Roxburgh rose thorn-removing method

A technology for removing thorns and prickles, which is applied in the field of de-thorn treatment of purchased raw materials of prickly pears, can solve the problems of workers' hands being injured, high labor intensity, low efficiency, etc., and achieves sufficient friction, guarantees the efficiency of thorn removal, and is convenient. Feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

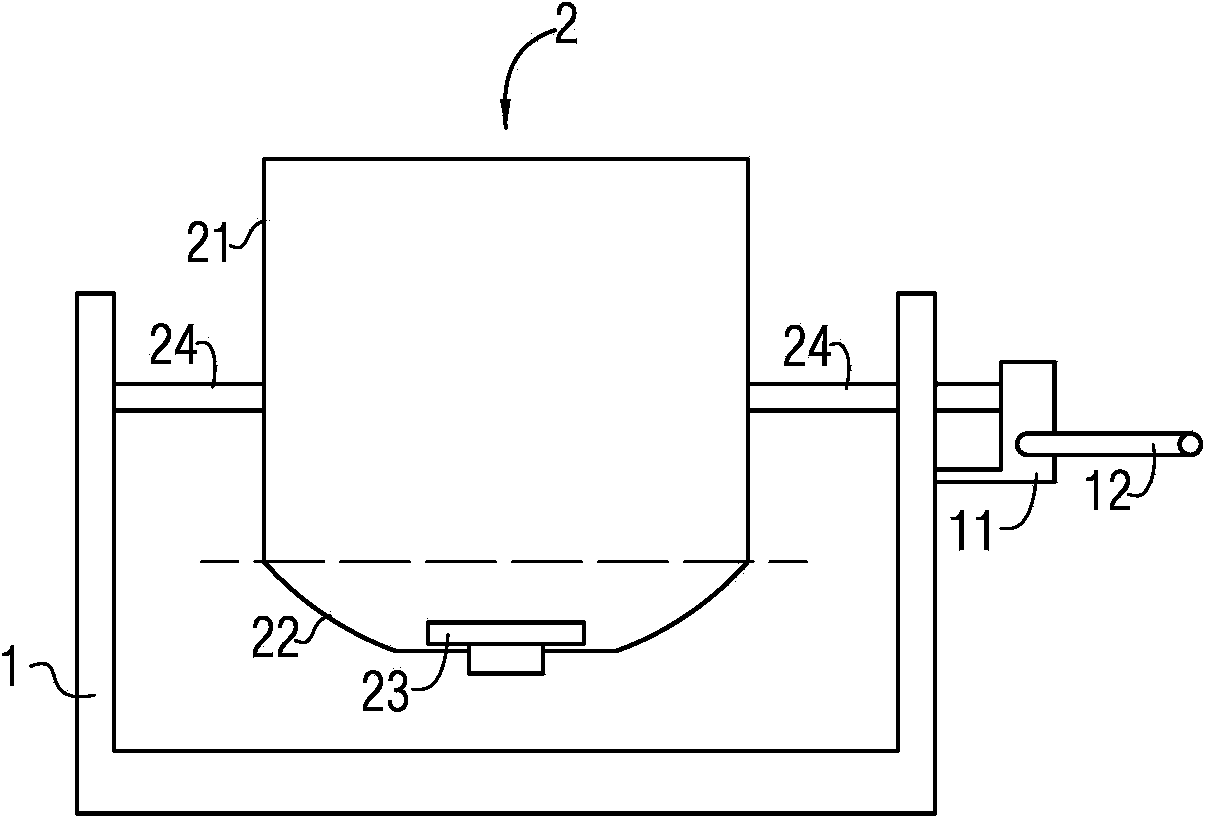

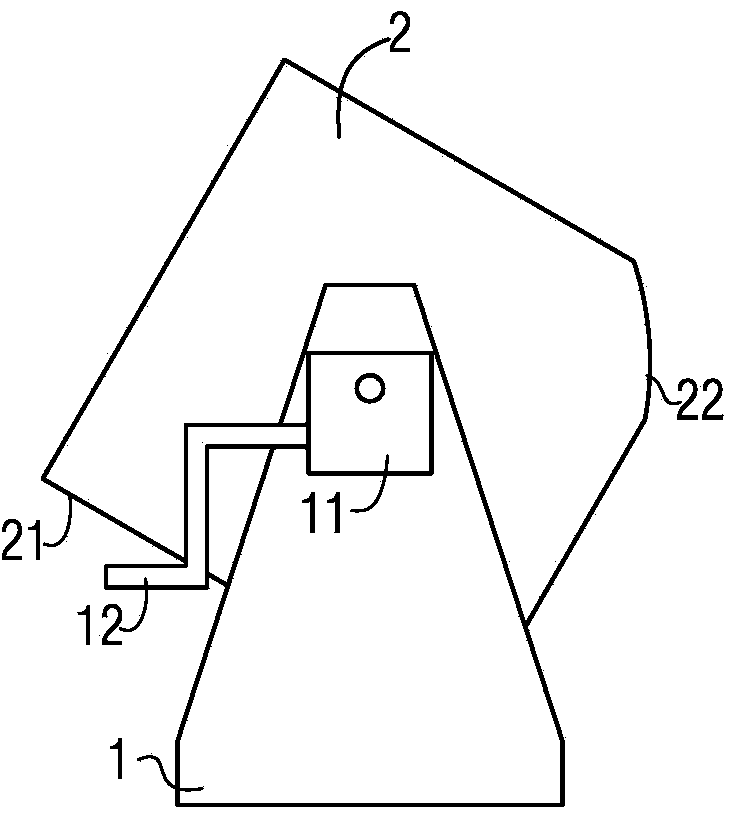

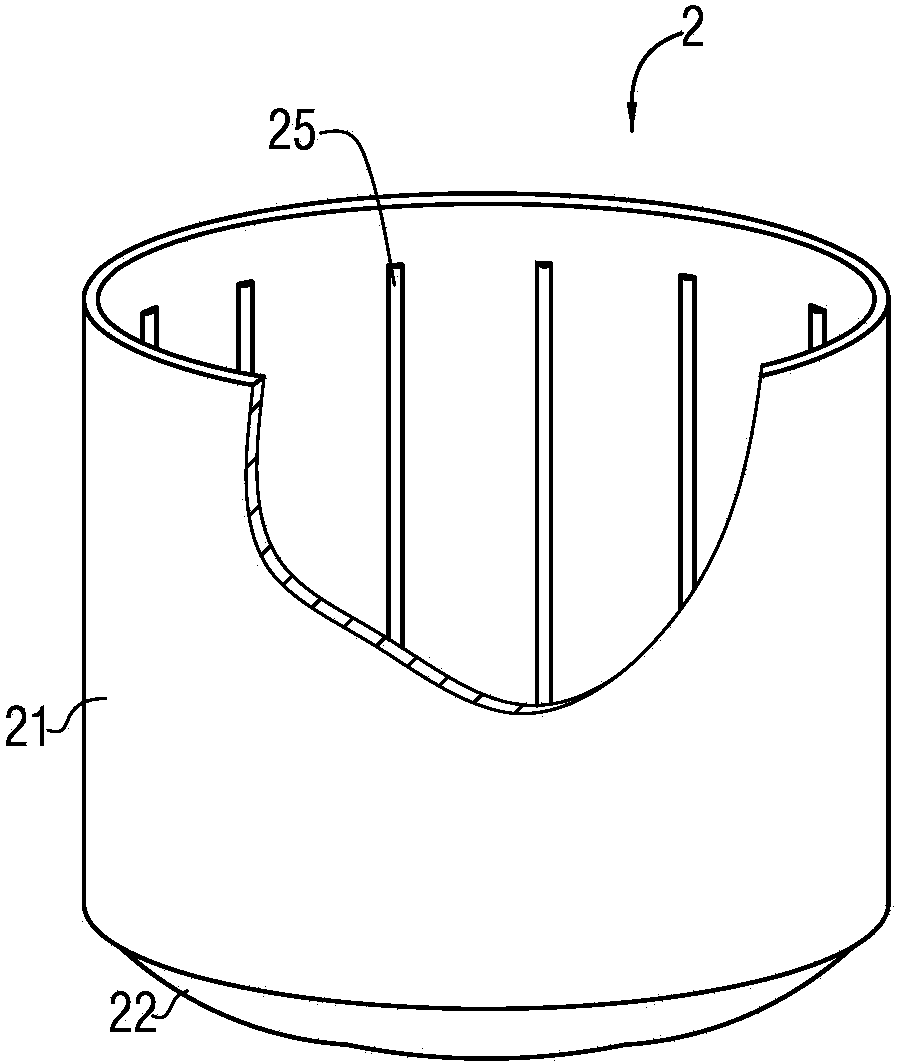

[0018] figure 1 It is a structural schematic diagram of a kind of prickly pear dethorning equipment used in a kind of thorn pear dethorning method according to a specific embodiment of the present invention; figure 2 for figure 1 The schematic diagram of the feed working state of the debarring equipment shown; see figure 1 , 2 As shown, the present invention proposes a method for removing thorns from thorn pears, which utilizes dethorning equipment to carry out dethorning treatment to incoming materials of thorn pears. Dethorn cylinder 2, described dethorn cylinder 2 comprises cylindrical cylinder body 21, and the bottom of described cylinder body 21 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com