Patents

Literature

270results about How to "Improve deburring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device for grinding burrs on surface of rotating shaft of commercial coil motor

The invention discloses a device for grinding burrs on the surface of a rotating shaft of a commercial coil motor. The device comprises a base, groove holes, a first driving motor, a threaded bushing, bearing seats, clamping threaded couplers, a threaded sleeve, a third driving motor and a grinding wheel, wherein the groove holes are formed in the base, an output shaft of the first driving motor is vertically upward and connected with a screw rod A, the threaded bushing is arranged on the screw rod A in a threaded mode, the two sets of bearing seats are fixedly arranged on the upper surface of a machine table, and the bearing seats are further rotationally provided with the clamping threaded couplers. According to the device, movement and fixation can be freely switched, on the one hand, the stability of the device during production and processing can be improved, and on the other hand, the situation that universal wheels are scrapped due to the fact that the universal wheels are under stress for a long time can be prevented, and the service life of the universal wheels is prolonged; and meanwhile, omni-directional grinding can be carried out on the rotating shaft in the rotating process of the rotating shaft, and therefore the burring effect on the rotating shaft can be improved, and the situation that parts of the rotating shaft are too thick or too thin in the grinding process of the rotating shaft can be effectively avoided.

Owner:李晔

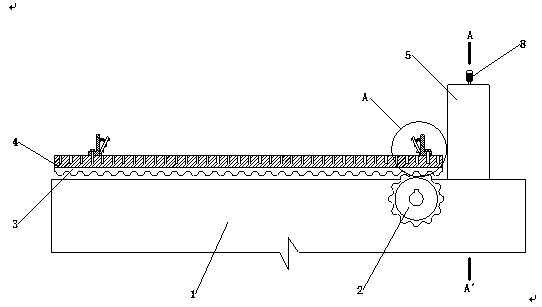

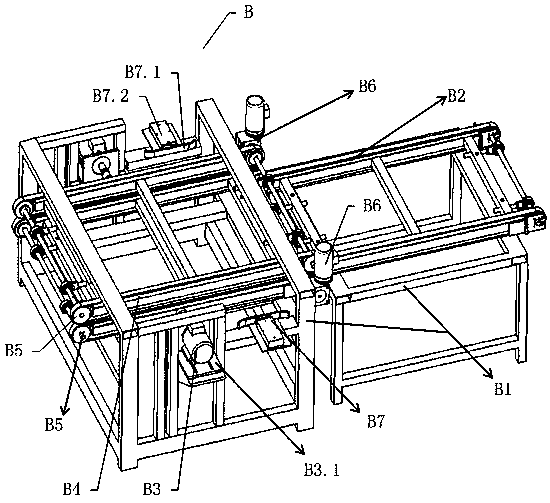

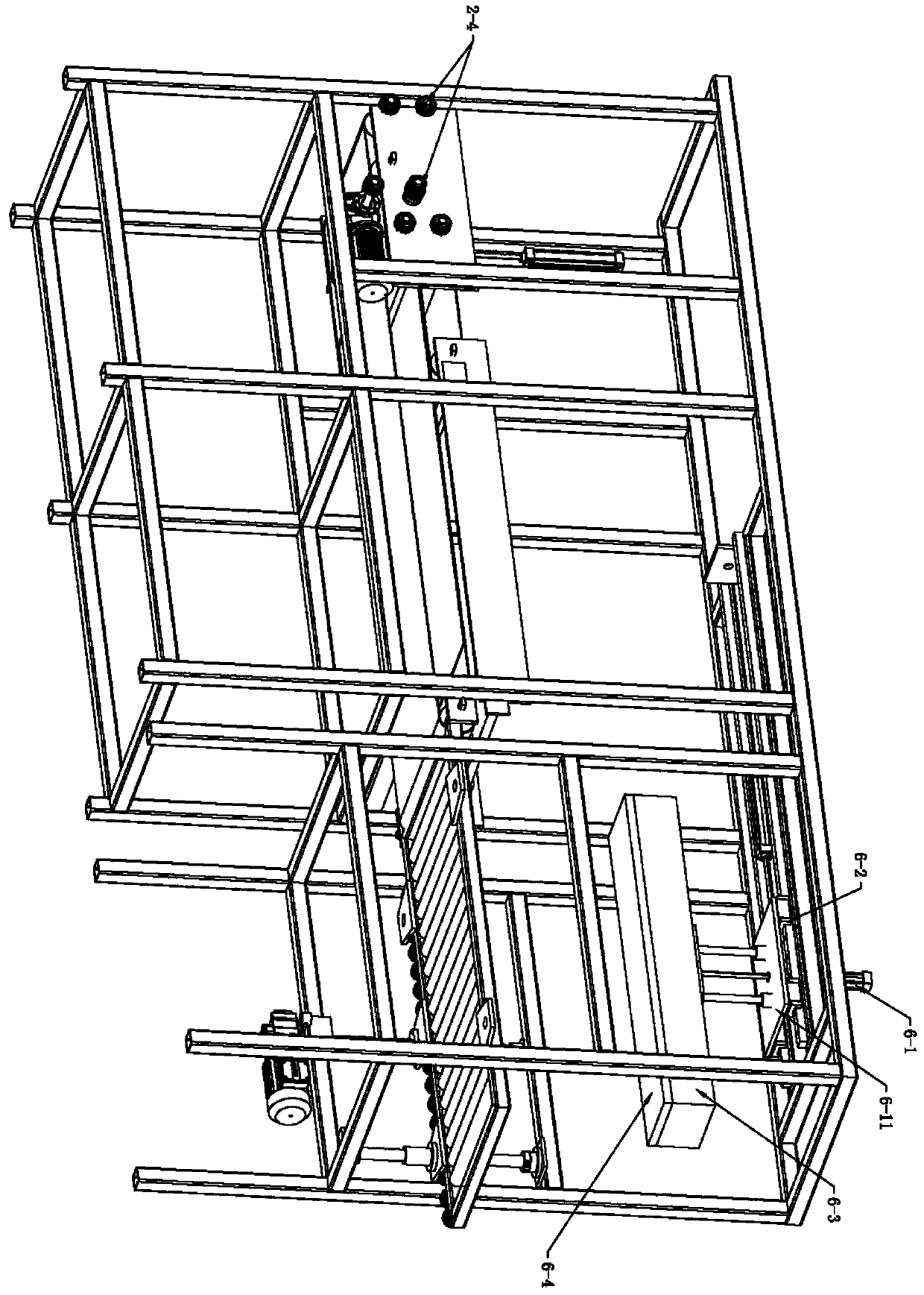

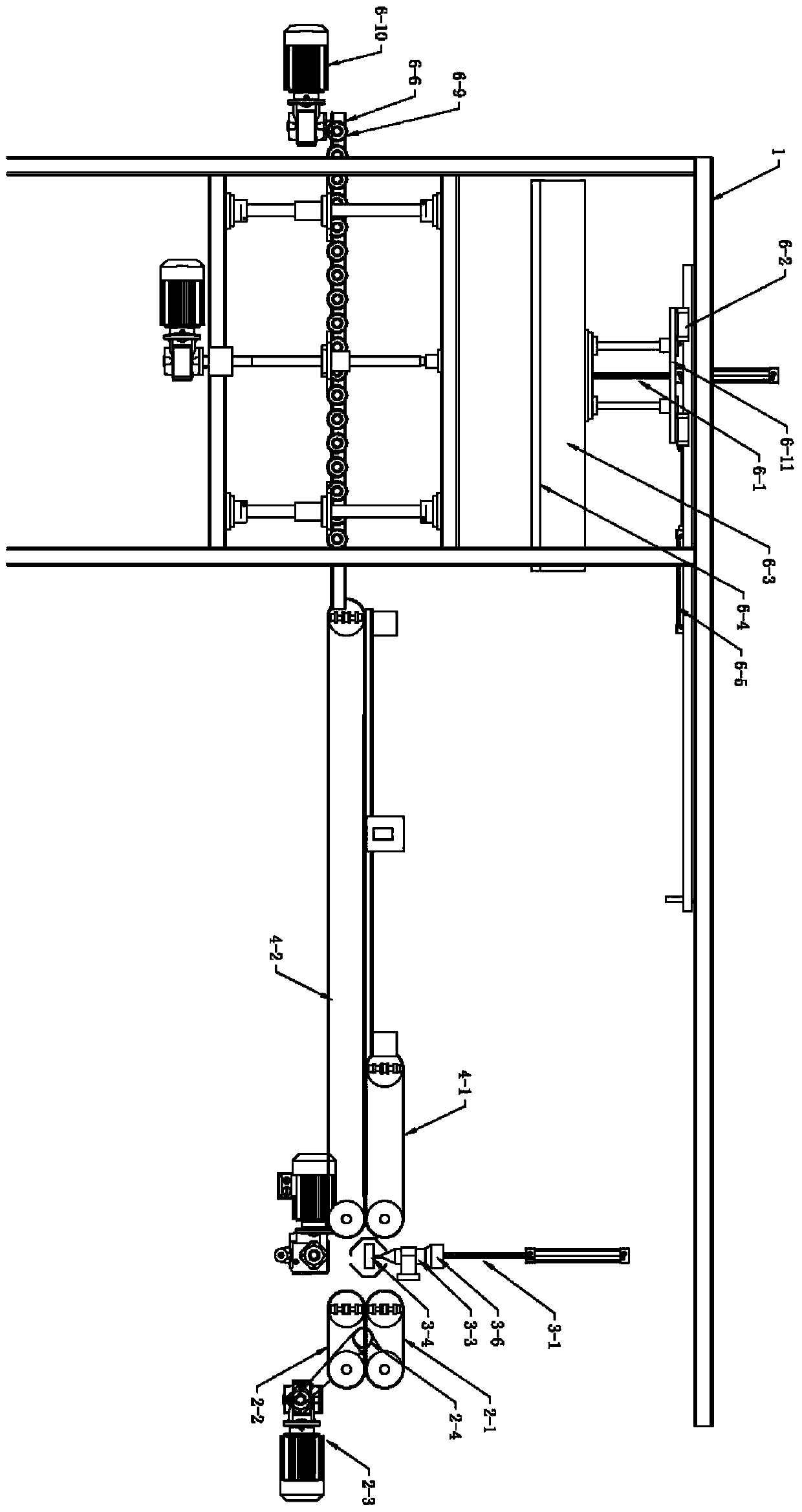

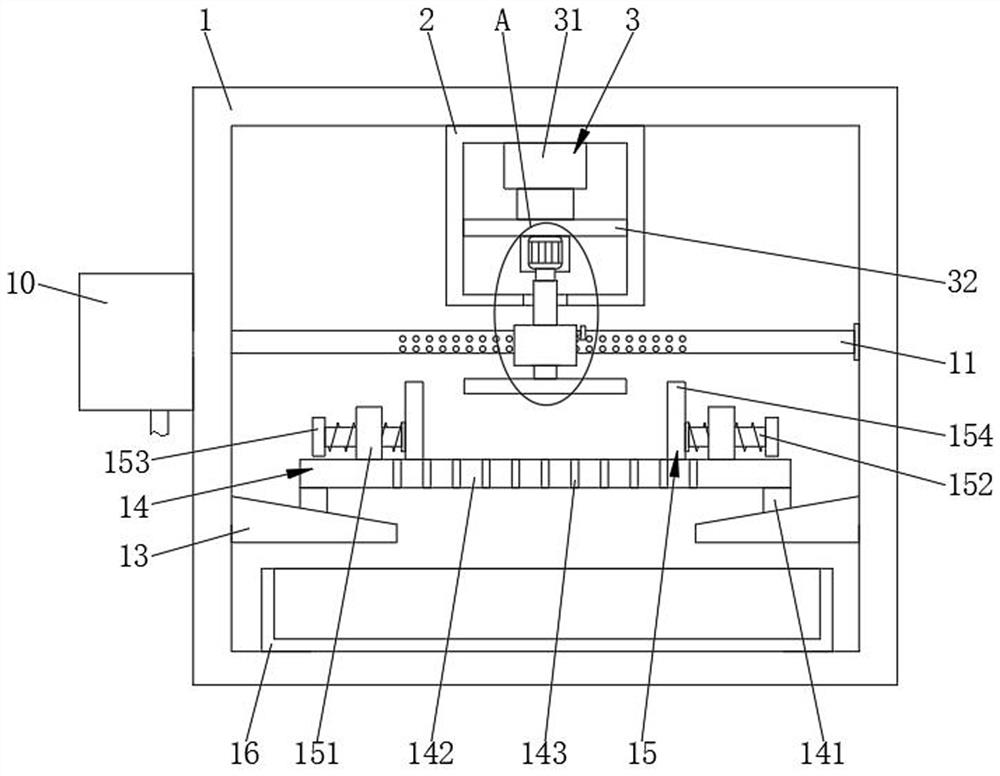

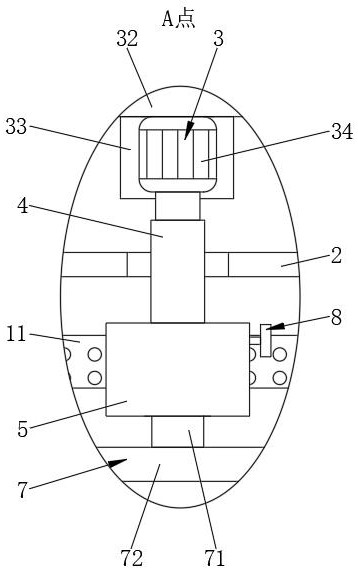

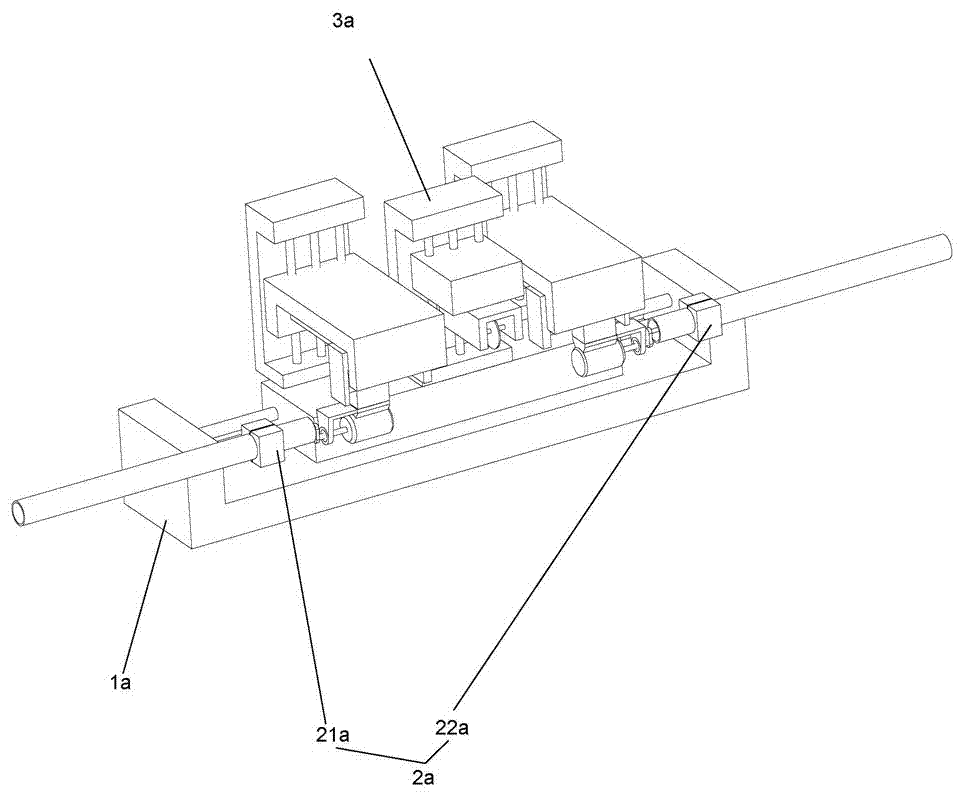

Worm deburring machine

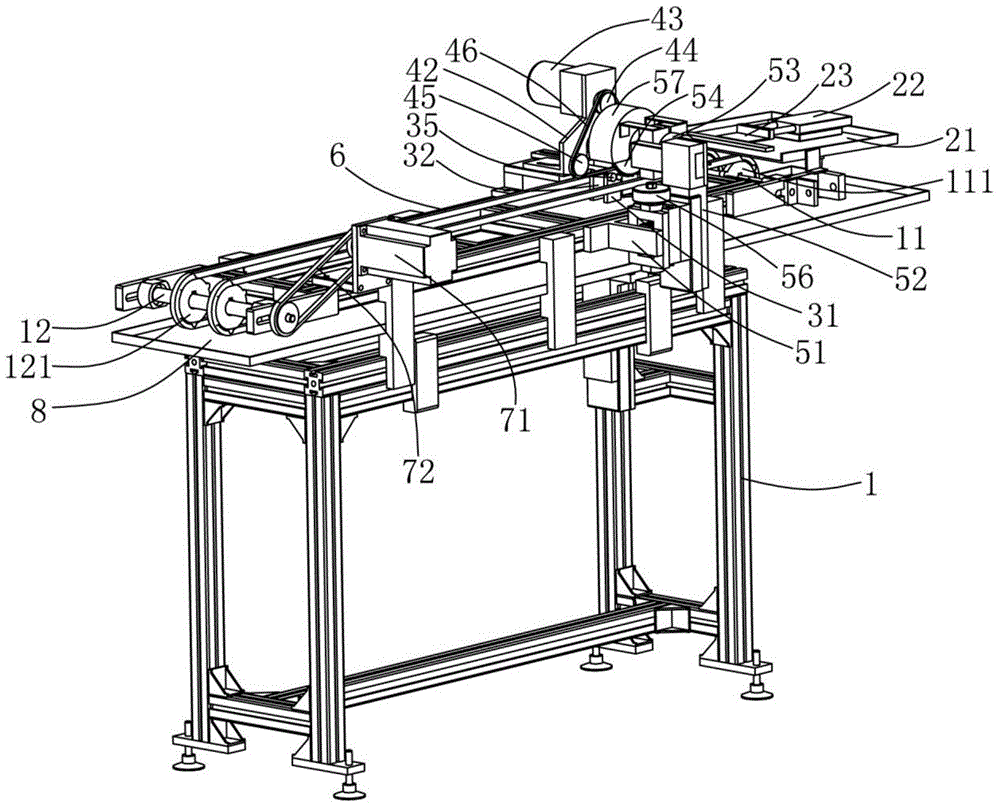

ActiveCN105081918AReduce labor intensityFully contactedEdge grinding machinesGrinding carriagesEngineeringGrinding wheel

The invention discloses a worm deburring machine which comprises a machine frame. A feeding mechanism, a locating mechanism, a clamping mechanism and an abrasion wheel grinding mechanism are arranged on the machine frame. The machine frame is further provided with a feeding belt and a driving mechanism driving the feeding belt to move, wherein the feeding belt is used for conveying worm workpieces to the locating mechanism from the feeding mechanism; a receiving disc is arranged below the feeding belt and extends out of the discharging end of the feeding belt. The worm deburring machine is simple and reasonable in structure, convenient to use, low in manufacturing cost, high in work efficiency, capable of effectively lowering the labor intensity of workers and the product machining cost and good in deburring effect.

