Patents

Literature

39results about How to "Evenly diced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chilli sauce containing mushroom and edible fungus and processing method thereof

InactiveCN102106531ARefreshing tasteEvenly dicedFood preparationShiitake mushroomsZanthoxylum chalybeum

The invention relates to the technical field of food, and discloses a chilli sauce containing mushroom and edible fungus and a processing method thereof. The raw materials of the chilli sauce comprise: diced chilli or shredded chilli, soaked mushrooms, soaked edible fungus, red oil, zanthoxylum oil, gingers, garlic, salts, white sugar, monosodium glutamate and chicken powder. The chilli sauce disclosed by the invention is carefully prepared by adopting nutritive soaked mushrooms, soaked edible fungus and four-flat head chilli specially used by Xierdan company as raw material, and using accessories like zanthoxylum, white sugars, plant oils, etc. according to scientific and nutritive prescription. The product perfectly combines the unique crisp mouthfeel of the edible fungus, delicious taste of the mushrooms and appetizing function and nutrition of chilli. The product is savoury, hot, crisp, refreshing and with even dices, and can greatly stimulate appetite; and the product also has the functions of anticancer and health care.

Owner:新疆西尔丹食品有限公司

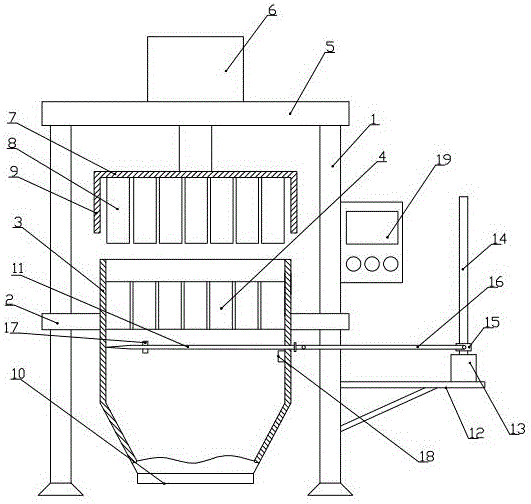

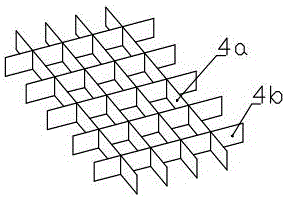

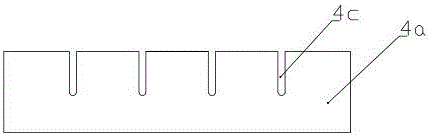

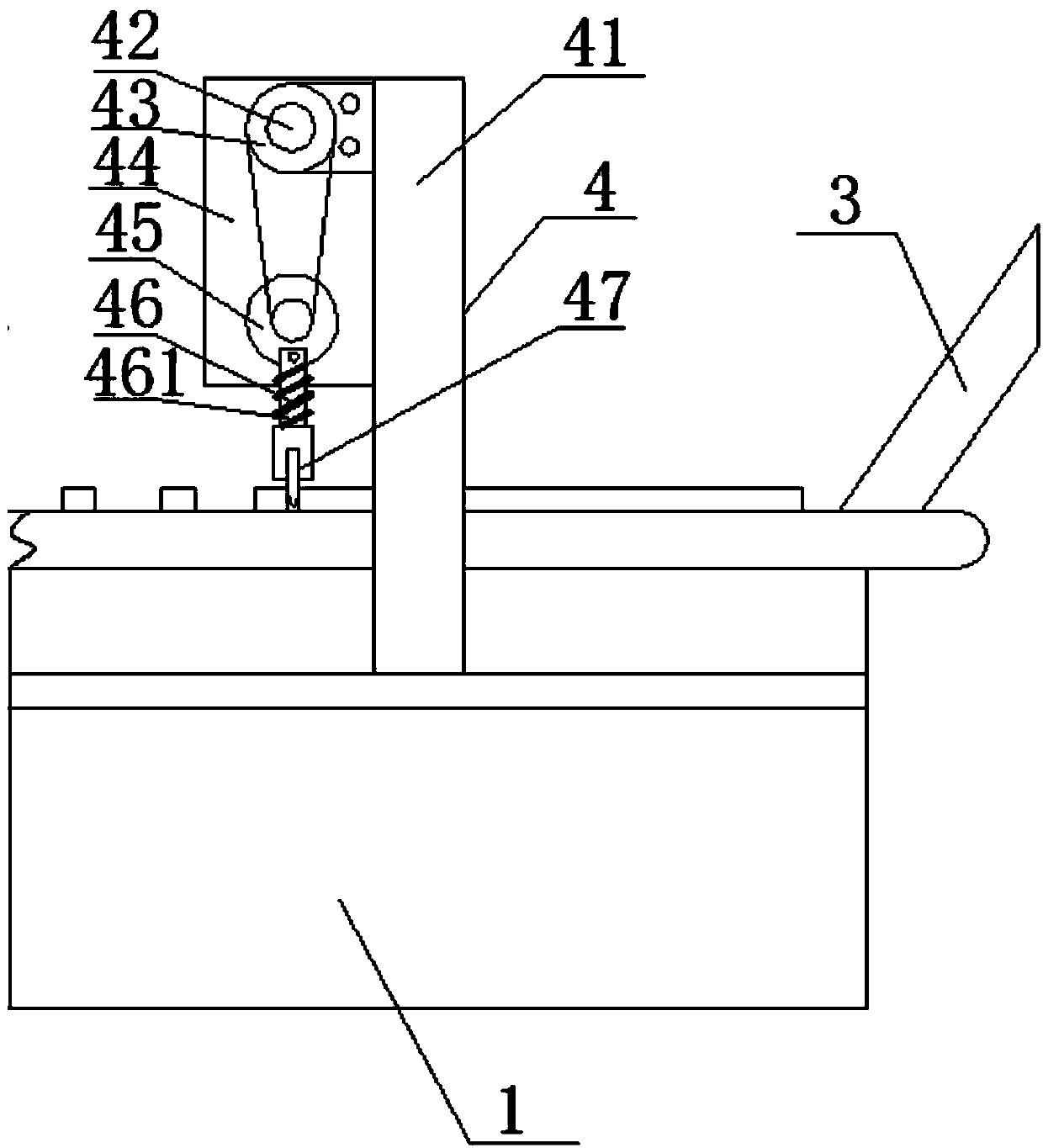

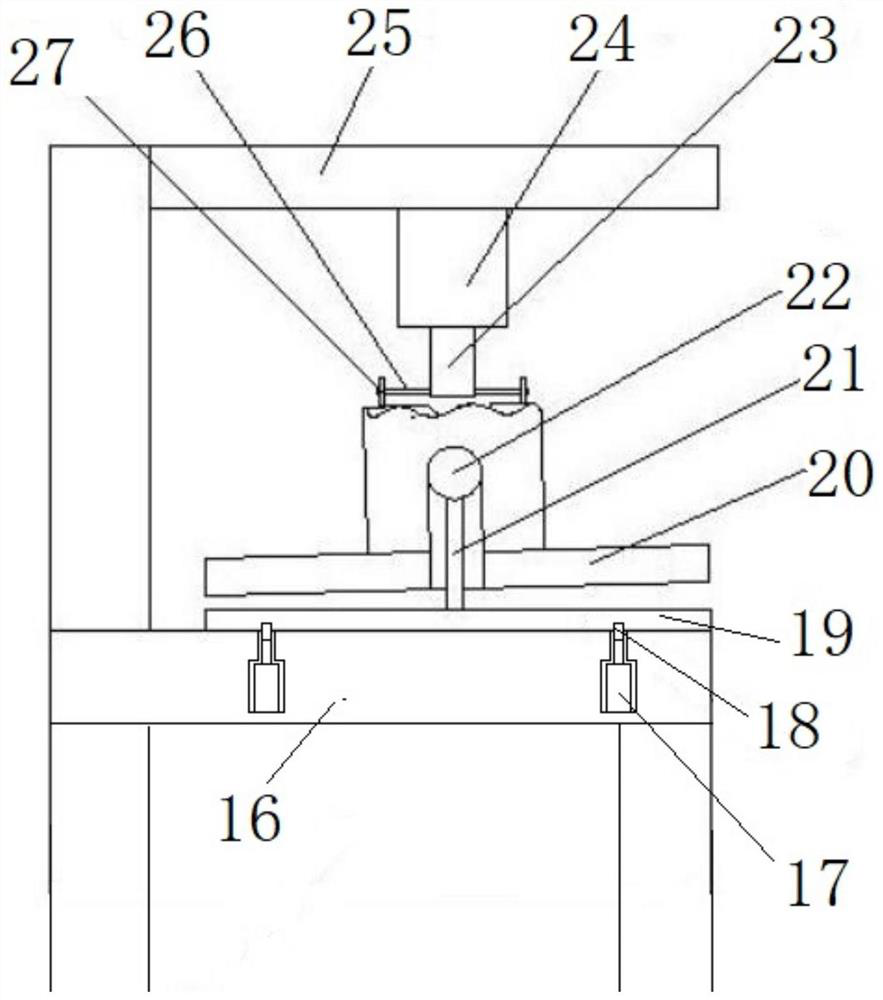

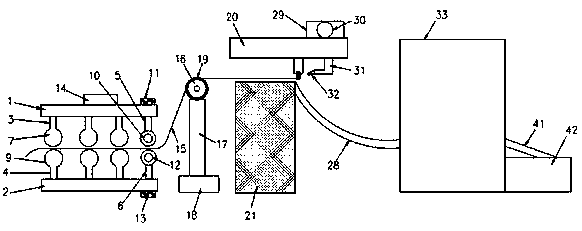

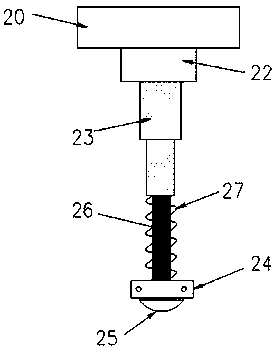

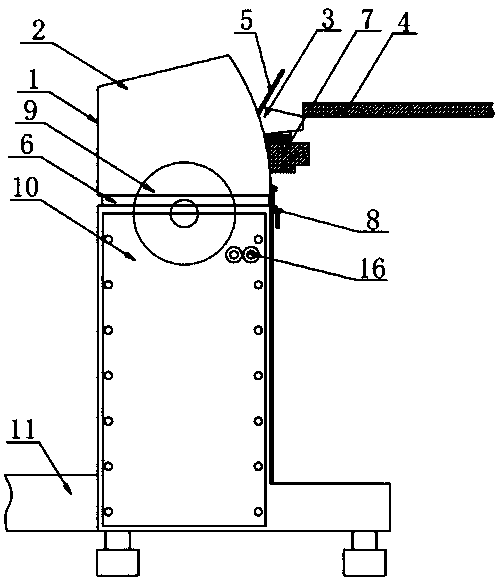

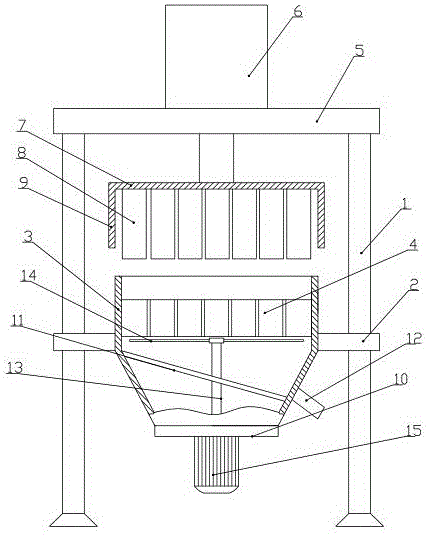

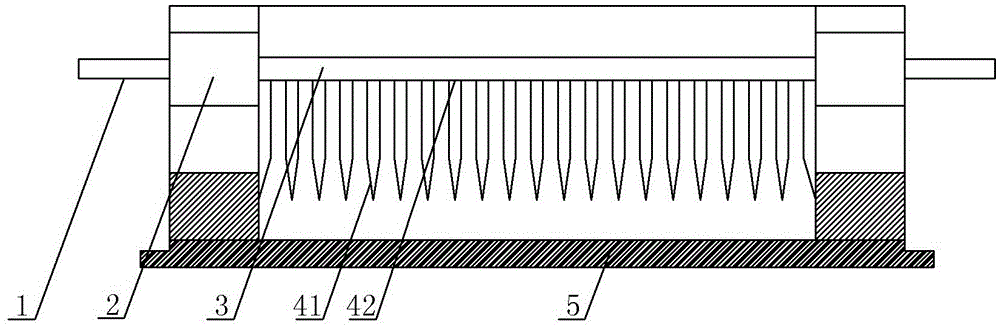

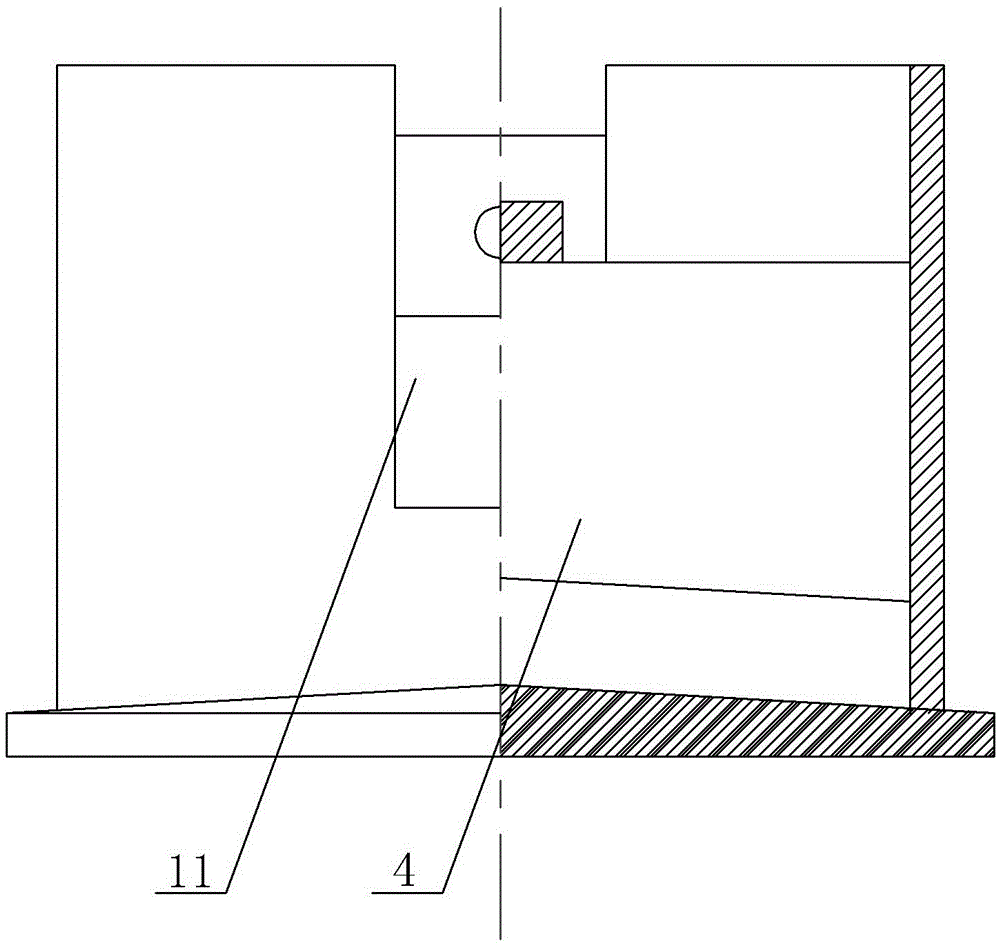

Multi-functional dicer

The invention discloses a multi-functional dicer, and relates to the field of technical equipment for fruit dicing. The multi-functional dicer comprises two stand columns and a fixed frame mounted on the stand columns. A hopper is fixedly mounted on the fixed frame. A grid-shaped dicing knife is mounted in the hopper. A slideable slitting knife is arranged below the dicing knife. The tail of the slitting knife penetrates from the hopper. A mounting rack is mounted on the stand columns. A driving motor is mounted on the mounting rack. A screw rod is fixedly connected with an output shaft of the driving motor by means of a coupling. A nut matched with the screw rod is arranged on the screw rod. A connecting rod is hinged to the nut. The other end of the connecting rod is hinged to the tail of the slitting knife. A mounting plate is fixedly mounted at the upper ends of the two stand columns. A pushing cylinder is mounted on the mounting plate. A piston rod of the pushing cylinder penetrates the mounting plate downwards. A fixed plate is mounted on the piston rod of the pushing cylinder. A plurality of push rods disconnected with one another are arranged on the fixed plate. The multi-functional dicer has the advantages that dicing is uniform, manual operation is not needed, use is convenient, and the labor is reduced.

