Patents

Literature

102results about How to "Full friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reducing contact resistance based on low-melting-point metal and oxide thereof

ActiveCN103066475AReduce contact resistanceImprove efficiencyLine/current collector detailsMetal/alloy conductorsIndiumRubidium

The invention relates to a method for reducing contact resistance based on low-melting-point metal and an oxide thereof. By coating the low-melting-point metal and the oxide thereof between electric terminals connected with machinery, the contact resistance between the mechanical electric terminals is reduced effectively. The invention further relates to a conductive paste composing of the low-melting-point metal and the oxide thereof. The oxide takes 0.05% to 50% of the total weight of the conductive paste. The low-melting-point metal is one type or a combination of any two types selected from sodium, potassium, lithium, rubidium, cesium, gallium, indium, mercury, lead bismuth alloy, gallium-base binary alloy, gallium-base complex alloy, indium-base alloy, bismuth-base alloy, mercury-base alloy and sodium-potassium alloy which are lower than 200 DEG C in melting point. With the compound of the low-melting-point metal and the oxide thereof as the conducting medium, the method for reducing contact resistance can effectively reduce the contact resistance between the electric terminals connected with the machinery, significantly reduce the contact resistance heat effect, improve transmission efficiency of electric energy and prolong the service life of the machinery. The method for reducing contact resistance based on the low-melting-point metal and the oxide thereof can be widely applied to the technical fields of electric power and energy.

Owner:郭瑞

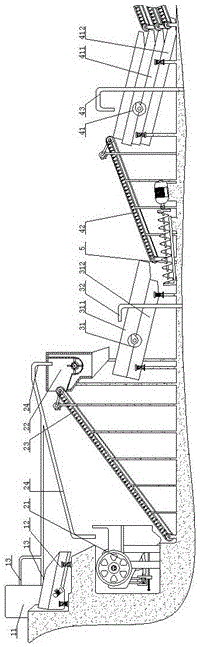

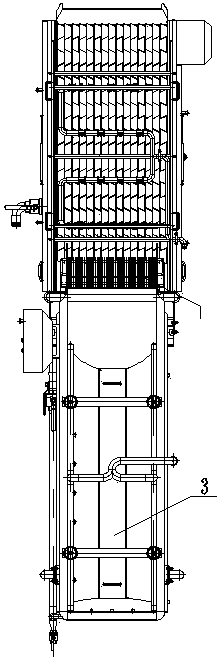

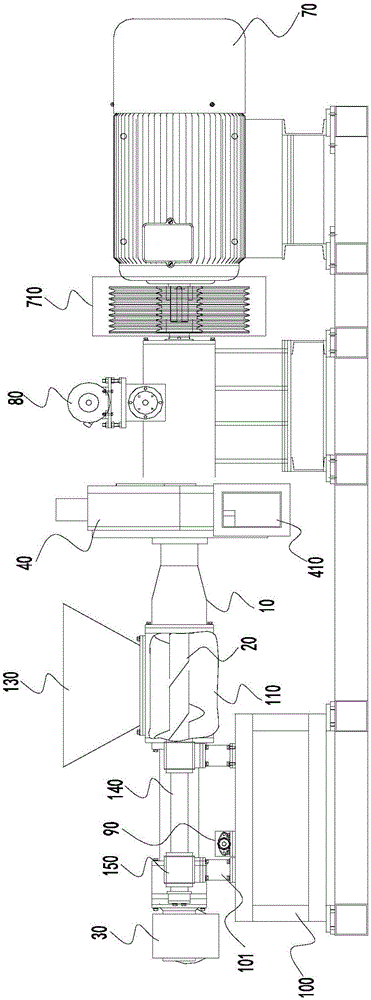

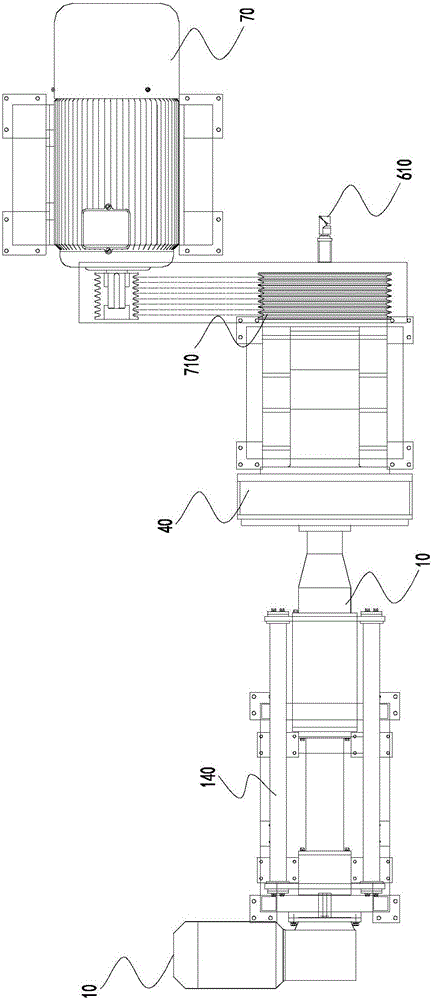

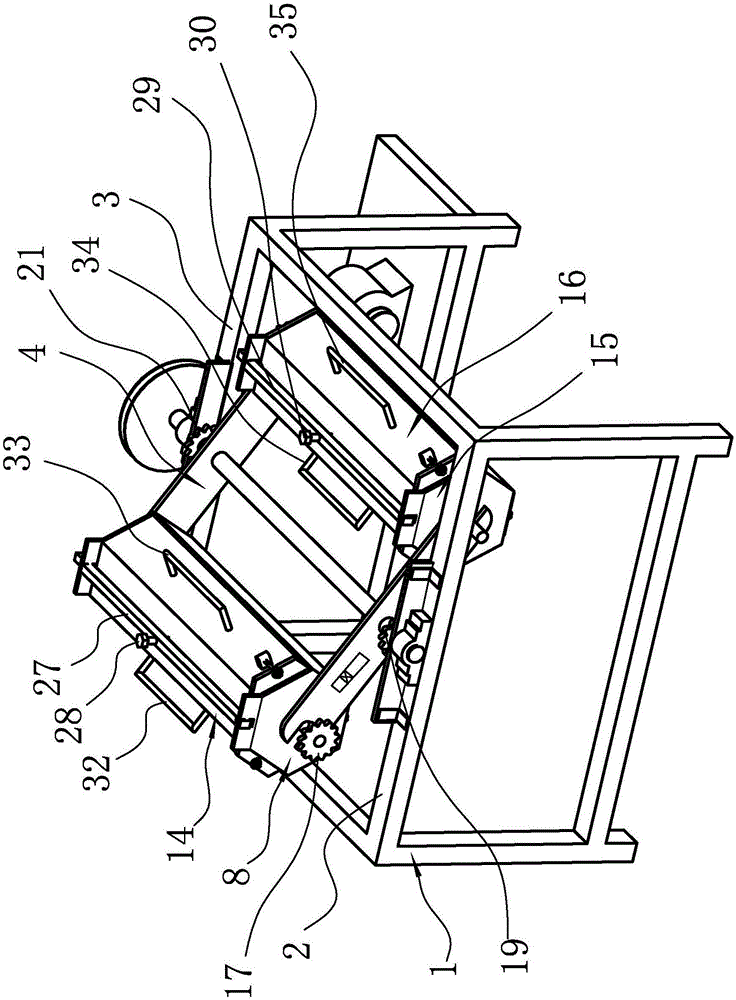

Mudstone environmental protection regeneration system

The invention discloses a mudstone environmental protection regeneration system. The mudstone environmental protection regeneration system comprises a feeding mechanism; the feeding mechanism comprises a stock bin, a vibrating feeding machine, a crushing mechanism which comprises a jaw type rough crushing machine and a hammer type fine crushing machine, a sand and gravel separating mechanism, a gravel fine separating mechanism and a mud and sand water passing mechanism; the sand and gravel separating mechanism comprises a rough separating vibrating screen; the rough separating vibrating screen comprises a gravel layer and a mud and sand layer; the gravel fine separating mechanism comprises a fine separating vibrating screen; the fine separating vibrating screen comprises a multi-layer finished product layer and a fine sand layer; the mud and sand water passing mechanism comprises a spiral conveyer; other devices except the spiral conveyer is provided with a spraying water pipe respectively. The mudstone environmental protection regeneration system can crush and clean gravel residues containing soil to enable the gravel residues to be recycled and has huge economic benefits and a remarkable environmental friendly effect.

Owner:魏根友

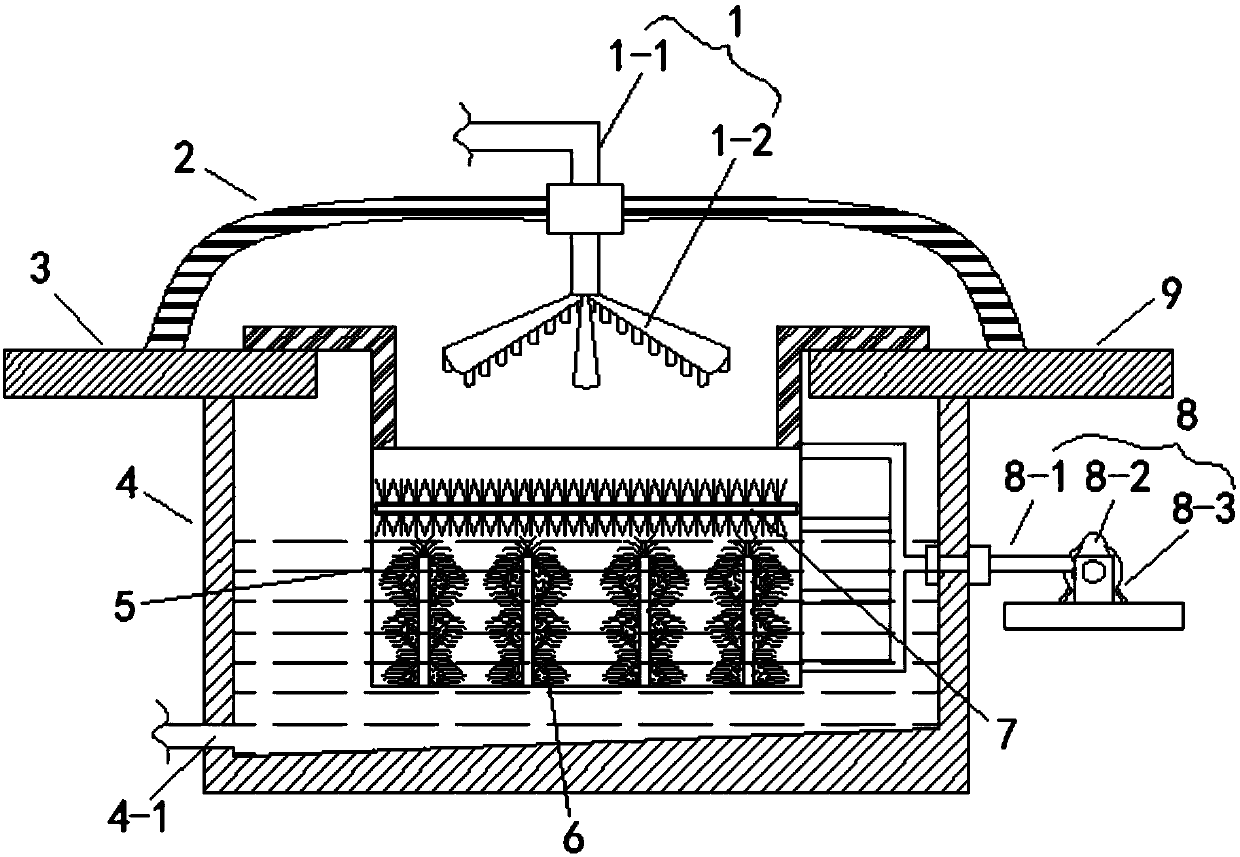

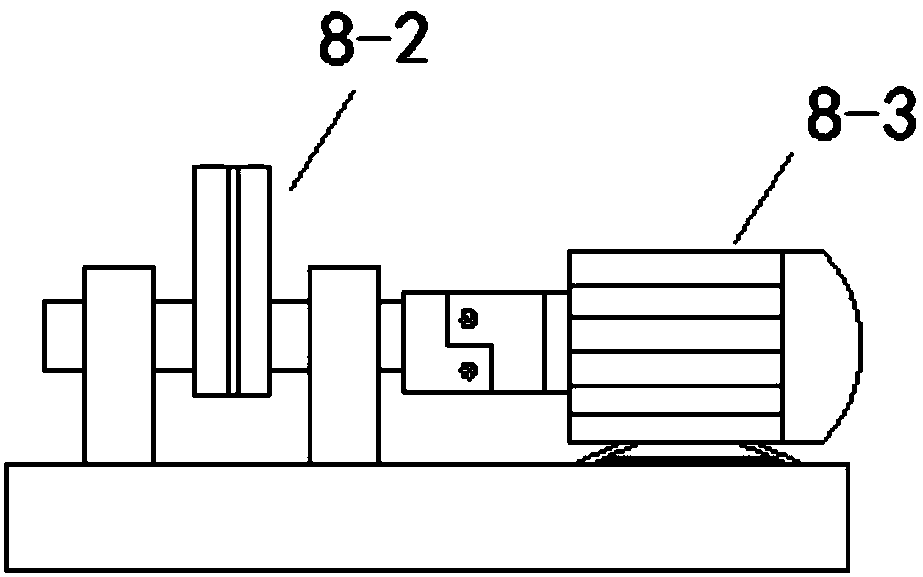

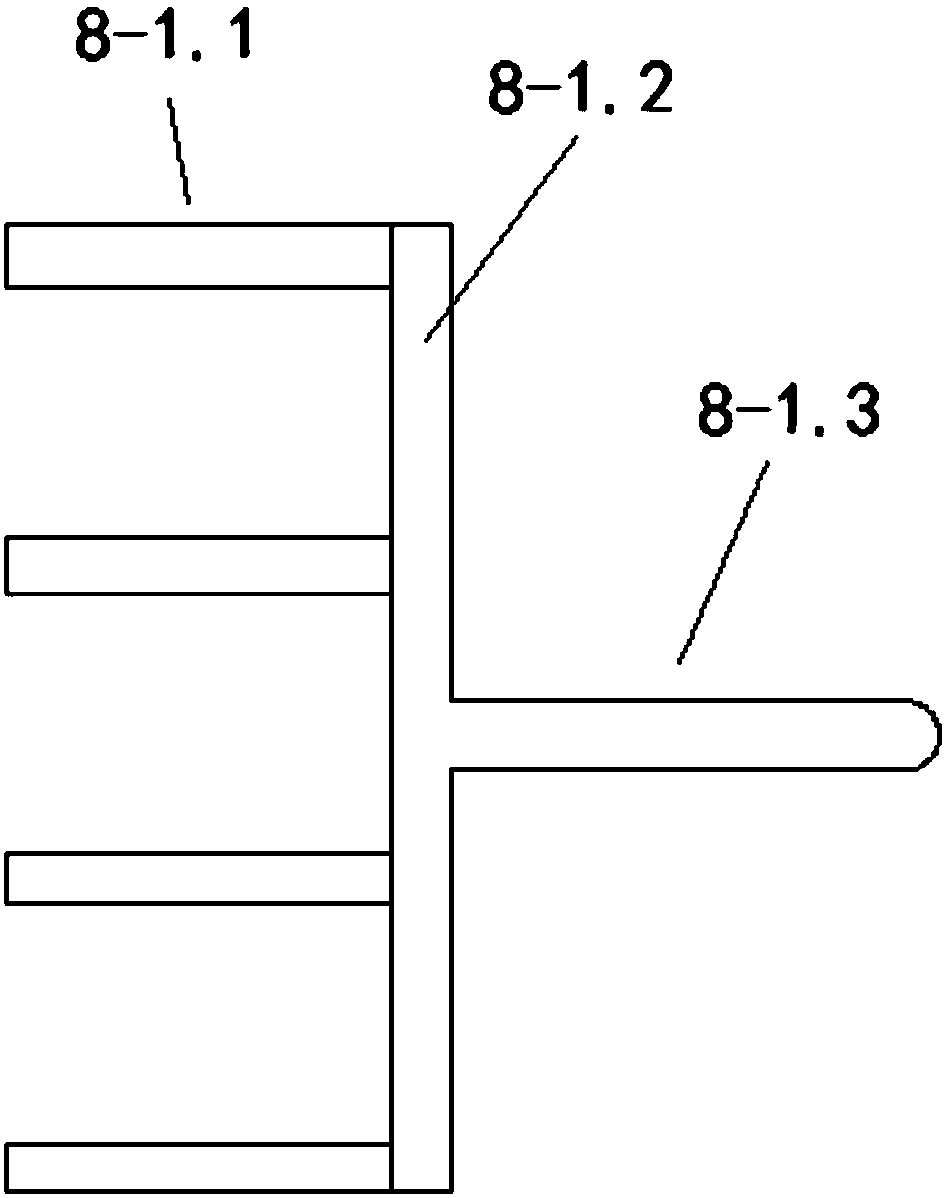

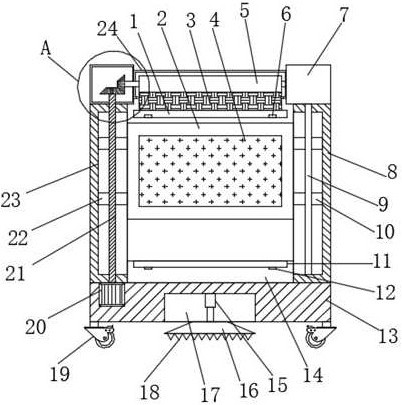

Medicinal material cleaning device

InactiveCN107671035AIntegrity guaranteedSimple structureCleaning using toolsCleaning using liquidsMedicinal herbsEngineering

The invention discloses a medicinal material cleaning device and relates to the technical field of medicinal material machining equipment. The medicinal material cleaning device comprises a cleaning box of which the upper end is provided with an opening and the bottom is provided with a water outlet; the opening of the cleaning box is symmetrically provided with a left supporting plate and a rightsupporting plate, and a cleaning mesh basket which is arranged inside the cleaning box and provided with an upper end opening is erected between the left supporting plate and the right supporting plate; first-stage flexible brushing assemblies and second-stage flexible brushing assemblies are arranged in the cleaning mesh basket from top to bottom in sequence; a spraying assembly for spraying cleaning water to the cleaning mesh basket is arranged above the cleaning mesh basket; and the side wall of the cleaning mesh basket is connected with a vibration assembly capable of driving the cleaningmesh basket to be reciprocating vibration leftwards and rightwards in the cleaning box. Through the medicinal material cleaning device, soil adhering to the surfaces of medicinal materials can be completely removed without damaging skins of the medicinal materials, and integrity of the medicinal materials is maintained.

Owner:成都元始信息科技有限公司

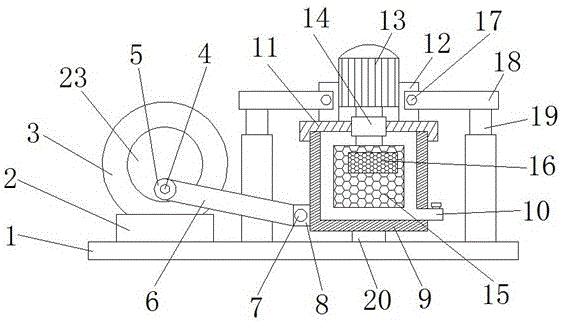

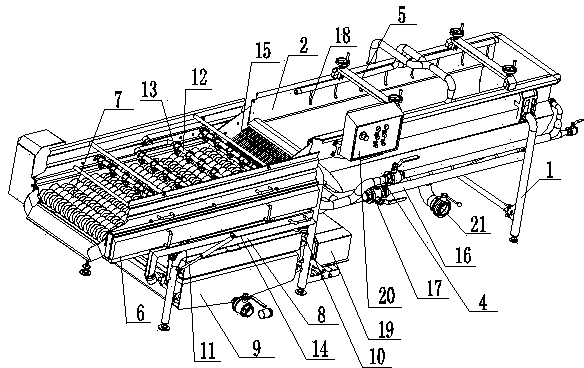

Vegetable cleaning machine

The invention discloses a vegetable cleaning machine which comprises a base plate. A base is fixedly connected to the upper surface of the base plate. A first motor is fixedly connected to the upper surface of the base. A rotating disc is fixedly connected with a rotating shaft of the first motor. The front face of the rotating disc is movably connected with the interior of a first bearing through a first rotating shaft. A first connection rod is fixedly connected to the surface of the first bearing. The end, away from the first bearing, of the first connection rod is fixedly connected with one end of a first fixing rod through a first pin shaft. The other end of the first fixing rod is fixedly connected with one side face of a box body. The other side face of the box body is fixedly connected with a water outlet. By means of cooperation of the first motor and a second motor, the first motor works, water in the box body is rolled, and the second motor works, so that vegetables in a net barrel are rotated, friction force between the vegetables and water is larger, and the vegetable cleaning effect is better.

