Extrusion gelatinization device and system

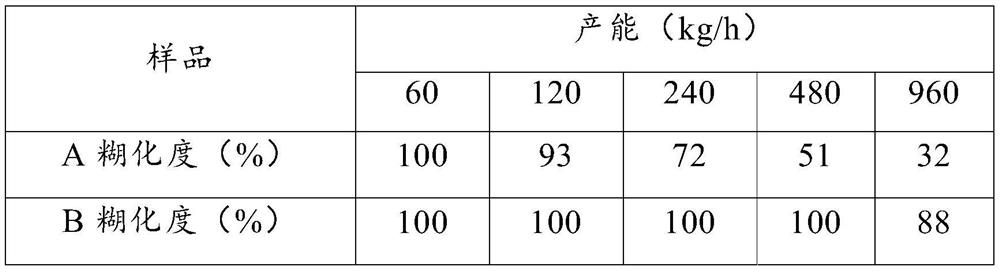

An extrusion cavity and material technology, applied in the field of extrusion gelatinization devices and systems, can solve the problems of reduced product gelatinization degree, insufficient product gelatinization degree, affecting product quality, etc. Efficient gelatinization and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

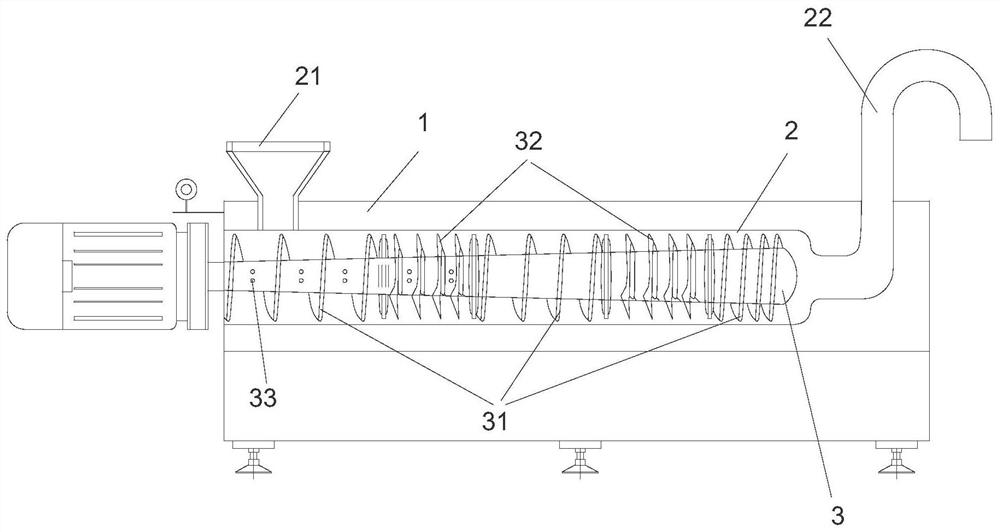

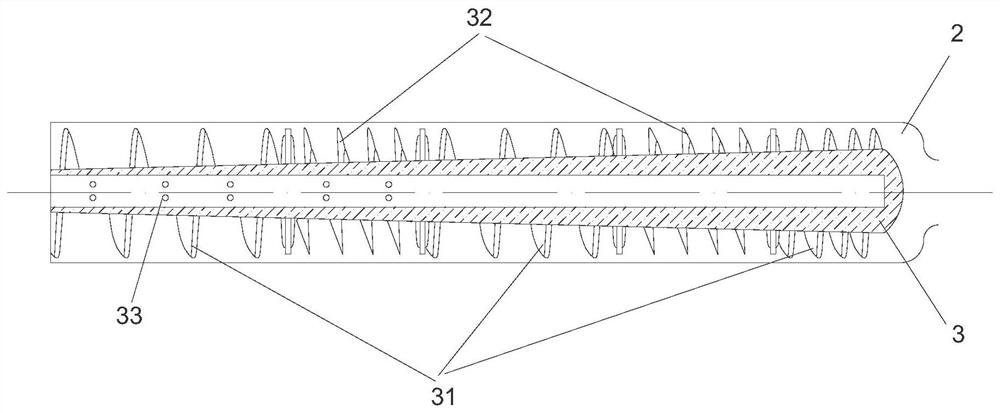

[0046] like figure 1 and figure 2 As shown, this embodiment provides an extrusion gelatinization device, which is mainly used for extrusion gelatinization of starch-based materials. It includes: a machine base 4 , a heating cavity 1 , an extrusion cavity 2 and a screw 3 .

[0047] The heating chamber 1 is fixed on the machine base and is a hollow interlayer heating chamber with a steam inlet and a steam outlet. The steam enters the heating chamber 1 from the steam inlet and indirectly heats the materials in the extrusion chamber 2 After that, the steam outlet is connected to the pipeline to flow back to the steam generating source to save energy.

[0048] The extrusion cavity 2 is the inner cavity of the heating cavity 1 and is formed by the inner wall of the heating cavity 1. The extrusion cavity 2 has a feeding port 21 and a discharging port 22, and the feeding port 21 and the discharging port 22 are respectively located in Both ends of the extrusion cavity 2 along the axi...

Embodiment 2

[0071] This embodiment provides an extrusion gelatinization system, including a rotary drive mechanism 5 , a steam source, and the extrusion gelatinization device of Example 1.

[0072] Wherein, the rotation driving mechanism is connected with the driving section of the screw rod 3 in a transmission, and is used for driving the screw rod 3 to rotate. In this embodiment, the rotary drive mechanism includes a motor and a gear reduction transmission mechanism. The motor is connected to the input gear of the gear reduction transmission mechanism, and then the driving section is connected to the output gear of the gear reduction transmission mechanism, so that when the motor starts, it can drive The screw 3 rotates.

[0073] The steam source is in dynamic sealing communication with the driving section, and is used for delivering steam into the inner cavity of the screw 3 . Specifically, the end of the driving section is communicated with the external steam source through a pipe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com