Owner:NINGBO NEWSTAR PRECISION MACHINERY

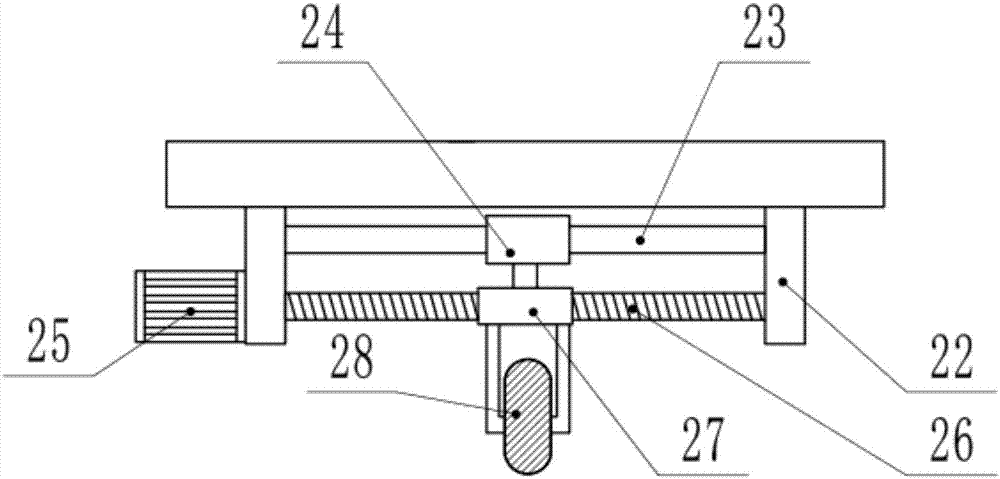

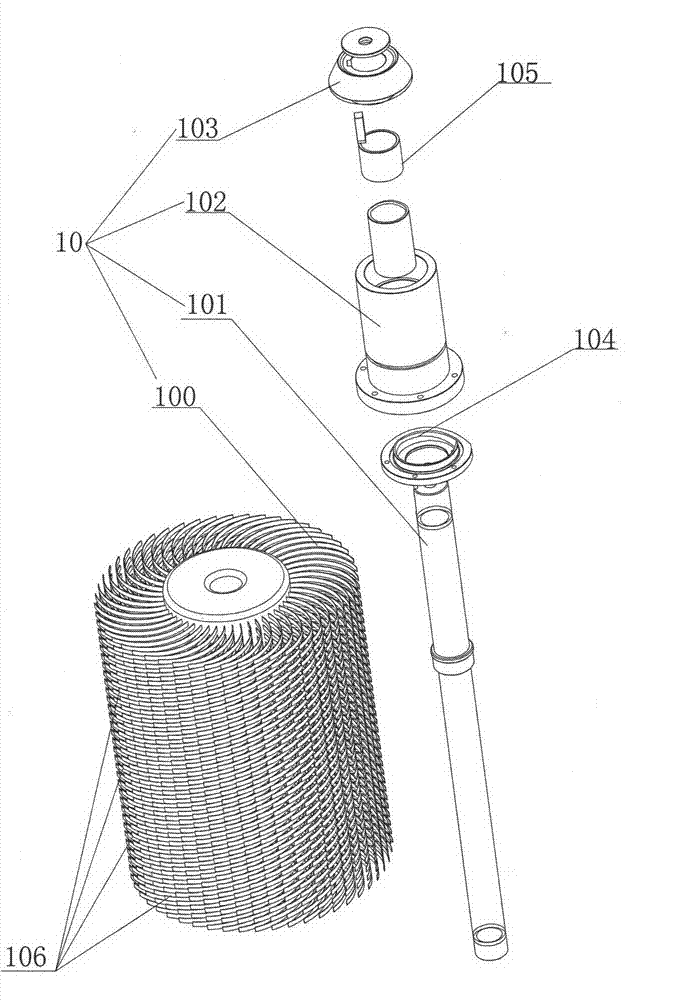

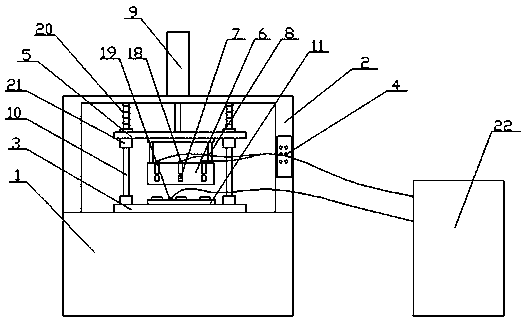

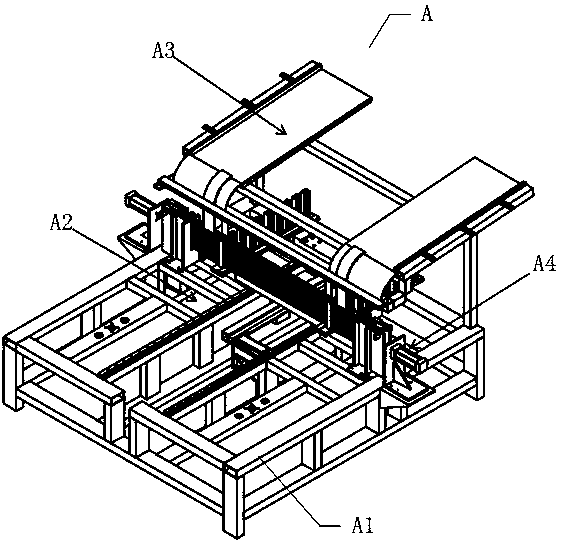

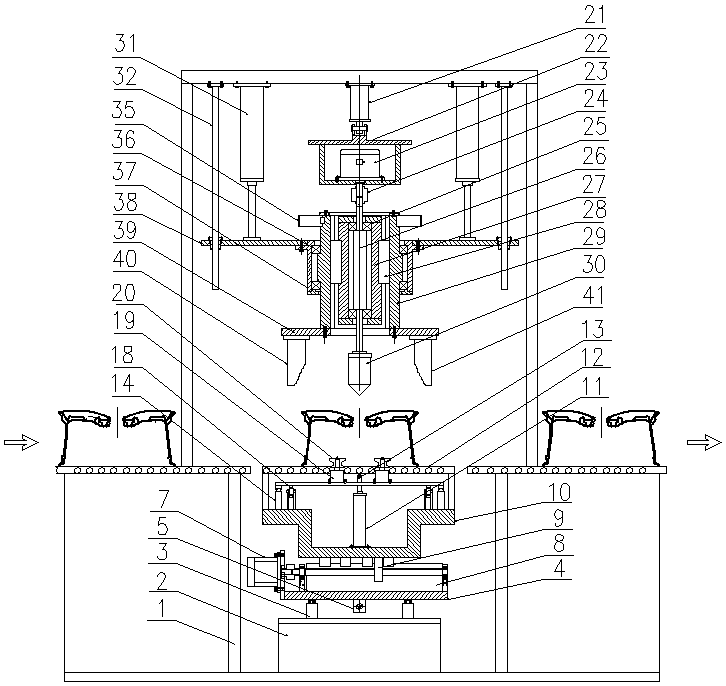

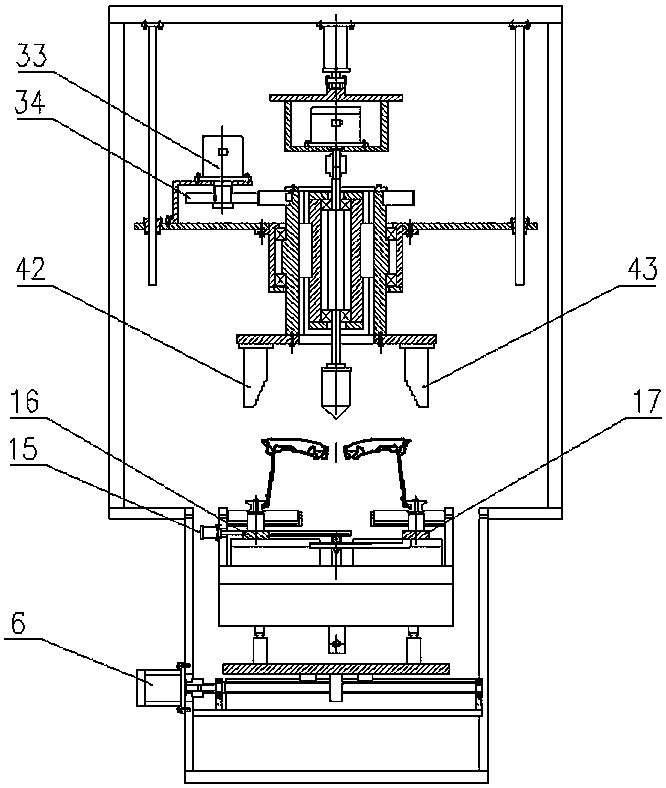

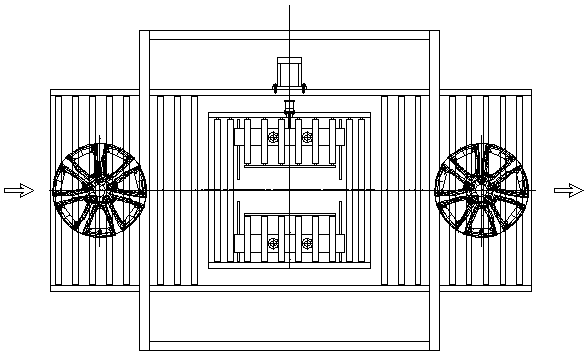

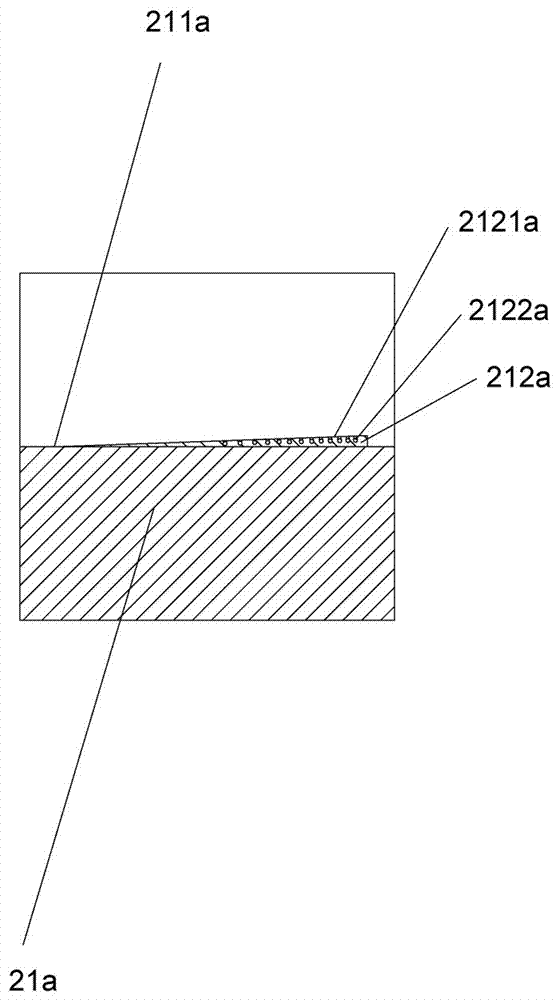

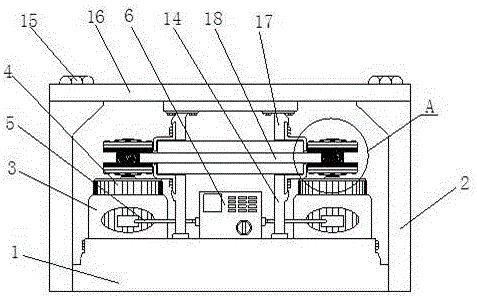

Polishing wheel device and automatic deburring machine provided with same

ActiveCN103481215AImprove work efficiencyReduce labor costsEdge grinding machinesFlexible-parts wheelsEngineeringMechanical engineering

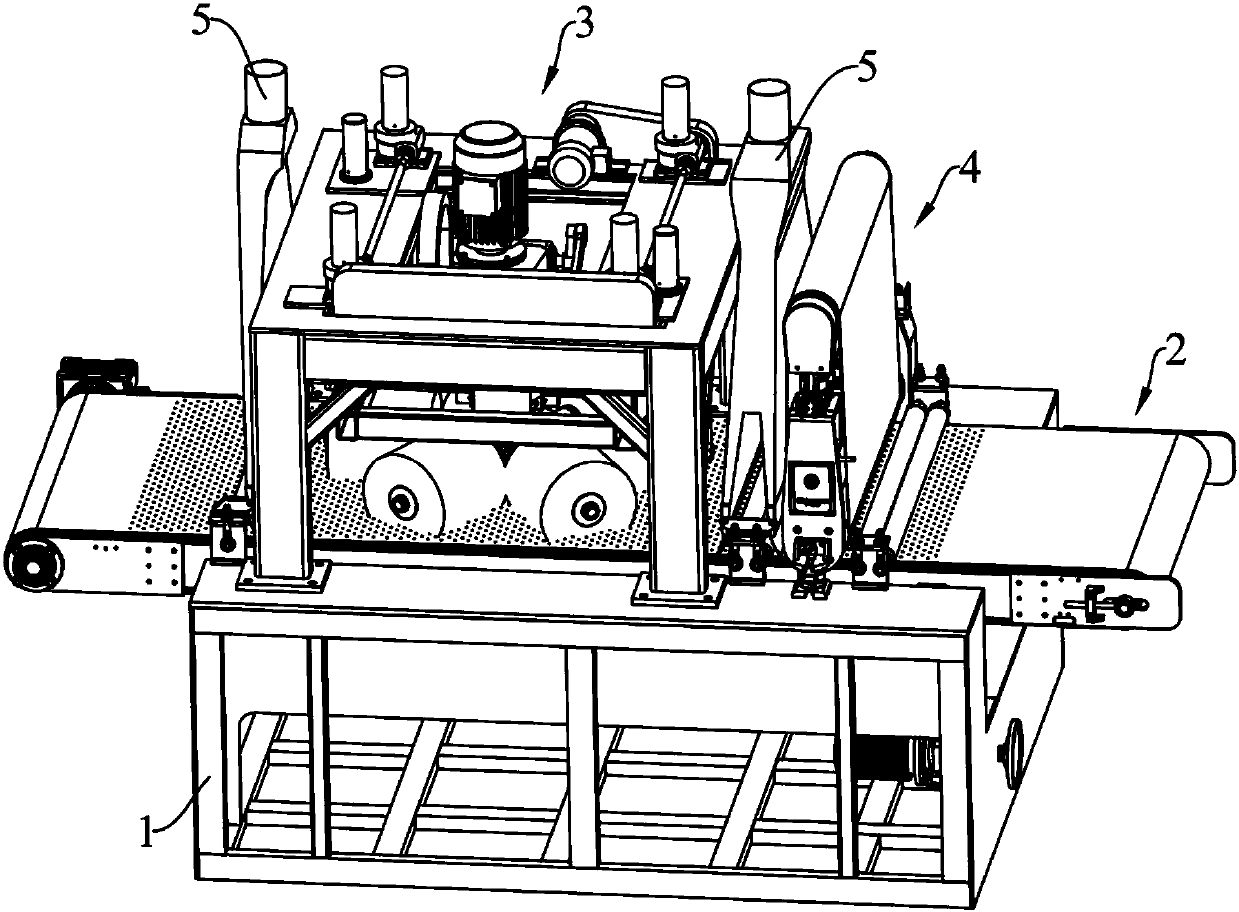

The invention discloses a polishing wheel device and an automatic deburring machine provided with the polishing wheel device. The automatic deburring machine comprises an even number of polishing wheel devices, a spindle device, a conveying device, a control device, a machine frame and a lifter used for adjusting the space between the polishing wheel devices and the conveying device; the polishing wheel devices and the spindle device are connected and fixedly arranged in the machine frame, an accommodation part is arranged on the machine frame, the conveying device is fixedly arranged in the accommodation part and positioned under the polishing wheel devices, the control device and the lifter are both fixedly arranged on the outer side of the machine frame, and the control device is electrically connected with the spindle device and the conveying device respectively; a spindle motor and a turnover motor are mounted in the two sides of the top end of the machine frame. According to the polishing wheel device and the automatic deburring machine provided with the polishing wheel device, the rotational velocity and the turnover velocity of polishing wheels, and the speed of a conveying belt of the conveying device are intelligently adjusted according to different products, so that the deburring conditions are enabled to better meet the demands of different products, the application range of the deburring machine is extended, and the automation degree and applicability of the deburring machine are further improved.

Owner:松泰精技(深圳)有限公司

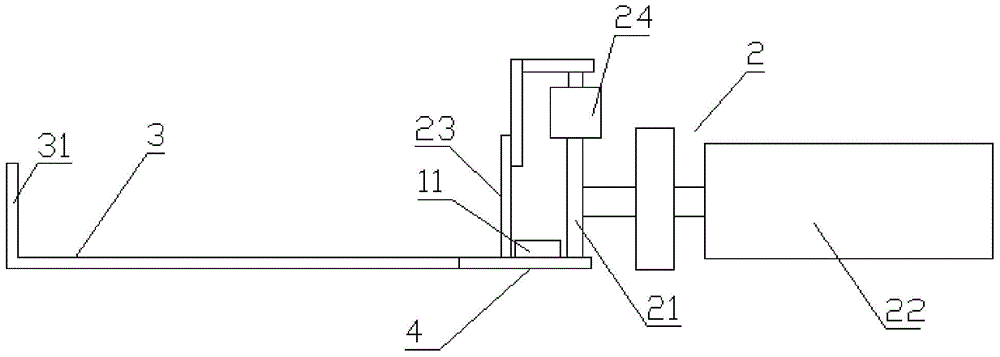

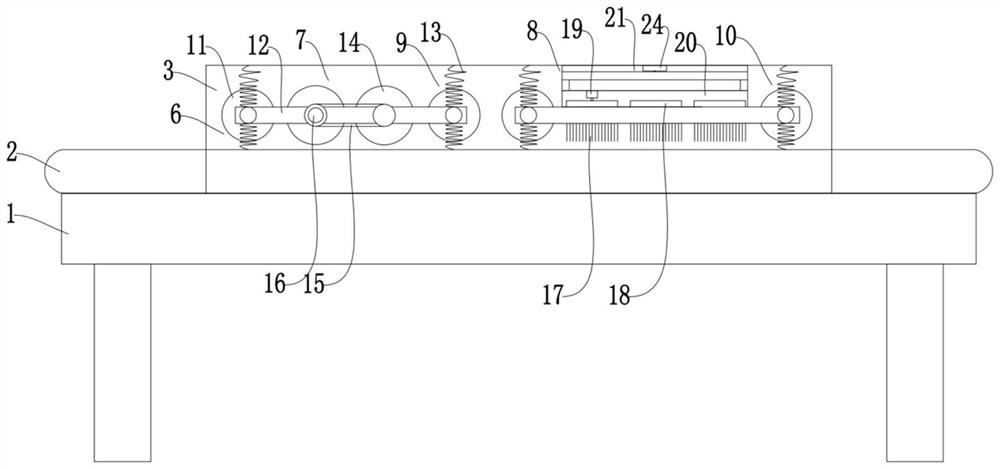

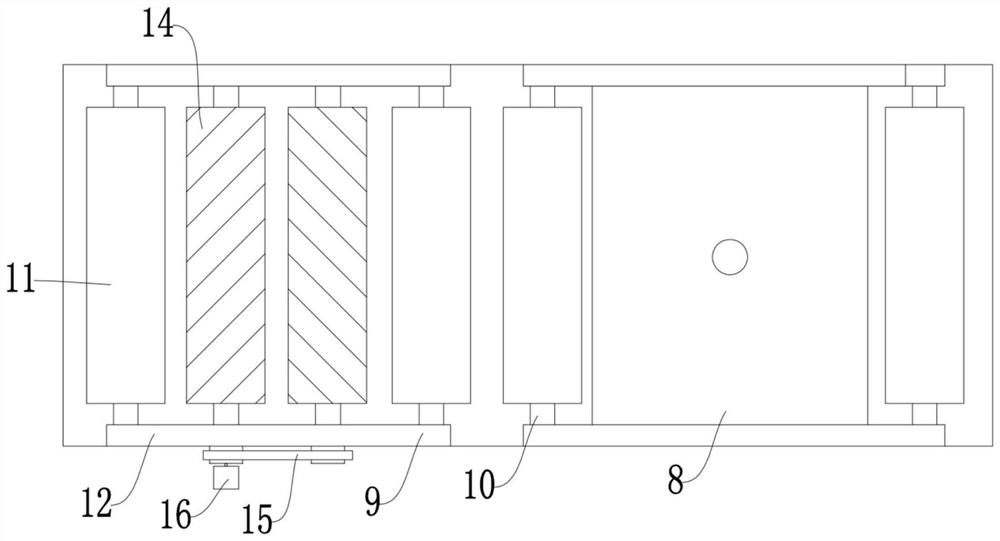

Deburring device for wood board processing

InactiveCN109732436AAvoid affecting the working environmentQuick clampingEdge grinding machinesGrinding drivesFurringPulp and paper industry

The invention provides a deburring device for wood board processing. The deburring device includes a workbench, a feeding flat board, two deburring frames, a moving transverse-grinding roller, a moving vertical-grinding roller, a fixed vertical-grinding roller and a fixed transverse-grinding roller, the feeding flat board is slidably arranged at the upper portion of the workbench, a rack is fixedly connected with the bottom of the feeding flat board, two L-shaped supporting boards are fixedly connected with the upper portion of the feeding flat board, and an elastic splint is rotatably connected with the inner side of each L-shaped supporting board; and a return stopping strip is fixedly connected with the surface of each elastic splint, the two deburring frames are movably arranged at oneend of the workbench, the moving vertical-grinding roller is slidably connected with the upper end of a rotating shaft, the moving transverse-grinding roller meshes with outer periphery of a cone gear, a fixed vertical-grinding roller is fixedly connected with the outer periphery of the lower end of the rotating shaft, and the fixed transverse-grinding roller meshes with the bottom of the fixed vertical-grinding roller. According to the deburring device, the feeding flat board is matched with the deburring frames, the wood board can be fixed on the feeding flat board through the elastic splints and the L-shaped supporting boards, so that the side end surface of the wood board can be scraped and polished in a reciprocating mode, and the deburring effect is improved.