Owner:四川苍溪梨研究所

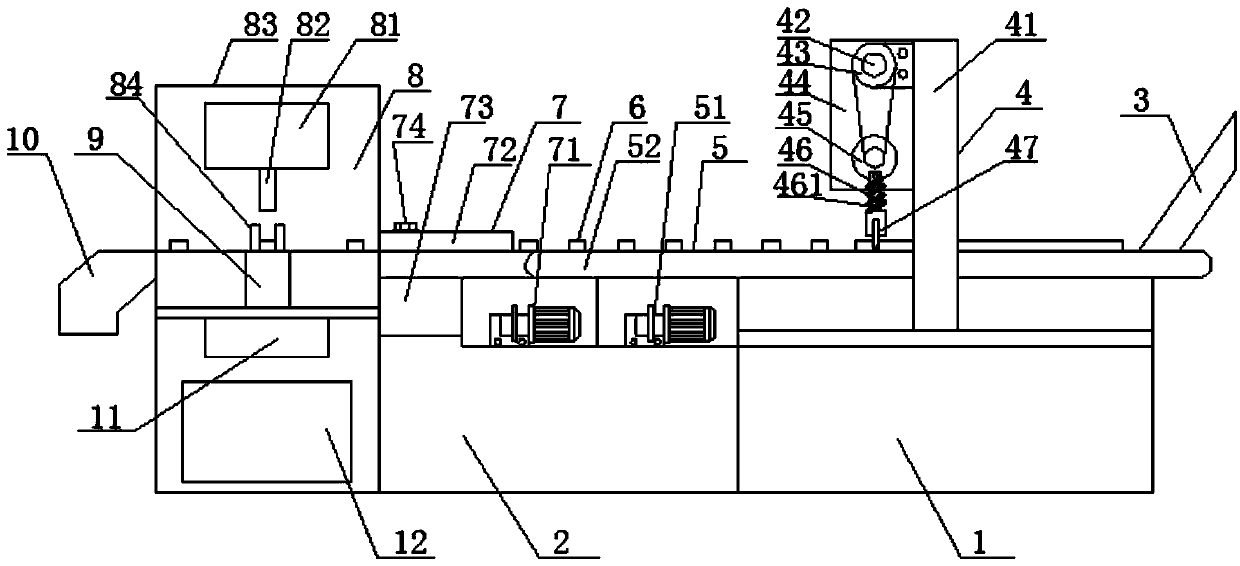

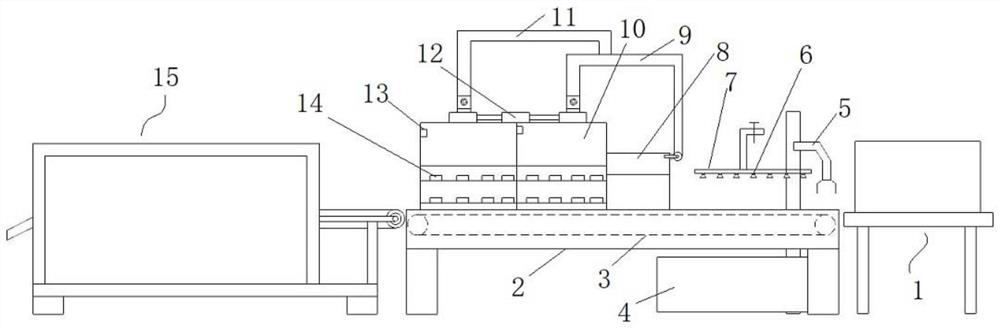

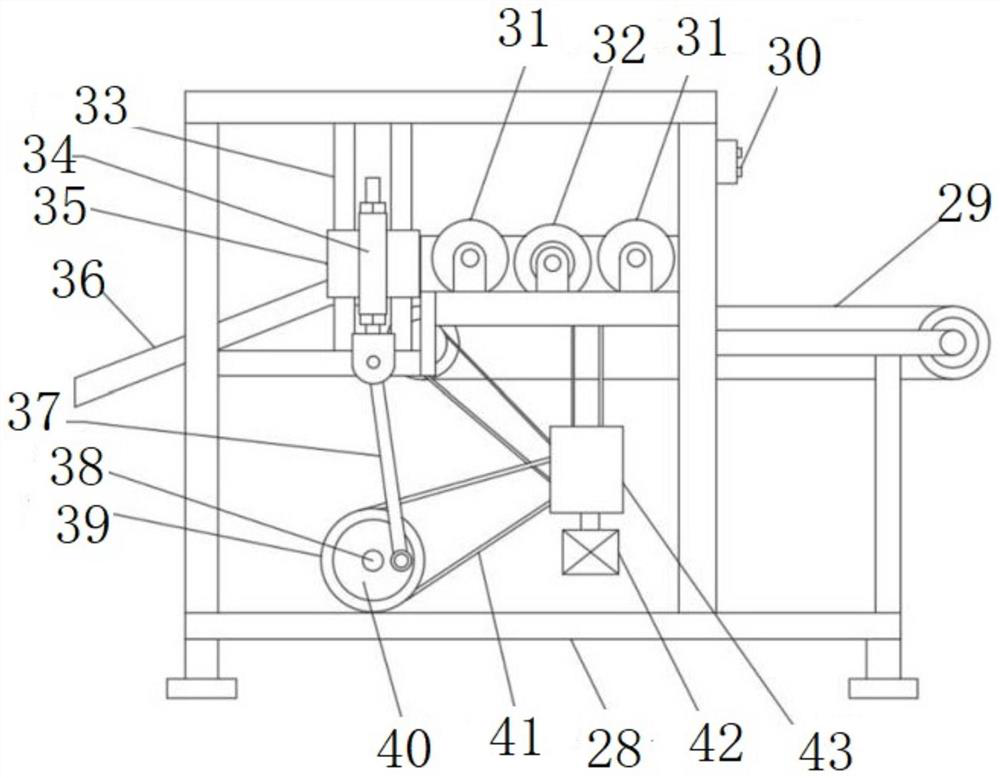

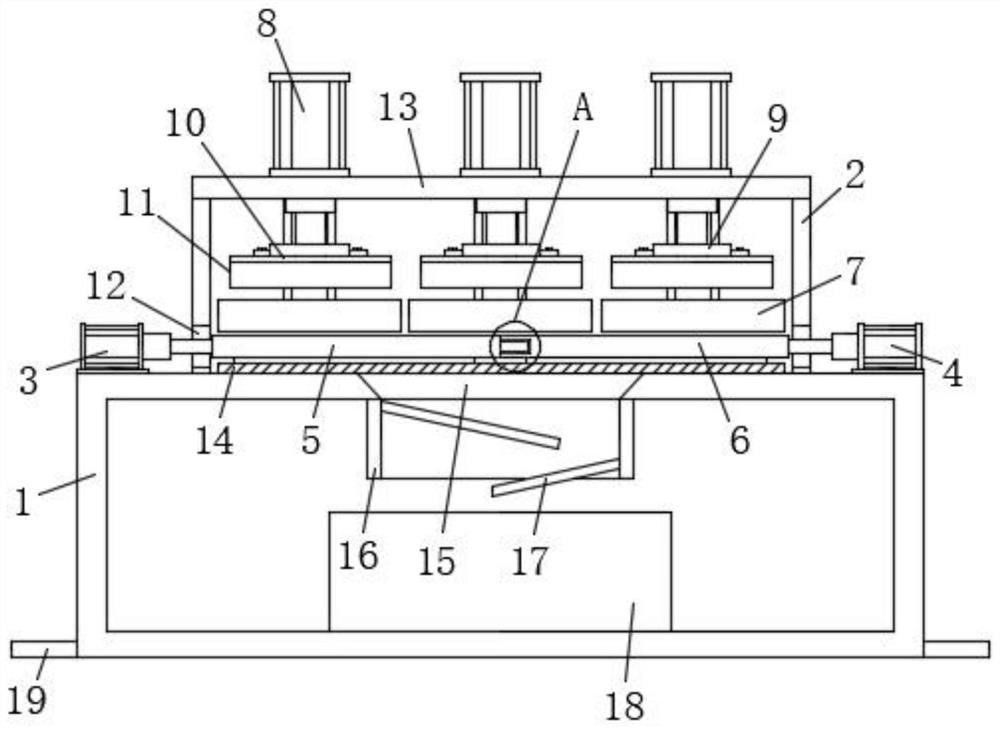

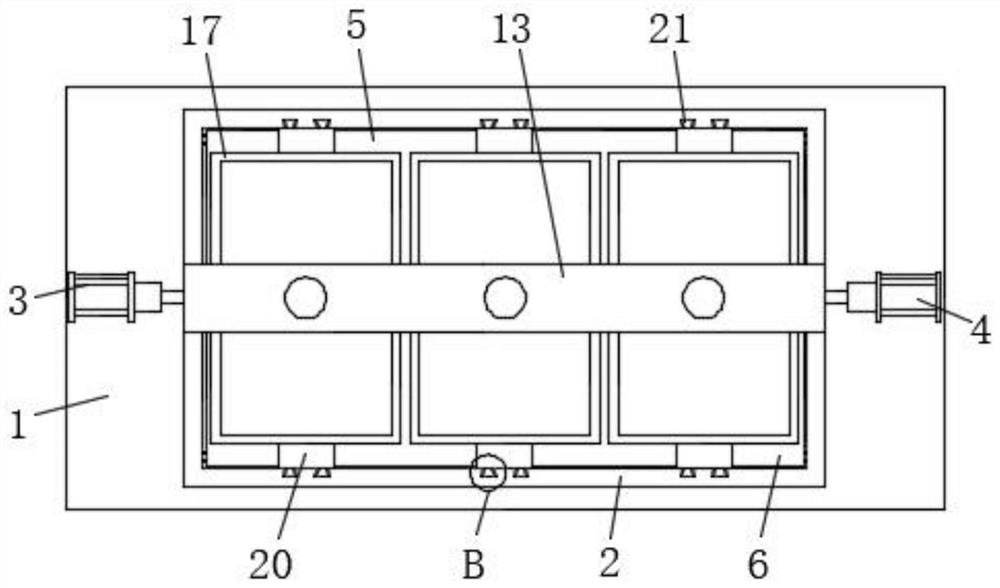

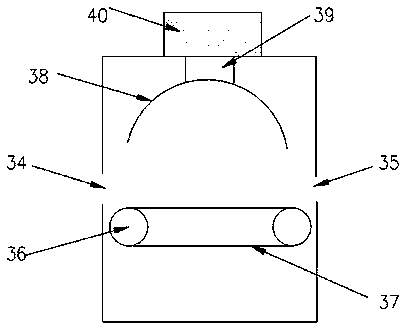

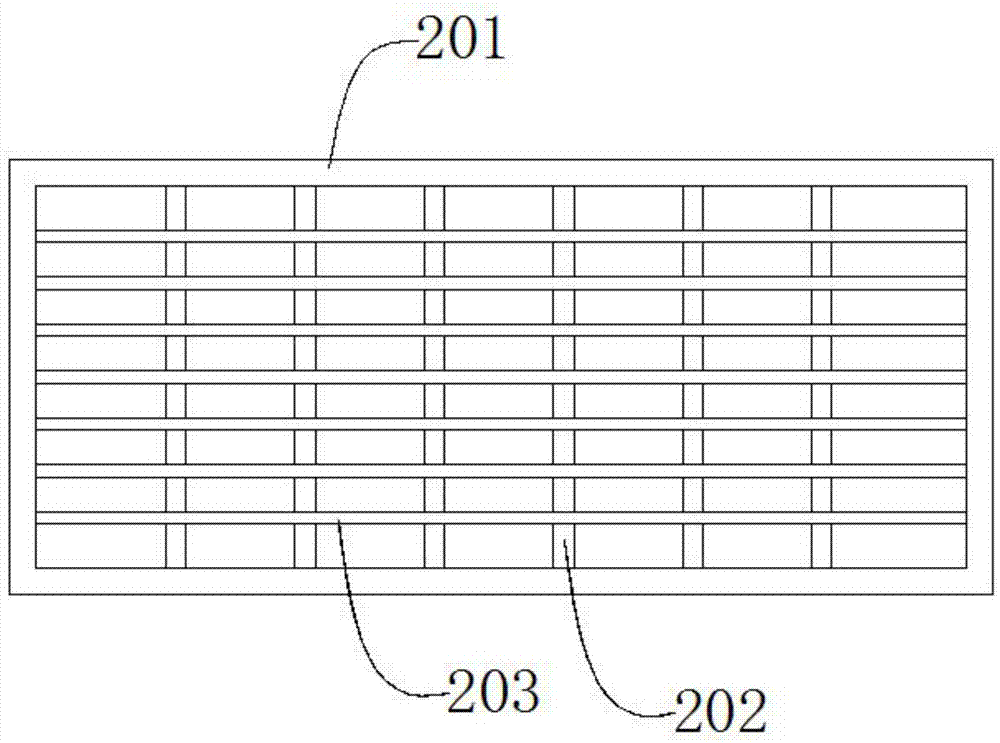

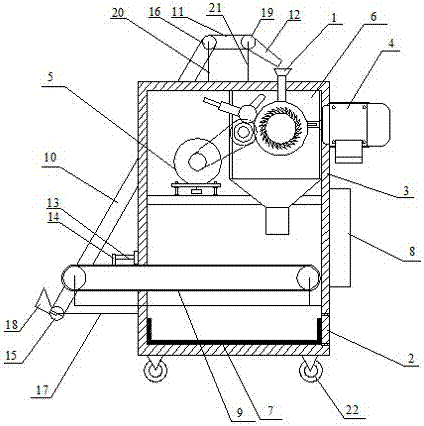

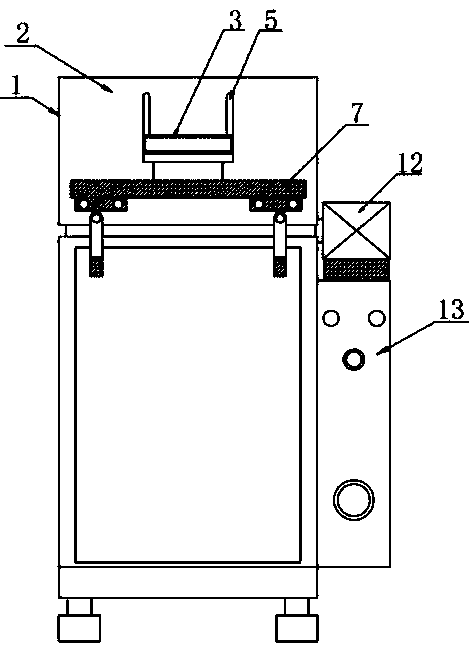

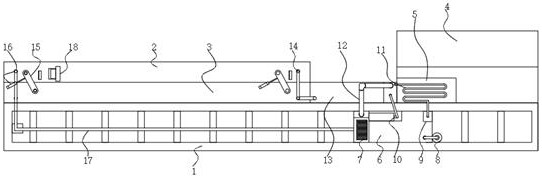

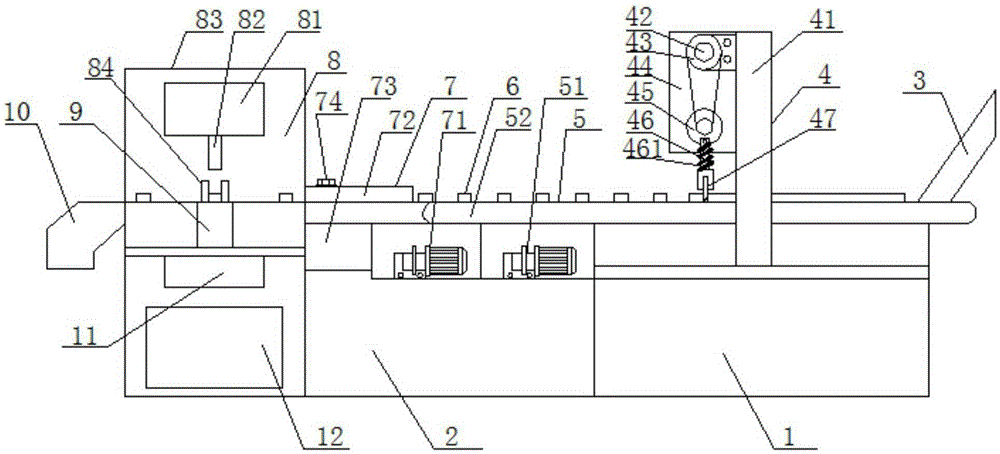

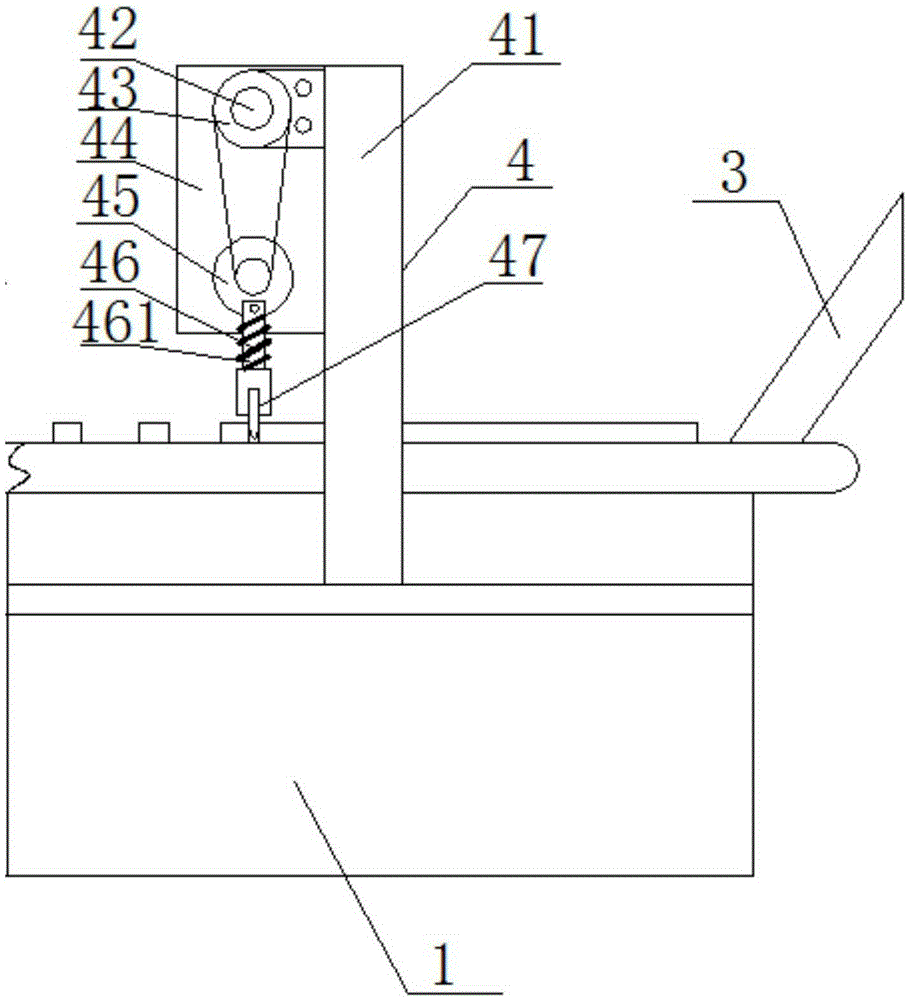

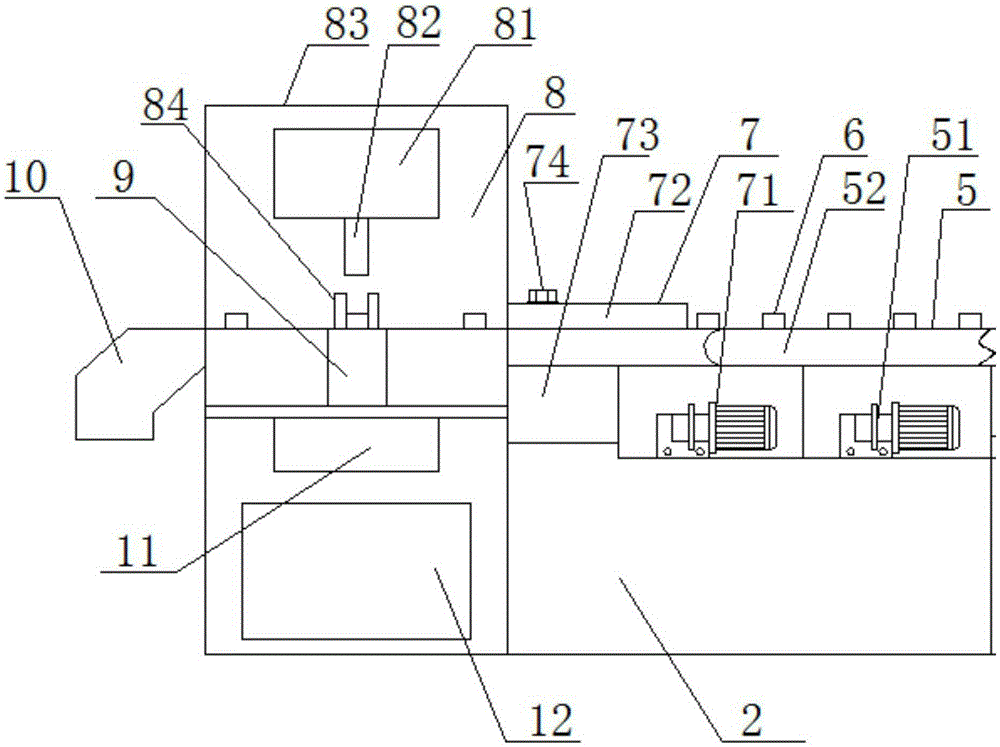

Candy dicing and packing all-in-one machine

InactiveCN104192377AReasonable structureAvoid sticking and buildupWrapper folding/bending apparatusPackaging automatic controlSettlingMechanical engineering

The invention discloses a candy dicing and packing all-in-one machine which comprises a dicing workbench and a packing workbench. The dicing workbench and the packing workbench are arranged in a connecting mode, and a feeding plate and a dicing mechanism are arranged on the dicing workbench. A candy conveying mechanism, a candy settling mechanism and a candy packing mechanism are arranged on the packing workbench in sequence, the candy conveying mechanism comprises a candy conveying motor and a conveying belt, and the candy settling mechanism comprises a candy settling motor, a candy dividing rod and a temperature controller. A paper feeding device is arranged on the packing workbench, the paper feeding device corresponds to the lower portion of the candy packing mechanism, and the paper feeding device is connected with a paper storage box. A control box is further arranged in the packing workbench and is arranged below the paper storage box, and the control box is connected with the paper feeding device and the candy packing mechanism. The candy dicing and packing all-in-one machine can evenly dice and pack candy, is reasonable in structure, avoids candy adhesion and accumulation, integrally completes dicing and packing, and is high in production efficiency.

Owner:祝建飞

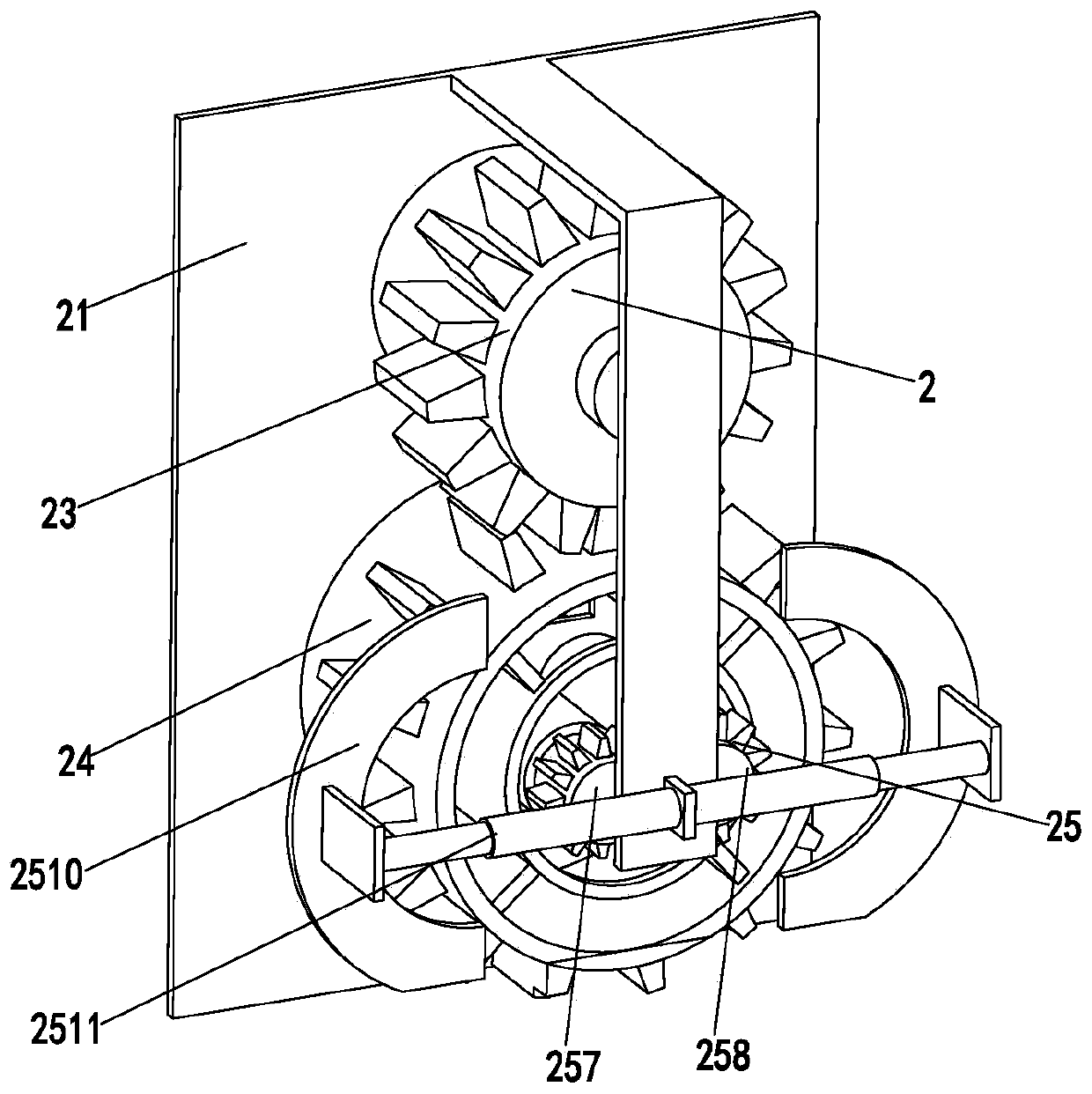

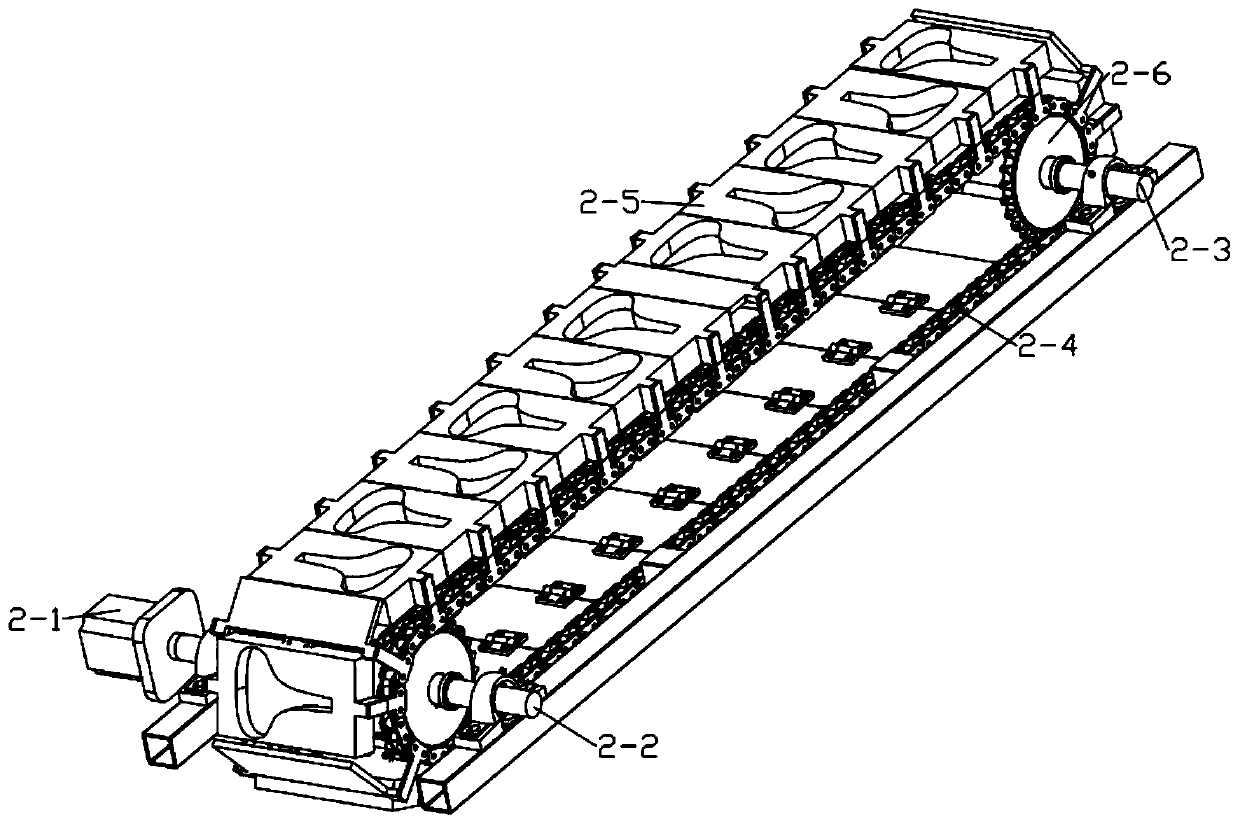

Automatic dicing machine of potato seeds

ActiveCN103283344AGood for mechanized sowingEvenly dicedSeed and root treatmentEngineeringGravity center

The invention provides an automatic dicing machine of potato seeds. The automatic dicing machine comprises roller motors, a cone frustum roller, a cutter and an automatic measuring and controlling device, wherein a feeding hopper and a discharging guide plate are arranged at two ends of a rack, an automatic weighing sensor is arranged on the discharging guide plate and is used for weighing diced potato in real time, the automatic measuring and controlling device is used for regulating the dicing angle of a step motor, roller motors are arranged at two ends of the rack, a transmission belt is arranged on the roller motors, the cone frustum roller is arranged above the transmission belt and is in tight contact with the transmission belt, materials enter from the hopper, the roller motors rotate to drive the transmission belt to rotate, the cone frustum roller follows, the potato seeds move, an included angle between the cone frustum roller at the inlet end of the hopper and the horizontal plane of the rack is between 35 DEG and 45 DEG so that gravity centers of the potato seeds are continuously regulated in a moving process; and an included angle between the cone frustum roller at the cutter end and the horizontal plane of the rack is between 45 DEG and 60 DEG, and thus the potato seeds move stably to ensure that the gravity centers of the potato seeds are within a moving track of the cutter. The automatic dicing machine is high in efficiency and excellent in performance.

Owner:贺州市八步区市场监督管理局

Novel dicing machine

InactiveCN106584567AEvenly dicedEasy to useMetal working apparatusAgricultural engineeringDrive motor

The invention discloses a novel dicing machine and relates to the field of fruit dicing technology equipment. The novel dicing machine comprises two stand columns and a fixing frame installed on the stand columns. A hopper is fixedly installed on the fixing frame, and a grid-shaped dicing knife is installed in the hopper. A transverse cutting knife capable of sliding is further arranged below the dicing knife. The tail portion of the transverse cutting knife penetrates out of the hopper, and gear teeth are arranged at the tail portion of the transverse cutting knife. An installation frame is installed on the stand columns, and a drive motor is installed on the installation frame. A gear engaged with the gear teeth is installed on an output shaft of the drive motor. An installation plate is further fixedly installed at the upper end of the two stand columns, and a push air cylinder is installed on the installation plate. A piston rod of the push air cylinder penetrates the installation plate to face downwards. A fixing plate is installed on a piston rod of the push air cylinder, and push rods which are not connected with one another are further arranged on the fixing plate. According to the novel dicing machine, dicing is even, in addition, dicing can be conducted without manual work, use is convenient, and the labor force is reduced.

