Slicing machine

A technology of slicer and frame, applied in metal processing and other directions, can solve the problems of high energy consumption and low efficiency of slicer, and achieve the effect of continuous cutting, improving cutting efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

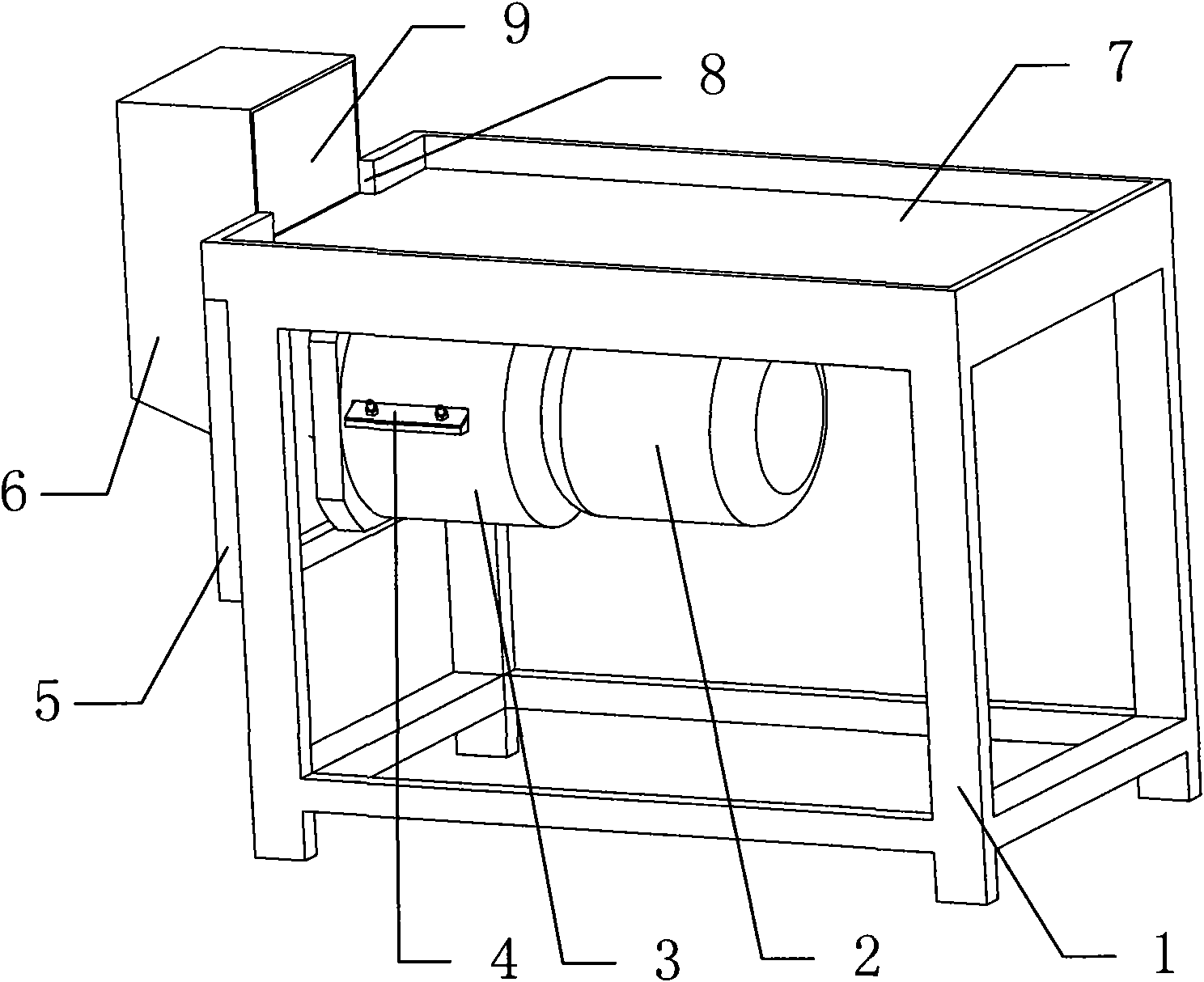

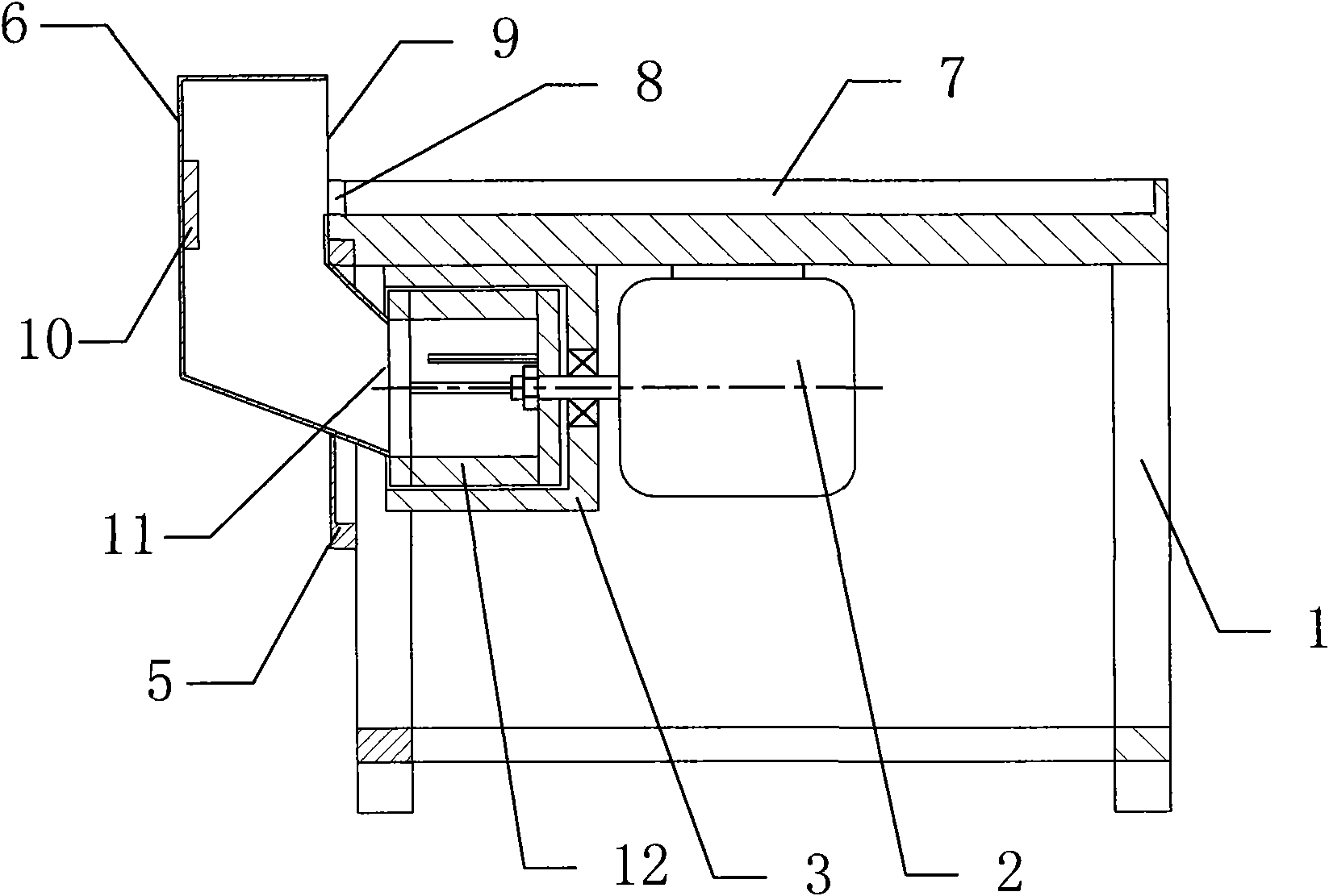

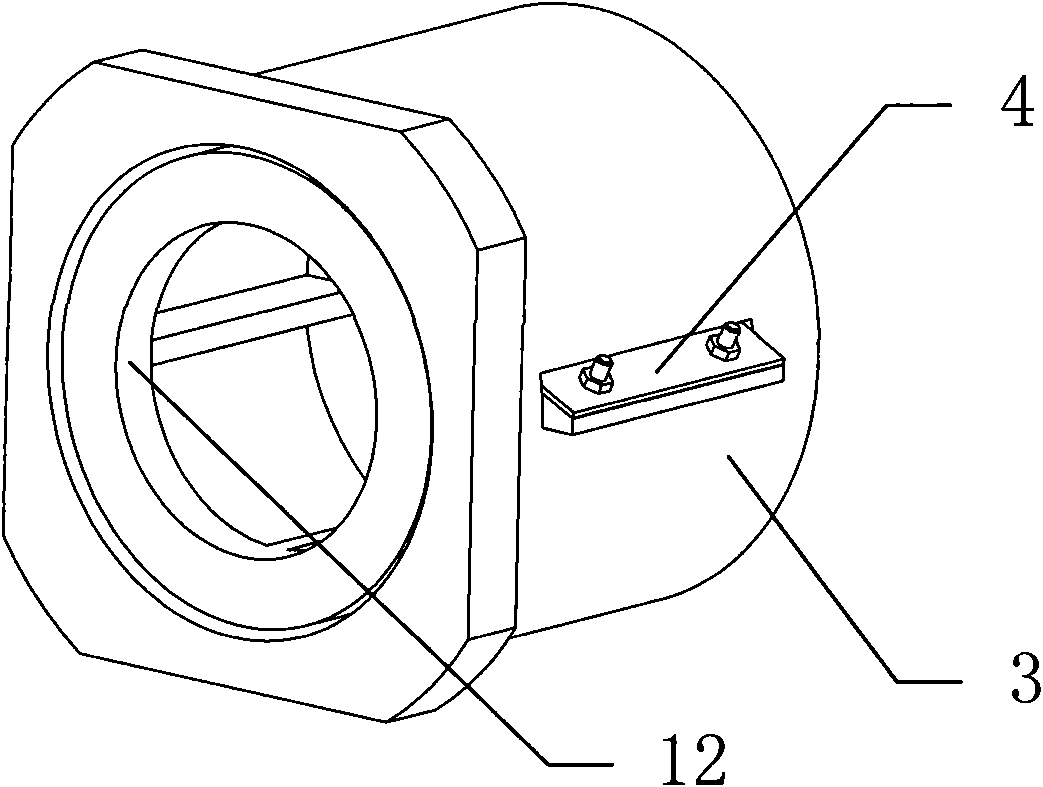

[0019] Figure 1~6 As shown, the slicer of the present invention includes a frame 1, a movable knife seat 3 is fixedly installed on the top of the frame 1, and a cylindrical working chamber is arranged in the movable knife seat 3, and the working chamber has an outward facing Open your mouth. A rectangular discharge channel is opened on the cavity wall of the working chamber, and the discharge channel is a through hole. A fixed knife 4 is fixed on the lower side of the through hole by bolts, and the blade of the fixed knife 4 extends into the working chamber. Mouth 13. In addition, a moving knife 12 is correspondingly provided in the working chamber, and a slicing gap 18 is arranged between the blade of the moving knife 12 and the blade of the fixed knife 4. The moving knife 12 is connected to the motor 2 installed on the frame 1 through a rotating shaft. , the motor 2 drives the movable knife 12 to rotate in the working chamber and complete the slicing work. On the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com