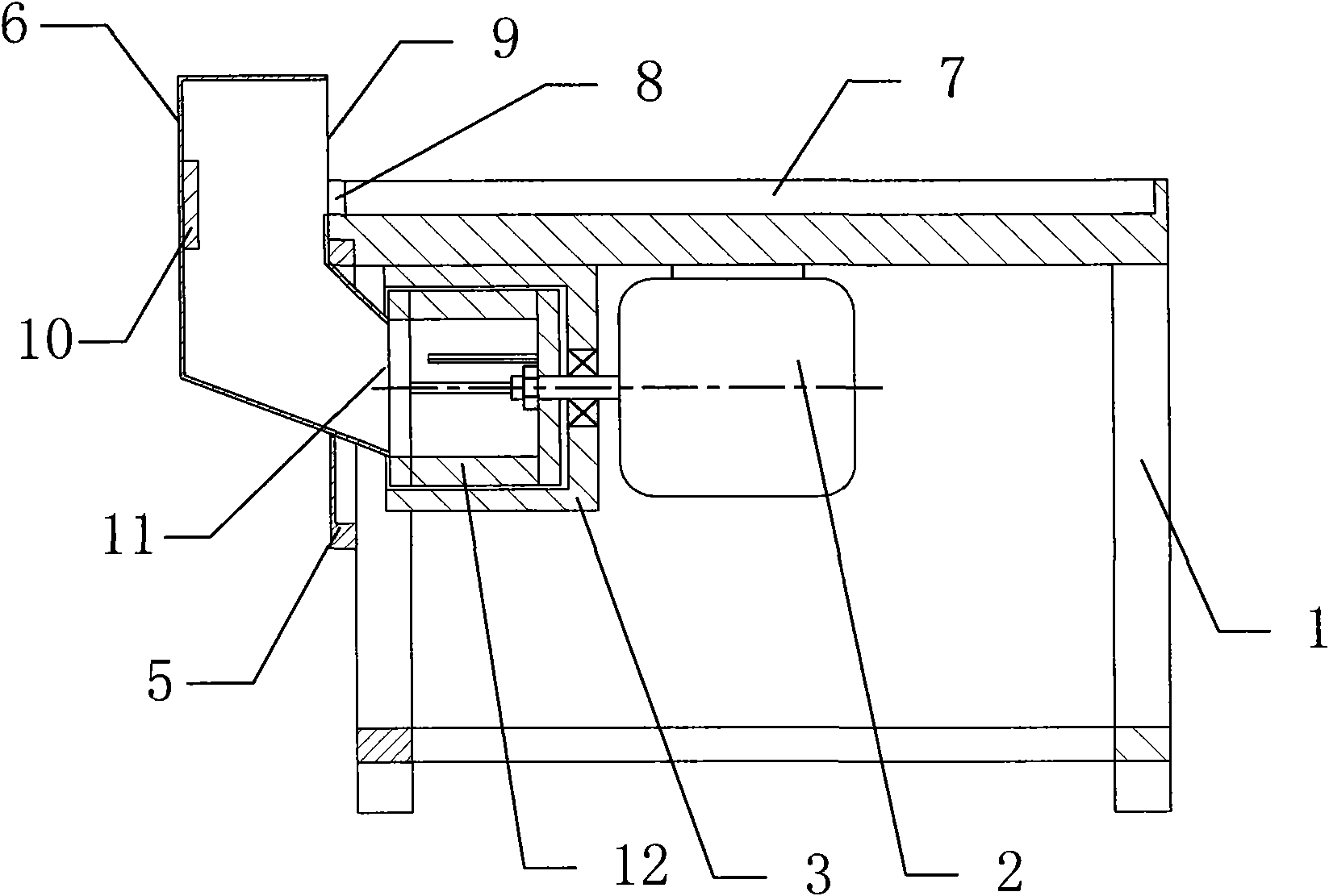

Multifunctional paperboard cutting device

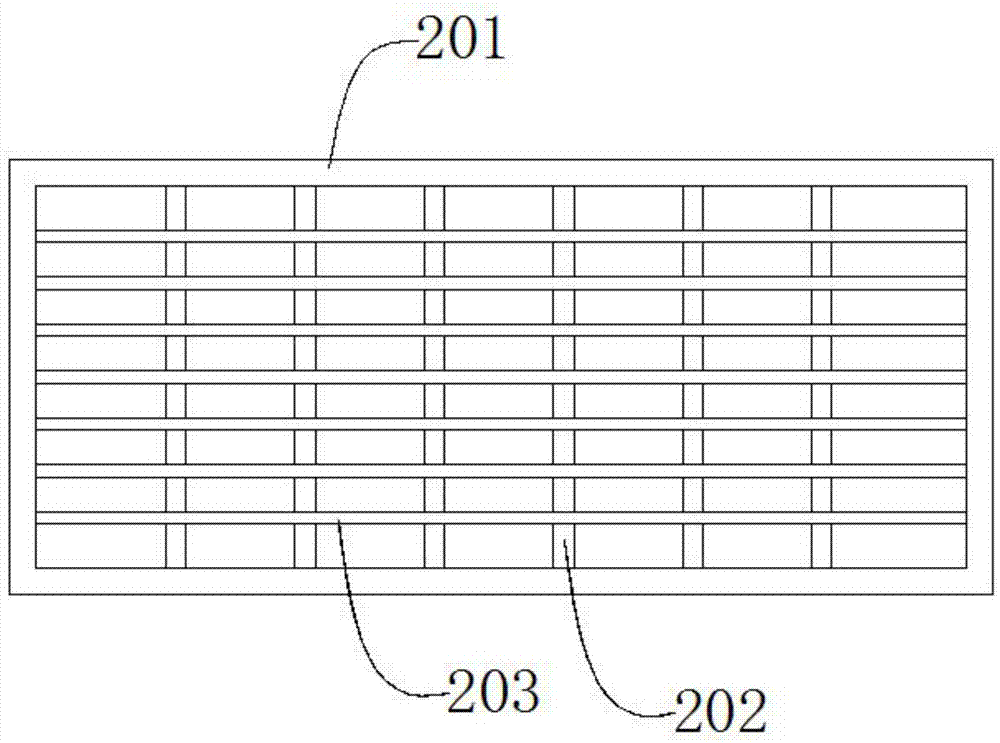

The invention provides a multifunctional paperboard cutting device. The multifunctional paperboard cutting device comprises a first conveying belt, a second conveying belt, a working table, a base and a cutting mechanism, wherein the first conveying belt and the second conveying belt are arranged on two sides of the working table in parallel; a plurality of cutting grooves are formed in the working table in the length direction of the working table; the cutting mechanism comprises a first mounting plate and a cutting assembly; the cutting assembly comprises a mounting rod and a cutting knife; the mounting rod is movably mounted on a first mounting plate; the cutting knife is arranged at one end, which is close to the working table, of the mounting rod; a first driving mechanism is used for driving the first conveying belt to rotate; a second driving mechanism is used for driving the second conveying belt to rotate; a third driving mechanism is used for driving the first mounting plate to move in the vertical direction; a fourth driving mechanism is used for driving the mounting rod to move in the direction perpendicular to the length direction of the working table; and a fifth driving mechanism is used for driving the mounting rod to move in the length direction of the working table. By the multifunctional paperboard cutting device, cutting efficiency is improved effectively, and paperboards with different sizes can be cut.

Owner:WUHU BEISI SCI & TECH PARK

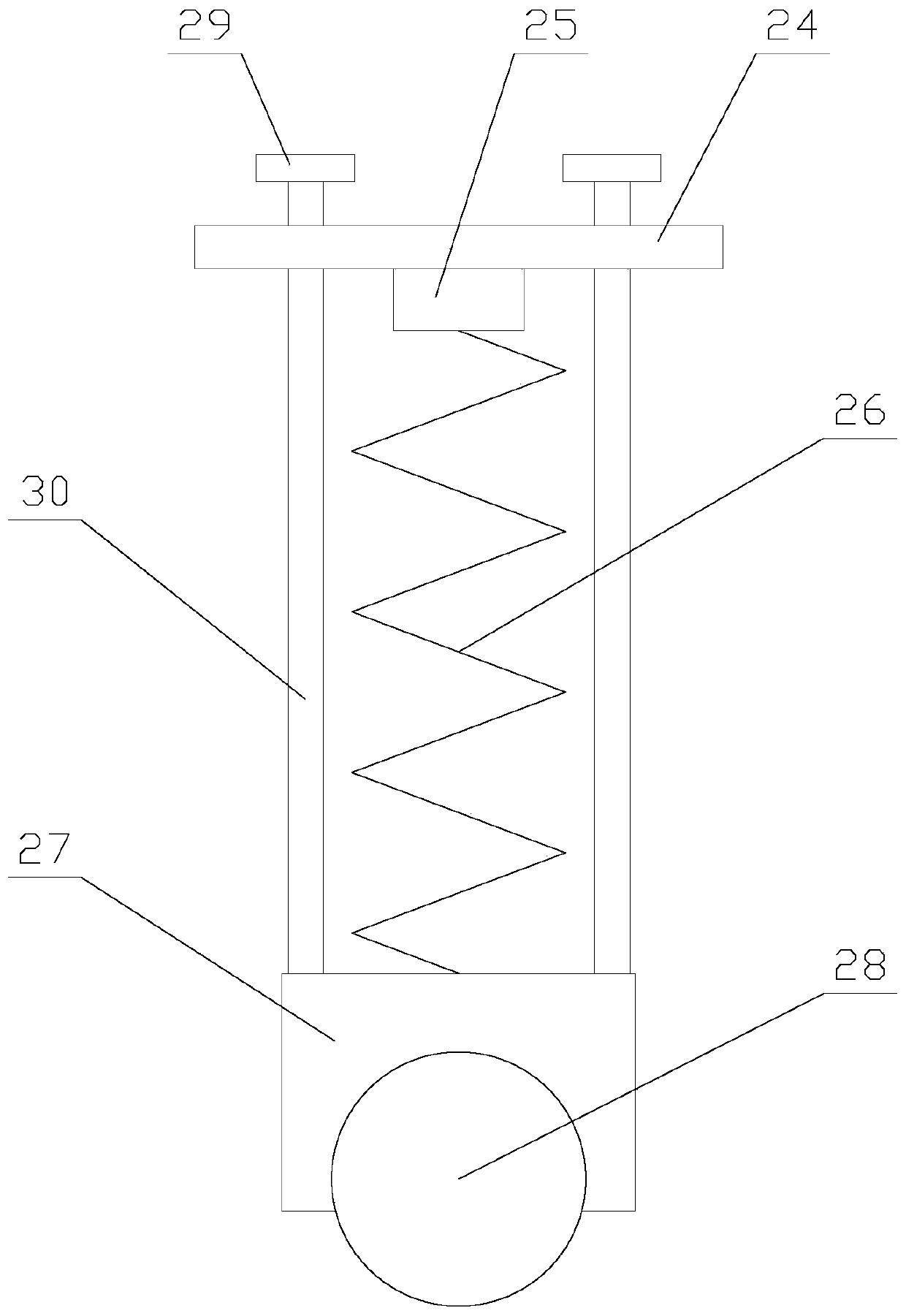

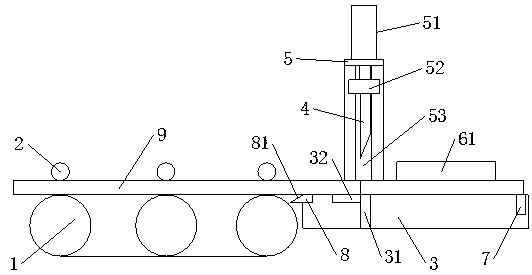

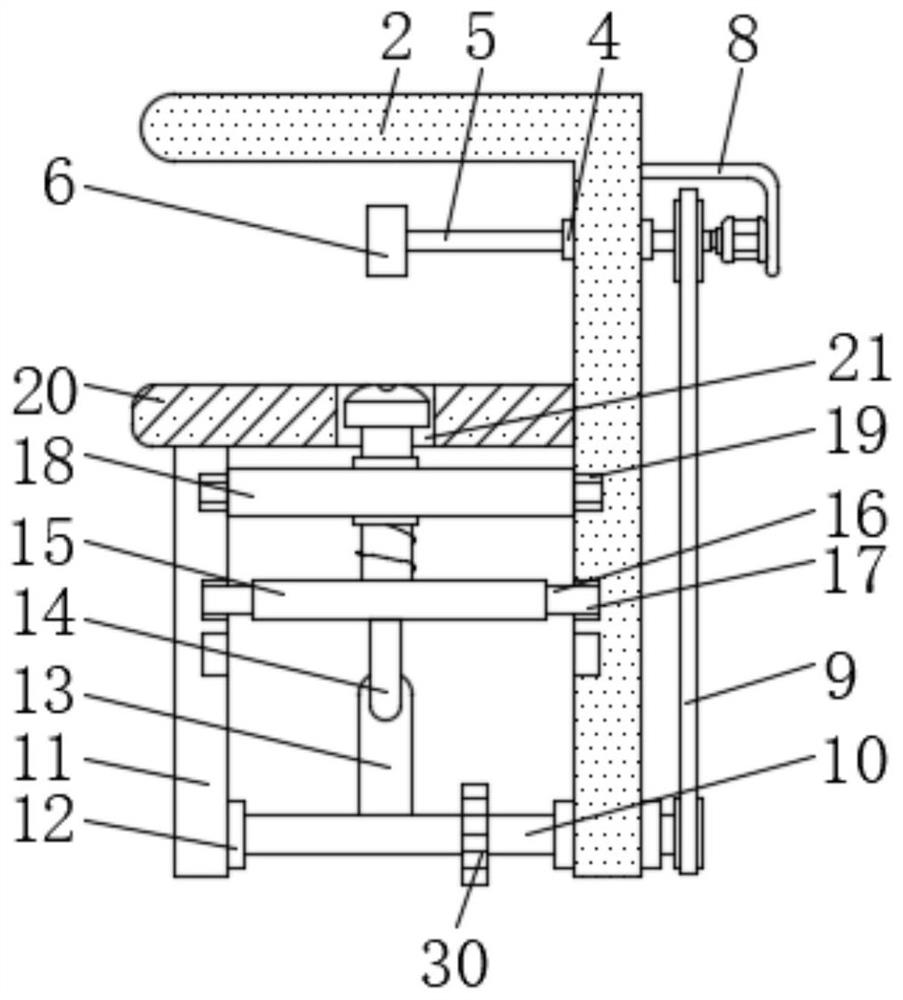

Cutting device for machining aluminum alloy plates

ActiveCN109175507AContinuous cuttingEasy to fixMetal sawing devicesMetal working apparatusRound tableThreaded rod

The invention belongs to the technical field of aluminum alloy machining equipment, and particularly relates to a cutting device for machining aluminum alloy plates. The cutting device comprises firstbottom frames, a second bottom frame and a support frame, wherein the first bottom frames comprise two edge frames and a middle frame, the edge frames and the middle frame are provided with first strip-shaped grooves, and a plurality of first roller wheels are transversely arranged in the first strip-shaped grooves. A hexagonal through hole is formed in the free end of a support plate. A hexagonal fixing rod is arranged in the hexagonal through hole. A threaded rod is integrally formed on the upper portion of the fixing rod. A nut on the upper end surface of the support plate is connected tothe threaded rod in a threaded mode. A round rod is integrally formed on the lower portion of the fixing rod. A round table is integrally formed at the bottom of the round rod. The diameter of the round rod is larger than that of the fixing rod and smaller than that of the round table. A rolling barrel sleeves the round rod. A blind hole matched with the round table is formed in the lower end surface of the rolling barrel. A compression spring above the round table is arranged in the blind hole. The cutting device for machining the aluminum alloy plates aims to solve the problems of continuouscutting incapabilities and poor positioning precision which are caused by structural defects of a prior cutting device.