Owner:江山市标龙装饰材料有限公司

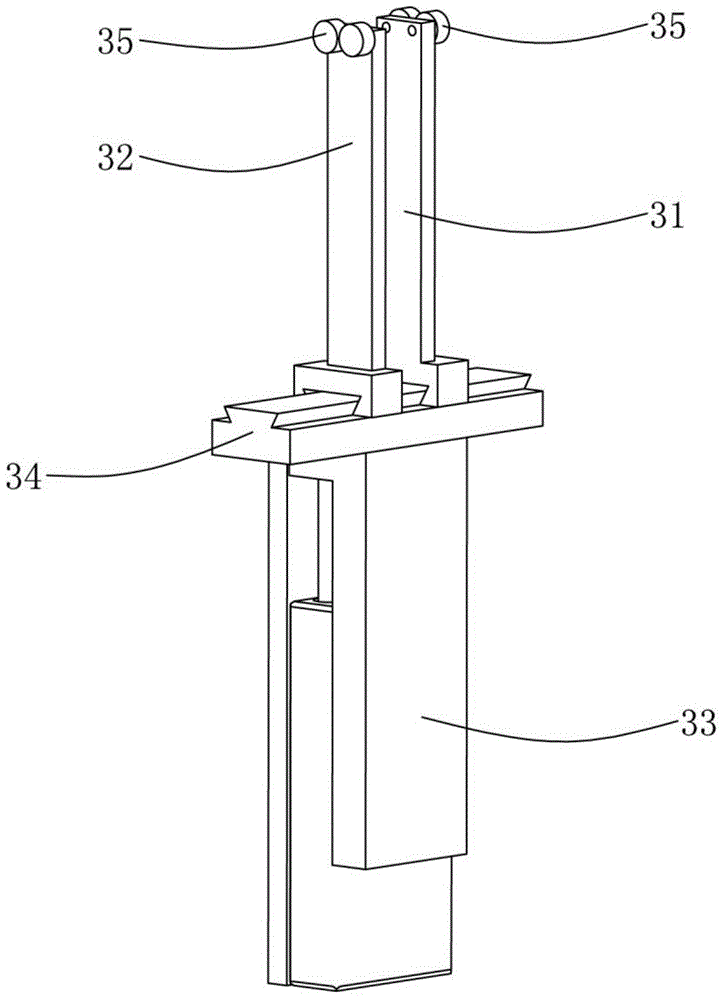

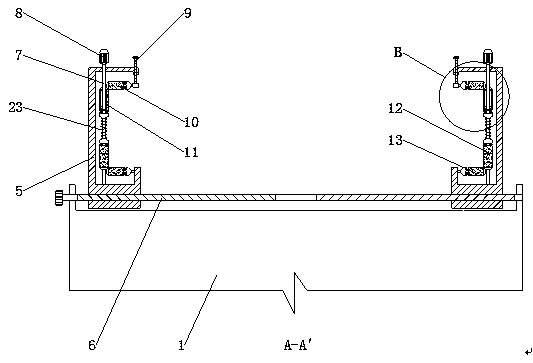

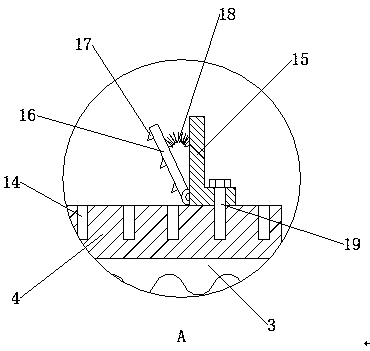

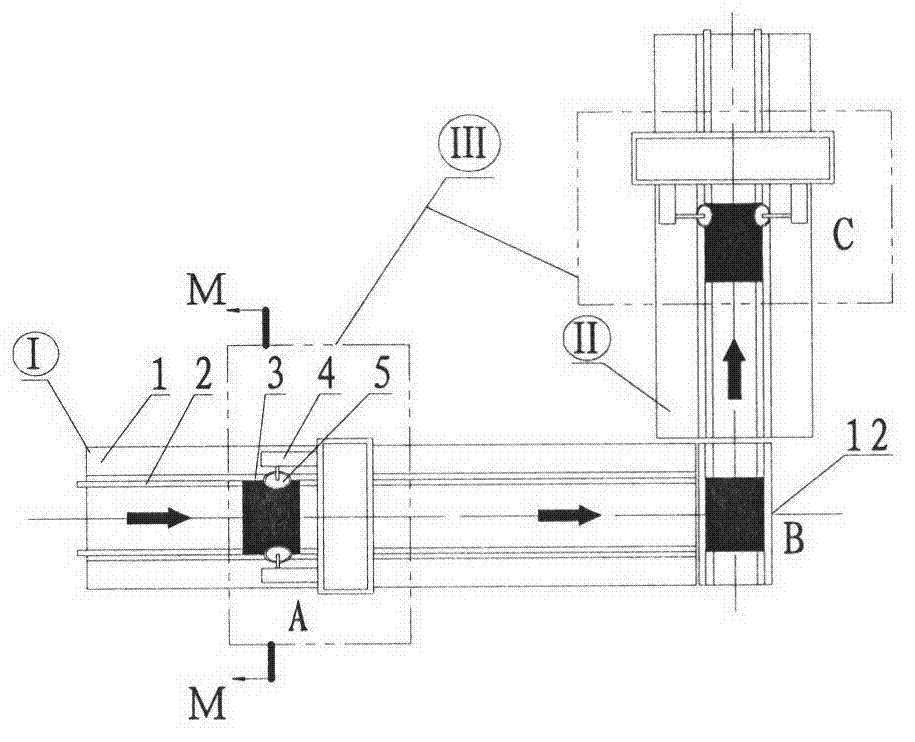

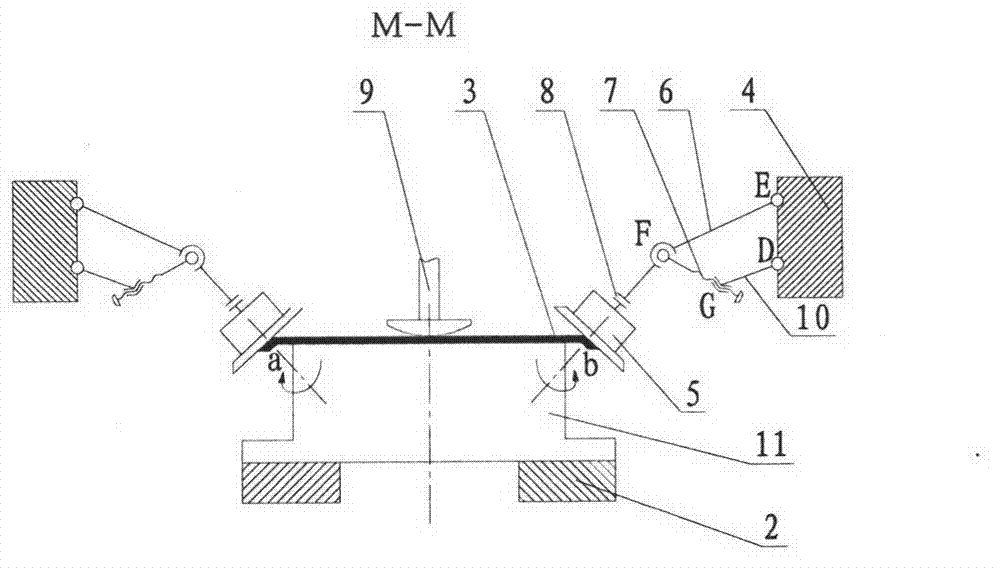

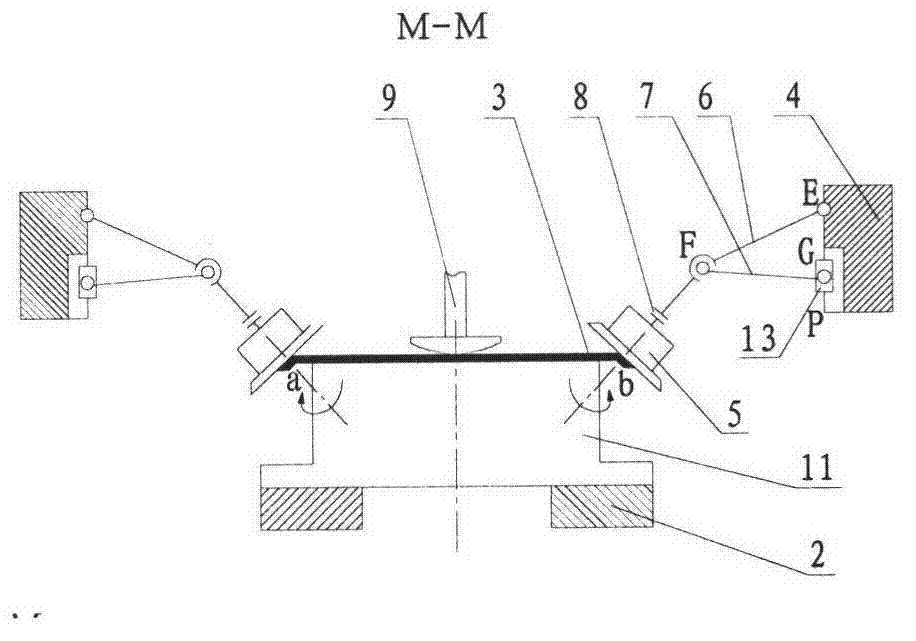

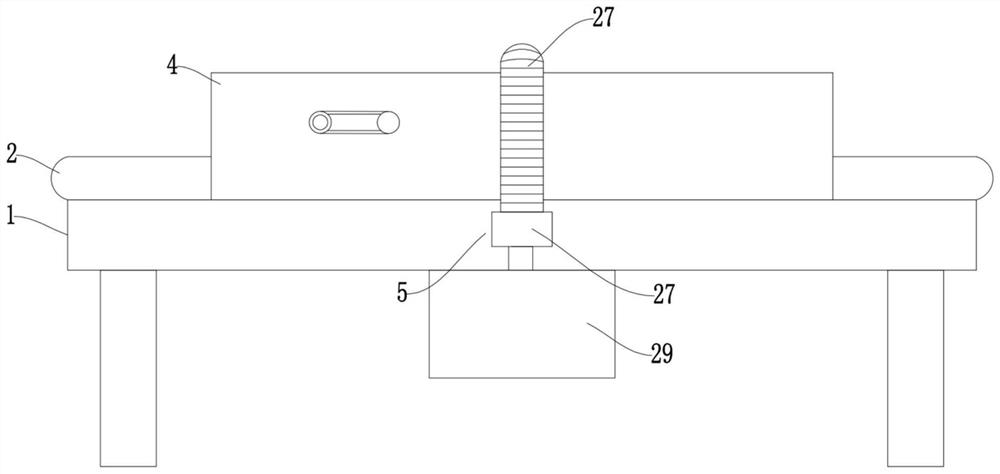

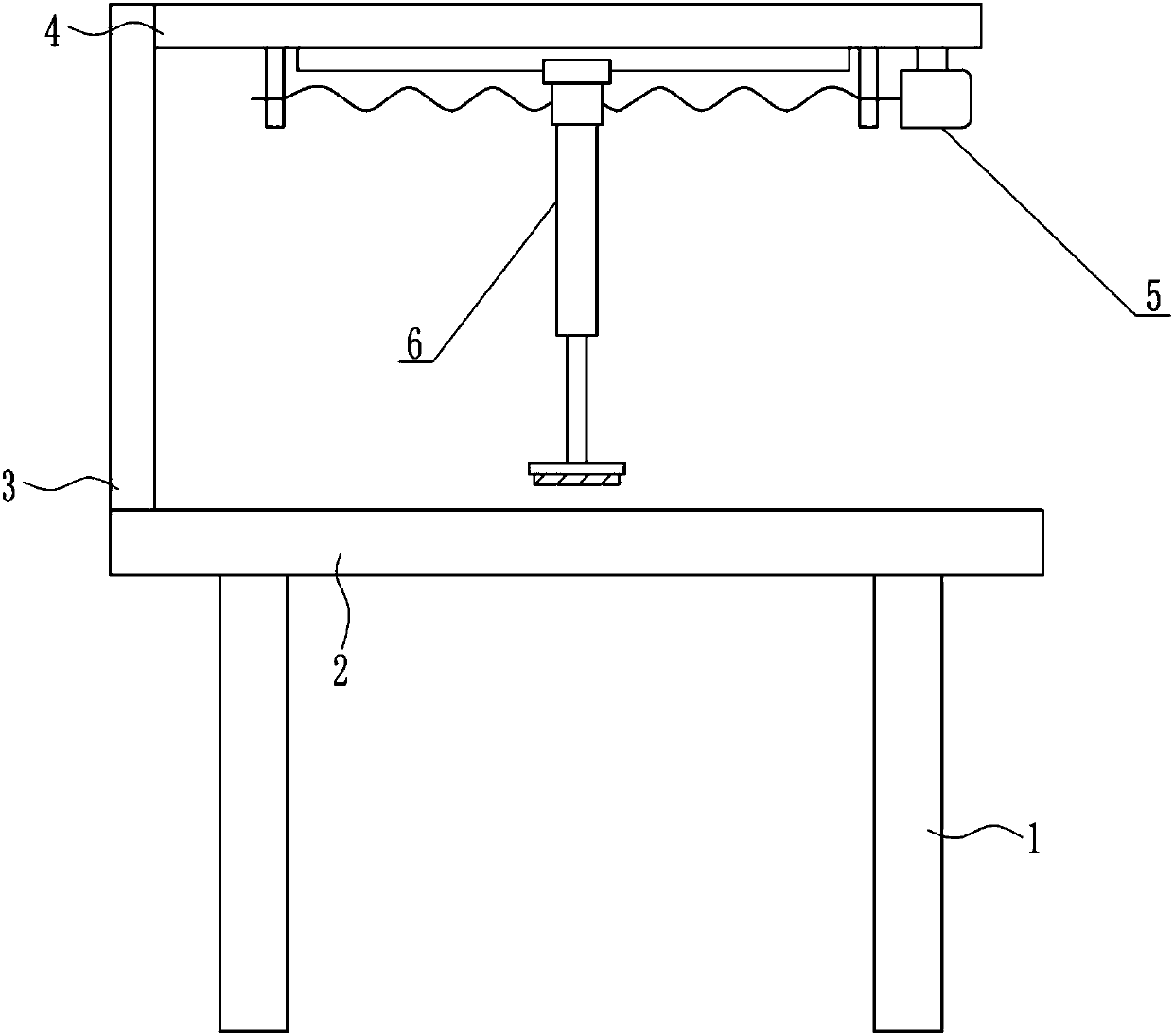

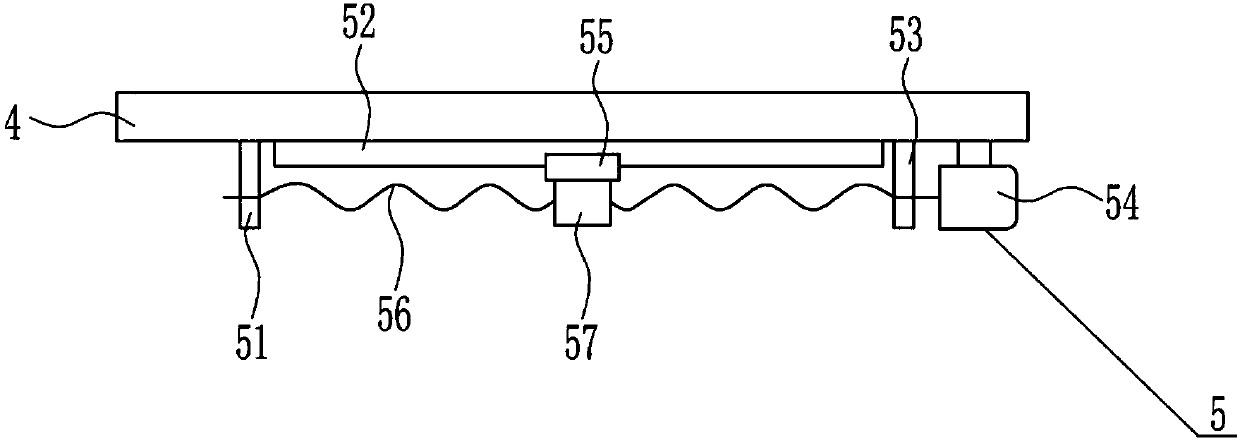

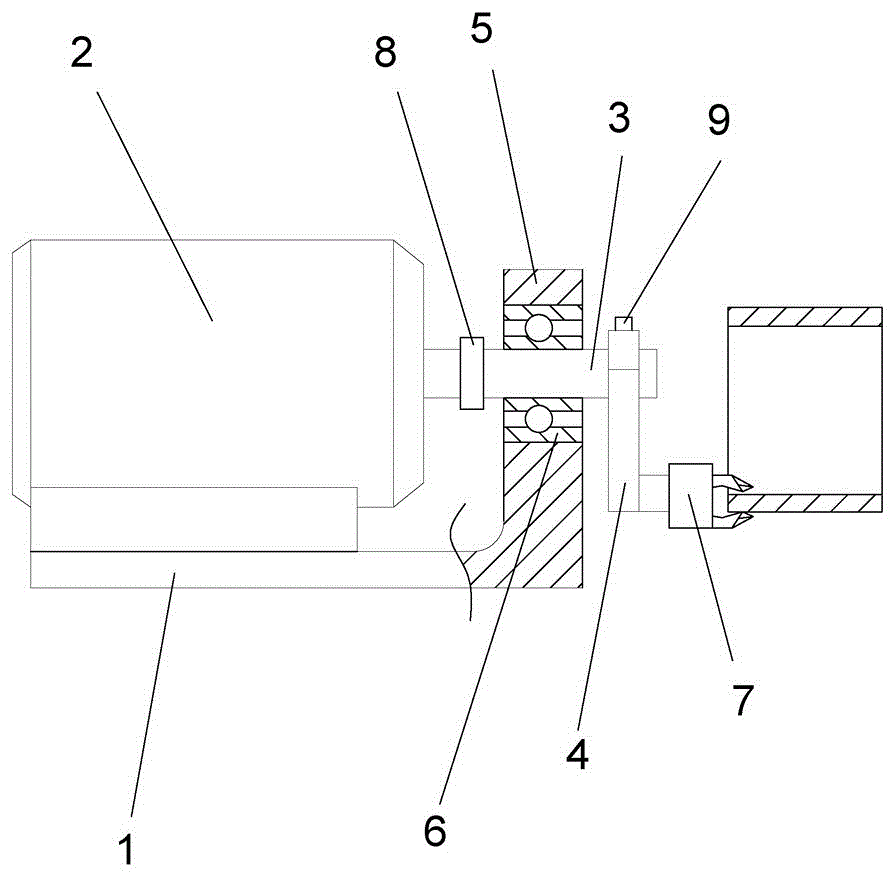

Side polisher for rectangular workpiece

InactiveCN102825518APolished evenlyImprove deburring effectEdge grinding machinesFixed frameEngineering

A side polisher for a rectangular workpiece comprises a conveying device and a polishing device. The conveying device comprises a frame (1), a first conveying line (I) of a conveying belt (2), a second conveying line (II) of the conveying belt (2) and a lifting turning table (12). The first conveying line (I) is connected with the second conveying line (II) through the lifting turning table (12). The polishing device comprises a fixed frame (4), a polishing head (5), a main arm (6), an auxiliary rod (7), a rocker (10), a flange (8), a clamping head (9), and a positioning block (11). The main arm (6) is connected with the fixed frame (4) through a first revolute pair (E) and connected with one end of the auxiliary rod (7) through a ball pair (F). A screw rod part at the other end of the auxiliary rod (7) is in a screw rod thread transmission with a nut (G) fixed at one end of the rocker (10). The other end of the rocker (10) is connected with the fixed frame (4) through a second revolute pair (D). The polishing head (5) is connected to the tail end of the main arm (6) through the flange (8). The rectangular workpiece (3) is positioned by positioning blocks (11) symmetrically disposed on two sides of the conveying belt (2) and clamped by the clamping head (9). The side polisher is simple in structure, easy to control, fine in adaptability, high in automation level and fine in polishing quality.

Owner:CHANGZHOU UNIV

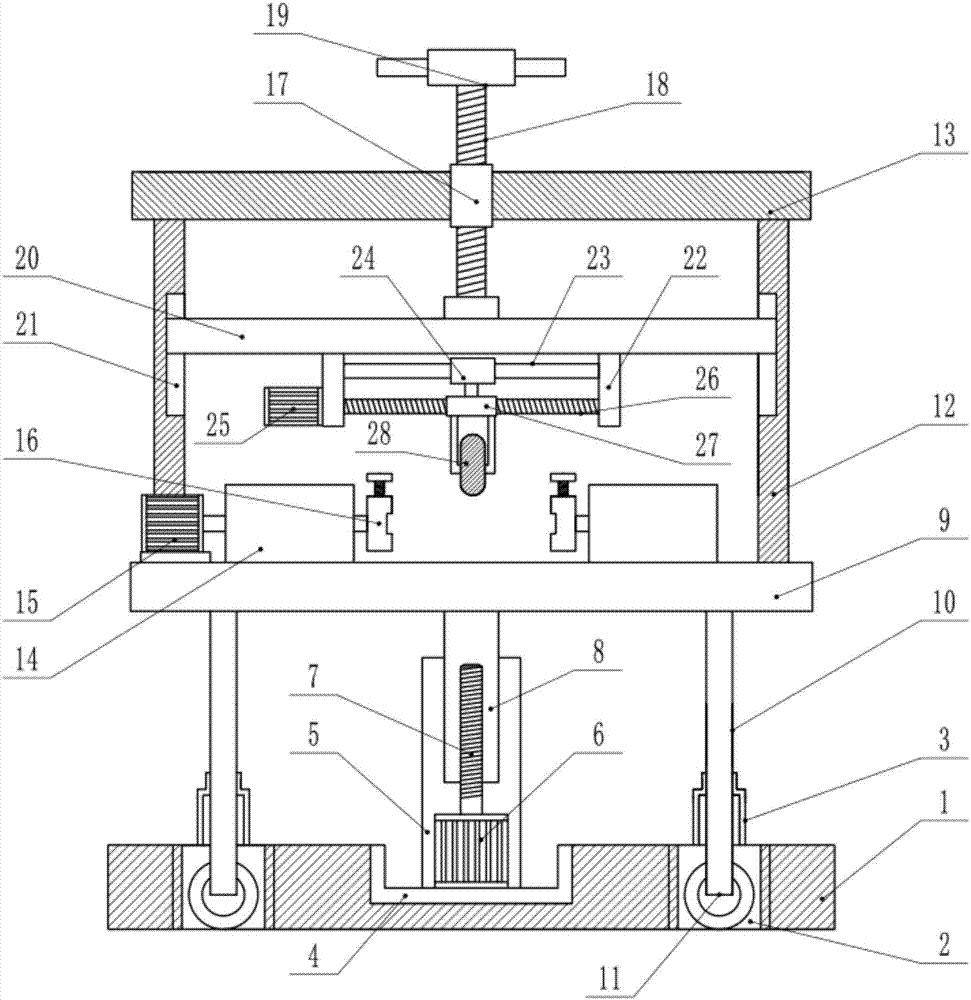

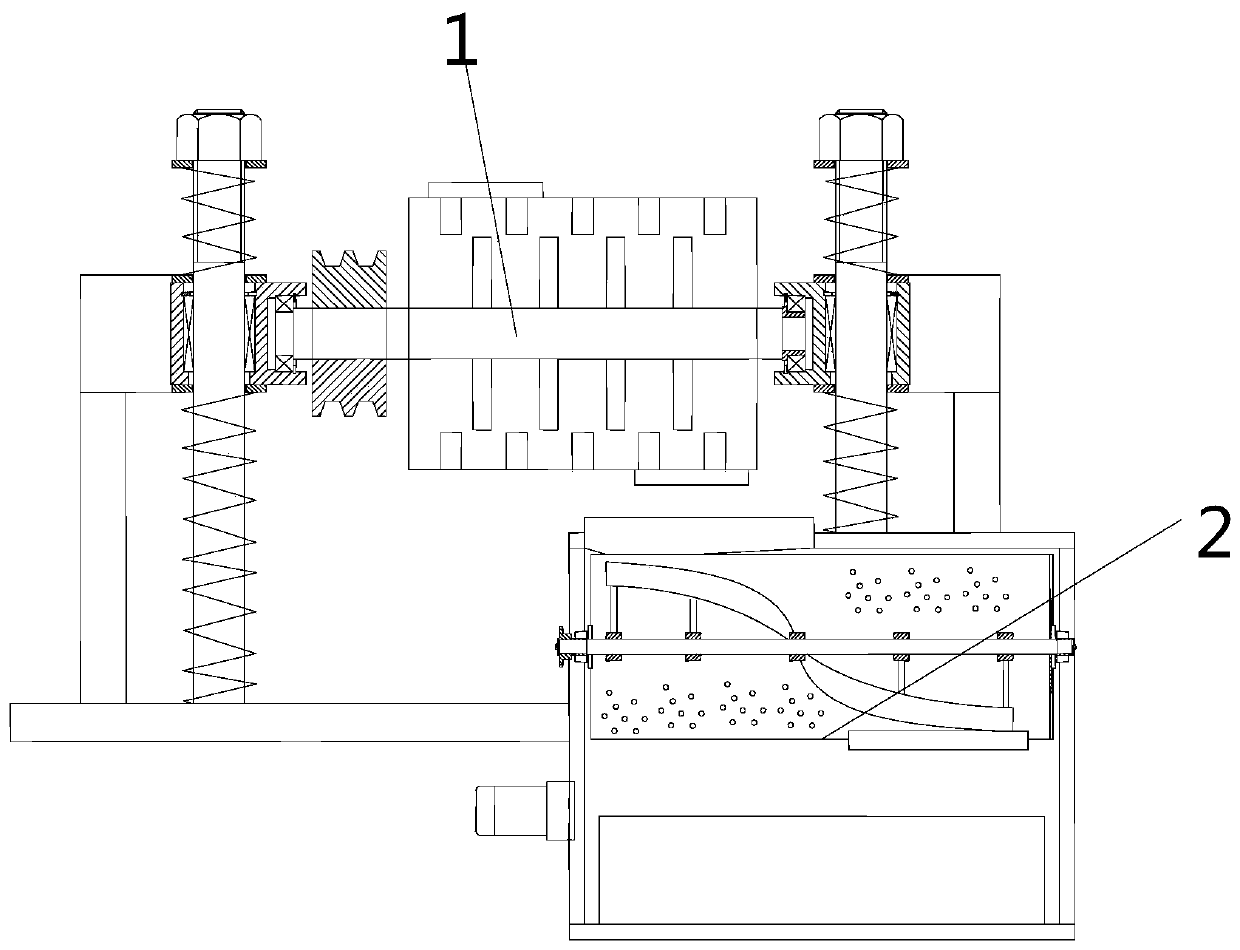

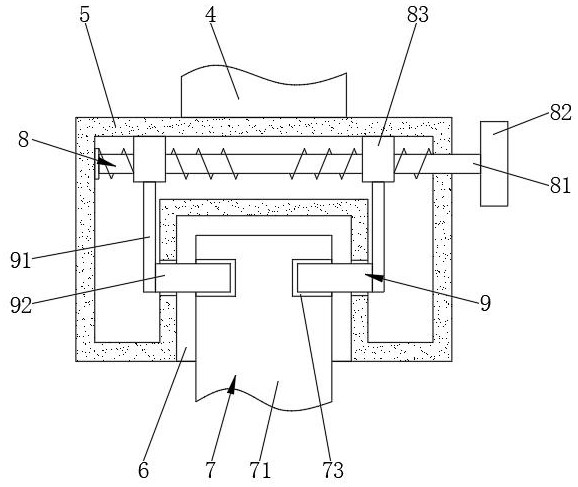

Drum-type deburring device for small part

InactiveCN110860994ANot easy to depositComplete structureEdge grinding machinesPolishing machinesStructural engineeringMechanical engineering

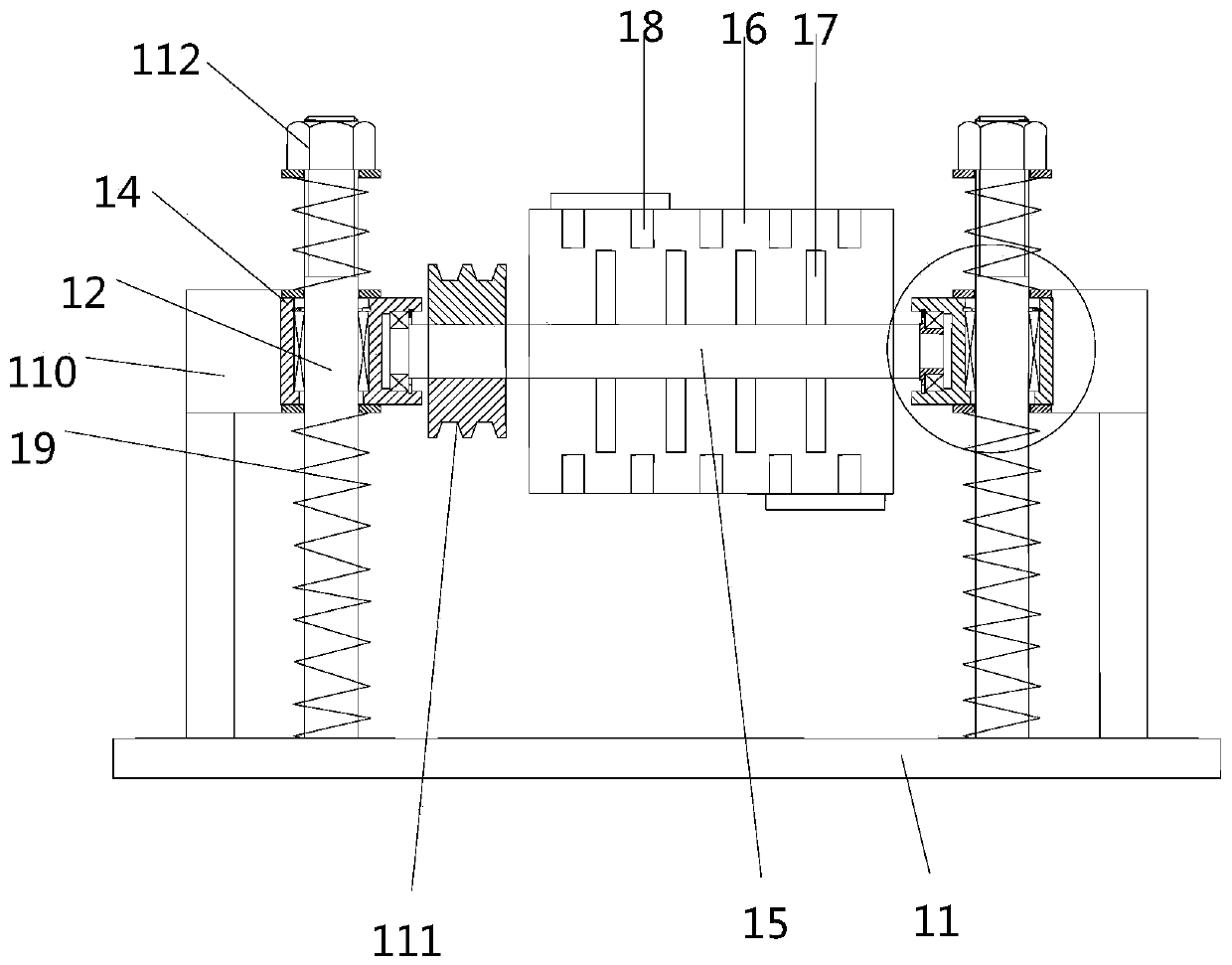

The invention discloses a drum-type deburring device for a small part. The drum-type deburring device comprises a drum deburring mechanism, wherein a discharge port of the drum deburring mechanism isconnected with an abrasive separating mechanism; the drum deburring mechanism comprises a base, a pair of upright posts are arranged on the base, sliding blocks with built-in sliding sleeves are respectively arranged on the pair of upright posts, bearing blocks are arranged on the sliding blocks, a rotating shaft is arranged through the bearing blocks, a drum fixed with the rotating shaft is arranged on the rotating shaft, a first stirring blade is arranged on the rotating shaft positioned in the drum, a second stirring blade is arranged on the inner wall of the drum, compression springs sleeved on the upright posts are arranged on the upper parts and the lower parts of the sliding blocks, reciprocating vibrators are also connected with the sliding blocks, and a transmission device is arranged on the rotating shaft at one side of the drum. The drum-type deburring device for the small part has the advantages of good deburring effect and high working efficiency.

