High-strength PE (polyethylene) wood-plastic composite material and preparation method thereof

A wood-plastic composite material, high-strength technology, applied in the field of high-strength PE wood-plastic composite material and its preparation, to achieve good tensile strength, promote interface properties, and excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

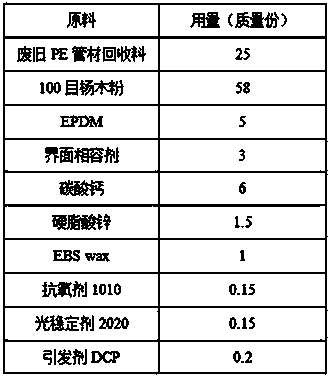

Embodiment 1

[0021] A high-strength PE wood-plastic composite material, its raw material composition is as follows:

[0022] Table 1:

[0023]

[0024] Wherein, described interfacial compatibilizer is prepared like this:

[0025] 250 mass parts of acrylic acid, 250 mass parts of anhydrous polyethyleneimine (M w =2000) and 0.5 parts by mass of phenothiazine were added into the reactor, nitrogen gas was passed through, heated to 130°C, stirred and reacted for 2 hours, and the product was obtained.

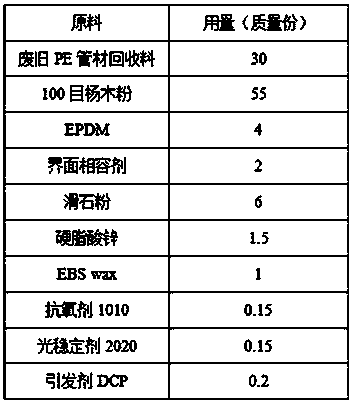

Embodiment 2

[0027] A high-strength PE wood-plastic composite material, its raw material composition is as follows:

[0028] Table 2:

[0029]

[0030] Wherein, described interfacial compatibilizer is prepared like this:

[0031] 150 parts by mass of methacrylic acid, 400 parts by mass of anhydrous polyethyleneimine (M w =2000) and 0.7 parts by mass of 1,4-hydroquinone were added into the reactor, nitrogen was introduced, heated to 110°C, stirred and reacted for 3 hours to obtain the product.

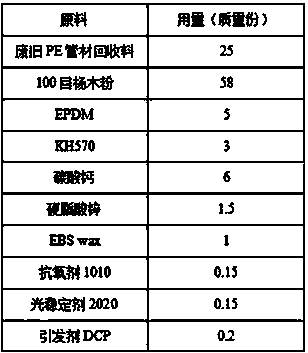

Embodiment 3

[0033] A high-strength PE wood-plastic composite material, its raw material composition is as follows:

[0034] table 3:

[0035]

[0036] Wherein, described interfacial compatibilizer is prepared like this:

[0037] 100 parts by mass of acrylic acid, 500 parts by mass of anhydrous polyethyleneimine (M w =4000) and 0.3 parts by mass of 2,4-dimethyl-6-tert-butylphenol were added to a 1L reactor, nitrogen gas was passed through, heated to 150°C, stirred and reacted for 1 hour, and the product was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com