Owner:四川苍溪梨研究所

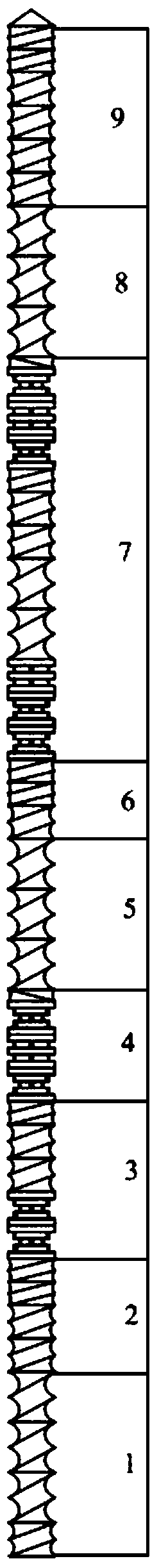

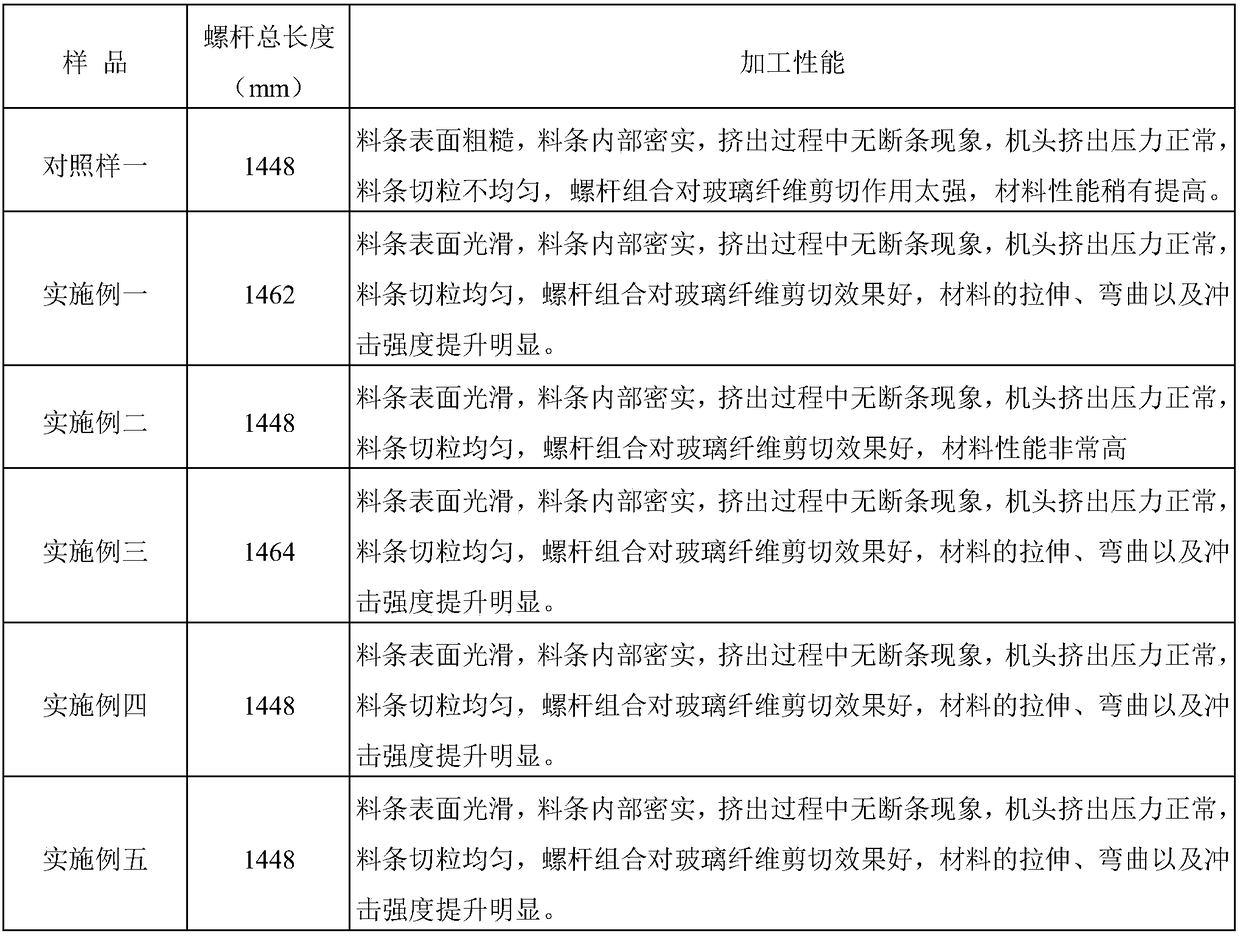

Double-screw assembly for extrusion molding processing of nylon and glass fiber, and processing method thereof

Owner:QINGDAO GON TECHNOLOGY CO LTD

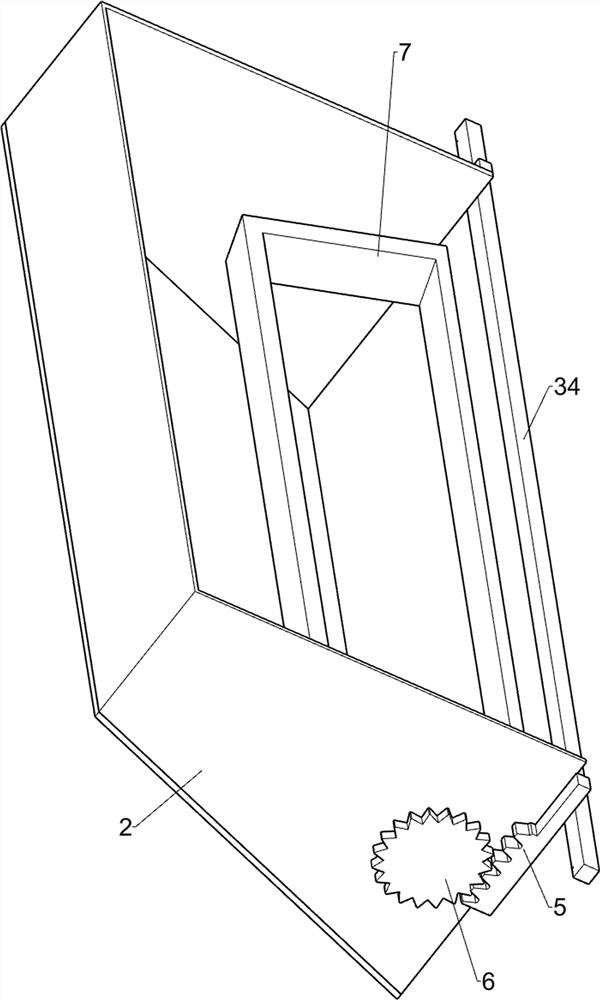

Device for dicing, stoving and conveying foods

InactiveCN107637615AEvenly dicedAvoid compromising qualityBaking ovenBaked article cutting/slicingEngineeringProcessing cost

The invention discloses a device for dicing, stoving and conveying foods. The device comprises a bottom support plate; one side of the top of the bottom support plate is fixedly connected to symmetrical support fixing rods; the tops of the support fixing rods are fixedly connected to a box body; one side of the bottom of the inner wall of the box body is fixedly connected to a first motor; one endof the first motor is rotationally connected to a first gear through an output shaft; both sides of the top of the inner wall of the box body are fixedly connected to fixing blocks; and the bottoms of the two fixing blocks are fixedly connected to vertical rods. The present invention relates to the technical field of food processing and transportation machinery and equipment. The device for dicing, stoving and conveying foods solves the problem that food processing equipment in the prior art is bulky, complex in structure and low in efficiency, and cannot be adopted to automatic assembly lineworks; and the device improves the processing precision of dicing and processing quality, improves heating and stoving efficiency, reduces energy waste thereby reducing processing costs, and has improved flexibility and enlarged application scope.

Owner:湖州创通输送设备有限公司

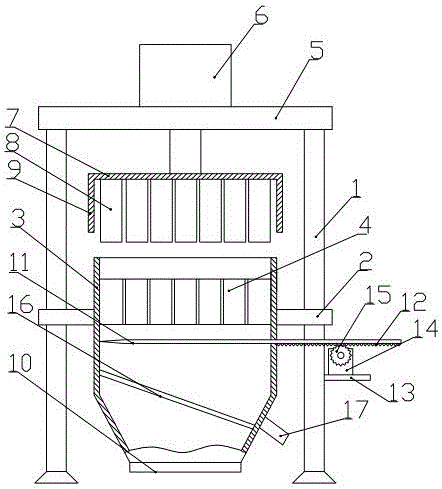

PVC plastic particle granulation equipment

ActiveCN113696368AEasy to useEasy to cleanPlastic recyclingCleaning using toolsCarbonizationMaterials science

The invention relates to PVC plastic particle granulation equipment. The PVC plastic particle granulation equipment comprises a bottom plate frame, a connecting frame and a granulation device, the connecting frame is installed at the upper end of the bottom plate frame, the section of the connecting frame is of a U-shaped structure, and the granulation device is installed in the connecting frame. According to the PVC plastic particle granulation equipment, the problems that when existing equipment is used for processing plastic particles, raw materials cannot be effectively filtered, the plastic raw materials are prone to blockage and accumulation, the raw materials are carbonized, black spots are prone to appearing on the plastic particles, a filter screen is poor in dismounting effect and inconvenient to clean, the forming effciency of the plastic particles is affected, when the existing equipment is used for pelletizing the plastic particles, the pelletizing effect is poor, the sizes of cut raw materials are different, and the cut plastic particles are prone to adhesion are solved.

Owner:广东万泰塑胶科技有限公司

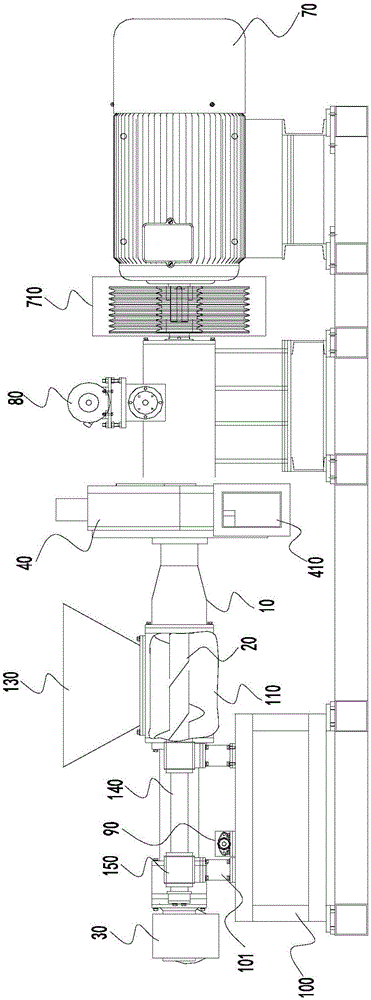

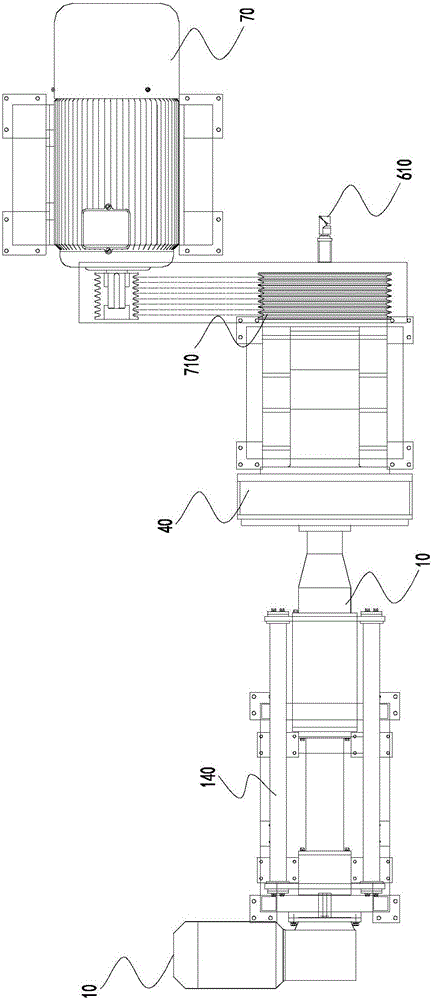

Eucommia ulmoides processing device and method

InactiveCN113288928AIncrease the number ofImprove the efficiency of kneading and pokingDrying solid materials with heatDrying machines with progressive movementsBiotechnologyBiochemical engineering

The invention provides an eucommia ulmoides processing device and method. The processing device comprises a rubbing mechanism used for applying force to eucommia ulmoides and rubbing the eucommia ulmoides, a conveying mechanism used for conveying the rubbed eucommia ulmoides, a cleaning mechanism used for cleaning the eucommia ulmoides at the feeding end of the conveying mechanism, a drying mechanism used for drying the eucommia ulmoides cleaned by the cleaning mechanism, and a dicing mechanism used for dicing the dried eucommia ulmoides. The production line processing of rubbing, cleaning and drying machine dicing of eucommia ulmoides can be achieved. The production and processing efficiency and quality are improved.

Owner:怀化林泉药业有限公司 +1

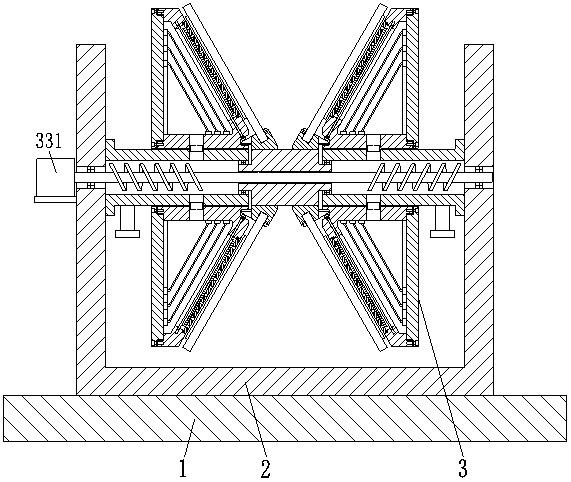

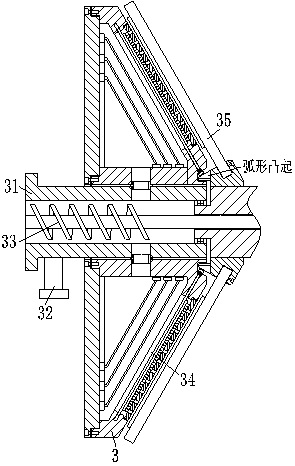

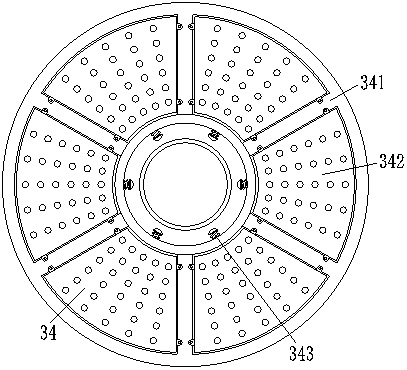

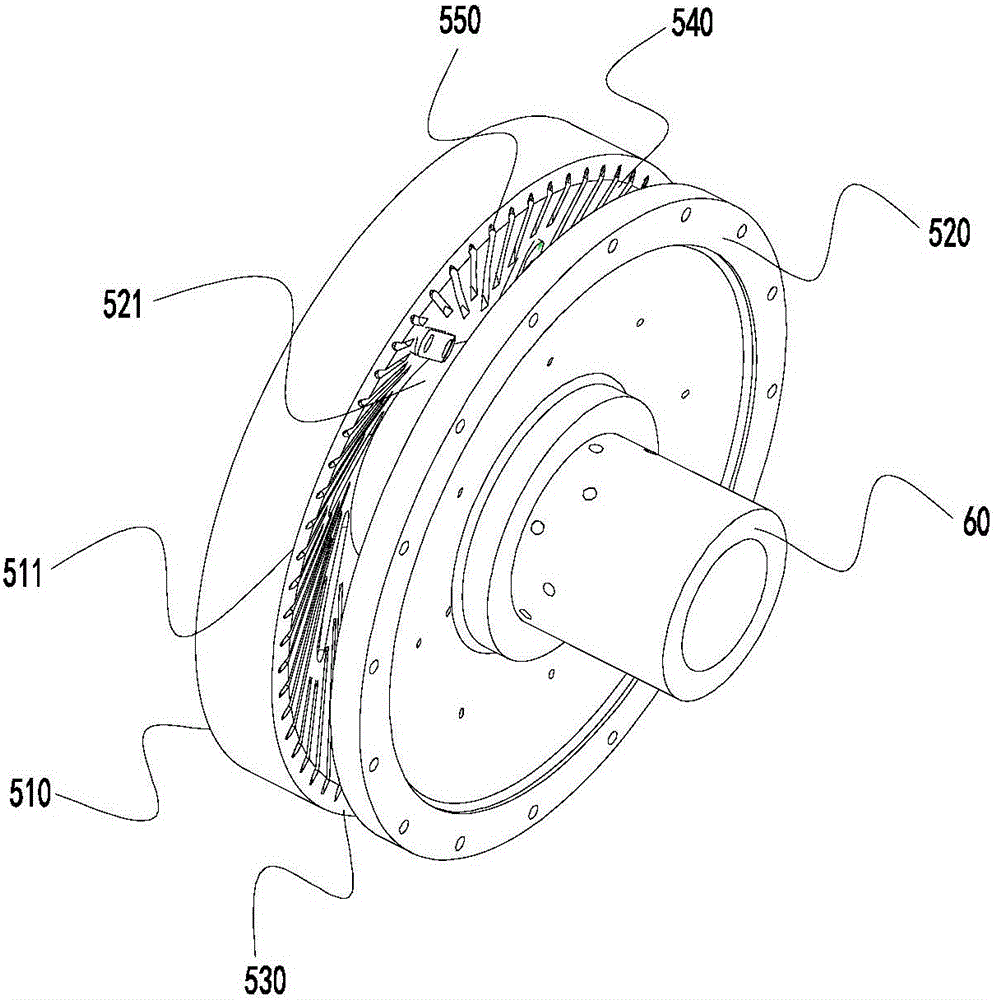

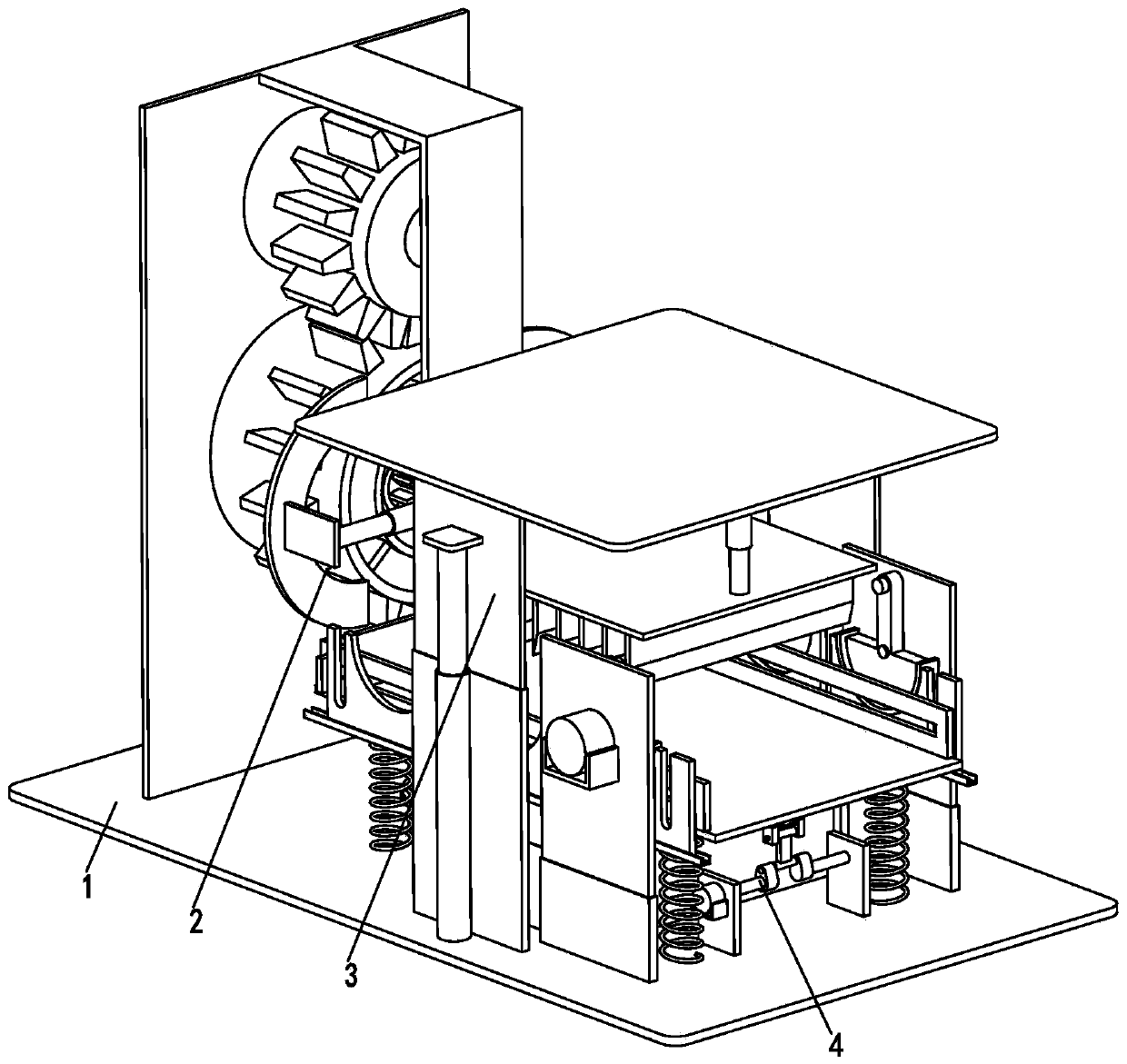

Full-automatic aggregation machine

ActiveCN105034194ASolve extrusionSolve the pelletizing problemGrain treatmentsEngineeringCentrifugal force

The invention relates to a full-automatic aggregation machine. The full-automatic aggregation machine comprises a feeding barrel with a feeding cavity, a feeding spiral part located in the feeding cavity, a first drive device driving the feeding spiral part to rotate, a fixed cutter head, a movable cutter head opposite to the fixed cutter head, a main shaft sleeved with the movable cutter head in a connected manner, a second drive device driving the main shaft to rotate, a third drive device driving the main shaft to move along the center axis, and a controller. A grinding cavity is formed between the fixed cutter head and the movable cutter head. The grinding cavity is internally provided with a temperature sensor electrically connected with the controller. The controller is electrically connected with the second drive device and the third drive device. Materials are fed into the grinding cavity through rotation of the feeding spiral part, the movable cutter head rotates to enable the materials entering the grinding cavity to rub, and the materials are thrown out of the edge of the cutter heads through the centrifugal action so that particle cutting can be achieved, and the purposes of material extruding and particle cutting are achieved at a time. A gap between the movable cutter head and the fixed cutter head can be adjusted through the third drive device, the control over balanced feeding and aggregating effects is achieved, and the quality of products is guaranteed.

Owner:GUANGZHOU 3E MACHINERY

Dicing device for potato planting

ActiveCN113748779AQuickly swipe to collectImprove cutting efficiencyAgriculture gas emission reductionPotato seed cluttersHydraulic cylinderButt joint

The invention belongs to the technical field of dicing devices, and discloses a dicing device for potato planting. The dicing device comprises a workbench, a placement assembly, an insertion assembly and a dicing assembly, wherein the top end of the workbench is provided with an outer frame body, the upper surface wall of the workbench is provided with a leak hole, and the two side walls of the outer frame body are symmetrically provided with through holes; and the placement assembly comprises a placement part and a limiting part, and the limiting part is arranged above the placement part. According to the dicing device for potato planting, potatoes to be diced can be placed in a partitioned mode through the placement assembly and the limiting part, and the plurality of potatoes can be diced at a time, so that the dicing efficiency is high, and dicing is uniform; and in addition, after the potatoes on a first movable placement plate and a second movable placement plate are diced, the first movable placement plate and the second movable placement plate can be separated through a first hydraulic cylinder and a second hydraulic cylinder, and the diced potatoes can be quickly swept down from openings of the butt joint ends of the two placement plates to be collected, so that convenience is achieved.