Owner:WUXI YONGYI PRECISION CASTING

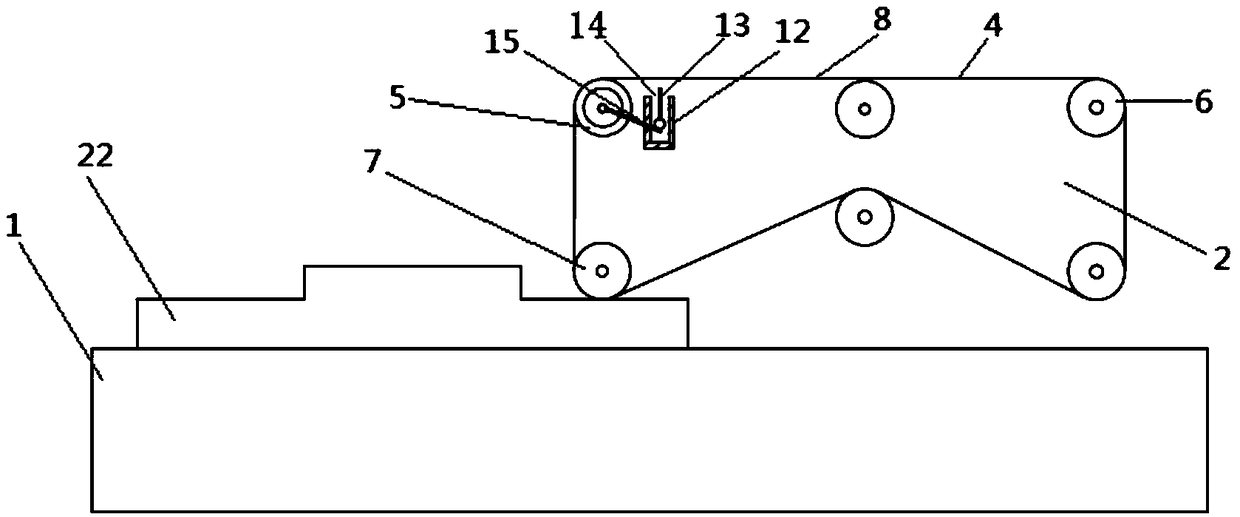

Device for cleaning brake disc

ActiveCN108620353AEasy flipQuick washDrying solid materials without heatCleaning using toolsTraffic accidentEngineering

The invention belongs to the technical field of automobile auxiliary equipment, in particular to a device for cleaning a brake disc. The device comprises a support base, a cleaning part and a power unit, wherein the cleaning part is provided with a rotating belt, a conveying roller, a rotating roller and resisting and pressing rollers; the rotating belt is wound on the conveying roller, the rotating roller and the resisting and pressing rollers; the rotation roller is driven by the power unit to be rotated; the rotation belt comprises a plurality of cleaning belts and a rotating shaft which ishinged to the head parts and the tail parts of the cleaning belts; the cleaning belts are divided into upper layers and lower layers made of different materials; the upper layers and the lower layersare respectively water absorption layers and cleaning layers; the cleaning part also comprises a turning mechanism which is used for turning the cleaning belts; the turning mechanism comprises a turning rod, a sliding slot for guiding the turning rod and a stirring rod which is connected with the end surface of the conveying roller; and a plurality of brace rods for turning the cleaning belts arearranged on the turning rod. By adopting the technical scheme, the requirements on mechanical cleaning and drying-up of the brake disc can be met, and traffic accidents caused by brake failure due tostains formed in the brake disc are avoided.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

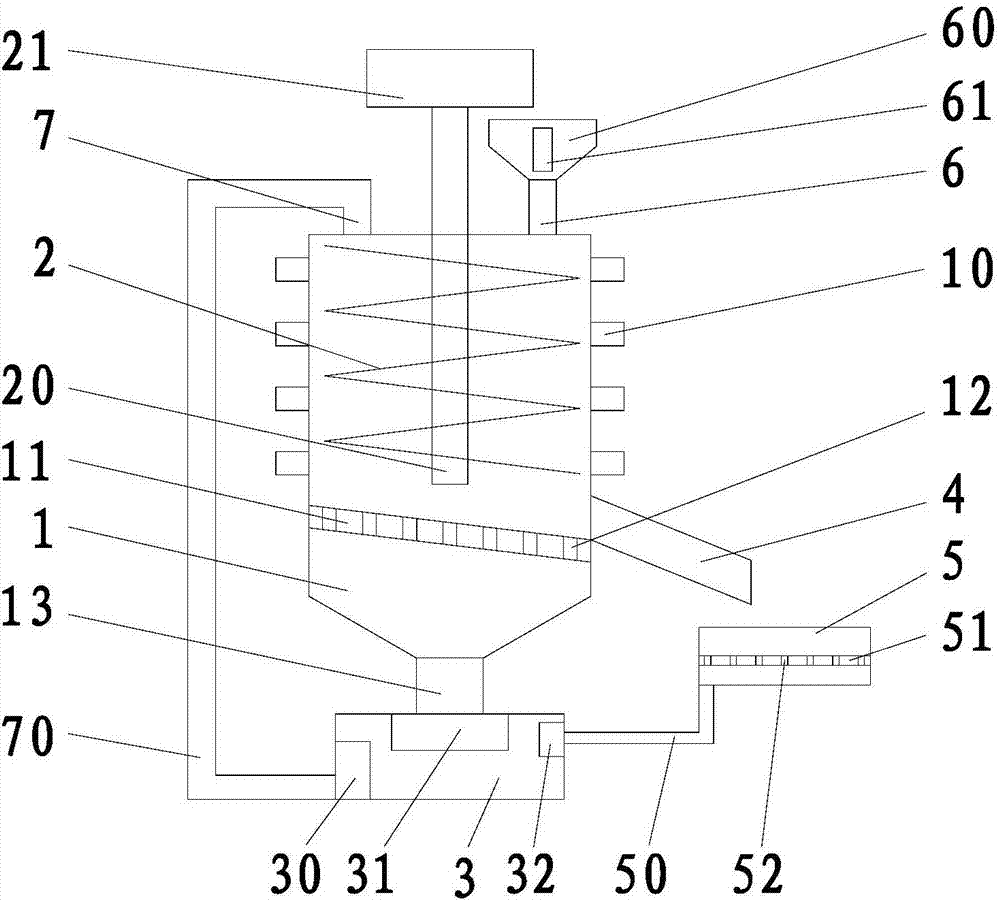

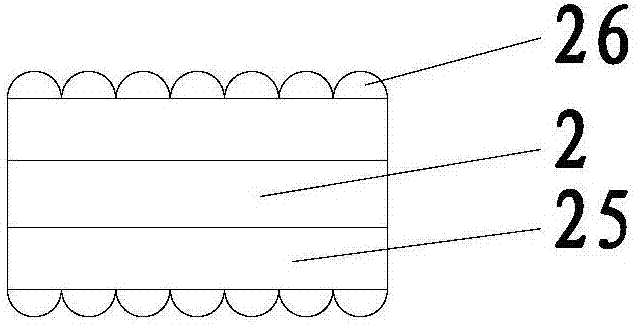

Vertical blueberry cleaning equipment

The invention discloses vertical blueberry cleaning equipment. The vertical blueberry cleaning equipment comprises a cleaning barrel, a rotating shaft, spiral directing vanes, a water storage tank, afirst barrier plate and a material outlet pipe, wherein a material inlet pipe and a water inlet pipe are arranged at the top of the cleaning barrel, the rotating shaft extends into the cleaning barrelfrom the top of the cleaning barrel, the top of the rotating shaft is connected with a motor, the spiral directing vanes in a spiral shape are fixed on the rotating shaft, the spiral directing vanesare positioned in the cleaning barrel, the first barrier plate is arranged in the cleaning barrel, a plurality of first through holes penetrating through the upper and lower ends of the first barrierplate are formed in the first barrier plate, the first barrier plate is positioned below the rotating shaft, the material outlet pipe is arranged outside the cleaning barrel and the material outlet pipe is communicated with the inside of the cleaning barrel. According to the vertical blueberry cleaning equipment, the spiral directing vanes are arranged in the cleaning barrel, so the outer surfacesof blueberries can be sufficiently rubbed, contaminations on the blueberries can be effectively separated from the blueberries and the blueberries can be cleaned thoroughly.

Owner:王荣忠

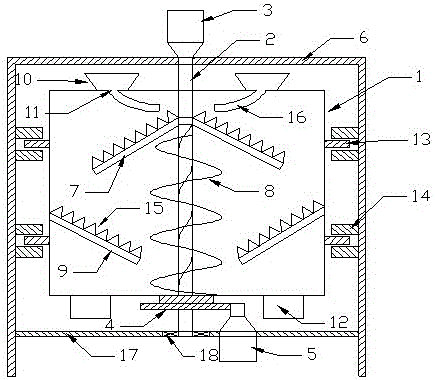

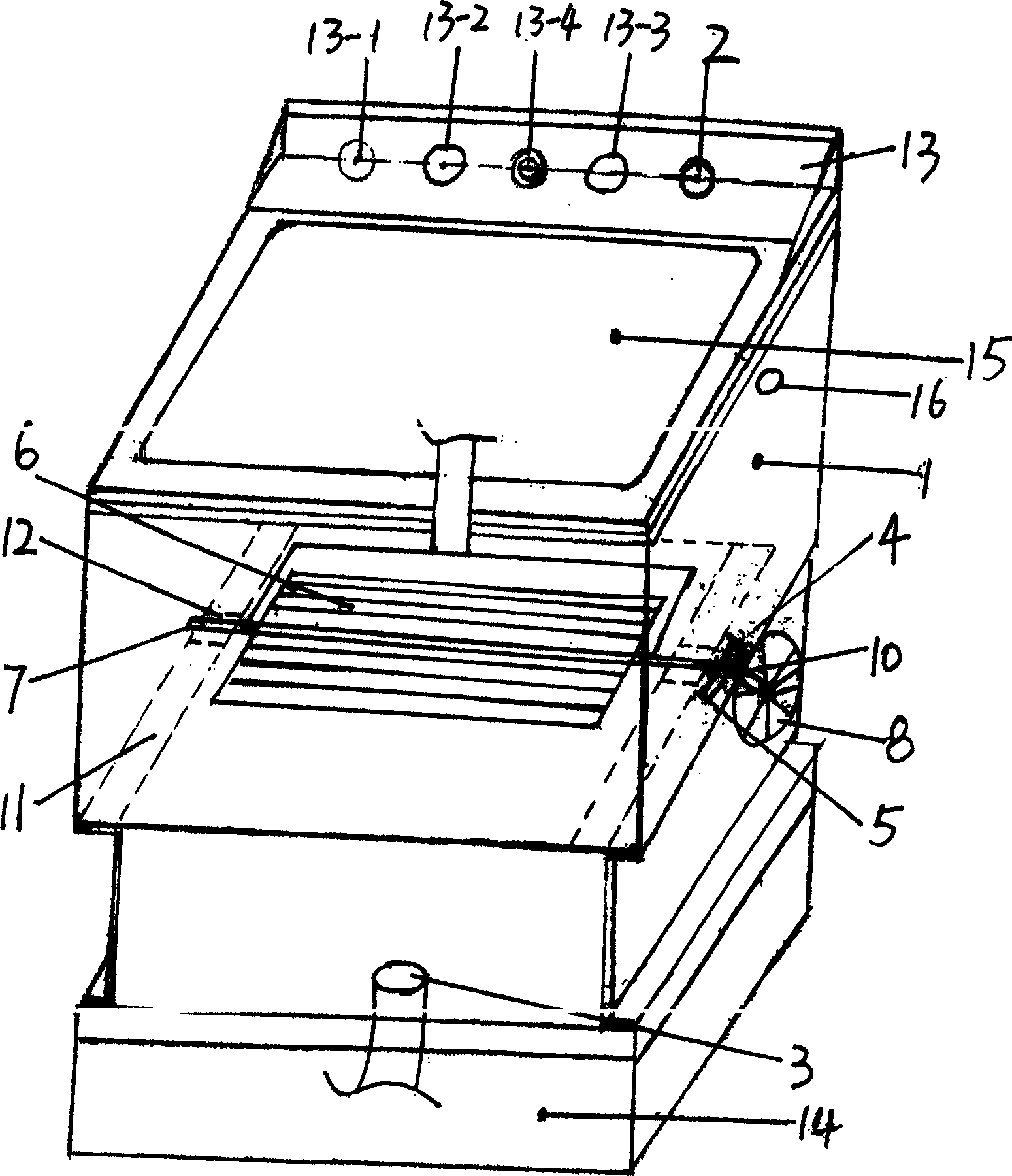

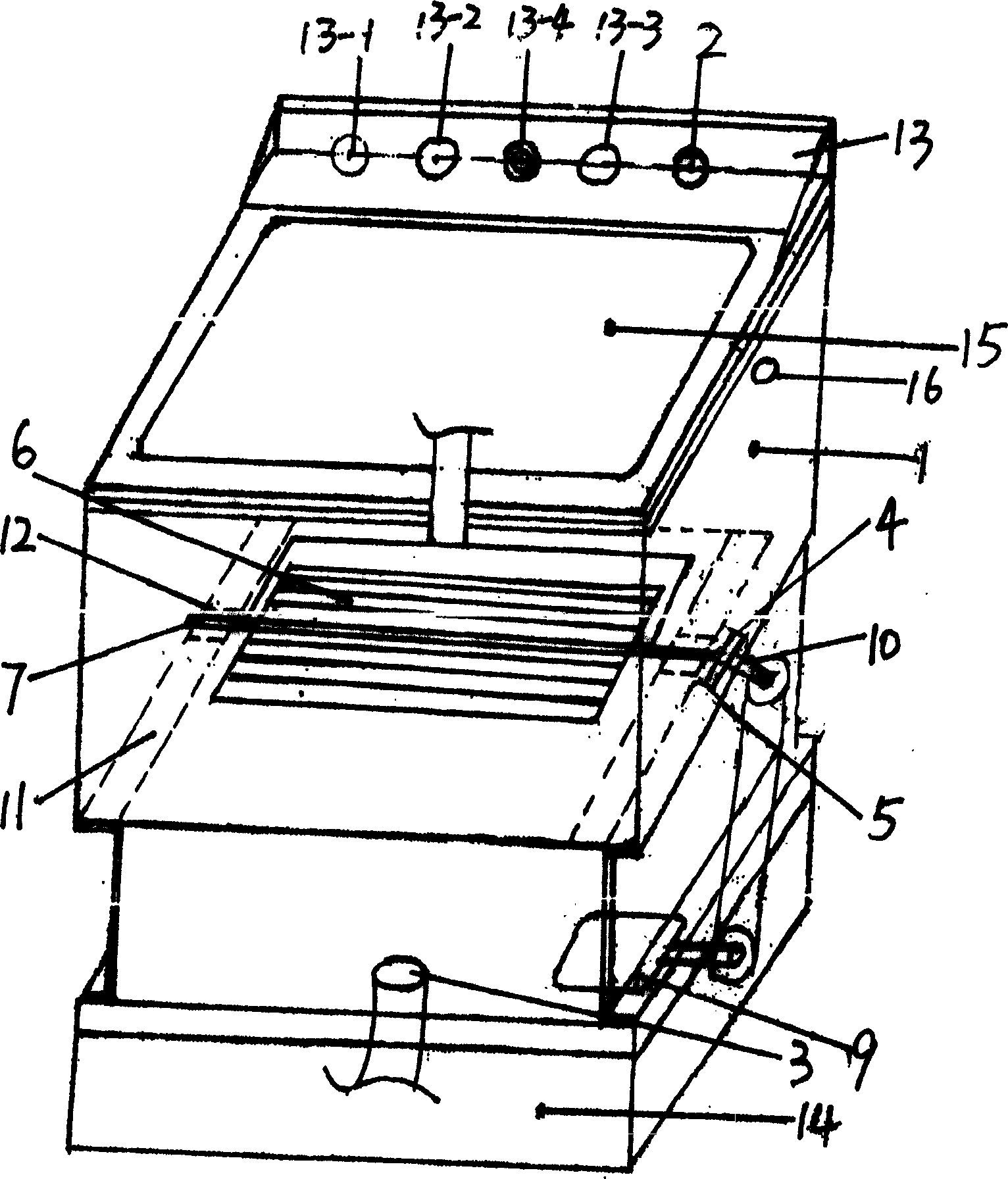

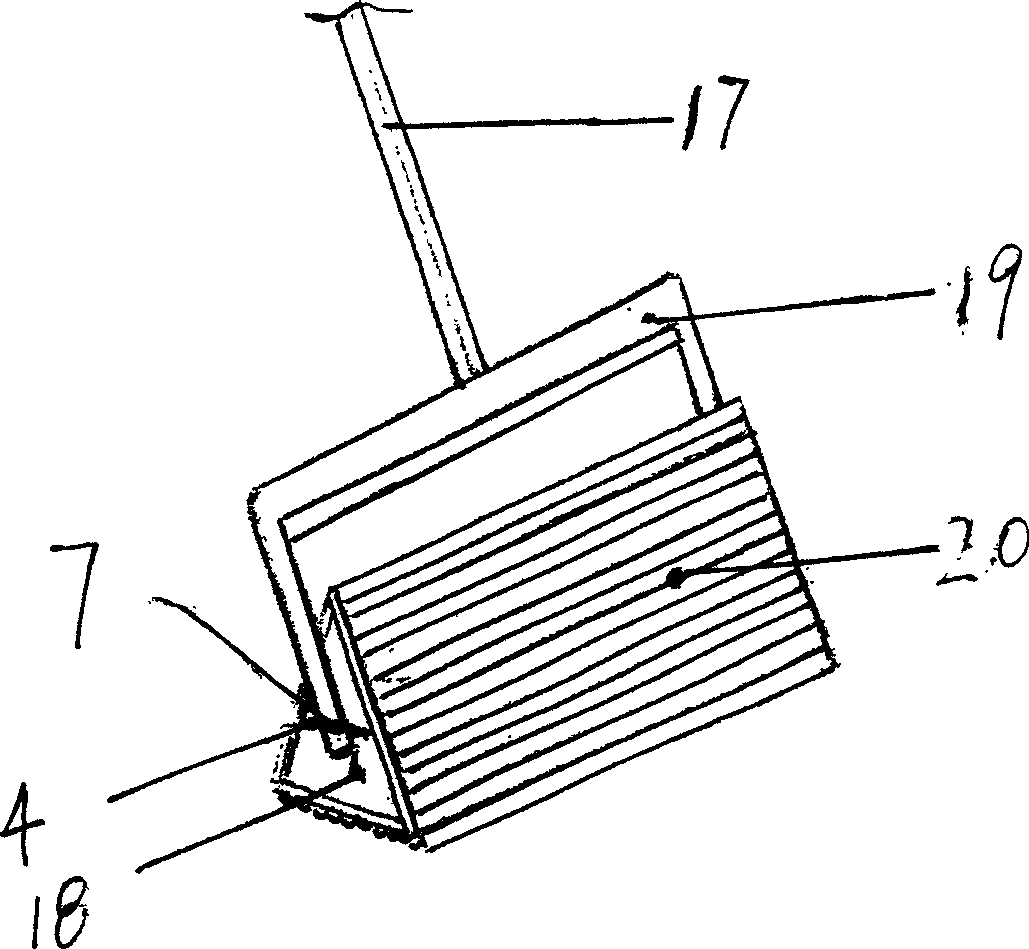

Chinese date comprehensive cleaning integral machine

The invention relates to a Chinese date comprehensive cleaning integral machine, which comprises support legs, wherein a box body is arranged on the support legs, a filter hole punching plate is arranged in the box body, two sides of the box body are provided with a circulation pipeline system capable of realizing the vortex rotation of water in the box body, a cross flow type spraying and punching device is arranged above the box body, the tail end of the box body is connected and provided with a hairbrush machine frame, cone-shaped hairbrush rollers are arranged on the hairbrush machine frame, every two adjacent rows of cone-shaped hairbrush rollers are in reverse arrangement, a fast draw-pull type water collecting hopper is arranged under the hairbrush machine frame, and a circulation water box device for collecting water and supplying water for whole machine cleaning is arranged under the fast draw-pull type water collecting hopper. The Chinese date comprehensive cleaning integral machine has the beneficial effects that cross flows are utilized for impacting, spraying and flushing materials floating on the water surface so that the materials do curved order movement during the rotation, the full friction is realized between the materials and the moisture, the cleaning effect is good, the cone-shaped hairbrush rollers can be adopted for cleaning the surface as well as the front and back surfaces of Chinese dates, and in addition, the materials cannot be easily accumulated.

Owner:山东科迈达智能食品装备有限公司

Clothing drying machine

InactiveCN101328677AAvoid bendingExtended service lifeTextiles and paperHome appliance efficiency improvementElectric machineryEngineering

The present invention relates to a clothes drying machine which is characterized by comprising the following components: a body; a roller which is rotatably installed in the body; a motor which is installed on the lower base of the body; and a two-segment pulley which is used for transferring the rotating force of the motor to the roller, wherein, the two-segment pulley is provided with an axis which is parallel with the rotating axis of the motor between the rotating axis of the motor and the rotating axis of the roller.

