Two-level conveyor type broccoli automatic cutting and core production line

A broccoli and conveying technology, which is applied in the field of two-stage conveying broccoli automatic cutting and coring production line, can solve the problems of discontinuous feeding, limit cutting efficiency, increase worker training costs, etc., and achieve efficiency and reliability High, high work efficiency, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing.

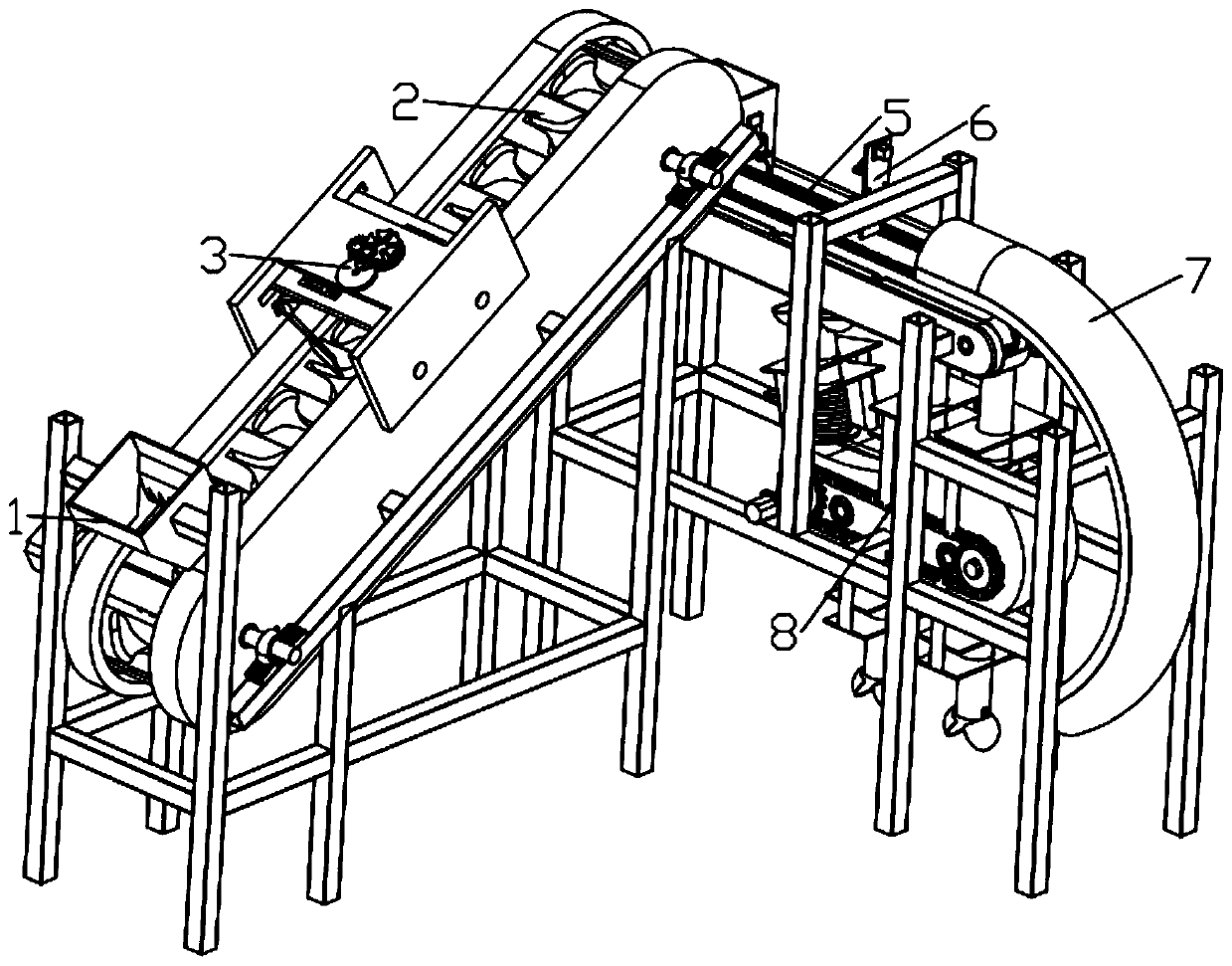

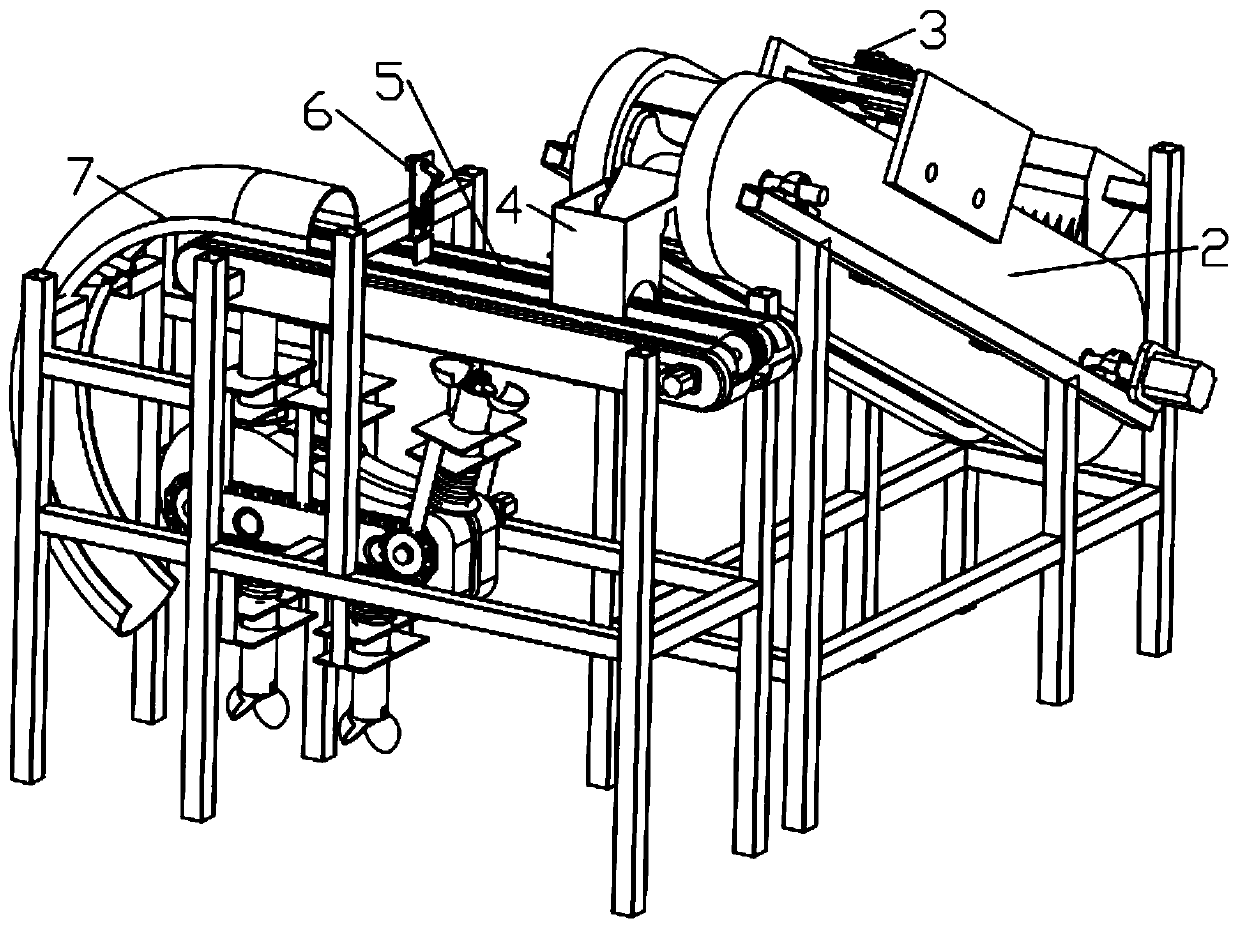

[0045] Such as figure 1 with 2 As shown, the two-stage conveying type broccoli automatic dicing and coring production line includes a frame, a feeding device 1, a primary conveying device 2, a dialing device 3, a guiding device 4, a secondary conveying device 5, an isolation device 6, Arc guide plate 7, block cutting device 8 and arc-shaped flower cutting knife 9.

