Continuous cast extrusion molding device

A forming device and casting extrusion technology, which is applied in the field of metal material processing, can solve problems such as insufficient friction and affecting the quality of bars, and achieve the effects of smooth heating, improved ductility, and improved fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

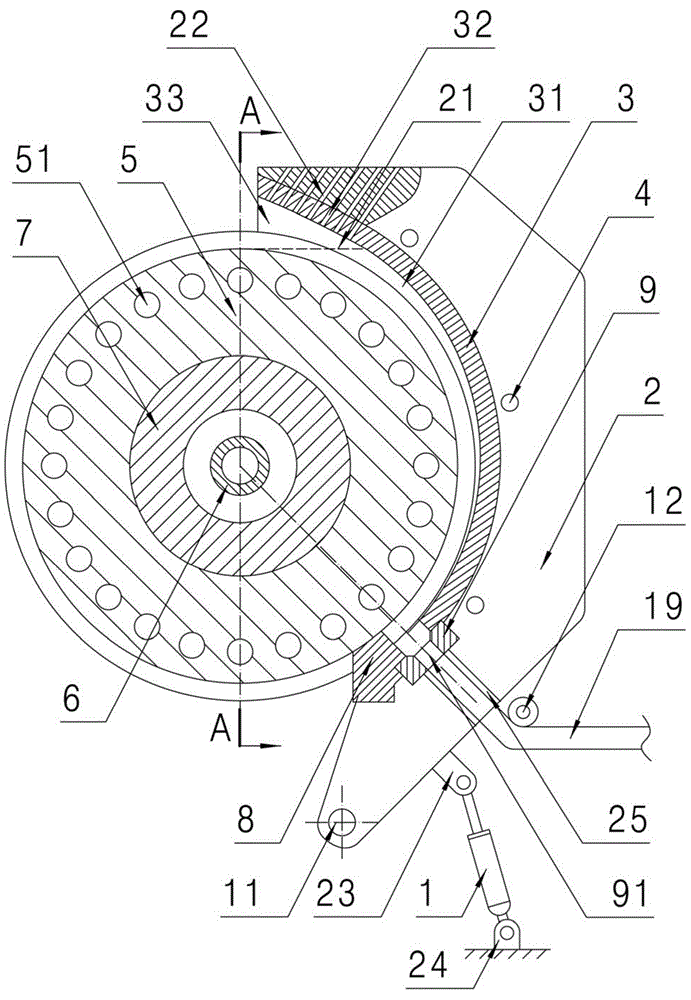

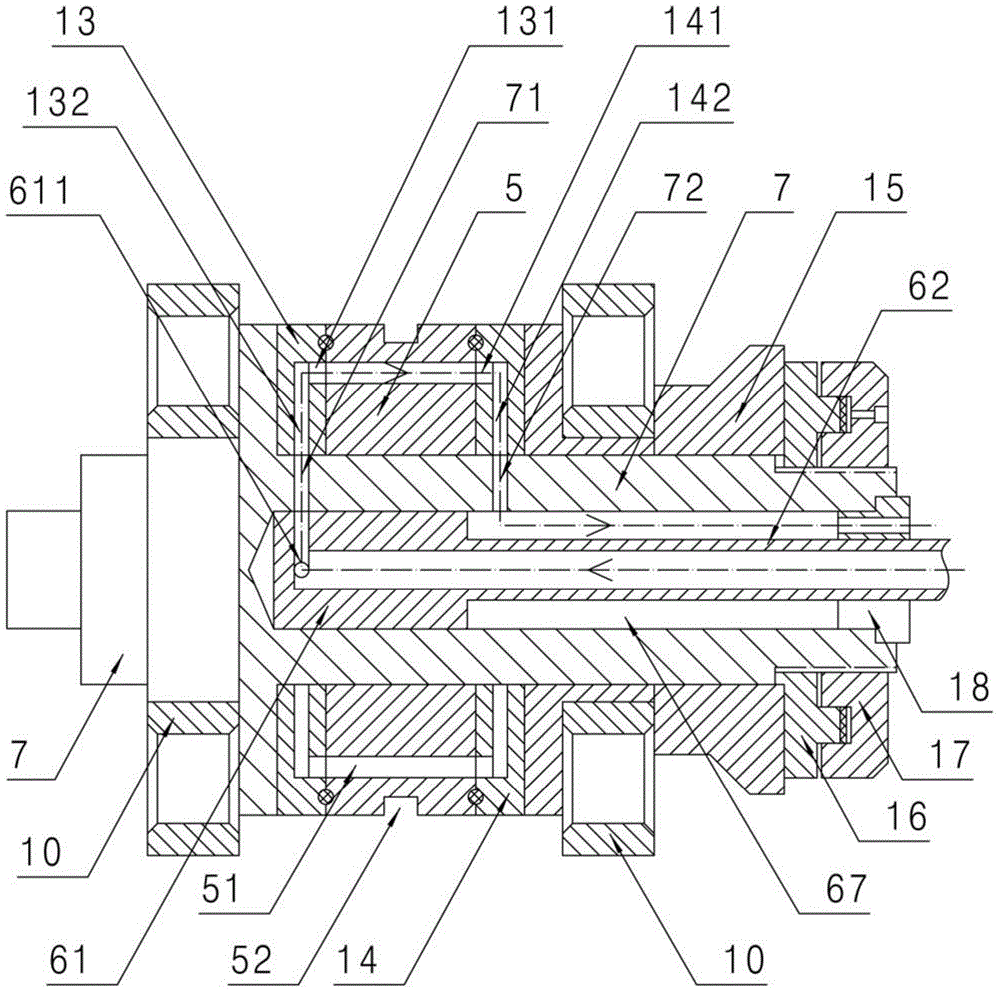

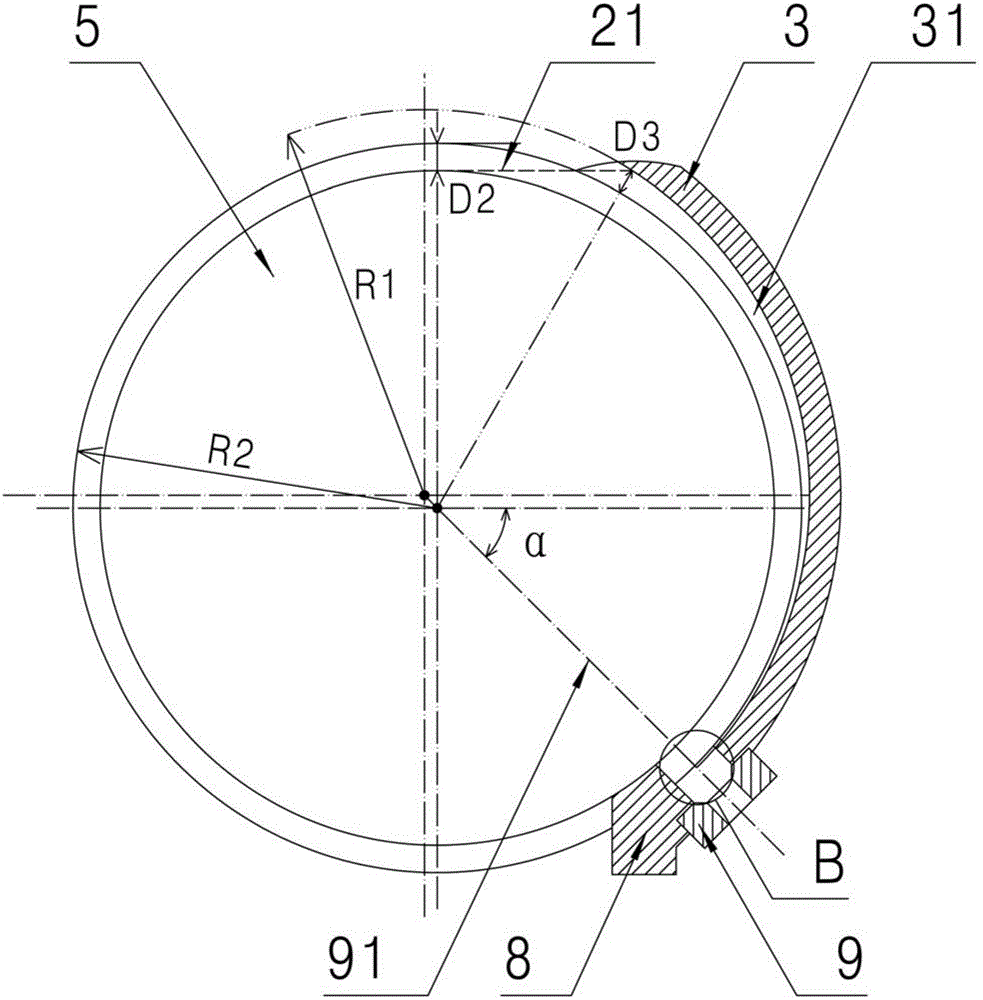

[0021] Such as figure 1 with figure 2 As shown, the continuous casting extrusion molding device of the present invention includes: a frame (which belongs to the conventional technology in the art, not shown in the figure), a rotating shaft 7 which is movably arranged on the frame by a pair of bearings 10, through The hinged shaft 11 is movably hinged to the cast extrusion shoe seat 2 on the frame, the axis line of the hinged shaft 11 is parallel to the axis line of the cast extrusion wheel 5, and the cast extrusion wheel 5 and the cast extrusion wheel 5 are arranged on the rotating shaft 7. The left side roller 13 (away from the water inlet side) and the right side roller 14 (closer to the water inlet side) on both sides, also on the right side of the right side bearing 10 on the rotating shaft 7, are successively provided with a pusher 15, an annular plunger 16 and An annular cylinder liner 17, an annular casting groove 52 is provided on the casting wheel 5, and a casting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com