Owner:NANJING LG PANDA APPLIANCES

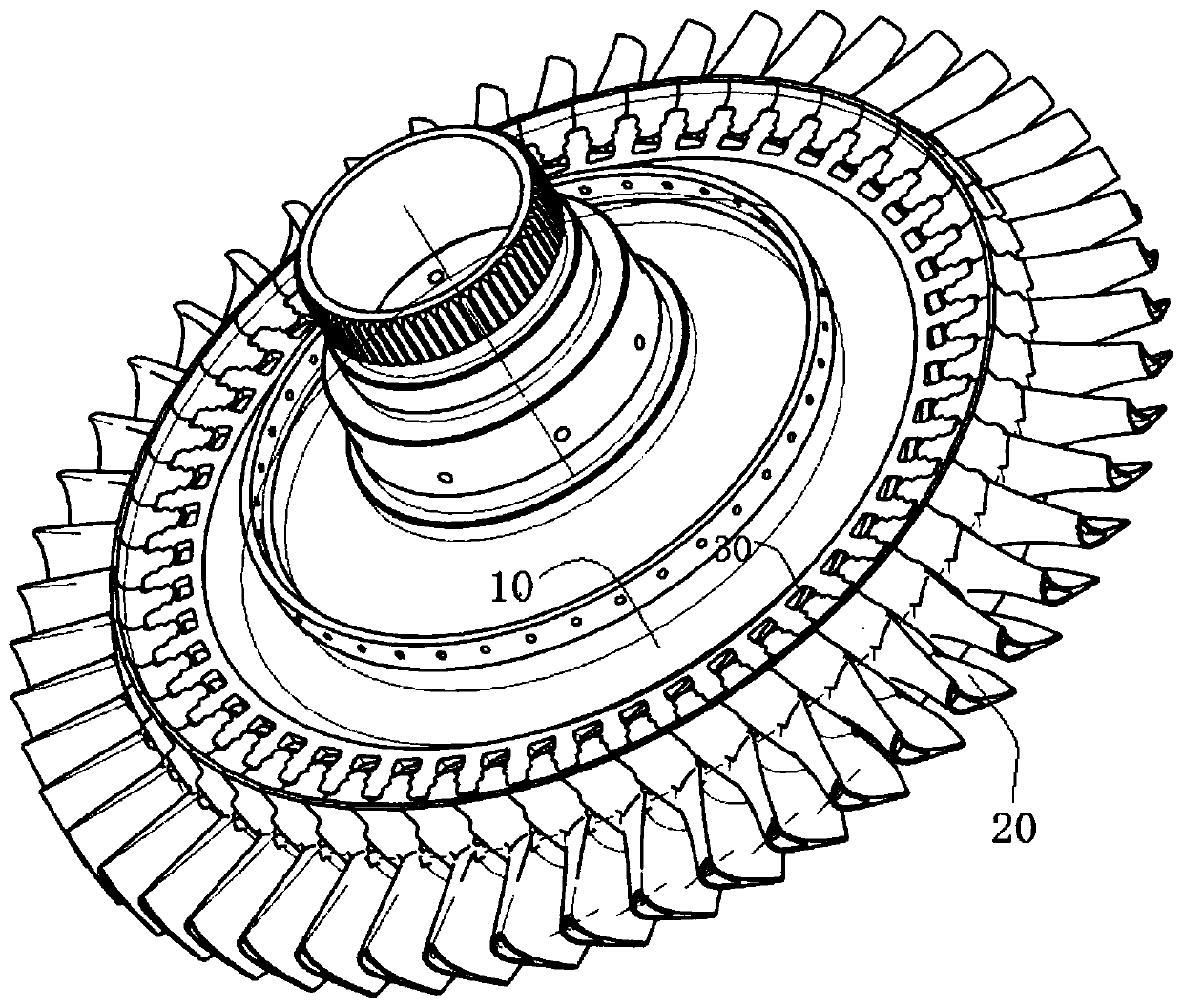

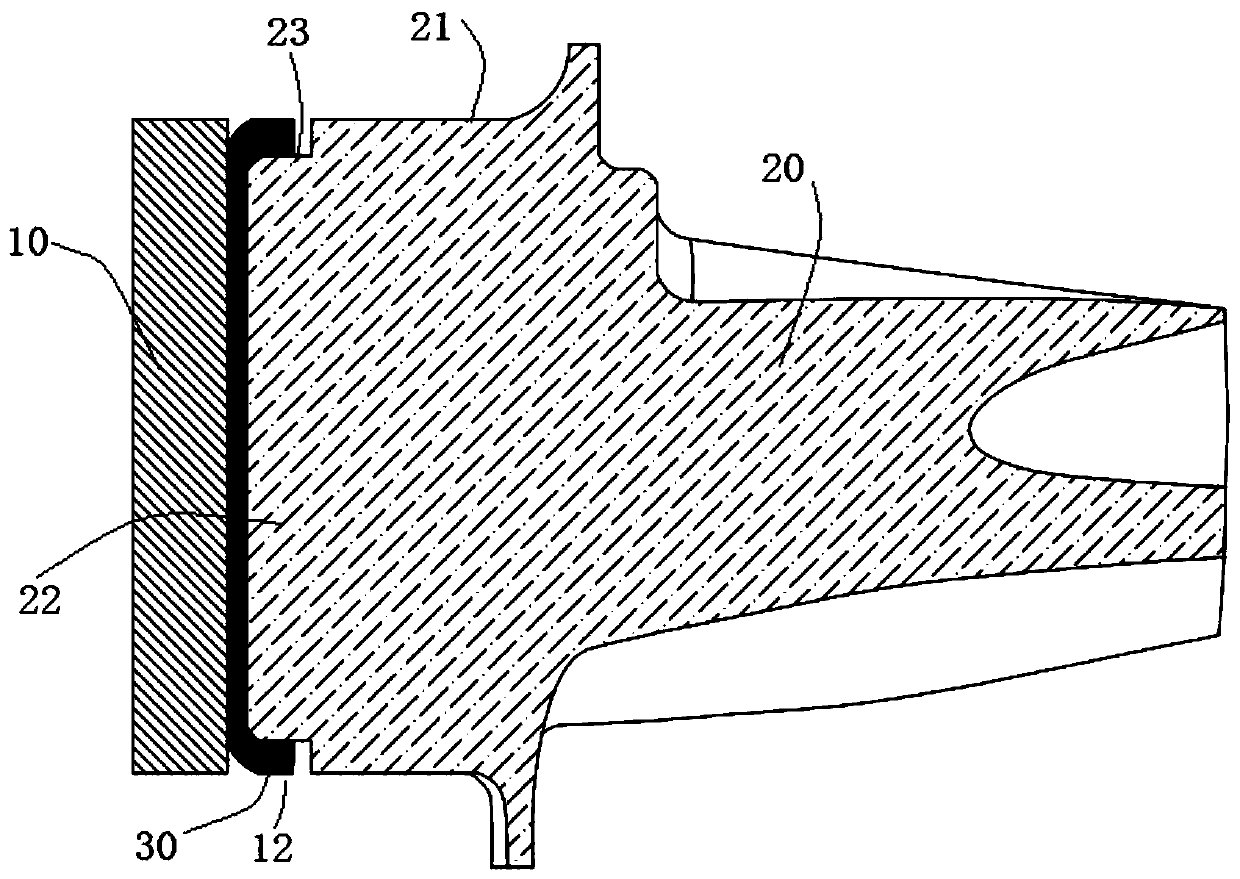

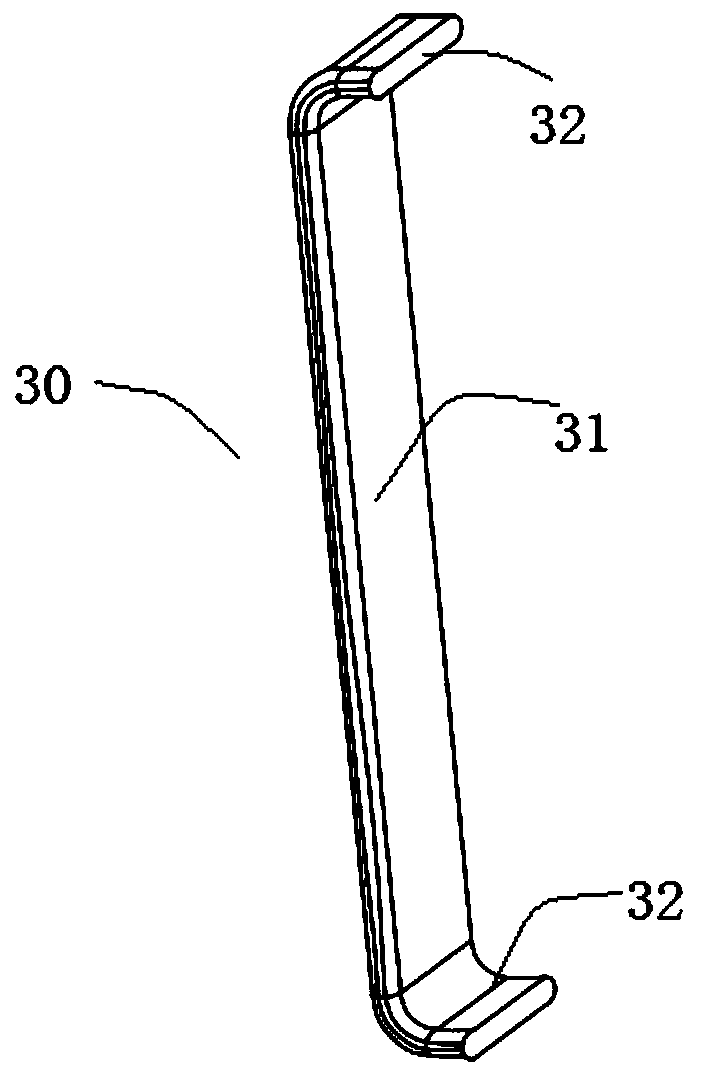

Turbine disc and blade locking mechanism for turboprop engine

PendingCN111472845AReduce processing timeImprove production efficiencyBlade accessoriesMachines/enginesTurbineTurboprop

The invention discloses a turbine disc and blade locking mechanism for a turboprop engine. The turbine disc and blade locking mechanism comprises a turbine disc and a plurality of blades which are uniformly distributed at the periphery of the turbine disc, wherein mortise structures are uniformly distributed at the periphery of the turbine disc; each mortise structure is composed of a first mortise at the outer side and a second mortise at the inner side, and the first mortise communicates with the second mortise; the root parts of the blades are provided with tenon structures; each tenon structure is composed of a first tenon and a second tenon on the end part of the first tenon; the first tenons are embedded into the first mortises; the second tenons are embedded into the second mortises, and are locked and fixed through blocking plates embedded between the second tenons and the seond mortises. According to the turbine disc and blade locking mechanism for the turboprop engine disclosed by the invention, the blades are matched with the turbine disc though the tenons and the mortises, so that only the locking plates need to insert and bend, and therefore, operations are simple; andmoreover, the turbine disc and blade locking mechanism is novel in design, is simple and convenient in assembly, is high in practicability, is excellent in stable performance, and can be widely applied to turbines of various functions.

Owner:上海尚实航空发动机股份有限公司

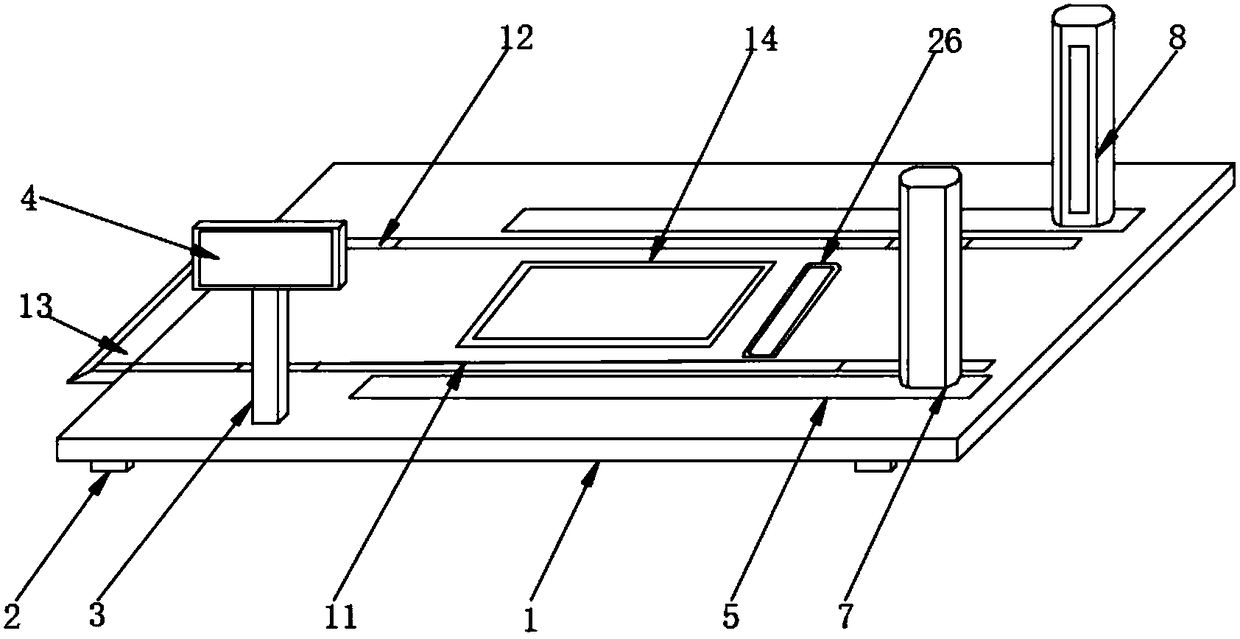

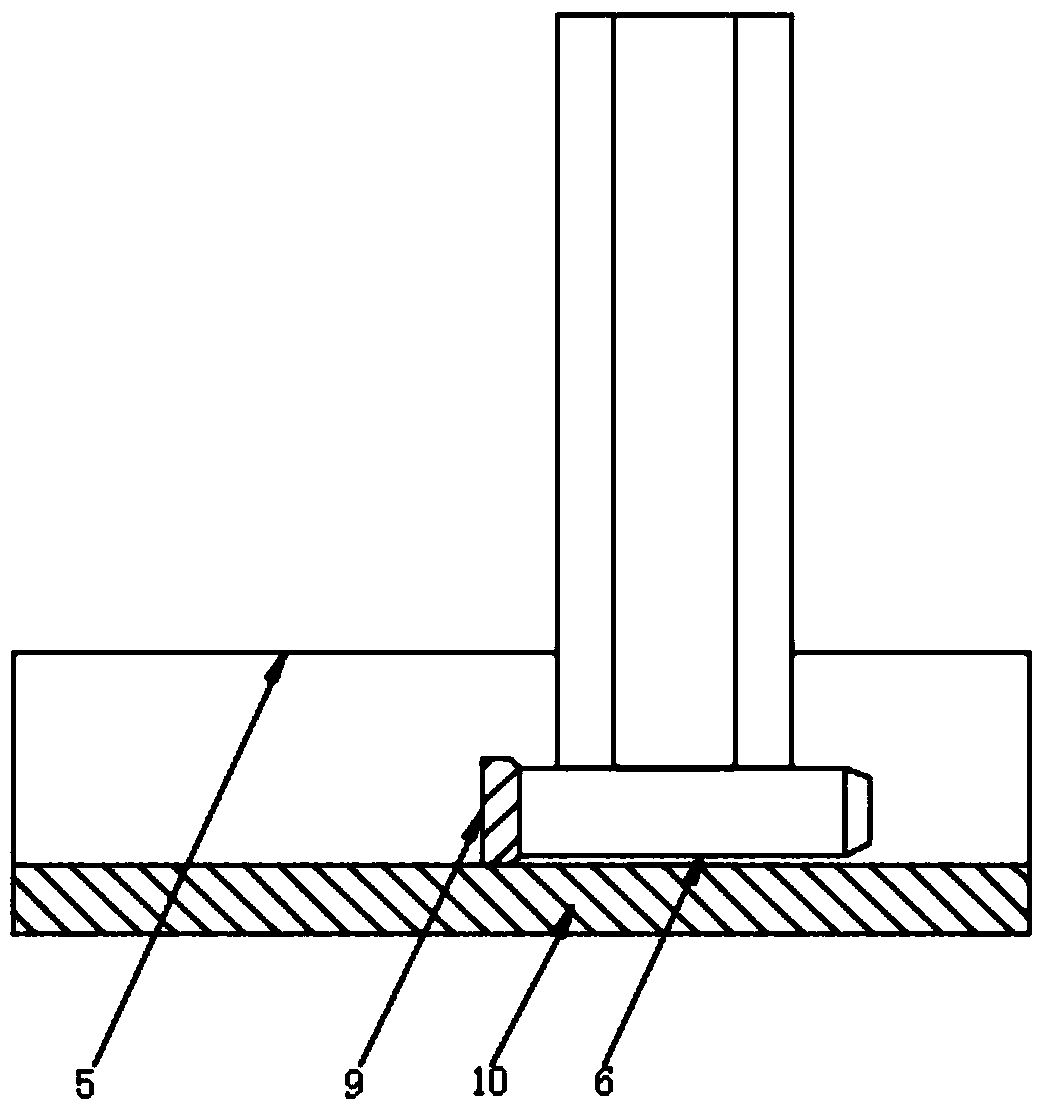

Ultrasonic detection device used for automobile maintenance

InactiveCN108362775AImprove maintenance speedSave human effortAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecial purpose weighing apparatusMaterial resourcesUltrasound

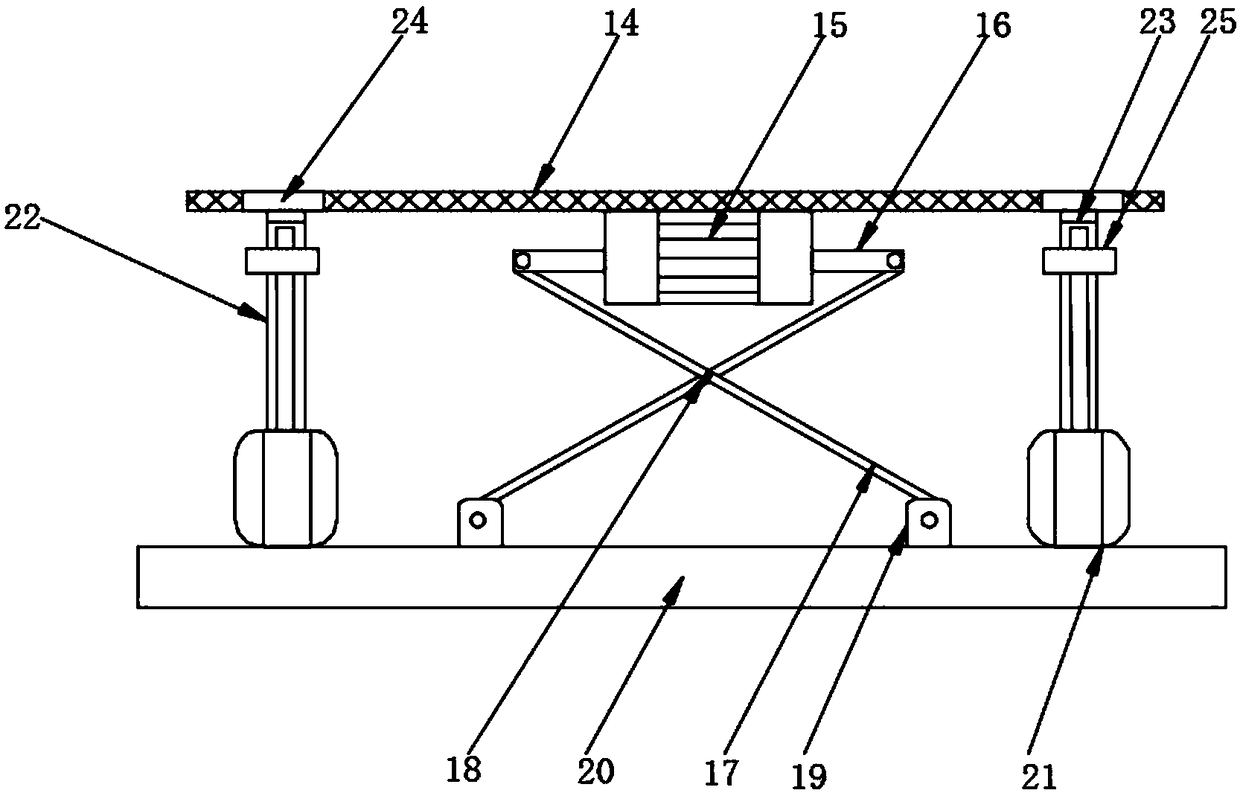

The invention discloses an ultrasonic detection device used for automobile maintenance. The ultrasonic detection device used for automobile maintenance comprises a groove steel plate, a plurality of pressure measuring devices, a telescopic rod, an operation screen, a groove, a motor, an ultrasonic detector, an anti-interference protective casing, a plurality of gears, a gear belt, a skidproof stripe belt, a limiting block, a backing plate, a supporting plate, a bidirectional hydraulic device, a balance hydraulic device and a balance hydraulic rod, wherein the pressure measuring devices are mounted at four corners of the bottom of the groove steel plate respectively; each pressure measuring device comprises a supporting base, a pressure tester, a support pillar and a rubber base, each pressure tester is mounted at the bottom of the corresponding supporting base, and each support pillar is mounted at the bottom of the corresponding pressure tester. The device is scientific and reasonablein structure and safe and convenient to use, the gears are driven by the motor, the ultrasonic detector can be driven to move freely through mutual rotation of the gears and the gear belt, and the ultrasonic detector or an automobile does not need to move manually any more during automobile maintenance, so that the maintenance speed is improved, and the manpower and material resources are saved.