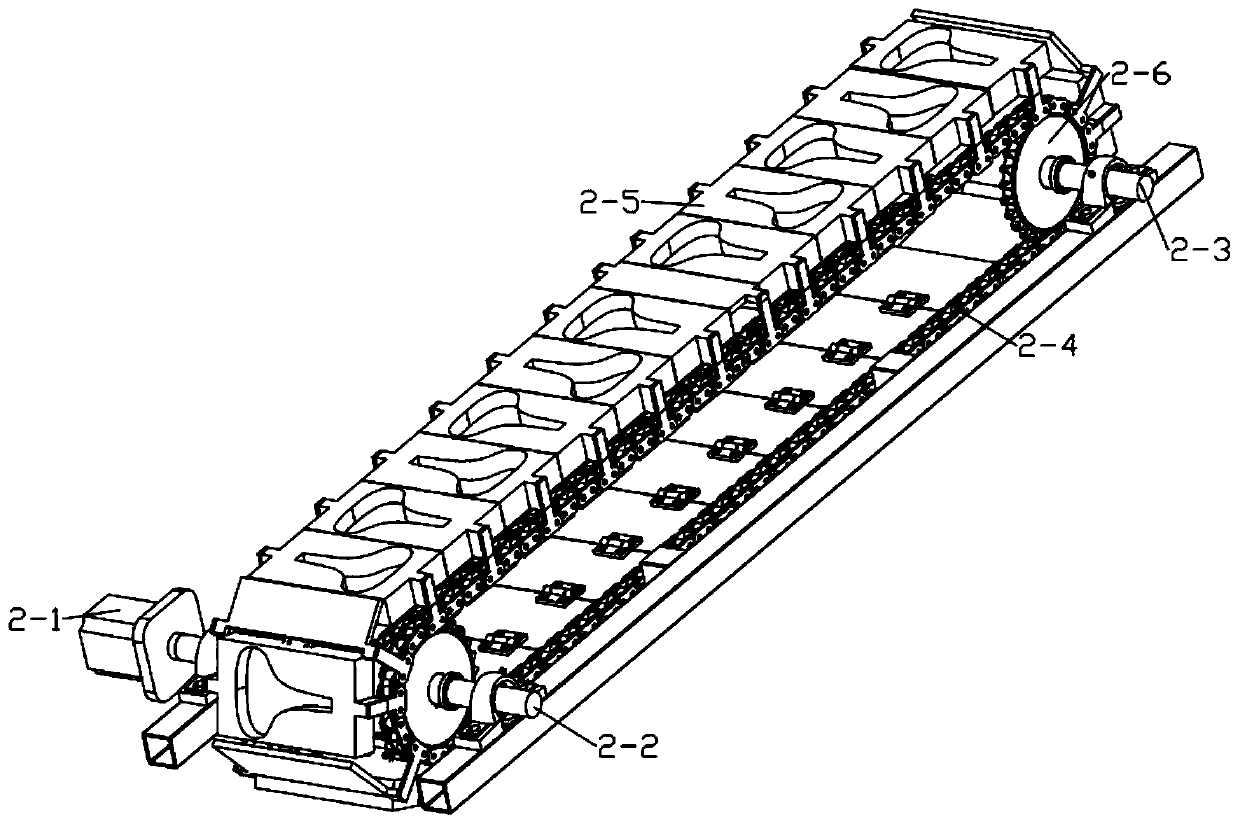

[0046] Such as figure 1 , 2 As shown in and 3, the primary conveying device 2 includes a first stepper motor 2-1, a primary inlet shaft 2-2, a primary outlet shaft 2-3, a chain cover, a conveyor sprocket 2-6, a conveyor chain 2- 4 and transport block groups. The horizontally arranged primary inlet shaft 2-2 and primary outlet shaft 2-3 are all supported on the frame. The primary inlet shaft 2-2 is arranged at the inlet end of the primary conveying device. The primary outlet shaft 2-3 is arranged at the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com