Owner:黑龙江省农业科学院园艺分院

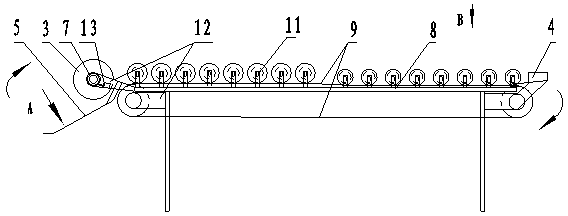

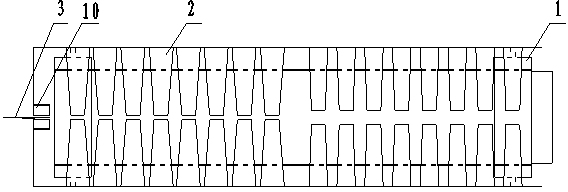

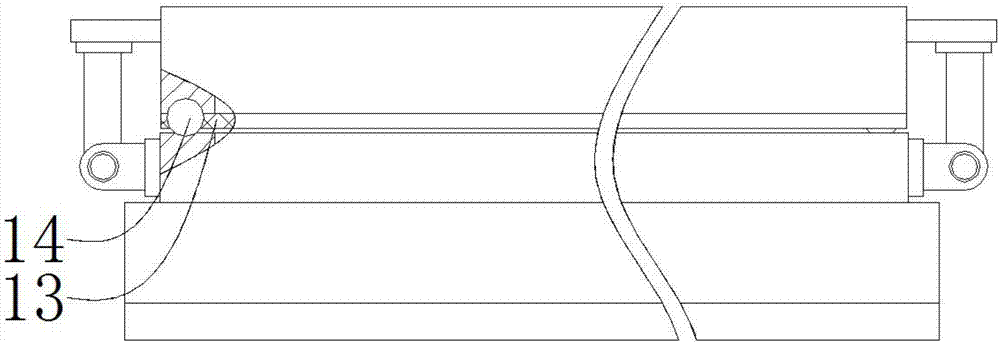

Plastic granulating device and method thereof

The invention discloses a plastic granulating device and a method thereof. The plastic granulating device comprises a conveying mechanism, a guide component and a material cutting mechanism, a coolingmechanism and a drying mechanism, wherein the conveying mechanism comprises an upper bracket, a lower bracket, first roller brackets and second roller brackets, a first conveying wheel installation frame and a second conveying wheel installation frame. The lower end of the upper bracket is provided with a plurality of the first roller wheel brackets, wherein each first roller wheel bracket is provided with a corresponding first roller wheel. The upper end of the lower support is provided with the second roller wheel brackets which are symmetrical in respect to the first roller wheel brackets,wherein each second roller wheel bracket is provided with a corresponding second roller wheel. The first conveying wheel installation frame is arranged at the right end part of the lower end surfaceof the upper bracket, and the second conveying wheel installation frame is arranged on the right end part of the upper end surface of the lower bracket. The guide component is arranged on one side ofthe conveying mechanism, the material cutting mechanism is arranged on the right side of the guide component, and the cooling mechanism is arranged on the right side of the material cutting mechanism.The plastic granulating device and the method thereof has the advantages of being novel in structural design and high in automation degree, and can achieve the conveying, grain cutting, cooling and drying of plastic strips and obtain high efficiency and good uniformity in the grain cutting.

Owner:龚有晨

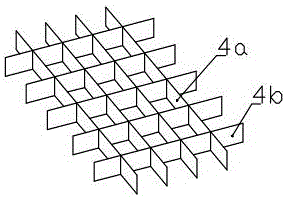

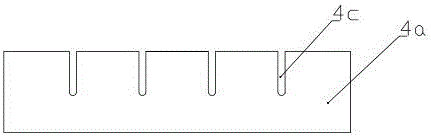

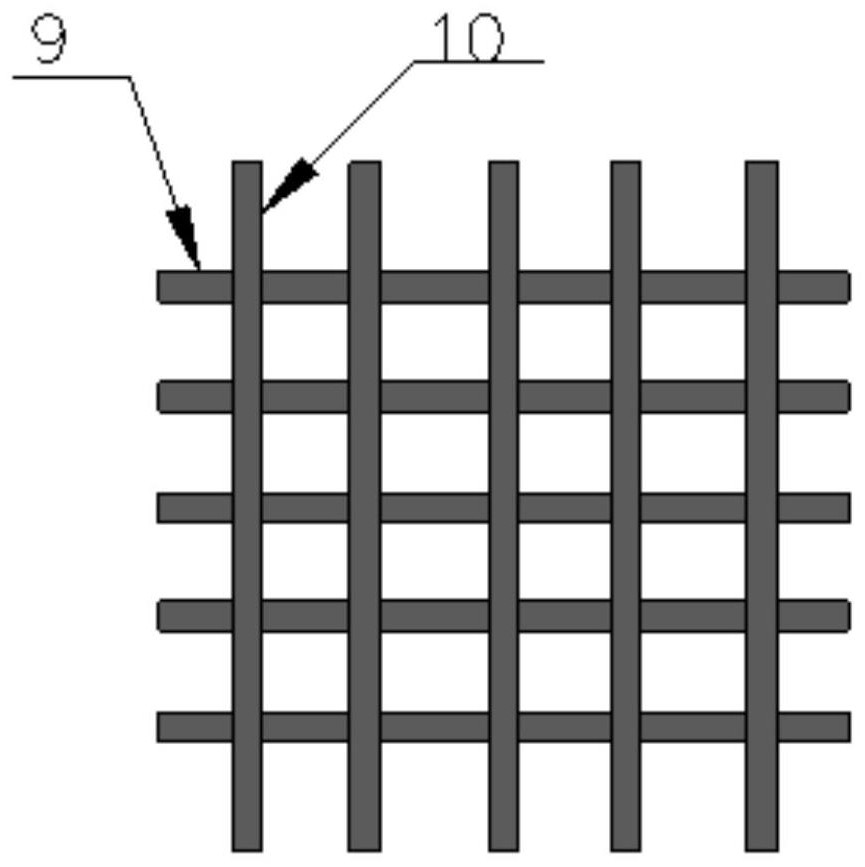

Sludge shredding device

The invention discloses a sludge shredding device which comprises a support plate, a lower grating, guide rods, an upper grating, a bracket, a power mechanism, a rotary shaft, a cam, a sliding plate, a guide wheel, a connecting plate, a resetting mechanism, a limiting plate and a steel ball. When sludge falls on the upper grating, the power mechanism drives the cam to rotate through the rotary shaft to push the sliding plate fixedly connected with the guide wheel to slide so as to further drive the upper grating to move along the guide rods; when the sliding plate moves leftwards, a spring is compressed; the cam begins to return after the cam reaches the maximum stroke, and the spring is recovered to push the sliding plate to move rightwards, so that the upper grating does reciprocal rectilinear motion along the guide rod; and the sludge is shredded transversely and longitudinally under the combined action of the lower grating as well as a transverse blade and a longitudinal blade arranged on the upper grating. The sludge shredding device is simple in structure; the upper grating can automatically do reciprocating motion, and the sludge is shredded transversely and longitudinally under the combined action of the upper grating and the lower grating; the degree of automation is high; and the sludge is uniformly, continuously and rapidly shredded into blocks.

Owner:东至县文元瓷砖加工厂

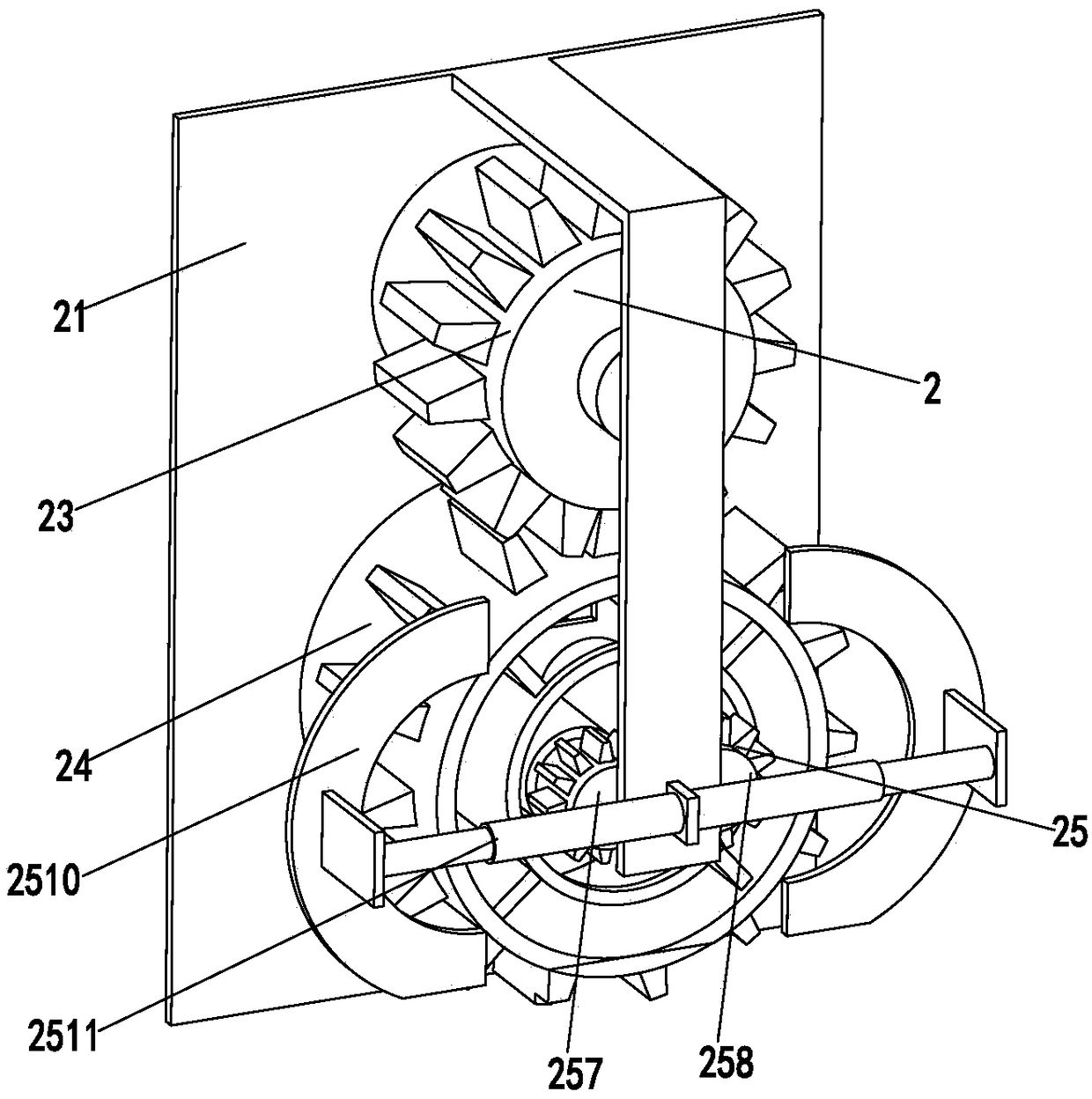

Plastic film machining production line and production and machining method thereof

ActiveCN109016250AIncrease labor costImprove work efficiencyPlastic recyclingProduction linePlastic film

The invention relates to a plastic film machining production line and a production and machining method thereof. The plastic film machining production line comprises a bottom plate, a grinding device,a pelleting device and auxiliary devices. The bottom plate is sequentially provided with the grinding device and the pelleting device from left to right. The auxiliary devices are symmetrically mounted at the left end and the right end of the pelleting device and mounted on the bottom plate. The grinding device comprises a working frame, a rotary motor, a driving rotary barrel, a driven rotary barrel and a grinding mechanism. Each auxiliary device comprises buffer springs, a first auxiliary supporting plate, a second auxiliary supporting plate, an auxiliary motor, rotary shafts, cams, a connecting rotary frame, a vibrating frame, a limiting frame and a fixing column. The problems that in the existing plastic film lug material recycling and treating processes, the labor cost is high, the working efficiency is low, potential safety hazards exist, and grinding is not complete can be solved, the functions of automatically grinding and pelleting plastic film lug materials can be achieved,and the plastic film machining production line has the beneficial effects that the labor cost is high, the working efficiency is high, the safety is high, and grinding is complete.