Owner:安徽祥拓智能环保科技有限公司

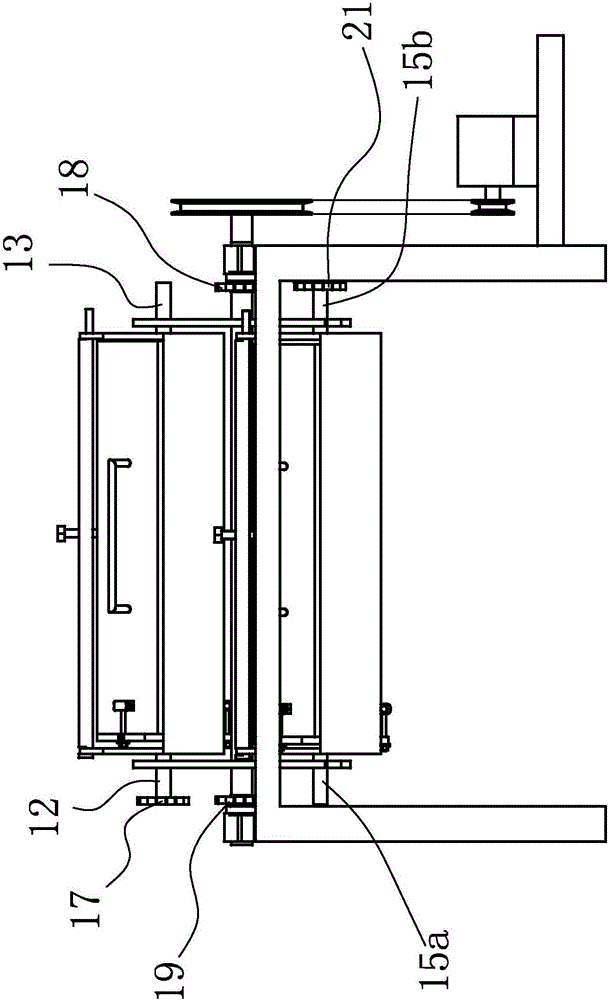

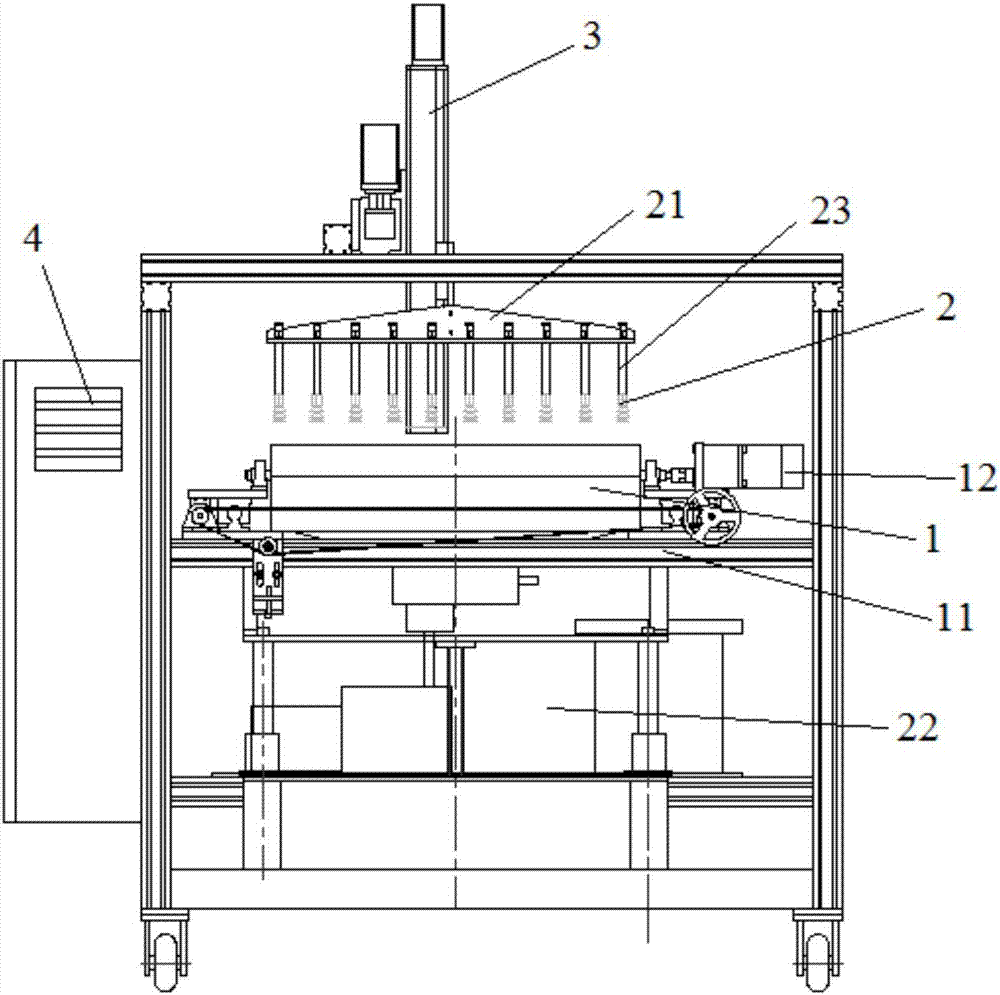

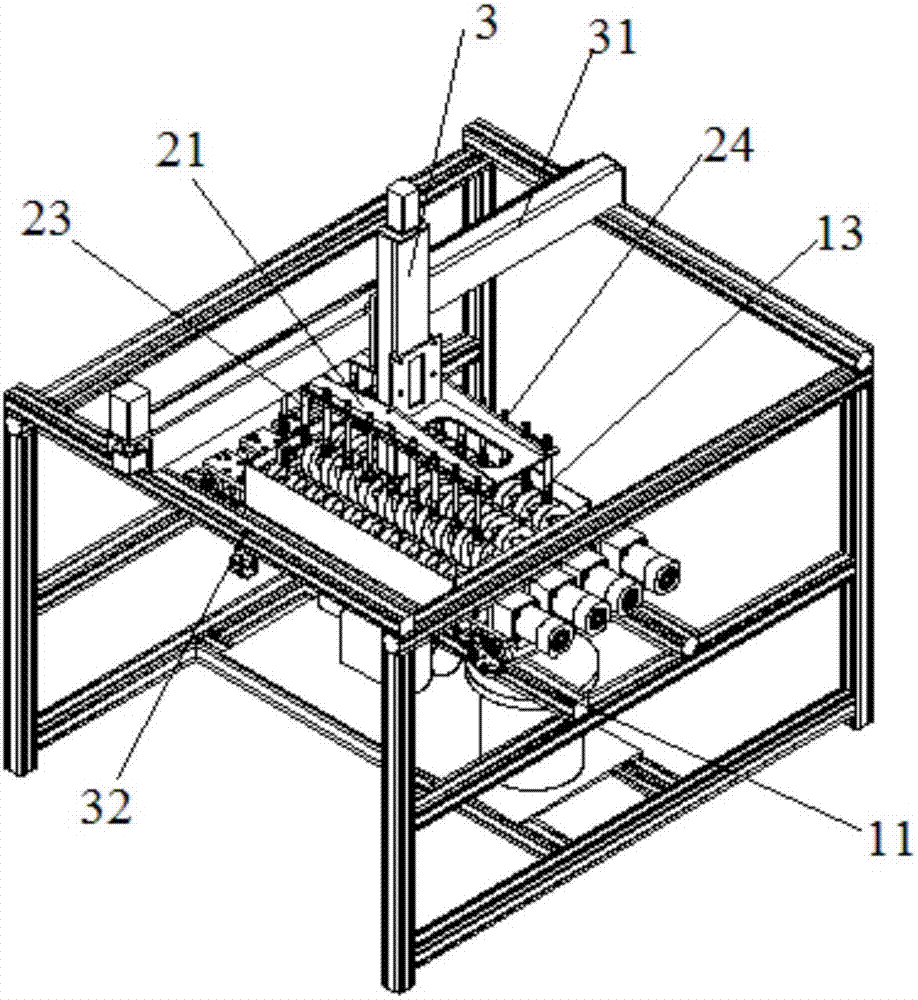

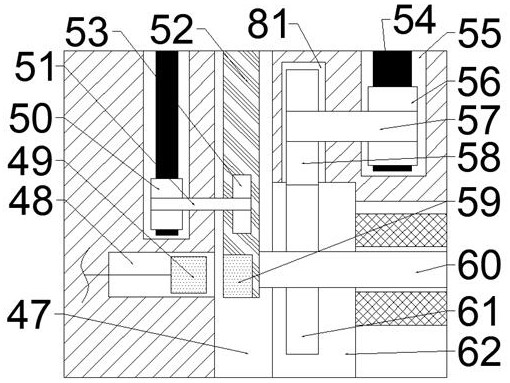

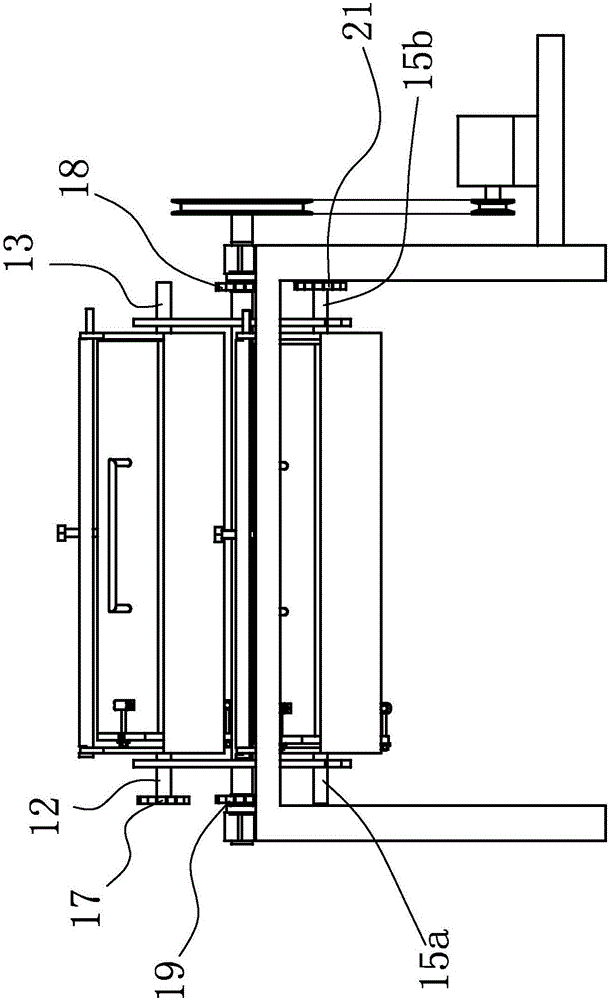

Intelligent defect repairing and automatic disc stacking system and operation method

PendingCN107186565AFix bugsReduce human interventionEdge grinding machinesGrinding carriagesControl systemEngineering

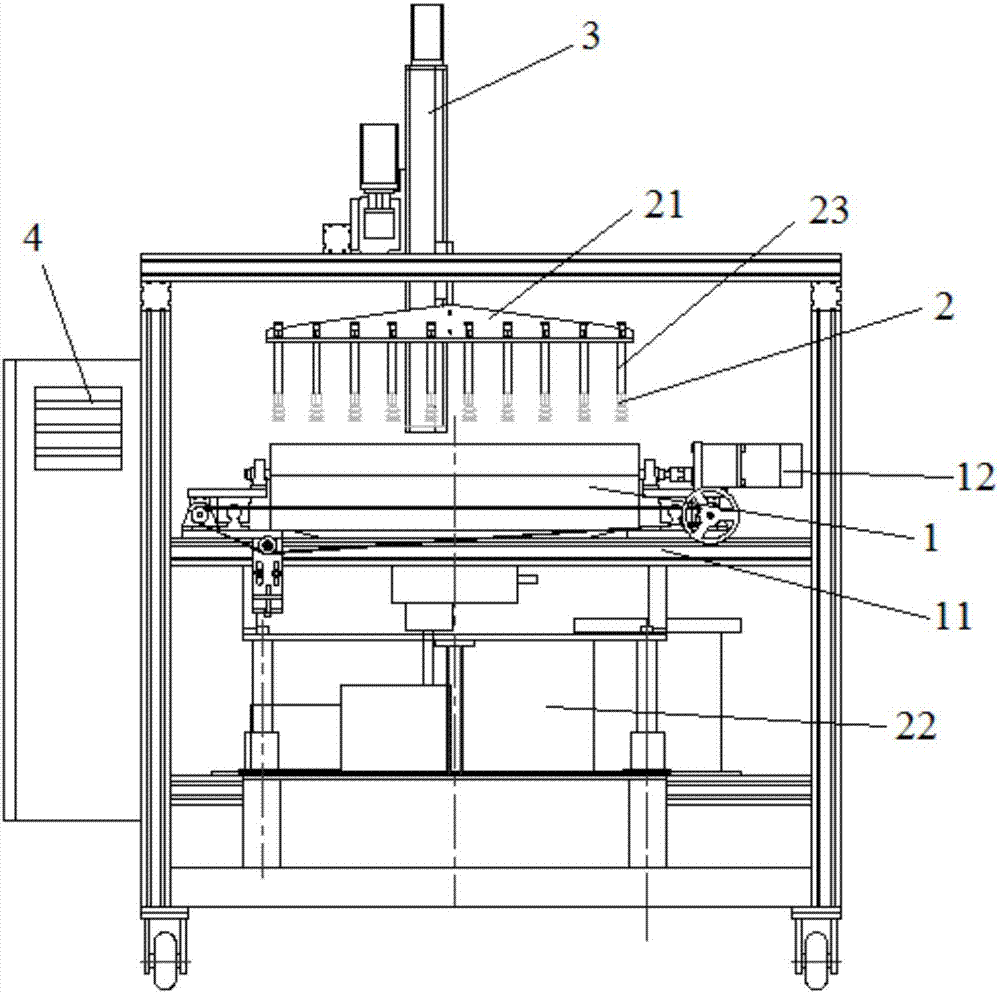

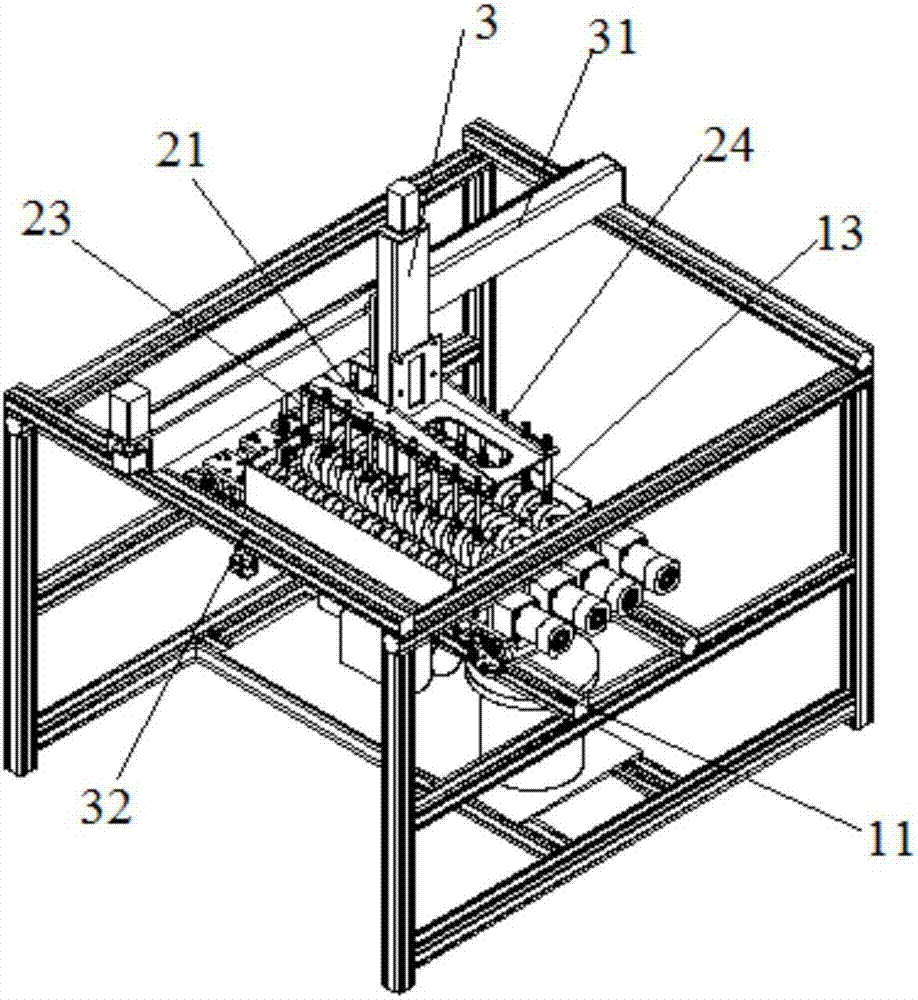

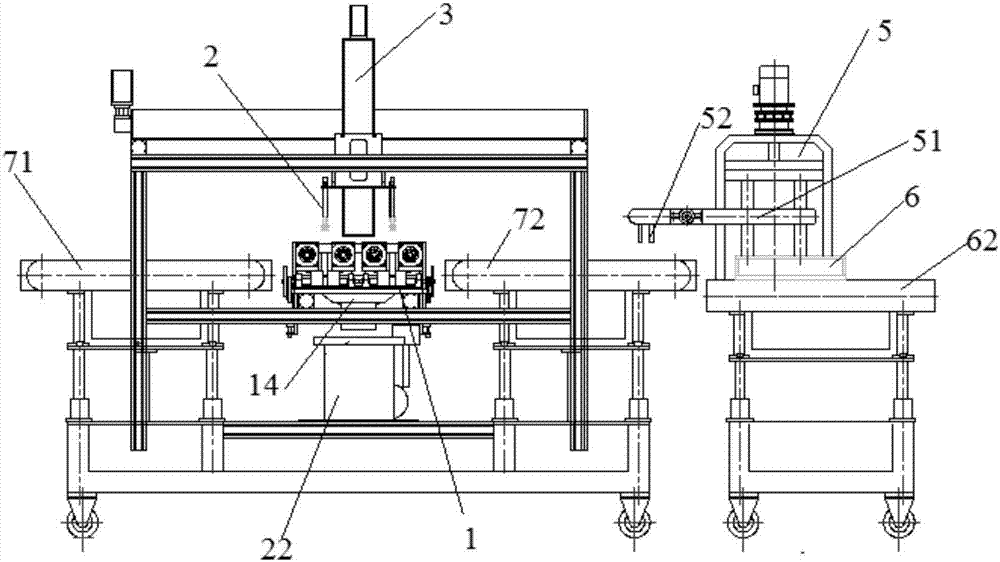

The invention discloses an intelligent defect repairing and automatic disc stacking system and an operation method and belongs to the technical field of magnetic material machining equipment. The system comprises a product defect treating device, a product absorbing head, a single-shaft robot moving arm, an intelligent on-line control system and an automatic disc stacking device, wherein the product absorbing head is fixed to the lower portion of the single-shaft robot moving arm, the product defect treating device is located below the product absorbing head, the automatic disc stacking device is located on one side of the product defect treating device, and the product defect treating device, the product absorbing head, the single-shaft robot moving arm and the automatic disc stacking device are connected with the intelligent on-line control system. The system solves the problem that for the surface of a magnetic material product in the prior art, manual repairing and disc stacking are low in efficiency, automatic disc stacking is achieved, and the product quality is improved.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

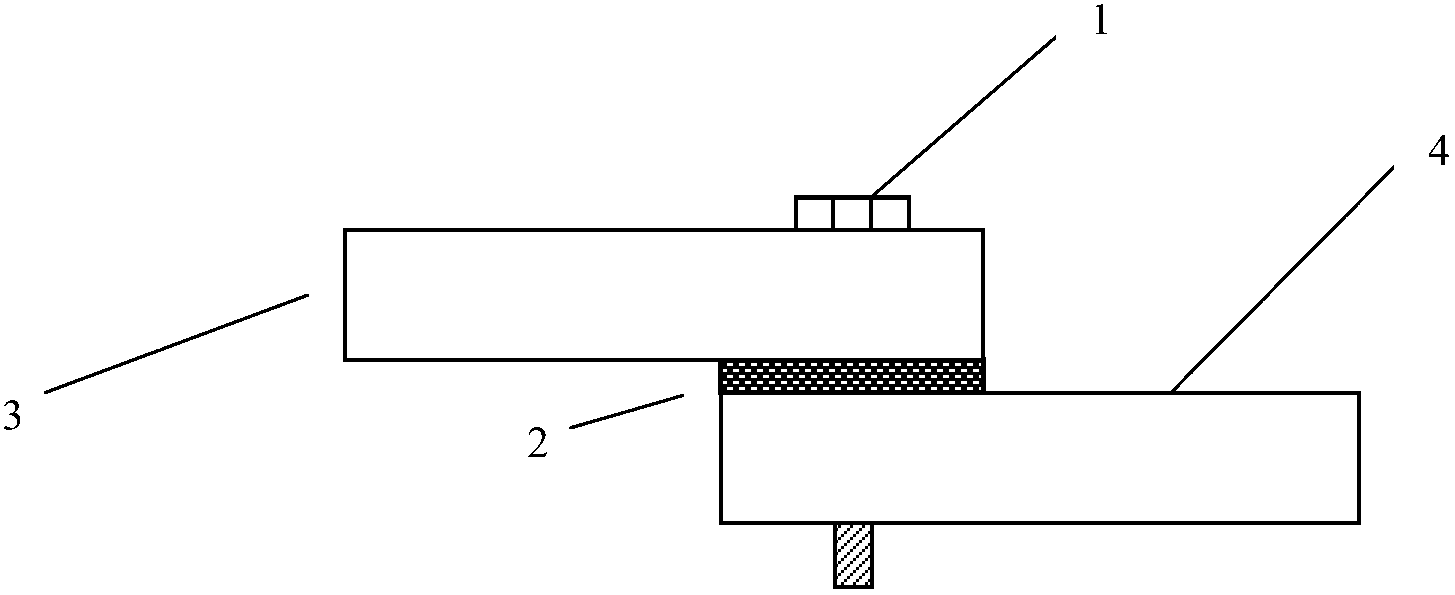

Continuous cast extrusion molding device

The invention discloses a continuous cast extrusion molding device. The continuous cast extrusion molding device is capable of dissipating heat sufficiently and enables metal grains to rub sufficiently. The continuous cast extrusion molding device comprises a rack, cast extrusion wheels and a cast extrusion boot base are movably arranged on the rack, annular cast extrusion grooves are formed in the cast extrusion wheels, and arc cast extrusion grooves matched with the annular cast extrusion grooves are arranged on the cast extrusion boot, a stopping block and a discharging mold which are matched with the annular cast extrusion grooves are arranged on the cast extrusion shoe plate, and the center of the section, corresponding to the center lines of a discharging mode hole and the annular cast extrusion grooves and the center of the section, corresponding to the center lines of the discharging mode hole and the arc cast extrusion grooves are located at the center line of the discharging mode hole. A diversion groove communicated with the arc cast extrusion groove is formed in the upper end of the arc cast extrusion groove, heat conduction holes communicated with the diversion groove are formed in the cast extrusion boot, and heat emission hole corresponding to the heat conduction holes one by one is formed in the cast extrusion boot base. The continuous cast extrusion molding device is used for manufacturing aluminium rods with high quality.

