Plant-oil-based asphalt modifier, modified asphalt containing modifier and preparation of plant-oil-based asphalt modifier

A kind of asphalt modifier, vegetable oil-based technology, applied in the direction of building structure, building components, building insulation materials, etc., can solve the problems of single composition, low modification equipment requirements, etc., achieve low production cost, reduce additives and additives Dosage, to improve the effect of low temperature brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

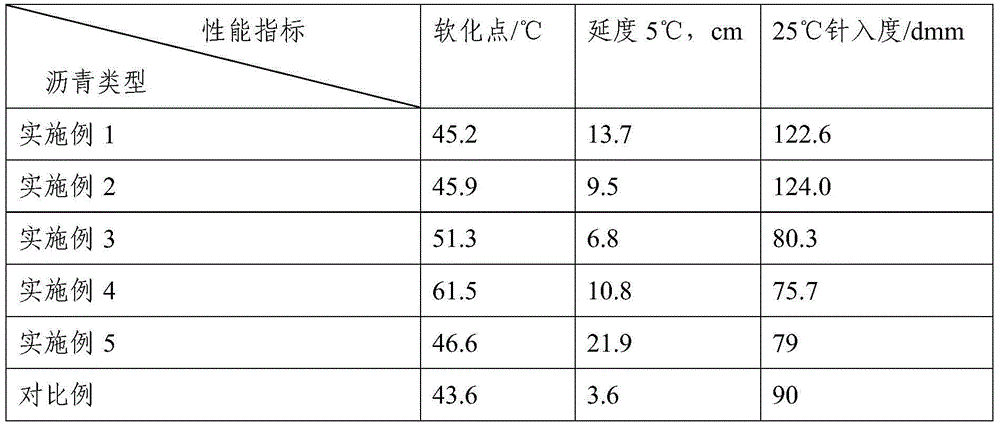

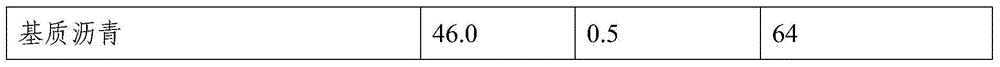

Examples

Embodiment 1

[0041] The formula of vegetable oil-based polyurethane modifier is as follows:

[0042] Calculate the corresponding amount of liquefied diphenylmethane diisocyanate (MDI-100LL, produced by Yantai Wanhua Company, with a free NCO content of 28-30%) as the isocyanate index R (NCO / OH) is 1.8, and the corresponding amount of castor oil polyol (Sinopharm Group, AR, hydroxyl value 164mgKOH / g), account for 1% inhibitor orthophosphoric acid of liquefied MDI and castor oil polyol gross mass, account for the acetone solvent of 8% of total reactant volume: in order to regulate system viscosity, 8% of the total volume of solvent is added in step 1), and 10% and 82% are added in step 2) and step 3).

[0043] Dehydration of vegetable oil polyols: castor oil polyols were dehydrated under vacuum at 110° C. for 2 hours at 0.1 MPa, and cooled to room temperature under vacuum conditions.

[0044] The preparation method is:

[0045]1) Add 1% of the total mass of the polymerization inhibitor orth...

Embodiment 2

[0051] The formula of present embodiment modifying agent is as follows:

[0052] Calculate the corresponding amount of liquefied diphenylmethane diisocyanate (MDI-100LL, produced by Yantai Wanhua Company, with a free NCO content of 28% to 30% by mass) according to the isocyanate index R (NCO / OH) of 1.6, and the corresponding amount of castor oil Polyhydric alcohol (Sinopharm Group, AR, hydroxyl value 164mgKOH / g), account for 1% inhibitor orthophosphoric acid of castor oil polyol and liquefied MDI gross mass, 7% acetone solvent regulation system viscosity of whole reactant volume. In order to adjust the viscosity of the system, 5% of the total solvent volume is added in step 1), and 10% and 85% are added in step 2) and step 3).

[0053] The content of free NCO groups in the liquefied MDI is in excess of 60% relative to the content of active hydrogen contained in the hydroxyl groups in castor oil.

[0054] The dehydration steps for preparing vegetable oil-based polyurethane mod...

Embodiment 3

[0058] The formula of present embodiment modifying agent is as follows:

[0059] Calculate the corresponding amount of liquefied diphenylmethane diisocyanate (MDI-100LL, produced by Yantai Wanhua Company, with a free NCO content of 28-30%) as the isocyanate index R (NCO / OH) is 1.6, and the corresponding amount of castor oil polyol (Sinopharm Group, AR, hydroxyl value 164mgKOH / g), the 1% inhibitor orthophosphoric acid of total mass, the acetone solvent that accounts for 15.8% of total reactant volume is used for regulating system viscosity, wherein free NCO group in the liquefied MDI The amount of the substance of the group is in excess of 60% relative to the amount of the substance of the active hydrogen contained in the hydroxyl group in the castor oil.

[0060] The dehydration steps for preparing vegetable oil-based polyurethane modifier and vegetable oil polyol are the same as in Example 1.

[0061] Wherein, the isocyanate index in step 1) is R=1.6, and the heat preservati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com