Owner:重庆新久融科技有限公司

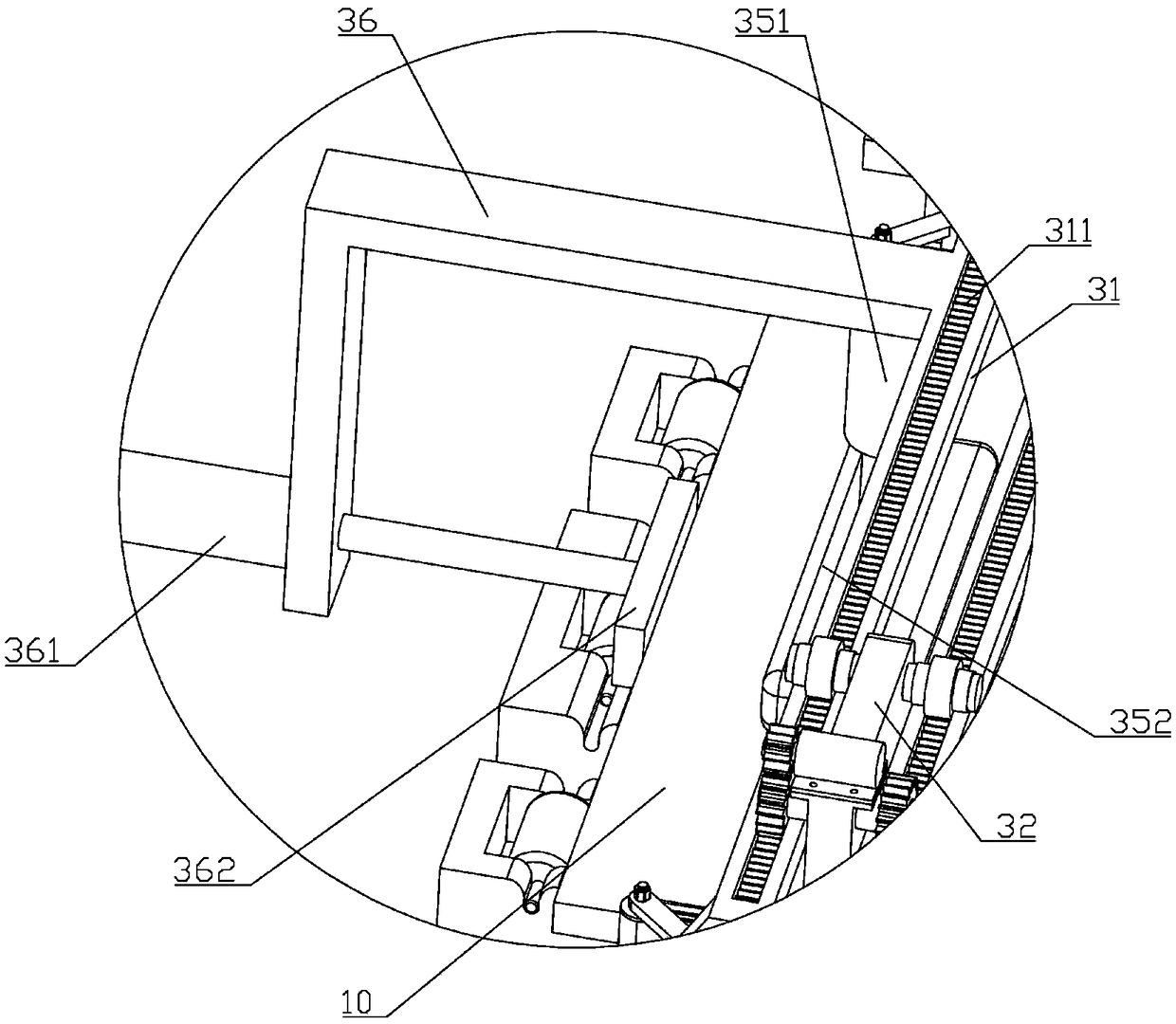

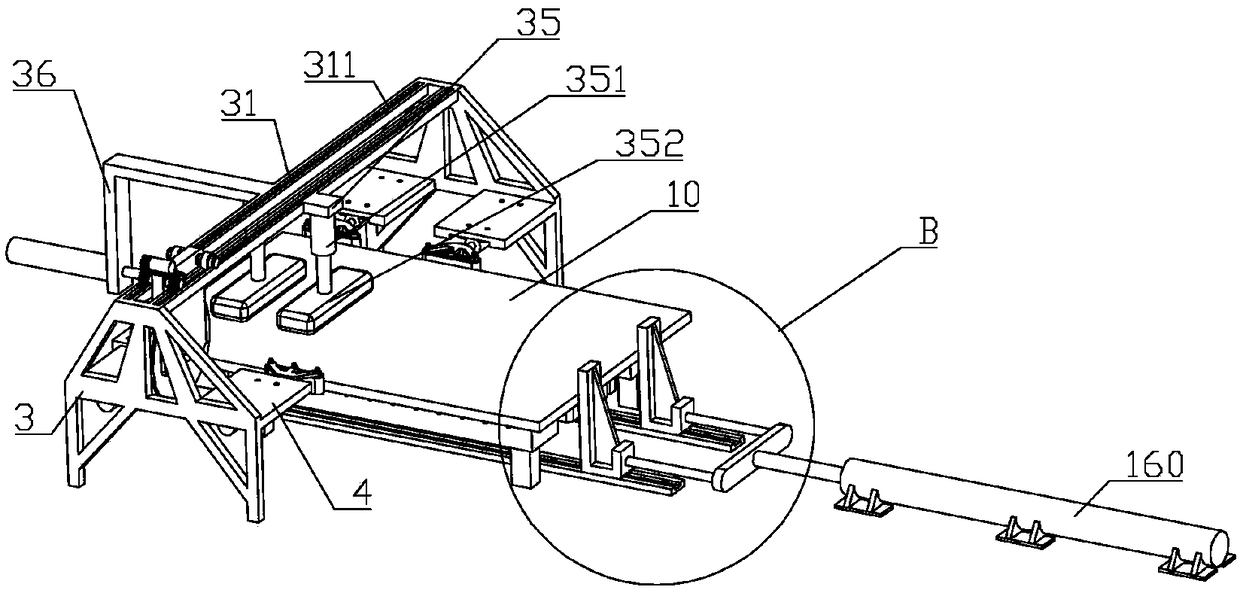

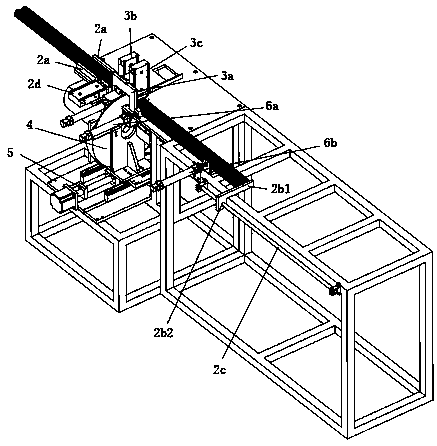

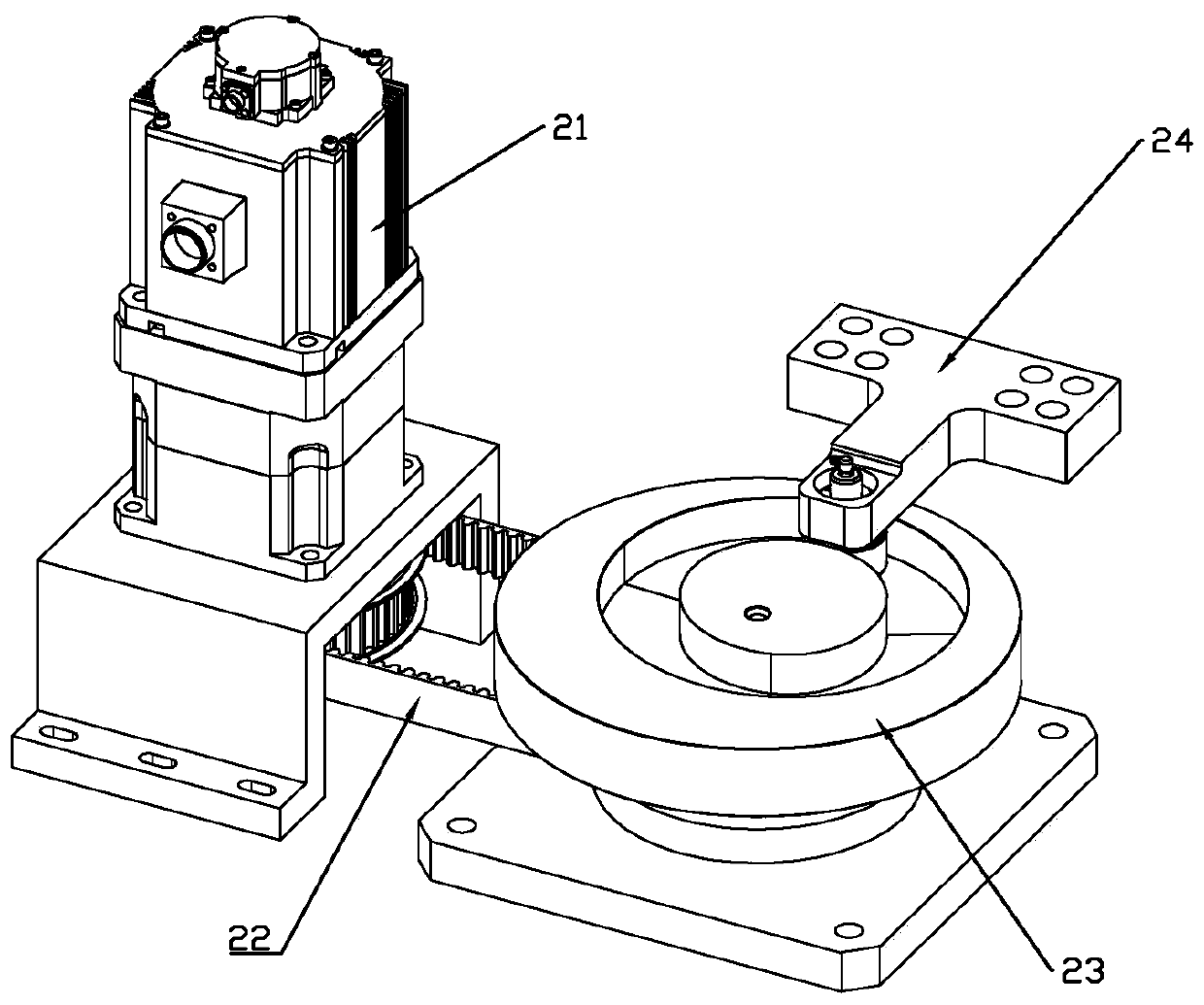

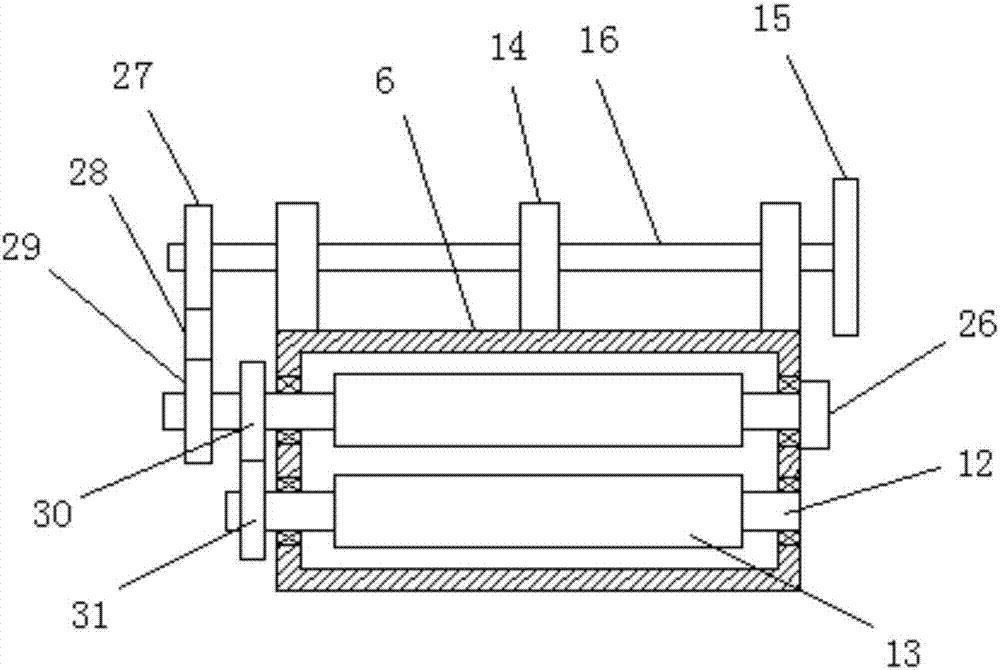

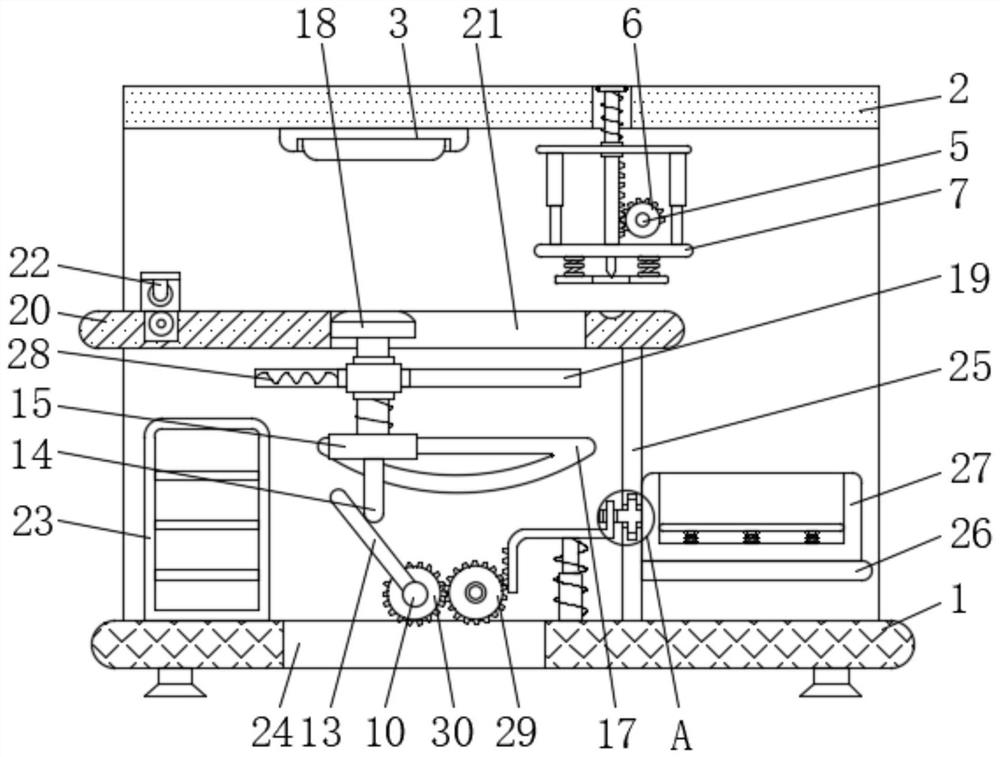

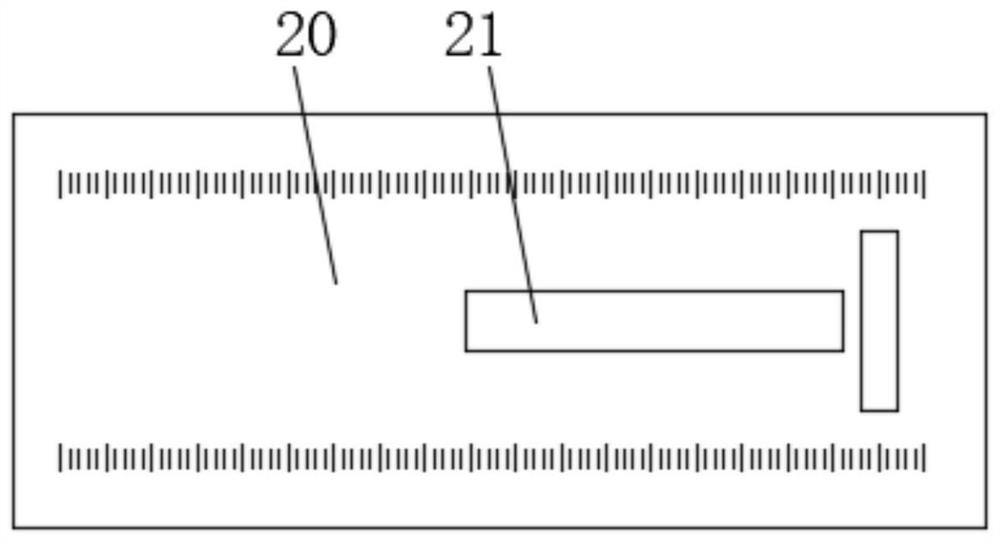

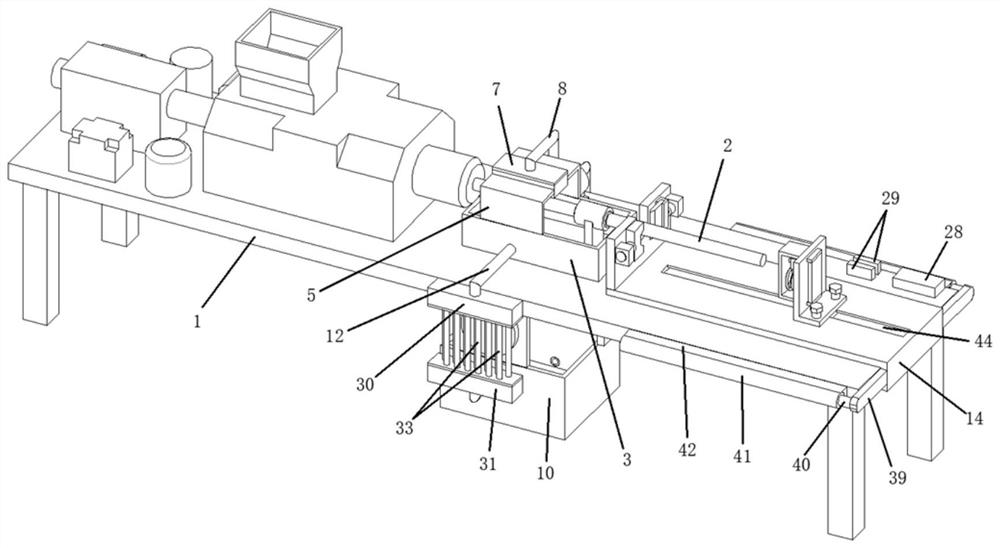

Sectional material cutting equipment

InactiveCN108145236APrecise positioningNo displacementMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention relates to the field of cutting machines, and particularly relates to sectional material cutting equipment. The sectional material cutting equipment comprises a bearing table, a locationmechanism, a compression mechanism, a cutting mechanism, a transverse movement mechanism and a stacking movement, wherein the location mechanism is arranged on the bearing table, and the compressionmechanism is suspended above the bearing table; the transverse movement mechanism is arranged below the bearing table, the cutting mechanism is fixed to the transverse movement mechanism, and the transverse movement mechanism is used for driving the cutting mechanism to carry out transverse movement to cut sectional materials; and the stacking mechanism is arranged at the outer side of the bearingtable. The sectional material cutting equipment disclosed by the invention is capable of carrying out accurate location on the sectional materials through the location mechanism, so as to guarantee the cutting length and cutting accuracy; the compression mechanism is capable of compressing the sectional materials onto the bearing table to ensure no displacement of the sectional materials during cutting; the cutting is realized in a simple and effective manner that the transverse movement mechanism drives the cutting mechanism to carry out transverse movement to cut the sectional materials, and automatic cutting working is realized; and the cut sectional materials are orderly stacked on the bearing table through the stacking mechanism, so that the cutting can be continuously carried out toensure the efficiency.

Owner:周挺娜

Adjustable paperboard cutting device for packaging box

ActiveCN105922627AContinuous cuttingAvoid damageBox making operationsPaper-makingPaperboardEngineering

The invention provides an adjustable paperboard cutting device for a packaging box. The device comprises a base, a first working table, a second working table, a first mounting plate, a transmission roller set and a cutting mechanism; a plurality of parallel first cutting grooves are formed in the first working table, and a second cutting groove is formed in the second working table; the cutting mechanism comprises a first cutting assembly and a second cutting assembly which are used for cutting a paperboard; the first cutting assembly comprises a first mounting rod and a first cutting knife; the second cutting assembly comprises a second mounting rod and a second cutting knife; a first drive mechanism is used for driving the first mounting plate to move in the vertical direction; a second driving mechanism is used for driving the first mounting rod to move in the length direction of the first working table; a third driving mechanism is used for driving the second mounting rod to move in the length direction of the second working table; a fourth driving mechanism is used for driving the first mounting rod to move in the length direction of the first working table; and a fifth driving mechanism is used for driving the transmission roller set to rotate. According to the device, the cutting efficiency is effectively improved.