Owner:青岛正大环保科技有限公司

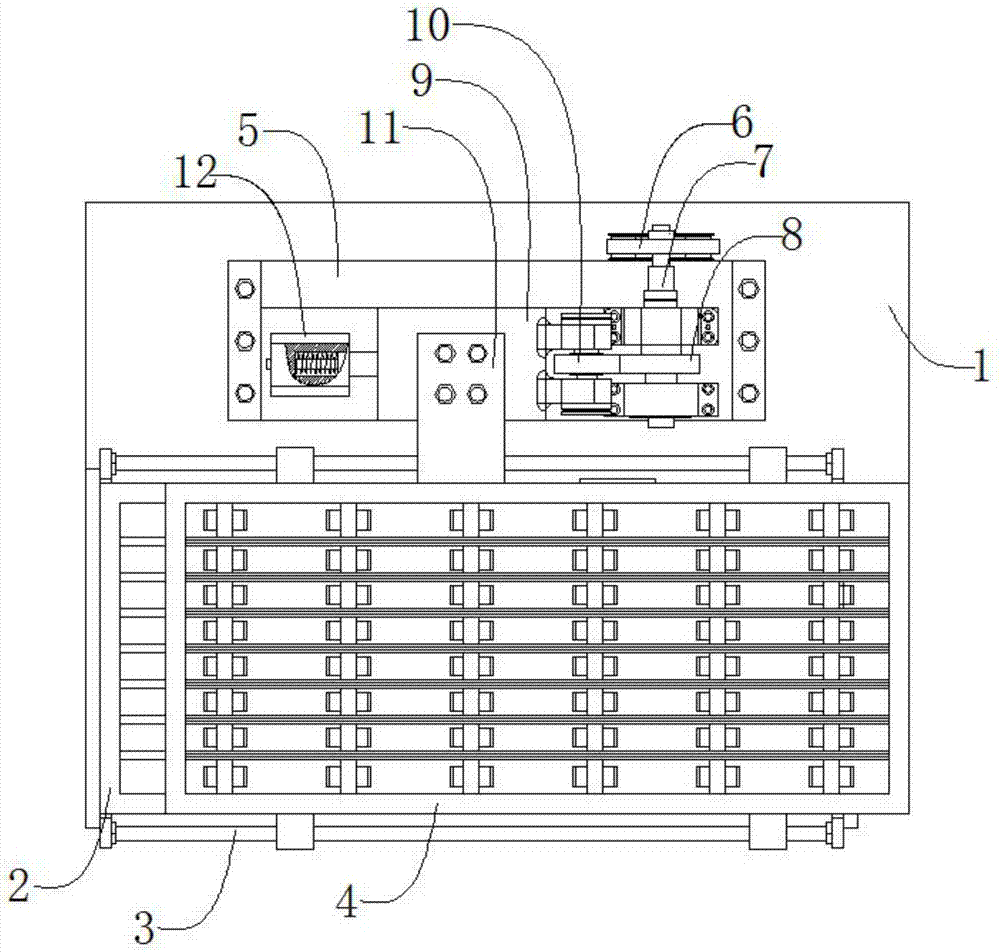

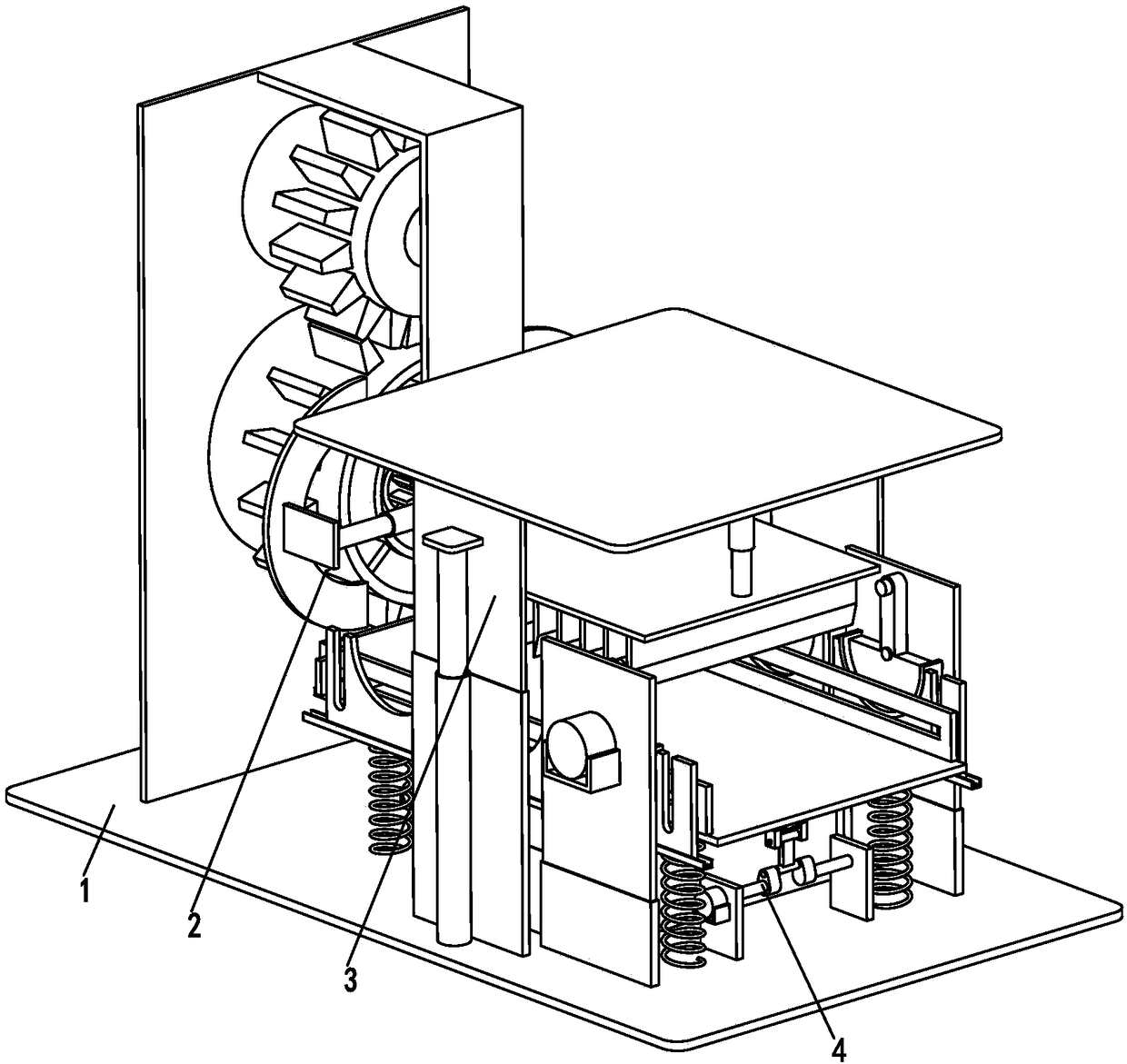

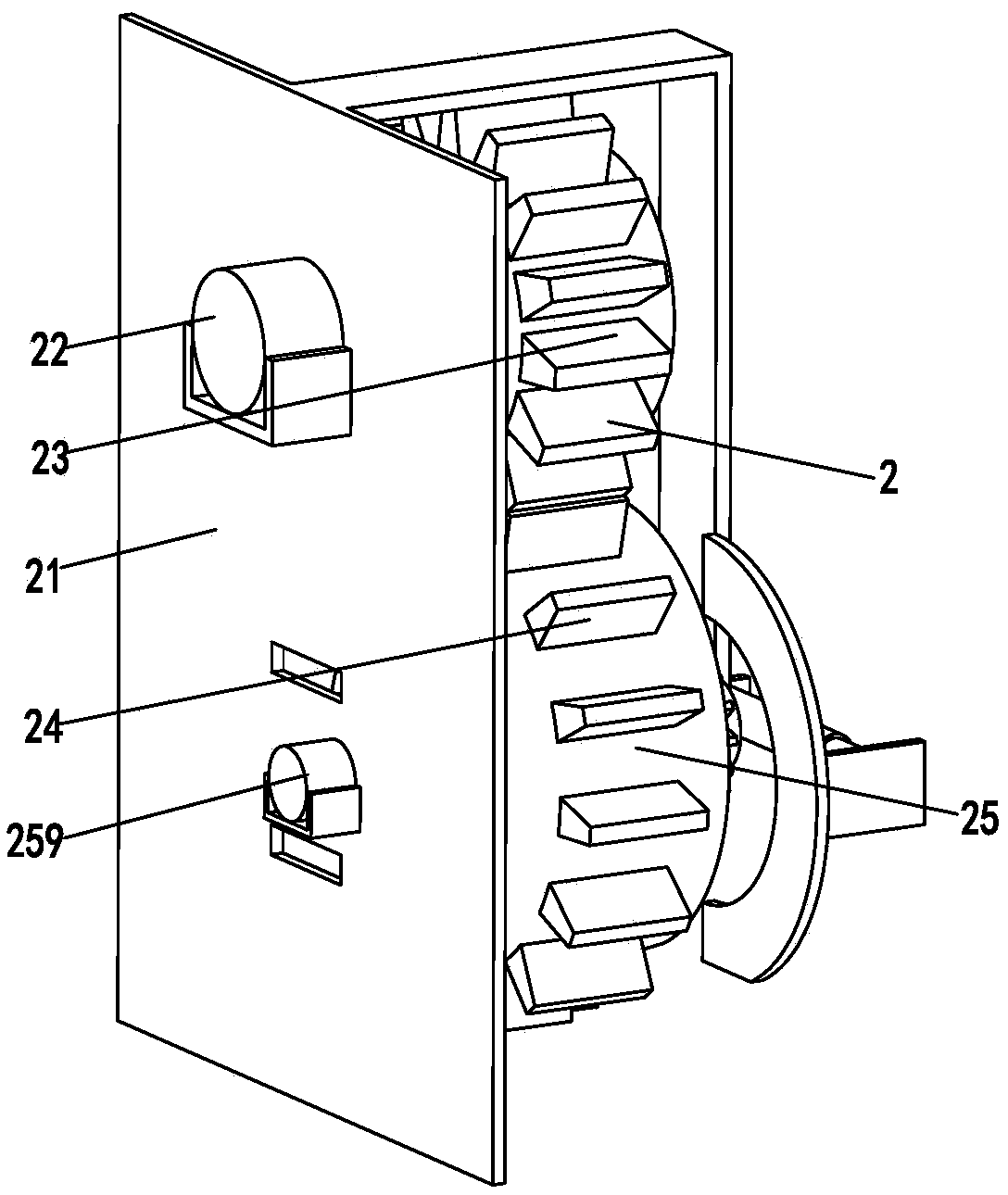

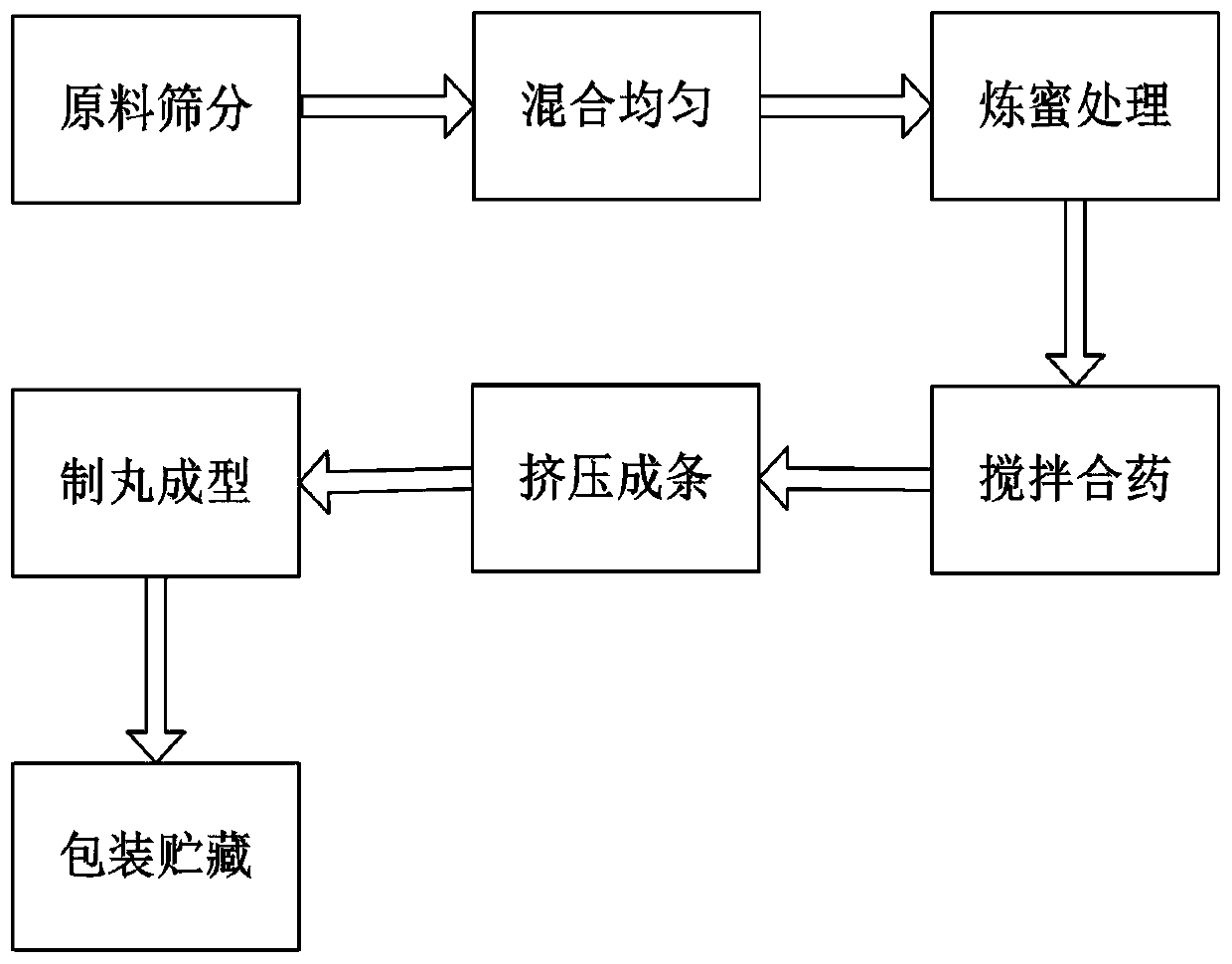

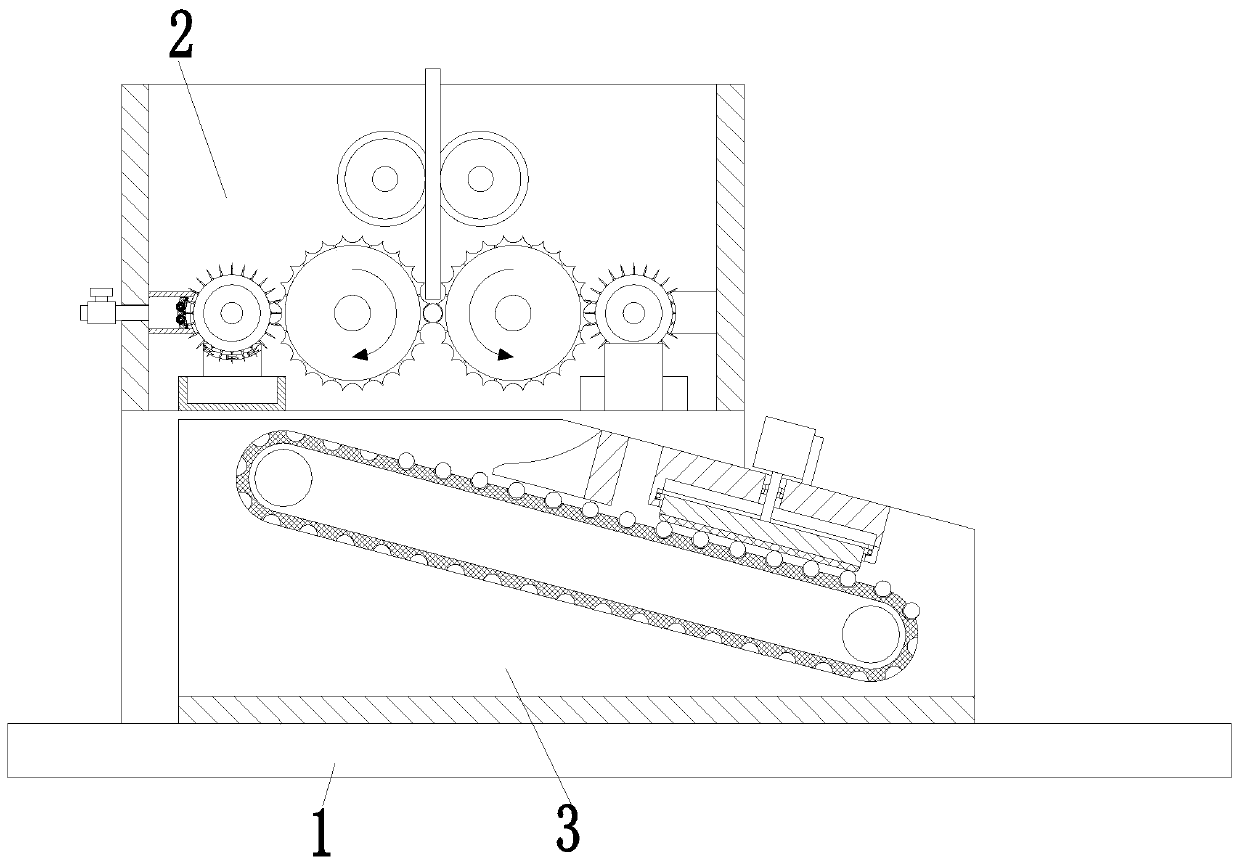

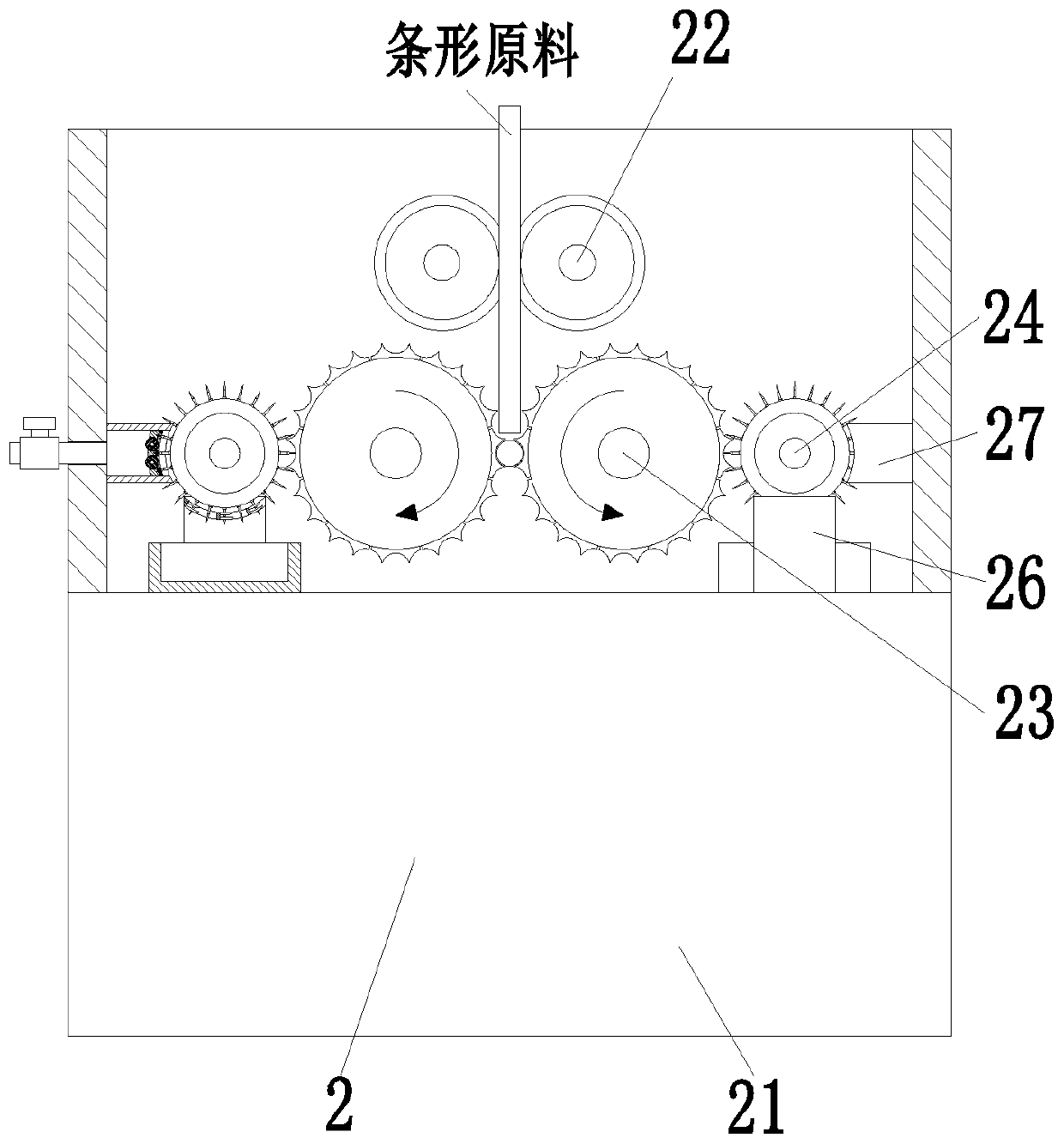

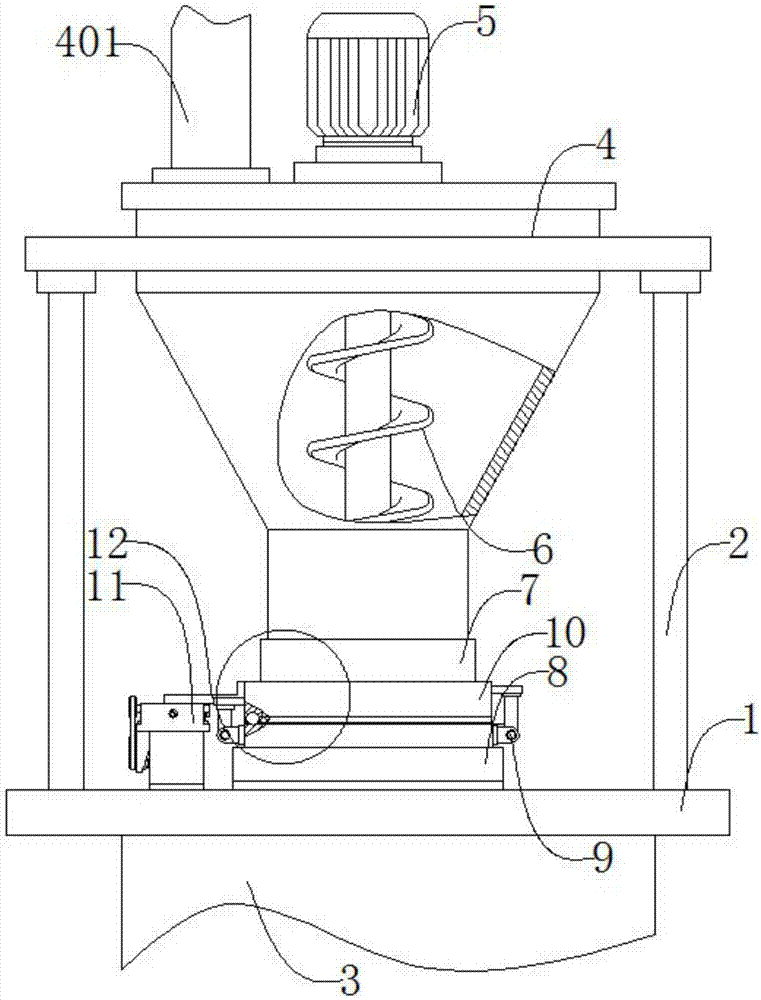

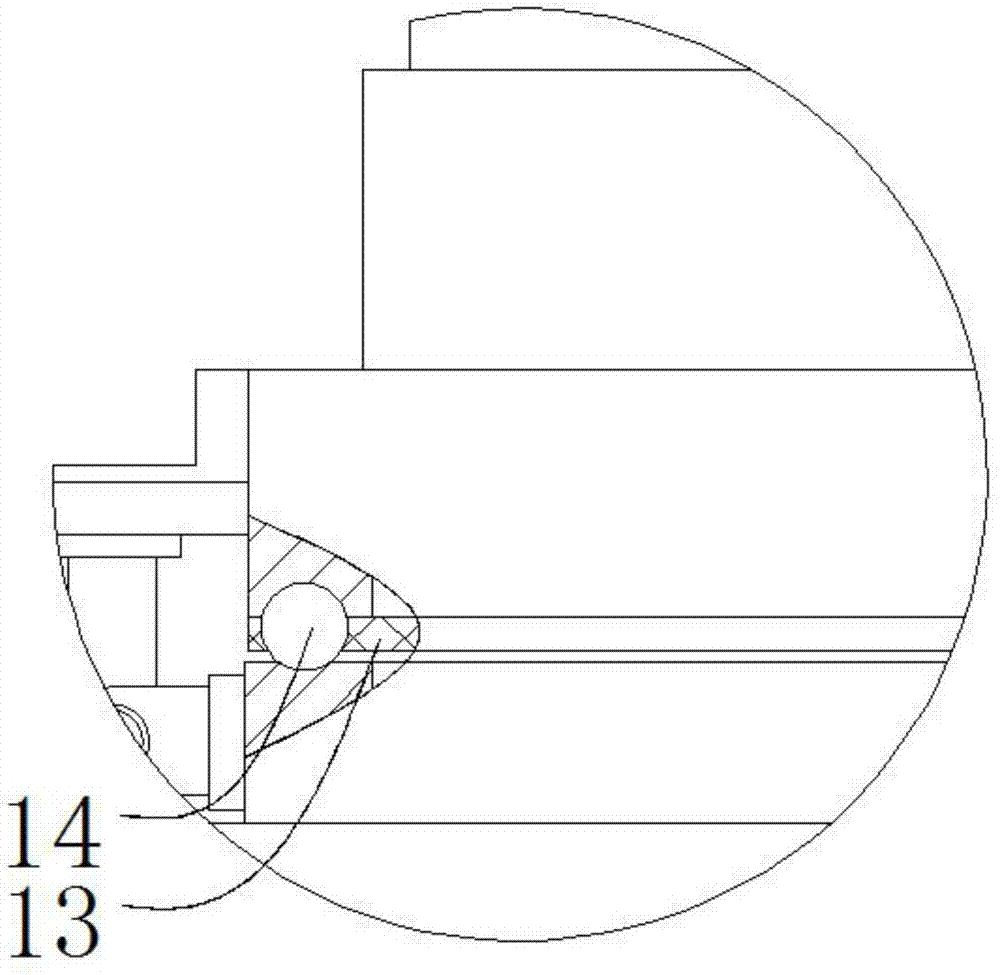

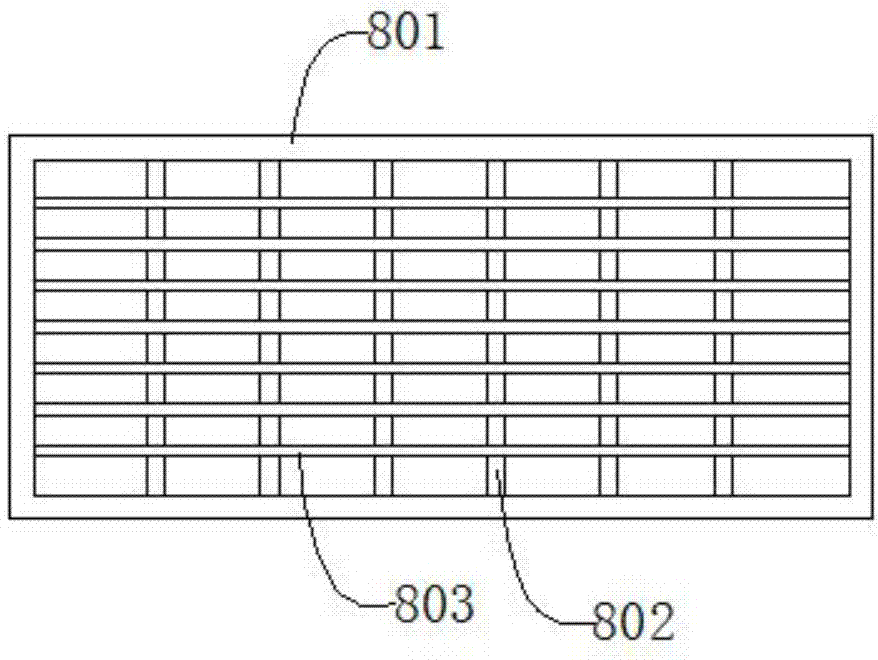

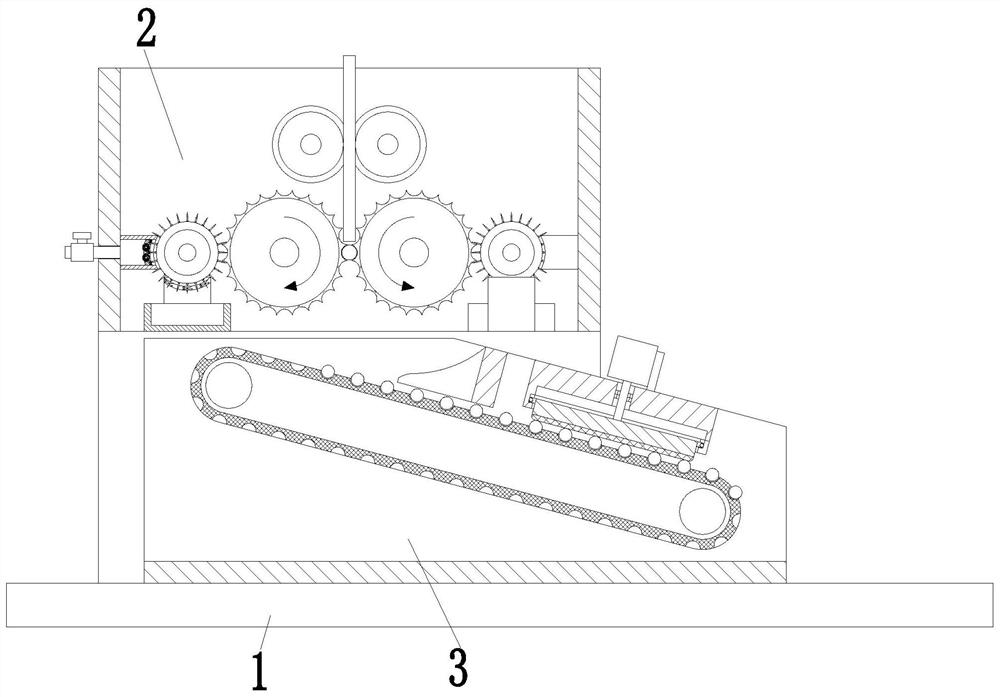

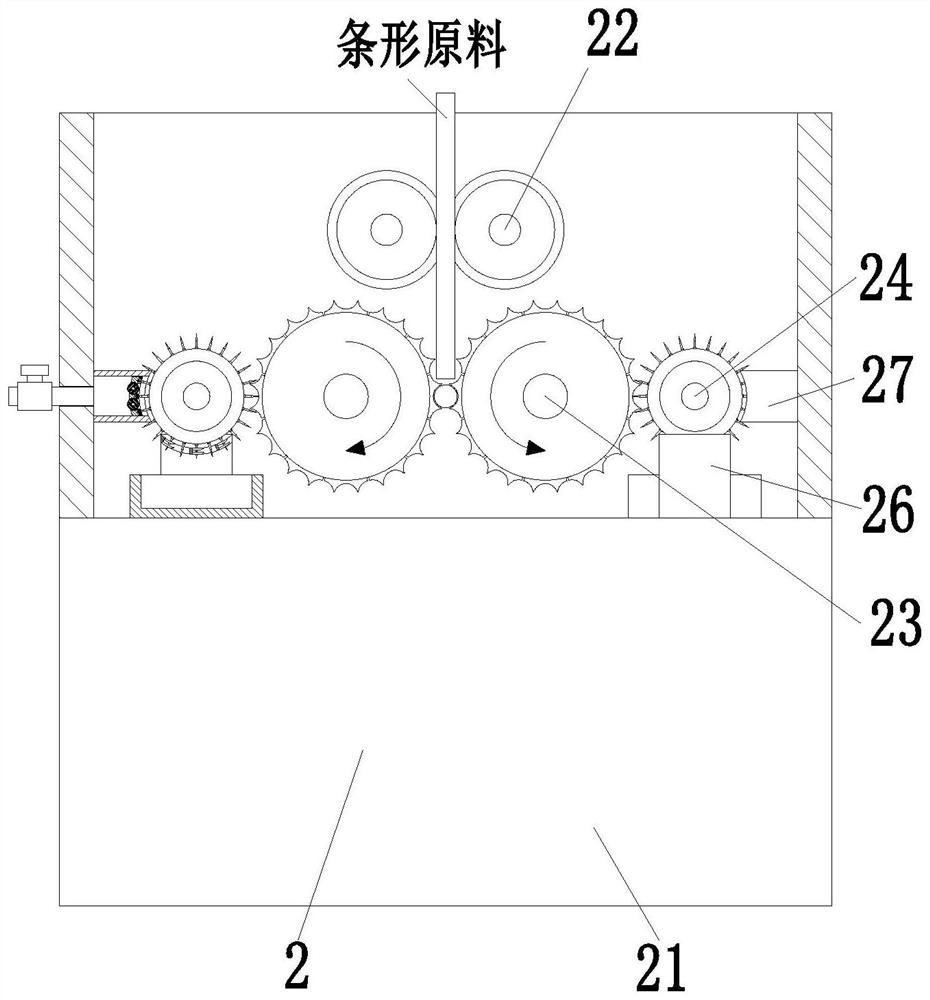

Preparation process of eight-material pills

ActiveCN111590950AGood cutting effectEvenly dicedPharmaceutical product form changeShaping pressStructural engineeringMechanical engineering

The invention relates to a preparation process of eight-material pills. The preparation process comprises a bottom plate, a granulating device and a rubbing device, wherein the granulating device is mounted at the upper end of the bottom plate; an empty groove is formed in the middle of the lower end of the granulating device; the rubbing device is arranged in the empty groove; and the rubbing device is mounted on the bottom plate. By adopting the preparation process provided by the invention, the difficulties that the diameters of the prepared eight-material pills are not uniform, a cutting roller after cutting cannot be rapidly cleaned, a lot of impurities are easily accumulated on the cutting roller and the cutting effect is influenced, and meanwhile, when existing equipment is used forprocessing the eight-material pills, the cut raw materials cannot be effectively finished, so that the prepared pills are irregular, subsequent processing of the pills is influenced and the like, caused by the fact that the existing equipment is used for cutting the raw materials and the cutting is not uniform can be solved.

Owner:池州市九华府金莲智慧农业有限公司

Circular uniform pelletizer

InactiveCN107225705AImprove finished product qualityReduce noiseSievingScreeningPelletizingTransfer mechanism

A circular uniform granulator, including a feed inlet, a discharge outlet, a frame, a motor, a frequency converter, a cutting chamber, a pellet collector, a control box and a transmission mechanism, the transmission mechanism includes a conveyor belt 1, a conveyor belt 2, The conveyor belt three and the chute, the conveyor belt one of the conveyor belt one is a porous filter screen, the outer surface of the frame is provided with push rods and scrapers, the conveyor belt one and the two conveyor belts are arranged on different surfaces, and the pellets pass through the outlet of the conveyor belt one The material end falls into the feed end of the second conveyor belt, and the third conveyor belt is respectively connected with the second conveyor belt and the chute, and the end of the chute corresponds to the feed inlet. The invention can realize the uniform granulation of plastics, sieve the primary cut plastic granules with a conveyer belt, and drop the plastic granules with a particle size less than 5mm into the granule collector, and send the large granule back to the cutting room for secondary cutting. It is beneficial to improve the quality of finished products.