Owner:ZHANGJIAGANG CITY GUANGCHUAN ELECTRONICS

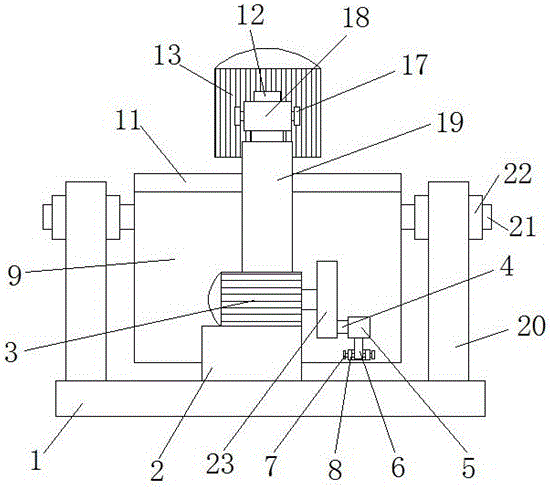

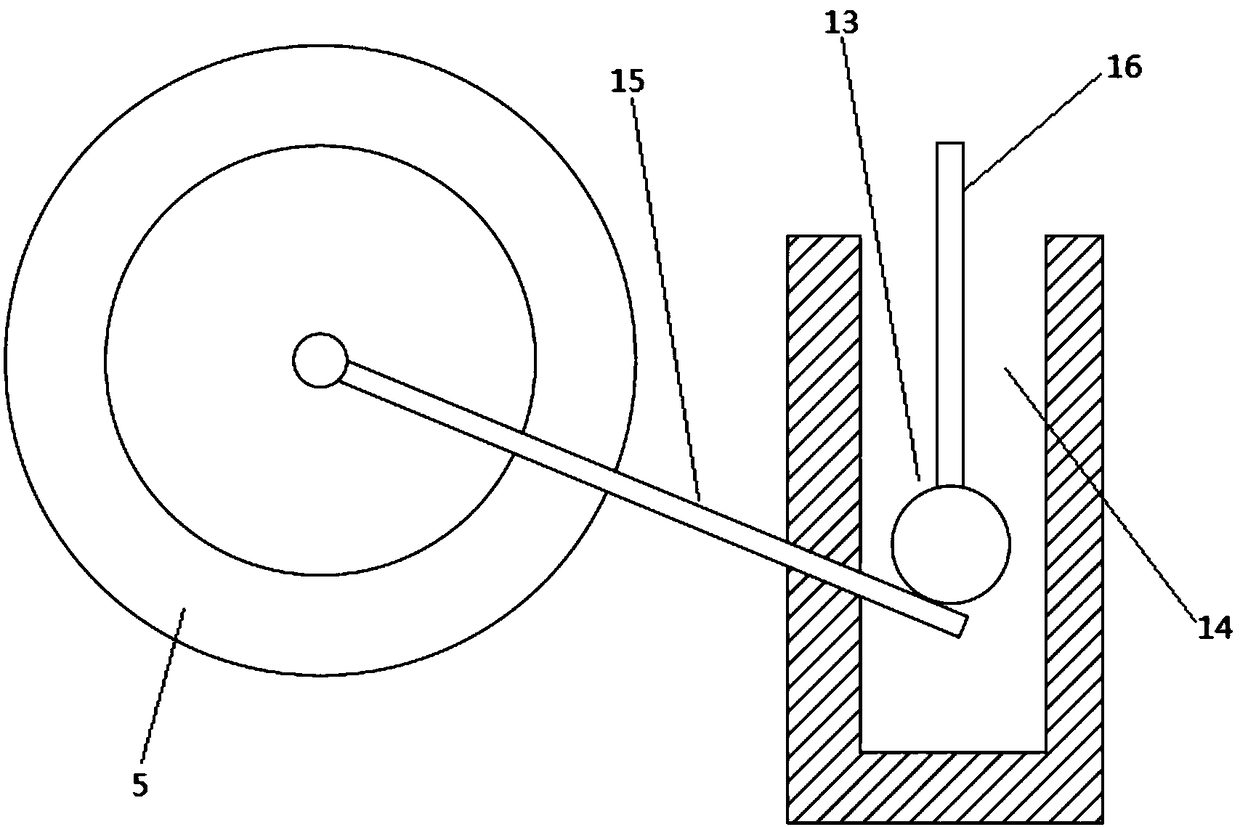

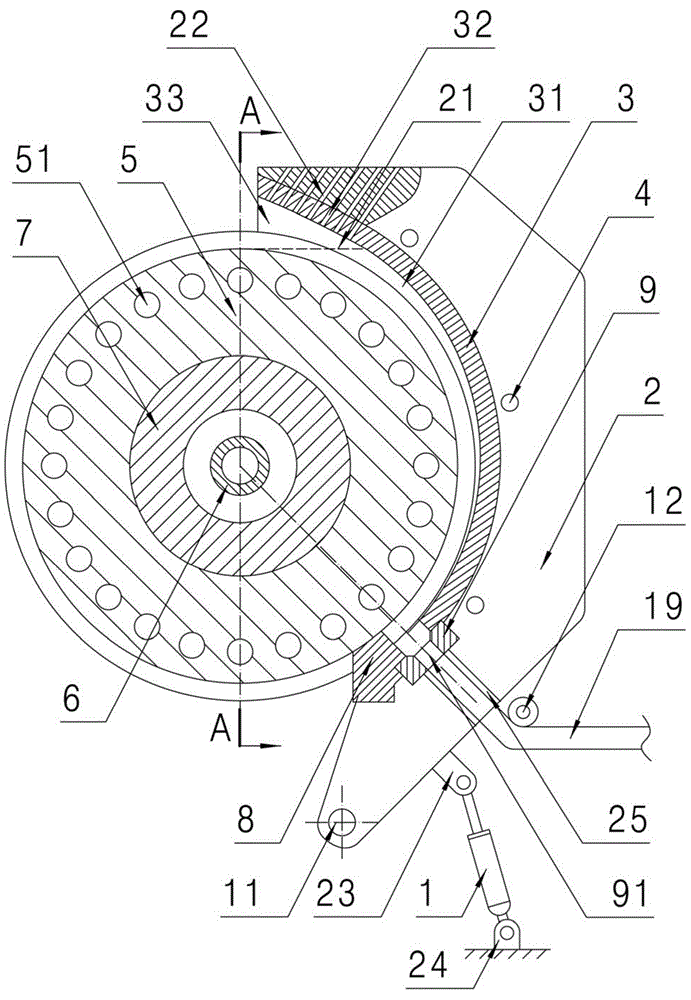

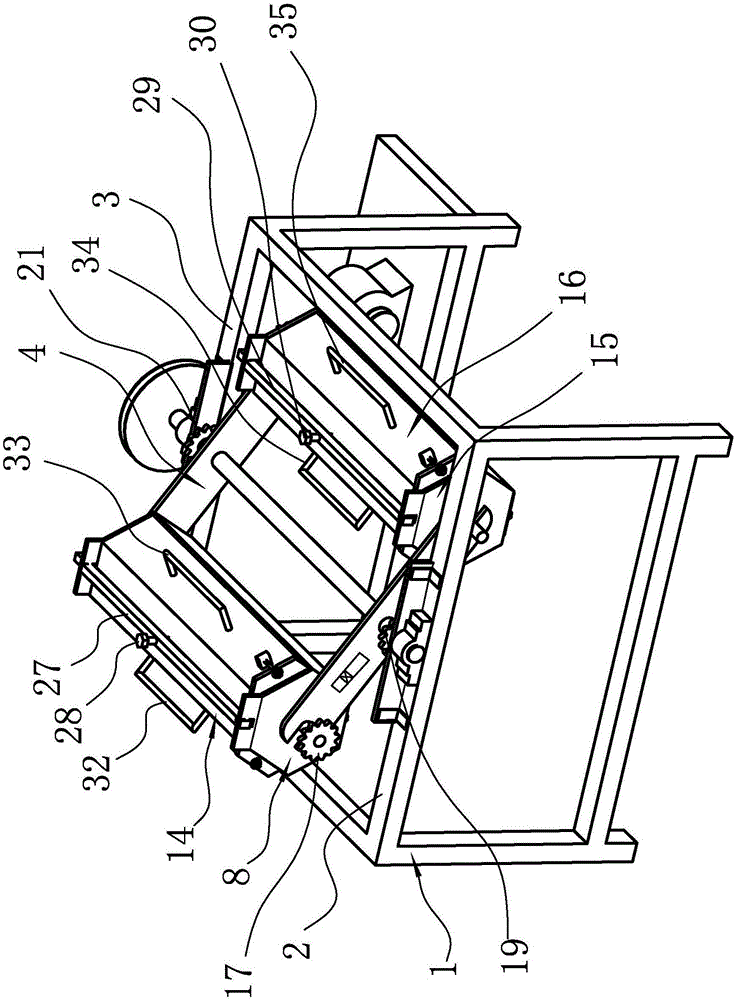

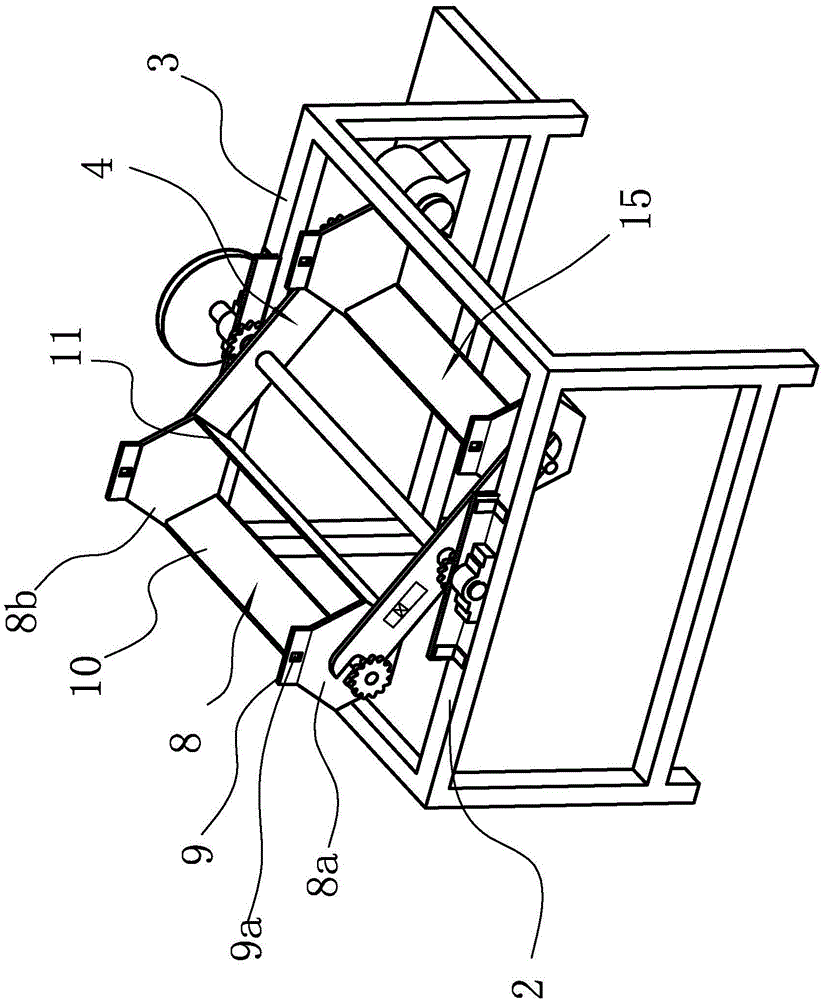

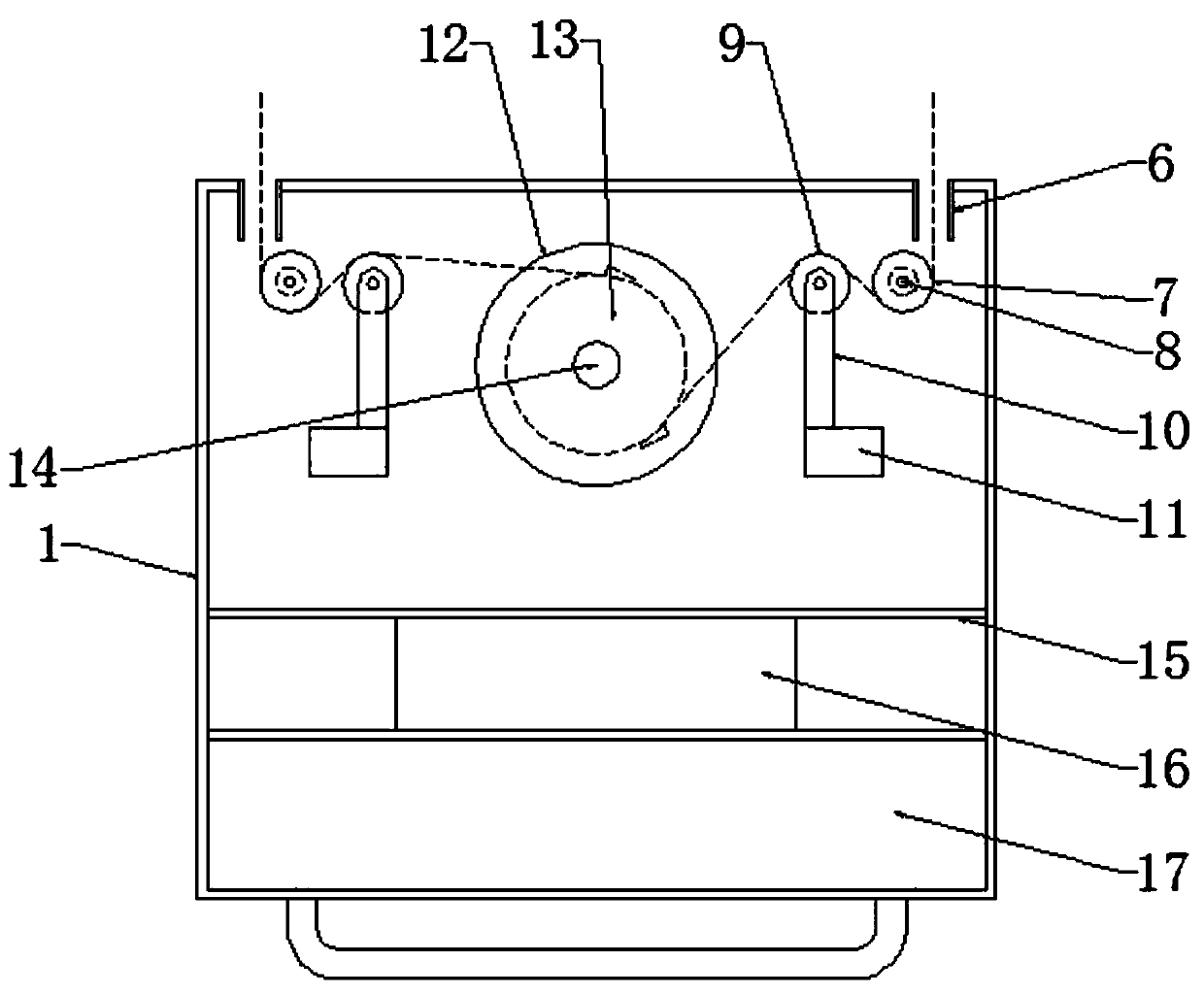

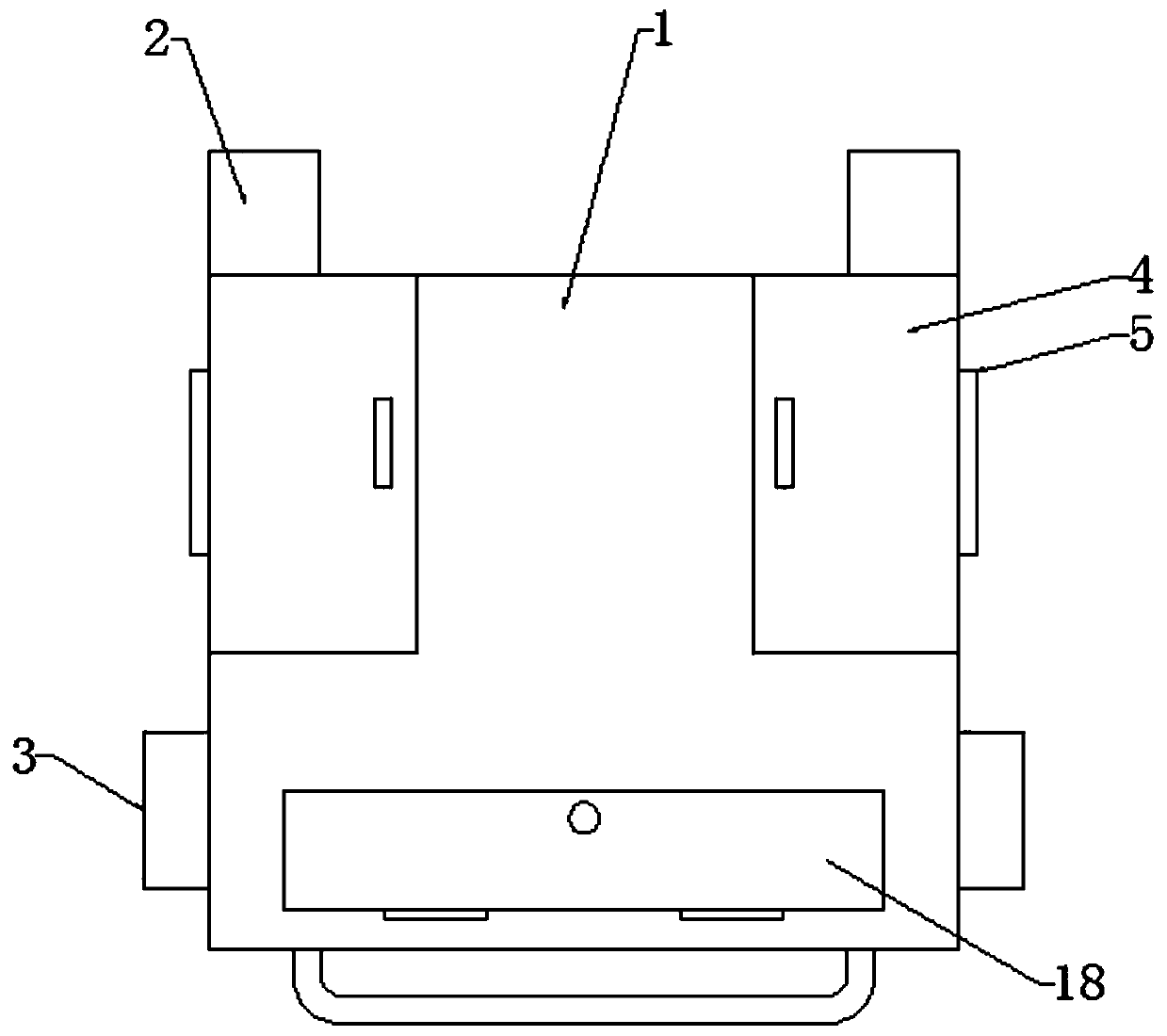

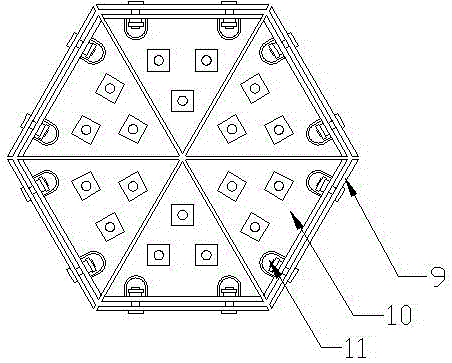

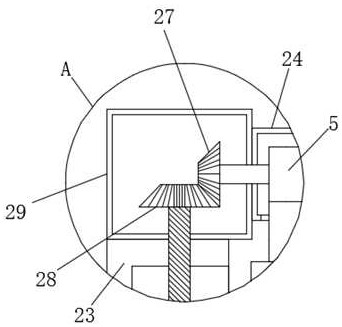

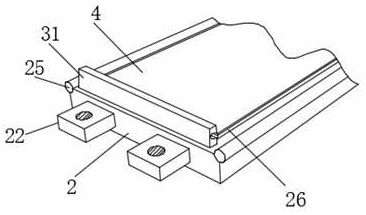

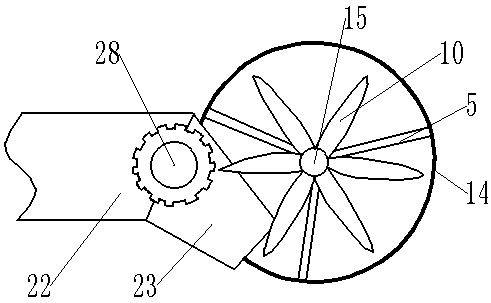

Improved rotating grinding machine

InactiveCN106312785AFull frictionImprove deburring effectEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

The invention provides an improved rotating grinding machine and solves technical problems that existing grinding machines are poor in grinding deburring effect, large in vibration and the like. The improved rotating grinding machine comprises a rack and is characterized in that a rotating frame is rotationally arranged in the rack; a grinding box I and a grinding box II are symmetrically arranged on the rotating frame; and the grinding box I and the grinding box II do not rotate in the rotating process, the deburring effect on ground parts in box bodies is improved, and vibration of the grinding machine is reduced through arrangement of a balancing sliding block I and a balancing sliding block II. The grinding machine has the advantages of being good in grinding deburring effect and small in vibration.

Owner:台州市椒江鑫明眼镜配件厂

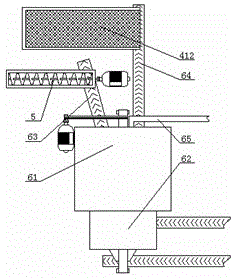

Label impurity separator for plastic bottle sheets

InactiveCN107650297AEfficient separationEasy to separatePlastic recyclingMechanical material recoveryImpurityAirflow

The invention discloses a label impurity separator for plastic bottle sheets. A feeding opening is formed in the upper side wall of one end of a stirring box. A bottle sheet discharging opening is formed in the upper side wall of the other end of the stirring box. An airflow outlet is formed in the upper side wall of the stirring box between the feeding opening and the bottle sheet discharging opening. An airflow inlet is formed in the bottom wall of the stirring box below the airflow outlet. A feeding hopper is arranged in the feeding opening of the upper side of the stirring box. Screw blades stir the plastic bottle sheets in the stirring box under the driving action of a motor and push the plastic bottle sheets from the feeding opening to the bottle sheet discharging opening. A wind inlet impurity removing net is arranged in the airflow inlet of the bottom wall of the stirring box. A bottom cover opening of an absorbing cover communicates with the airflow outlet of the upper side wall of the stirring box. A wind inlet of a suction fan communicates with a top cover opening of the absorbing cover. A first wind closing device is arranged in the feeding opening of the stirring box.A second wind closing device is arranged in the bottle sheet discharging opening of the stirring box. The label impurity separator for the plastic bottle sheets separate labels and impurities more efficiently and thoroughly.

Owner:临武县华湘再生资源回收有限公司

Hydraulic pipeline cleaning method

InactiveCN107639085AReduce string washing timeReduce cleaning costsHollow article cleaningEngineeringCleaning methods

The invention relates to a hydraulic pipeline cleaning method. The method mainly comprises the following steps of shooting sponge bullets, wherein a cleaning blower gun shoots the sponge bullets intoa hydraulic pipeline with the help of high-pressure blast at high speed; intermingling and cleaning, wherein oil the same as the oiliness of oil at work is selected, and the oil is poured into the hydraulic pipeline to be intermingled and cleaned; testing pressure, wherein a safety threshold valve of a system is adjusted to a selected pressure testing value to supply oil to the system, when pressure is tested, grading pressure test is normally adopted, when a grade is added, inspection is carried out once, and a prescribed pressure testing value is achieved by grading step by step; flushing, wherein a flushing loop is determined, and a recycle flushing method is adopted to flush the hydraulic pipeline continuously. The hydraulic pipeline cleaning method has the advantages that the hydraulic pipeline shoots the sponge bullets in a workshop to replace workshop intermingling and cleaning work, part of pipeline inner wall dirt is removed in advance, therefore, the pipeline intermingling and cleaning time is shortened, the overall efficiency is improved, the intermingling and cleaning period is shortened, and the cleaning cost of the hydraulic pipeline workshop is effectively reduced.

Owner:NVISION ELECTRICAL APPLIANCE

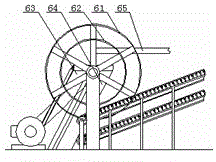

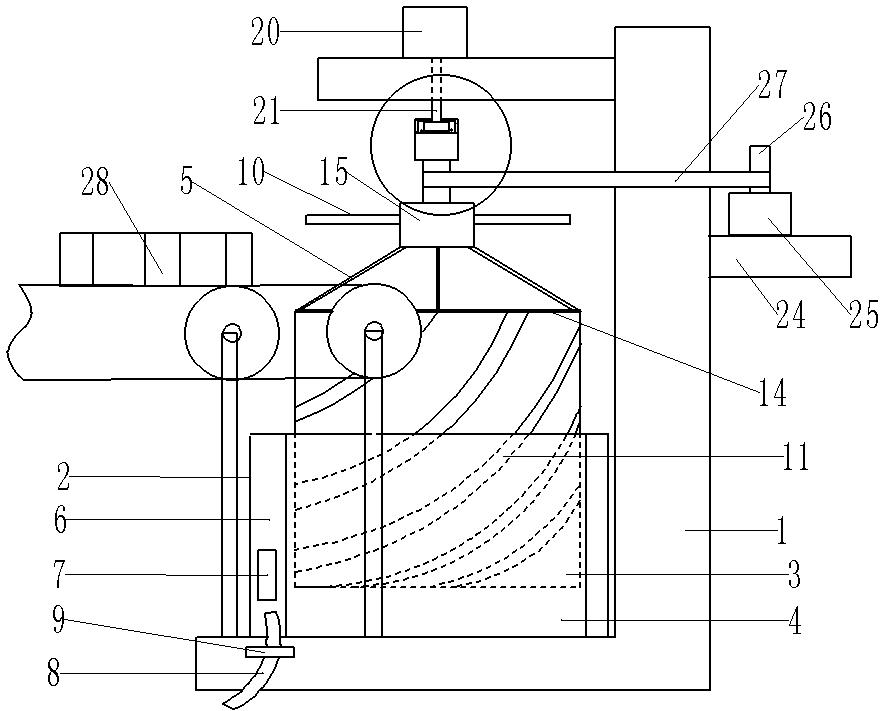

Efficient double rotation regeneration device for foundry used sand

InactiveCN106493288AEasy to enter sandNot deflectedMould handling/dressing devicesFoundrySpiral blade

The invention discloses an efficient double rotation regeneration device for foundry used sand. The efficient double rotation regeneration device for the foundry used sand comprises a vertically arranged sand cylinder, a rotating shaft arranged on the center axis of the sand cylinder, a first rotary motor coaxially connected to the top end of the rotating shaft, a transmission gear arranged at the position of the geometric center of the bottom of the sand cylinder, a second rotary motor in transmission cooperation with the transmission gear, and a sand cylinder support; first downwards-inclined crushing and stirring rods are arranged above the rotating shaft; the position, below the first crushing and stirring rods, on the rotating shaft is provided with spiral blades; the inner wall of the sand cylinder is provided with second downwards-inclined crushing and stirring rods; slide rails are arranged on the sand cylinder in a horizontal encircling manner; and slide grooves matched with the slide rails are arranged on the sand cylinder support. According to the efficient double rotation regeneration device for the foundry used sand, due to opposite rotation of the sand cylinder and the rotating shaft, the foundry used sand achieves sufficient friction, an inert membrane on the surface of the used sand is more effectively removed, the regeneration quality and efficiency of the used sand is improved, and regeneration of the used sand can be continuously performed.

Owner:绵阳易简环保科技有限公司

Full-automatic aggregation machine

ActiveCN105034194ASolve extrusionSolve the pelletizing problemGrain treatmentsEngineeringCentrifugal force

The invention relates to a full-automatic aggregation machine. The full-automatic aggregation machine comprises a feeding barrel with a feeding cavity, a feeding spiral part located in the feeding cavity, a first drive device driving the feeding spiral part to rotate, a fixed cutter head, a movable cutter head opposite to the fixed cutter head, a main shaft sleeved with the movable cutter head in a connected manner, a second drive device driving the main shaft to rotate, a third drive device driving the main shaft to move along the center axis, and a controller. A grinding cavity is formed between the fixed cutter head and the movable cutter head. The grinding cavity is internally provided with a temperature sensor electrically connected with the controller. The controller is electrically connected with the second drive device and the third drive device. Materials are fed into the grinding cavity through rotation of the feeding spiral part, the movable cutter head rotates to enable the materials entering the grinding cavity to rub, and the materials are thrown out of the edge of the cutter heads through the centrifugal action so that particle cutting can be achieved, and the purposes of material extruding and particle cutting are achieved at a time. A gap between the movable cutter head and the fixed cutter head can be adjusted through the third drive device, the control over balanced feeding and aggregating effects is achieved, and the quality of products is guaranteed.