Owner:WUHU BEISI SCI & TECH PARK

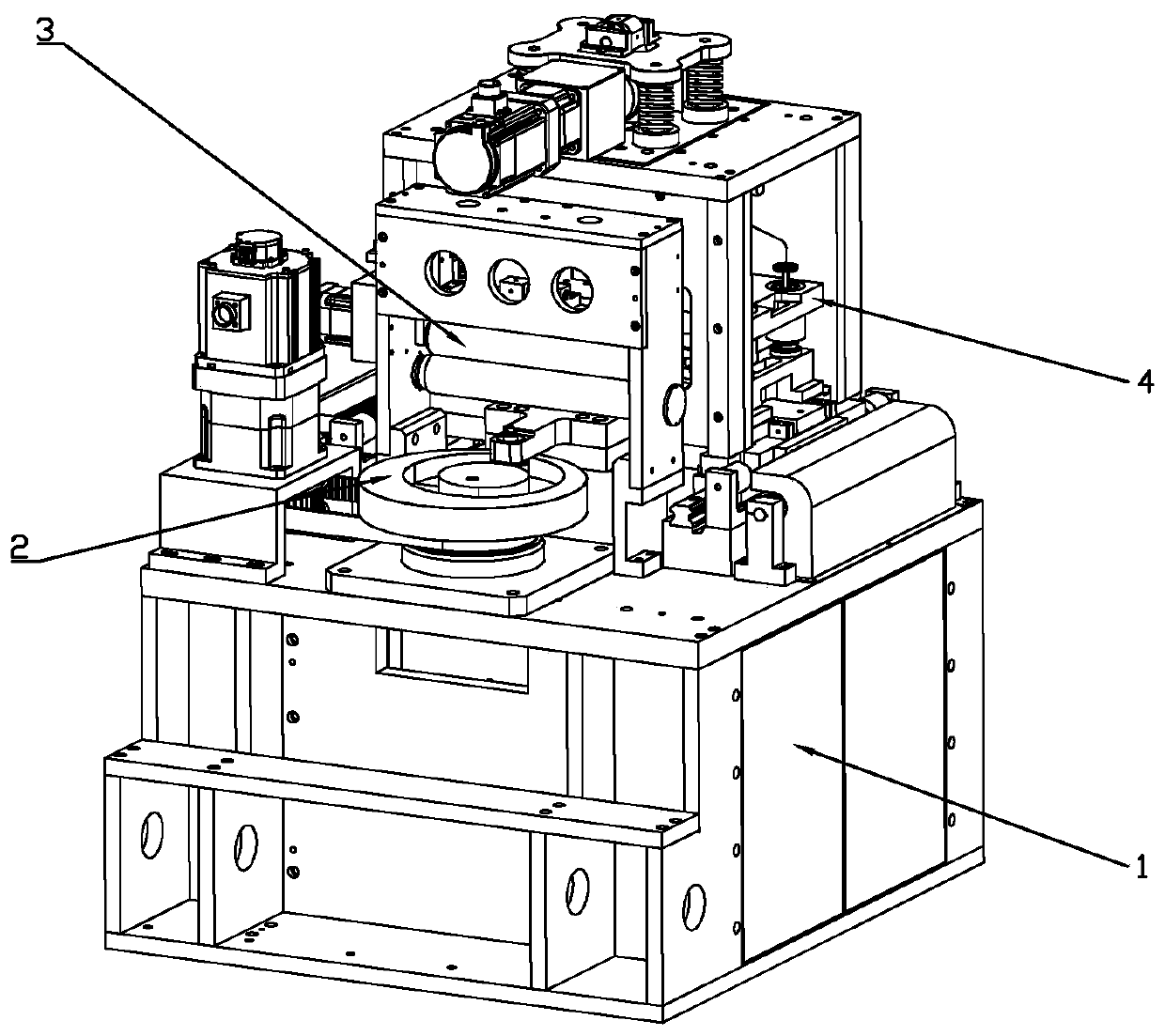

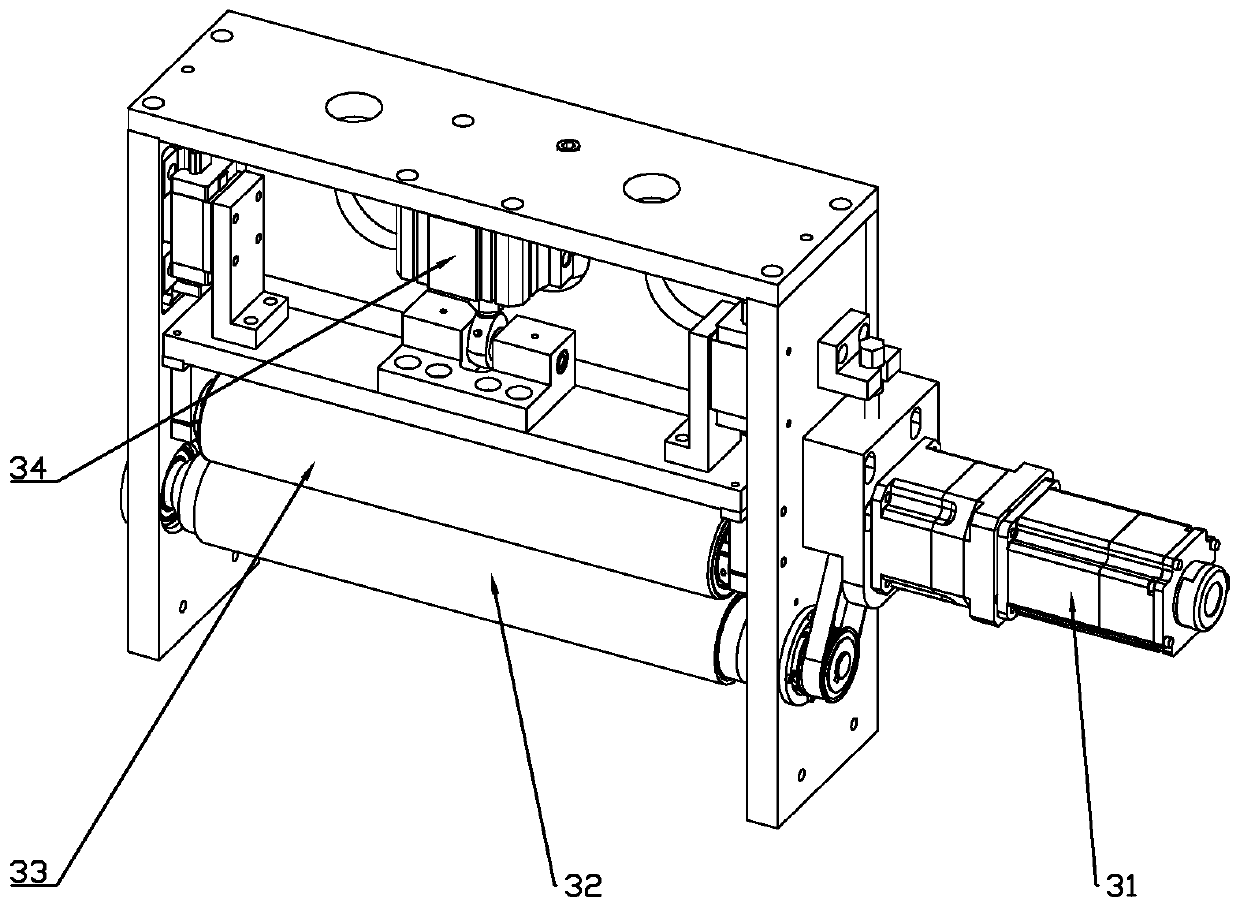

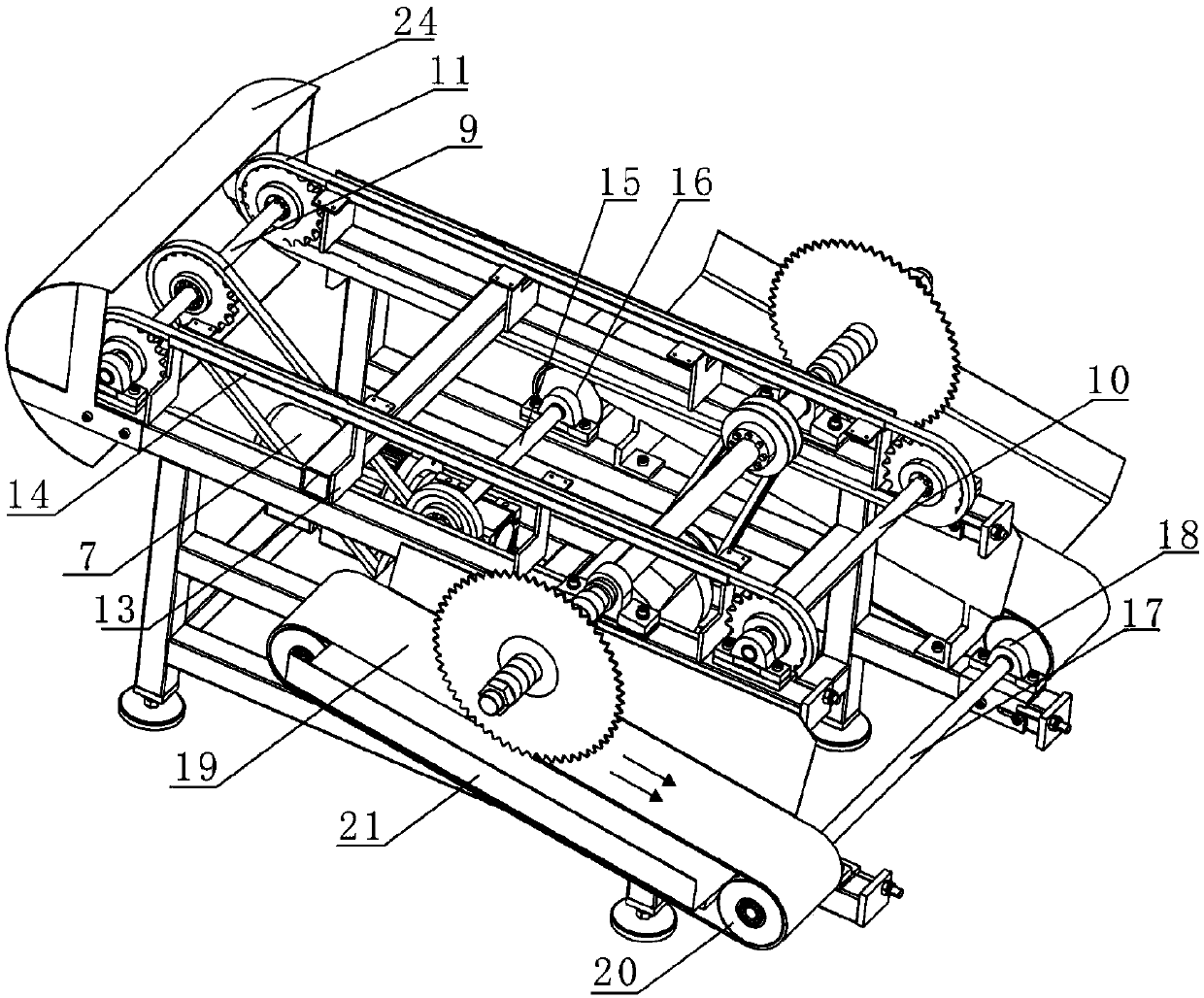

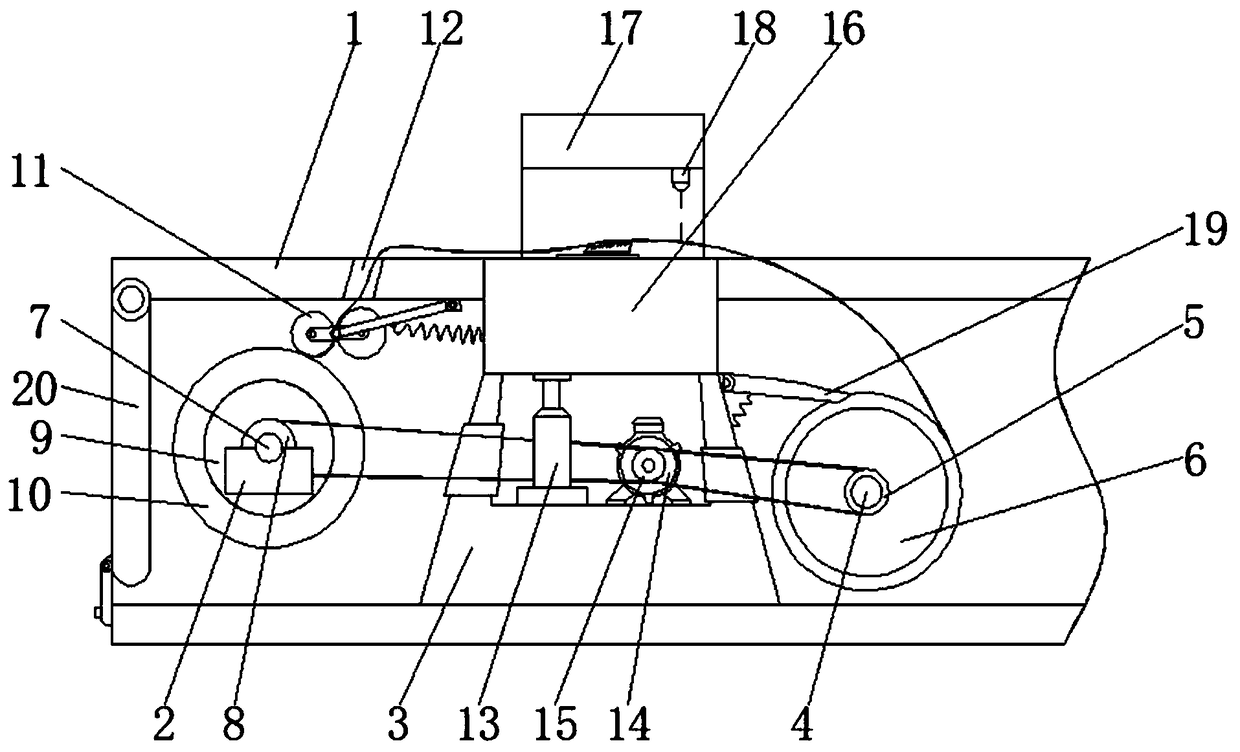

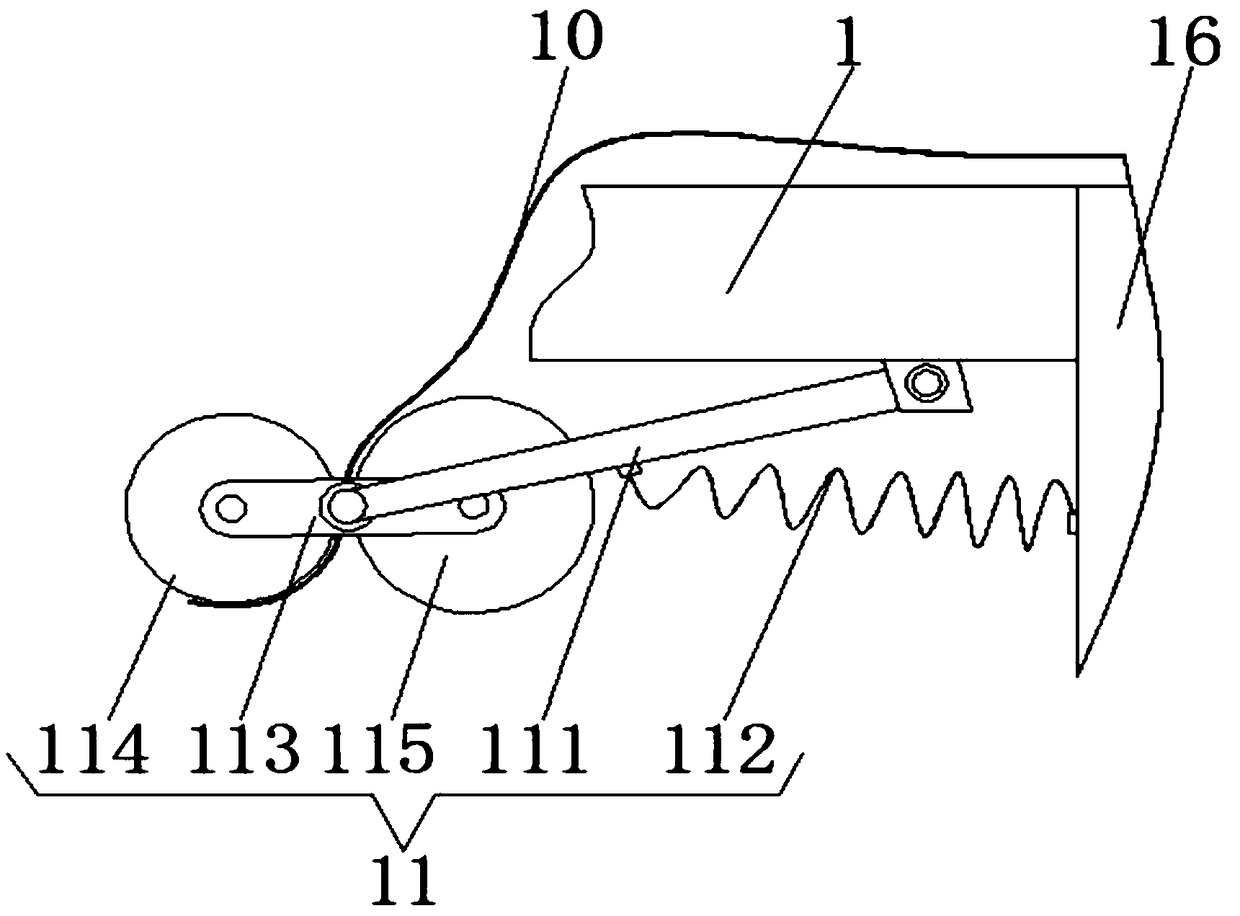

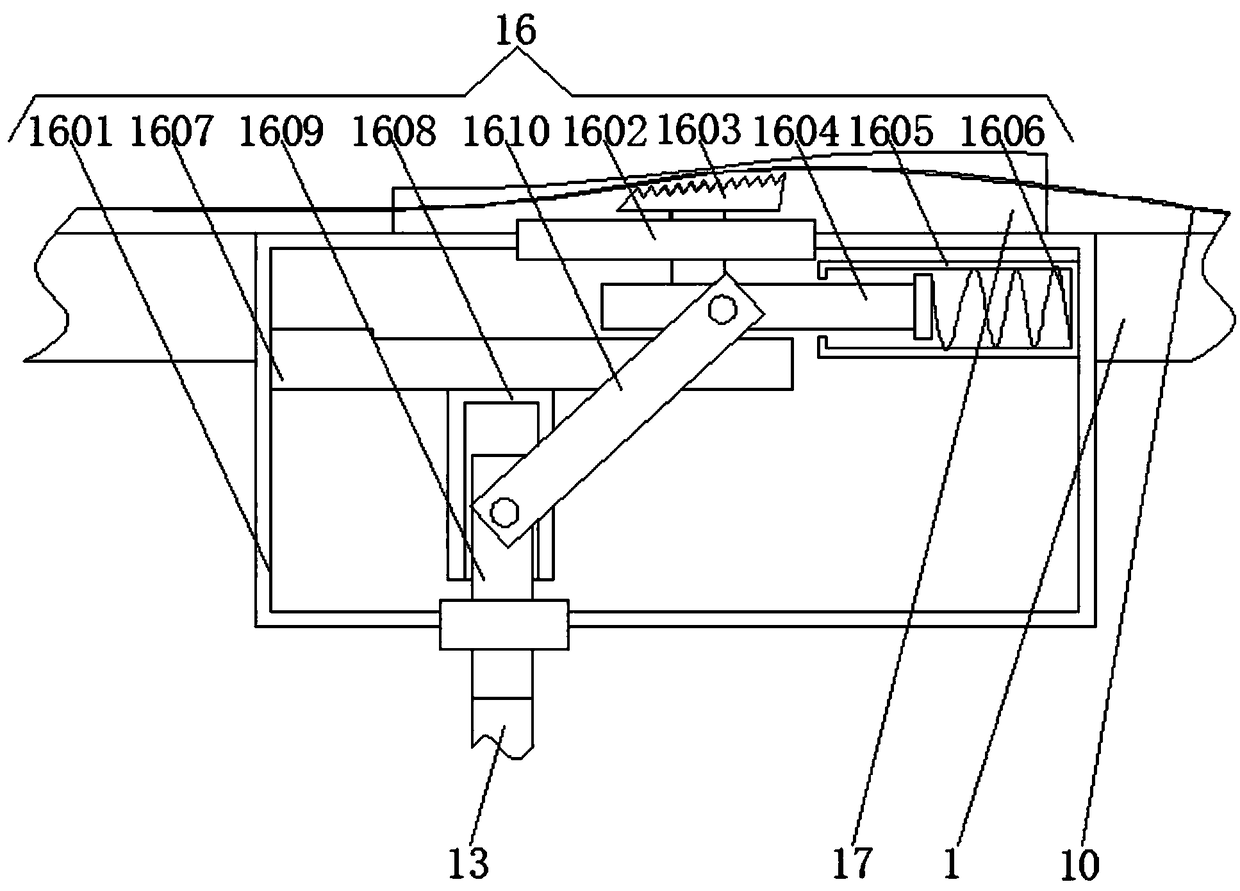

High-speed pole piece cutting device and cutting method thereof

PendingCN110355259AImprove cutting efficiencyContinuous cuttingElectrode manufacturing processesMetal-working feeding devicesCamMachine tool

The invention discloses a high-speed pole piece cutting device. The device comprises a die cutting bottom frame, a cam mechanism, a rolling feeding mechanism and a die cutting mechanism; the die cutting bottom frame is fixedly arranged on a machine tool or any one stable horizontal plane, the cam mechanism is arranged on the upper surface of the front end of the die cutting bottom frame, the die cutting mechanism is arranged on the upper surface of the rear end of the die cutting bottom frame, the cam mechanism and the die cutting mechanism are connected through a driven connecting rod, and arolling belt feeding mechanism is arranged in the die cutting mechanism. According to the high-speed pole piece cutting device, and a cutting method thereof, in the process that a pole belt is kept feeding moving, the pole belt is cut into a pole piece in the stipulated shape, continuous cutting is achieved, the pole belt does not need to stop feeding, the pole piece cutting efficiency is improved, when the cutting mold cuts the pole piece, the pole belt is kept static, feeding action is stopped, after cutting action is finished, the pole belt recovers the conveying action, the above action iscirculated, and pole piece cutting is carried out.

Owner:SHENZHEN GDLASER TECH CO LTD

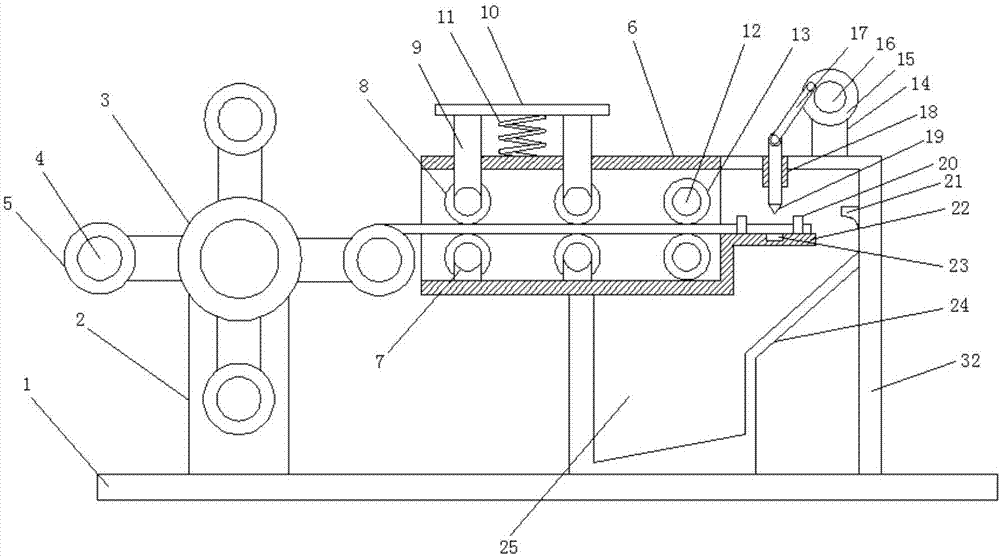

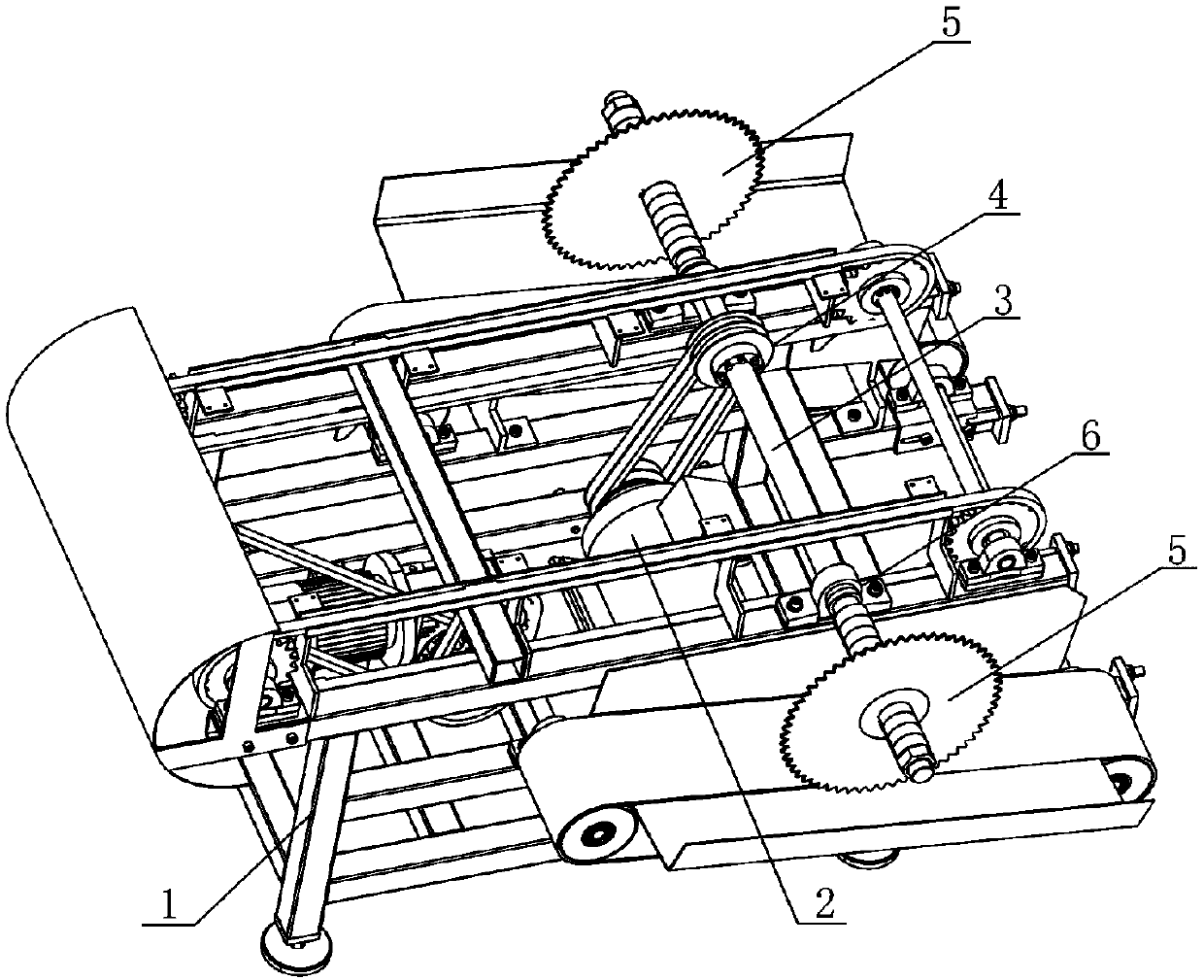

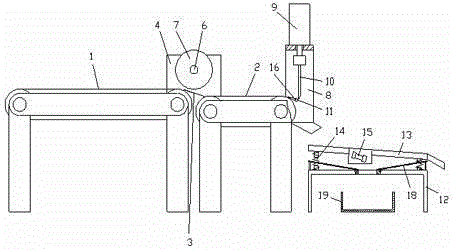

Automatic dried tofu slitting device

InactiveCN105269620AContinuous cuttingHigh degree of automationMetal working apparatusEngineeringBelt conveyor

The invention discloses an automatic dried tofu slitting device. The automatic dried tofu slitting device comprises a first belt conveyor, a second belt conveyor, a transition supporting plate, a longitudinal slitting device, a transverse slitting device and a controller. When the automatic dried tofu slitting device works, large dried tofu is placed on the first belt conveyor, the controller controls the first belt conveyor to work to convey the dried tofu to the longitudinal slitting device and controls a servo motor to work, the servo motor drives a longitudinal slitting knife to rotate to longitudinally slit the dried tofu; and the slit dried tofu enters the second belt conveyor through the transition supporting plate, the controller then controls the second belt conveyor to feed the dried tofu into the transverse slitting device and controls an electric cylinder to drive a transverse slitting knife to move up and down, and the dried tofu is transversely slit. By means of the slitting device, the dried tofu can be continuously slit, and the automation degree and the production efficiency are high.

