Array interlaced friction nano generator and preparation method thereof

A technology of nano generators and arrays, which is applied in the field of nano semiconductor materials and new energy, and can solve the problems of complex preparation process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

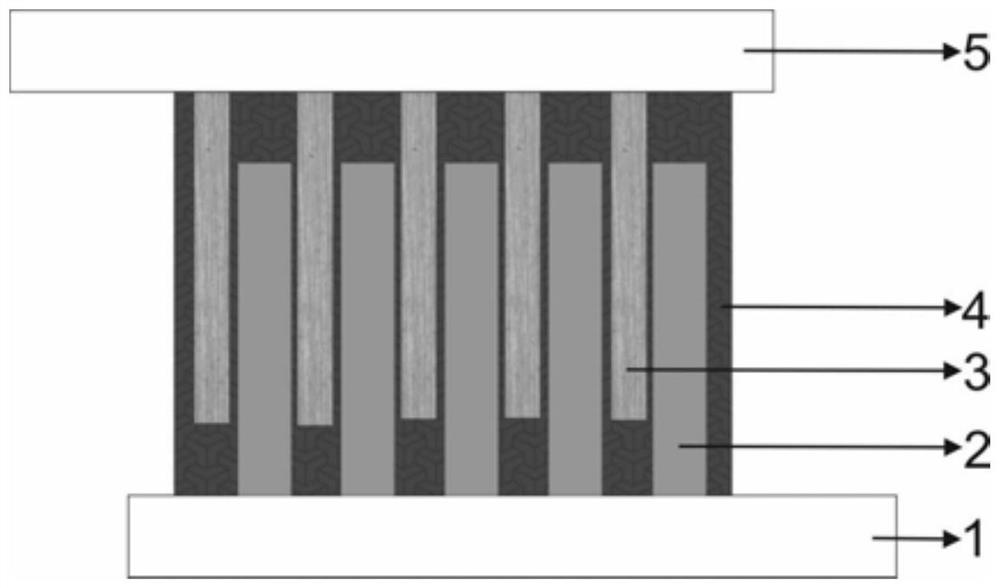

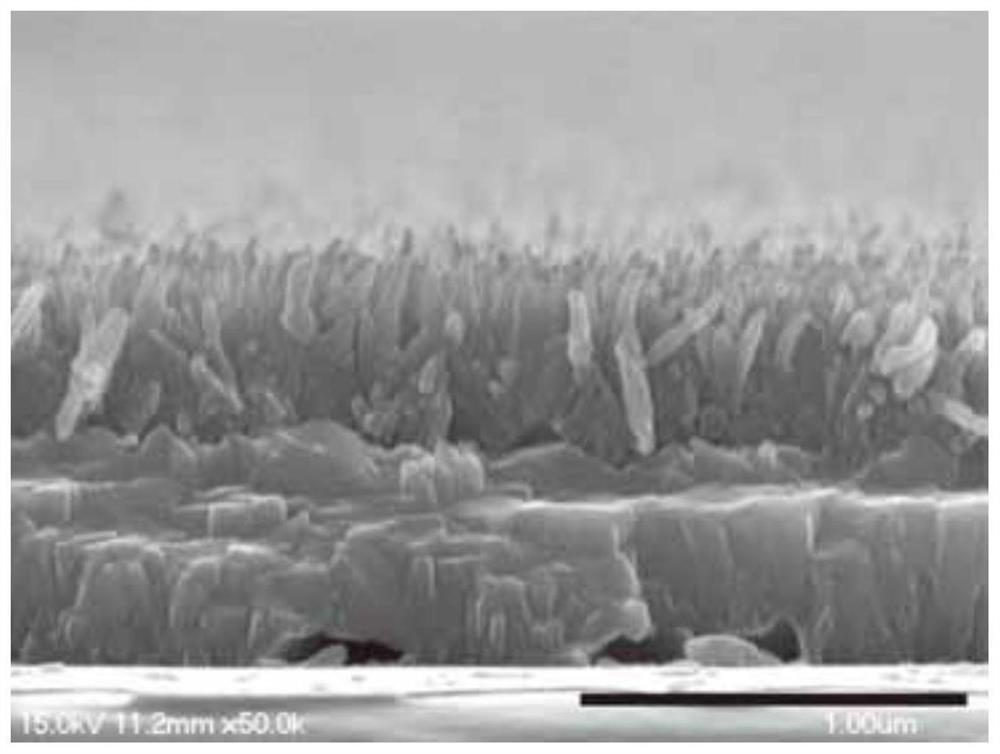

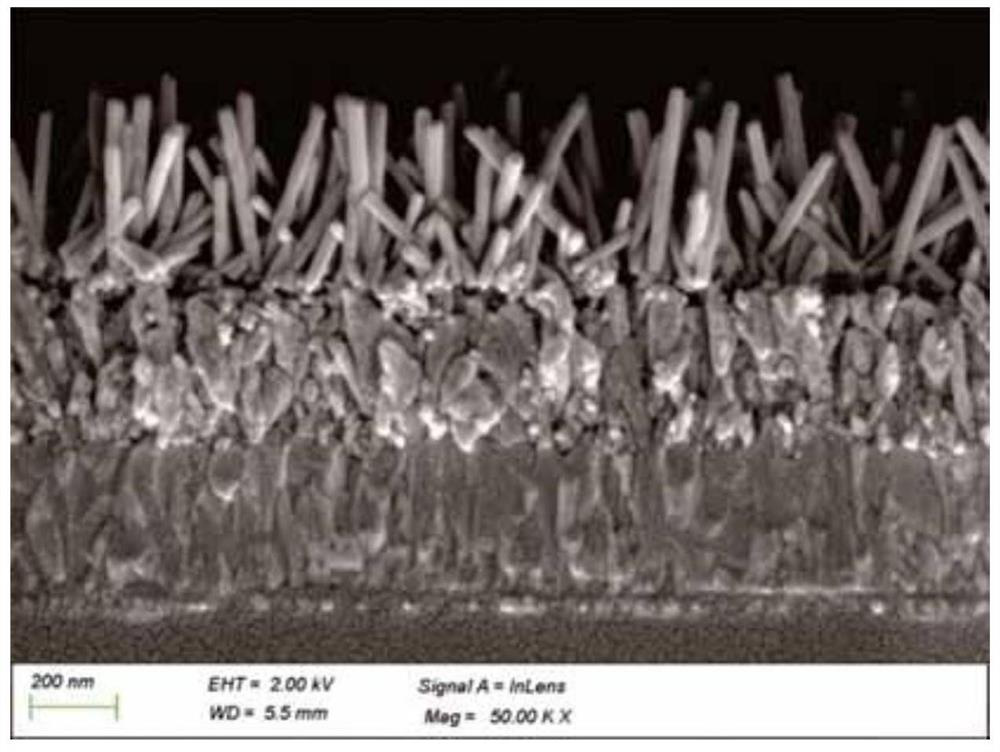

[0057] Example 1: CuO nano-array / ZnO nano-array power generation device.

[0058] (3-1) Clean the FTO conductive glass with acetone, isopropanol, and ultrapure water ultrasonically, and then treat it with ultraviolet and ozone for 30 minutes after drying to obtain a clean FTO conductive glass for use;

[0059] (3-2) 0.10 g of copper acetate was dissolved in 5 ml of absolute ethanol, and the resulting mixture was stirred at room temperature for 2 hours to obtain a blue clear solution;

[0060] (3-3) Spin-coat the blue clear solution obtained in step (3-2) on the treated FTO conductive glass at a speed of 2000 rpm / min, and then place it on a heating table for annealing at 100 °C for 1 minute. This process Repeat four times to obtain a uniform copper acetate film;

[0061] (3-4) Calcining the copper acetate film prepared in step (3-3) in a muffle furnace at 250°C for 60 minutes to obtain a CuO dense seed layer film covering the FTO conductive substrate,

[0062] (3-5) Place the...

Embodiment 2

[0069] Embodiment 2: CuO nano-array / ZnO nano-array power generation device.

[0070] (4-1) Preparation of CuO nanorod arrays: except that the reaction time in step (3-5) is 4 hours, the others are the same as in Example 1.

[0071] (4-2) Preparation of ZnO nanorod array: except that the reaction time in step (3-9) is 4 hours, the others are the same as in Example 1.

[0072] (4-3) Overlay the CuO nanoarrays obtained in step (4-1) and the ZnO nanoarrays obtained in step (4-2), and use capillary action to infiltrate the I - / I 3 - Electrolyte, complete the nano triboelectric power generation device.

[0073] Characterization of the battery

[0074] In Comparative Example 1, when CuO nano-arrays and planar ZnO thin films are used to form a nano-triboelectric power generation device, the current density of the device J sc 0.23 uA / cm 2 ; In comparative example 2, when using planar CuO film and ZnO nanometer array to form nano triboelectric power generation device, the curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com