Preparation method of tensile transparent conductive membrane material

A transparent conductive film and film material technology, which is applied in the field of energy nanometers, can solve the problems of irregularity, material conductivity drop, and material conductivity change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In another aspect of the present invention, a method for preparing a stretchable transparent conductive film material is provided, the method comprising the following steps:

[0039] (1) Formulating different polar solvents, non-polar solvents, surfactants and polymers into emulsions;

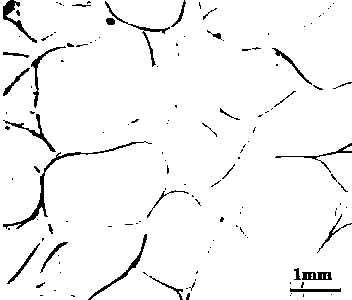

[0040] (2) Control the surface polarity of metal nanowires, distribute them in emulsion, drop-coat them into sheets, dry them under control, wash and remove surfactants and polymers, heat them and dry them again, and perform metal nanowire network leveling treatment ;

[0041] (3) The initial organic film materials such as metal nanowires and polydimethylsilane are made into stretchable transparent conductive film materials, and the polarity treatment and surface roughness of metal nanowires are adjusted to improve the metal nanowires and organic materials. Cohesion of polymer virgin film materials.

[0042] The step (1) is carried out in ultrasonic vibration or mechanical stirring.

[...

Embodiment 1

[0046] Example 1: First, prepare 20ml of emulsion with chloroform as non-polar solvent, water as polar solvent, El-10 as surfactant, and polystyrene (PS) added. During the preparation process, vibration and stirring are required. Carried out at room temperature to obtain a stable emulsion.

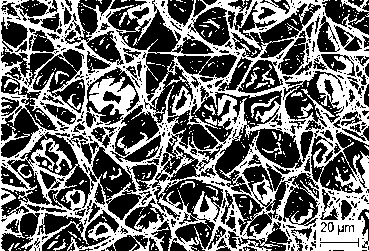

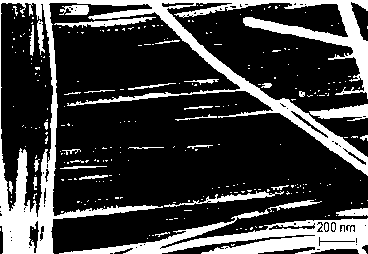

[0047] Add the dispersion of silver nanowires with high aspect ratio (diameter 5nm-500nm, length 0.5μm-2000μm) in water to the above emulsion, ultrasonically oscillate evenly and drop it on a glass sheet. After drying, soak it in chloroform After 6 hours, soak in methanol or distilled water for 4 hours, take it out, and dry it at 220° C. for 1 hour to obtain an ordered transparent and conductive network structure of silver nanowires.

[0048] Polydimethylsilane is used as the initial film material, dissolved in an organic solvent, and then added dropwise on the above-mentioned glass sheet with a transparent and conductive network structure of silver nanowires. After drying, it is peeled o...

Embodiment 2

[0051] Example 2: First, prepare 20ml of emulsion with xylene as non-polar solvent, water as polar solvent, El-10 as surfactant, and polystyrene (PS) added. During the preparation process, vibration and stirring are required. Performed at room temperature to obtain a stable emulsion.

[0052] Add the dispersion of silver nanowires with high aspect ratio (diameter 5nm-500nm, length 0.5μm-2000μm) in water to the above emulsion, ultrasonically oscillate evenly and drop on the glass sheet, after drying, wash with xylene Soak for 6 hours, then soak in methanol or distilled water for 4 hours, take it out, and dry at 220° C. for 1 hour to obtain an ordered transparent and conductive network structure of silver nanowires.

[0053] Polydimethylsilane is used as the initial film material, dissolved in an organic solvent, and then added dropwise on the above-mentioned glass sheet with a transparent and conductive network structure of silver nanowires. After drying, it is peeled off, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com