Owner:CHONGQING YUPAI AGRI PROD DEV

Protective film cutting device

InactiveCN107263568AContinuous cuttingImprove cutting efficiencyMetal working apparatusWebs handlingHorizontal axisEngineering

The invention discloses a protective film cutting device, which comprises a bottom plate and a vertical plate. A mounting frame is arranged on the outer wall of the rotating rod, and a protective film reel is mounted on the mounting frame. A guide is provided on the right side of the mounting frame. channel, the right end of the inner cavity of the guide channel is provided with two horizontal shafts, driving rollers are provided on the two horizontal shafts, the bottom plate is also provided with a right side plate, and the top of the right side plate is provided with a second bracket and a cutting knife rod, the second bracket is provided with a rotating shaft, one end of the rotating shaft is connected to one of the horizontal shafts through a transmission mechanism, and the other end of the rotating shaft is provided with a rotating disc, and the rotating disc and the cutting The cutter bar is provided with a connecting rod, a cutting platform is provided under the cutting tool bar, and a collection groove is provided under the cutting platform. The invention has the advantages of simple structure, high cutting efficiency, continuous operation and no manual operation. It is easy to arrange and collect the protective film, and has strong practicability.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

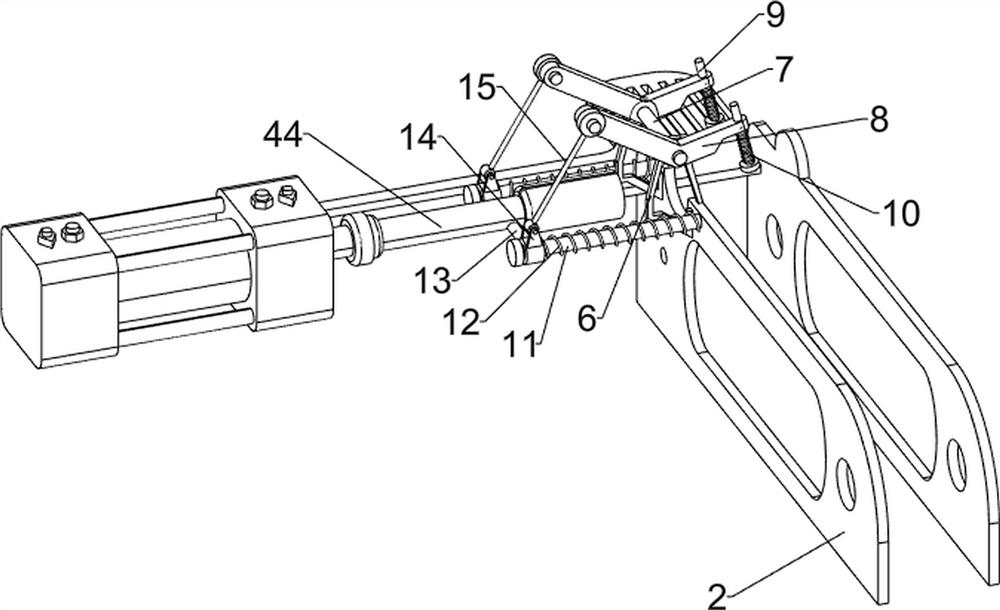

Device for steel pipe cutting

InactiveCN109663971AContinuous cuttingImprove cutting efficiencyMetal sawing devicesMetal sawing accessoriesArchitectural engineeringSteel tube

The invention discloses a device for steel pipe cutting. The device comprises a frame, a cutting control motor, a cutting execution mechanism and a steel pipe clamping motion mechanism; after improvement, the steel pipe clamping motion mechanism drives steel pipes to move, and the cutting execution mechanism cuts two ends of the steel pipes; compared with a traditional steel pipe cutting device, the device is reasonable in overall structure and better in linkage, can realize continuous cutting of the steel pipes, and preferably improves the cutting efficiency of the steel pipes; and meanwhile,when the steel pipes move along with a clamping motion chain, the steel pipes are fixed by a steel pipe clamping base, so that the steel pipes are stably clamped in the cutting process to prevent shaking, the continuous cutting of multiple sets of the steel pipes can be met, and the pipe cutting efficiency is greatly improved.

Owner:徐蒙蒙

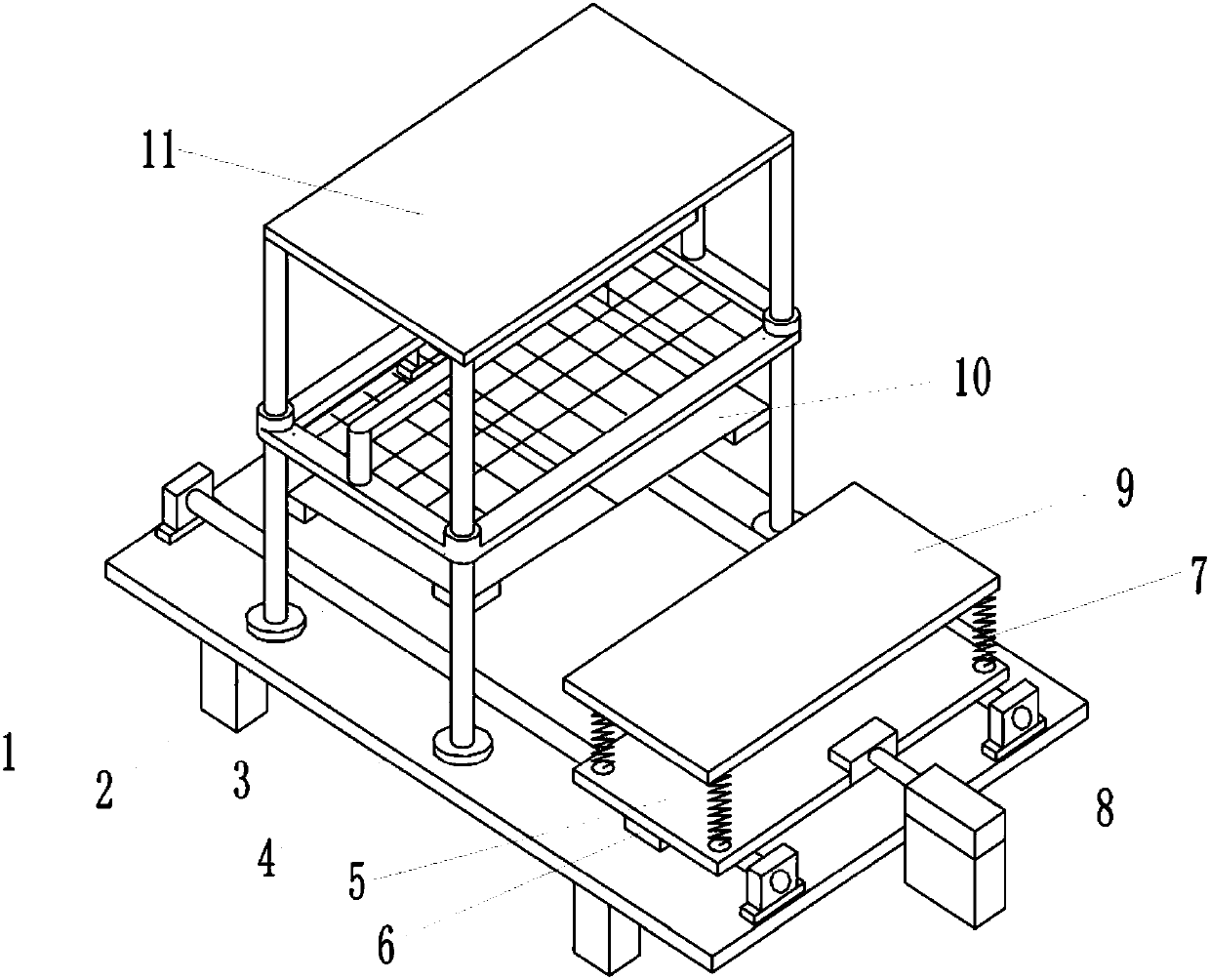

Toufu slabbing machine

ActiveCN107627338AImprove stabilityGuaranteed stabilityMetal working apparatusDevice formEngineering

The invention belongs to the technical field of food processing plants, and discloses a toufu slabbing machine. The toufu slabbing machine comprises a base, a first cutting device formed by a cuttingdisc, a tray structure and a second cutting device composed of a plurality of transverse metal wires and longitudinal metal wires. A horizontal guide rail and a vertical guide rail are connected to the base. The tray structure is connected to the horizontal guide rail in a sliding manner, the second cutting device is connected to the vertical guide rail in a sliding manner, and the first cutting device is connected to the vertical guide rail and is located below the second cutting device. The tray structure comprises a chassis and a tray, and a plurality of springs are arranged between the chassis and the tray. The tray is used for containing toufu, the tray structure slides on the horizontal guide rail, a layer of toufu is cut off through the first cutting device, and the layer of toufu is cut into blocks through the second cutting device. As the toufu slabbing machine cuts one layer of toufu each time, the problem that too much toufu blocks are stacked, and consequently collapsing orscattering is caused is solved, and the integrity of the toufu blocks is guaranteed.

Owner:枣庄夫宇食品有限公司

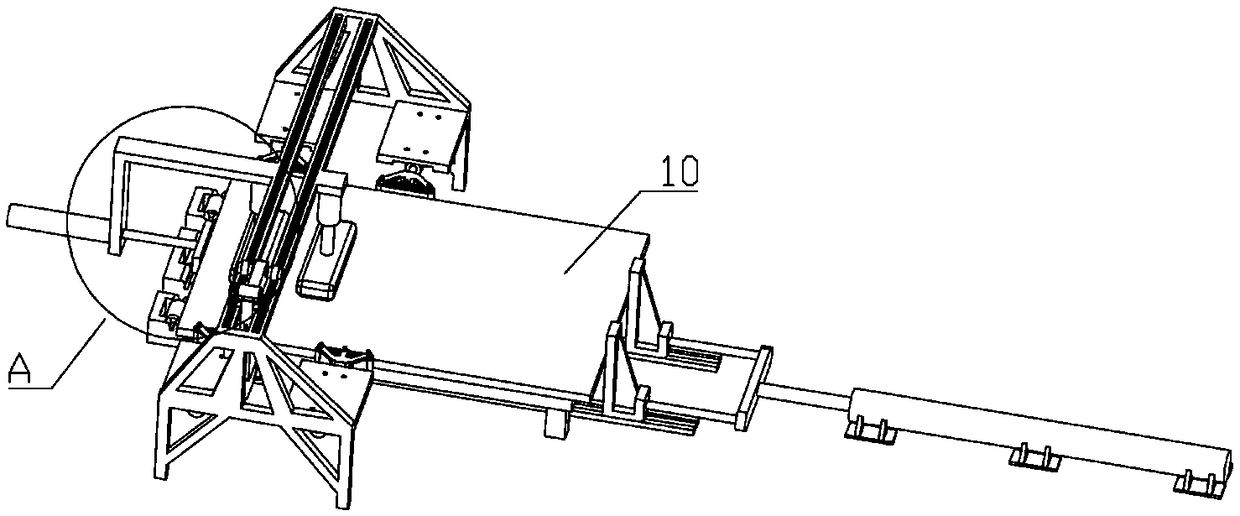

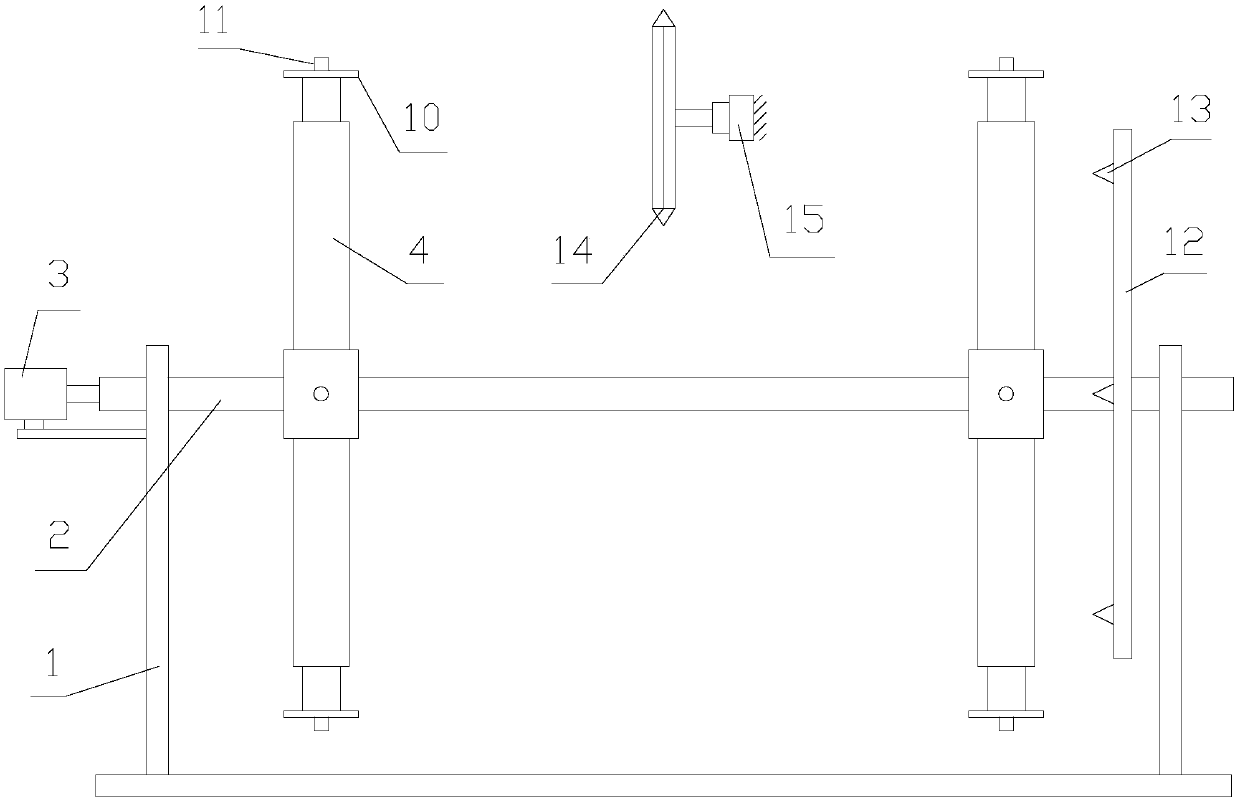

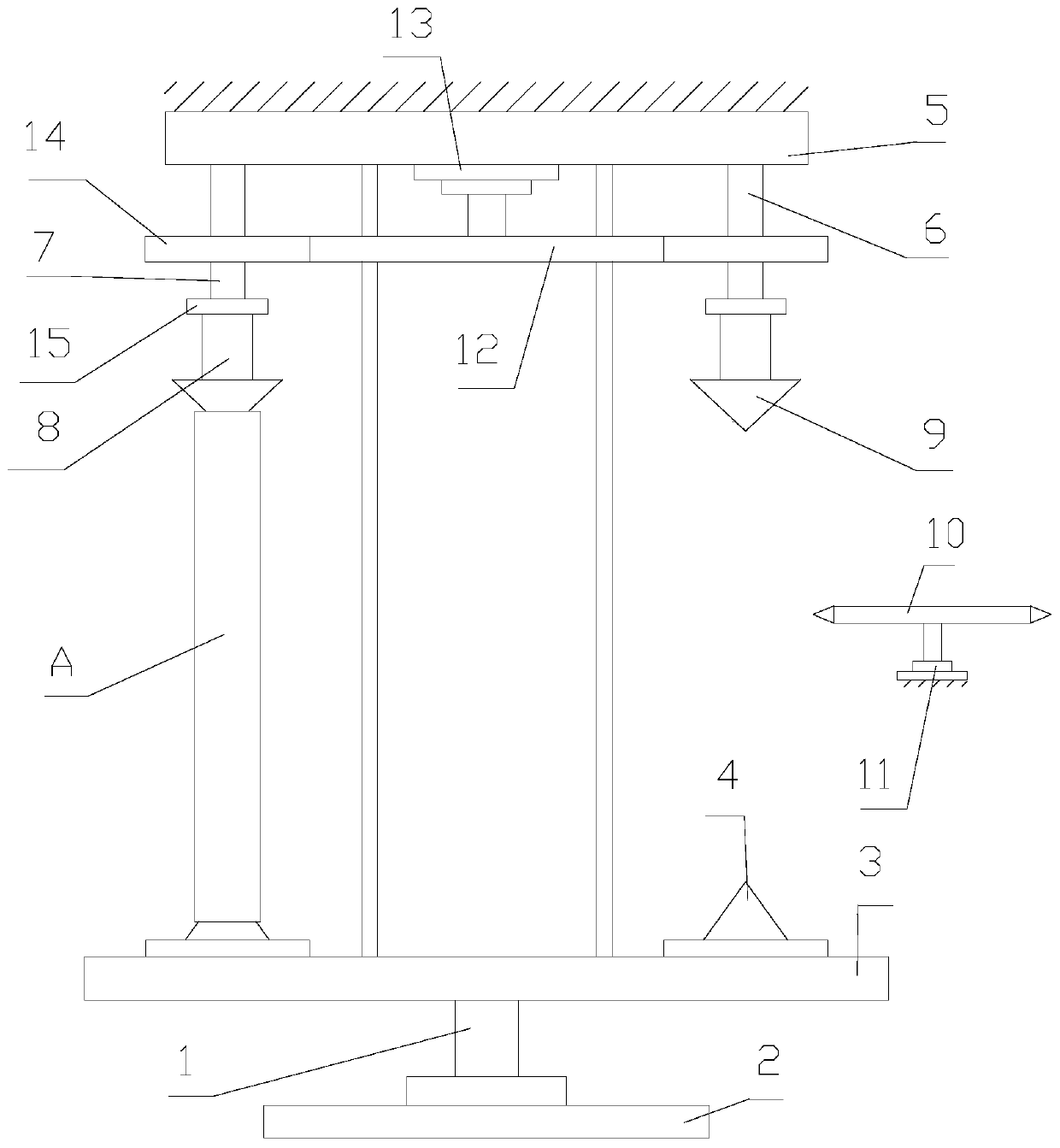

Convenient conveying type cutting device for natural gas pipeline production

ActiveCN107322089AEasy and labor-saving cuttingContinuous cuttingMetal sawing devicesMechanical engineeringNatural gas

The invention relates to a cutting device, in particular to a convenient conveying type cutting device for natural gas pipeline production. The invention aims at solving the technical problem of providing a convenient conveying type cutting device for natural gas pipeline production, wherein the convenient conveying type cutting device can save both time and labor and can be used for continuously cutting natural gas pipelines. In order to solve the above-mentioned technical problem, the convenient conveying type cutting device for natural gas pipeline production is provided and comprises an installing rack and the like, wherein a lifting mechanism is arranged on the upper portion of the installing rack, a cutting mechanism is arranged on the lower portion of the installing rack, and the cutting mechanism is located on the lower side of the lifting mechanism. According to the convenient conveying type cutting device for natural gas pipeline production, the cutting mechanism can be used for cutting the natural gas pipelines in a convenient and labor-saving manner, the lifting mechanism can drive the cutting mechanism to cut the natural gas pipelines in a convenient and labor-saving manner, an arc-shaped plate is arranged and can be used for fixing the pipelines, and therefore the pipelines can be prevented from moving in the cutting process.

