Shifting-piece and shifting-fork horizontal transmission type machine for washing and drying mop by centrifugation

A drying machine and mop technology, applied in cleaning machinery, carpet cleaning, floor cleaning, etc., can solve the problem of inconvenient cleaning of mops, and achieve the effect of good cleaning effect, low water consumption and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

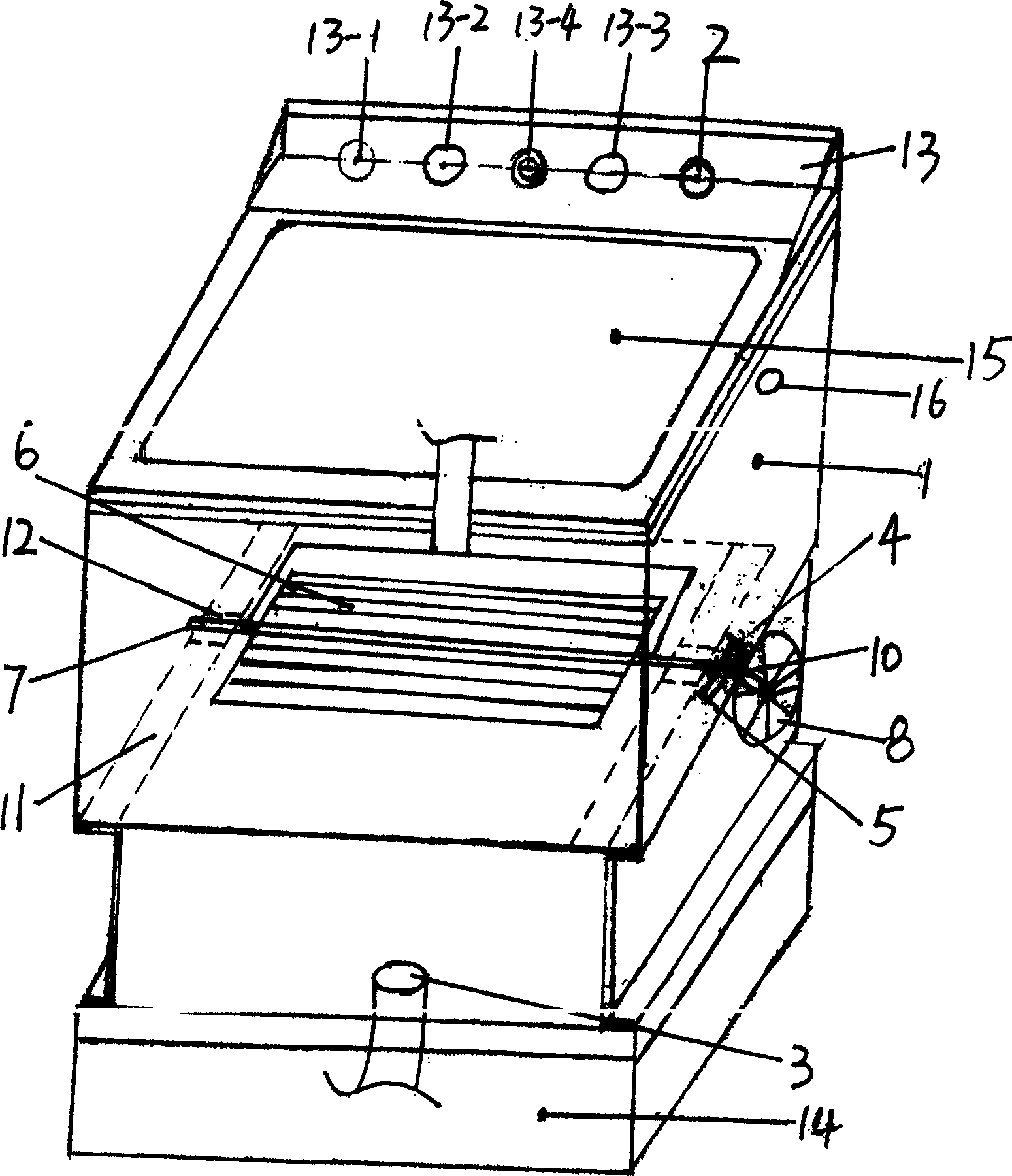

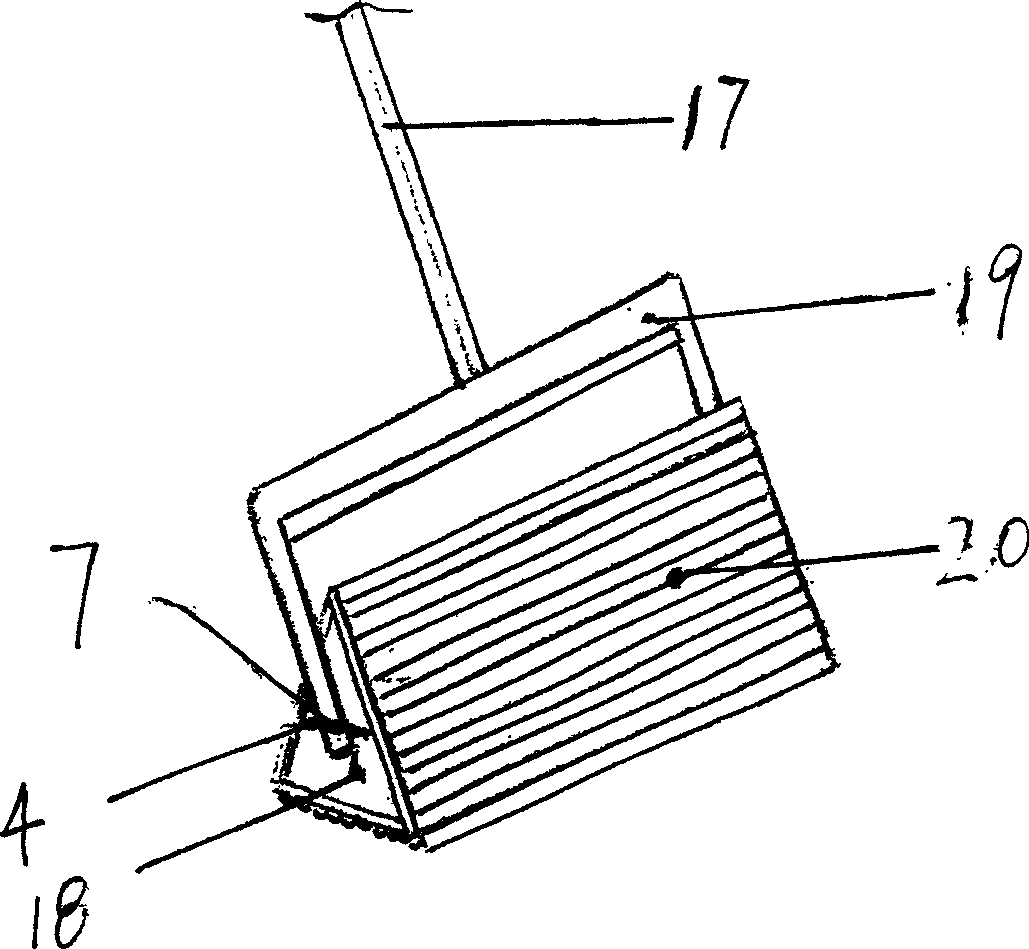

[0023] Such as figure 1 As shown, the mop cleaning and drying machine of the present invention with a plectrum and a shift fork transverse transmission includes a cleaning bucket 1, the bucket body is made of ceramic material, a water inlet 2 installed on the top of the cleaning bucket and a water outlet 3 installed at the bottom of the cleaning bucket , the mop cleaning machine is provided with a pair of interlocking paddles 4 and shift forks 5 (such as image 3 shown), the plectrum is installed on the rotating shaft 7 of the mop 6 whose mop head can rotate axially, the fork is installed in the cleaning bucket, and is connected with the output shaft 10 of the power unit, and the power unit is installed Outside the cleaning bucket, the power unit is a manual wheel 8. A pair of symmetrically arranged support frames 11 are installed parallel to the two sides of the barrel body in the barrel, and a clamping hole 12 is provided at the middle position of the top support surface of...

