Full-automatic aggregation machine

A granulator and fully automatic technology, which is applied in the field of plastic granulation processing, can solve the problems of a large amount of leftover materials, high energy consumption of equipment, and low production efficiency, so as to achieve high production efficiency, good effect and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

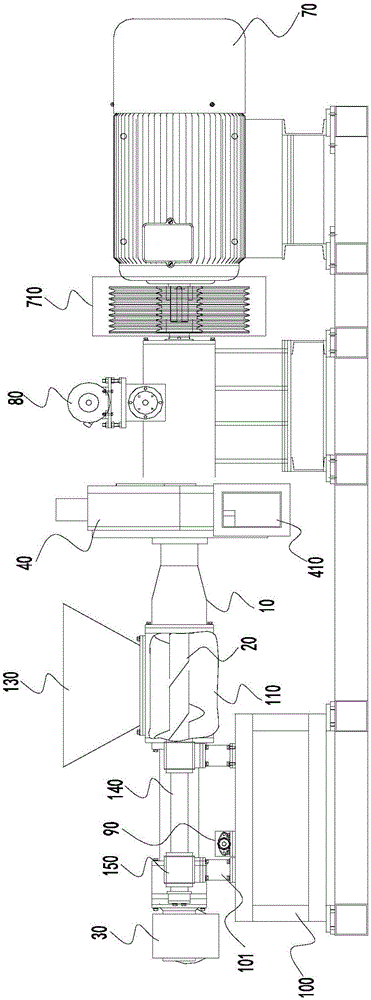

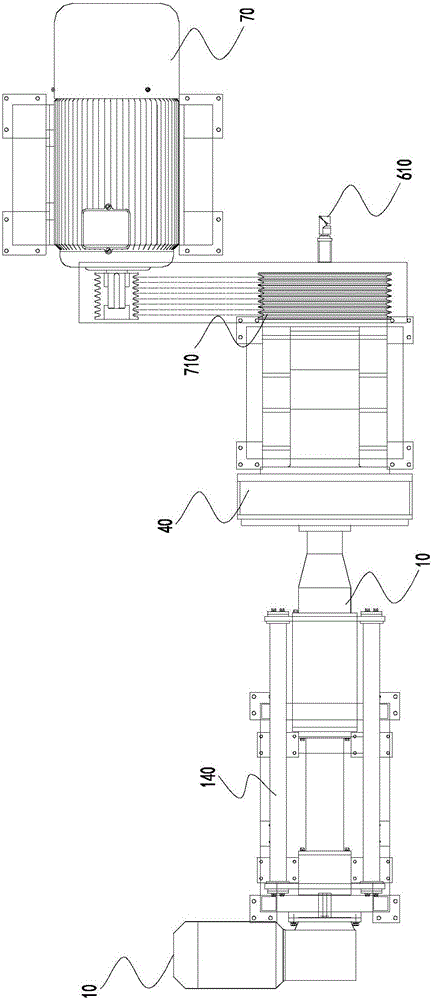

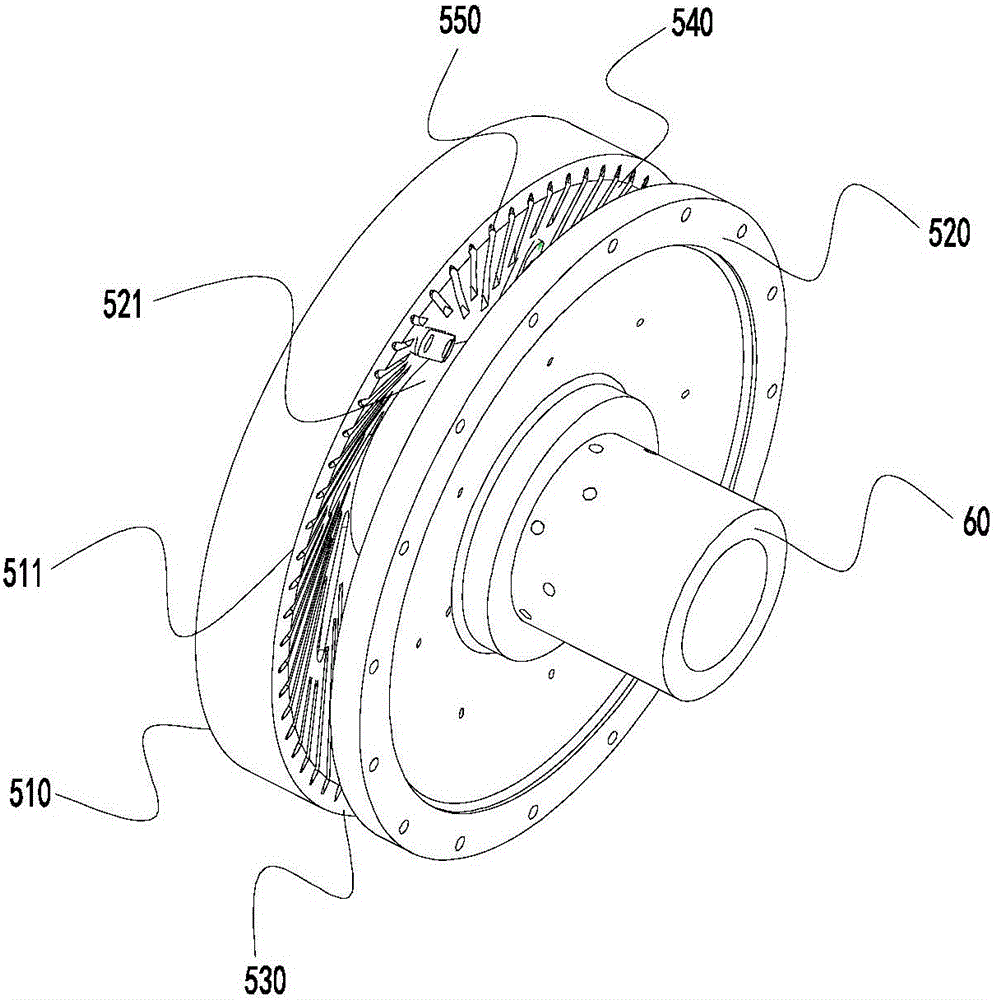

[0026] Such as Figure 1 to Figure 3 As shown, a fully automatic agglomeration machine includes a feed cylinder 10 provided with a feed chamber 110, a feed screw 20 located in the feed chamber 110, a first drive device 30 for driving the feed screw 20 to rotate, and a grinding disc shell 410, the fixed cutterhead 510 and the movable cutterhead 520 located in the grinding disc shell 410, the main shaft 60 sleeved with the movable cutter head 520, the second drive device 70 for driving the main shaft 60 to rotate, and the third drive device for driving the main shaft 60 to move along the central axis. Drive device 80, controller (not identified in the accompanying drawings), fixed cutter head 510 and movable cutter head 520 are arranged oppositely, and form abrasive material chamber 530 between movable cutter head 520, and the bottom of grinding disc shell 410 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com