Owner:新昌县兴欧智能科技有限公司

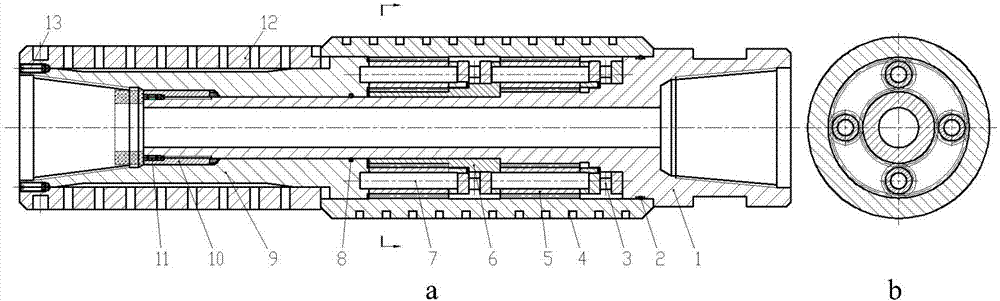

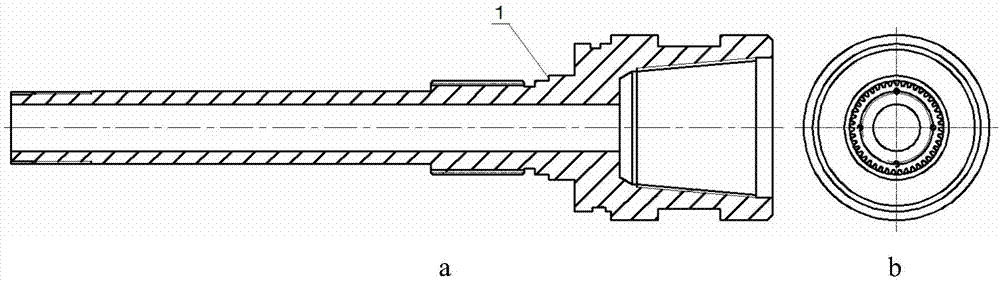

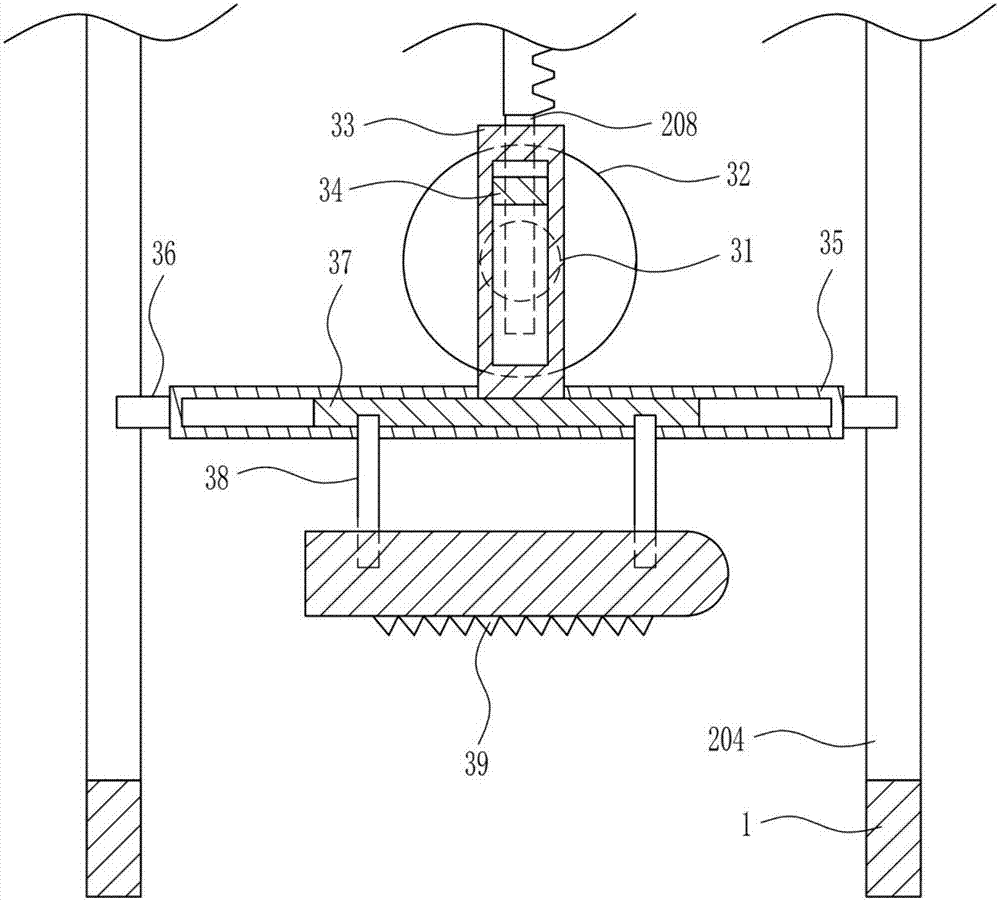

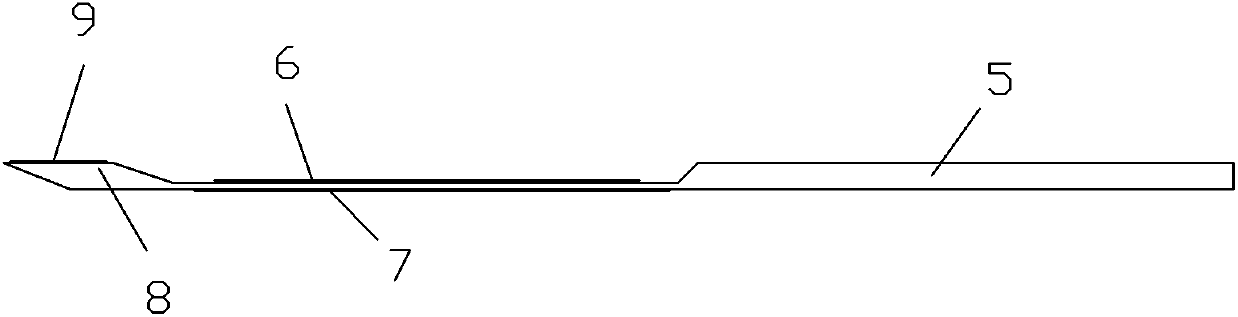

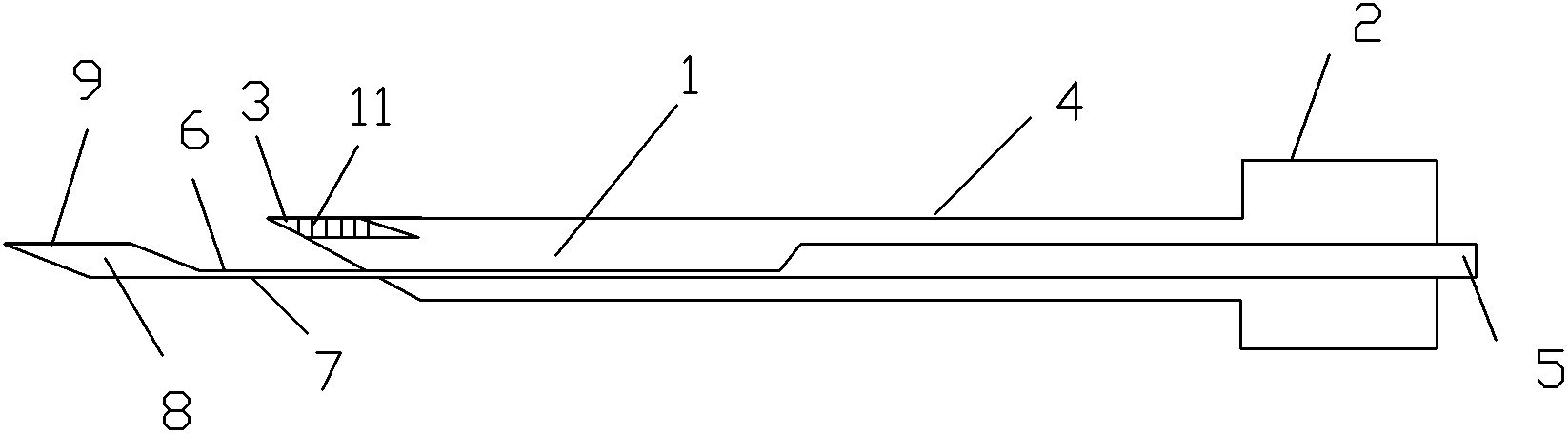

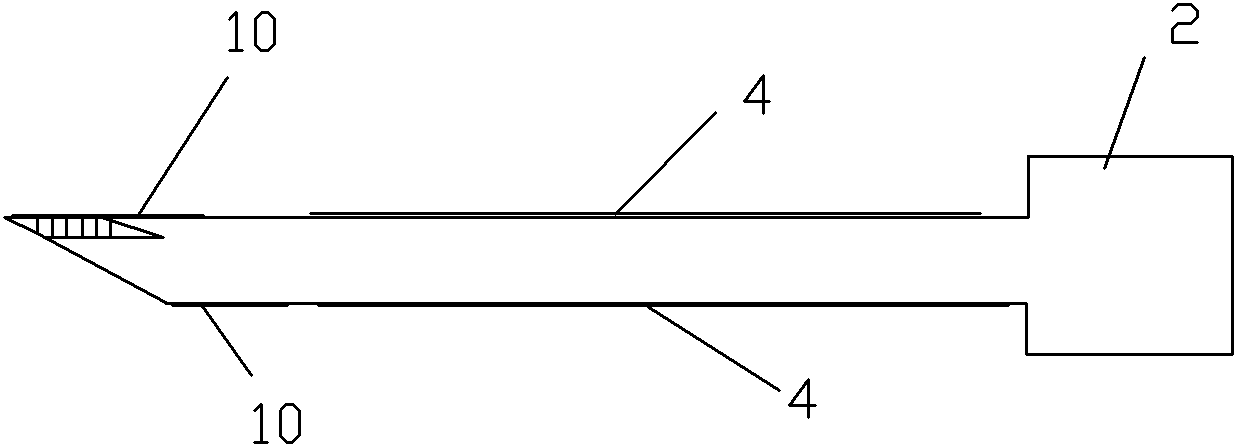

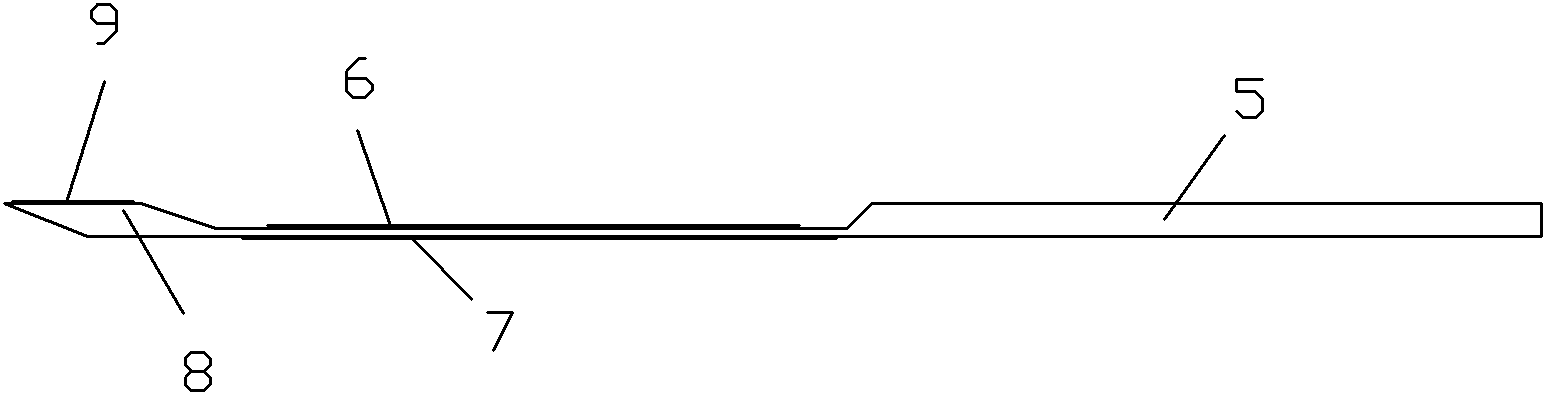

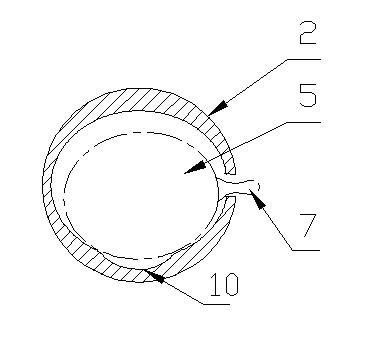

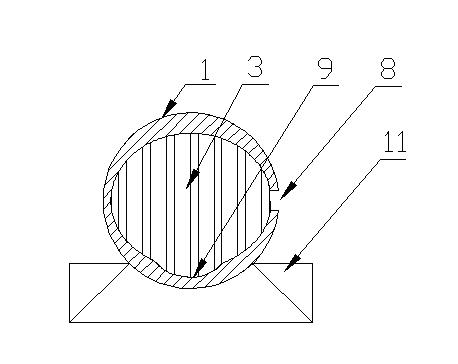

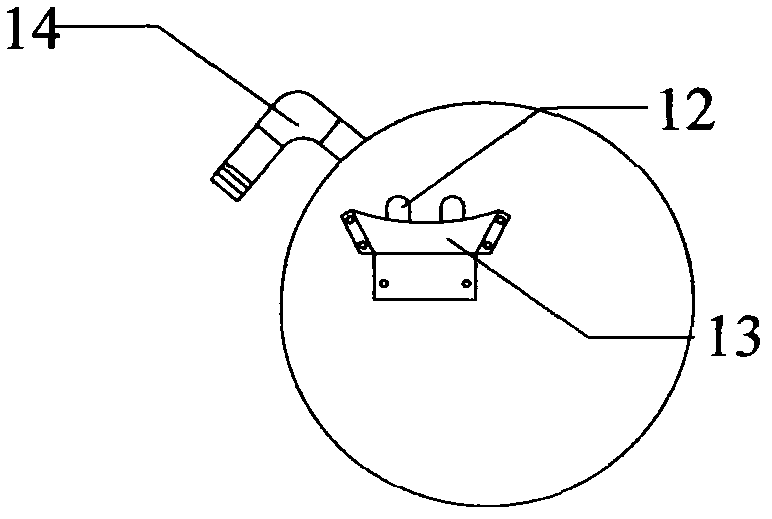

Multi-coating biopsy puncture needle capable of sampling by multiple times

A multi-coating biopsy puncture needle capable of sampling by multiple times comprises a biopsy puncture needle core and a needle barrel. A sampling groove is arranged on the biopsy puncture needle core, a tissue pushing block is disposed in an end of the needle barrel, a transverse line which is perpendicular to a long axis of the needle barrel is arranged on the pushing block and faces to the surface of one side of the sampling groove, two sides of the pushing block are inclined surfaces, and an included angle between the inclined surfaces is identical to an included angle between conical inclined surfaces of the biopsy puncture needle core; the length of the sampling groove of the biopsy puncture needle core is increased to be twice larger than the standard length, and a polytetrafluoroethylene coating is covered in the surface of the sampling groove; and the total length of the biopsy puncture needle is larger than or equal to 90mm, the inner diameter of the needle barrel is larger than or equal to 0.64mm, the outer diameter of the needle barrel is larger than or equal to 0.91mm, the length of a cone of a needle tip is 5mm, the included angle of the conical inclined surfaces ranges from 15 degrees to 20 degrees, an included angle of cutting surfaces ranges from 20 degrees to 25 degrees, and polytetrafluoroethylene coatings are covered on the surface of the needle barrel and the surface of the tip end of the biopsy puncture needle core. The multi-coating biopsy puncture needle has the advantages that the multi-coating biopsy puncture needle is simple in structure and convenient in use and can continuously cut viable tissues, cut biopsy tissue strips are complete, operation time is greatly shortened, and sufferings of patients are reduced to the greatest extent.

