Coal dust depressor and preparation method thereof

A dust suppressant, coal technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of easy mold cost, complex synthesis process, corrosion and other problems, and achieve good water retention performance and high chemical stability , the effect of high cellulose content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

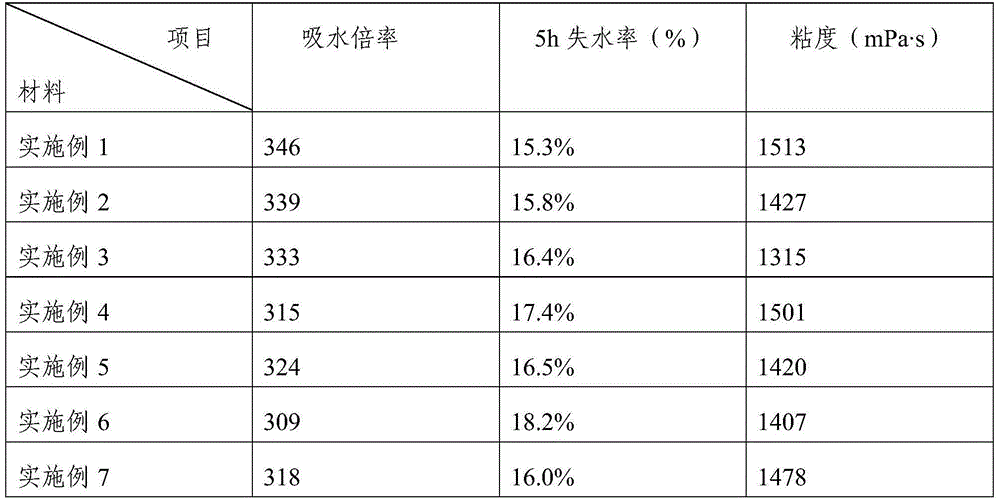

Examples

Embodiment 1

[0030] The coal dust suppressant of this embodiment is made of the following raw materials in parts by weight: 1 kg of modified sunflower stalks, 20 kg of acrylic acid solution with a neutralization degree of 70%, 0.01 kg of ethylene glycol dimethacrylate, and 0.6 kg of purified diatomaceous earth. kg, initiator 0.04kg; the initiator is potassium persulfate; the modified sunflower stalk is the sunflower stalk after alkalization; the preparation method of the acrylic acid solution with a neutralization degree of 70% is as follows: The sodium hydroxide solution with a concentration of 21% was added to the acrylic acid, stirred evenly to make it completely neutralized, and the molar ratio of the acrylic acid to the sodium hydroxide in the sodium hydroxide solution was 1:0.7.

[0031] The preparation method of the modified sunflower stalks is as follows: crush the sunflower stalks and pass through an 80-mesh sieve, take the undersieve and place them in a sodium hydroxide solution w...

Embodiment 2

[0040] The coal dust suppressant of this embodiment is made of the following raw materials in parts by weight: 1 jin of modified sunflower stalks, 22 jin of acrylic acid with a neutralization degree of 70%, 0.008 jin of ethylene glycol dimethacrylate, purified diatomaceous earth 0.8 jin, 0.04 jin of initiator; the initiator is hydrogen peroxide; the modified sunflower stalk is the sunflower stalk after alkalization treatment; the preparation method of the acrylic acid solution with a neutralization degree of 70% is as follows: Sodium hydroxide solution with a mass concentration of 21% was added to acrylic acid, stirred evenly to completely neutralize, and the molar ratio of the acrylic acid to sodium hydroxide in the sodium hydroxide solution was 1:0.7.

[0041] The preparation method of the modified sunflower stalks is as follows: crush the sunflower stalks and pass through a 100-mesh sieve, take the undersieve and place them in a sodium hydroxide solution with a mass concentr...

Embodiment 3

[0050] The coal dust suppressant of this embodiment is made of the following raw materials in parts by weight: 1 kg of modified sunflower stalks, 18 kg of acrylic acid solution with a neutralization degree of 70%, 0.012 kg of ethylene glycol dimethacrylate, and 0.4 kg of purified diatomaceous earth. kg, initiator 0.03kg; the initiator is potassium persulfate; the modified sunflower stalks are alkalized sunflower stalks; the preparation method of the acrylic acid solution with a neutralization degree of 70% is as follows: The sodium hydroxide solution with a concentration of 21% was added to the acrylic acid, stirred evenly to make it completely neutralized, and the molar ratio of the acrylic acid to the sodium hydroxide in the sodium hydroxide solution was 1:0.7.

[0051] The preparation method of the modified sunflower stalks is as follows: crush the sunflower stalks and pass through a 120-mesh sieve, take the undersieve and place them in a sodium hydroxide solution with a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com