Owner:GUANGZHOU 3E MACHINERY

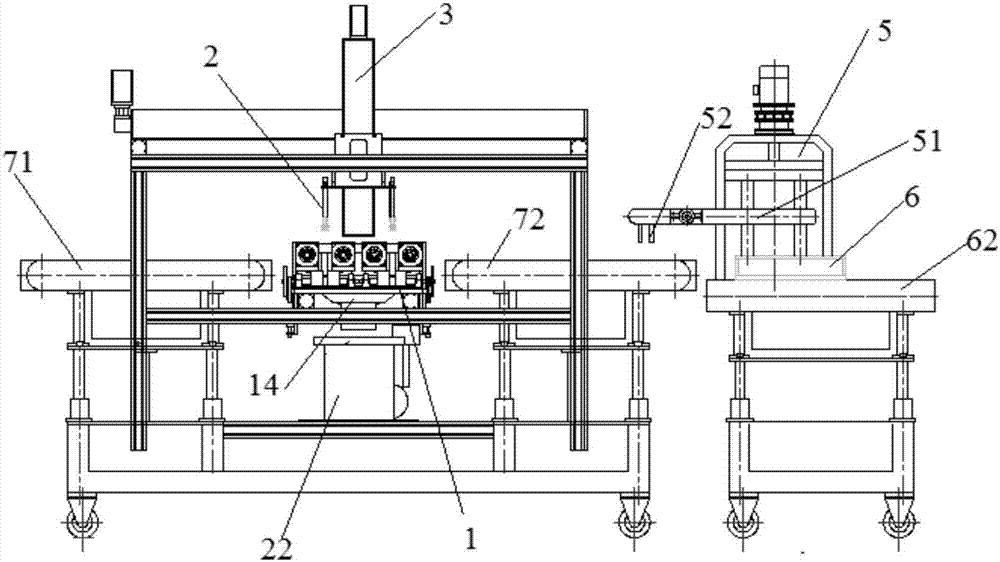

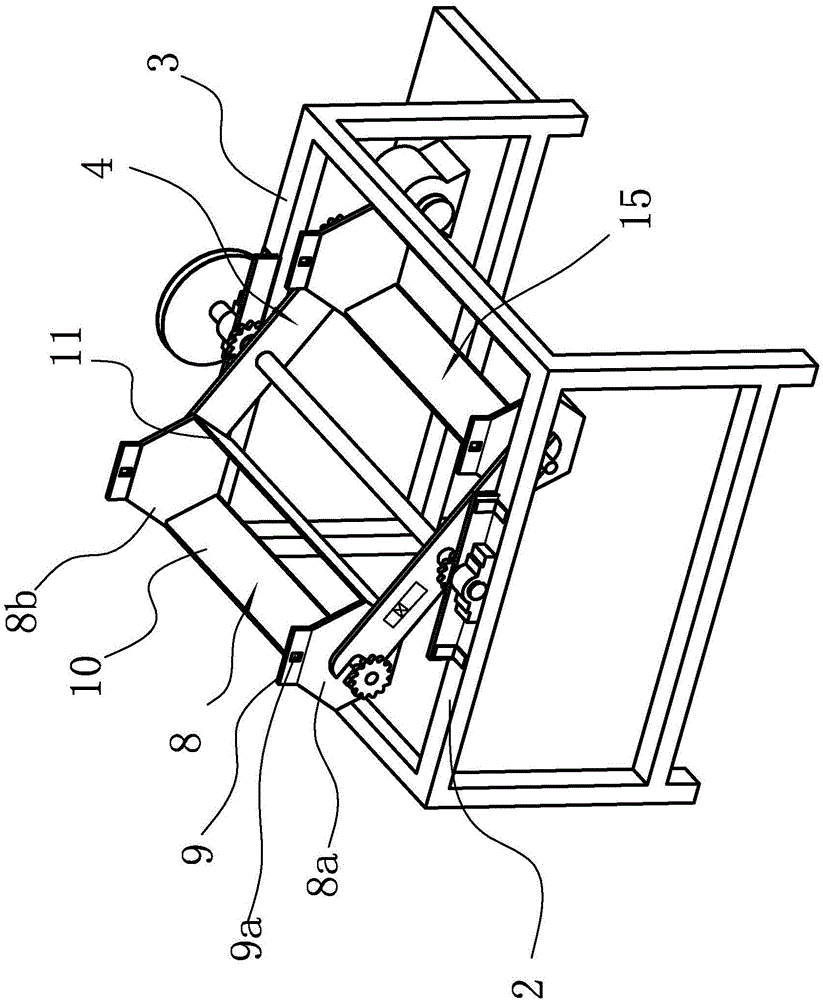

Magnetic material product automatic stacking device and method

PendingCN107160258AFix bugsReduce human interventionEdge grinding machinesGrinding drivesMaterials processingIndustrial engineering

The invention discloses a magnetic material product automatic stacking device and method and belongs to the technical field of magnetic material processing equipment. The magnetic material product automatic stacking device comprises an automatic stacking device body, a robot stacking arm and a stacker, wherein the automatic stacking device body and the stacker both are located on a product postposition moving platform. The robot stacking arm is arranged in the automatic stacking device body. Product storing grooves are formed in the stacker. The product postposition moving platform is located on one side of a product middle moving platform, and a repairing frame is arranged on the other side of the product middle moving platform. Manual participation is reduced, and the yield rate of products is increased. Aiming at the problem that manual stacking of the surfaces of magnetic material products in the prior art is low, automatic stacking can be achieved, and the production efficiency is improved.

Owner:MAANSHAN QILI ELECTRICAL & MECHANICAL EQUIP CO LTD

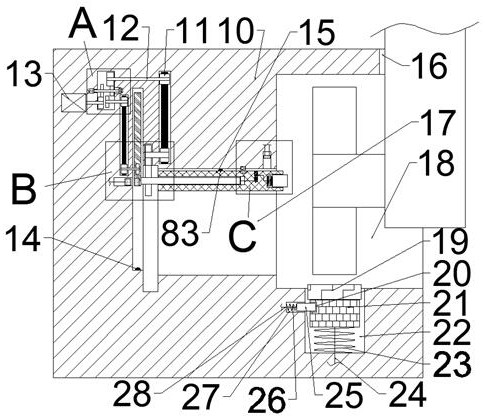

Device capable of polishing waste resin grinding wheel automatically

InactiveCN112171514AFull frictionAchieve reuseAbrasive surface conditioning devicesGear wheelPolishing

The invention relates to the related field of grinding tools, and discloses a device capable of polishing a waste resin grinding wheel automatically. The device comprises a main box body, wherein a working cavity with a rightward opening is formed in the main box body, a grinding wheel machine cavity which is open upwards with a linear opening is formed in the upper side of the working cavity in acommunicating manner, an outer side friction block cavity is formed in the lower side of the working cavity in a communicating manner, a pin shaft cavity is formed in the left side of the outer sidefriction block cavity in a communicating manner, a telescopic rod cavity is formed in the left side of the working cavity in a communicating manner, and a lead screw gear cavity is formed in the leftside of the telescopic rod cavity in a communicating manner. According to the device, an outer side friction block and a side end friction block abut against the outer end face and the side end face of the resin grinding wheel respectively to conduct friction on the two faces at the same time, so that the polishing efficiency is greatly improved; through the up-down movement of a telescopic rod, friction on the side end face of the resin grinding wheel can be more comprehensive, and the polishing effect is remarkable; the device can automatically work, so that the probability of injury duringmanual polishing is avoided; and besides, recycling of the waste resin grinding wheel is achieved, so that resource waste is reduced.

Owner:福州鼓楼卓穆尼奥科技有限公司

Shifting-piece and shifting-fork horizontal transmission type machine for washing and drying mop by centrifugation

InactiveCN1718151AImprove stabilityTo achieve the purpose of disinfectionCarpet cleanersFloor cleanersCentrifugationEngineering

A washing and centrifugally dewatering machine with transverse drive for mop is composed of a washing pail with water inlet and water outlet, a pair of the drive plate installed to the rotational axle of mop and the drive fork installed in said washing pail, which are engaged for driving the mop to rotate, a power unit with an output shaft connected to said drive fork, and a pair of supporting frames with the jamming hold for fastening the mop.

Owner:赵洪琪

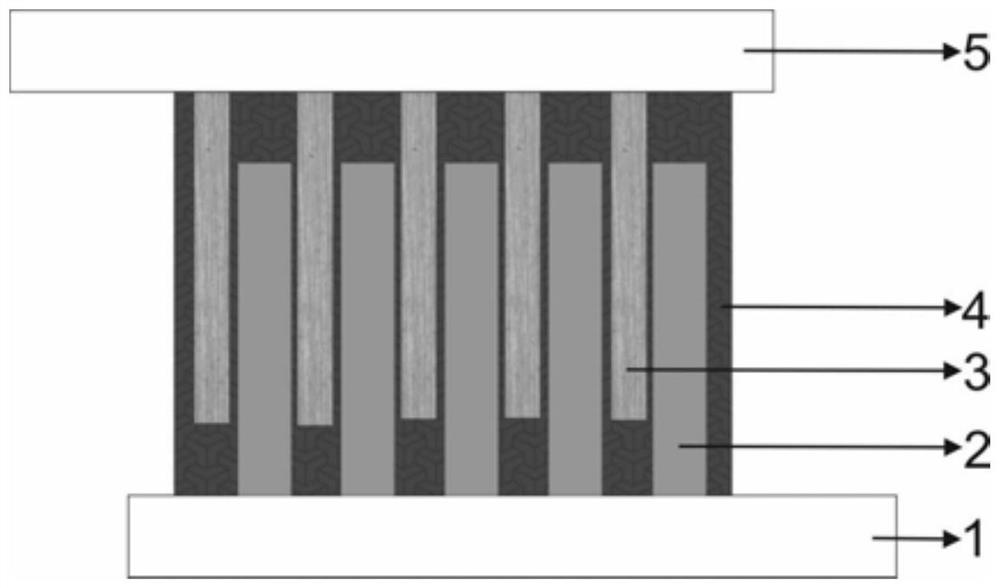

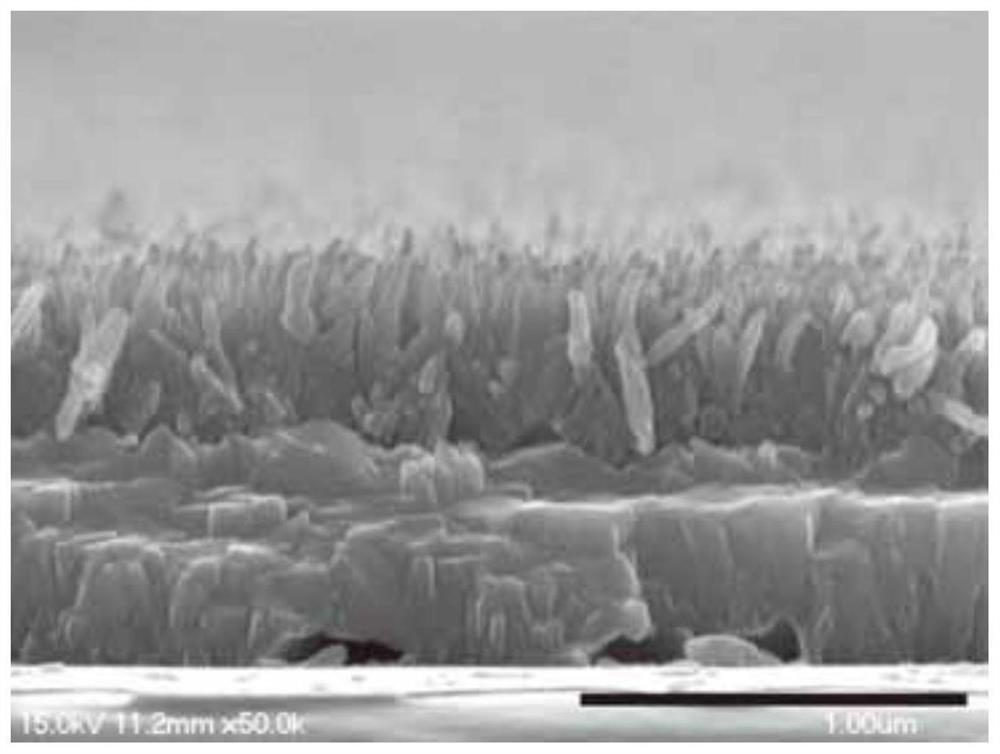

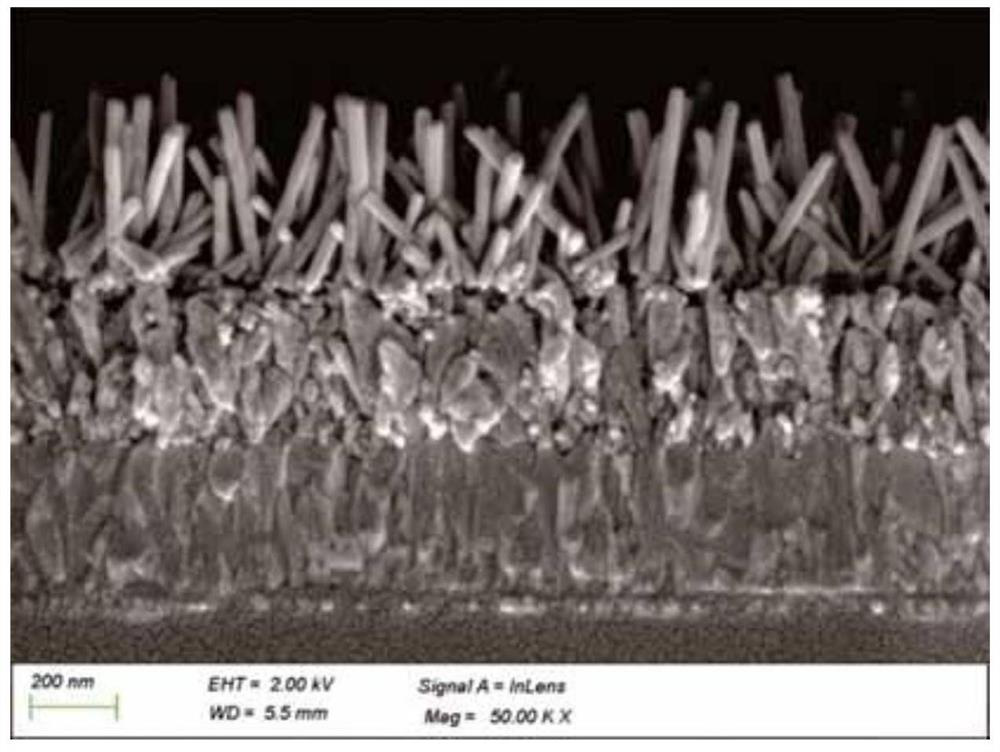

Array interlaced friction nano generator and preparation method thereof

ActiveCN113395011ALow equipment requirementsSuitable for large-scale applicationsMaterial nanotechnologyFriction generatorsElectron holeThin membrane

The invention discloses an array interlaced friction nano generator and a preparation method thereof. The invention relates to a nano friction power generation device formed by directly and mutually overlapping a p-type semiconductor CuO nano array and an n-type semiconductor ZnO nano array, and a preparation method thereof. When the CuO nano array and a planar ZnO thin film are used to form a nano friction power generation device, the current density Jsc of the device is 0.23 uA / cm<2>; when the planar CuO thin film and the ZnO nano array are used to form a nano friction power generation device, the current density Jsc of the device is 0.48 uA / cm<2>; and compared with the two devices, the current density Jsc of the nano friction power generator formed by the CuO nano array and the ZnO nano array is as high as 8 uA / cm<2>. Therefore, the p-type semiconductor CuO nano array and the n-type semiconductor ZnO nano array are directly overlapped with each other, so that the interface area of CuO and ZnO is greatly increased, the friction between CuO and ZnO is more sufficient, and the generated electron hole concentration is richer.

Owner:HUZHOU TEACHERS COLLEGE

Machining method for eyeglass spring hinge strip material

The invention provides a machining method for an eyeglass spring hinge strip material. The machining method solves the technical problem that machining of the eyeglass spring hinge strip material at present is not convenient. The machining method for the eyeglass spring hinge strip material is characterized in that the machining method comprises the following steps that a, a metal plate is selected; b, cleaning is conducted, and dirt of the metal plate is subjected to acid pickling; c, drying is conducted; d, punching is conducted, and a punch is used for punching the metal plate into the shape of the spring hinge strip material; and e, deburring treatment is conducted, a rotary grinding machine is used for conducting grinding and deburring treatment on the spring hinge strip material. The machining method has the beneficial effects that the machining efficiency is high, and the quality of the machined spring hinge strip material is good.

Owner:台州市椒江鑫明眼镜配件厂

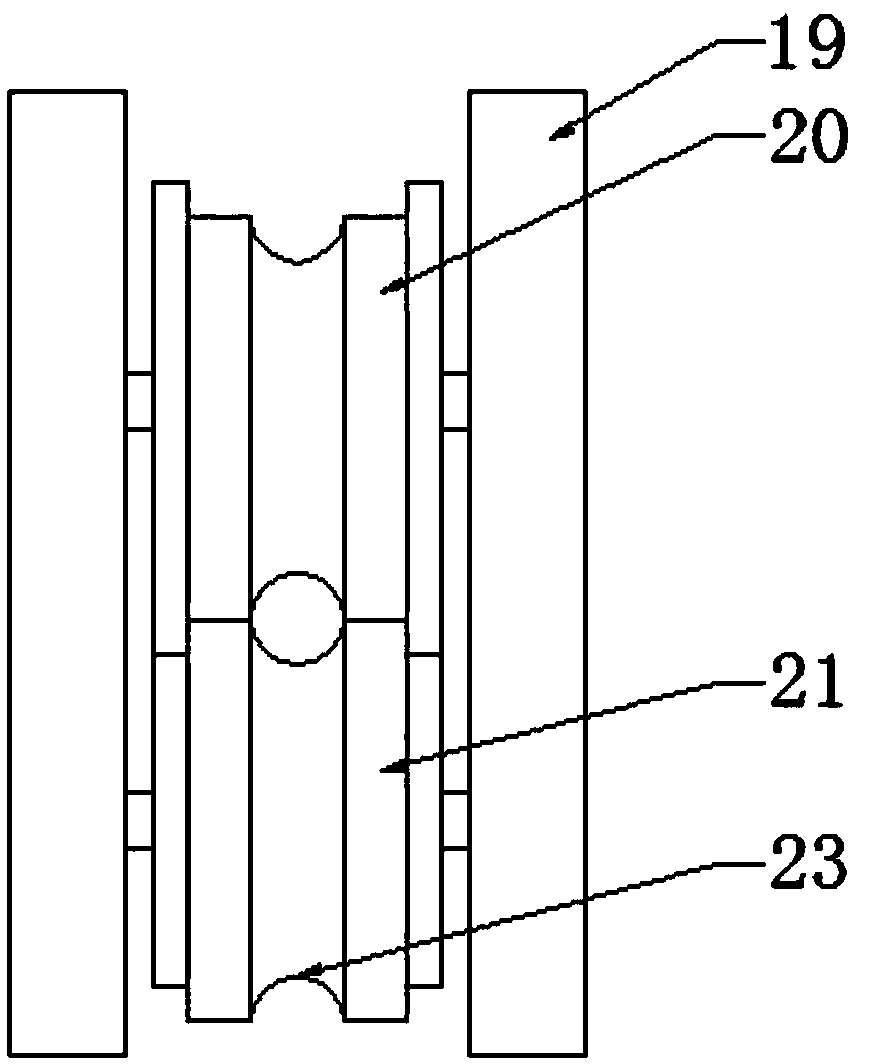

Overhead branch sawing machine for power construction

The invention discloses an overhead branch sawing machine for power construction. The overhead branch sawing machine comprises a machine box, wherein guide mechanisms are symmetrically arranged at twosides of the top part of the machine box; a fixing mechanism is arranged at one side of the lower part of the machine box; movable doors are respectively arranged at two sides of the upper part of the machine box, and are respectively connected with the machine box through self closing and hinges; guide sleeves are arranged at the top part of the inner side of the machine box; the top ends of theguide sleeves penetrate through the machine box and extend to the top surface of the machine box; and first drive wheels are symmetrically arranged at the inner side of the machine box, and are matched with the guide sleeves. The overhead branch sawing machine disclosed by the invention has the beneficial effects that by changing a traditional branch sawing mechanism, branches are cut by cuttinglines, so that a transmission mechanism is not needed, and the loss of kinetic energy is smaller; and meanwhile, the size is smaller, and carrying is convenient.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