Owner:闫涛

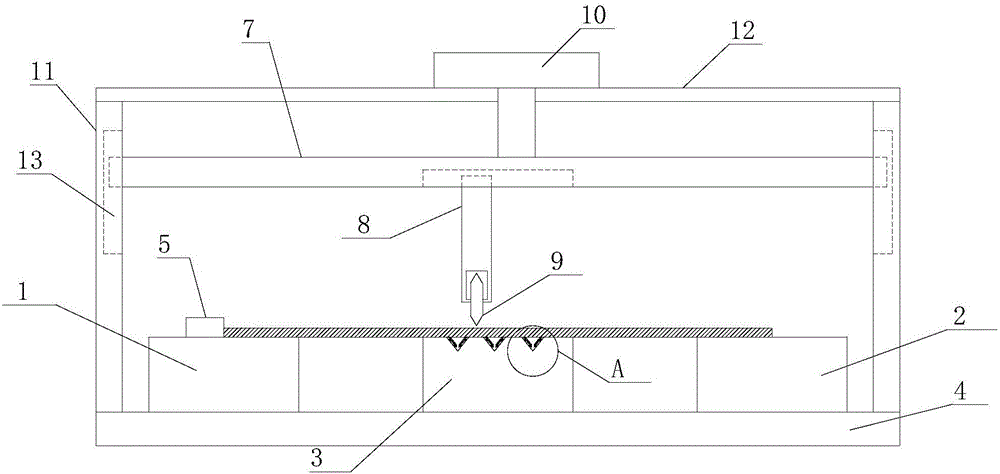

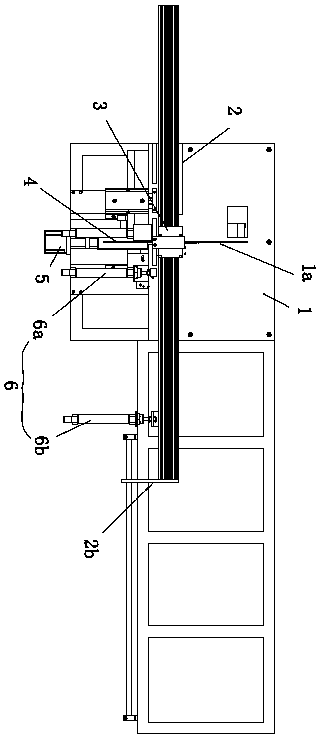

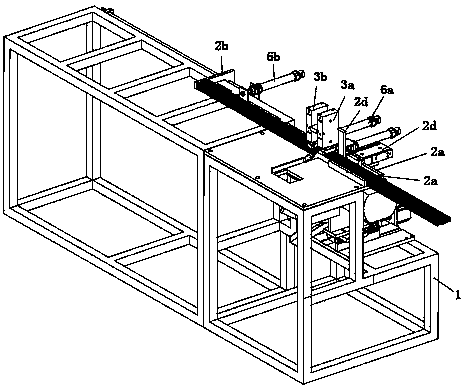

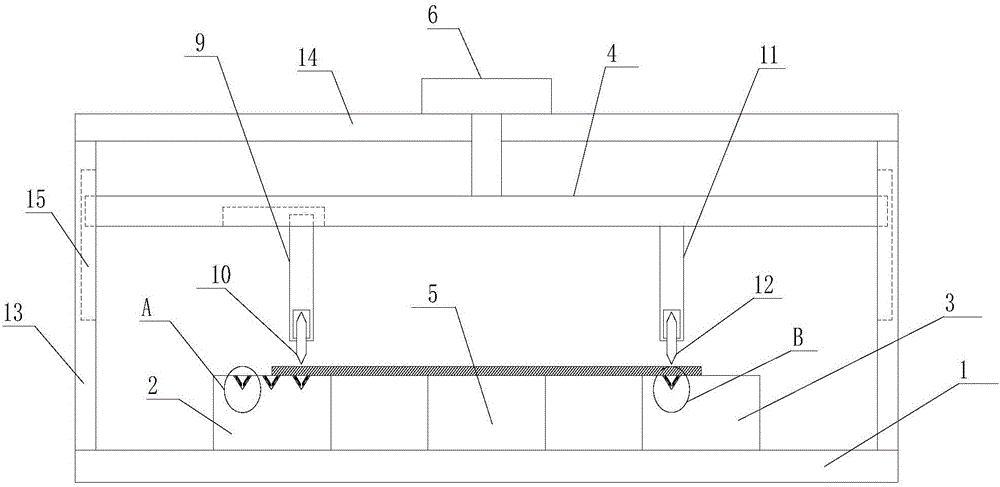

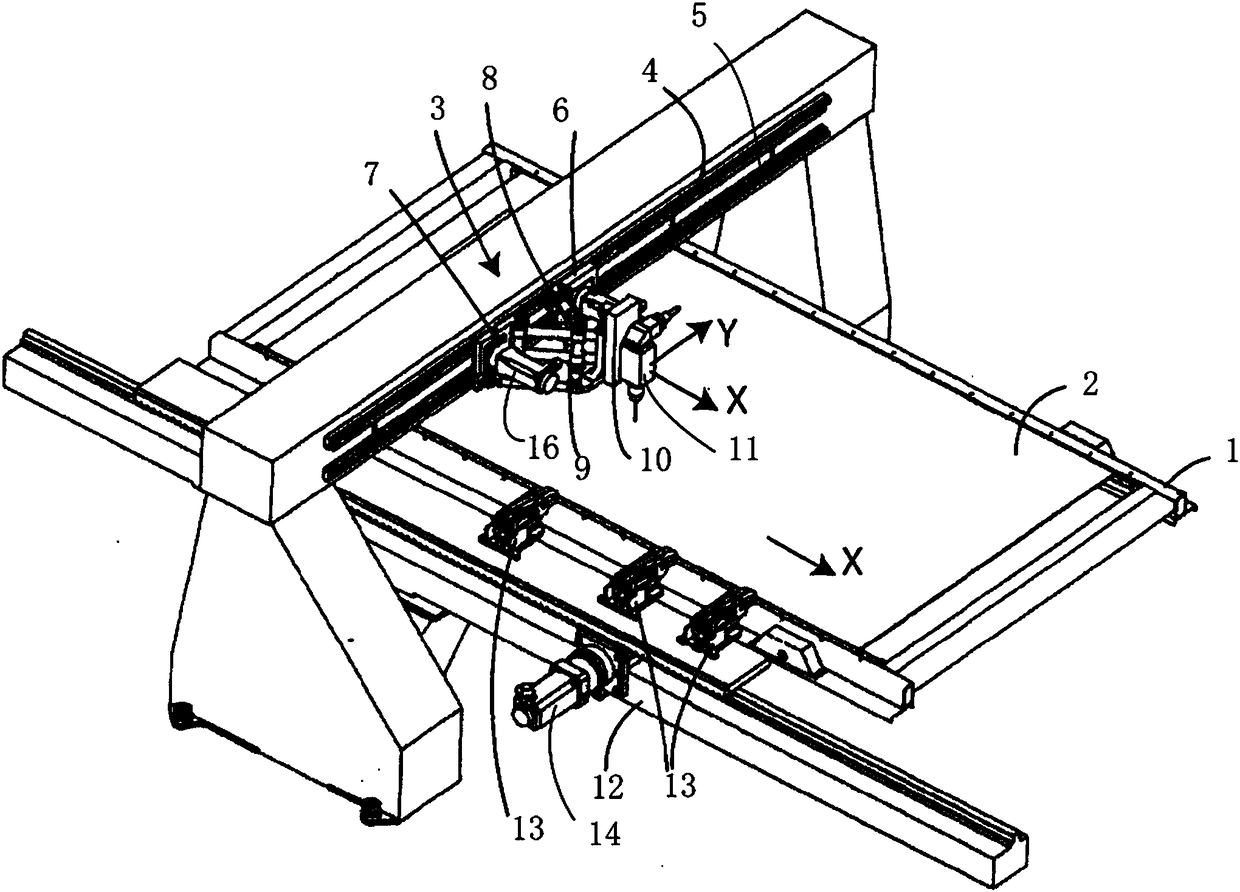

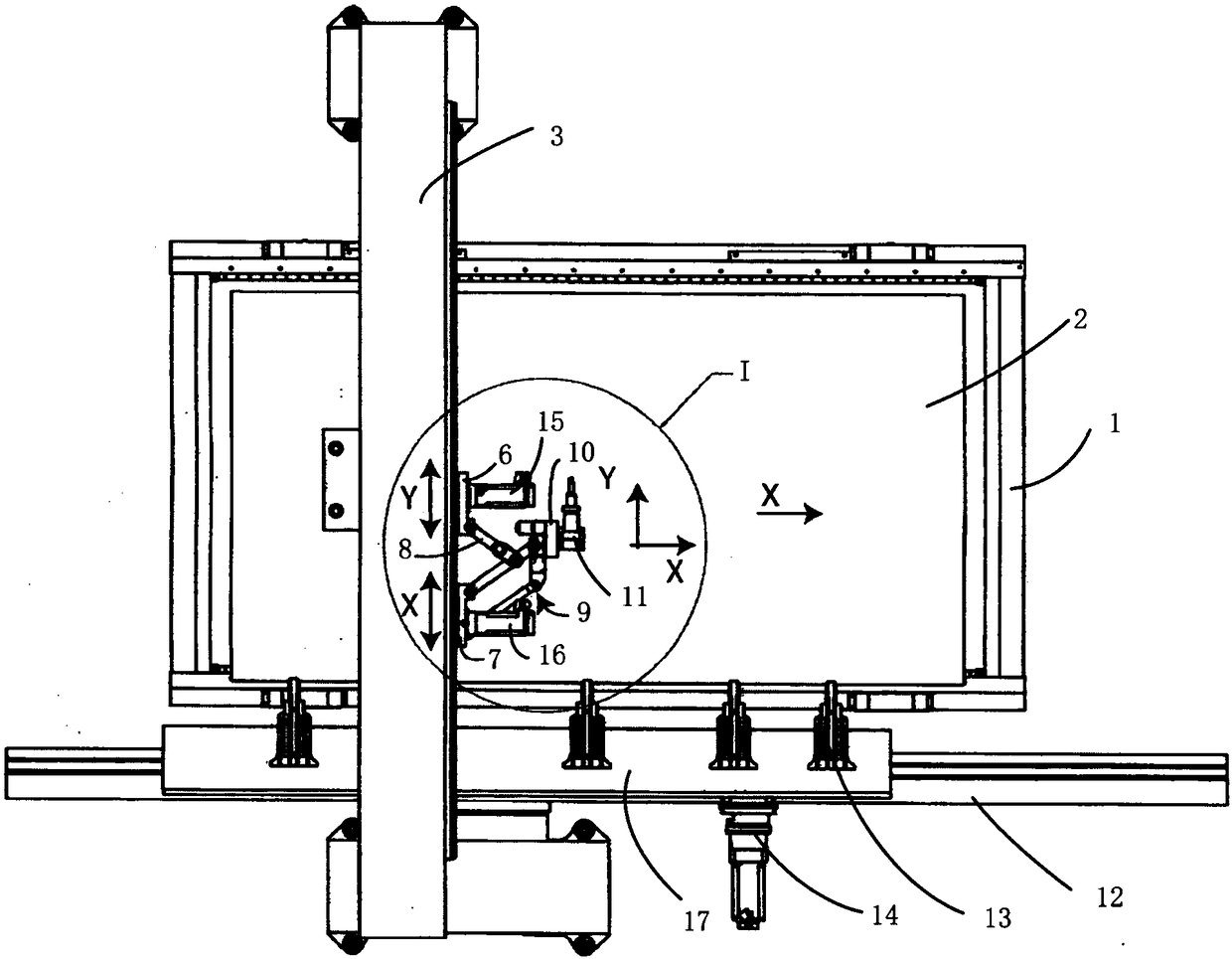

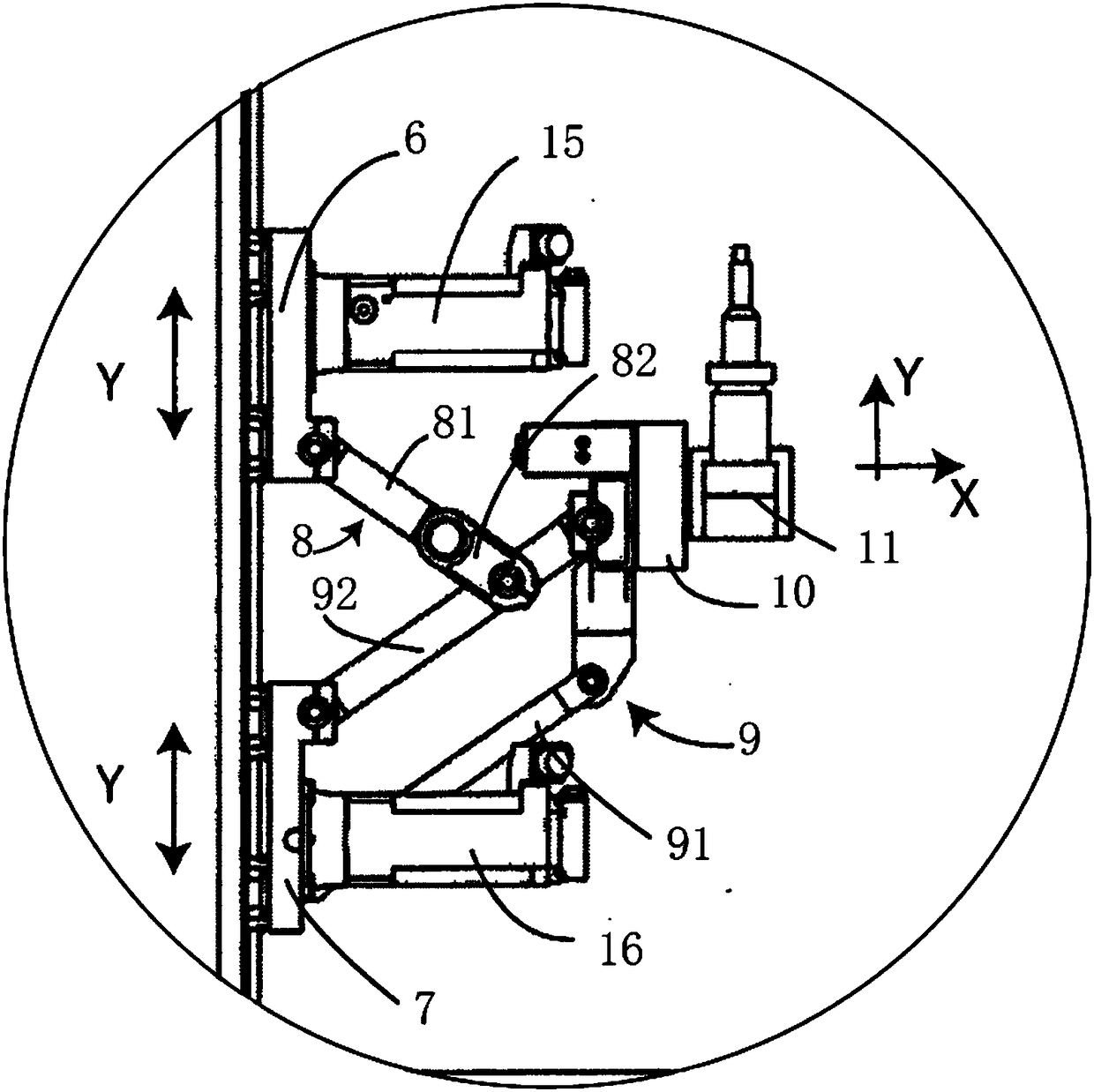

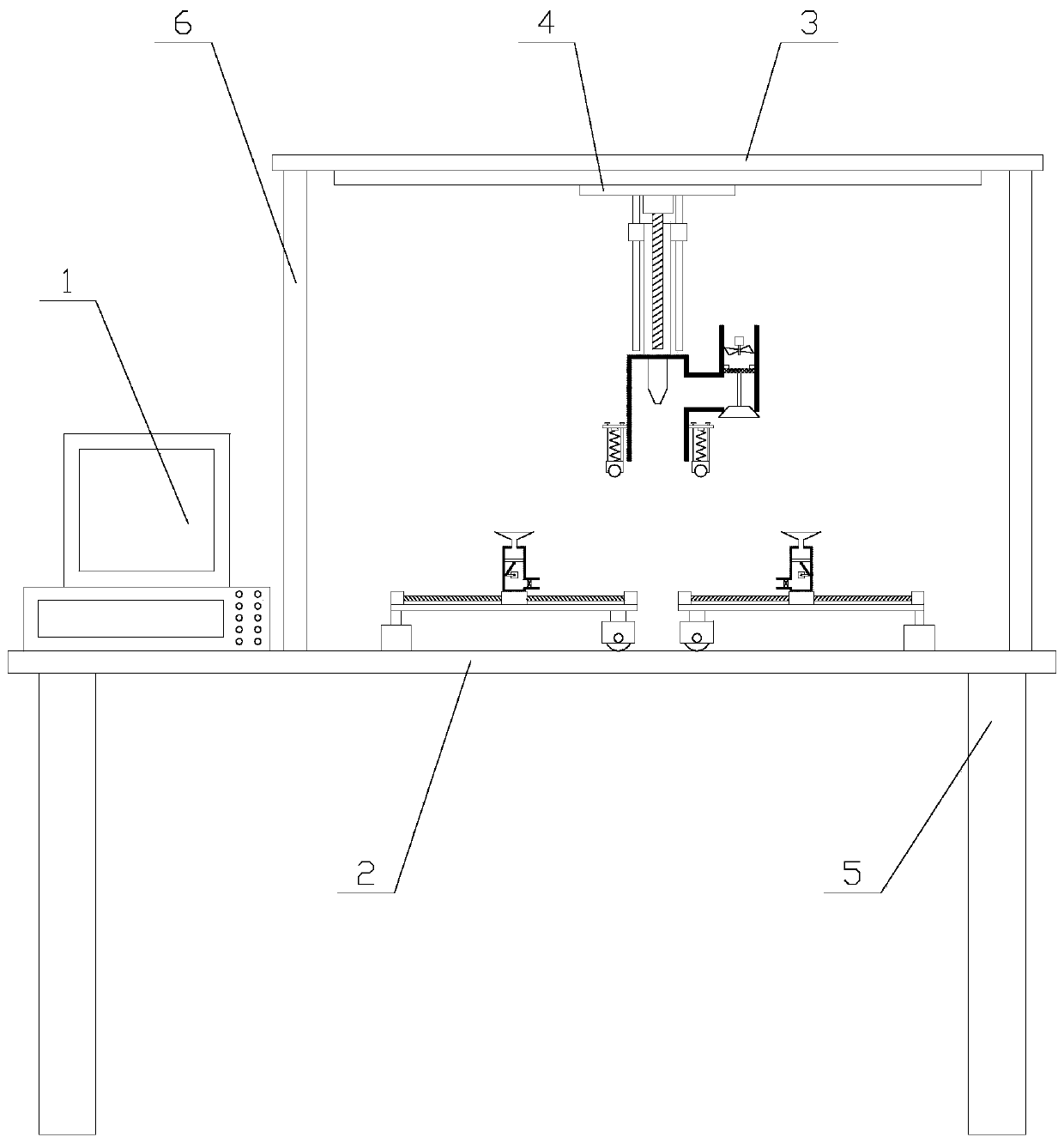

Laser cutting machine of board or strip

PendingCN108406136AGood for controlling inertiaHigh cutting precisionWelding/cutting auxillary devicesAuxillary welding devicesLaser cuttingPortal frame

The invention discloses a laser cutting machine of a board or a strip. The laser cutting machine of the board or the strip comprises a working table surface, a laser head and a portal frame crossing the upper part of the work table surface, and the board or the strip can be pulled to move horizontally and vertically on the working table surface. The portal frame is slidably and horizontally provided with a first sliding block and a second sliding block in the transverse direction, the laser head is installed on an installation seat and is arranged downwards, and a first connecting rod mechanism is connected between a first sliding seat and the installation seat in a hinged mode. A second connecting rod mechanism is connected between a second sliding seat and the installation seat or between the second sliding seat and the first connecting rod mechanism, and the first sliding block and the second sliding block are separately driven by a first transverse power device and a second transverse power device to move independently, so that the laser head can move in the transverse direction or in the longitudinal direction or in the resultant movement direction of the first sliding block and the second sliding block. The laser cutting machine of the board or the strip can reduce inertia and improves cutting accuracy.

Owner:金凯达(佛山)智能装备有限公司

Multi-coating biopsy puncture needle capable of sampling by multiple times

A multi-coating biopsy puncture needle capable of sampling by multiple times comprises a biopsy puncture needle core and a needle barrel. A sampling groove is arranged on the biopsy puncture needle core, a tissue pushing block is disposed in an end of the needle barrel, a transverse line which is perpendicular to a long axis of the needle barrel is arranged on the pushing block and faces to the surface of one side of the sampling groove, two sides of the pushing block are inclined surfaces, and an included angle between the inclined surfaces is identical to an included angle between conical inclined surfaces of the biopsy puncture needle core; the length of the sampling groove of the biopsy puncture needle core is increased to be twice larger than the standard length, and a polytetrafluoroethylene coating is covered in the surface of the sampling groove; and the total length of the biopsy puncture needle is larger than or equal to 90mm, the inner diameter of the needle barrel is larger than or equal to 0.64mm, the outer diameter of the needle barrel is larger than or equal to 0.91mm, the length of a cone of a needle tip is 5mm, the included angle of the conical inclined surfaces ranges from 15 degrees to 20 degrees, an included angle of cutting surfaces ranges from 20 degrees to 25 degrees, and polytetrafluoroethylene coatings are covered on the surface of the needle barrel and the surface of the tip end of the biopsy puncture needle core. The multi-coating biopsy puncture needle has the advantages that the multi-coating biopsy puncture needle is simple in structure and convenient in use and can continuously cut viable tissues, cut biopsy tissue strips are complete, operation time is greatly shortened, and sufferings of patients are reduced to the greatest extent.

Owner:闫涛

Efficient laser cutting machine with cooling function

ActiveCN109848579AWith cooling functionHigh-efficiency laser cutting with cooling function facilitatesLaser beam welding apparatusCold airLaser cutting

The invention relates to an efficient laser cutting machine with a cooling function. The efficient laser cutting machine with the cooling function comprises a host, a workbench, a top plate, a plane moving device, a horizontal moving plate, a cutting mechanism, a fixing mechanism, four landing legs and two fulcrum bars. The cutting mechanism comprises a lifting assembly, a lifting pipe, a laser head, a transverse pipe, a vertical pipe, a cooling assembly and a plurality of detecting assemblies. The cooling assembly comprises a draught fan, a filter screen, a vertical rod and a sealing block. The fixing mechanism comprises a plurality of fixing assemblies. Each fixing assembly comprises a first motor, a moving plate, a horizontal moving assembly, a horizontal moving block and a fixing unit.According to the efficient laser cutting machine with the cooling function, when the cutting mechanism is used for carrying out cutting, the draught fan continuously pumps away hot air so that the cutting position is surrounded by cold air, cooling is achieved, continuous cutting of the equipment is facilitated, and therefore the machining efficiency is improved, a workpiece is fixed through thefixing mechanism, the situation that during cutting, the detecting assembly drives the workpiece to slide is avoided, and therefore the cutting precision is guaranteed, and the practicality of the equipment is improved.

Owner:JIANGSU HUYUN LASER EQUIP CO LTD

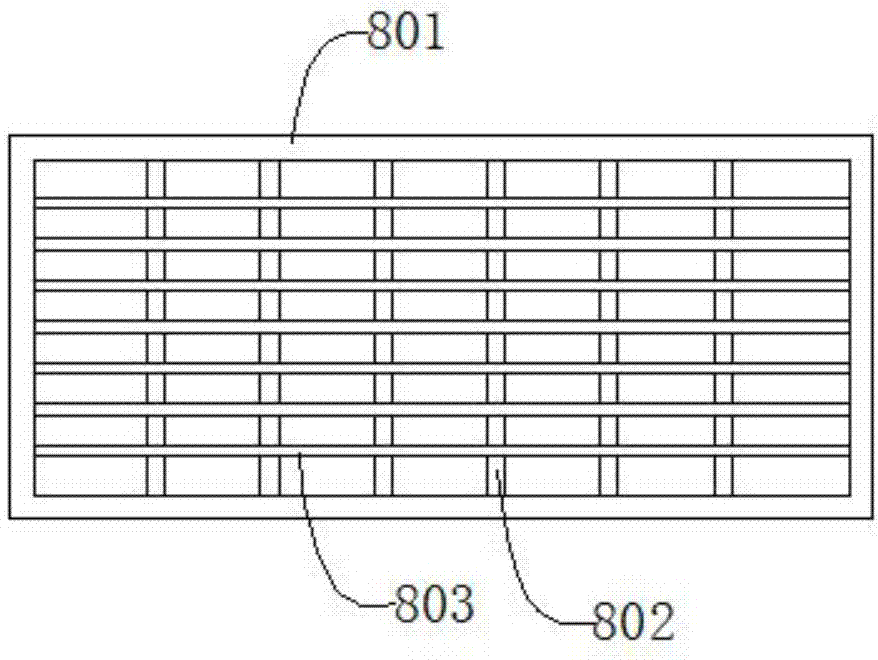

Slicing machine

InactiveCN101623875AContinuous cuttingImprove cutting efficiencyMetal working apparatusEngineeringBlade plate

The invention relates to a slicing machine which comprises a frame and a driving system, wherein, a stationary knife base is fixedly arranged on a frame; a cylindrical operating cavity is arranged in the stationary knife base; a discharging channel which penetrates the stationary knife base body in the radial direction is arranged in the stationary knife base; a stationary knife is fixed on the stationary knife base at the inner opening of the discharging channel; a moving knife which is in transmission connection with a driving system is correspondingly and rotatively arranged in the operating cavity; the moving knife comprises more than three moving knife boards which are distributed along a circumference and arranged in the radial direction; the edge of each moving knife board is correspondingly matched with that of the stationary knife; a feeder is arranged on the frame; the discharging hole of the feeder is communicated with an outer end hole arranged on the outer end of the operating cavity. The slicing machine has the advantages that the rotating moving knife is correspondingly matched with the stationary knife, the continuous cutting is realized, the cutting efficiency is improved, and the slicing machine is energy-saving. Simultaneously, the slicing machine has simple structure and is easy to be operated.

Owner:ZHENGZHOU GUXIANGQING FOOD TECH

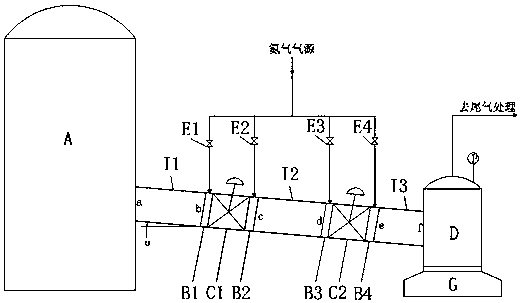

Safe slag discharging device for boiling furnace

InactiveCN107676801AAvoid cloggingAvoid getting stuckLighting and heating apparatusSlagFluidized bed

The invention relates to the technical field of chemical production, and discloses a safety slag discharge device for fluidized fluidized furnace. The device includes a slag discharge pipe, a gas purging ring, a slag discharge cut-off valve, a gas cut-off valve, a slag discharge tank and a slag receiving hopper. The invention has simple equipment, uses nitrogen to purge the material in the slag discharge shut-off valve and the slag discharge pipeline through the gas purging ring, avoids the blockage or jamming of the slag discharge shut-off valve by granular materials, and realizes the safety, continuity and reliability of the fluidized fluidized furnace. Controlled slag discharge eliminates the safety accidents and environmental protection accidents caused by it.

Owner:张园园

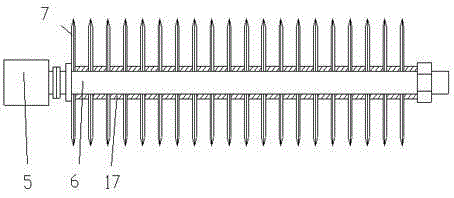

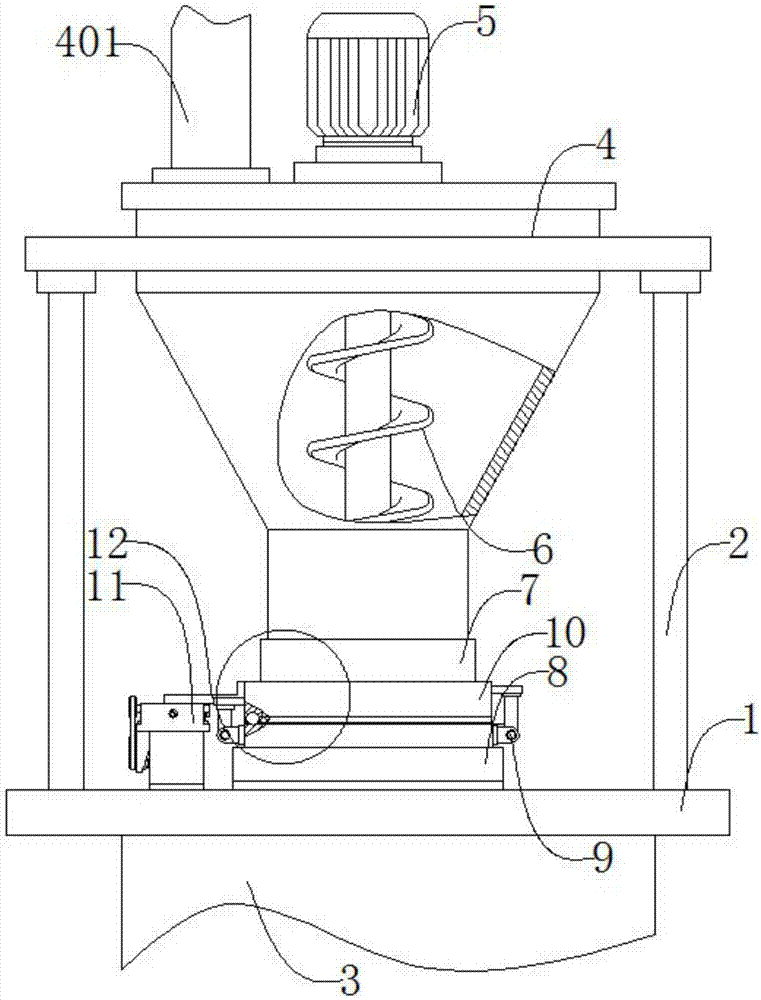

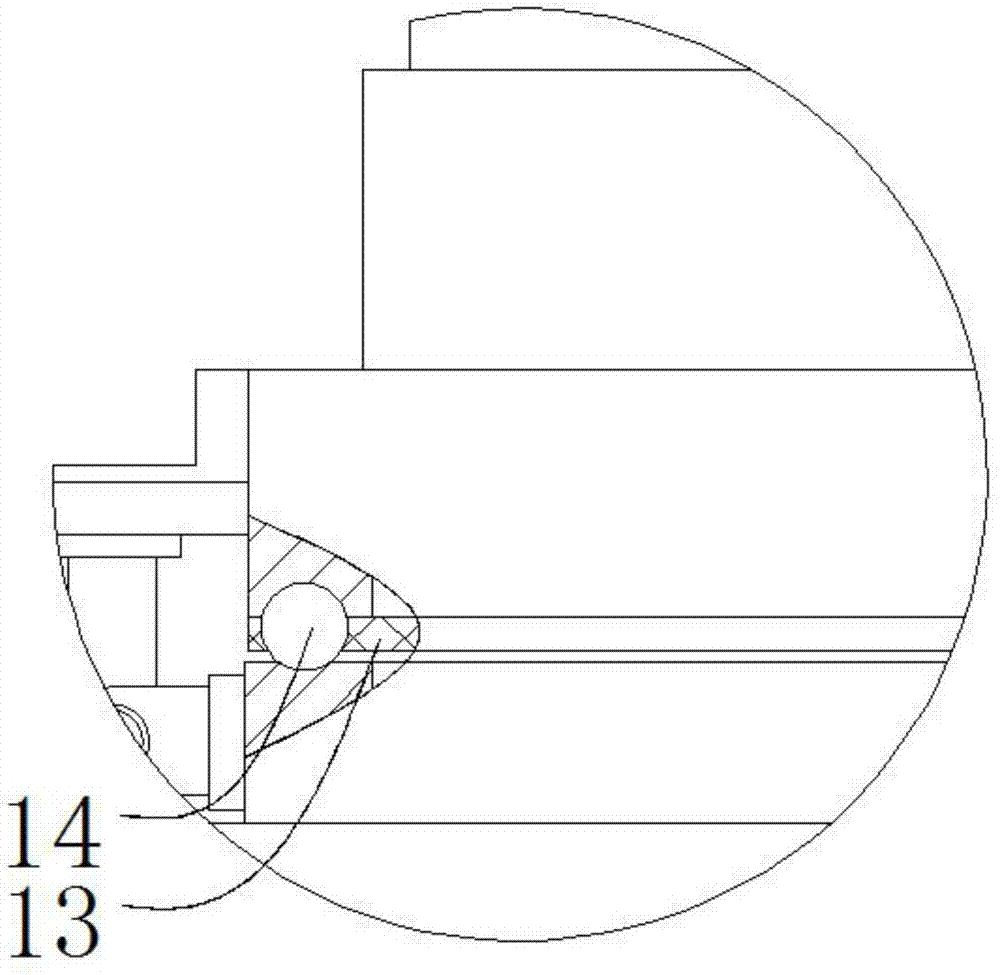

Trichosanthes slicing machine

InactiveCN101898364AEnsure consistencyHigh medicinal valueMetal working apparatusPistonUniform - quality

The invention relates to a trichosanthes slicing machine which comprises a horizontal tubular casing and is characterized in that a discharging guide groove is arranged on an opening at the upper side of the middle part of the horizontal tubular casing; a group of parallel slicing blades are arranged at the front side of the horizontal tubular casing, and the edge of each slicing blade faces to the back side; and a reciprocating piston which is used for pushing the trichosanthes falling into the horizontal tubular casing and enabling the trichosanthes to be sliced is arranged at the back side of the horizontal tubular casing. The device can be used for slicing the trichosanthes in the fixed positions and directions according to the botanical characteristics to enable the sliced trichosanthes to simultaneously contain trichosanthes bark, trichosanthes pulp and trichosanthes seeds, thereby ensuring that medicinal trichosanthes decoction pieces have uniform quality and medicinal effect; and the invention can effectively improve the processing efficiency of trichosanthes slices and reduce the labor intensity of operators, and is very suitable for industrialized production.