Owner:湖州市漾西电化有限公司

Deburring machine

InactiveCN107855889AImprove the effectImprove quality and efficiencyPolishing machinesBelt grinding machinesSurface finishingBelt grinding

The invention discloses a deburring machine, and belongs to the technical field of workpiece surface treatment. The deburring machine comprises a machine base, a conveying device used for conveying aworkpiece, a universal rolling brush grinding machine head used for deburring of edges and holes of the workpiece and an abrasive belt grinding machine head used for grinding the workpiece surface arearranged on the machine base, the universal rolling brush grinding machine head and the abrasive belt grinding machine head are sequentially arranged at an interval in the conveying direction of theconveying device, and the universal rolling brush grinding machine head and the abrasive belt grinding machine head are both located above the conveying device. Through combination of the universal rolling brush grinding machine head and the abrasive belt grinding machine head, the surface treatment machining procedure can be finished when the workpiece passes through the conveying device at a time, and the surface quality and the machining efficiency of the workpiece are improved.

Owner:LANUSS LNDUSTRIAL EQUIP SUZHOU CO LTD

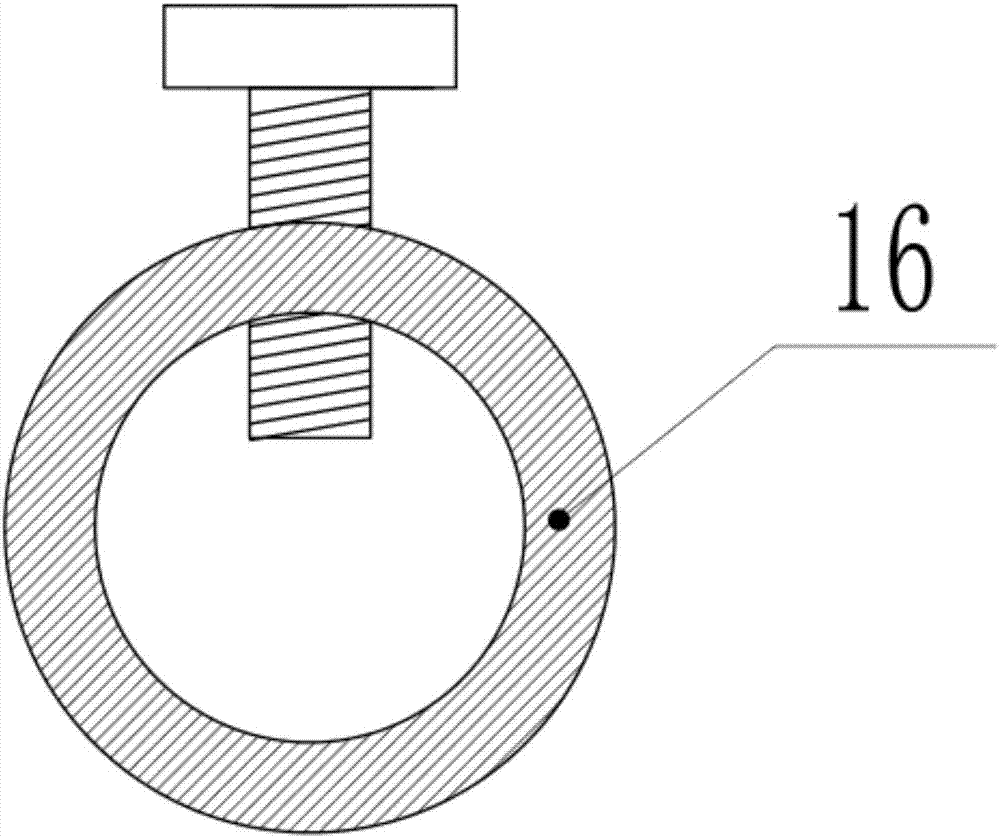

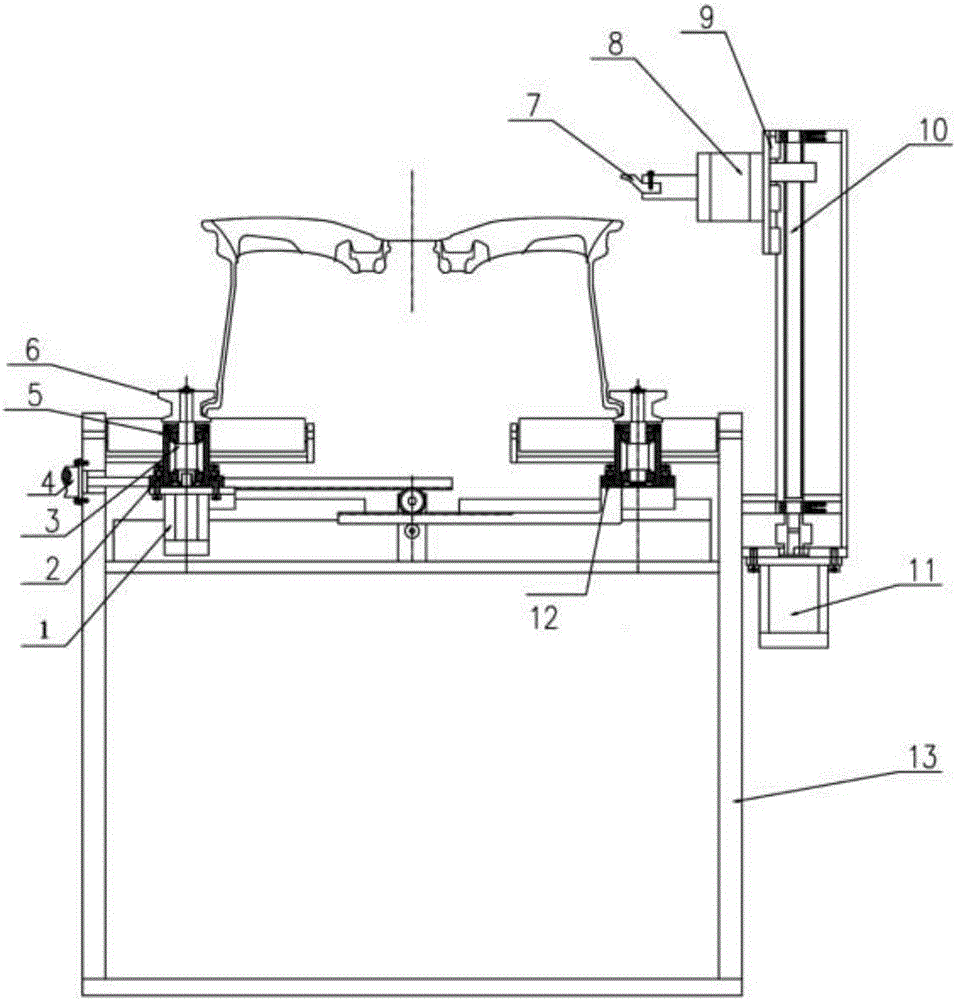

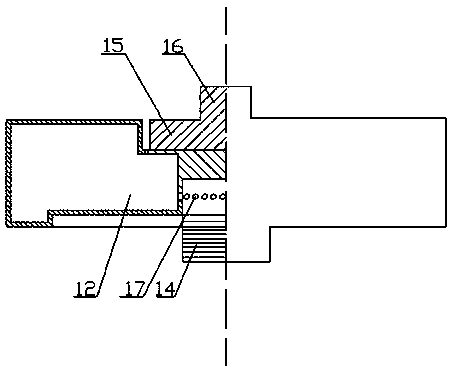

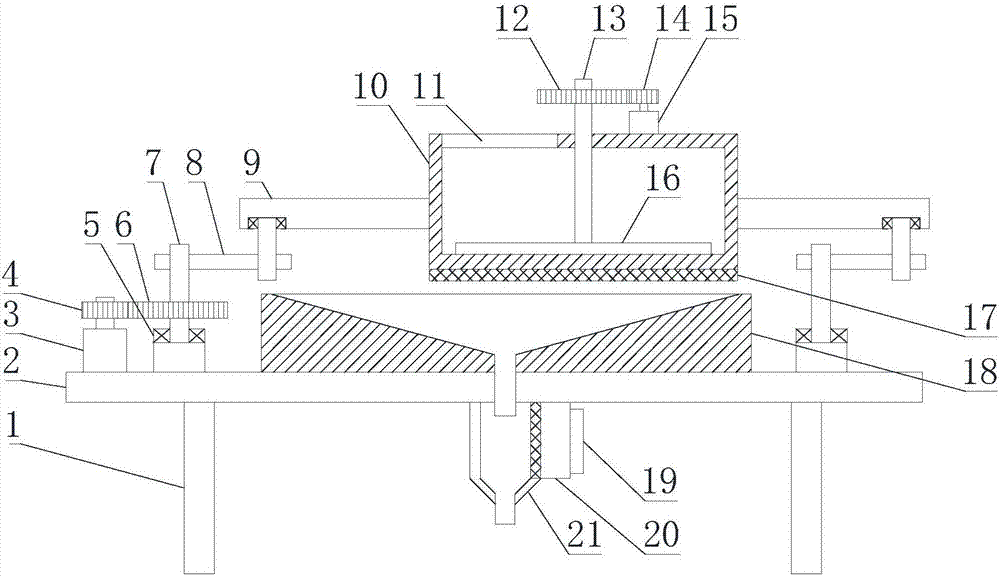

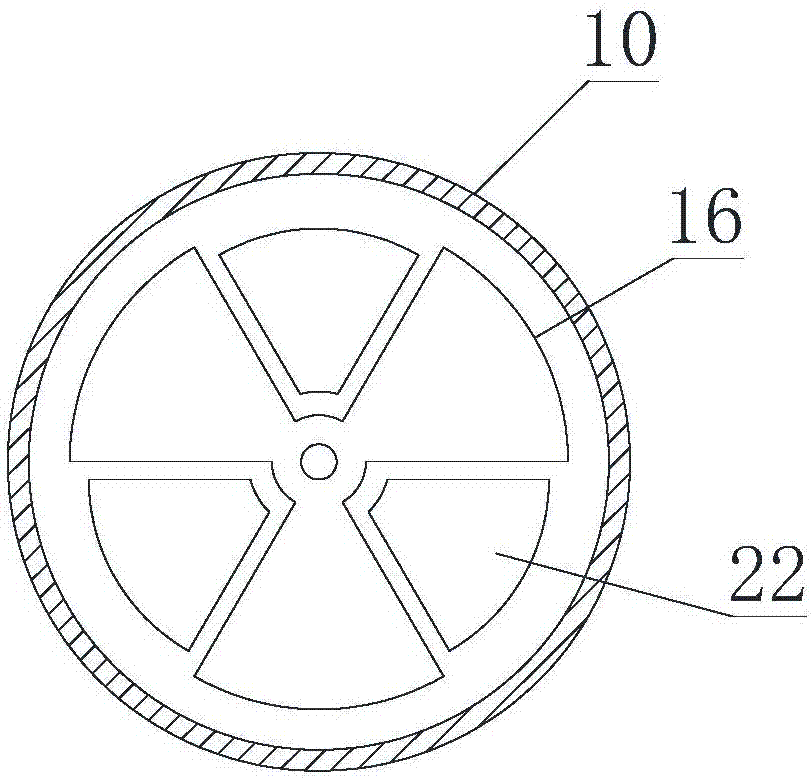

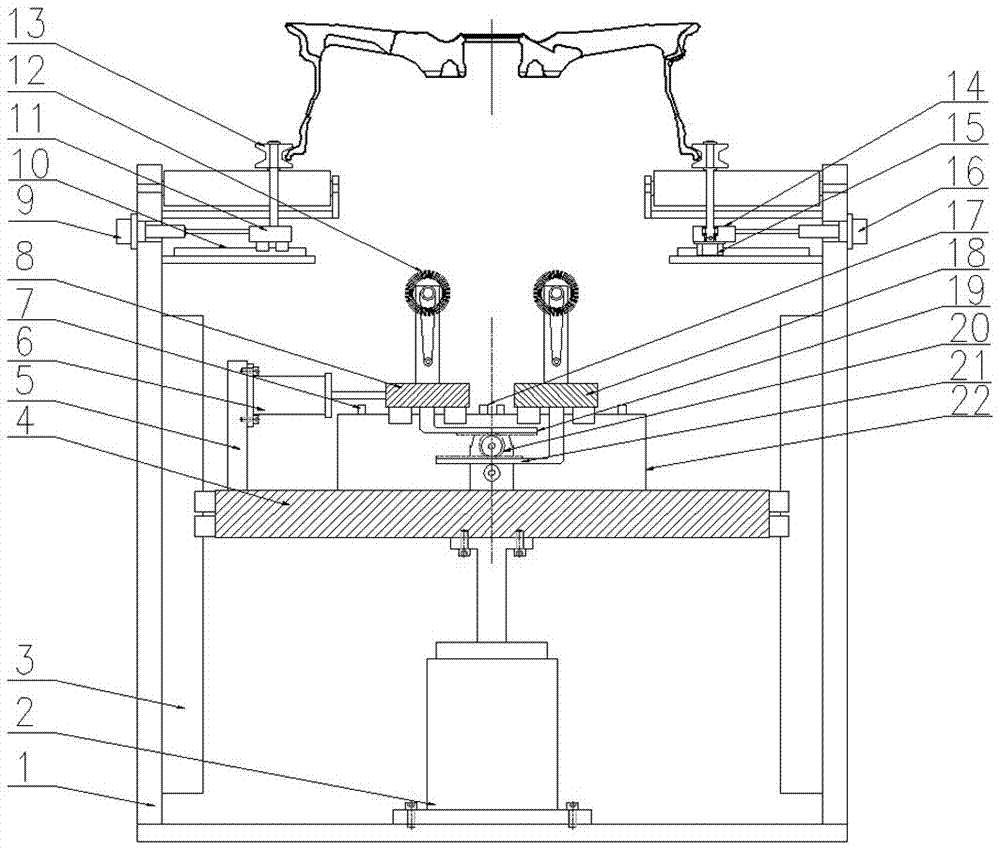

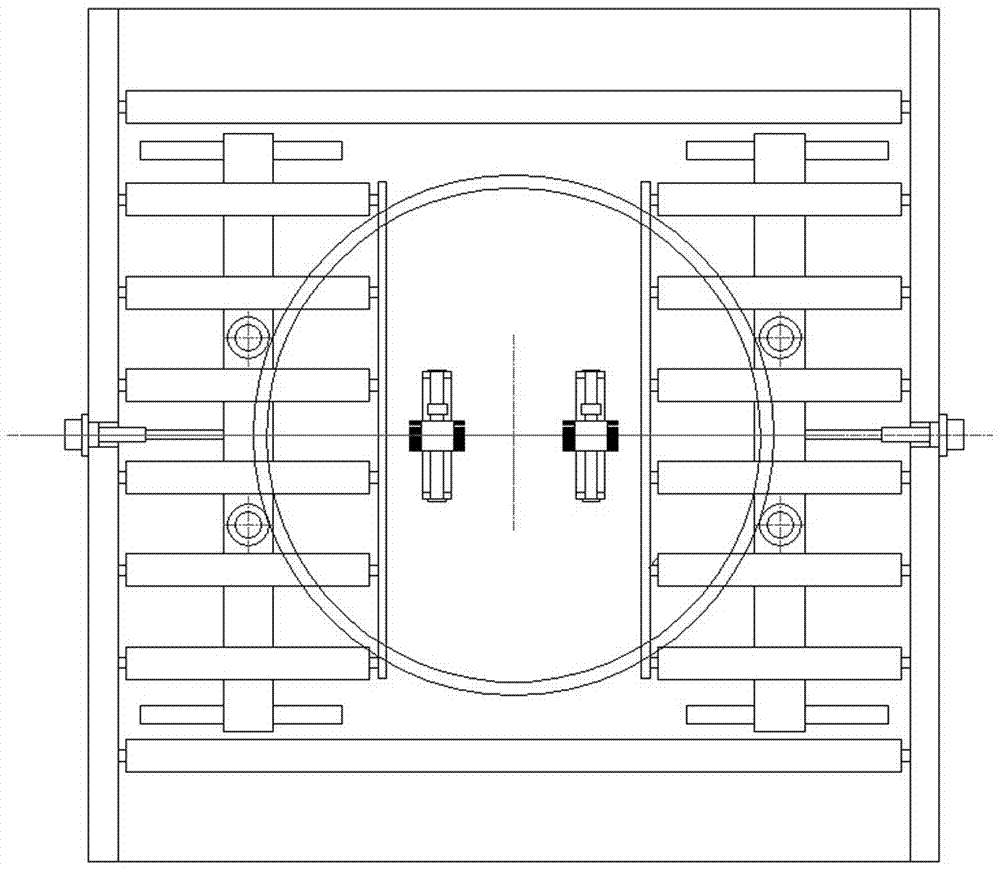

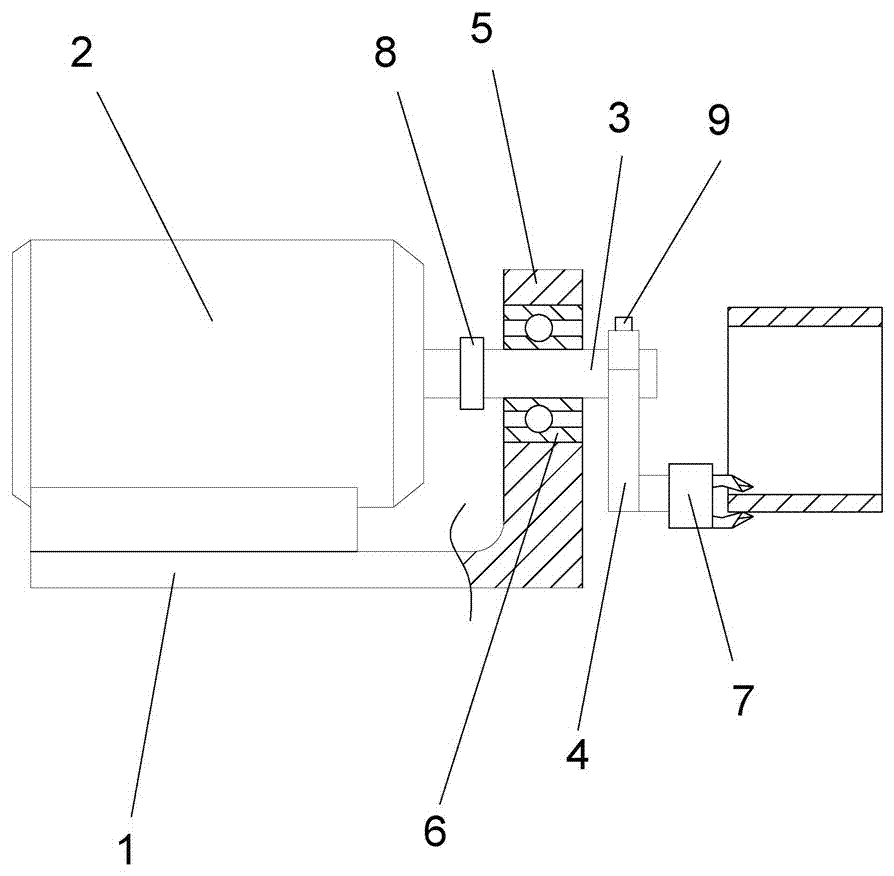

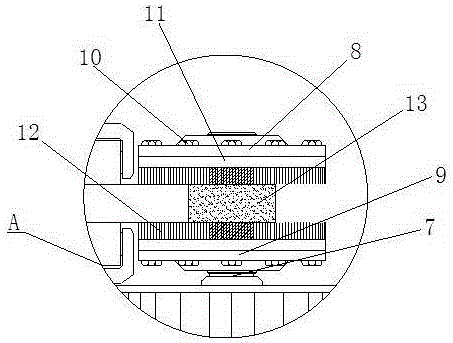

Device for removing hub rim burrs

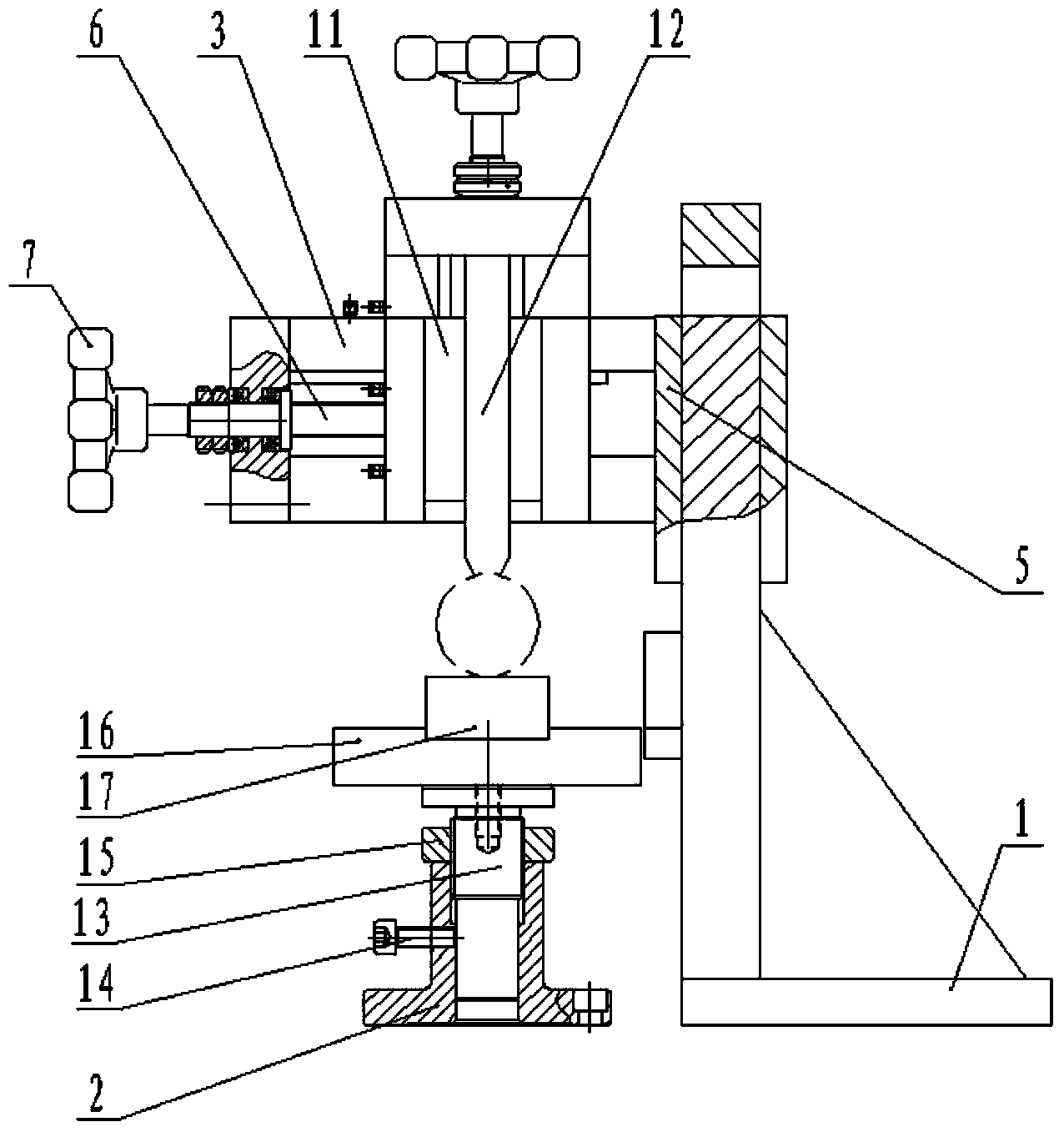

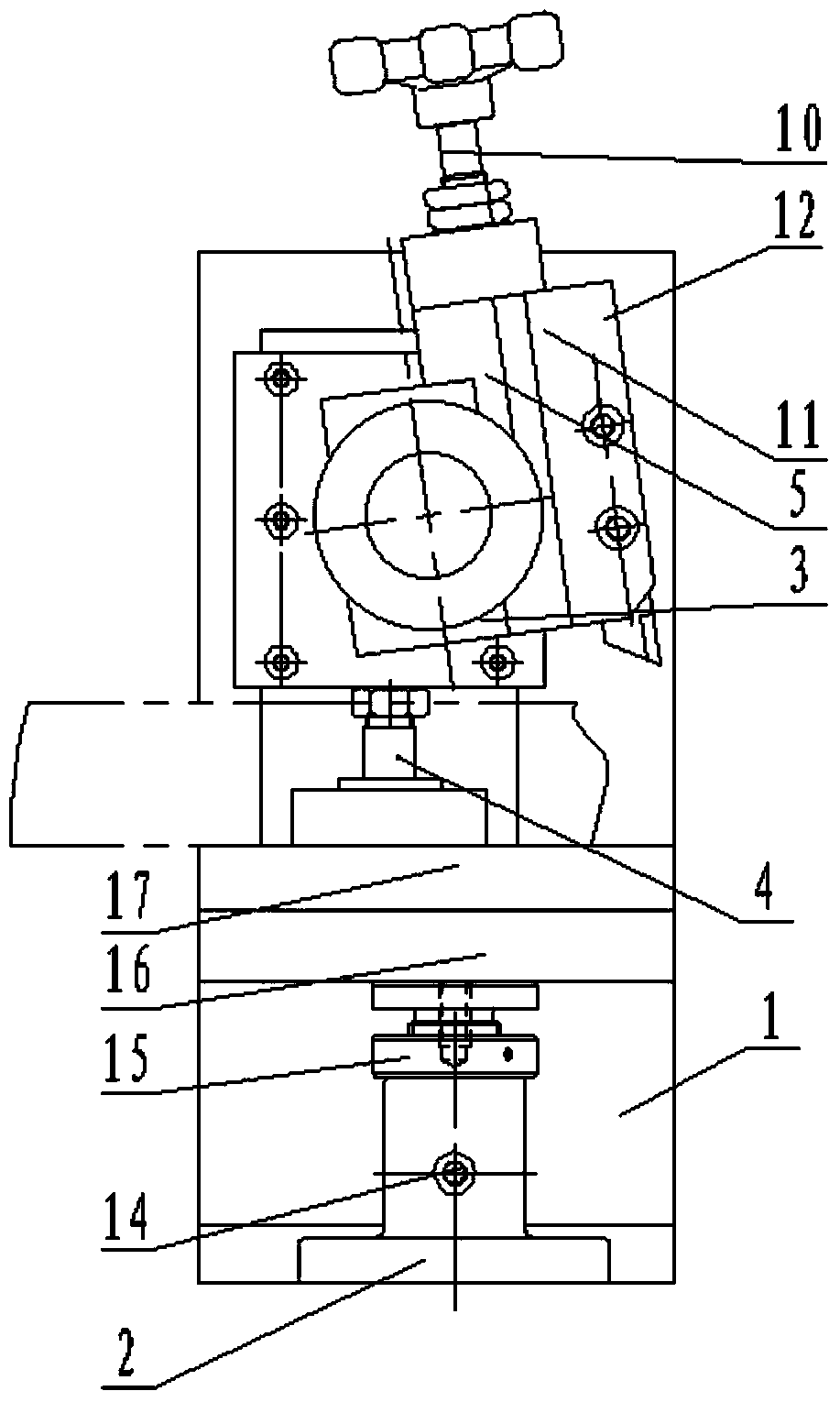

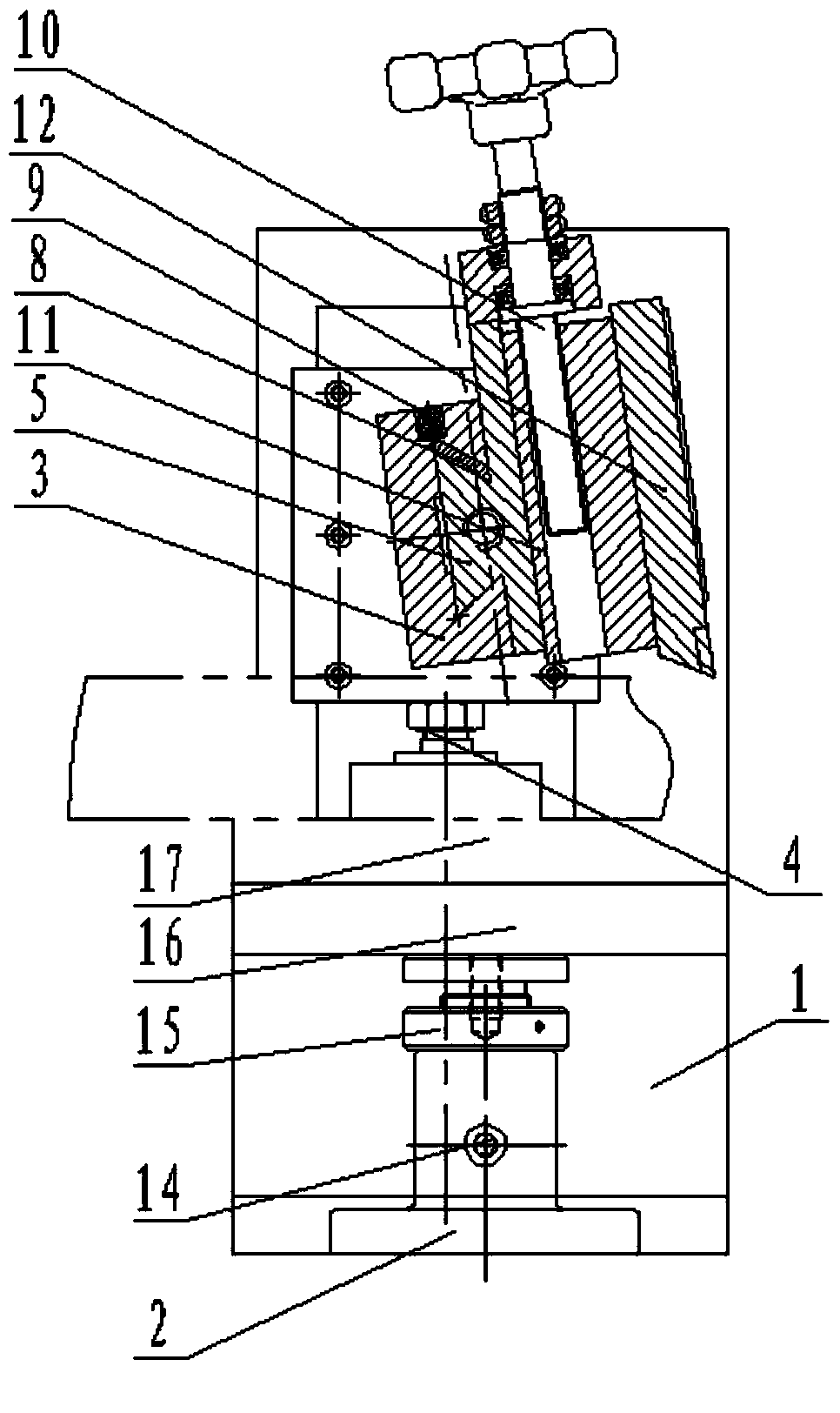

A device for removing burrs from the rim of a wheel hub, which consists of a clamping roller servo motor (1), a left slide (2), a shaft (3), a clamping cylinder (4), a bearing seat (5), and a clamping roller ( 6), burr knife (7), linear motor (8), lifting platform (9), ball screw (10), lifting motor (11), right slide plate (12), frame (13), support plate (14 ), rack (15), gear (16) and guide rail (17), the left slide (2) and the right slide (12) are connected through the gear (16) and rack (15), and the clamping cylinder (4) drives The rack (15) moves, and the synchronous movement of the left slide (2) and the right slide (12) is realized through the engagement of the rack (15) and the gear (16), thereby controlling the synchronous clamping and loosening of the clamping rollers (6). The beneficial technical effect of the invention is that it can meet the requirement of automatic deburring of the wheel, greatly improve the deburring effect, have a higher degree of automation, reduce the labor cost, and evenly remove the burrs.

Owner:CITIC DICASTAL

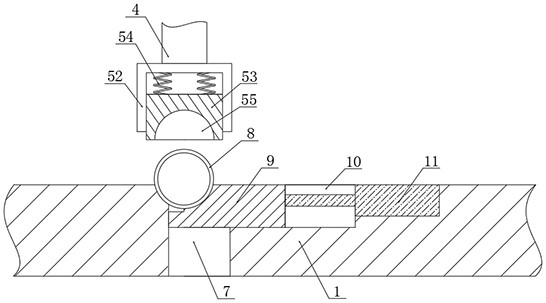

Scraper device for welded joint of welded tube

InactiveCN104227115AReduce wearGood removal effectWelding/cutting auxillary devicesPlaning/slotting machinesEngineeringWeld seam

The invention discloses a scraper device for a welded joint of a welded tube, which has a good using effect and long service life. The scraper device comprises a tool holder and a supporting seat, wherein a cross arm capable of moving vertically and a cylinder capable of driving the cross arm to move are arranged on the tool holder, a sliding seat capable of moving horizontally is arranged on the cross arm, a carriage capable of being vertically adjusted is arranged on the sliding seat, a planer tool, which is at an angle of 60-85 degrees to the top surface of the welded tube, is arranged on the carriage, the supporting seat is arranged under the planer tool, the supporting seat can be vertically adjusted, and a supporting plate is arranged at the top of the supporting seat.