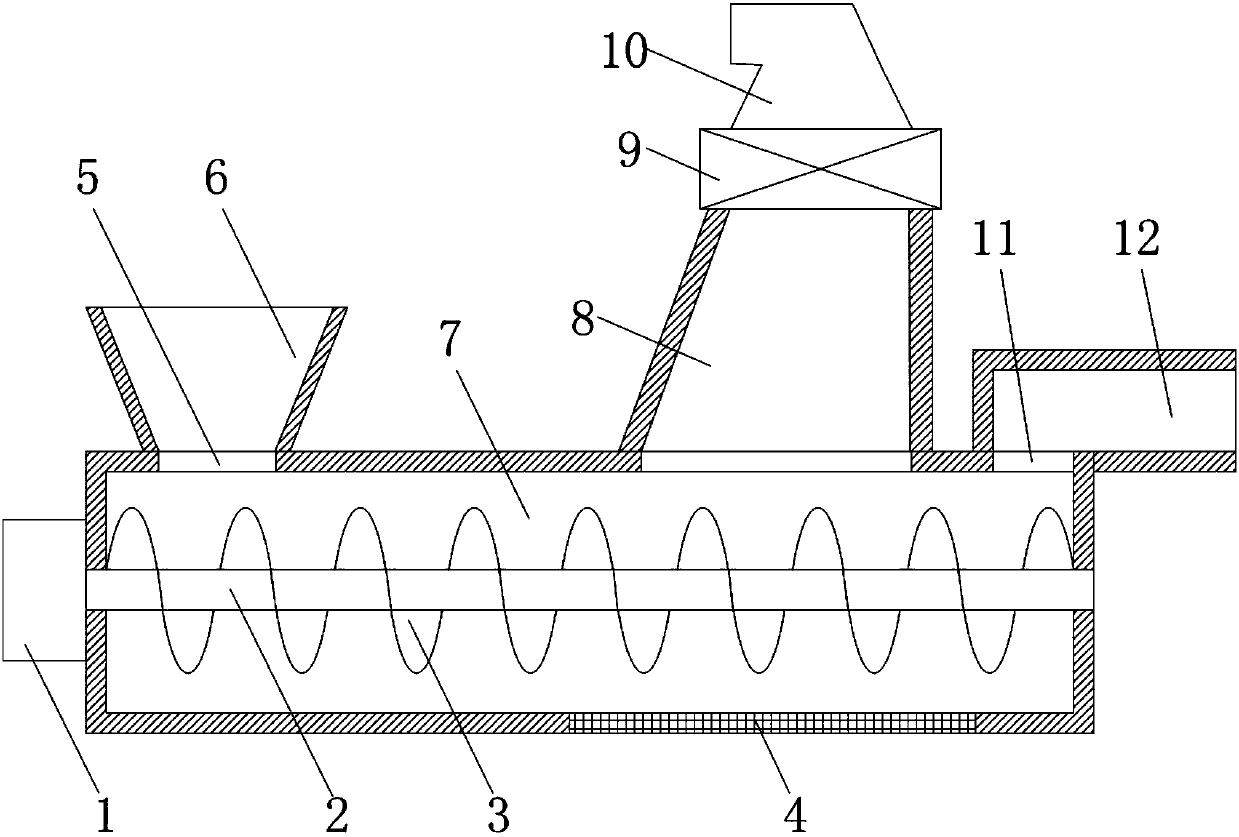

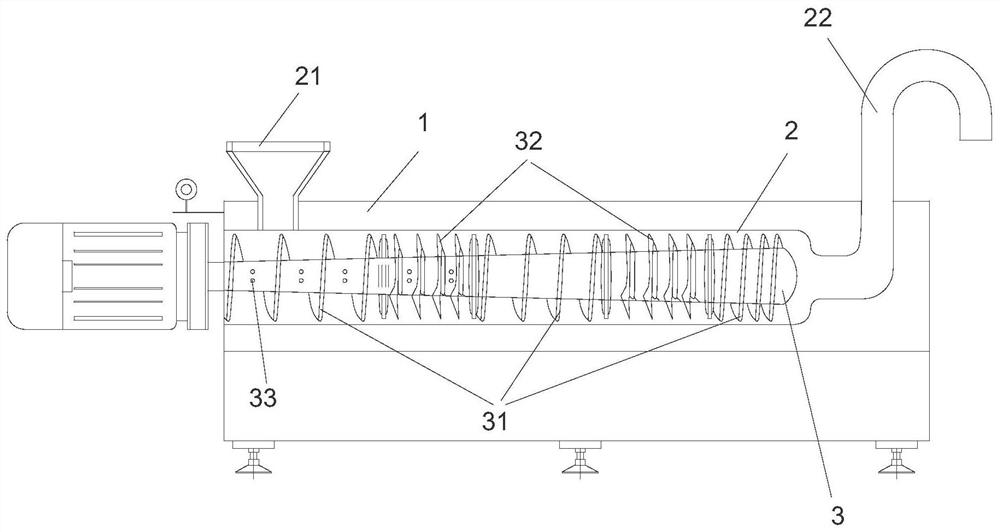

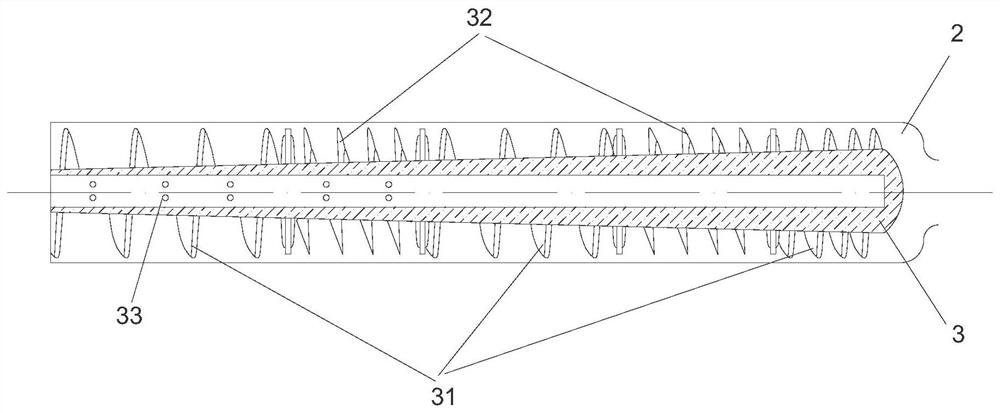

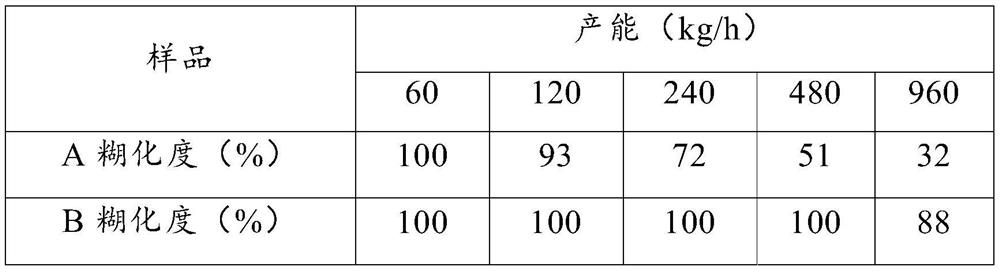

Extrusion gelatinization device and system

ActiveCN113273711AImprove gelatinizationGuaranteed gelatinizationFood shapingMechanical engineeringPhysics

The invention provides an extrusion gelatinization device and a system. The device comprises a heating cavity, an extrusion cavity and a screw rod. The heating cavity is provided with a steam inlet and a steam outlet. The extrusion cavity is located in the heating cavity, and provided with a feeding port and a discharging port which extend out of the heating cavity. The screw rod is of a hollow structure, can rotate in the circumferential direction and comprises a driving section and a working section. The working section is located in the extrusion cavity and used for fitting with the cavity wall of the extrusion cavity when rotating the screw rod so that materials can be extruded and gelatinized while being conveyed from the feeding port to the discharging port. The driving section extends out of the extrusion cavity, and is provided with an opening on the end for communicating with an external steam source and connecting with an external rotary driving mechanism. A through hole for overflowing steam into the extrusion cavity is arranged on the working section. Therefore, materials in the extrusion cavity can be heated at extremely high heating rate with extremely high heating uniformity under the action of the double-layer steam, thereby ensuring gelatinization of the materials under high productivity.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