Owner:福建承天农林科技发展有限公司

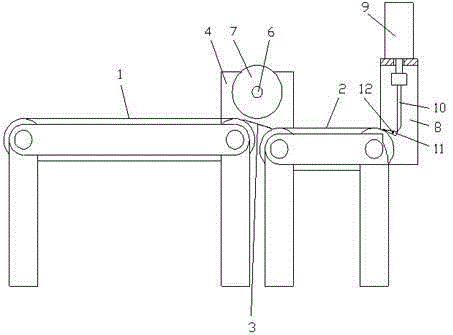

Automatic cutoff device of filter cotton of aquarium

The invention relates to a cutoff device, in particular to an automatic cutoff device of filter cotton of an aquarium. The automatic cutoff device comprises a conveying belt, a cutoff knife, a liftingdevice, a pushing device and a locating device. Rolling wheels are mounted above the conveying belt and press the filter cotton onto the conveying belt. A cutoff plate is mounted at one end of the conveying belt. A cutoff trough is formed in the cutoff plate and right faces the cutoff knife. The cutoff knife is located above the cutoff plate and is mounted on the lifting device. The locating device is mounted at one end of the cutoff plate and is away from the cutting trough. The locating device controls the cutoff length of the filter cotton by controlling starting and stopping of the conveying belt. The pushing device is located on one side of the cutoff plate, the pushing device pushes the cut filter cotton into a transfer box, and the transfer box is located on the other side of the cutoff plate. The automatic cutoff device is small in size, low in cost, high in automation degree, capable of achieving continuous cutoff, good in cutting knife face quality and high in work efficiency and can be suitable for adjusting and cutting filter cotton of different sizes.

Owner:宜兴市于氏特种玻璃有限公司

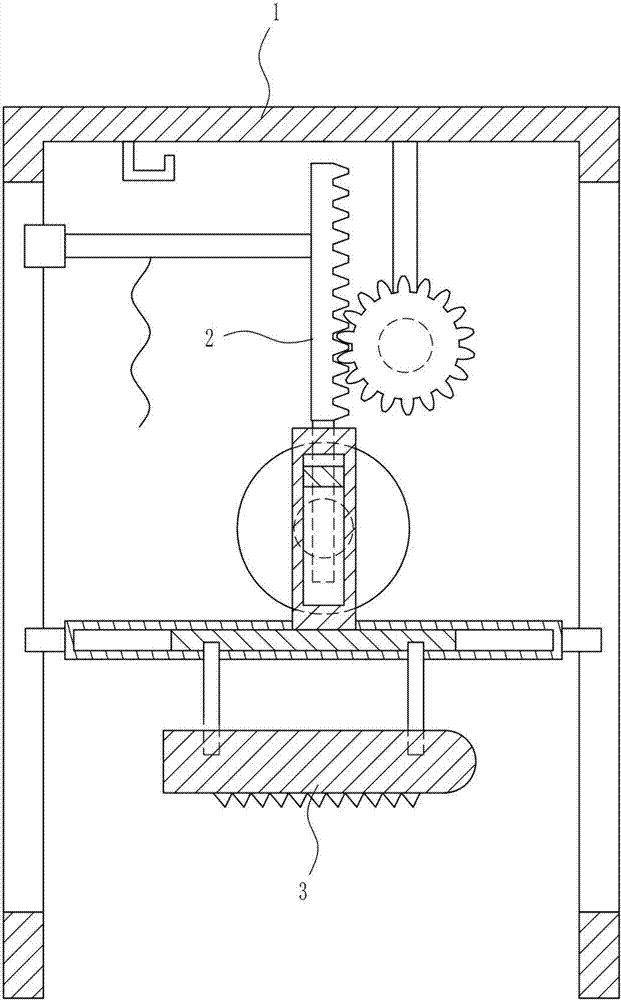

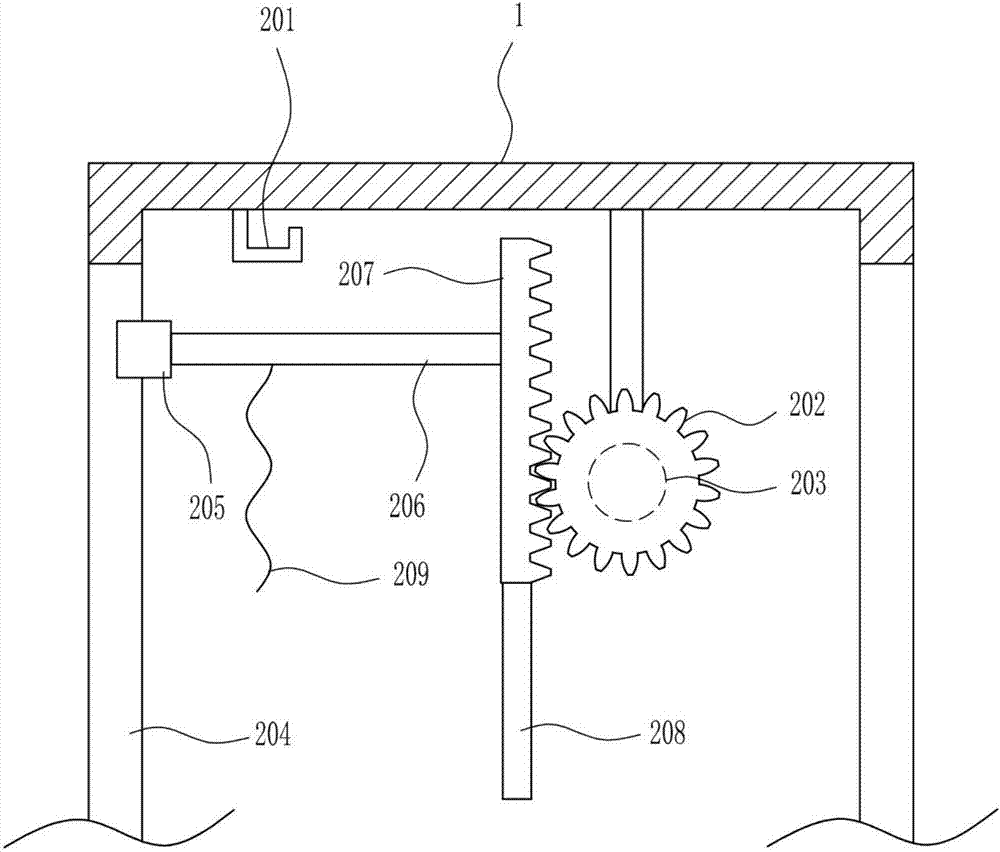

Circuit board production pin machining device

The invention discloses a circuit board production pin machining device, and belongs to the technical field of circuit board machining. The circuit board production pin machining device comprises a bottom plate, wherein a supporting frame is arranged on the upper surface of the bottom plate, a cutting assembly mechanism is arranged on the back surface of the inner wall of the supporting frame, thecutting assembly mechanism is engaged with a half gear, and a first rotating shaft is clamped on the back surface of the half gear. According to the circuit board production pin machining device, byarranging a toothed bar, the half gear, a motor, a push rod, a stop lever, a sliding rail, a top plate, a pressing plate and a cutter, the half gear drives the toothed bar and the cutter to downwardscut raw materials, cut pins fall into a buffer storage box, and the circuit board production pin machining device can automatically feed the raw materials; and meanwhile, the circuit board productionpin machining device can be matched with the cutting process to achieve continuous cutting operation on the raw materials, it can be guaranteed that the raw materials are stably placed through the pressing plate while cutting is conducted, it is guaranteed that the raw material cutting process is accurately conducted to a certain extent, and it is guaranteed that the efficiency and the yield of the pin machining process are ideal.

Owner:陆诚香

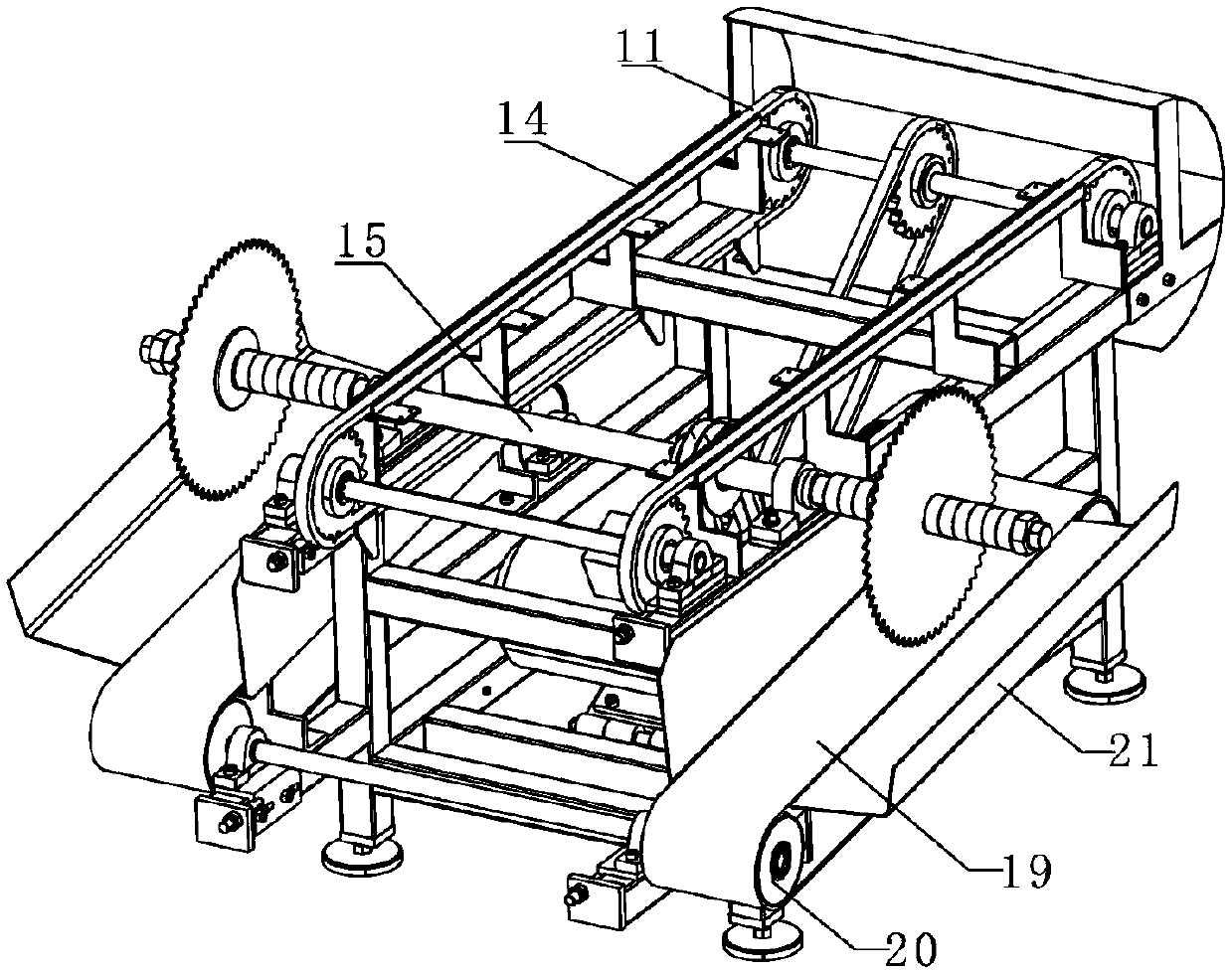

Automatic dried bean curd slitting device with sorting function

InactiveCN105252574AAchieving vertical slittingRealize horizontal slittingSievingScreeningEngineeringBelt conveyor

The invention discloses an automatic dried bean curd slitting device with a sorting function. The automatic dried bean curd slitting device comprises a first belt conveyor, a second belt conveyor, a transition supporting plate, a longitudinal slitting device, a transverse slitting device, a vibrating and screening device and a controller. In work, a large piece of dried bean curd is placed on the first belt conveyor, the controller controls the first belt conveyor to work for conveying the dried bean curd to the longitudinal slitting device, and controls a servo motor to work for driving a longitudinal slitting cutter to rotate, so that longitudinal slitting of the dried bean curd is realized; the slit dried bean curd enters the second belt conveyor through the transition supporting plate; the controller controls the second belt conveyor for feeding the dried bean curd into the transverse slitting device, and controls an electric cylinder to drive a transverse slitting cutter to move up and down, so that transverse slitting of dried bean curd is realized, slitting operation is continuously carried out and production efficiency is high; and the vibrating and screening device is used for sorting the slit dried bean curd, and the sorted dried bean curd is higher in overall quality.

Owner:CHONGQING YUPAI AGRI PROD DEV

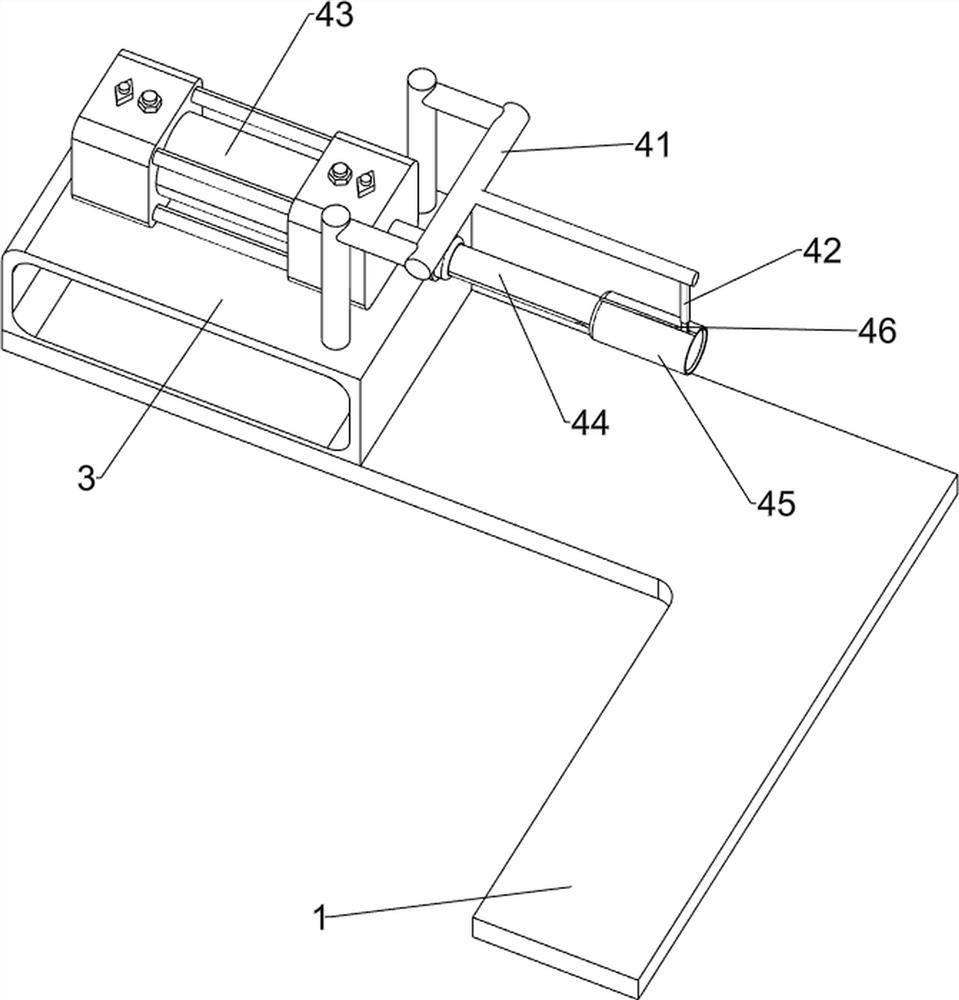

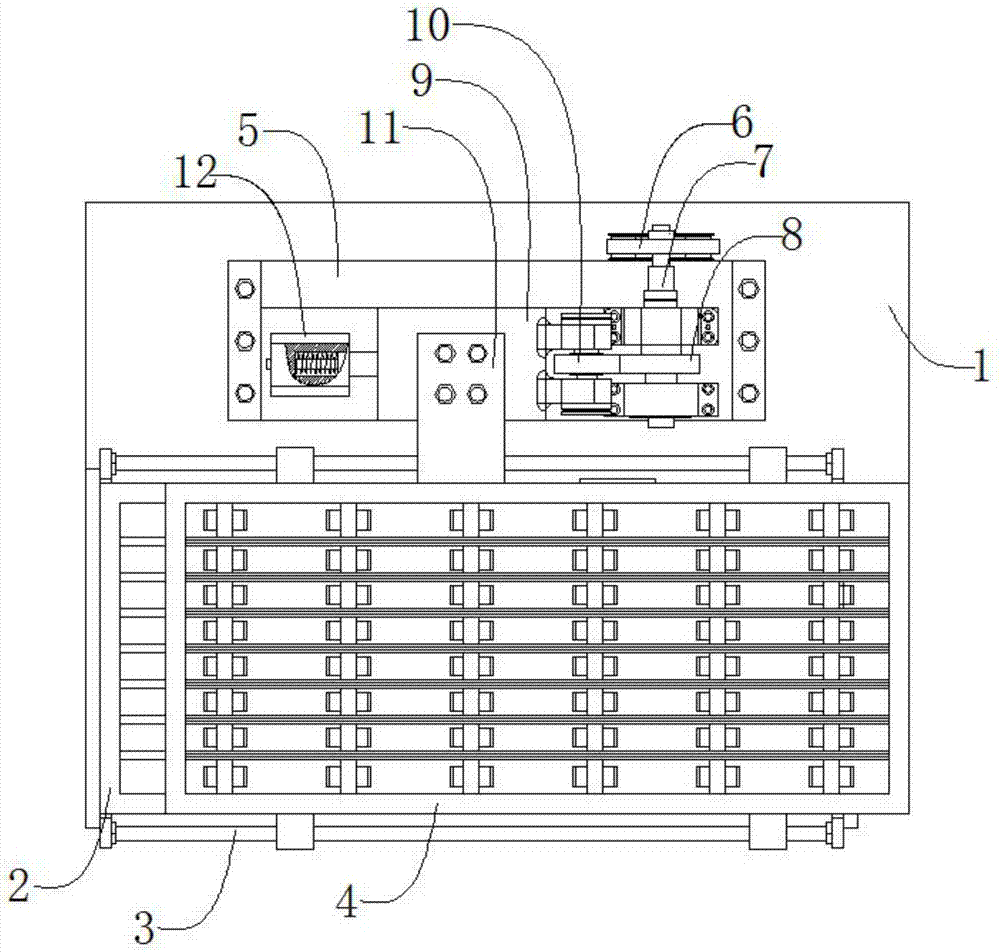

Oak plug manufacturing device

InactiveCN112045790ARealize automatic interval feedingContinuous cuttingSievingScreeningMechanical engineeringIndustrial engineering

The invention relates to a manufacturing device, in particular to an oak plug manufacturing device. The oak plug manufacturing device is safe, reliable and high in yield. The oak plug manufacturing device comprises a base, wherein mounting plates are arranged at the two sides of the bent position of the top of the base; a mounting table, which is arranged at the side, away from the mounting plates, of the top of the base; a fetching device, which is arranged at the top of the mounting table; and a feeding device, which is arranged between the two mounting plates. According to the device, automatic and alternate feeding of oak is realized, the oak can be continuously cut through cooperation of the fetching device and the feeding device, the hands of a worker can keep away from a cylindricalknife under the action of a sliding ejector rod and a conveying belt, the safety of the device is enhanced, and the personal safety of the worker is protected.