Owner:YANCHENG SHENYUAN PLASTIC

Sludge pretreatment device

PendingCN107382021AEvenly dicedContinuous cuttingSludge treatment by de-watering/drying/thickeningSludgeReciprocating motion

The invention discloses a sludge pretreatment device which comprises a support plate, a support, a discharge nozzle, a loading bin, a motor, an impeller, a keep-off nozzle, a lower grid, guide rods, an upper grid, a swinging mechanism, a connecting plate, a spacing plate and a steel ball. The swinging mechanism further comprises a bracket, a power mechanism, rotating shafts, cams, sliding plates, guide wheels and a reset mechanism; the reset mechanism further comprises a push top, a spacing rod, and a spring. The sludge pretreatment device is simple in structure, sludge is continuously pressed into the upper grid through the impeller, the swinging mechanism pushes the upper grid to move reciprocatingly, the sludge is crushed horizontally and longitudinally under the common action of the upper grid and the lower grid, the sludge can be sliced evenly, continuously and rapidly, the sludge is allowed to fall into the discharge nozzle rapidly through continuous conveying of the impeller, and high efficiency is achieved.

Owner:东至县文元瓷砖加工厂

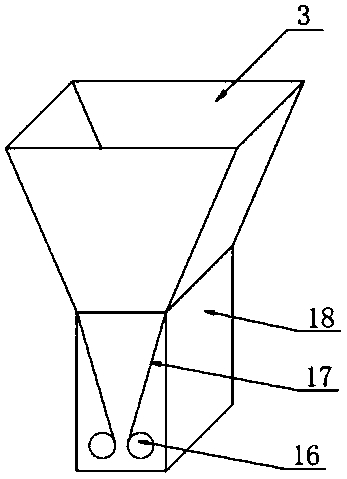

Granulator for PPS modified materials

InactiveCN110919898AReduce energy consumptionFor precise cuttingMetal working apparatusElectric machineryStructural engineering

The invention discloses a granulator for PPS modified materials. The granulator comprises a granulator body, a horn mouth mechanism and a cutter mechanism. The granulator body is provided with a granulation box top cover, a horn mouth mechanism, a feeding groove, a granulator box, the cutter mechanism, a discharging opening, a drive motor, a ring-shaped bearing, a fixing bayonet, a guide roller, aguide plate, a discharging pipeline and a granulation table board. The cutter mechanism is arranged in the granulator box of the granulator body. A granulation table is installed on one side of the cutter mechanism. The feeding groove is formed in the front side face of the granulation box top cover on the top of the granulator box. The horn mouth mechanism is installed in the granulator box. A top end opening of the horn mouth mechanism is connected with one end of the feeding groove. According to the device, bars pass through one horn mouth before entering the granulator, the bars are parallel to a cutter, the bars will not be broken by pressure before granulating, in this way, granulating is uniform, long bars are avoided, and noise generated by the device is small.

Owner:江苏邦正新材料有限公司

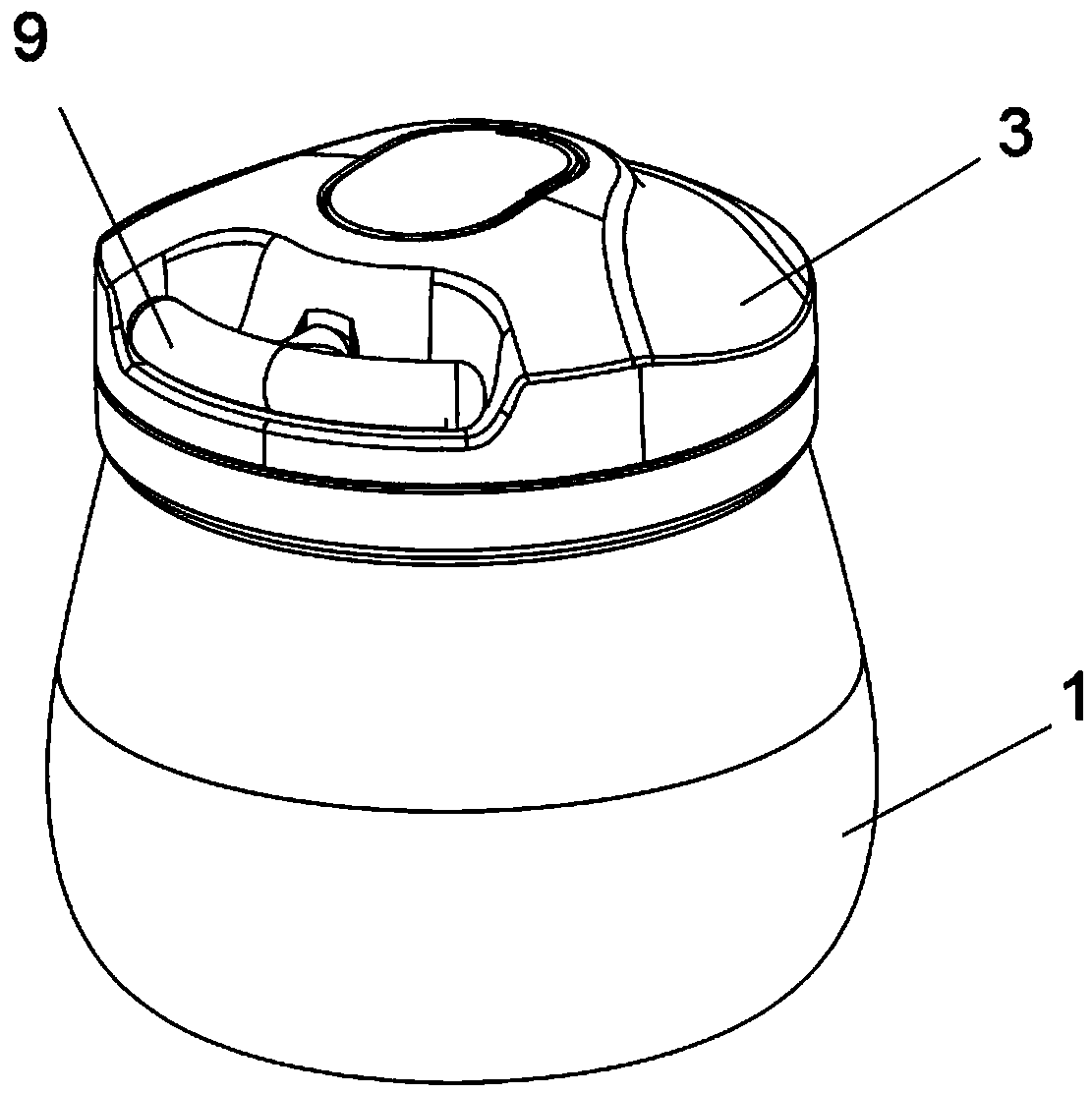

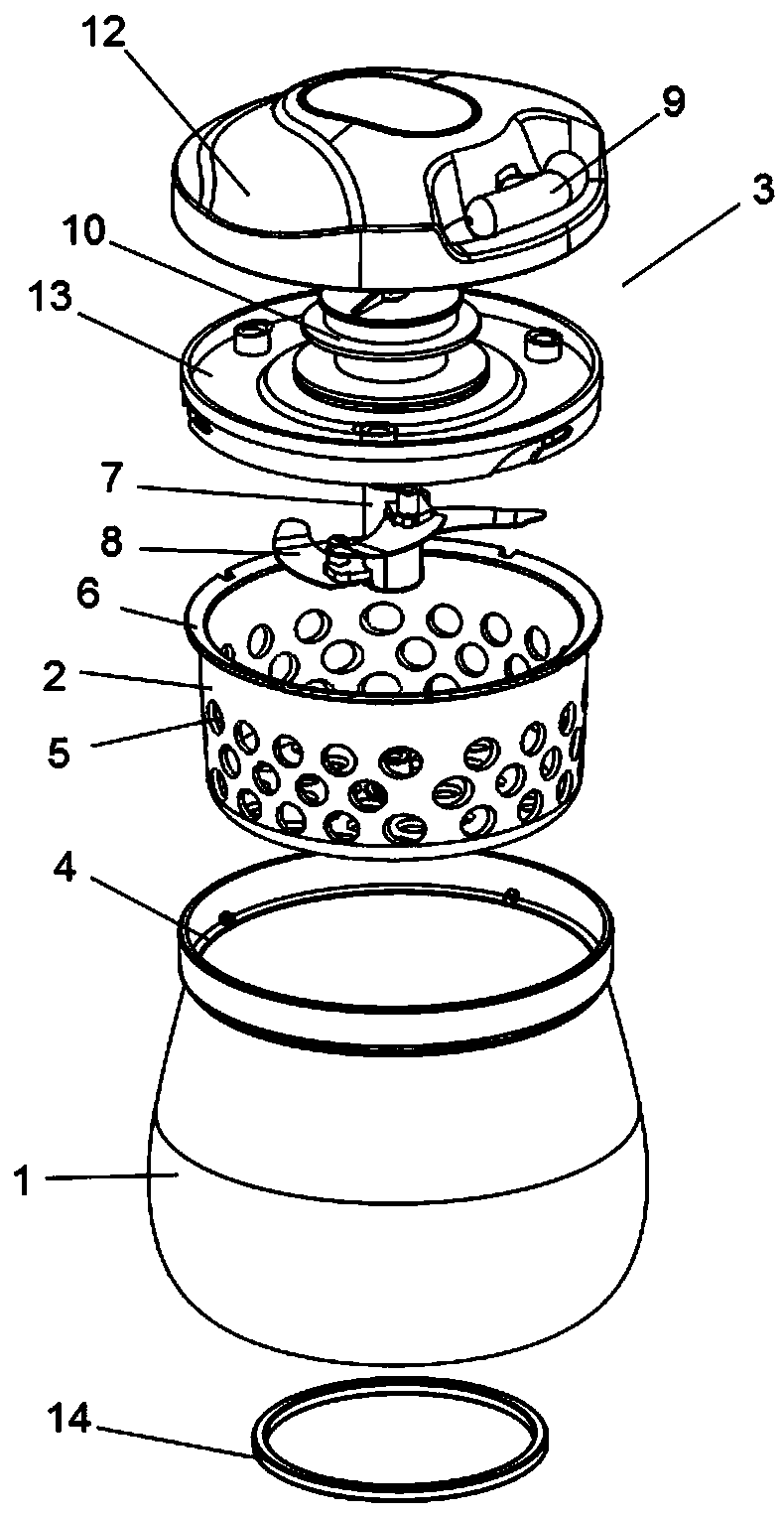

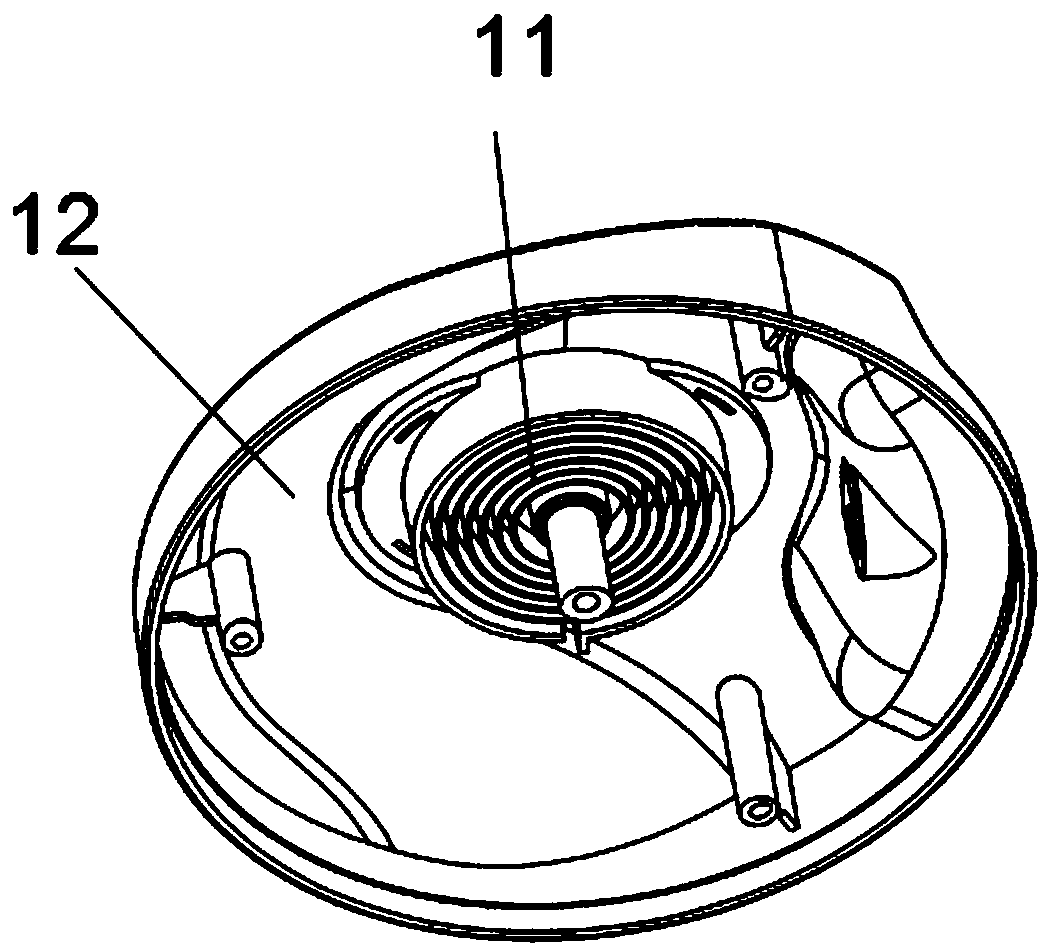

Chopping processor

The invention discloses a chopping processor. According to the technical scheme, the chopping processor comprises an outer-layer food tank, an inner-layer screen tank and a chopping device, a step which protrudes inwards is arranged at the upper end of the inner surface of the outer-layer food tank, a plurality of passing holes are formed in the surface of the inner-layer screen tank and used forallowing chopped fruits and vegetables to pass, the top of the inner-layer screen tank is provided with an outward-protruding outer edge, and the top of the inner-layer screen tank is buckled on the step at the upper end of the outer-layer food tank through the outer edge; and the minimum distance between the passing holes and the side wall of the outer-layer food tank is larger than the diameterof each passing hole, a knife rest is connected below the chopping device, blades are connected to the knife rest, when the chopping device is buckled on the top of the outer-layer food tank, the knife rest is located in the inner-layer screen tank, and the chopping device electrically or manually drives the knife rest to rotate. According to the chopping processor, food such as fruits, dried fruits, vegetables and the like can be diced, moreover, chopped dices can be ensured to be uniform, the cut dices can be effectively collected, the cutting process is convenient and sanitary, and the cutting efficiency is high.

Owner:刘伟国

Fruit dicing equipment

InactiveCN106564081AEvenly dicedEasy to useMetal working apparatusAgricultural engineeringPiston rod

The invention discloses fruit dicing equipment and relates to the field of technical fruit dicing equipment. The equipment comprises two stand columns and a fixing frame mounted on the stand columns; a hopper is fixedly mounted on the fixing frame; a grid-shaped dicing knife is mounted in the hopper; an inclined separating plate is mounted below the dicing knife; a discharging port is arranged at the lower end of the separating plate; a vertical rotating shaft is further mounted at the bottom of the hopper; the upper end of the rotating shaft penetrates through the separating plate to reach the position below the dicing knife; rotating cutting knives perpendicular to the rotating shaft are fixedly mounted at the upper end of the rotating shaft; a mounting frame is further fixedly mounted at the upper ends of the two stand columns; a push air cylinder is mounted on the mounting frame; a fixing plate is mounted on a piston rod of the push air cylinder; and a plurality of push rods which are not connected with one another are further arranged on the fixing plate and are matched with the dicing knife. With the equipment, uniform dicing is realized, manual work is not required, the equipment is convenient to use, and the manpower is reduced.

Owner:四川苍溪梨研究所

Color master batch production system based on water cooling circulation and production method thereof

InactiveCN112847892ASpeed up the cooling processRapid temperature exchangeThermodynamicsProcess engineering

The invention relates to the technical field of color master batch forming device processing, in particular to a color master batch production system based on water cooling circulation and a production method thereof. The color master batch production system comprises a base, a first sealing box is fixedly connected to the left side of the top of the base, second sealing boxes are hinged to the front side and the rear side of the first sealing box through two hinge ejector rods, and the sides, close to the hinge ejector rods, of the front side and the rear side of the first sealing box are movably connected with one ends of the hinge ejector rods through hydraulic telescopic air cylinders. By means of the design, it can be guaranteed that the temperature in the forming process is in a low state; due to full contact heat dissipation in a flowing water mode, linear color master batch forming can be more thorough and more uniform; through the built-in design, dust adhesion in the discharging process is avoided, and the master batch quality is improved; and as pelletizing is conducted in the cooling process, without existing independent drying treatment is not needed, the master batch does not need to be in contact with water for cooling in the whole operation process, the occupied area of equipment is effectively reduced, the purchase cost of the equipment is reduced, and the efficiency is higher.

Owner:李欢

Automatic pellet machine

The invention relates to a full-automatic aggregation machine. The full-automatic aggregation machine comprises a feeding barrel with a feeding cavity, a feeding spiral part located in the feeding cavity, a first drive device driving the feeding spiral part to rotate, a fixed cutter head, a movable cutter head opposite to the fixed cutter head, a main shaft sleeved with the movable cutter head in a connected manner, a second drive device driving the main shaft to rotate, a third drive device driving the main shaft to move along the center axis, and a controller. A grinding cavity is formed between the fixed cutter head and the movable cutter head. The grinding cavity is internally provided with a temperature sensor electrically connected with the controller. The controller is electrically connected with the second drive device and the third drive device. Materials are fed into the grinding cavity through rotation of the feeding spiral part, the movable cutter head rotates to enable the materials entering the grinding cavity to rub, and the materials are thrown out of the edge of the cutter heads through the centrifugal action so that particle cutting can be achieved, and the purposes of material extruding and particle cutting are achieved at a time. A gap between the movable cutter head and the fixed cutter head can be adjusted through the third drive device, the control over balanced feeding and aggregating effects is achieved, and the quality of products is guaranteed.

Owner:GUANGZHOU 3E MACHINERY

A plastic film processing production line and its production and processing method

ActiveCN109016250BIncrease labor costImprove work efficiencyPlastic recyclingProduction lineEngineering

The invention relates to a plastic film machining production line and a production and machining method thereof. The plastic film machining production line comprises a bottom plate, a grinding device,a pelleting device and auxiliary devices. The bottom plate is sequentially provided with the grinding device and the pelleting device from left to right. The auxiliary devices are symmetrically mounted at the left end and the right end of the pelleting device and mounted on the bottom plate. The grinding device comprises a working frame, a rotary motor, a driving rotary barrel, a driven rotary barrel and a grinding mechanism. Each auxiliary device comprises buffer springs, a first auxiliary supporting plate, a second auxiliary supporting plate, an auxiliary motor, rotary shafts, cams, a connecting rotary frame, a vibrating frame, a limiting frame and a fixing column. The problems that in the existing plastic film lug material recycling and treating processes, the labor cost is high, the working efficiency is low, potential safety hazards exist, and grinding is not complete can be solved, the functions of automatically grinding and pelleting plastic film lug materials can be achieved,and the plastic film machining production line has the beneficial effects that the labor cost is high, the working efficiency is high, the safety is high, and grinding is complete.