Owner:JIANGSU LONGYUAN METAL TECH

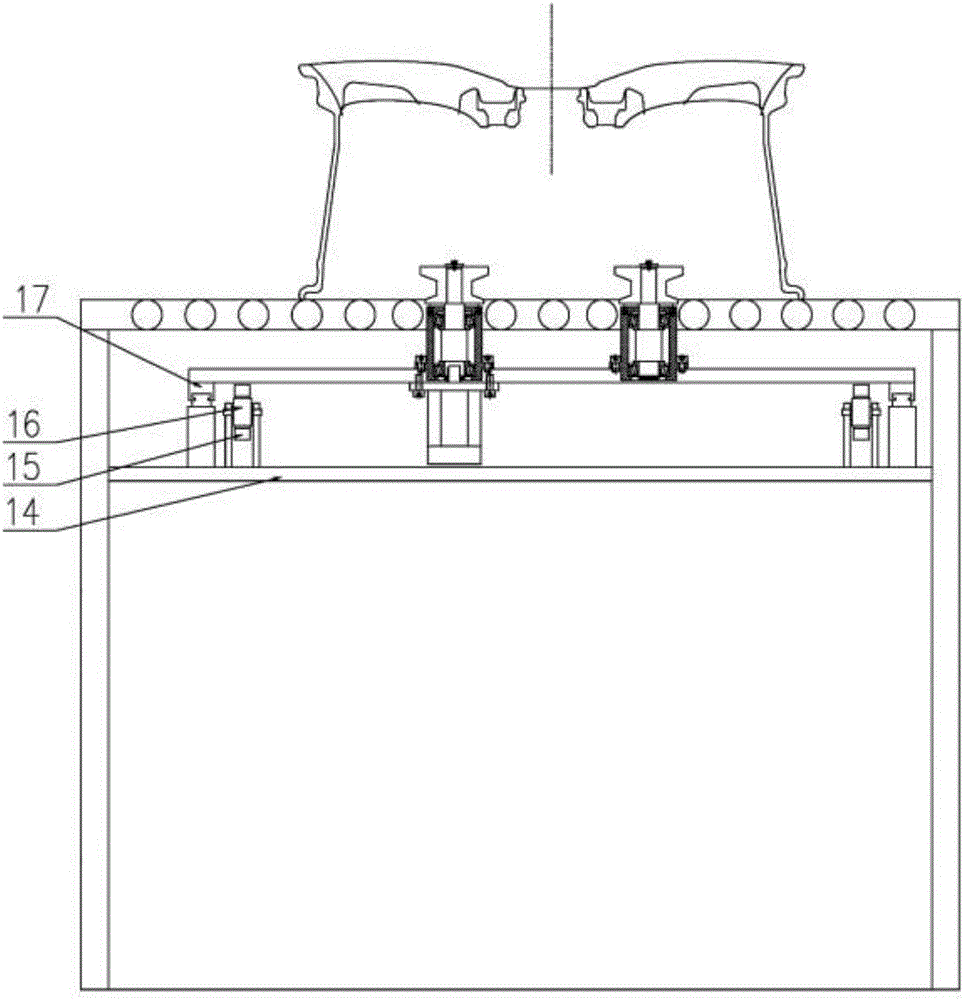

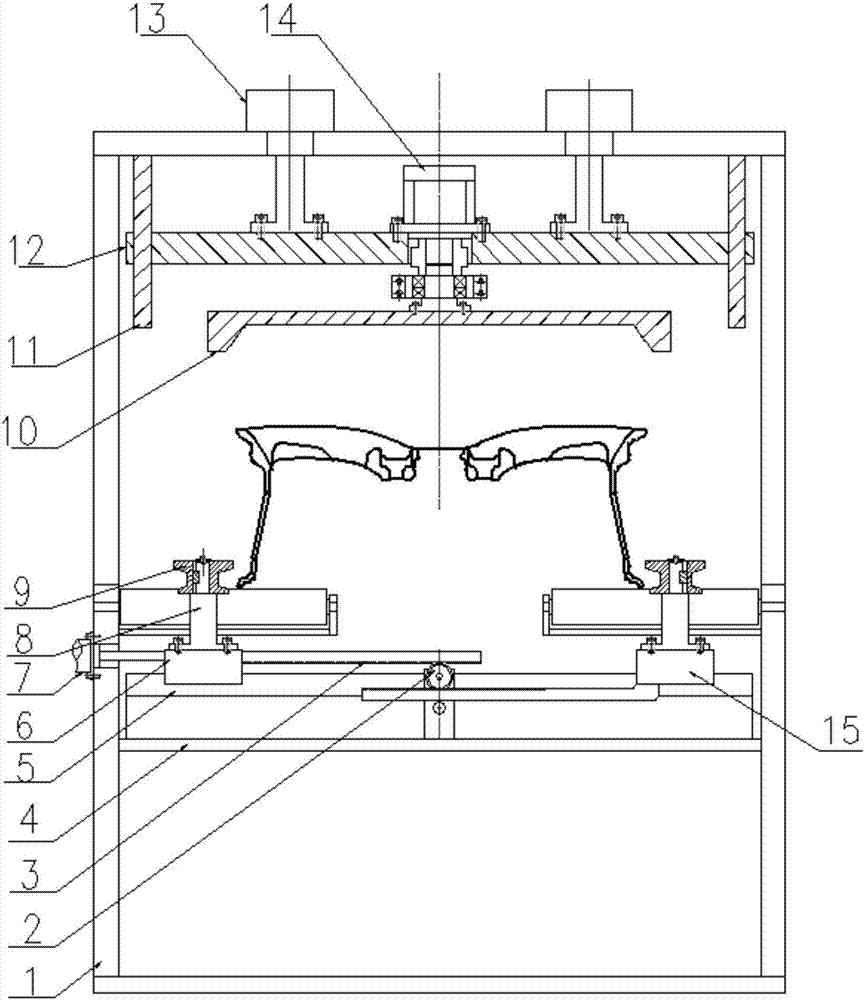

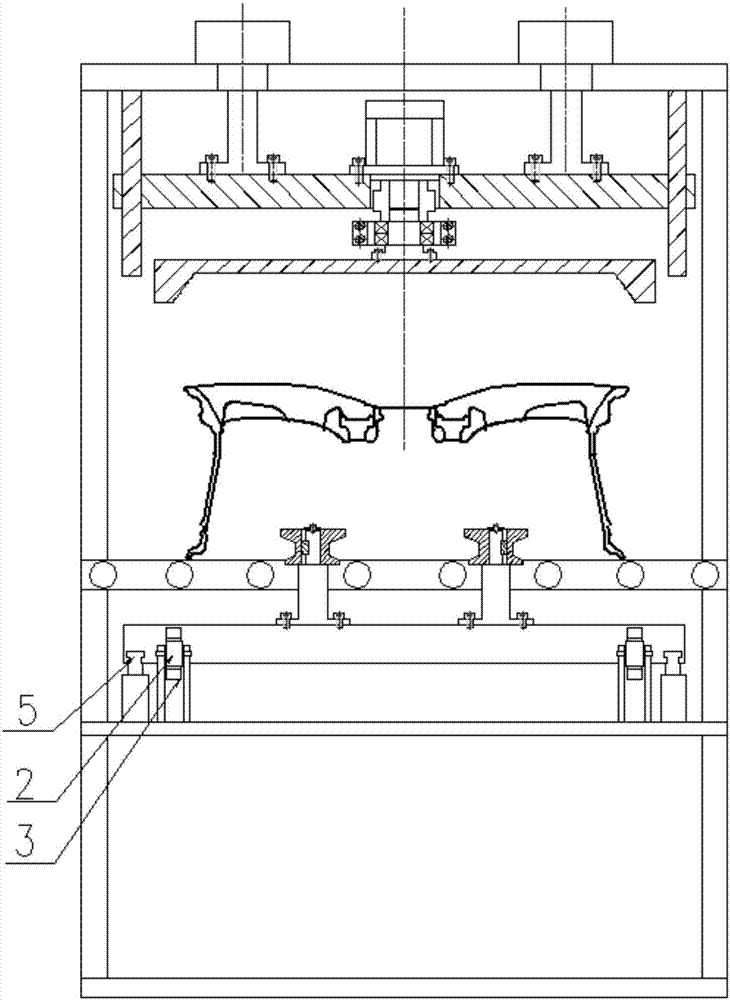

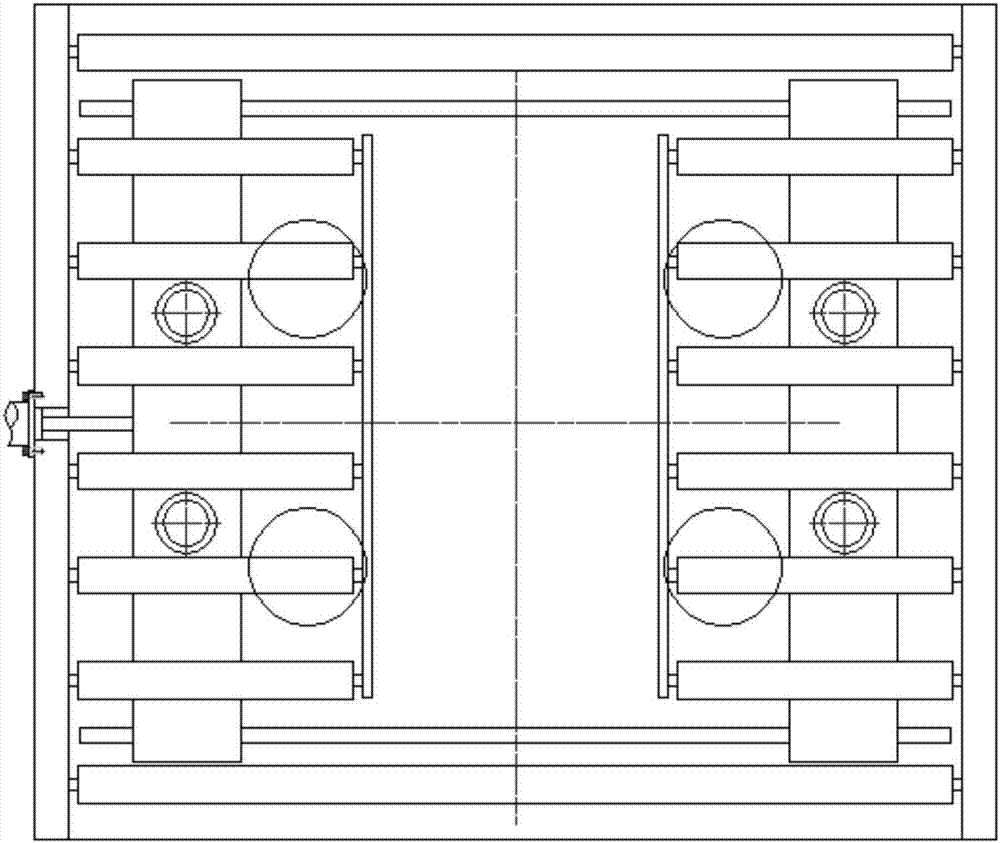

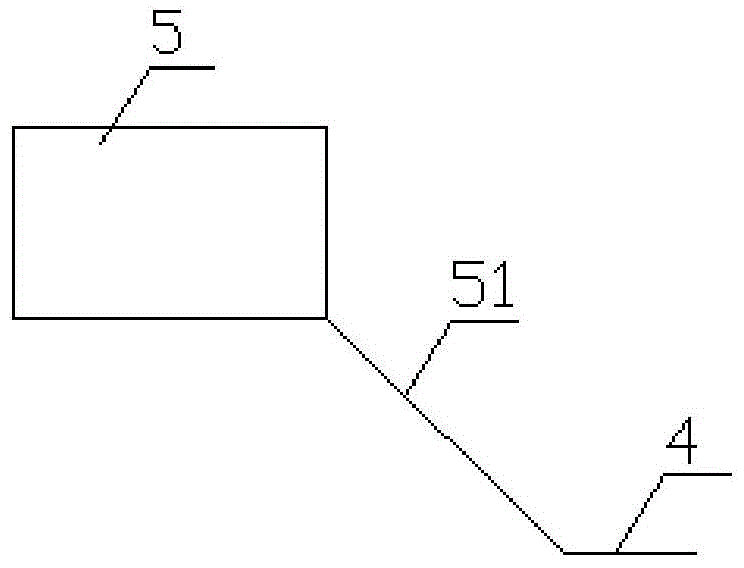

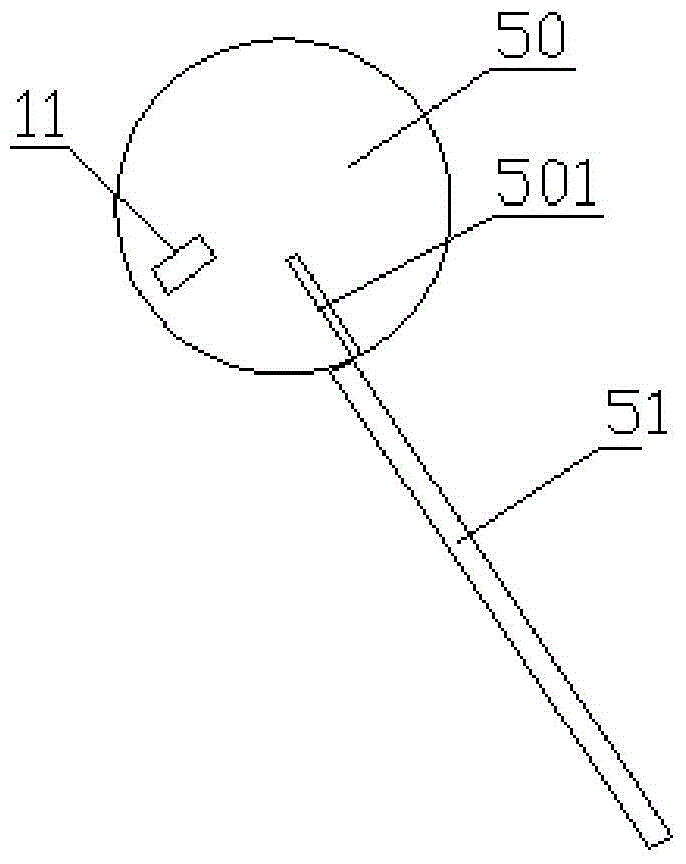

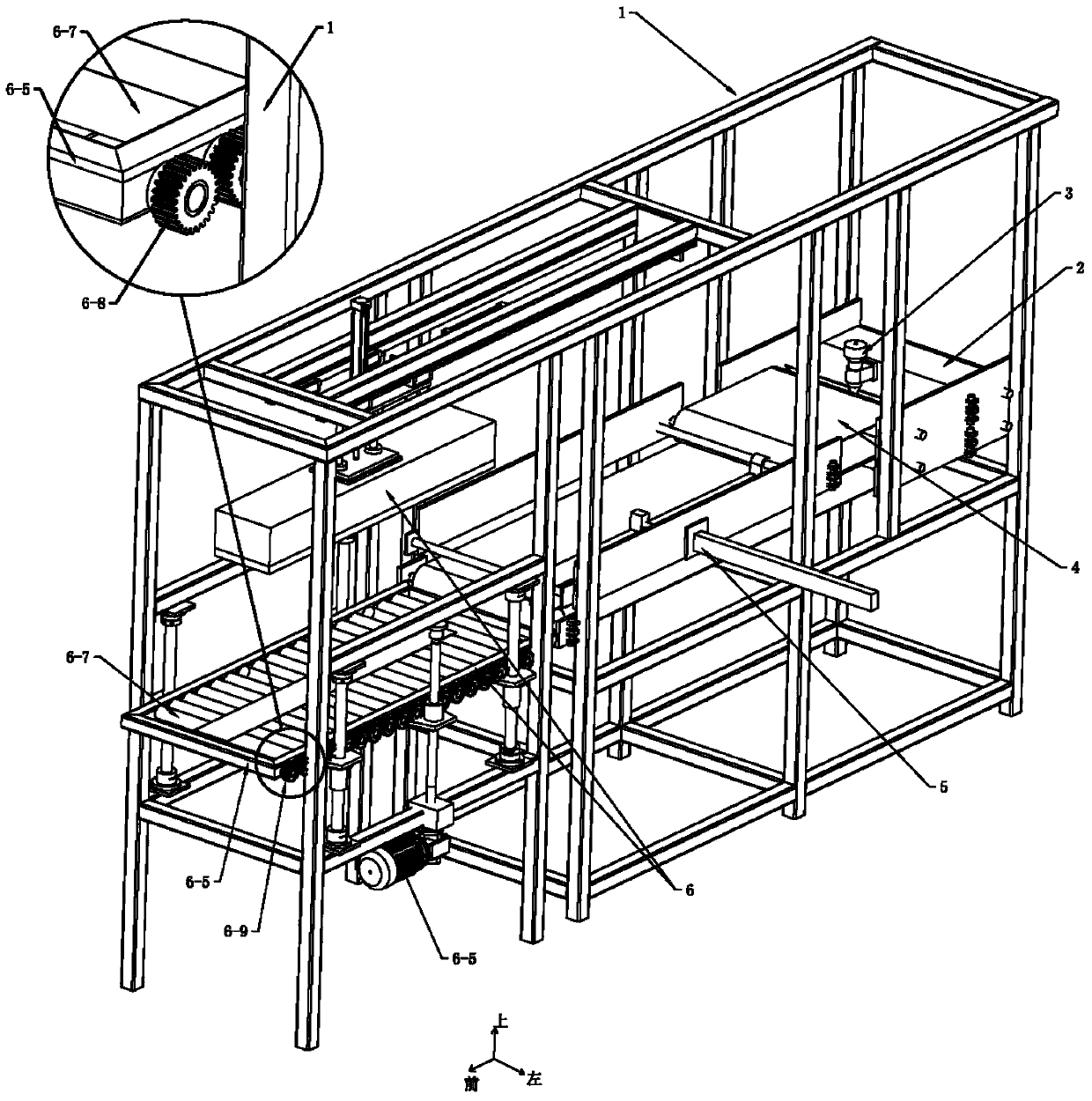

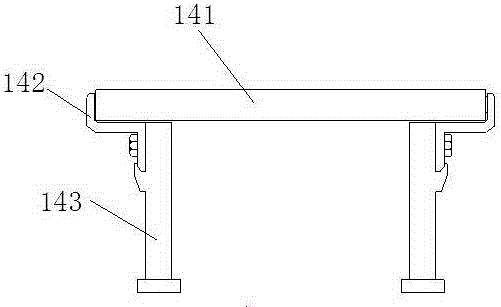

Device for automatically removing rim burrs

PendingCN106938417AHigh degree of automationImprove efficiencyEdge grinding machinesEngineeringSlide plate

The invention provides a device for automatically removing rim burrs. The device is formed by a machine frame (1), gears (2), racks (3), a fixed supporting plate (4), a guide rail (5), a left sliding plate (6), a clamping air cylinder(7), vertical columns (8), clamping wheels (9), a rotary cutter plate (10), guide columns (11), a movable supporting plate (12), upper air cylinders (13), a servo motor (14) and a right sliding plate (15). The device is characterized in that the clamping wheels (9) are fixed to the vertical columns (8), the two vertical columns (8) are fixed to the left sliding plate (6), the other two vertical columns (8) are fixed to the right sliding plate (15), and the left sliding plate (6) is structurally connected with the right sliding plate (15) through the gears (2) and the racks (3). The device can meet the requirement of automatic removal of burrs on a rim on the outer side of a wheel, the automation degree is high, the takt is short, efficiency is high, the burr removal effect is good, labor cost is reduced, and labor intensity is relieved. The device has the advantages of being compact in structure, stable in running, easy to operate and the like.

Owner:CITIC DICASTAL

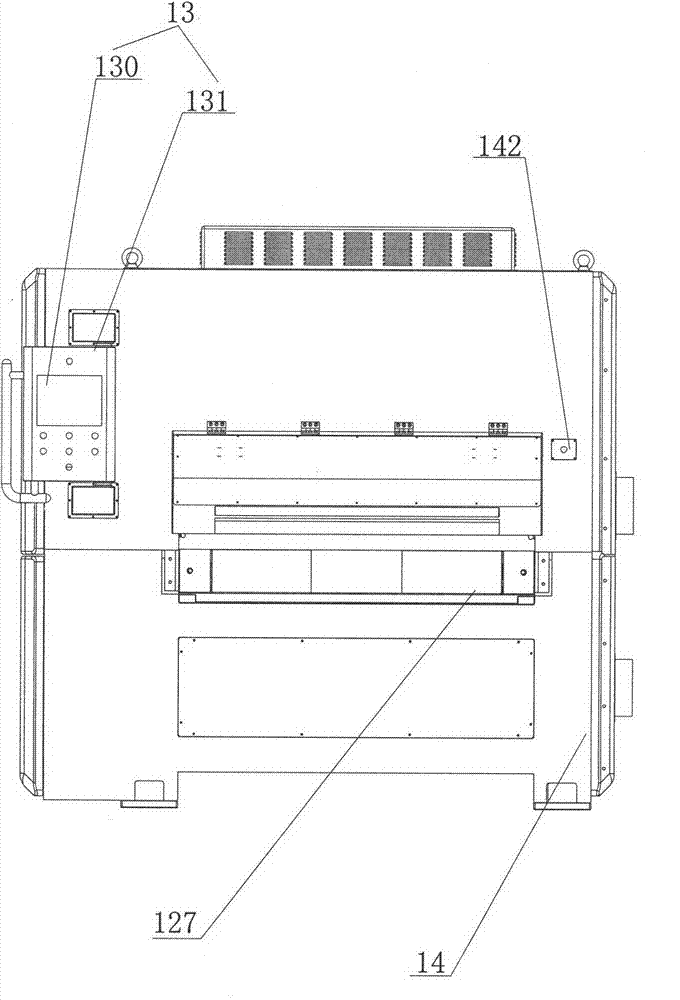

Multifunctional blanking device for magnetic cores

InactiveCN105035709AImprove efficiencyImprove deburring effectCleaningBristleElectrical and Electronics engineering

The invention discloses a multifunctional blanking device for magnetic cores. The multifunctional blanking device for the magnetic cores comprises a magnetic core conveying belt; a conveying track inclining downwards is arranged between a discharging outlet of a magnetic core press and the magnetic core conveying belt; a brush used for deburring is arranged above the conveying track; brush bristles of the brush make contact with the conveyed magnetic cores; a pushing device is arranged on one width side of the tail section of the magnetic core conveying belt; a discharging platform is arranged on the other side; the pushing device comprises a pushing board and a baffle which are arranged in parallel vertically; the pushing board is close to the pushing device side; the baffle is close to the discharging platform side; a material arraying channel for arraying the magnetic cores is formed between the pushing board and the baffle; the baffle is controlled by a horizontal air cylinder to horizontally act; the baffle is controlled by a lifting air cylinder to ascend or descend. The multifunctional blanking device for the magnetic cores not only improves the deburring efficiency of the magnetic cores, but also can array the magnetic cores orderly.

Owner:HAINING LIANFENG MAGNET IND

Technological method for deburring steel piece through chemical milling

InactiveCN102337102AEasy to useLow costOther chemical processesLapping machinesBenzoic acidMaterials science

The invention relates to a technological method for deburring a steel piece through chemical milling. The technological method comprises the following steps: mixing chemical raw materials hydrogen peroxide H2O2, ammonium bifluoride NH4HF2, carbamide CO(NH2)2, benzoic acid C6H5COOH and a small amount of additives according to a certain volume / weight ratio to obtain a concentrated solution, and then mixing with water according to a volume ratio of 1:(2-4) to obtain a chemical milling liquid; and carrying out ultrasonic deoiling, degreasing, microetching and cleaning on a punched piece or finished steel piece, immersing in the chemical milling liquid prepared in the step (1), and soaking for 30-90 seconds while ensuring the temperature of the chemical milling liquid to be 10-35 DEG C, thus cleanly deburring the piece. The technological method has the characteristics of convenient use, low cost, reliable operation process, good deburring effect and the like, and is comparable with CPL-100. Besides, the technological method is more than 100 times cheaper than CPL-100.

