Turbine disc and blade locking mechanism for turboprop engine

A locking mechanism, turbine disk technology, applied in the directions of engine components, machines/engines, blade support components, etc., can solve the problems of high difficulty in processing and assembly, complex structure, etc., to improve production efficiency, simple processing difficulty, shortening The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

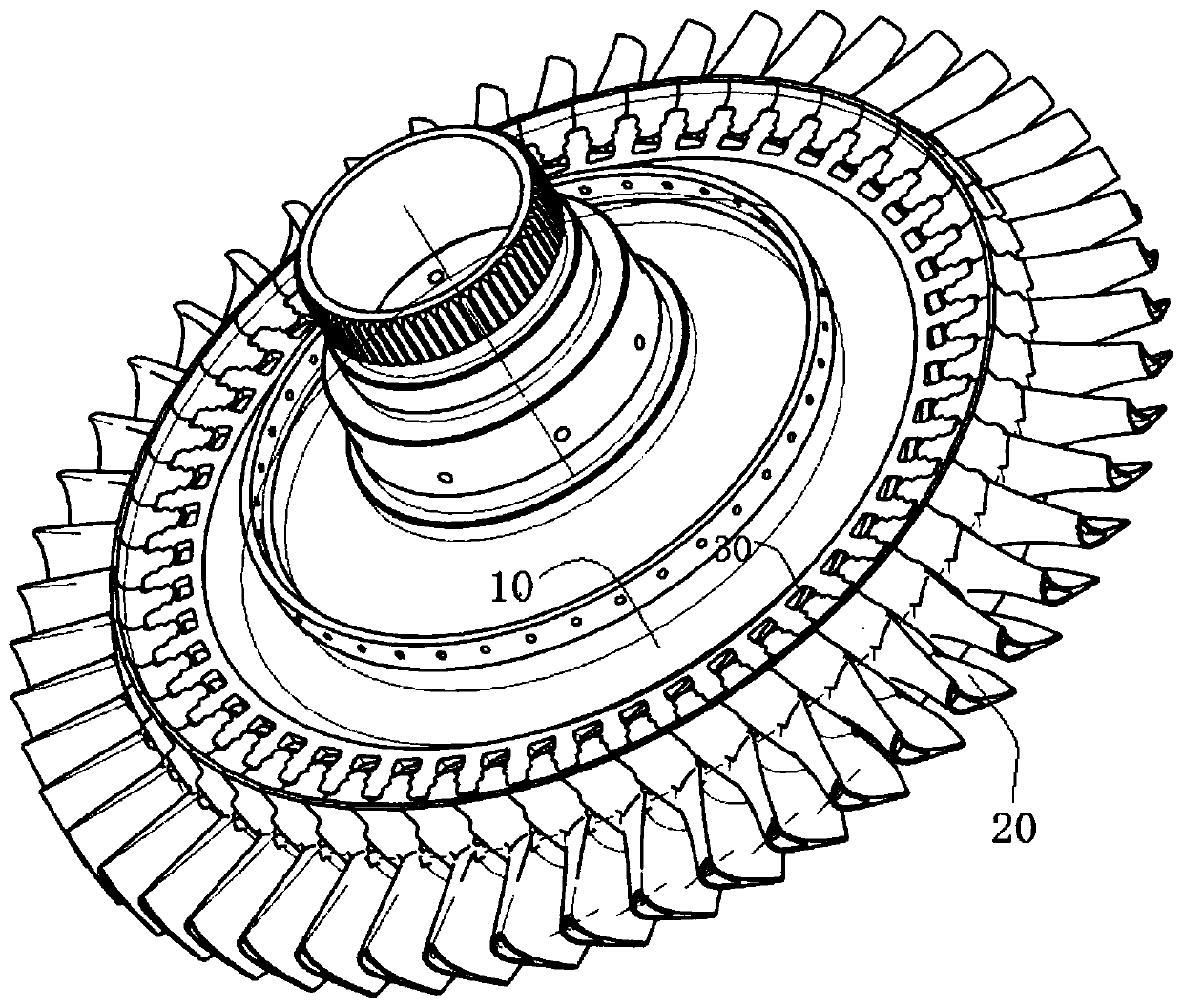

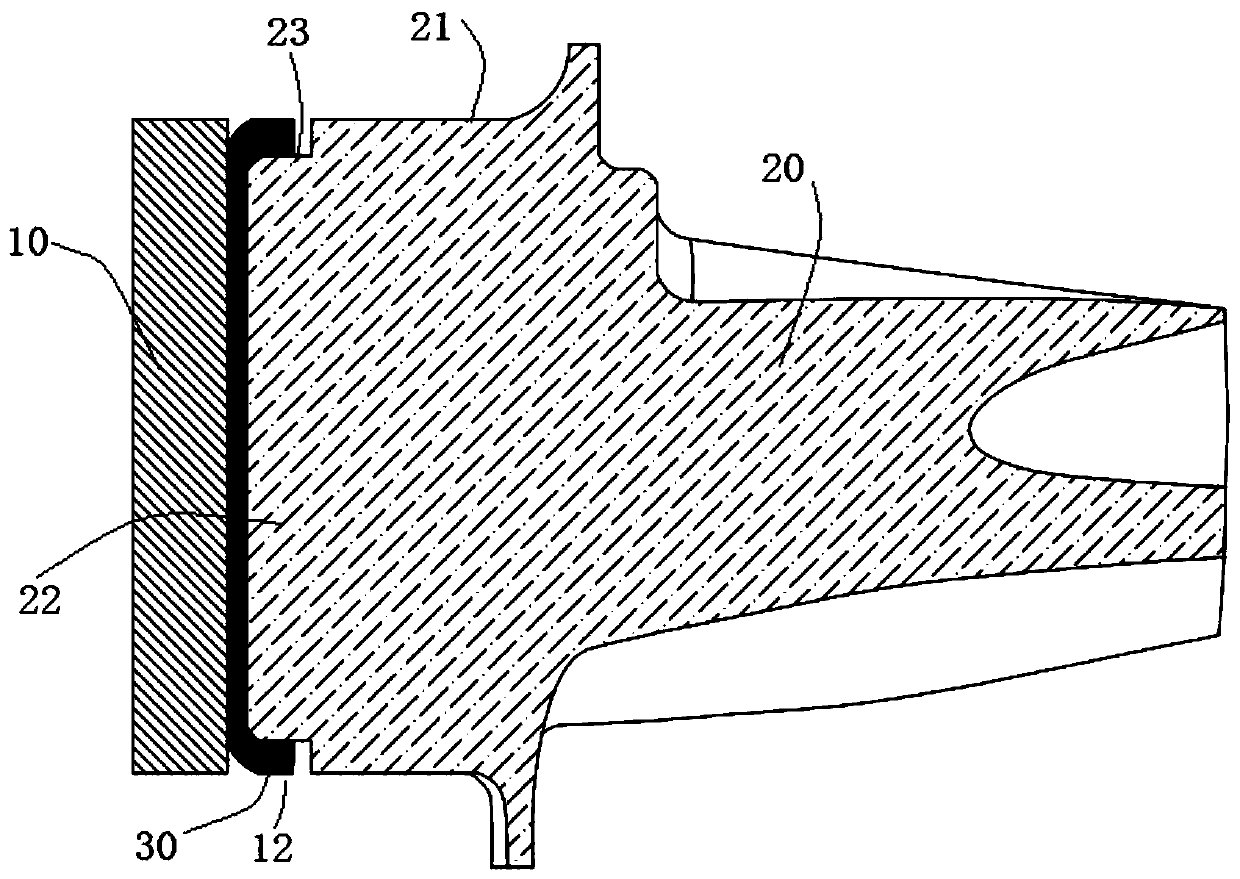

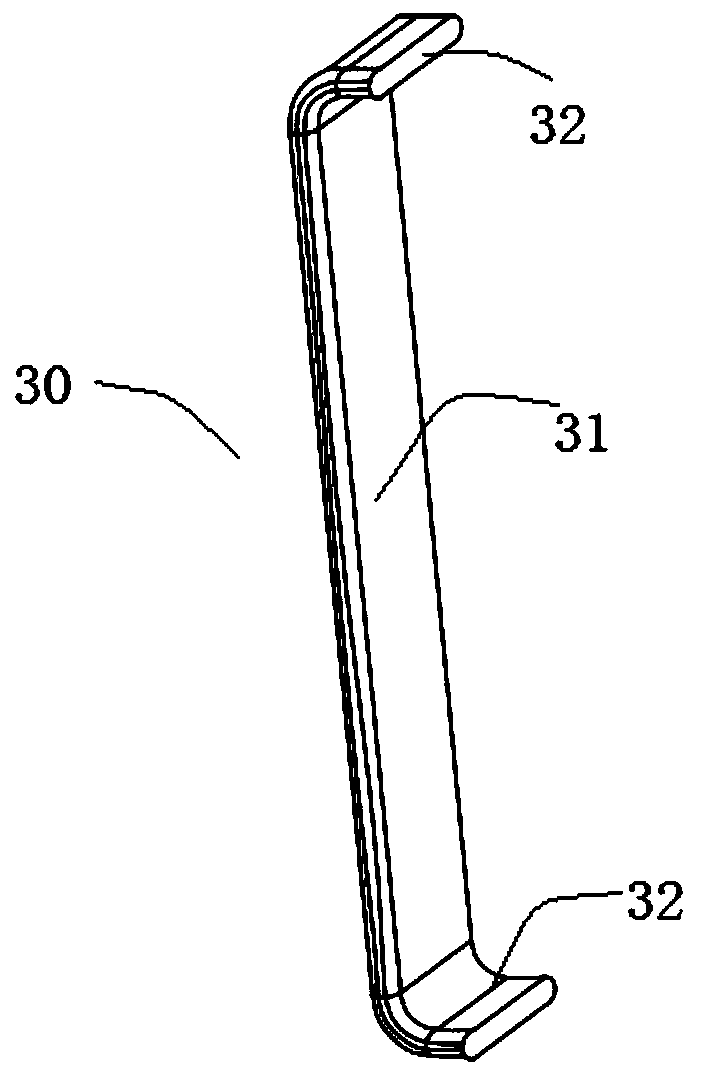

[0034] see figure 1 As shown, this embodiment provides a turbine disk and blade locking mechanism for a turboprop engine, including a turbine disk 10 and a number of blades 20 uniformly distributed around the periphery of the turbine disk 10, and several blades 20 adopt tenon grooves and tenons The connection is embedded on the outer periphery of the turbine disk 10 and locked and fixed by the locking piece 30 . Specifically, the blade 20 uses the tenon structure at its root to embed into the tenon-groove structure of the turbine disk 10 , and the blade 20 is fixed on the turbine disk 10 through the locking piece 30 .

[0035] In this example, see figure 2 As shown, the outer periphery of the turbine disk 10 is evenly distributed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com