Double-screw assembly for extrusion molding processing of nylon and glass fiber, and processing method thereof

A glass fiber and twin-screw technology, which is applied in the field of nylon extrusion processing, can solve the problems of the decline in the quality of nylon and glass fiber extrusion processing products, and the screw combination cannot be well satisfied, so as to improve the shearing efficiency and extrusion. Effect, the effect of uniform slitting of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

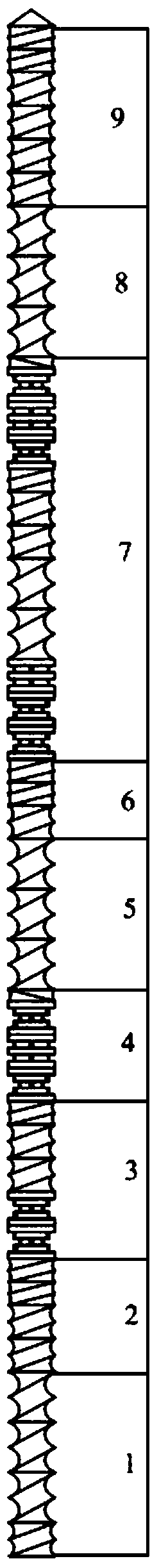

[0035] See attached figure 1 , a twin-screw combination used for nylon and glass fiber extrusion processing of the present invention includes two screws, the two screws mesh with each other, and each screw includes a plurality of threaded elements and a plurality of kneading elements; each screw is divided into Conveying section 1, conveying compression section 2, plasticizing mixing section 3, first dispersing mixing section 4, natural exhaust side feeding and glass fiber section 5, glass fiber distribution mixing section 6, second dispersing mixing section connected in sequence 7. The vacuum exhaust section 8 and the conveying homogenization section 9 have a total of 9 sections; multiple thread elements include multiple forward thread elements and multiple reverse thread elements, and multiple kneading elements include multiple forward kneading elements and multiple Reverse kneading elements, threaded elements include any one or more of 22 / 11, 22 / 22, 32 / 32 or 48 / 48, kneading...

Embodiment 2

[0051] A twin-screw combination used for nylon and glass fiber extrusion processing of the present invention comprises two screws, the two screws mesh with each other, and each screw includes a plurality of threaded elements and a plurality of kneading elements; each screw is divided into Conveying section, conveying compression section, plasticizing mixing section, first dispersion mixing section, natural exhaust side feeding plus glass fiber section, glass fiber distribution mixing section, second dispersion mixing section, vacuum exhaust section and conveying section connected in sequence The homogenization section has a total of 9 sections; multiple screw elements include multiple forward screw elements and multiple reverse screw elements, multiple kneading elements include multiple forward kneading elements and multiple reverse kneading elements, screw elements include 22 / Any one or several of 11, 22 / 22, 32 / 32 or 48 / 48, the kneading element includes any one or several of ...

Embodiment 3

[0067] A twin-screw combination used for nylon and glass fiber extrusion processing of the present invention comprises two screws, the two screws mesh with each other, and each screw includes a plurality of threaded elements and a plurality of kneading elements; each screw is divided into Conveying section, conveying compression section, plasticizing mixing section, first dispersion mixing section, natural exhaust side feeding plus glass fiber section, glass fiber distribution mixing section, second dispersion mixing section, vacuum exhaust section and conveying section connected in sequence The homogenization section has a total of 9 sections; multiple screw elements include multiple forward screw elements and multiple reverse screw elements, multiple kneading elements include multiple forward kneading elements and multiple reverse kneading elements, screw elements include 22 / Any one or several of 11, 22 / 22, 32 / 32 or 48 / 48, the kneading element includes any one or several of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com