Owner:PHENIX OPTICAL CO LTD

Gear burr removing technology

ActiveCN108746898AJet speedGood deburring effectElectrochemical machining apparatusTraffic volumeCorrosion

The invention relates to a gear burr removing technology. The technology comprises the following specific steps that 1, a burr removing device is constructed; 2, a gear is placed; 3, conducting and discharging are carried out; 4, an electrolyte is sprayed; 5, the gear is washed ultrasonically; 6, antirust treatment is carried out; and 7, the gear is naturally dried in air and delivered from storage. The technology has the following advantages that an anode terminal and a cathode terminal are utilized for conducting and discharging, the electrolyte is sprayed to the gear fast from bottom to top, the spraying speed is high, the electrolyte is sprayed in a centralized manner, and the burr removing effect is achieved; meanwhile, the burr removing effect is remarkable, the risk that the gear isbroken down is avoided, time for burr removing is short, and efficiency is high; the concentration of sodium nitrate is low, harm to the human body is avoided, corrosion to the surface of the gear isavoided, and meanwhile, the good burr removing effect can be ensured; and as the electrolyte spraying speed is high and the flow amount is large, the complex washing step in the later period is omitted, the gear only needs to be washed with clear water, the gear is washed ultrasonically, and thus greasy dirt on the surface of the gear can be decomposed and emulsified.

Owner:NANTONG ZHONGLV GEAR CO LTD

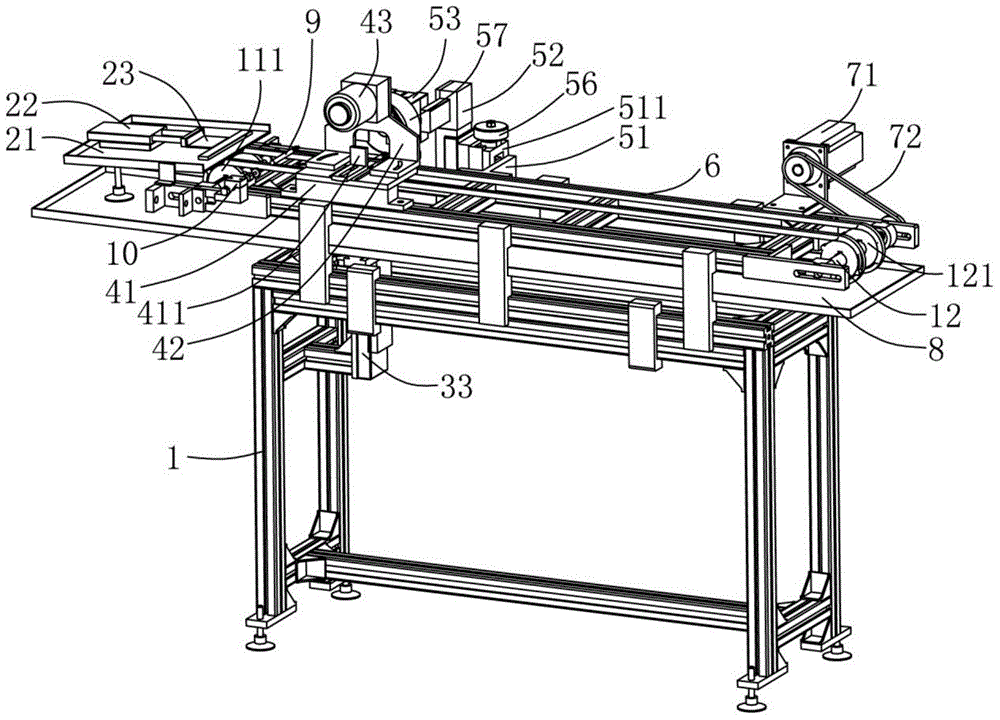

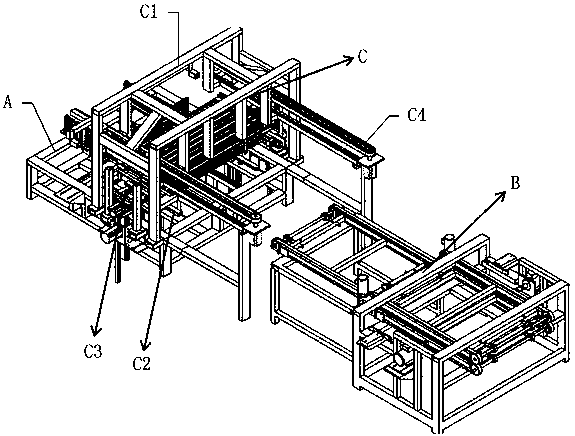

Stainless steel tube end machining device

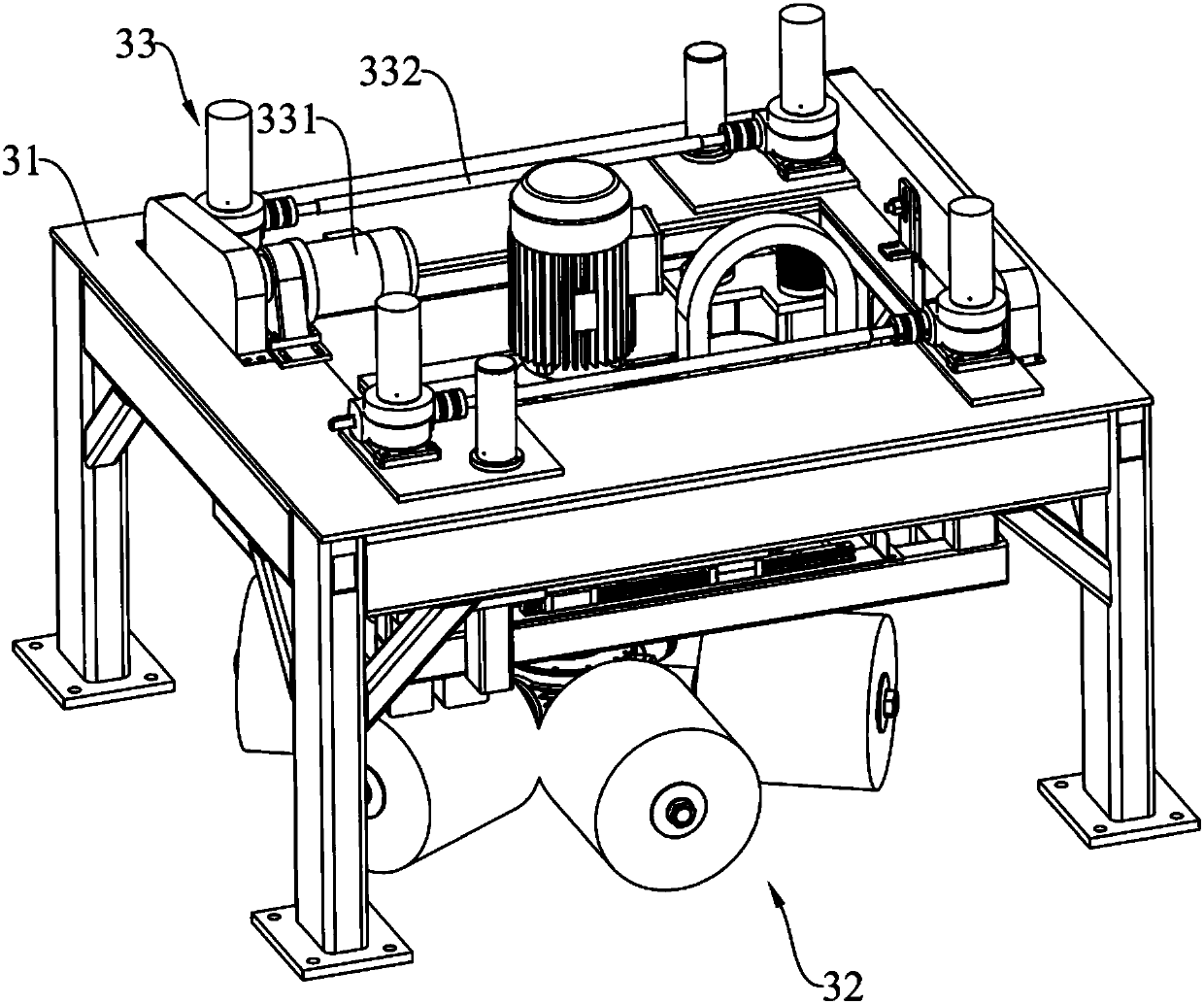

PendingCN108356098AFully automatedEasy to shapeMetal-working feeding devicesPositioning devicesSteel tubeMaterials science

The invention provides a stainless steel tube end machining device. The stainless steel tube end machining device comprises a shaping machine used for shaping the two ends of a stainless steel tube, adeburring machine used for conducting deburring on the two ends of the stainless steel tube and a transferring machine used for transferring the shaped stainless steel tube to the deburring machine from the shaping machine. The shaping machine comprises a first machine frame, a moving material storage device, an automatic feeding device and shaping devices. The deburring machine comprises a second machine frame, a first conveyer belt and polishing machines. The transferring machine can transfer the stainless steel tube from the moving material storage device onto the first conveyer belt. Thestainless steel tube end machining device has a good deburring effect, high efficiency and good stability.

Owner:FOSHAN POLYTECHNIC

Efficient deburring device for hinge

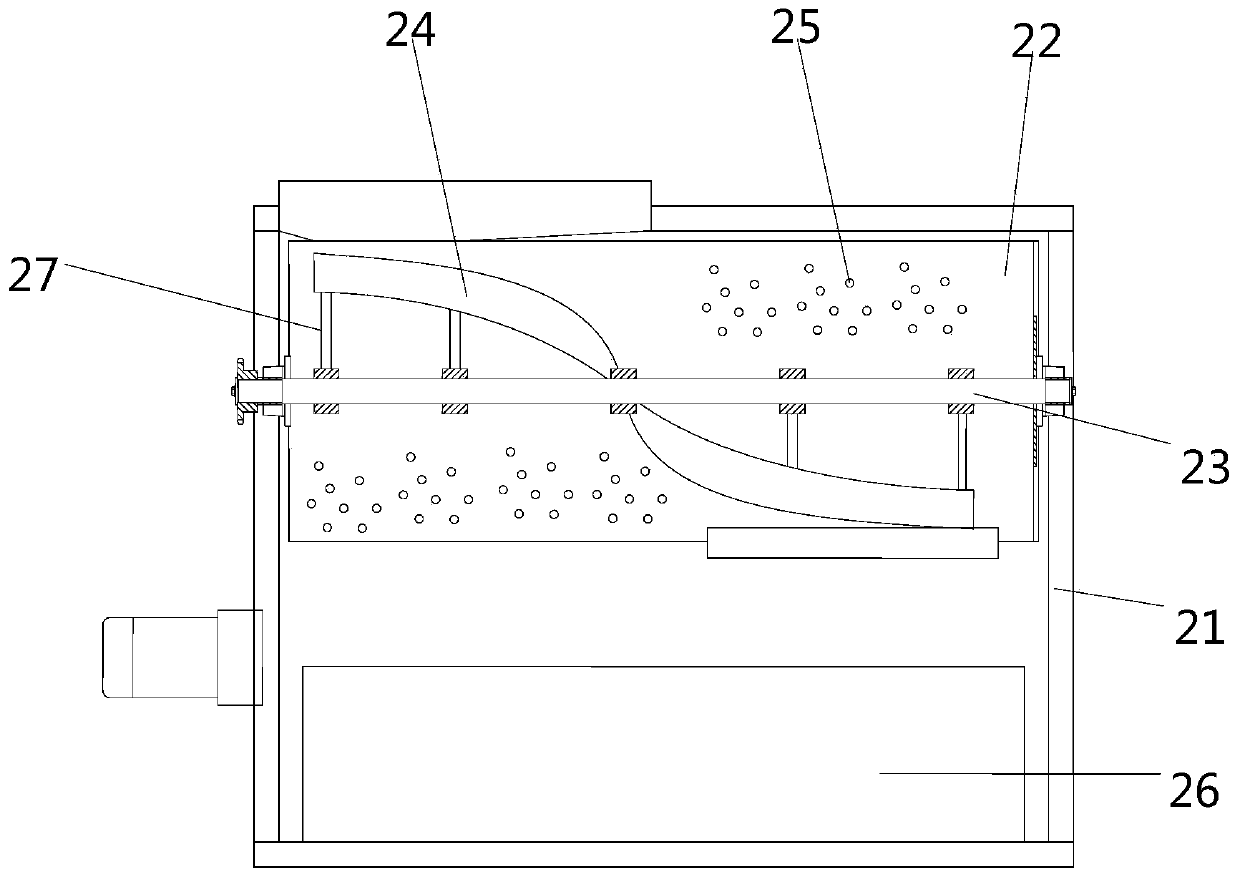

InactiveCN107160287AChangeable direction of movementSpeed up filteringEdge grinding machinesPolishing machinesMotor shaftHinge angle

The invention discloses an efficient deburring device for a hinge. The device comprises a support plate and a working barrel. Supports are arranged at the bottom of the support plate. The outer side wall of the working barrel is connected with a plurality of supporting arms. The bottoms of the supporting arms are rotationally connected with crank mechanisms through bearings. Each crank mechanism is connected with a mounted bearing through a first rotary shaft. One mounted bearing is provided with a first driven gear. A first motor is arranged on the support plate. A first drive gear is mounted at a motor shaft at the top end of the first motor. A baffle is arranged at the inner bottom of the working barrel. The top of the baffle is connected with a second rotary shaft. The second rotary shaft penetrates through the top of the working barrel to be connected with a second driven gear. A second motor is arranged at the top of the working barrel. A motor shaft at the top end of the second motor is connected with a second drive gear. According to the efficient deburring device for the hinge, through circumferential swinging of the working barrel, carborundum is driven to move so as to grind the surface of the hinge, a large number of hinges can be deburred at a time, the working efficiency is high, the moving direction of the carborundum is variable, and the deburring effect is good.