Owner:青岛正大环保科技有限公司

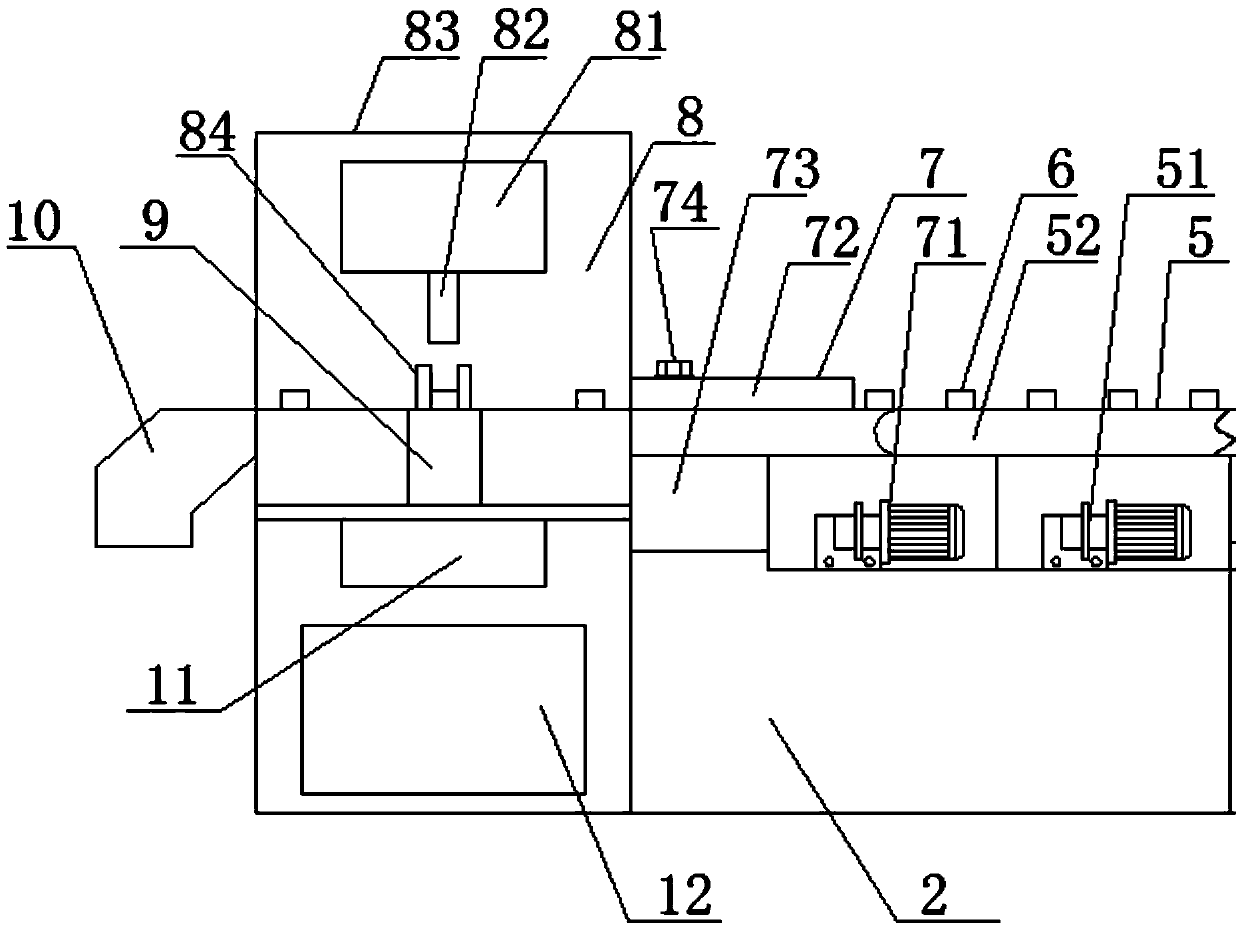

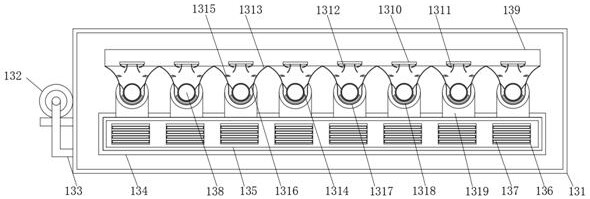

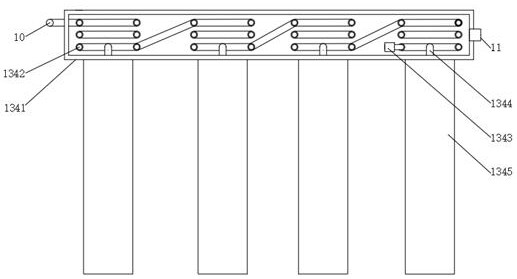

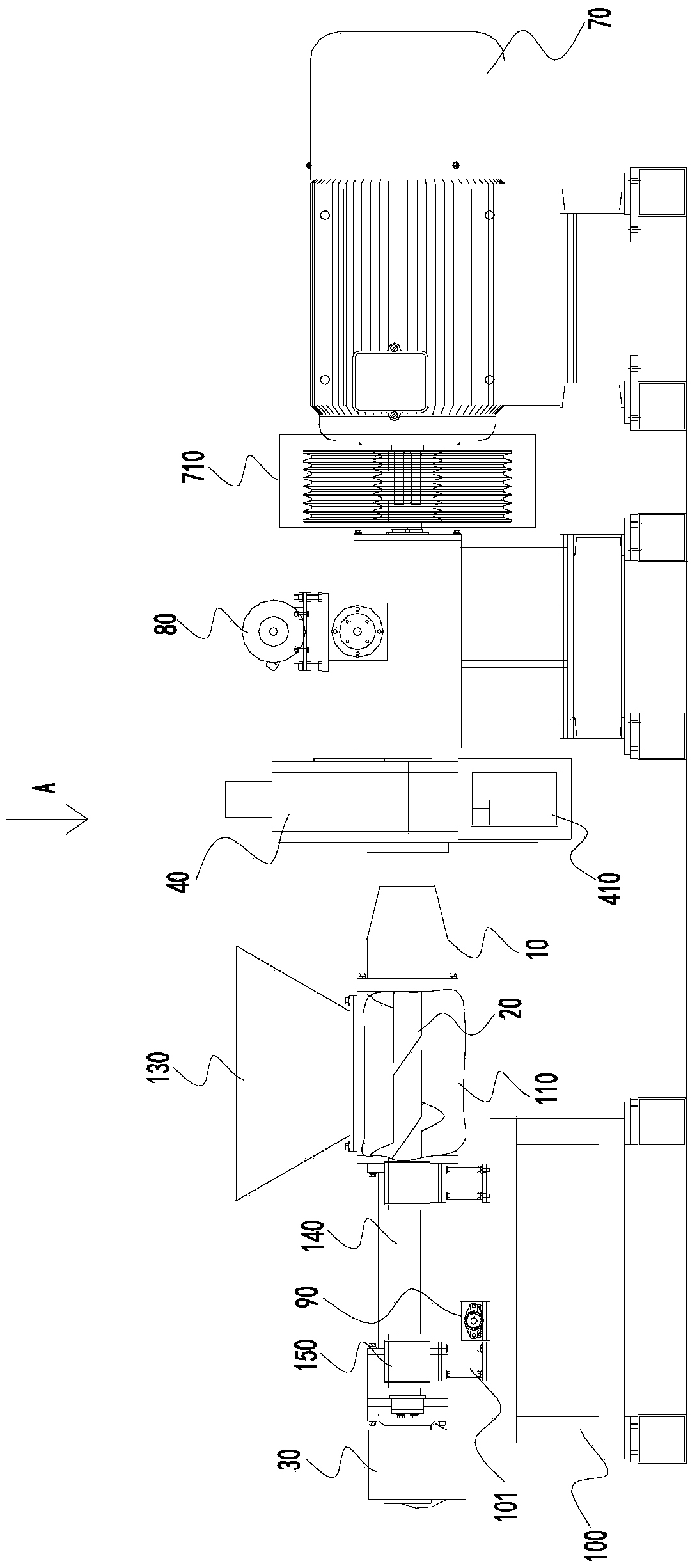

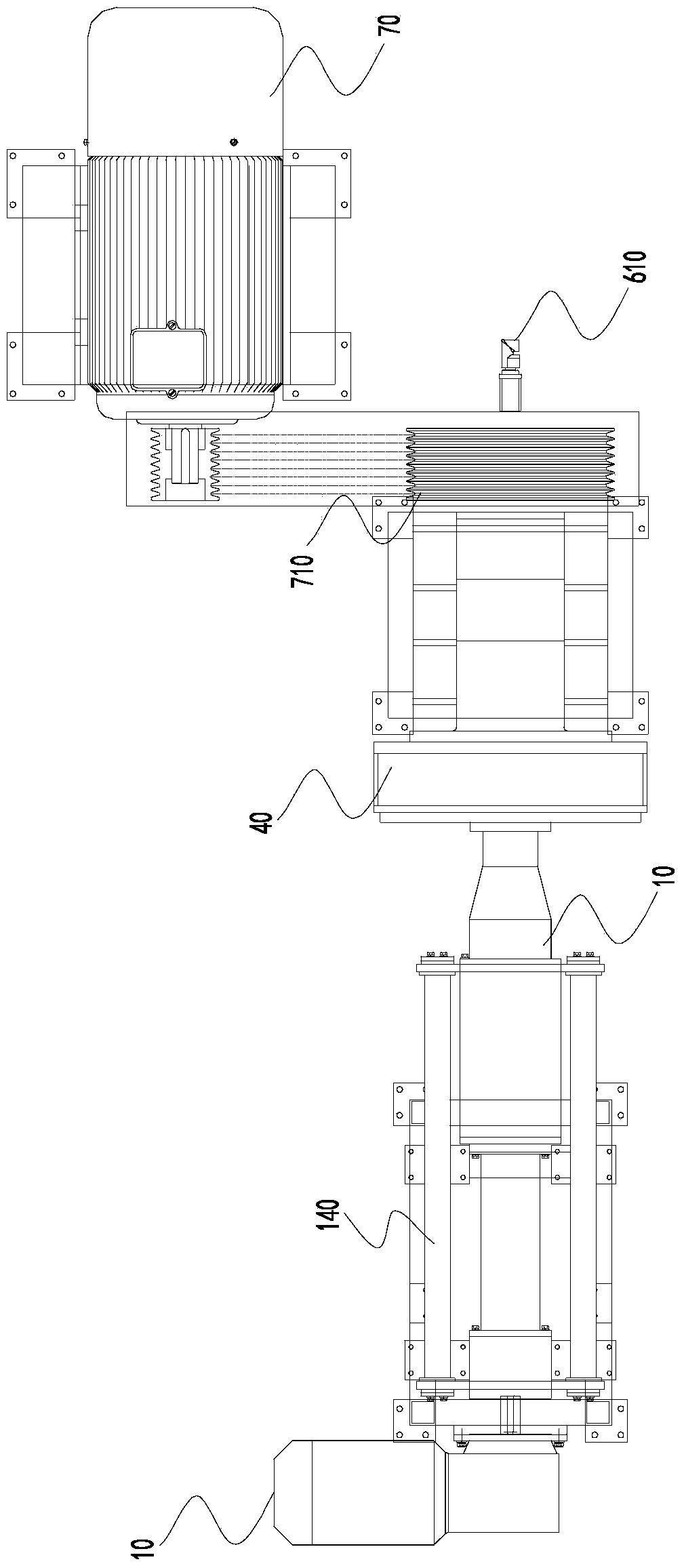

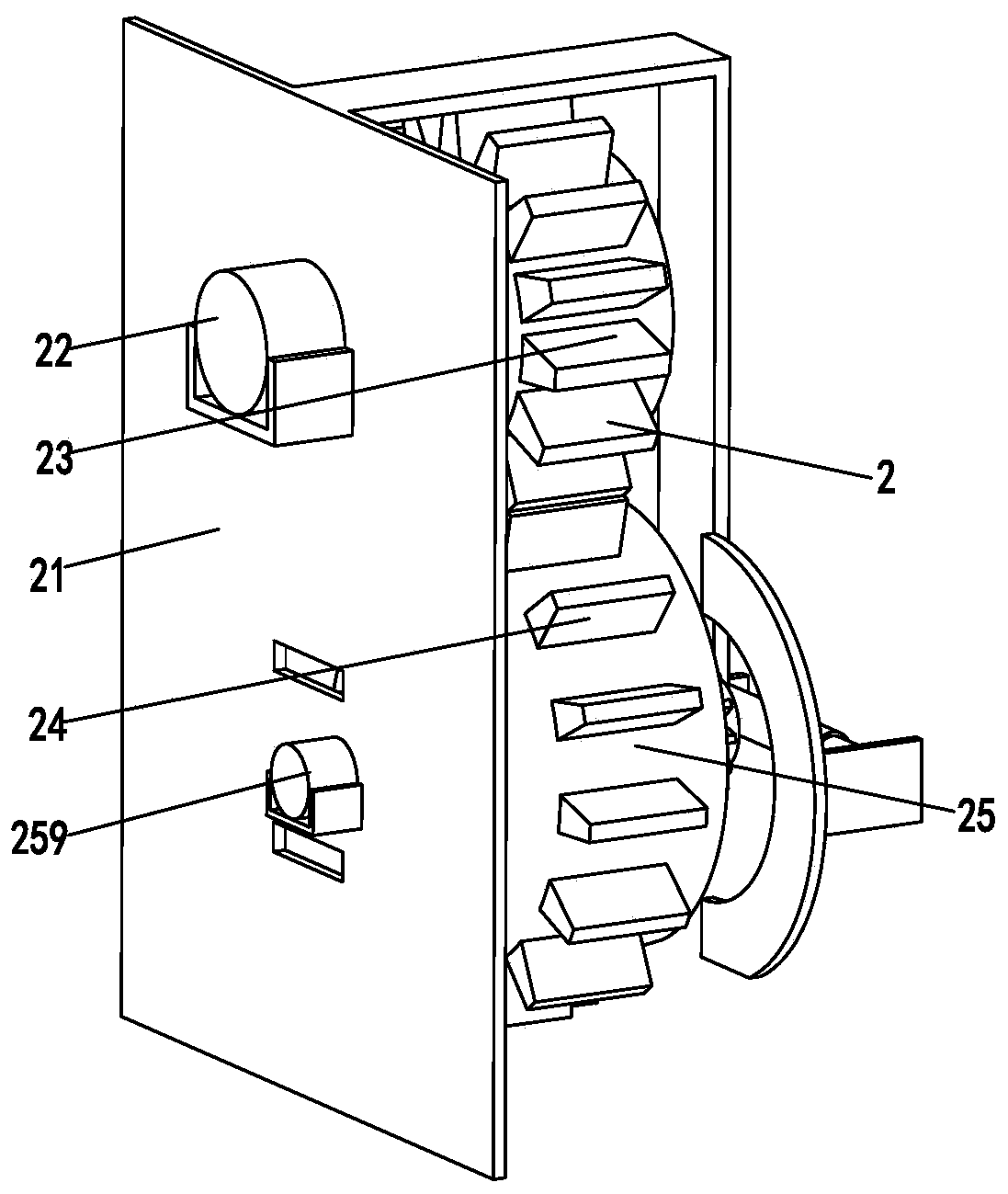

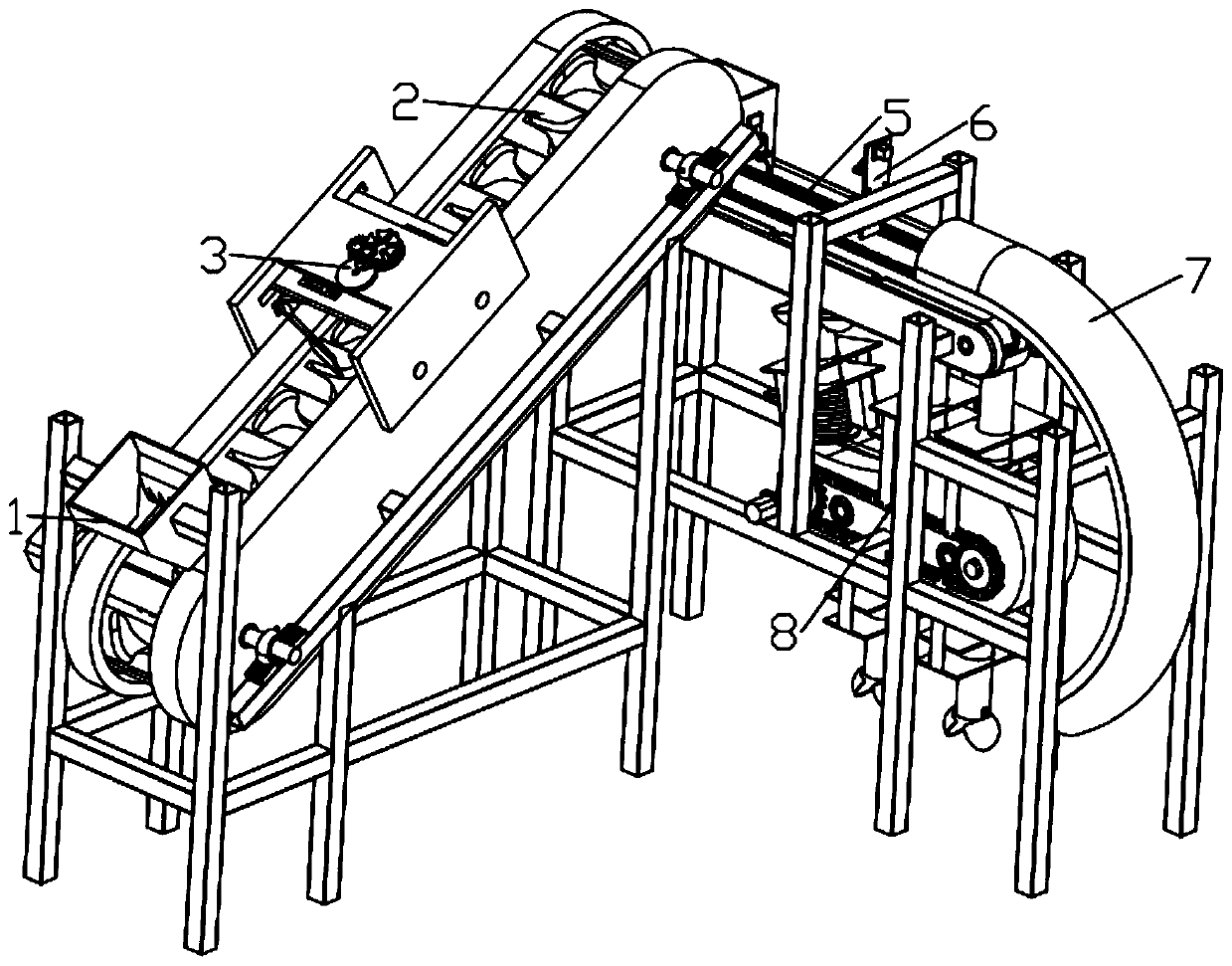

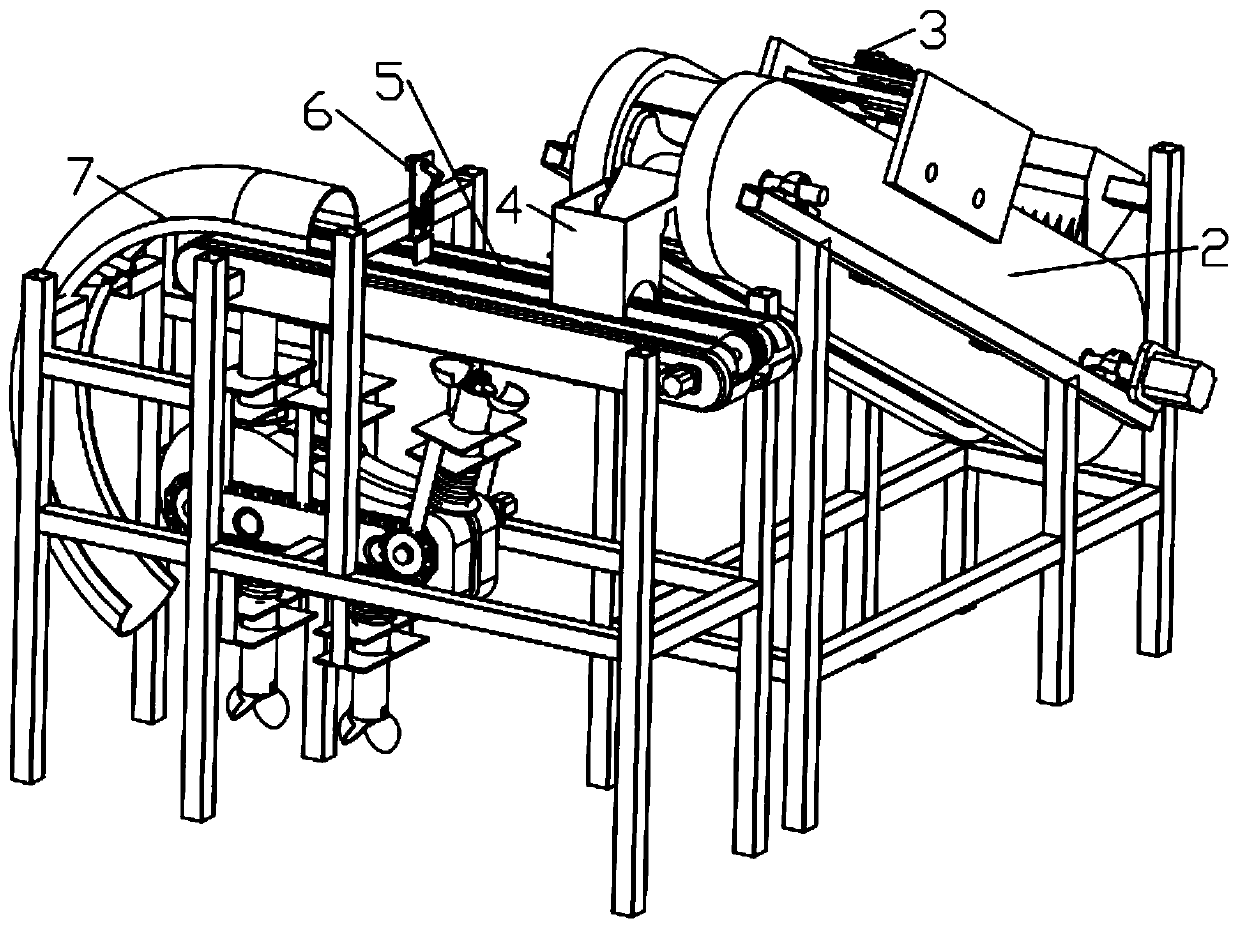

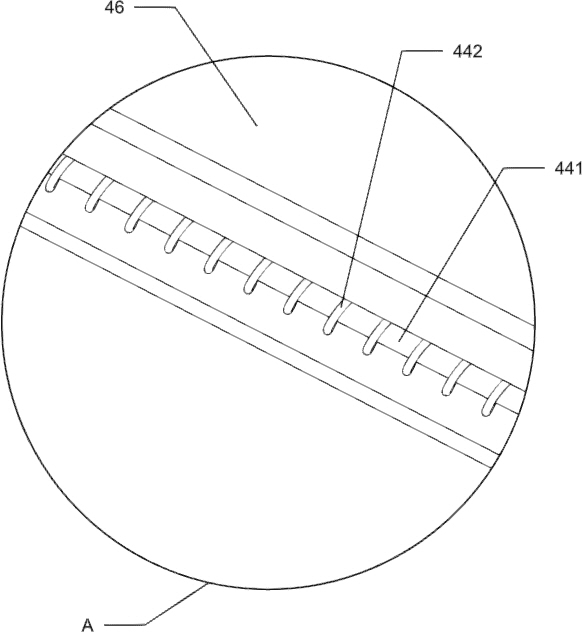

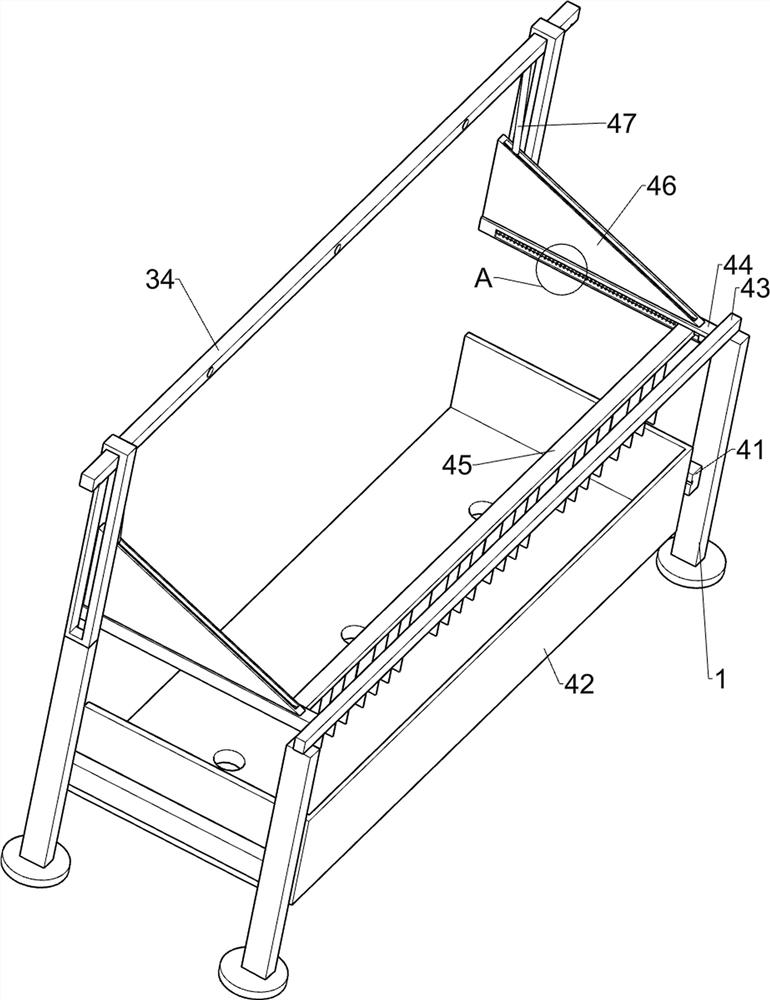

Two-level conveyor type broccoli automatic cutting and core production line

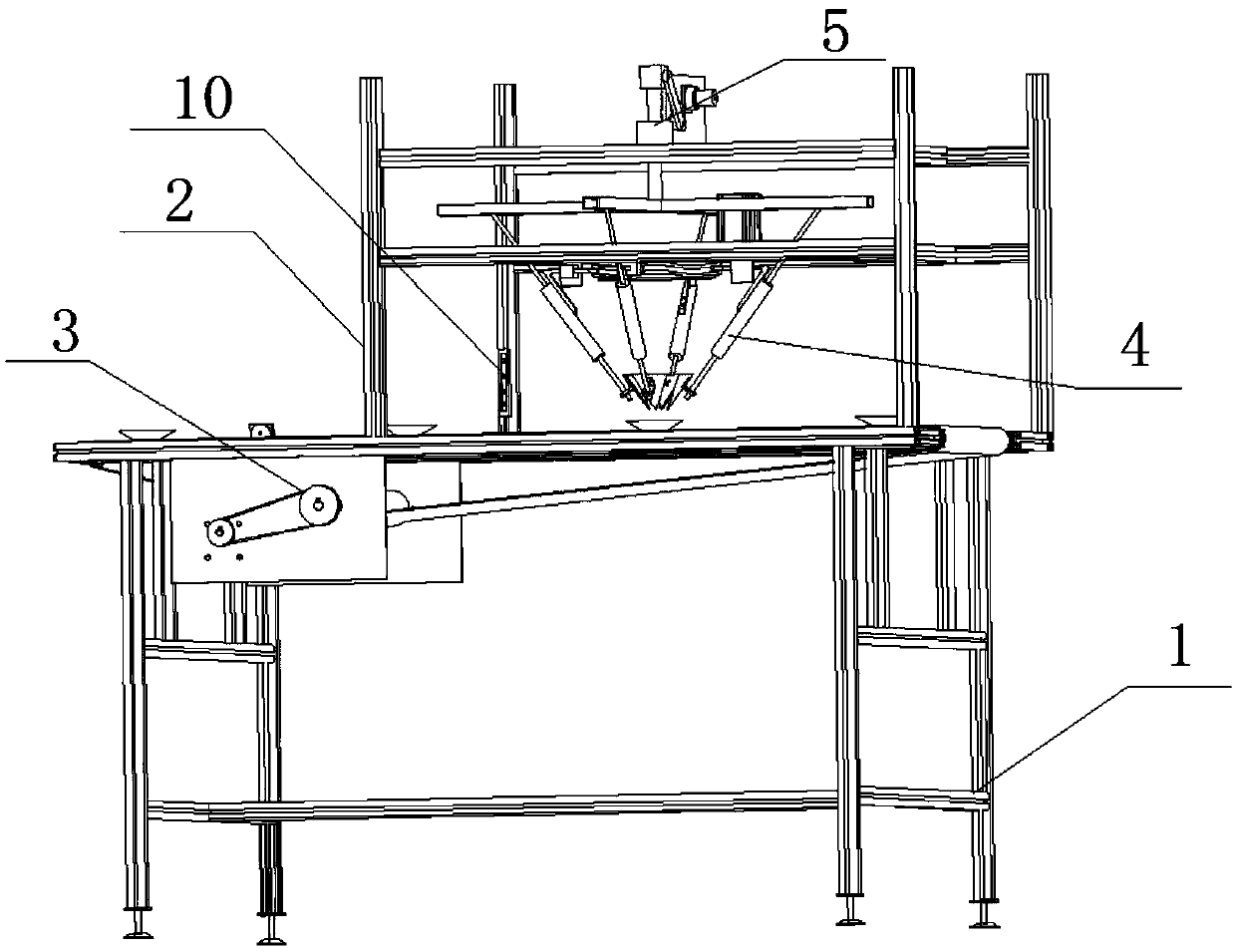

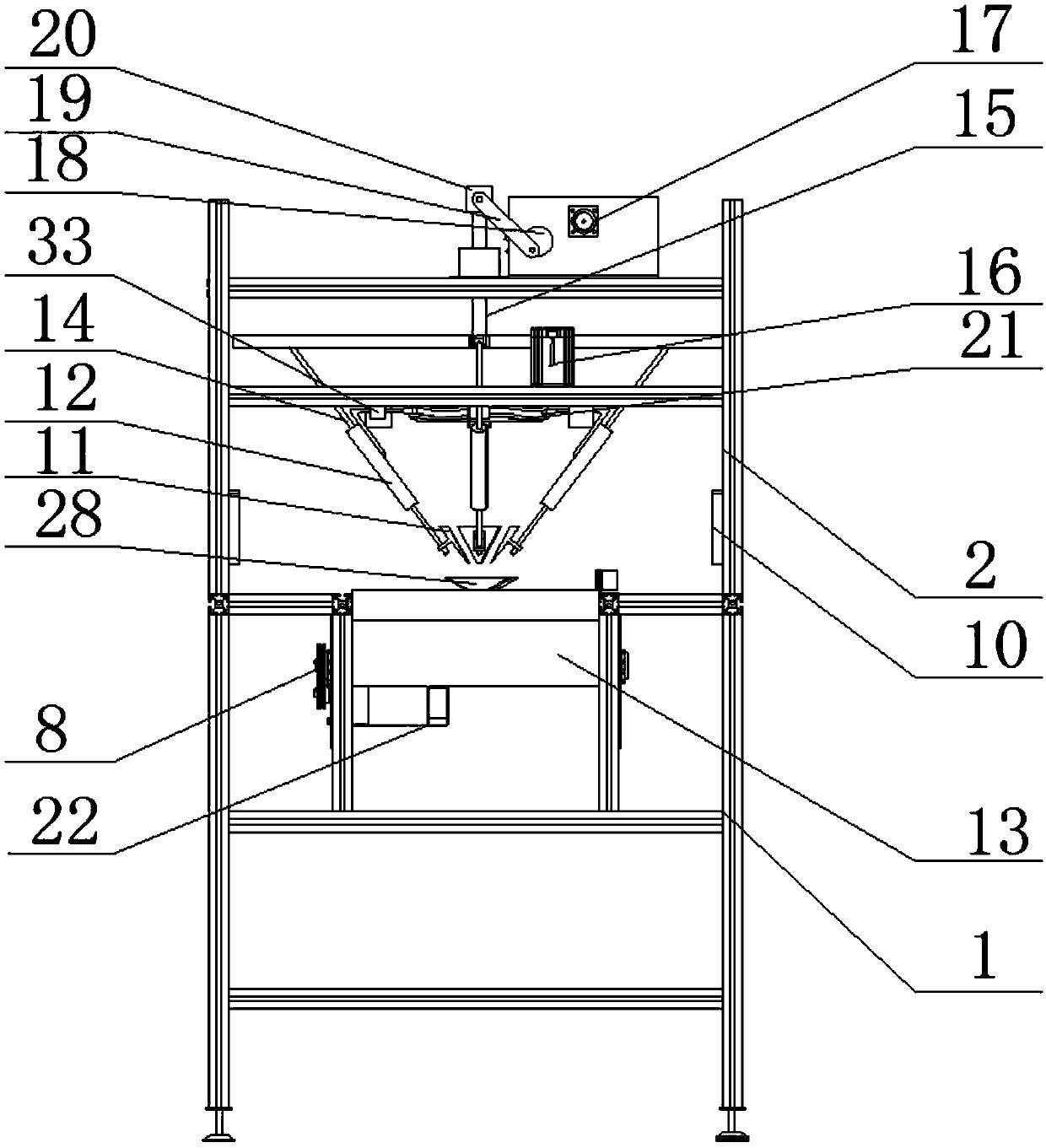

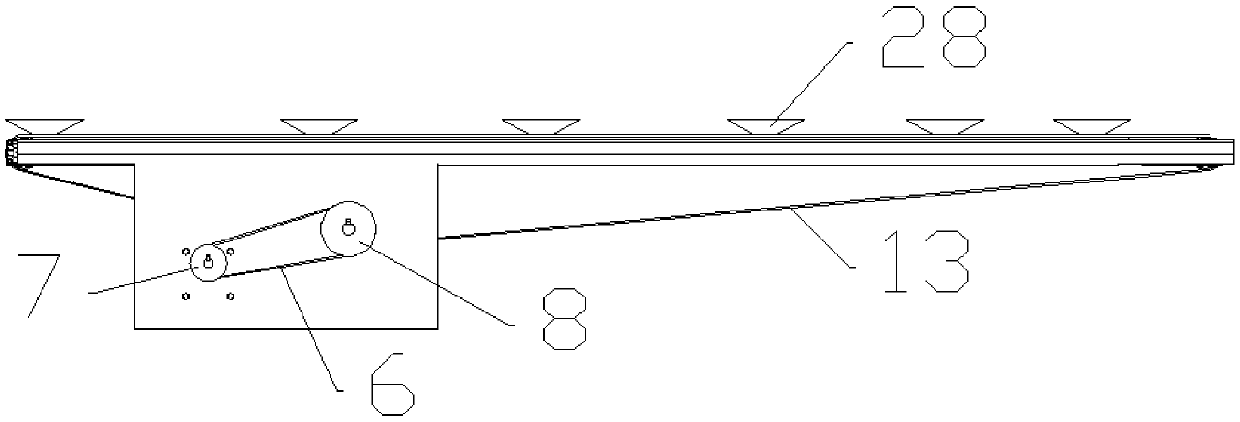

ActiveCN108189112BRealize continuous directional conveyingSuitable for cutting workMetal working apparatusFood treatmentProduction lineFixed frame

The invention discloses a two-stage conveying type automatic broccoli dicing and decoring production line. Existing broccoli dicing devices have the defect that feeding is discontinuous and consequently broccoli can be fed only after being placed in a specific form. The two-stage conveying type automatic broccoli dicing and decoring production line comprises a machine frame, a feeding device, a first-stage conveying device, a shifting device, a guide device, a second-stage conveying device, a separating device, an arc guide plate, a dicing device and an arc broccoli cutter. The feeding devicecomprises a feeding hopper and a rubber scraper plate. The guide device comprises a guide square pipe, a falling guide plate and a photoelectric sensor. The separating device comprises a separating motor, a fixed plate, a guide block, a crank, a connecting rod, a sliding rod and a separating plate. The dicing device comprises dicing rotating shafts, a third stepping motor, dicing chain wheels, fixing frame sets, dicing assemblies, springs, dicing chains and dicing cams. The two-stage conveying type automatic broccoli dicing and decoring production line can achieve continuous directional conveying of broccoli in a fixed posture, and thus workers can complete uniform dicing work of broccoli only by randomly loading broccoli into the feeding hopper.

Owner:贵州放心粮仓电子商务有限公司

A device for dicing canned pineapple

ActiveCN111923094BEasy to sliceEvenly dicedMetal working apparatusTinned pineappleStructural engineering

The invention relates to a cutting device, in particular to a cutting device for canned pineapple. A device for cutting canned pineapple with simple operation mode and high working efficiency is provided. A device for cutting canned pineapple, comprising: a mounting frame; a feeding frame mounted on the mounting frame; a lifting mechanism mounted on the mounting Swipe to work. In the present invention, a lifting mechanism is provided, and the pressing plate presses the pineapple so that the pineapple is automatically cut into pieces, and the pineapple core and the pineapple block are automatically separated through a cutting mold, so that the cutting method of the pineapple is more convenient. Cooperating with each other, the pineapple is cut twice to make the pineapple cut more uniform and improve the work efficiency of the workers. The use of the equipment is more convenient through the hollow board and the storage box.

Owner:浏阳骅韵实业有限公司

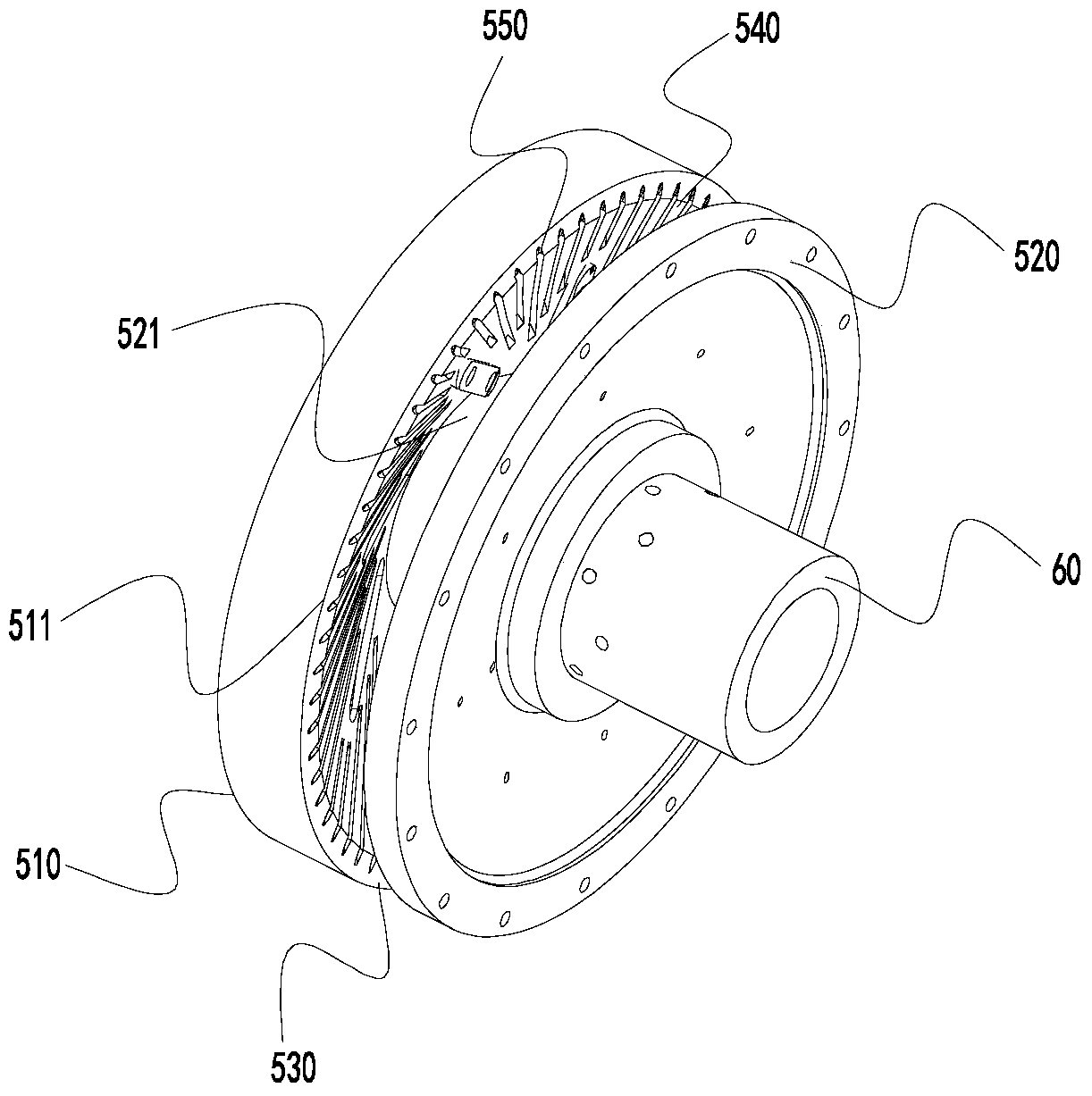

A kind of space cam type broccoli automatic dicing machine and its dicing method

ActiveCN107599034BImprove uniformity of cuttingHigh degree of intelligenceMetal working apparatusKnife bladesOpen mouth

Owner:NINGBO UNIV

A candy cutting and packaging machine

InactiveCN104192377BEvenly dicedAvoid stickingWrapper folding/bending apparatusPackaging automatic controlEngineeringPackaging machine

The invention discloses a candy dicing and packing all-in-one machine which comprises a dicing workbench and a packing workbench. The dicing workbench and the packing workbench are arranged in a connecting mode, and a feeding plate and a dicing mechanism are arranged on the dicing workbench. A candy conveying mechanism, a candy settling mechanism and a candy packing mechanism are arranged on the packing workbench in sequence, the candy conveying mechanism comprises a candy conveying motor and a conveying belt, and the candy settling mechanism comprises a candy settling motor, a candy dividing rod and a temperature controller. A paper feeding device is arranged on the packing workbench, the paper feeding device corresponds to the lower portion of the candy packing mechanism, and the paper feeding device is connected with a paper storage box. A control box is further arranged in the packing workbench and is arranged below the paper storage box, and the control box is connected with the paper feeding device and the candy packing mechanism. The candy dicing and packing all-in-one machine can evenly dice and pack candy, is reasonable in structure, avoids candy adhesion and accumulation, integrally completes dicing and packing, and is high in production efficiency.

