Intelligent defect repairing and automatic disc stacking system and operation method

A defect repair and code disc technology, applied in the direction of grinding feed motion, grinding drive device, grinder, etc., can solve problems such as the efficiency of manual repair of code discs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

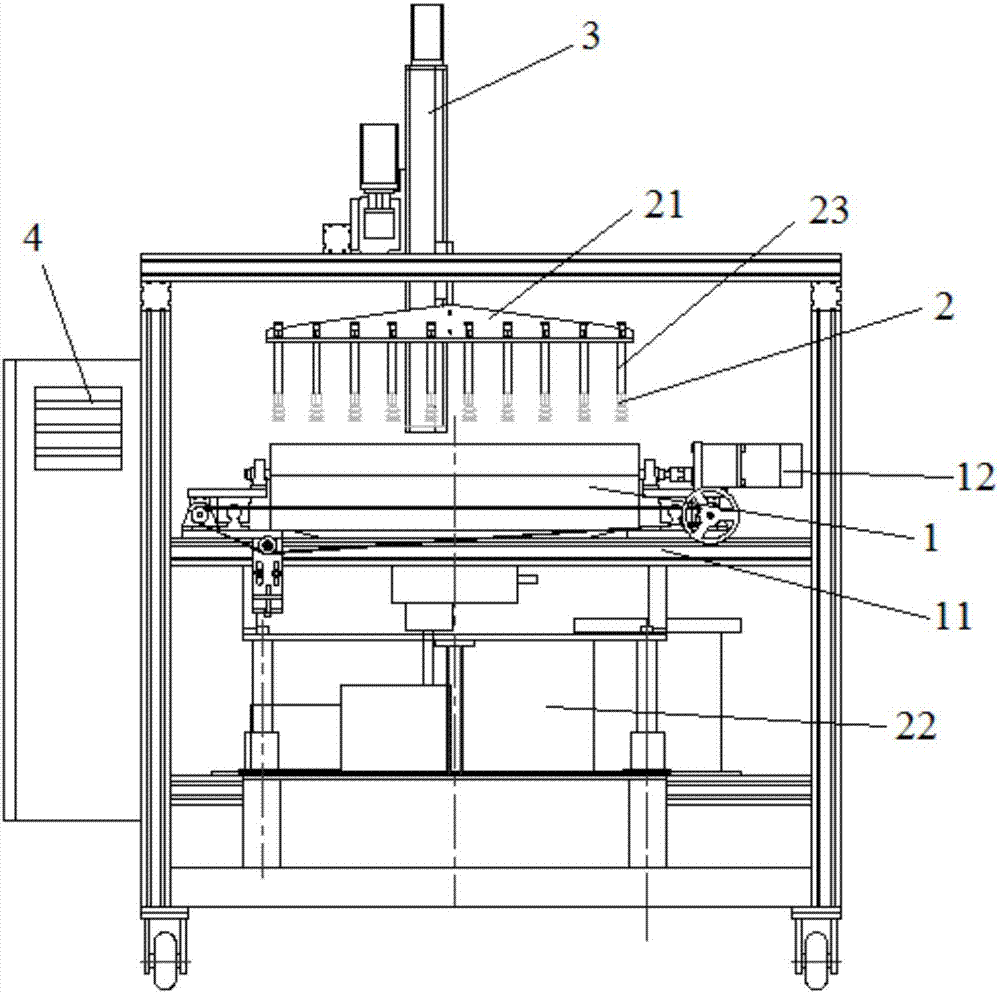

[0112] Such as figure 1 , 2 , 3 and 4, a magnetic material product defect repairing device, including a product defect processing device 1 and a product suction head 2, wherein the product defect processing device 1 includes a repair frame 11 and a brush roller 13, and the brush roller 13 is arranged in sequence On the repair frame 11, the brush rollers 13 are all connected to the drive motor 12, and the product suction head 2 is arranged above the gap between the adjacent brush rollers 13. Utilize automatic polishing of the surface of magnetic products to repair the defects of magnetic products after forming, reduce human intervention and improve product yield.

[0113] After the product suction head 2 sucks the magnetic product, the magnetic product is located in the gap between the adjacent brush rollers 13, and the brush roller 13 rotates to grind and rub the surface of the magnetic product, remove the burrs on the product surface and fill up the gaps on the product surfa...