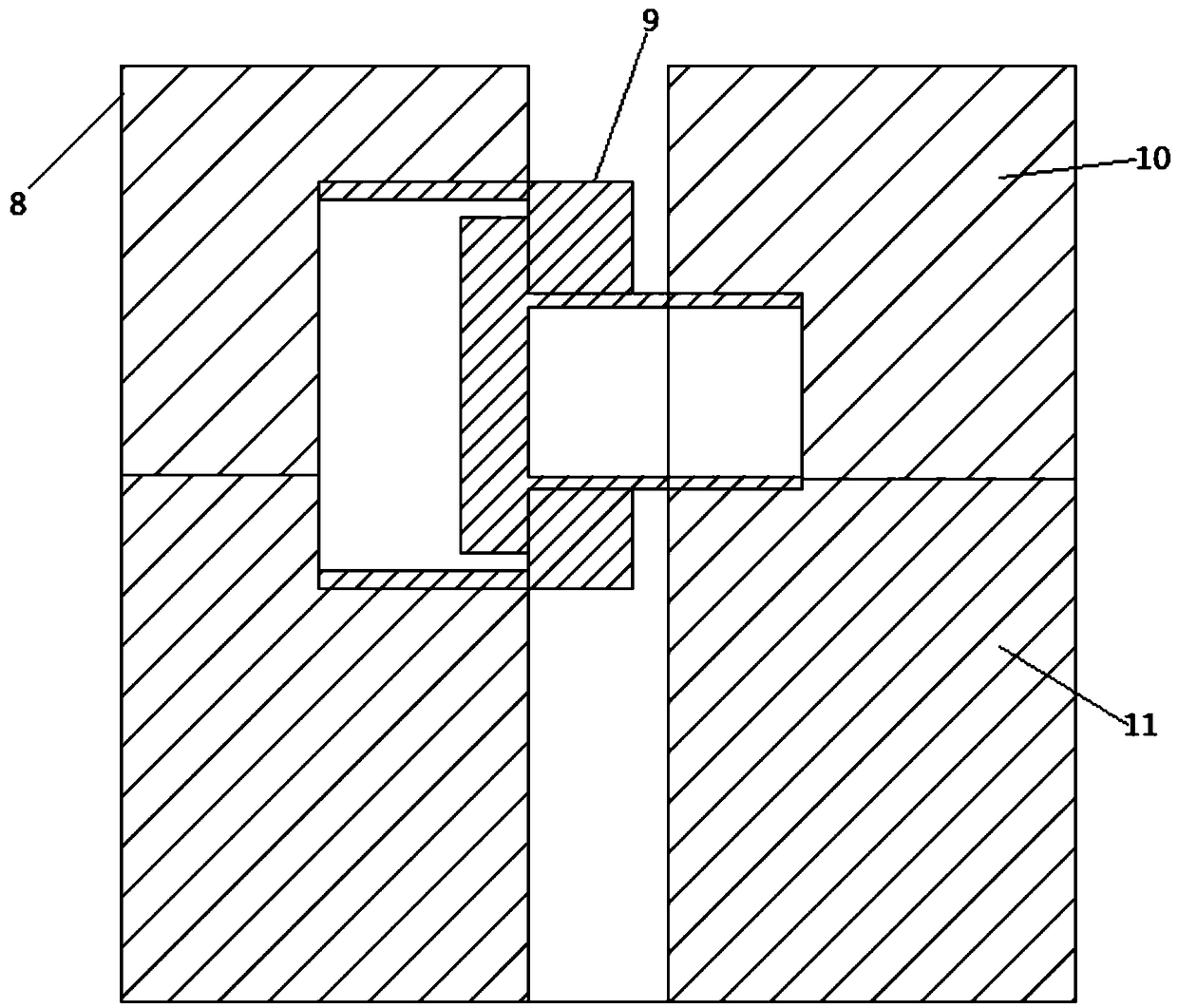

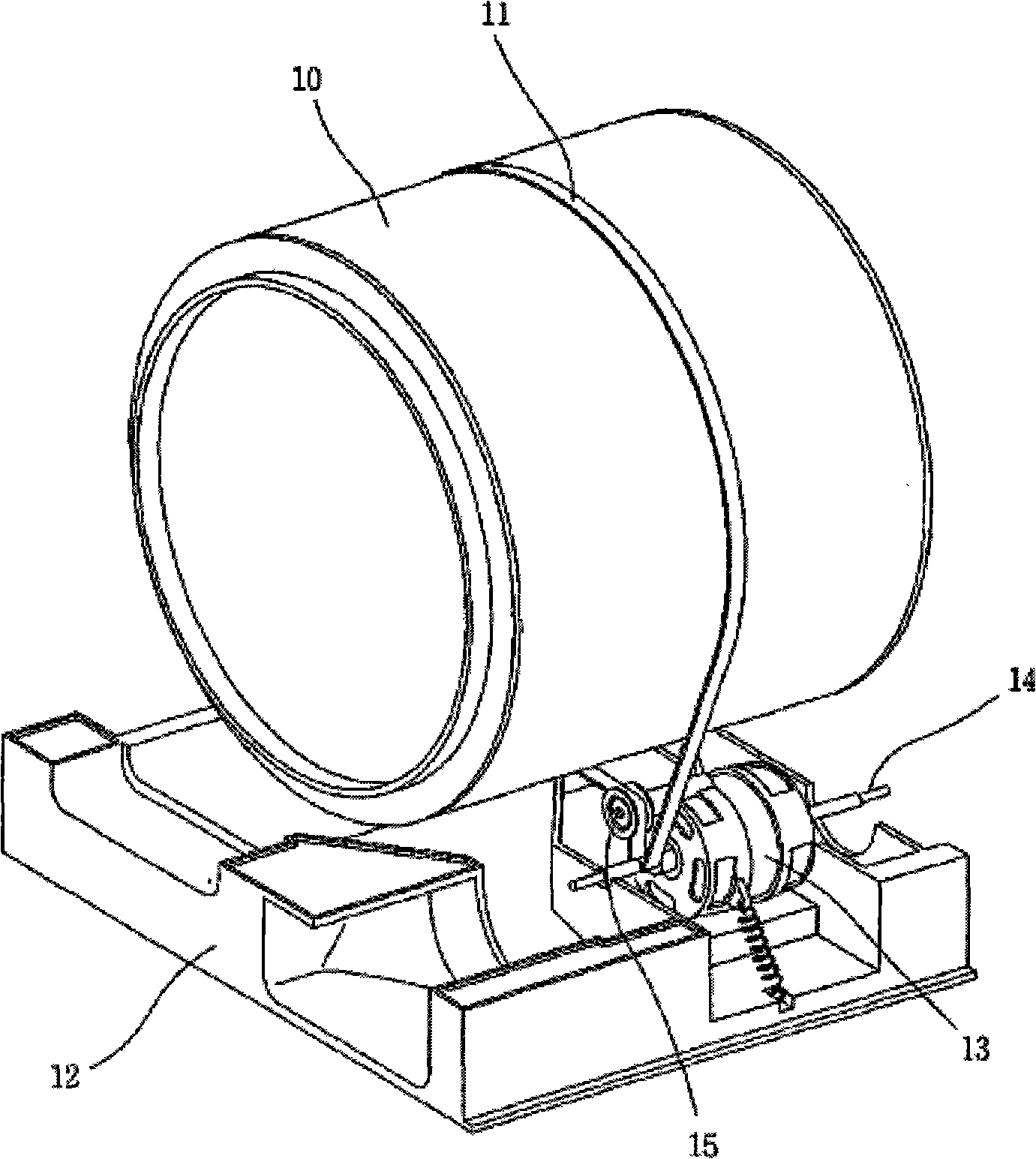

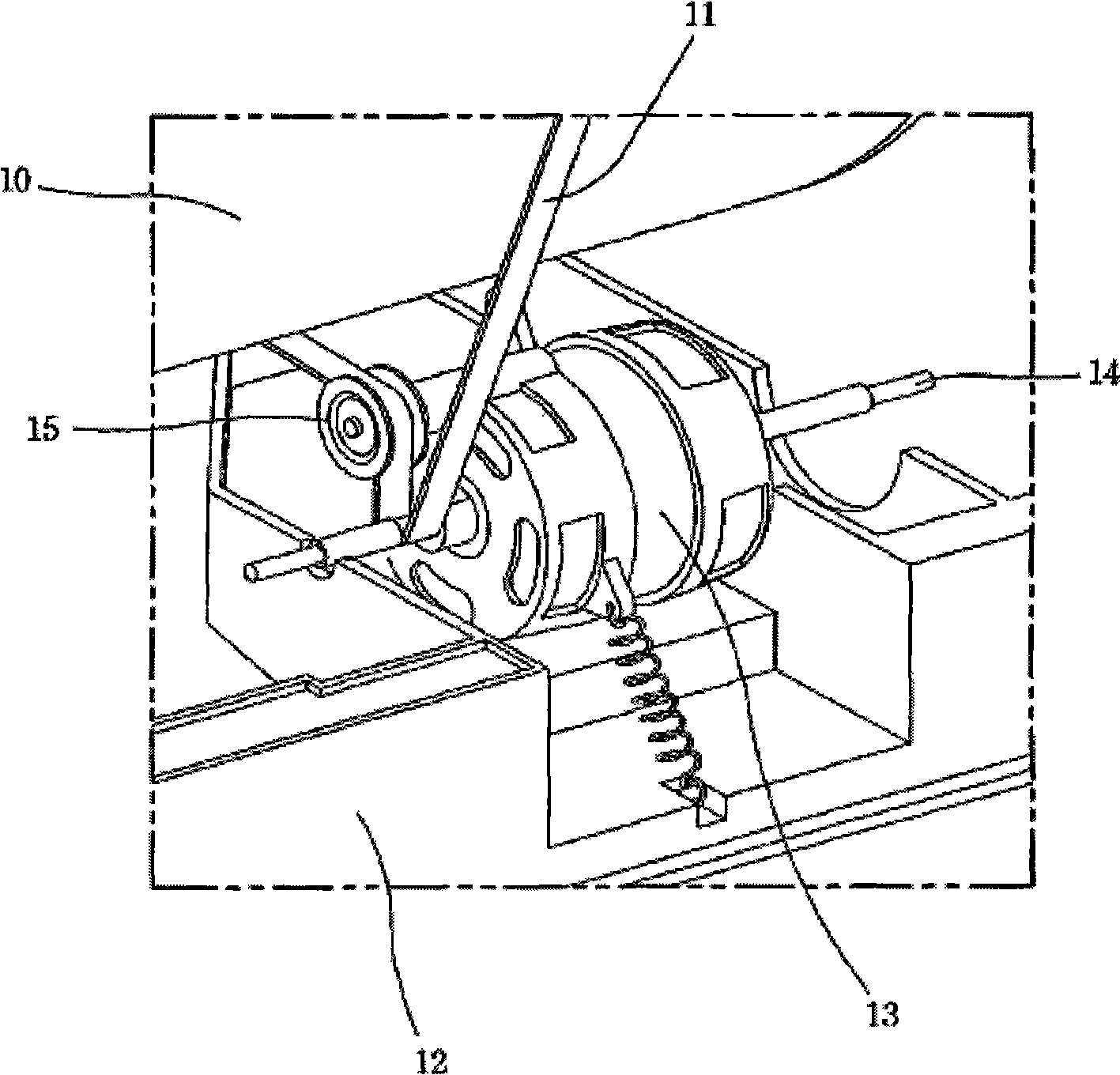

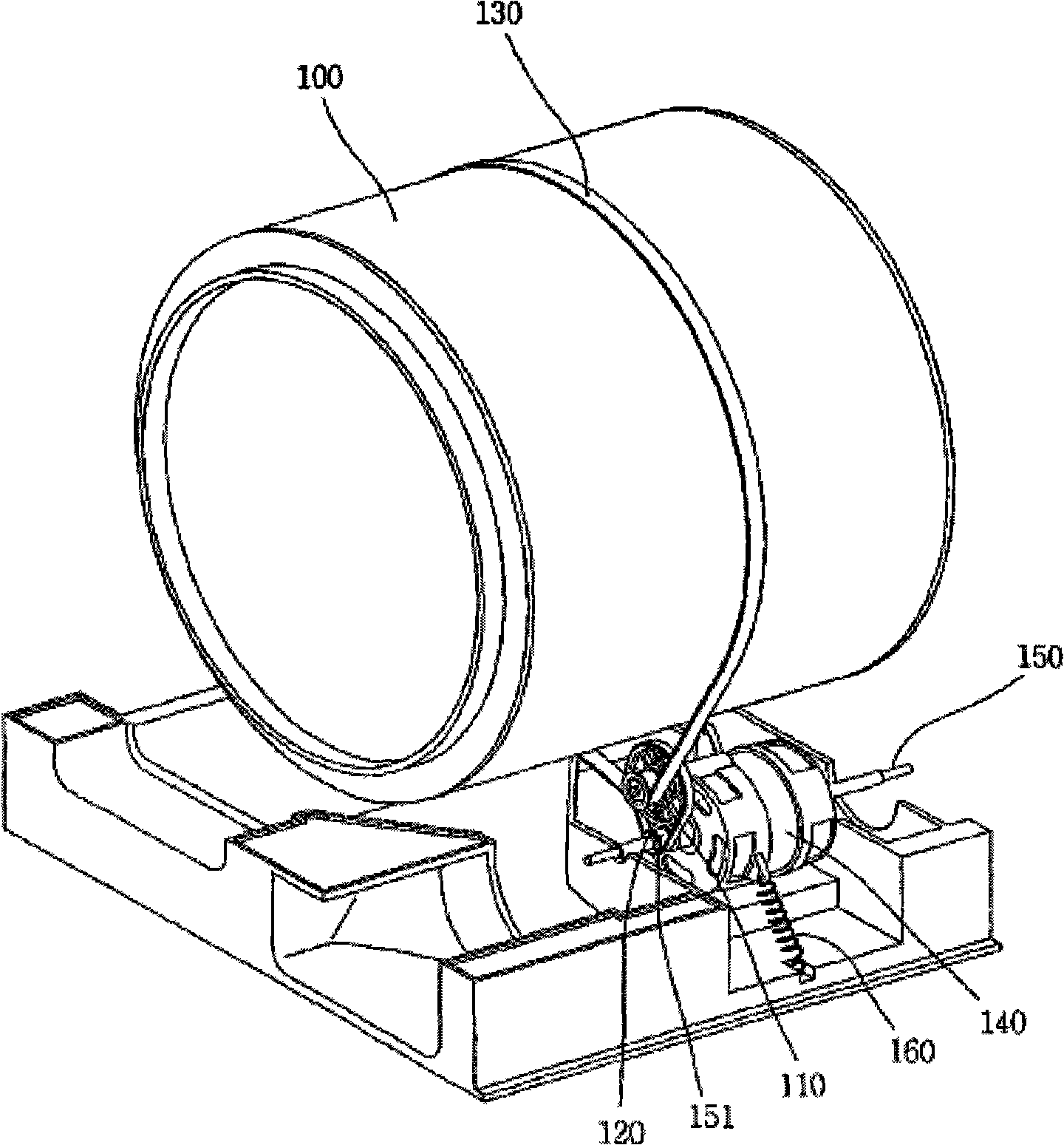

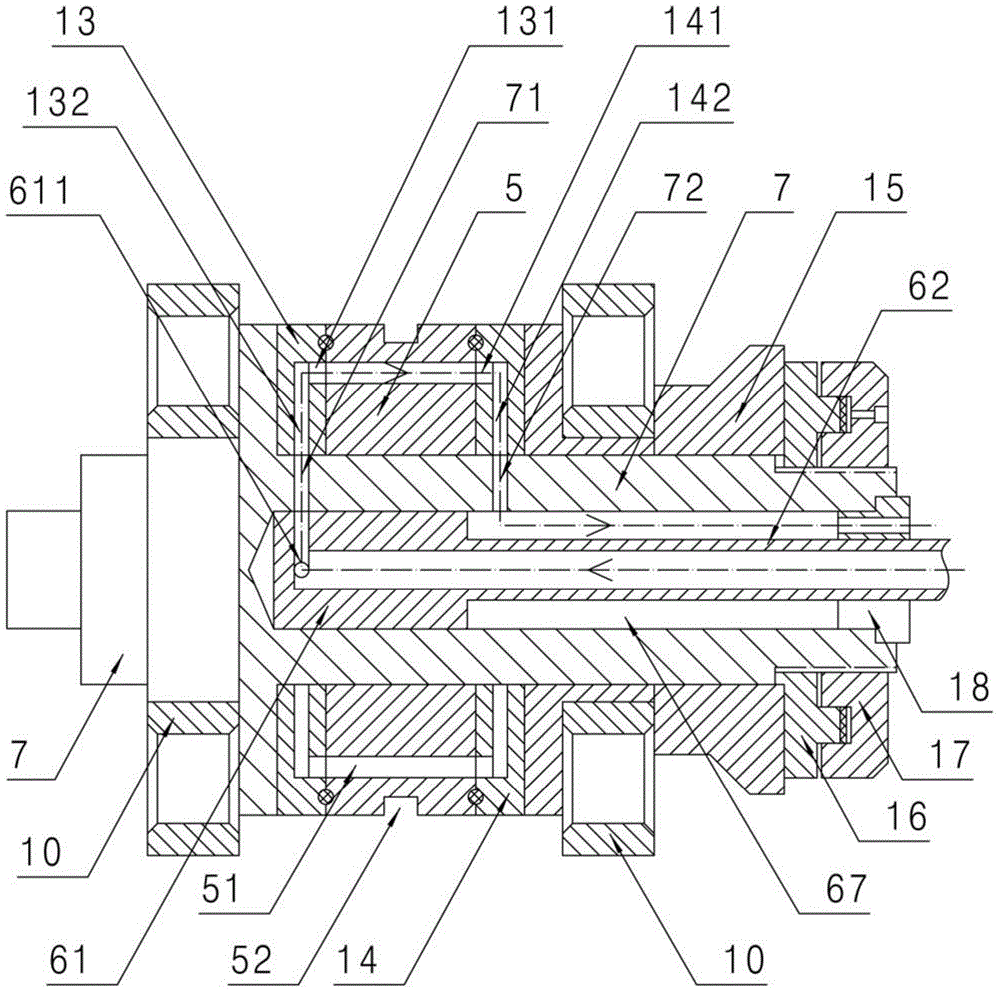

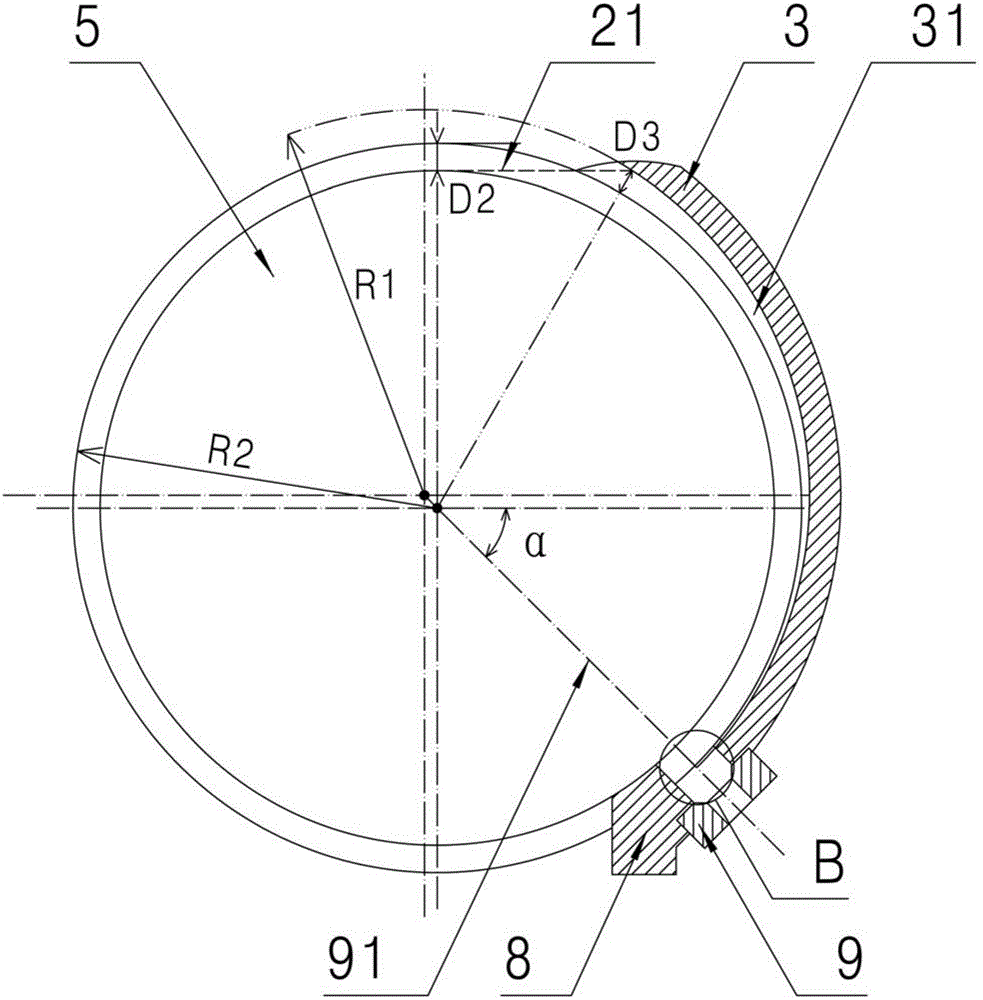

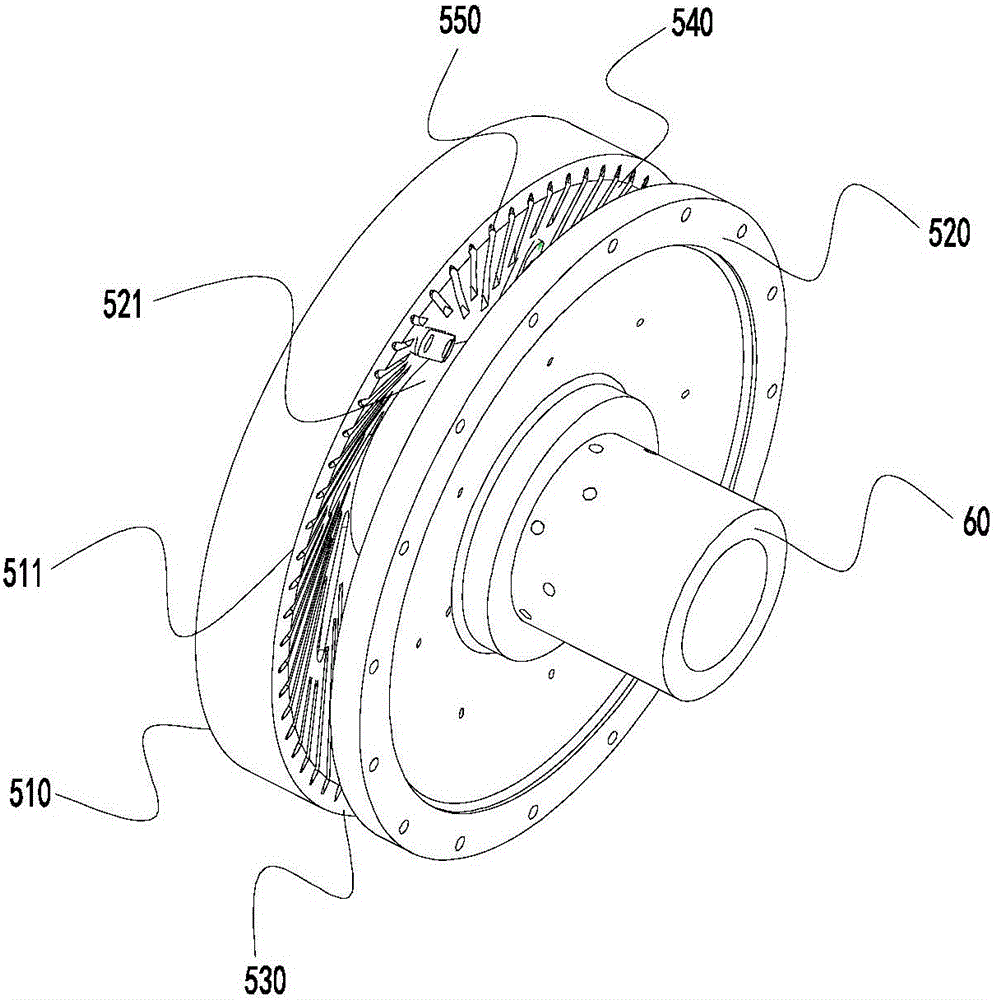

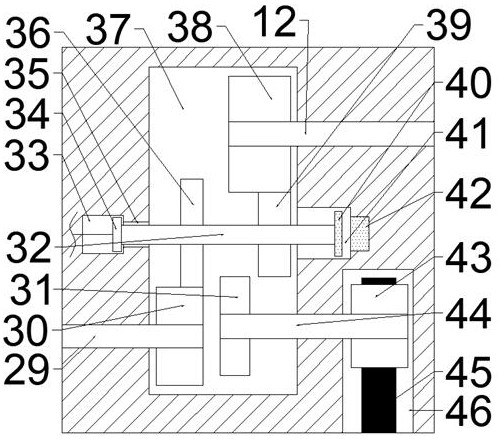

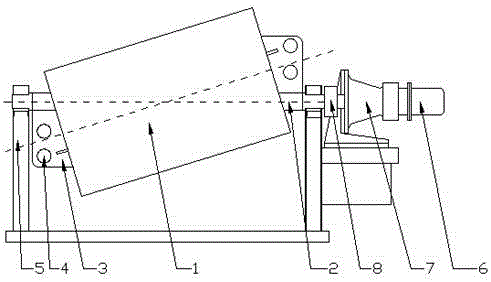

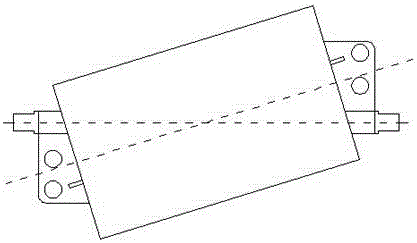

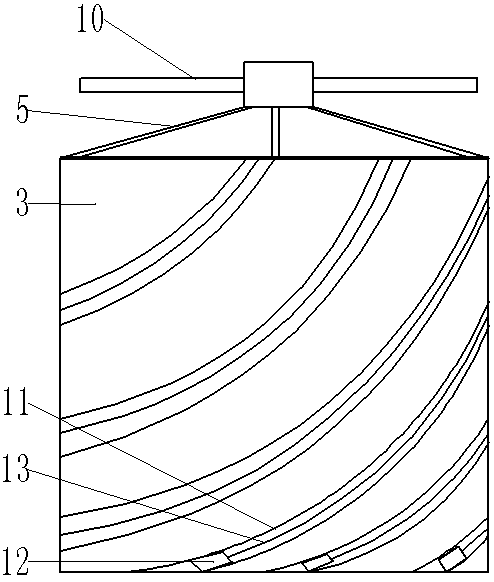

Burr removal roller mechanism

PendingCN106541328AFull frictionImprove work efficiencyEdge grinding machinesPolishing machinesReduction driveEngineering

The invention relates to a burr removal roller mechanism which comprises a roller mechanism body and a roller drive mechanism. The roller mechanism body comprises a hollow roller, an abrasion-resistant layer is arranged on the inner wall of the roller, the two ends of the roller in the axial direction are each provided with a rotary shaft, and an included angle smaller than 90 degrees is formed between the axis of each rotary shaft and the axis of the roller. The roller drive mechanism comprises a rotary support for bearing the rotary shafts. A drive source for driving the rotary shafts to rotate is arranged on the rotary support. The burr removal roller mechanism is mainly composed of a roller part and a motor part, wherein the roller part is a cylindrical container formed by splicing and welding steel plates, and the interior of the roller part is additionally lined with the abrasion-resistant cushion plate, so that the service life of the roller is prolonged; and the motor part comprises a motor and a speed reducer, and it is required that the rotation speed of the roller cannot be too high. The roller is arranged obliquely as a whole, in this way, sufficient mutual friction between parts inside the roller can be ensured during rotation, and accordingly work efficiency is improved.

Owner:江苏神山风电设备制造有限公司

Information display device for big data analysis

InactiveCN113409680AEasy to operateGood occlusionFouling preventionIdentification meansMagnetStructural engineering

The invention discloses an information display device for big data analysis, which comprises a base, a first support column with a hollow structure is fixed on one side of the outer wall of the top of the base through a screw, a second support column with a hollow structure is fixed on the other side of the outer wall of the top of the base through a screw, and a fixing block is arranged on the outer wall of the top of the first support column. A fixing box is arranged on the outer wall of the top of the second supporting column, a motor is arranged on the outer wall of the bottom of the second supporting column, an output shaft of the motor is connected with a lead screw through a coupler, the outer wall of the lead screw is sleeved with a second sliding plate, and one end of the second sliding plate is connected with a fixing frame; and a display screen is arranged on the outer wall of one side of the fixing frame. Under the action of magnetic force of a first magnet and a second magnet, the bottom end of the dustproof cloth is firmly fixed, when outdoor wind power is large, the dustproof cloth is not prone to being lifted up, a good shielding effect is achieved, and the dustproof effect is good.

Owner:何怀云

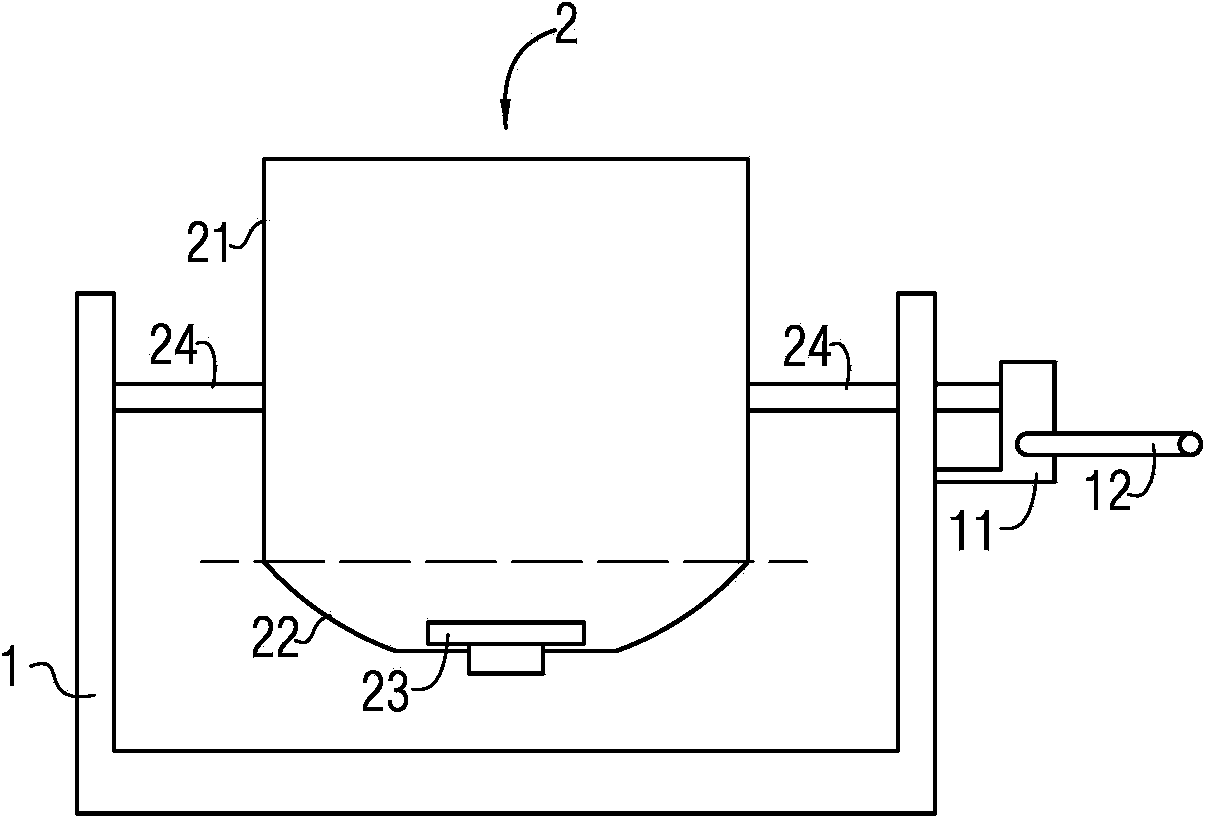

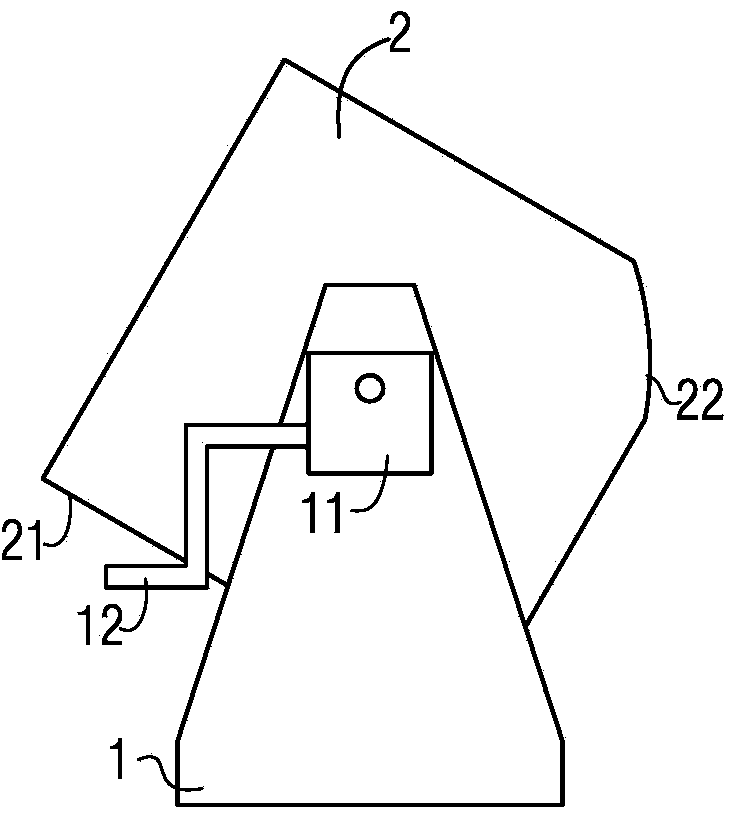

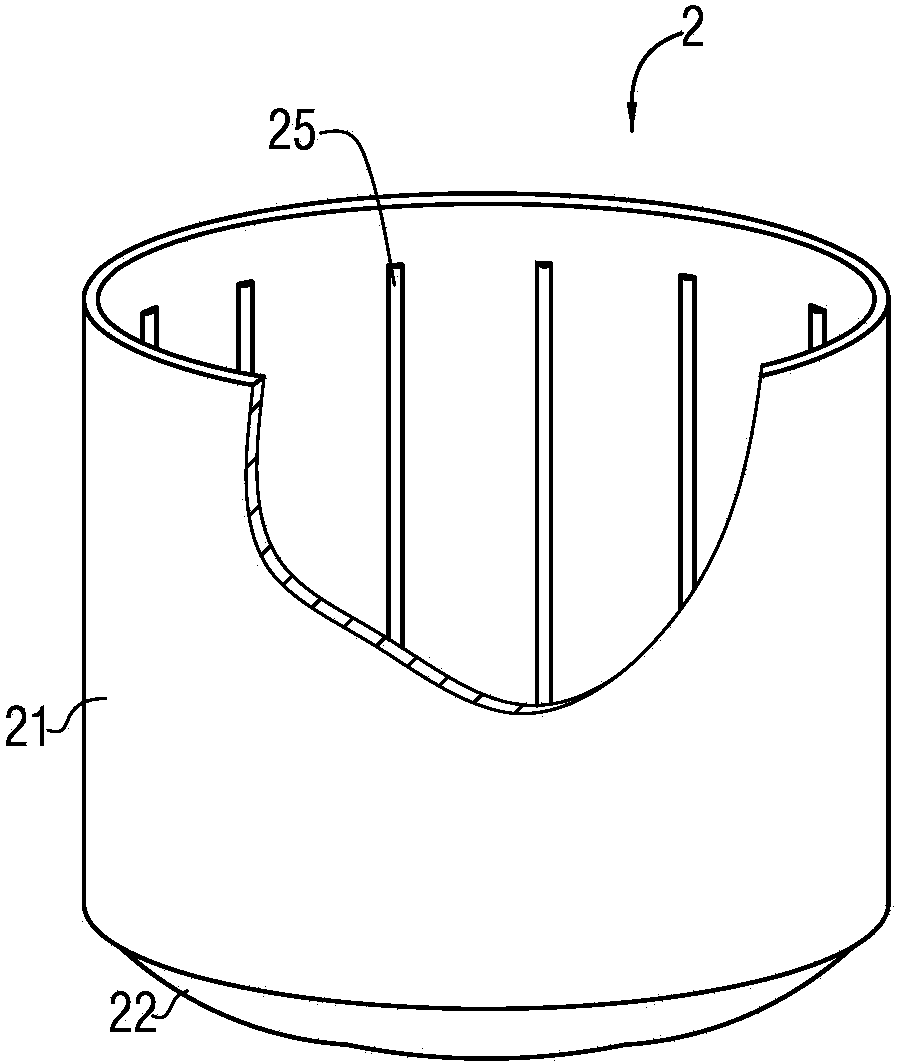

Roxburgh rose thorn-removing method

The invention provides a roxburgh rose thorn-removing method. The roxburgh rose thorn-removing method comprises the following steps: Step A, rotating a thorn-removing cylinder to form a 45-degree included angle with the horizontal plane, feeding a roxburgh rose raw material in the thorn-removing cylinder, in the material feeding process, gradually rotating the thorn-removing cylinder to be perpendicular with the horizontal plane, and finishing feeding; Step B, pouring fresh water into the thorn-removing cylinder, wherein the weight ratio of the poured fresh water to the roxburgh rose raw material fed in the thorn-removing cylinder is 1: (1 to 1.2), the water level in the thorn-removing cylinder 2 is 1-3 cm higher than the roxburgh rose raw material; Step C, starting a stirring impeller, enabling the rotating speed of the stirring impeller 23 to be 23-26 rpm, stirring the material for 15-20 min, and finishing thorn removal; Step D, gradually rotating the thorn-removing cylinder to form a negative 5-degree included angle with the horizontal plane, and discharging the roxburgh rose raw material without thorns from the thorn-removing cylinder. With adoption of the roxburgh rose thorn-removing method disclosed by the invention, the roxburgh rose raw material can be conveniently fed and discharged, and the roxburgh rose raw material is enabled to get friction sufficiently, so as to ensure the thorn removing efficiency of the roxburgh rose raw material.

Owner:GUIZHOU QIANBAO FOOD

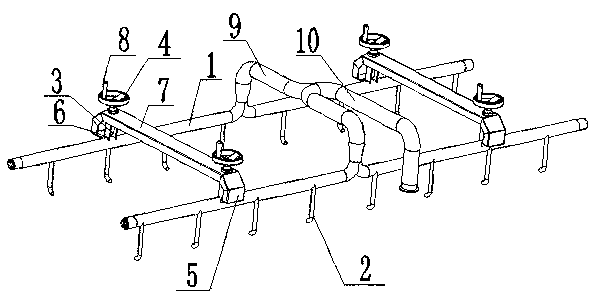

Cross-flow cleaning spray device

Owner:山东瑞帆果蔬机械科技有限公司

Anti-corrosion friction power generation coating material as well as preparation method and application thereof

InactiveCN112194943AGood triboelectric performanceImprove corrosion resistanceAnti-corrosive paintsBuoyConductive materials

The invention provides an anti-corrosion friction power generation coating material and a preparation method and application thereof, belonging to the technical field of coating materials. The anti-corrosion friction power generation coating material provided by the invention has good triboelectrification performance, can be applied to the surfaces of various conductive materials, and can effectively collect friction energy (such as wave energy) in an environment; ad meanwhile, a coating formed by the anti-corrosion friction power generation coating material provided by the invention has goodanti-corrosion performance, has a protection effect on a base material, and can effectively protect the base material in an ocean from being damaged by corrosion. The anti-corrosion friction power generation coating material provided by the invention can be used as an anti-corrosion power generation coating of overwater equipment (such as ships, maritime work equipment or overwater buoys) in a water environment (such as oceans, rivers, lakes and seas), and electric energy generated by friction can play roles in illumination, driving, sensing, cathodic protection, corrosion protection and the like.

Owner:青岛市资源化学与新材料研究中心 +1

Gear quenching anti-splash oil device

InactiveCN106755827BAchieve full quenchingImprove processing qualityFurnace typesHeat treatment furnacesImpellerGear oil

The invention relates to the technical field of processing of gears, and discloses an oil splashing preventing device for gear quenching. The oil splashing preventing device for gear quenching comprises a rack, wherein a quenching cylinder is arranged on the rack; the inside of the quenching cylinder is in threaded connection with an oil cylinder; an inflating cavity is formed between the bottom of the oil cylinder and the bottom wall of the quenching cylinder; air tubes are arranged on the outer side wall of the oil cylinder and communicate with the inflating cavity; a piston is arranged in each air tube; each piston is connected with a steel wire; annular elastic cloth is arranged at the upper end of the oil cylinder; the steel wires are connected with the elastic cloth; an impeller is arranged above the oil cylinder and is provided with a center shaft; struts are arranged at the upper end of the oil cylinder and are fixedly connected to the center shaft; the center shaft is connected with a spline shaft; the other end of the spline shaft is in key connection with a shaft sleeve; a slot is formed in the other end of the shaft sleeve; an air cylinder is arranged above the shaft sleeve and comprises a piston rod; the piston rod is clamped in the slot; a first conveying belt and a second conveying belt are arranged on the rack and positioned on the outer side of the quenching cylinder; and the second conveying belt is positioned between the oil cylinder and the impeller. By the oil splashing preventing device for gear quenching, the problem that oil is splashed during gear quenching can be solved.

Owner:滁州伏特威电气技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com