Owner:王八生

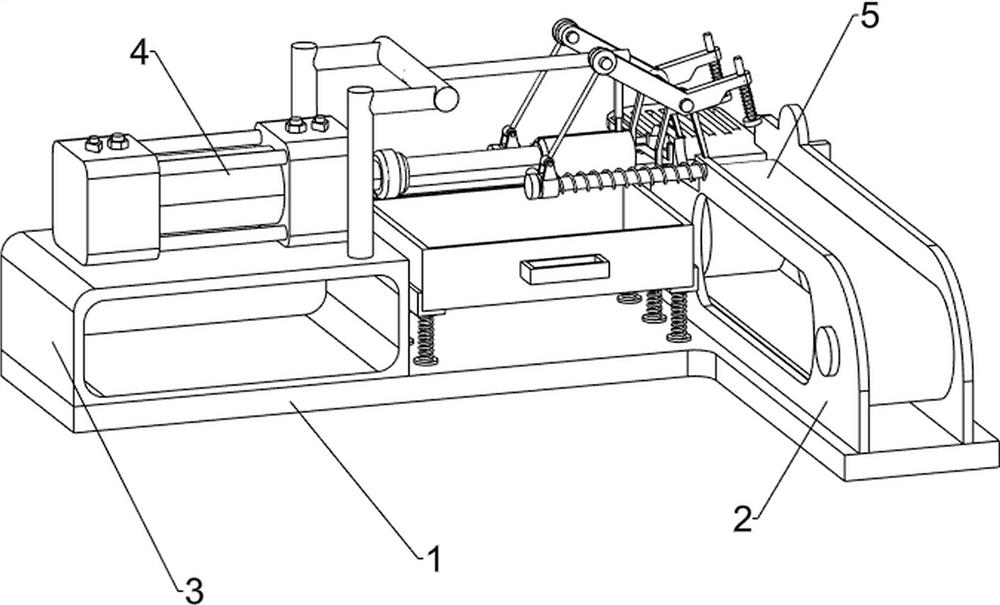

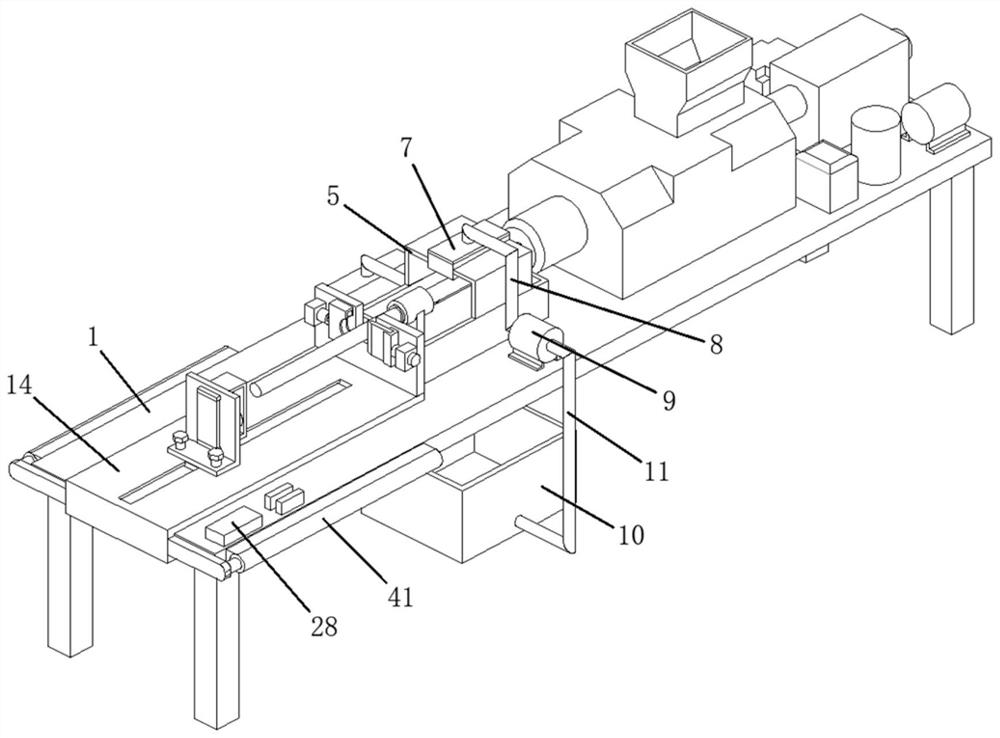

Steel pipe processing and production equipment

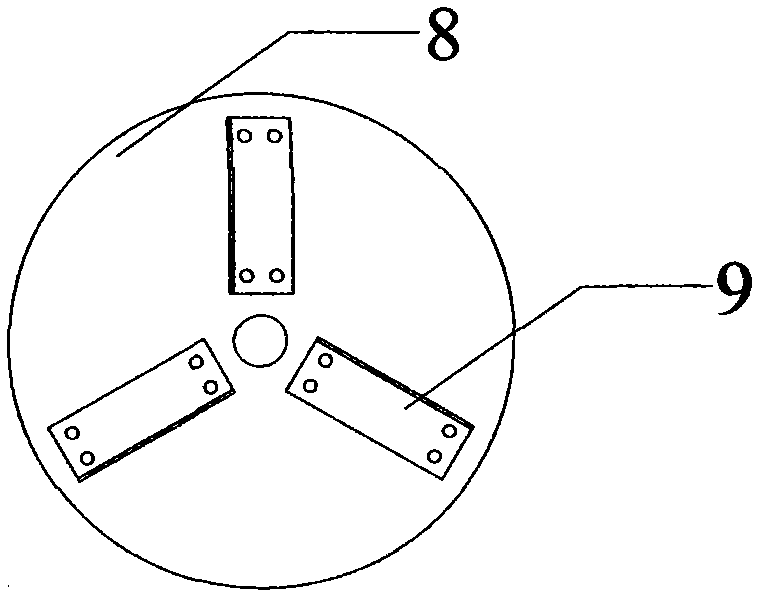

InactiveCN109570614AContinuous cutting and processingContinuous cuttingTube shearing machinesPositioning apparatusEngineeringMechanical engineering

The invention discloses steel pipe processing and production equipment which comprises a bracket, a support shaft, a rotating unit, two clamping portions and a cutting portion. The support shaft is horizontally mounted on the bracket; the rotating unit is in transmission connection with the support shaft; the two clamping portions are sequentially arranged in the length direction of the support shaft, and each clamping portion includes a support plate and a plurality of clamping units, wherein the support plate is mounted on the support shaft; each support plate is provided with a plurality ofthrough holes and a plurality of mounting holes, wherein the multiple through holes surround the circumference of the support shaft, and the multiple mounting holes communicate with the multiple through holes; and the multiple clamping units are in one-to-one correspondence with the multiple through holes, and each clamping unit comprises a first clamping plate, a second clamping plate, a connecting rod, a mounting plate and a screw, wherein the first clamping plate and the second clamping plate are located in the corresponding through holes, the first clamping plate and the second clamping plate are oppositely arranged, the first clamping plate and the second clamping plate are both curved, and the first clamping plate is connected to the corresponding support plate.

Owner:安徽长青建筑制品有限公司

Cutting device for polyester fiber cloth

The invention discloses a cutting device for polyester fiber cloth and relates to the technical field of cloth processing. The cutting device comprises a box body. A bearing fixing block and a storagebattery box are fixedly connected to the inner wall of the box body sequentially from left to right. A first rotating shaft is rotatably connected to the position, located on the right side of the storage battery box, of the inner wall of the box body. A first pulley is fixedly connected to the surface of one side of the first rotating shaft. A first friction cylinder is fixedly connected to theposition, located on the back surface of the first pulley, on the surface of the first rotating shaft. A second rotating shaft is rotatably connected to the top of the bearing fixing block. Accordingto the cutting device for the polyester fiber cloth, rotating rollers are driven to rotate by the rotation of the cloth on the surface of a second friction cylinder, so that the cloth moves upwards along with the clamping of the two rotating rollers and can be conveyed more quickly; and the two rotating rollers can achieve the function of cloth flattening, so that the device is easier to control after linkage.

Owner:葛丹峰

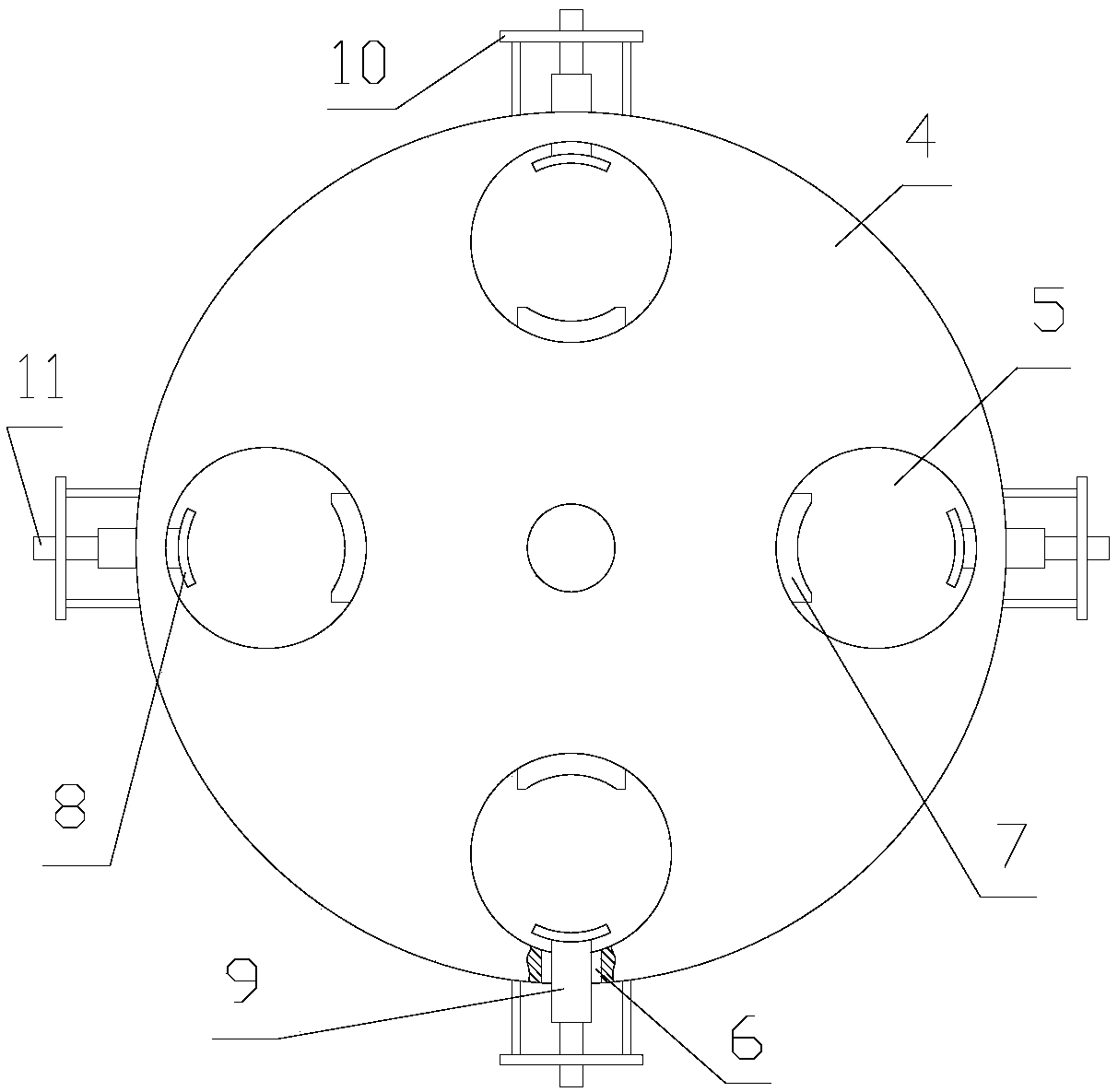

Scaffold production and machining equipment

InactiveCN109773257AEasy to cutContinuous cuttingTube shearing machinesShearing machine accessoriesThreaded pipeEngineering

The invention discloses scaffold production and machining equipment. The scaffold production and machining equipment is used for cutting a steel pipe and comprises a supporting shaft, a rotating unit,a supporting plate, a plurality of first positioning pieces, a support, a plurality of clamping parts and a cutting part; the rotating unit is used for driving the supporting shaft to rotate; the supporting plate is mounted on the supporting shaft; the multiple first positioning pieces are distributed on the periphery of the supporting shaft, and the multiple first positioning pieces are all mounted on the supporting plate; the support is connected with the supporting plate; the multiple clamping parts correspond to the multiple first positioning pieces one to one and comprise connecting rods, screws, threaded pipes and second positioning pieces; the connecting rods and the supporting shaft are arranged parallelly, and the connecting rods are mounted on the support; the screws and the connecting rods are coaxially arranged, and the screws are connected with the connecting rods; the threaded pipes are connected with the screws in a threaded mode; the second positioning pieces are mounted on the threaded pipes, and the second positioning pieces and the first positioning pieces are matched with each other; and the cutting part comprises a blade and a power unit, and the blade is located on a moving path of the steel pipe and is in transmission connection with the power unit.

Owner:安徽长青建筑制品有限公司

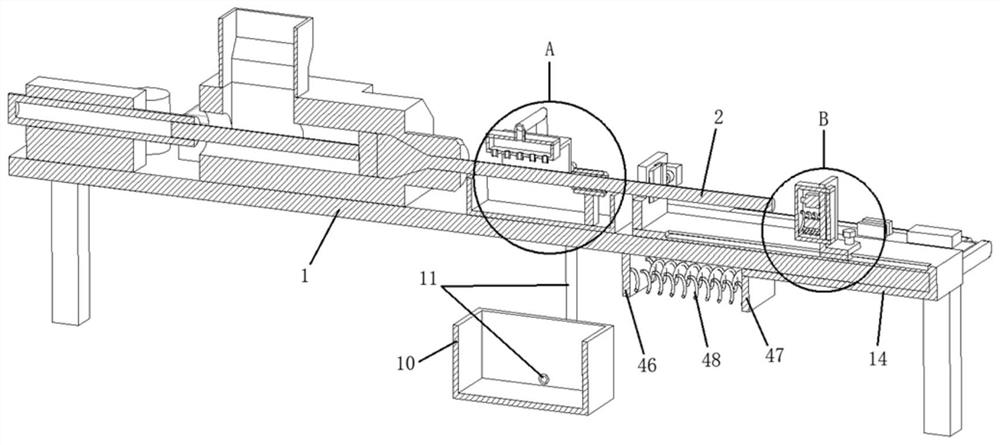

Integrated cooling type tin bar extruding machine

The invention relates to the technical field of extruding machines, in particular to an integrated cooling type tin bar extruding machine. The integrated cooling type tin bar extruding machine comprises an extruding machine body, and the extruding machine body comprises a working table plate, extruded materials, a processor and two electromagnetic valves, wherein a water receiving box is fixedly arranged on one side of the working table plate, a cooling box is arranged on one side of the water receiving box, and L-shaped connecting frames are fixedly arranged on the two sides, away from each other, of the cooling box correspondingly; one side of each L-shaped connecting frame is fixedly connected with one side of the water receiving box, a plurality of cooling holes are formed in one side of the cooling box, and cooling pipes are fixedly arranged on the inner sides of the cooling holes correspondingly. According to the integrated cooling type tin bar extruding machine, through the arrangement of the water receiving box, the cooling box, the cooling pipes, a water pump, a water tank, a cooling device, a cutting base, a tool apron, a hydraulic cylinder, a cutting tool, an L-shaped sliding frame, a touch switch, a spring, a U-shaped frame, a guide damping device, a U-shaped sliding frame and an automatic reset device, the integrated cooling type tin bar extruding machine has the functions of rapid cooling, circulating cooling, automatic slitting, length adjustment, continuous slitting and the like.

Owner:深圳市绿色千田锡业科技有限公司

Sludge shredding device

The invention discloses a sludge shredding device which comprises a support plate, a lower grating, guide rods, an upper grating, a bracket, a power mechanism, a rotary shaft, a cam, a sliding plate, a guide wheel, a connecting plate, a resetting mechanism, a limiting plate and a steel ball. When sludge falls on the upper grating, the power mechanism drives the cam to rotate through the rotary shaft to push the sliding plate fixedly connected with the guide wheel to slide so as to further drive the upper grating to move along the guide rods; when the sliding plate moves leftwards, a spring is compressed; the cam begins to return after the cam reaches the maximum stroke, and the spring is recovered to push the sliding plate to move rightwards, so that the upper grating does reciprocal rectilinear motion along the guide rod; and the sludge is shredded transversely and longitudinally under the combined action of the lower grating as well as a transverse blade and a longitudinal blade arranged on the upper grating. The sludge shredding device is simple in structure; the upper grating can automatically do reciprocating motion, and the sludge is shredded transversely and longitudinally under the combined action of the upper grating and the lower grating; the degree of automation is high; and the sludge is uniformly, continuously and rapidly shredded into blocks.

Owner:东至县文元瓷砖加工厂

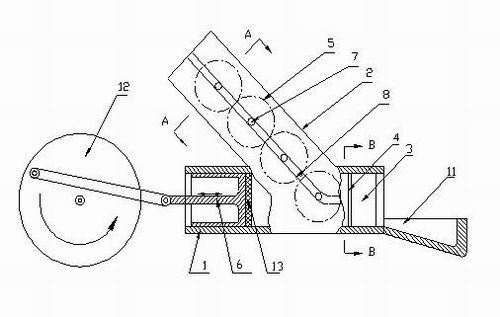

Burdock cutting machine

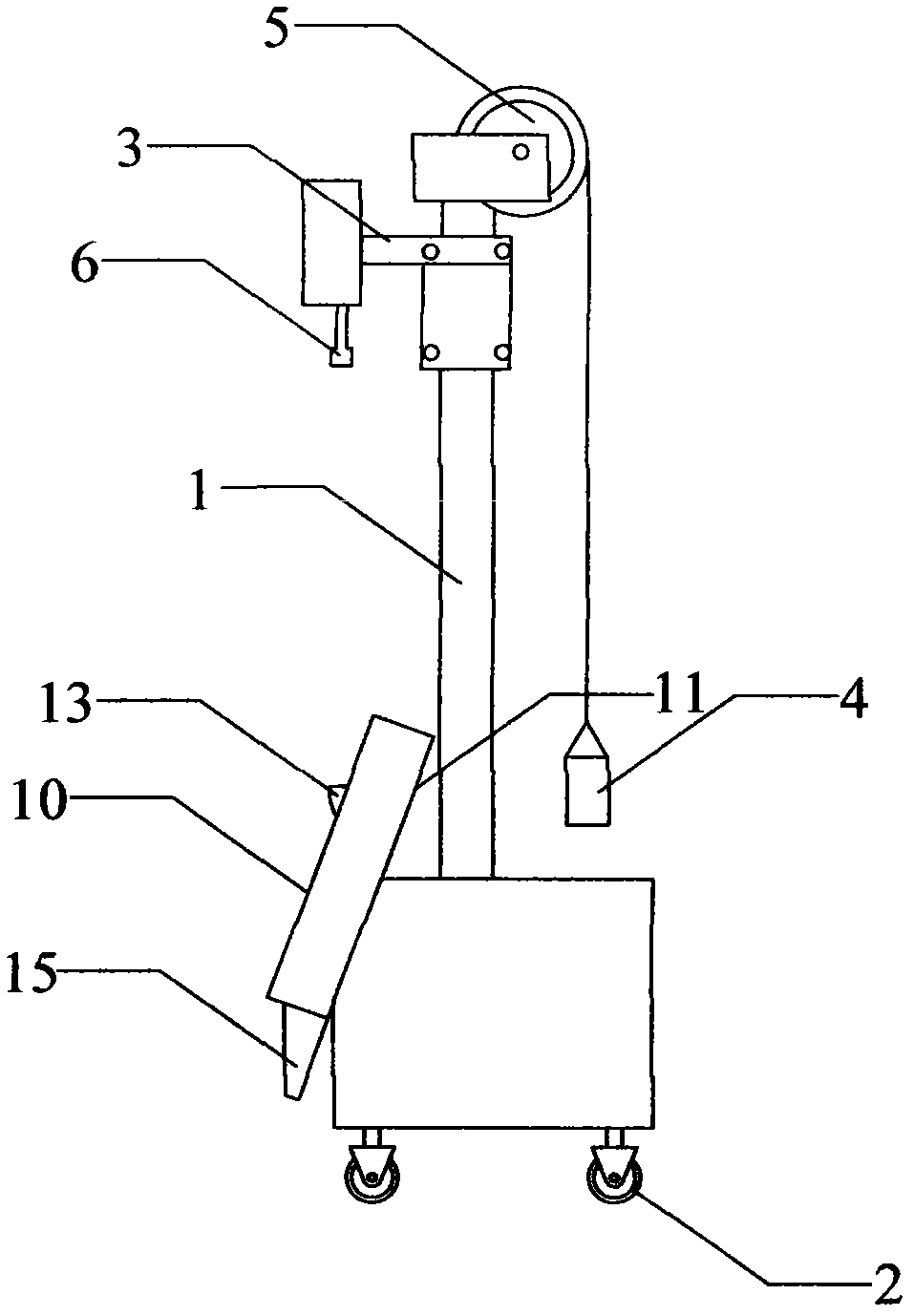

InactiveCN102179828AEnsure health and safetyEnsure hygiene and safetyMetal working apparatusEngineeringEvery Two Hours

The invention relates to a burdock cutting machine which comprises a stand, a feeding mechanism, a cutting mechanism and a driving mechanism, wherein the feeding mechanism comprises a clamping device, a balance weight and a pulley arranged on the top of the stand, the pulley is arranged between the clamping device and the balance weight, and the clamping device can move up and down along the stand through the internal pulley; and the cutting mechanism is obliquely arranged on the stand and comprises a rotating disc, and a rotary cutting blade is arranged on the rotating disc. An adjusting pad is arranged between the rotary cutting blade and the rotating disc and can be used for adjusting a distance between the blade and the rotating disc so as to change the thickness of a burdock slice; a rear cover of the cutting mechanism is provided with a water inlet; and when the cutting machine works, the rotating disc is flushed once every two hours so that the rotating disc can be cleaned in time, and therefore the burdock slice can be ensured to be safe and health. The burdock cutting machine has the advantages of reasonable design, simple structure and wide market prospect and can be used for carrying out continuous cutting on burdocks; and compared with manual slicing, the burdock cutting machine has the advantages of not only greatly improving the working efficiency and saving the labor cost, but also ensuring safety and health of foods and being wide in the market prospect.

Owner:青岛顺昌食品有限公司

Sludge pretreatment device

PendingCN107382021AEvenly dicedContinuous cuttingSludge treatment by de-watering/drying/thickeningSludgeReciprocating motion

The invention discloses a sludge pretreatment device which comprises a support plate, a support, a discharge nozzle, a loading bin, a motor, an impeller, a keep-off nozzle, a lower grid, guide rods, an upper grid, a swinging mechanism, a connecting plate, a spacing plate and a steel ball. The swinging mechanism further comprises a bracket, a power mechanism, rotating shafts, cams, sliding plates, guide wheels and a reset mechanism; the reset mechanism further comprises a push top, a spacing rod, and a spring. The sludge pretreatment device is simple in structure, sludge is continuously pressed into the upper grid through the impeller, the swinging mechanism pushes the upper grid to move reciprocatingly, the sludge is crushed horizontally and longitudinally under the common action of the upper grid and the lower grid, the sludge can be sliced evenly, continuously and rapidly, the sludge is allowed to fall into the discharge nozzle rapidly through continuous conveying of the impeller, and high efficiency is achieved.

Owner:东至县文元瓷砖加工厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com