Embodiment 2

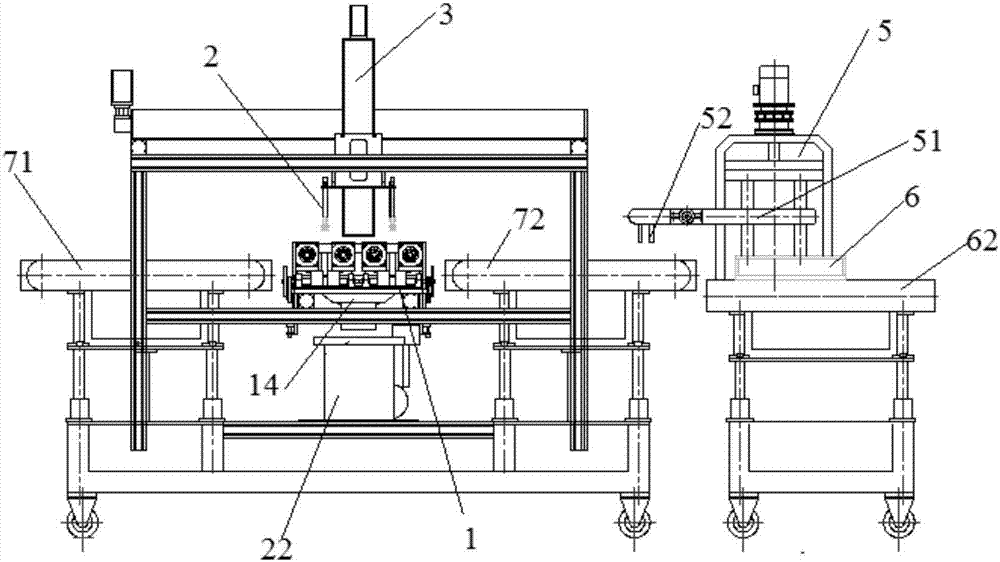

[0138] Such as figure 1 , 2 , 3 and 4, an automatic code disc device for magnetic material products, including an automatic code disc device 5, a robot code disc arm 51 and a code disc 6, wherein the automatic code disc device 5 and the code disc 6 are all located on the rear mobile platform of the product 62, the automatic code disc device 5 is provided with a robot code disc arm 51, the code disc 6 is provided with a product placement slot, and the product rear mobile platform 62 is located on one side of the product middle mobile platform 72, and on the other side A repair frame 11 is provided.

[0139] The robot code wheel arm 51 transfers the product from the moving platform 72 in the middle of the product to the code wheel groove on the code wheel 6, and places the repaired product in the code wheel 6, which reduces manual participation and improves the yield of the product.

[0140] The automatic code disc device 5 is provided with a code disc arm rotating shaft, and ...

Embodiment 3

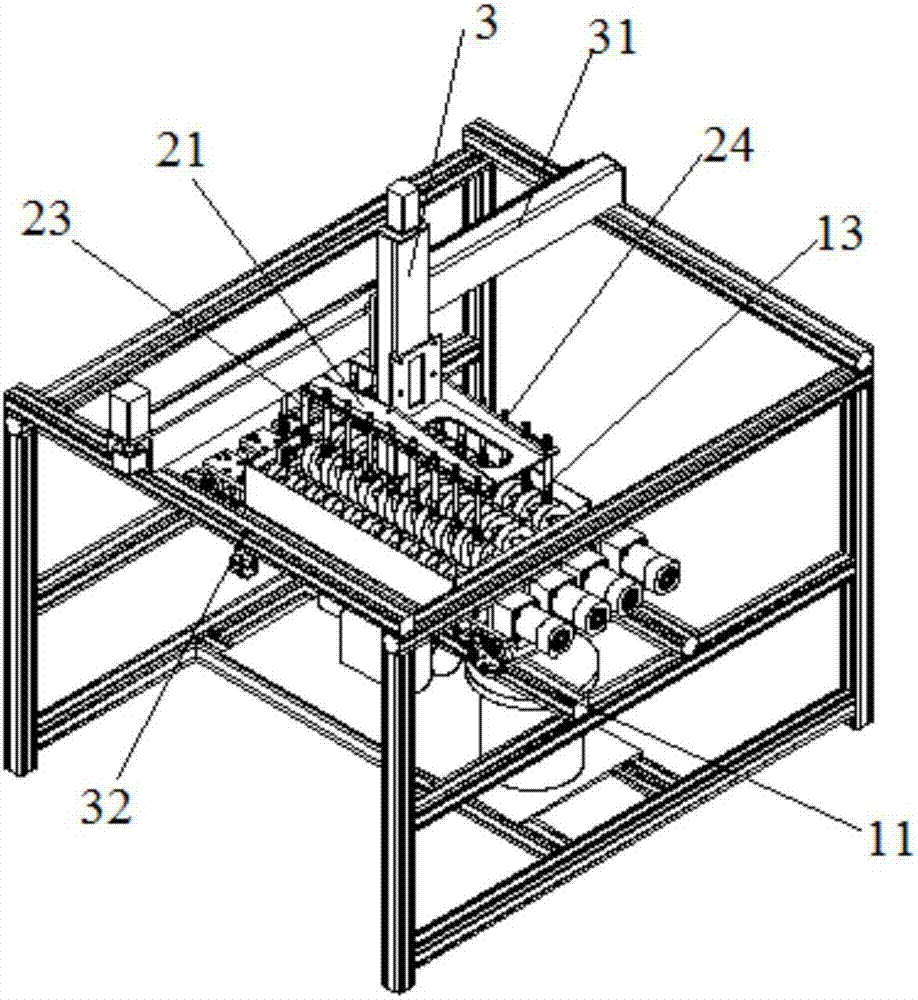

[0155] Such as figure 1 , 2 , 3 and 4, a kind of uniaxial robot mobile arm frame that is loaded with vacuum sucker, comprises fixed disk 21, uniaxial robot mobile arm 3, uniaxial robot mobile crossbeam 31 and uniaxial robot mobile track 32, wherein, fixed disk 21 Fixed on the lower part of the single-axis robot moving arm 3, the single-axis robot moving arm 3 is fixed on the single-axis robot moving beam 31, the single-axis robot moving beam 31 is arranged on the single-axis robot moving track 32, and the single-axis robot moving track 32 is arranged on the repairing frame 11 above.

[0156] The single-axis robot moving beam 31 carries the single-axis robot moving arm 3 to slide on the single-axis robot moving track 32, and the fixed plate 21 also moves forward and backward. After the product suction head 2 sucks the product, it moves to the space between the brush rollers 13. Above the gap, the single-axis robot moving arm 3 descends, the magnetic product enters the gap, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com