Embodiment 2

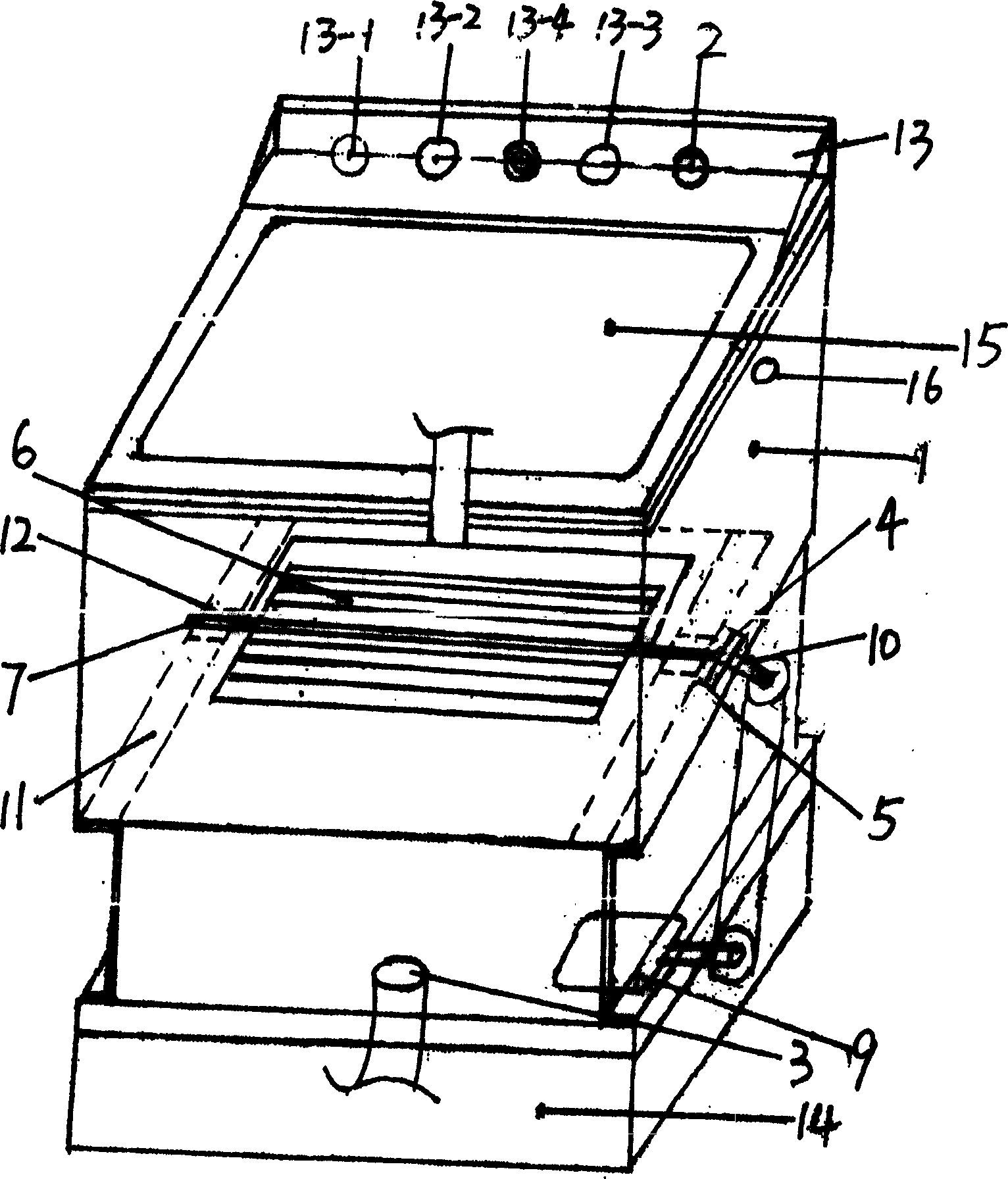

[0029] Such as figure 2 As shown, the mop cleaning and drying machine of the present invention with a plectrum and a shift fork transverse transmission includes a cleaning bucket 1, a water inlet 2 installed on the top of the cleaning bucket and a water outlet 3 installed at the bottom of the cleaning bucket. The mop cleaning machine is provided with a To mutually interlocking paddle 4 and shift fork 5 (such as image 3 shown), the plectrum is installed on the rotating shaft 7 of the mop 6 whose mop head can rotate axially, the fork is installed in the cleaning bucket, and is connected with the output shaft 10 of the power unit, and the power unit is installed Outside the cleaning bucket, the power device is a motor 9 connected through a transmission device. A pair of symmetrically arranged support frames 11 are installed parallel to the two sides of the barrel body in the barrel, and a clamping hole 12 is provided at the middle position of the top support surface of each su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com