Owner:祝建飞

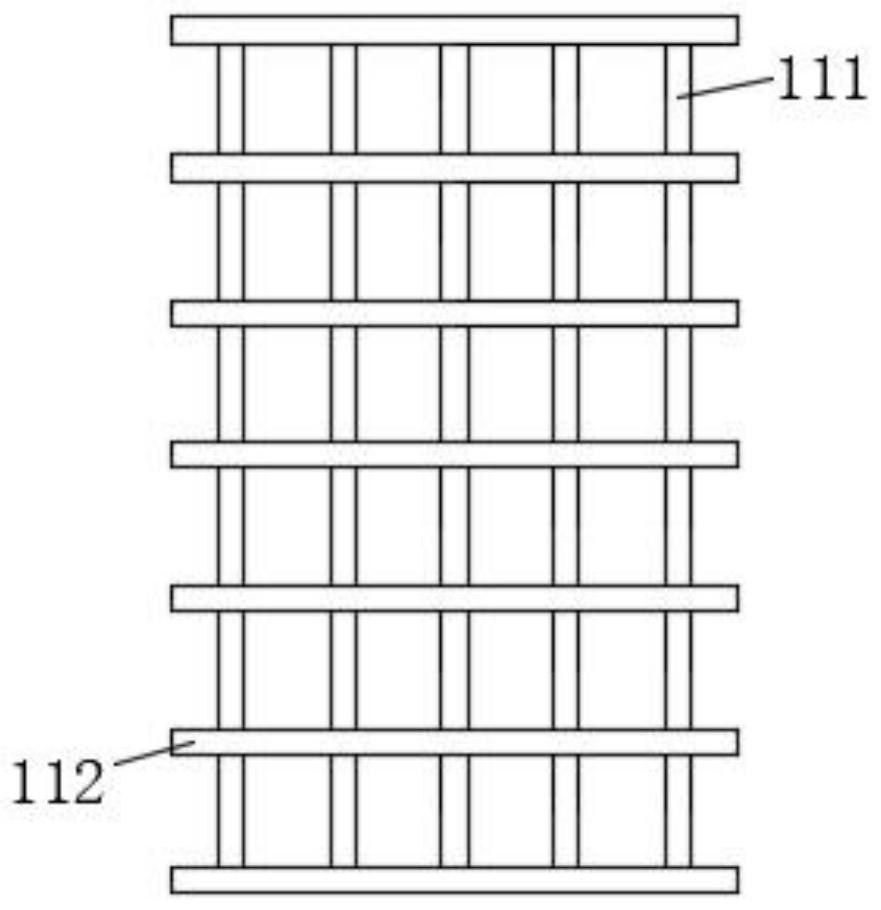

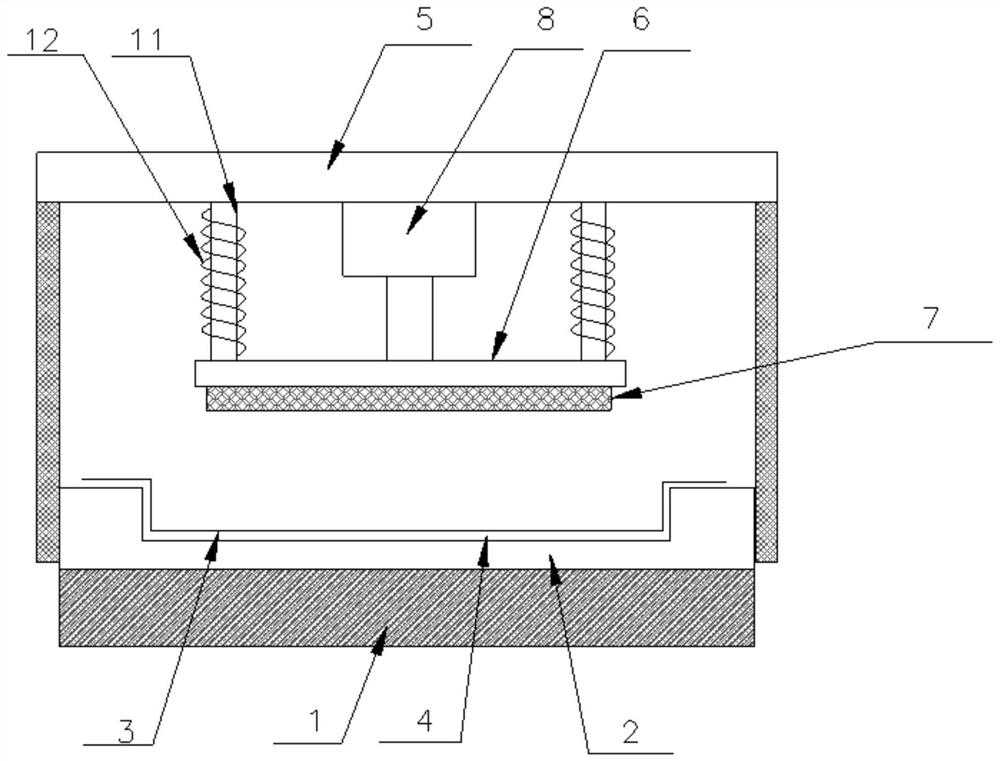

Bean curd cutting mold for bean curd processing

InactiveCN114274221AEvenly dicedImprove cutting efficiencyMetal working apparatusBiotechnologyEngineering

The invention discloses a tofu cutting mold for tofu processing, which comprises an upper mold mechanism and a lower mold mechanism, the lower mold mechanism comprises a bottom support, a lower mold and a placing groove, the lower mold is fixedly mounted on the bottom support, a groove is formed in the upper end surface of the lower mold, the placing groove is placed in the groove, and the upper mold mechanism comprises an upper support, an upper mold mounting rack, an upper mold assembly and a lifting assembly. The two sides of the upper support are fixedly installed on the two sides of the bottom support, the upper mold assembly is installed on the upper mold installation frame, and the lifting assembly is installed on a top plate of the upper support and an upper mold installation frame support. An adopted placing groove is convenient for operators to take and place tofu, and the tofu processing efficiency is further improved.

Owner:刘小平

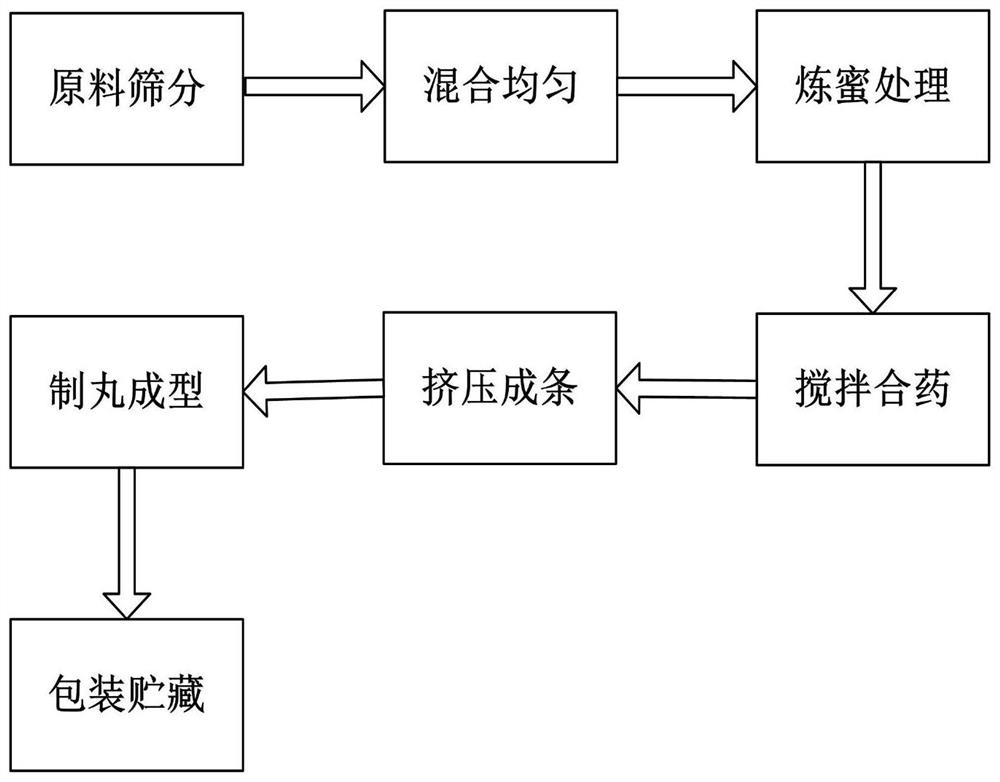

A kind of preparation technology of Bazhen pill

ActiveCN111590950BUniform diameterEfficient cuttingPharmaceutical product form changeShaping pressStructural engineeringProcess engineering

The invention relates to a preparation process of Bazhen Pills, which comprises a bottom plate, a granulation device and a kneading device. A granulation device is installed on the upper end of the bottom plate, and an empty groove is arranged in the middle of the lower end of the granulation device, and a kneading device is arranged in the empty groove. , The kneading device is installed on the bottom plate. The present invention can solve the problem that the existing equipment has poor cutting effect and uneven cutting when cutting raw materials, resulting in different diameters of the prepared Bazhen pills, and the inability to quickly clean the cutting rollers after cutting. As a result, a large amount of impurities are easy to accumulate on the cutting roller, which affects the cutting effect. At the same time, when the existing equipment is processing Bazhen pills, it cannot effectively finish the cut raw materials, resulting in irregular pills after preparation, which affects the cutting effect. Subsequent processing of pills and other problems.

Owner:池州市九华府金莲智慧农业有限公司

Sweet potato stripping and slicing device

InactiveCN105459174AEvenly dicedPrevent extrusionMetal working apparatusBlock matchMechanical engineering

The invention particularly discloses a sweet potato stripping and slicing device. The sweet potato stripping and slicing device comprises a box body and a cutter mechanism located in the box body. The box body comprises a hollow rectangular inner cavity. Two symmetrical vertical slide grooves are formed in the two symmetrical side faces of the box body. The cutter mechanism comprises two slide blocks matched with the vertical slide grooves, a cutter rod and a plurality of cutters used for stripping and slicing sweet potatoes. The two slide blocks are in sliding fit with the two vertical slide grooves respectively. The two ends of the cutter rod are welded to the slide blocks respectively. The cutters are evenly distributed in the length direction of the cutter rod. The cutting edges of the cutters vertically face downwards. The cutter backs are welded to the rod. The two sides of the cutters are in sliding fit with the side faces of the box body. Handles are arranged on the two slide blocks respectively. The sweet potato stripping and slicing device is simple in structure, convenient to use and practical, and the thickness of cut sweet potato blocks is uniform.

Owner:CHONGQING XUPENG ECOLOGICAL AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com