Owner:FOSHAN SUCCEED AUTOMATIC TECH

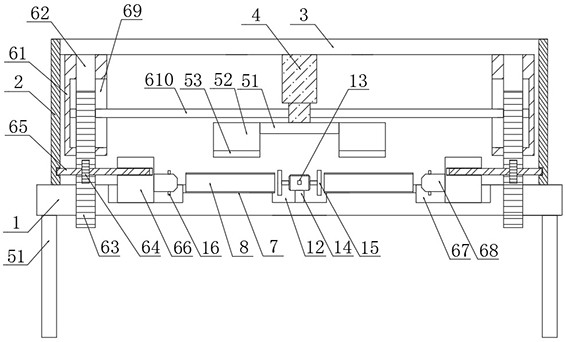

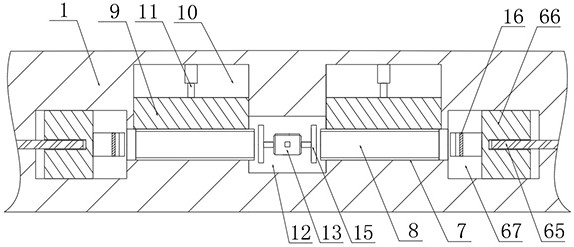

Device for removing wheel tool receiving ridge burrs

PendingCN108057931AWide versatilityImprove coaxialityEdge grinding machinesAutomatic control devicesBall screwElectric machinery

A device for removing wheel tool receiving ridge burrs is composed of a rack (1), a base (2), a guide rail I (3), a movable plate I (4), a ball screw I (5), a longitudinal motor (6), a transverse motor (7), a guide rail II (8), a ball screw II (9), a movable plate II (10), an electric cylinder (11), a moving roller bed (12), a circle center measuring sensor (13), an inner bearing (25), a shaft (26), a sleeve (27), a guiding key (28), a hollow shaft (29), a ridge cone tool (30), an outer air cylinder (31), a left blade (40), a right blade (41) and the like. By means of the device, outer side wheel edge and cap groove edge tool receiving ridge burrs can be removed at the same time, through inner side and outer side deburring tool integration, the space is saved, inner side and outer side independent feeding and independent rotating are achieved, tools on the inner side and the outer side have higher coaxiality, and the deburring effect is better.

Owner:CITIC DICASTAL

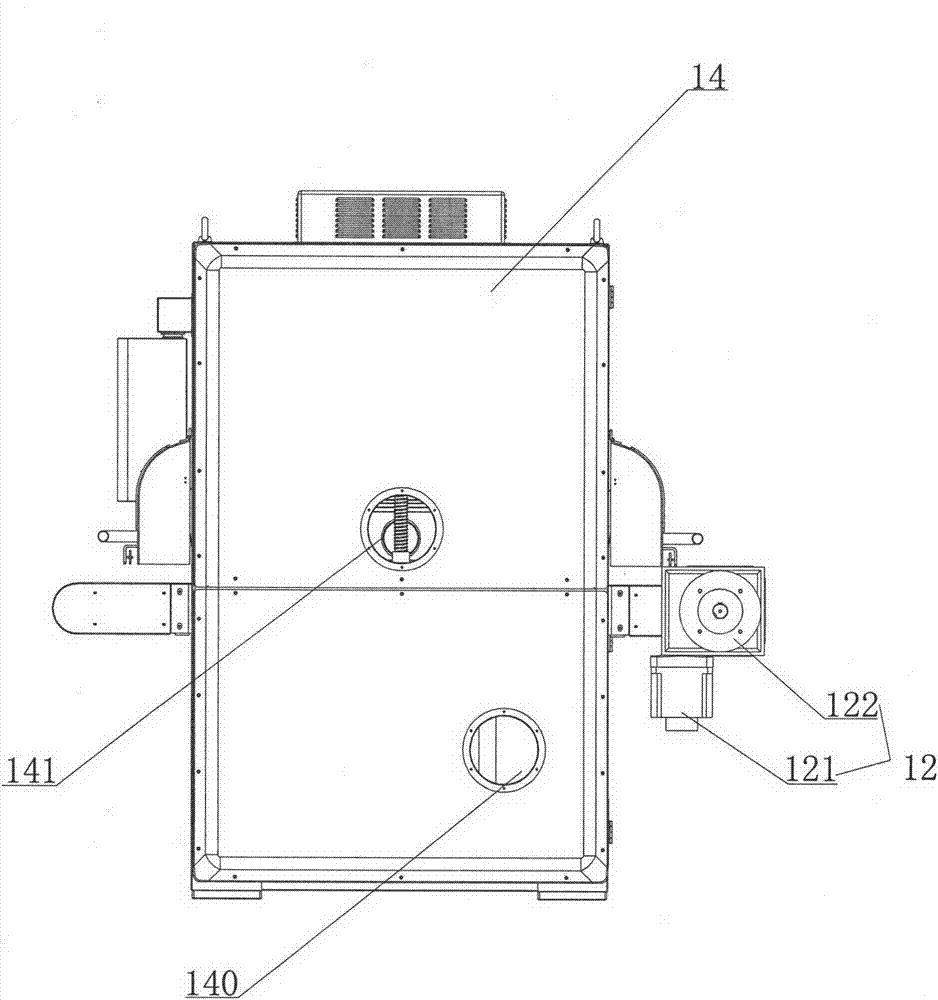

Furniture wood board deburring device

InactiveCN111644933AEasy to solveHigh degree of automationEdge grinding machinesGrinding carriagesWood plankWorkbench

The invention discloses a furniture wood board deburring device, and belongs to the technical field of furniture wood board manufacturing. The furniture wood board deburring device comprises a raiseddust prevention wood board deburring worktable, a wood board conveying belt, a self-adjusting multi-angle burr removal device, a deburring device fixing dustproof cover and a dust suction assembly, the deburring device fixing dustproof cover is erected on the raised dust prevention wood board deburring worktable, the wood board conveying belt is mounted on the raised dust prevention wood board deburring worktable and is located in the deburring device fixing dustproof cover, the dust suction assembly is mounted in the raised dust prevention wood board deburring worktable and is connected withthe deburring device fixing dustproof cover, particularly, through a self-adjusting lifting control assembly, after wood board conveying contact, the furniture wood board deburring device can be subjected to self ascending and descending to be attached to a wood board, the wood board can be comprehensively polished and ground, the wood board is subjected to comprehensive polishing and grinding from aspects of longitudinal height adaptation adjusting and transverse comprehensive covering, and meanwhile, raising of burr chippings generated in the grinding flow can be avoided.

Owner:徐州滨港木业有限公司

Deburring equipment for stainless steel plate for power distribution cabinet production

InactiveCN107932232ANot easy to moveReduce manufacturing costEdge grinding machinesGrinding carriagesSheet steelEngineering

The invention belongs to the technical field of power distribution cabinet production, and particularly relates to deburring equipment for a stainless steel plate for power distribution cabinet production. The deburring equipment for the stainless steel plate for the power distribution cabinet production has the advantages that the manufacturing cost is low, the deburring effect is good, and the operation is easy. The deburring equipment for the stainless steel plate for the power distribution cabinet production comprises supporting legs and the like; a placement plate is horizontally connected to the tops of the supporting legs in a bolted connection mode; a support is vertically arranged on the left side of the top of the placement plate in a bolted connection mode; a top plate is horizontally connected to the top of the right side surface of the support in a bolted connection mode; and a left-right moving device is arranged at the bottom of the top plate. According to the deburringequipment, a first motor is adopted for driving abrasive paper to move left and right continuously so as to carry out deburring work on the stainless steel plate, and therefore the effects of low manufacturing cost, good deburring effect and simple operation can be achieved.

Owner:郭昌磊

Deburring device applied to automobile exhaust pipes

The invention discloses a deburring device applied to automobile exhaust pipes. The deburring device comprises an installation frame, a motor, an output shaft, a driving gear, an inner gear, a rotary gear and a shaping cutter, wherein the motor is arranged on the installation frame, the output shaft is connected with the motor, the driving gear is arranged on the output shaft, the inner gear is fixed to the installation frame and shares the same axis with the driving gear, the rotary gear is meshed with outer teeth of the driving gear and inner teeth of the inner gear, and the shaping cutter is coaxially connected with the rotary gear, can shape pipe openings of the exhaust pipes and can perform deburring on outer walls and inner walls of the exhaust pipes at the same time. The deburring device disclosed by the invention can shape the pipe openings of the exhaust pipes and perform deburring on the outer walls and the inner walls of the exhaust pipes at the same time, so that the pipe openings are round and neat, used time is small, and deburring efficiency is high.

Owner:浙江新诚汽车部件有限公司

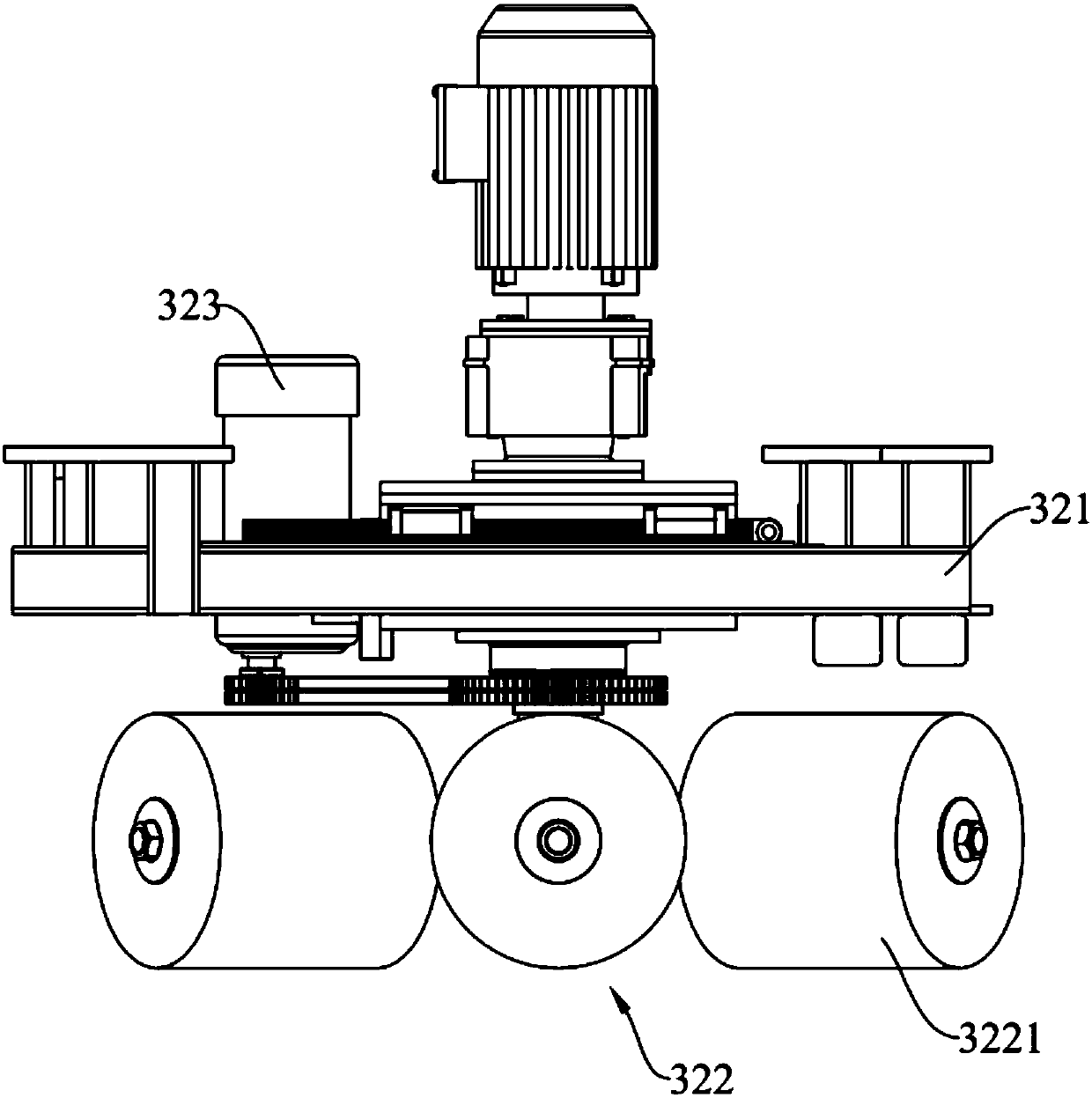

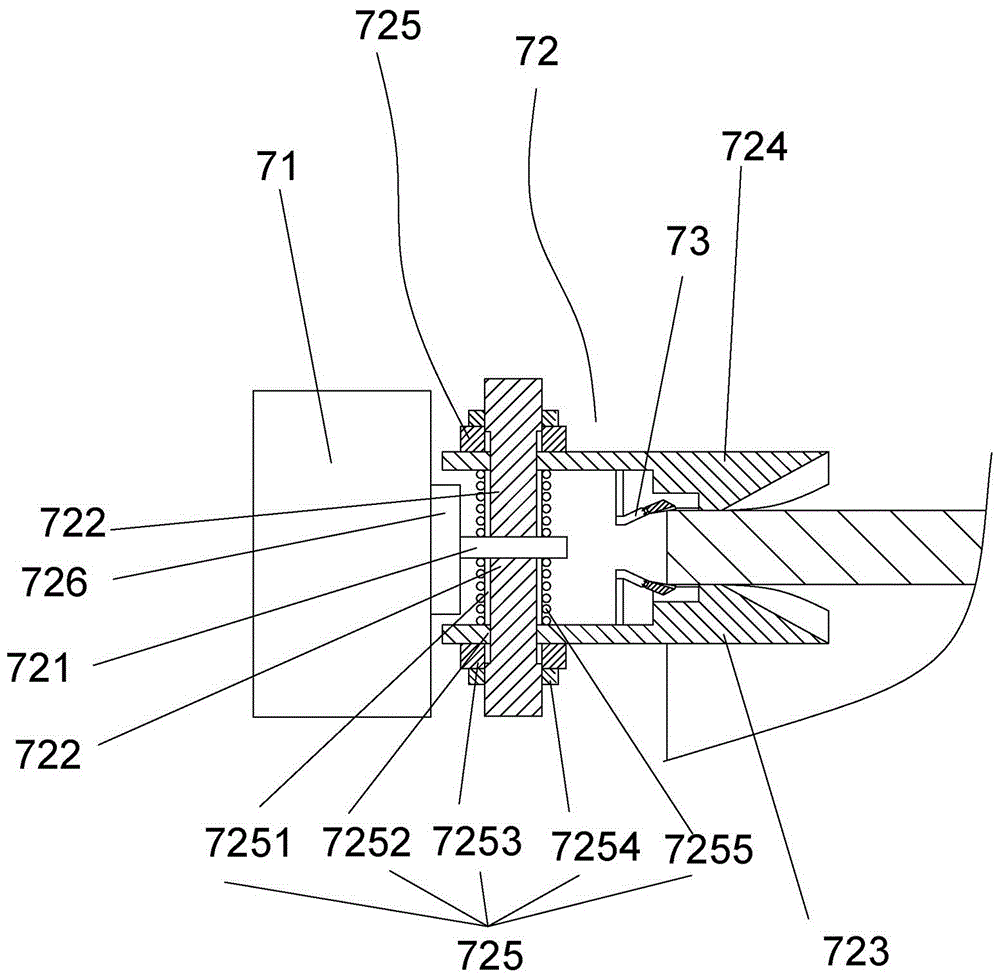

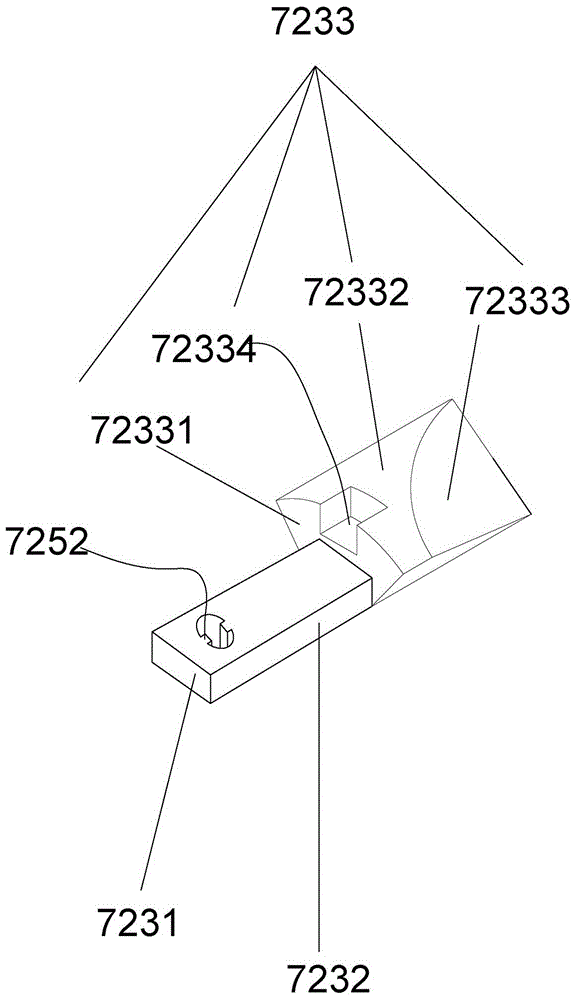

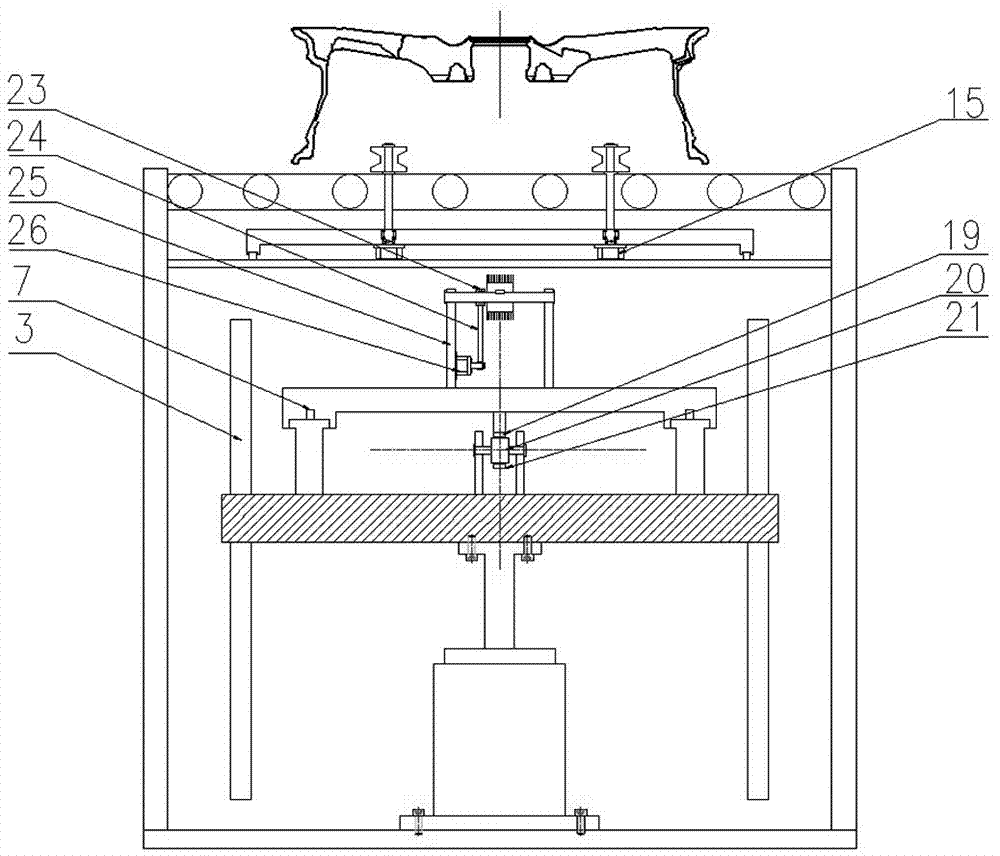

Wheel flange brush burr device

InactiveCN107297655AImprove deburring effectImprove deburring efficiencyEdge grinding machinesPolishing machinesTransmission beltElectric machine

A wheel flange brush burr device is composed of clamp roller motors, a right clamp cylinder, an inner stroke switch, a right feed slide, an upper rack, a gear, a lower rack, a feeding guide rail, a belt pulley, a transmission belt, a rotating-shaft support, a servo motor and the like. After materials are supplied, a left clamp cylinder and the right clamp cylinder move synchronously to have a wheel clamped; the clamp roller motors are started to drive the wheel to rotate; a lifting cylinder is started to pull a lifting platform to move upwards, meanwhile, a feeding cylinder is started to drive a left feed slide and the right feed slide to move back and forth, and the servo motor is started to drive a burr brush to move circularly and reversely; the lifting cylinder stops moving when the burr brush contacts the flange surface, the burr brush starts to brush burrs, the lifting cylinder contracts after the burrs are brushed, a lifting platform moves downwards to be reset, the wheel is released from the clamp roller motors, the wheel is transfer to the next process through a roller bed, another wheel with burrs to be brushed is received, and so on.

Owner:CITIC DICASTAL

Automatic deburring machine for steel plate

ActiveCN111002192APush will notPushing the steel plate will not make any flowersEdge grinding machinesGrinding carriagesEngineeringMachine

The invention relates to an automatic deburring machine for a steel plate. The machine is provided with a rack, a feeding mechanism, a front and rear end face polishing device, a flattening feeding device, a limiting side edge polishing device and an upper and lower surface deburring device. Compared with the prior art, coherent operation of removing burrs on four sides, the upper surface and thelower surface of the steel plate is realized, the automatic degree is high, labor force is saved, the efficiency is improved, and the deburring effect is good; and the feeding mechanism pushes the steel plate from front to back in a manner that an upper conveying belt device and a lower conveying belt device are pressed together, compared with single-roller conveying, the surface of the steel plate is smoother and is not prone to change, relative soft contact of the whole plate guarantees enough friction force to push the steel plate, and the steel plate is not scratched.

Owner:化州市英煌不锈钢制管有限公司

Deburring device for new material production

InactiveCN112405183AEasy to replace and reduce dustExtended service lifeEdge grinding machinesGrinding wheel securing apparatusPhysicsWater pipe

The invention discloses a deburring device for new material production. The deburring device comprises an operation box, a shell is fixedly connected to the top of an inner cavity of the operation box, a lifting mechanism is arranged at the top of the inner cavity of the shell, a connecting rod is arranged at the bottom of the lifting mechanism, and the bottom of the connecting rod penetrates through the bottom of the shell and is fixedly connected with a connecting base; a water pipe communicates with the water inlet end of the bottom of a water pump, finally, spraying holes in the front sideof a water pipe conduct dust falling on an inner cavity of the operation box, meanwhile, a polishing disc is cooled, a mounting rod and the polishing disc can be replaced by rotating a rotary knob, and the purposes of convenient replacement and dust falling are achieved; and the deburring device for new material production has the advantages of being convenient to replace and capable of achievingdust falling, water spraying for dust falling is conducted on the inner cavity of the operation box, meanwhile, new materials can be effectively cleaned, sprayed water can also cool the polishing disc, and the deburring effect is improved.

Owner:孙国林

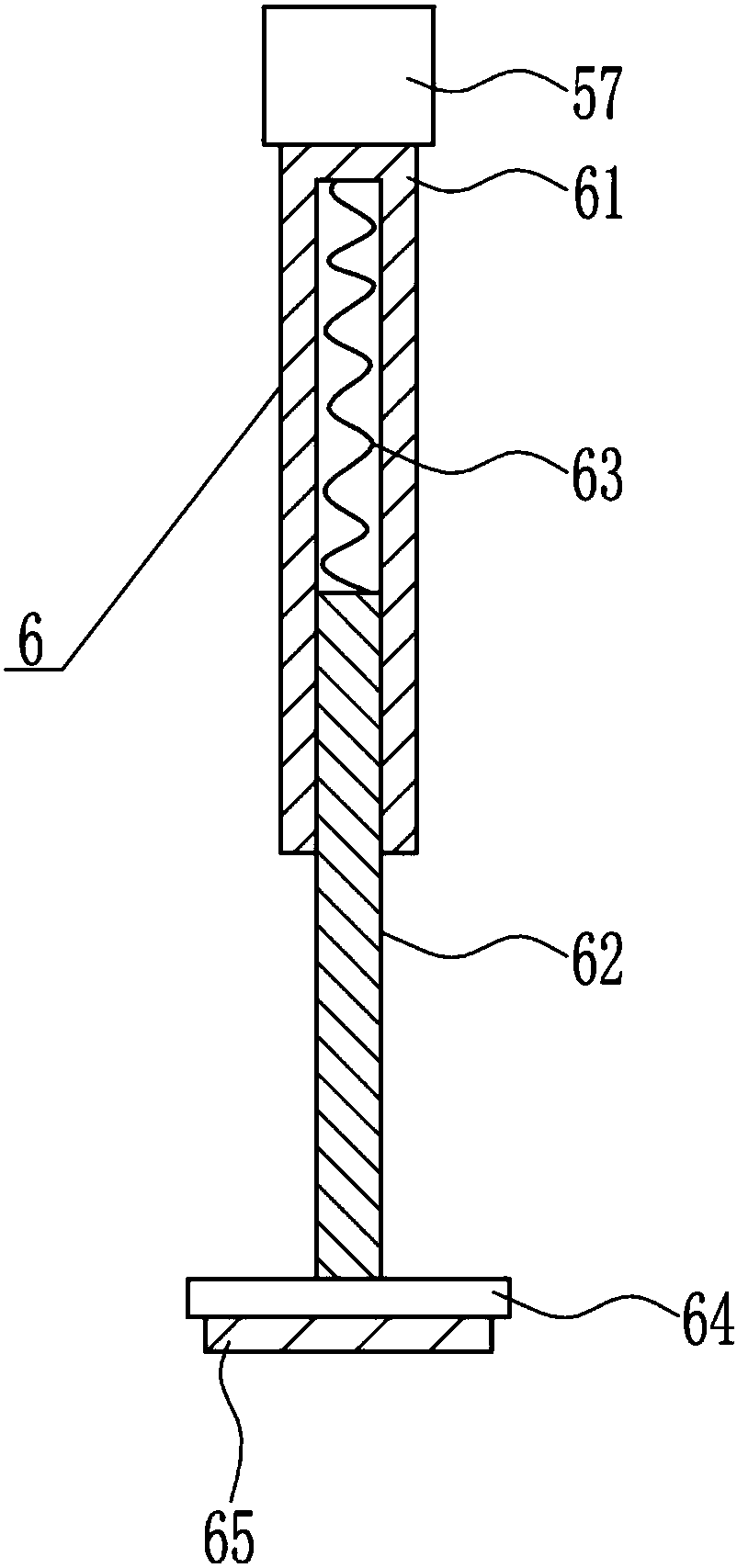

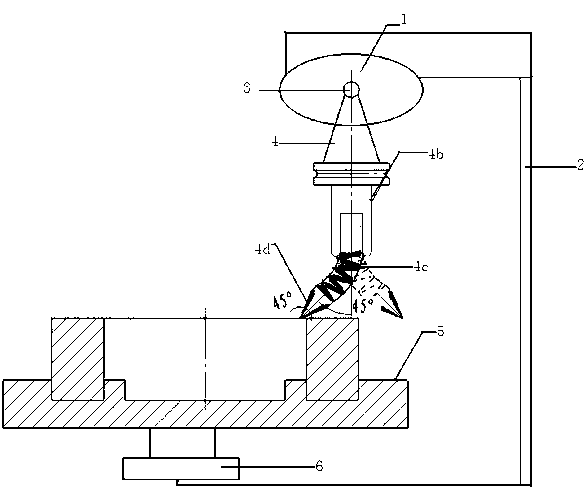

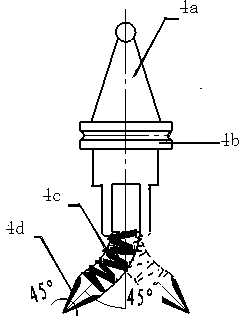

Spring tool for deburring of bearing holder

The invention belongs to the field of surface quality processing of a bearing holder, in particular to a spring tool for the deburring of the bearing holder. The spring tool comprises a first speed-adjusting motor, a rack, a rotating shaft, a tool structure, a turntable and a second speed-adjusting motor, wherein the first speed-adjusting motor is fixedly arranged at the upper end of the rack; the first speed-adjusting motor is connected with the rotating shaft; the tool structure is driven to rotate by the rotating shaft; the turntable is arranged at the lower end of the rack; the rotation of the turntable is controlled by the second speed-adjusting motor on the lower part of the turntable; the tool structure comprises a tool shank connected with the rotating shaft; a tool body is fixed on the tool shank; the tool body carries the spring; the blade is connected with the spring; the tool structure is rotated in the same direction along with the rotating shaft; when irregular burs are contacted with the tool disclosed by the invention, the burrs are started to be removed; the sizes and the hardness of the burrs are different; although the situations are not the same, the tool is controlled by the spring and is retractable automatically; the burrs can be removed automatically; the manual deburring is completely replaced; the deburring effect is good; and time and labor are saved.

Owner:DALIAN RUIGU SCI & TECH

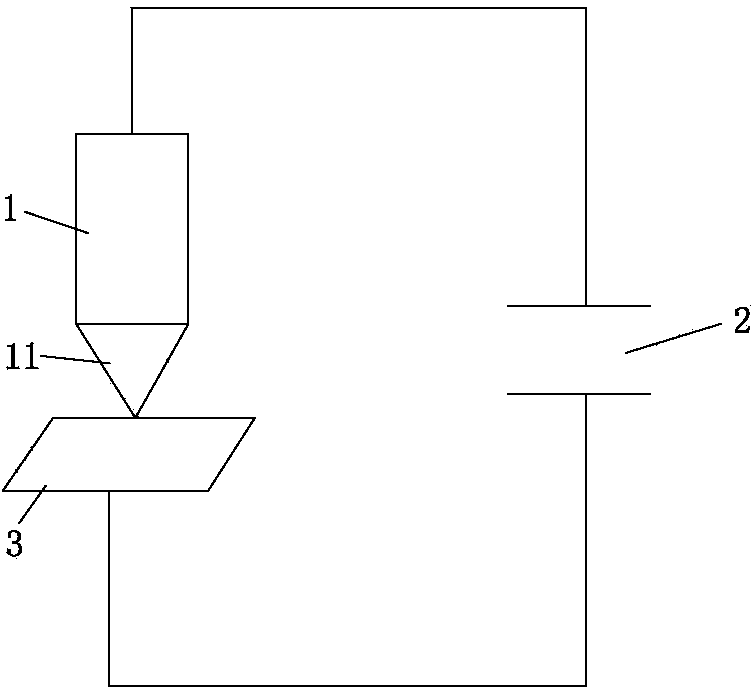

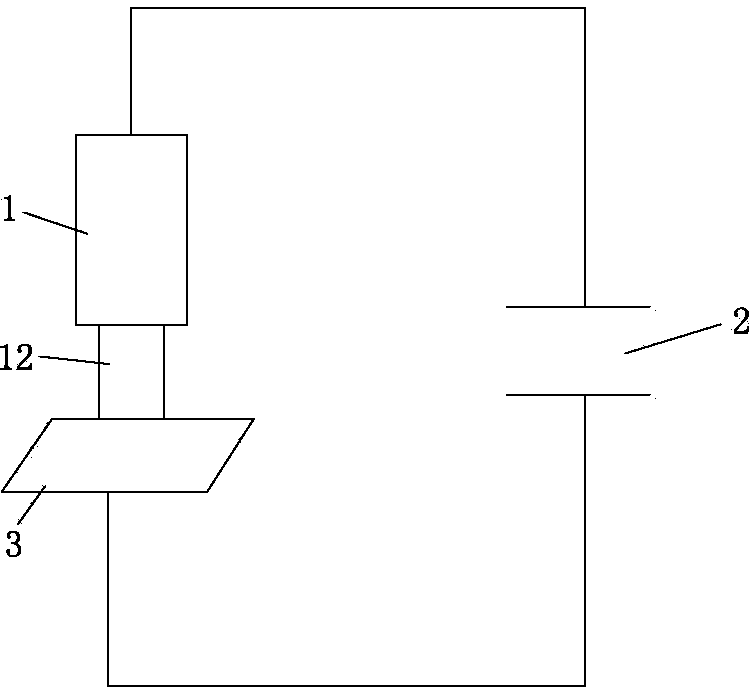

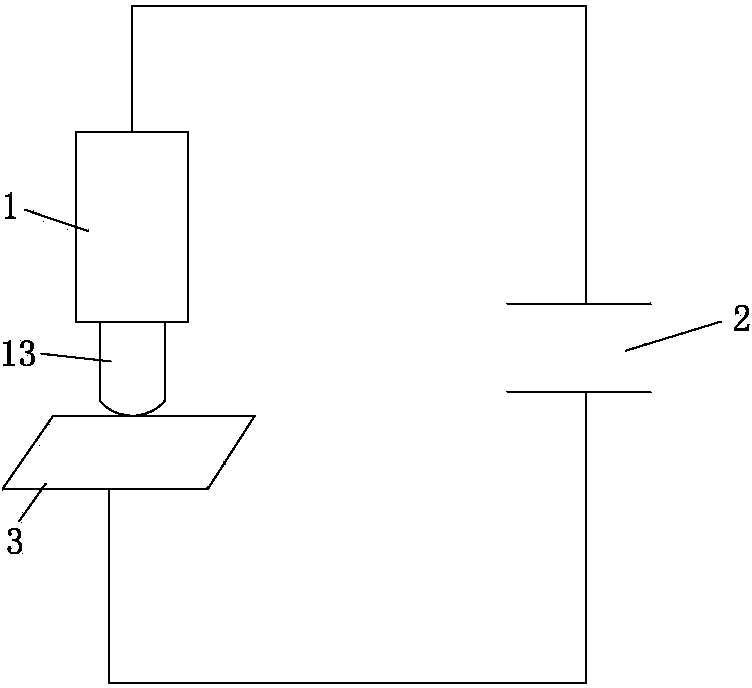

Deburring method for amorphous alloy

ActiveCN104384644AShort production hoursImprove deburring effectResistance welding apparatusCapacitanceHeating time

The invention relates to the technical field of surface treatment of amorphous alloys, in particular to a deburring method for an amorphous alloy. Electric energy stored in a capacitor is released through an electrode; the electric energy released by the electrode is used for heating burr positions of the amorphous alloy to a certain temperature within certain heating time to remove burrs; the amorphous alloy is prevented from undergoing a crystallization reaction based on a TTT (Isothermal Transformation) diagram. The heating time for the electrode to release electric energy is 1*10<-6> to 1*10<-3> seconds, so that the deburring method has the advantages of short production time and good deburring effect. Since an inert atmosphere of a certain pressure is blown towards the burr positions during deburring to fulfill the aim of cooling, so that the amorphous alloy can be prevented from undergoing an oxidation reaction and the crystallization reaction.

Owner:WINTOP DONGGUAN INDAL TECH

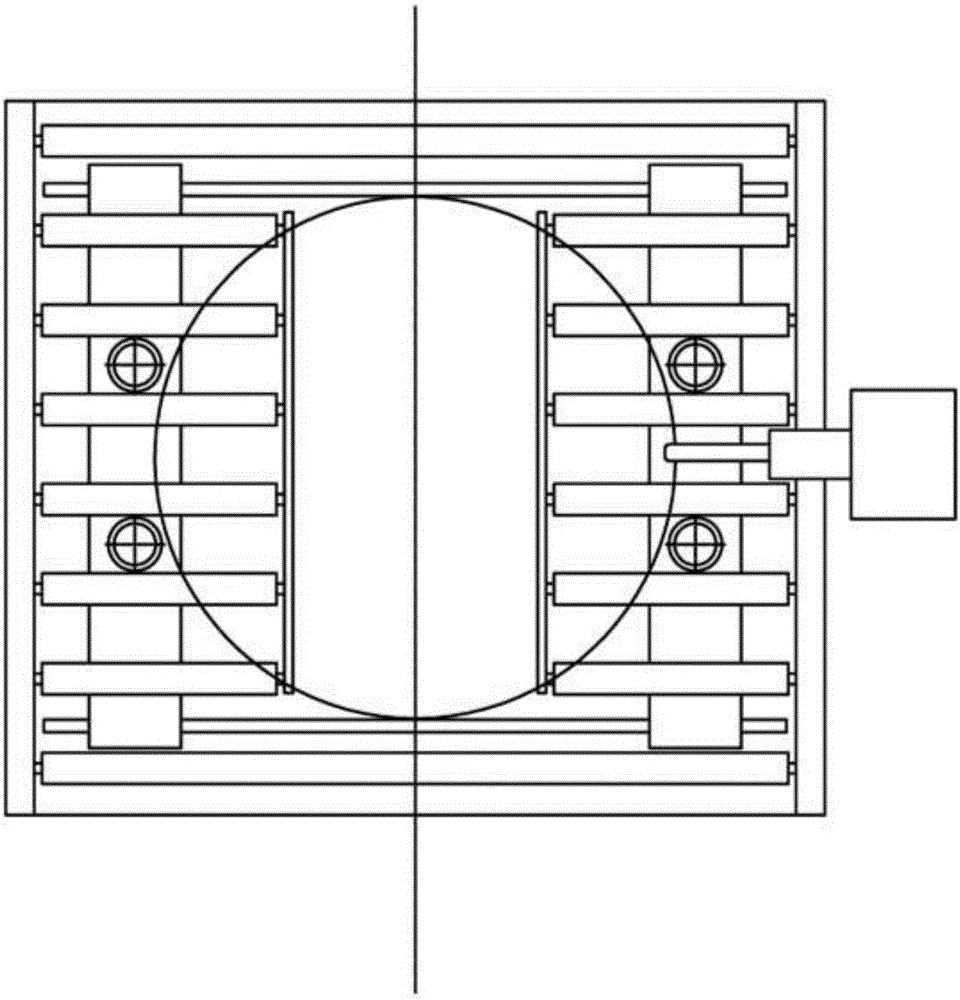

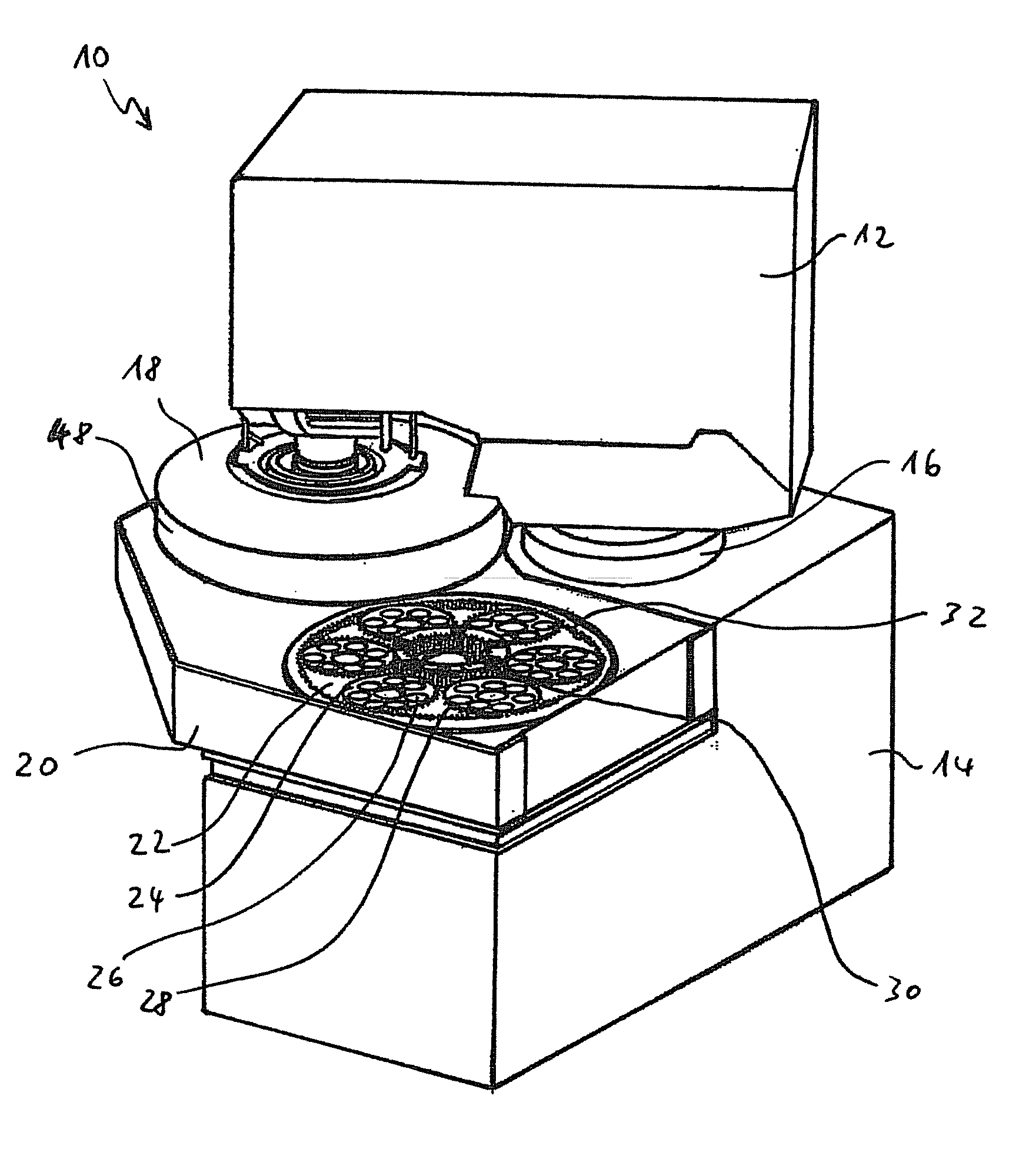

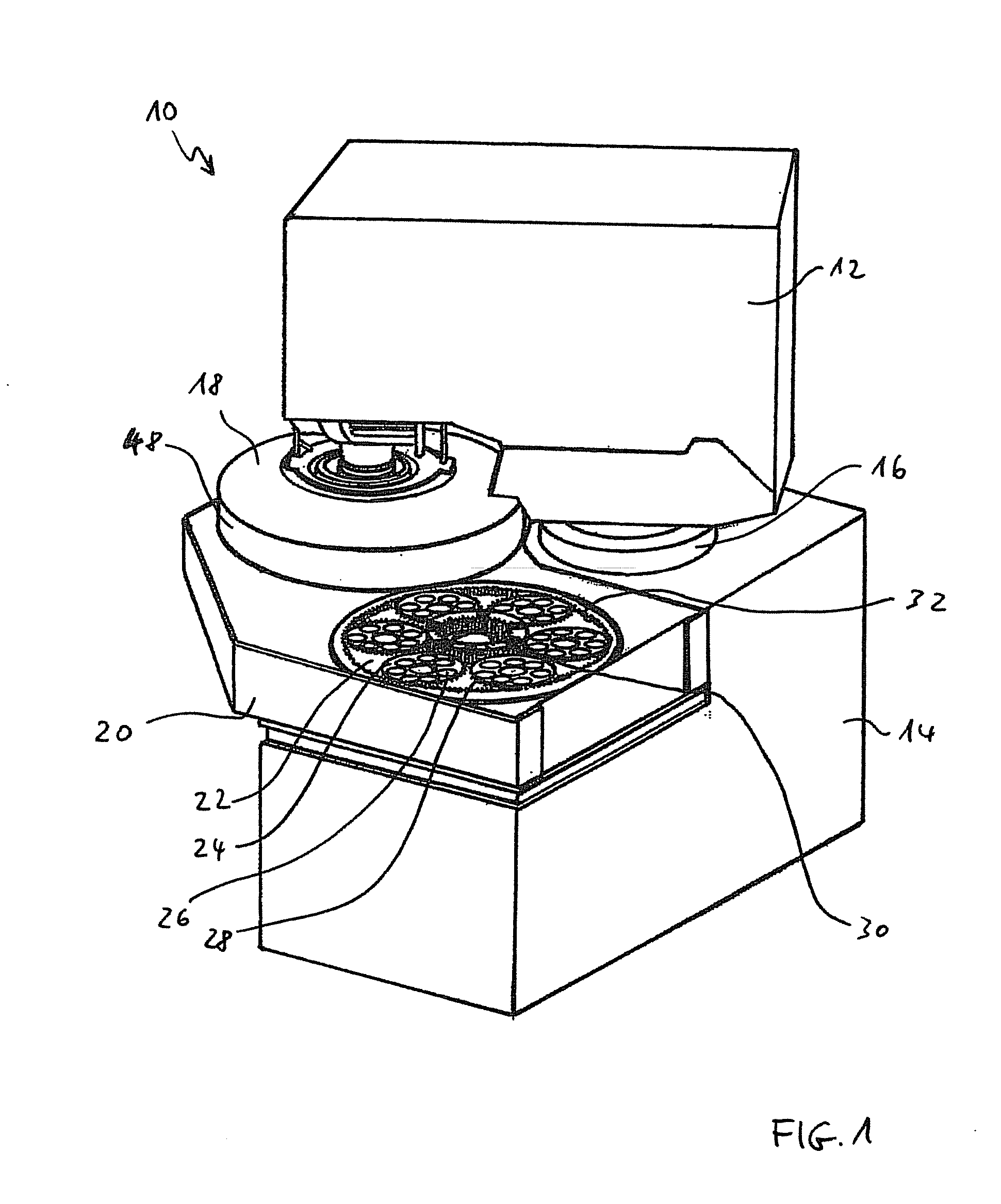

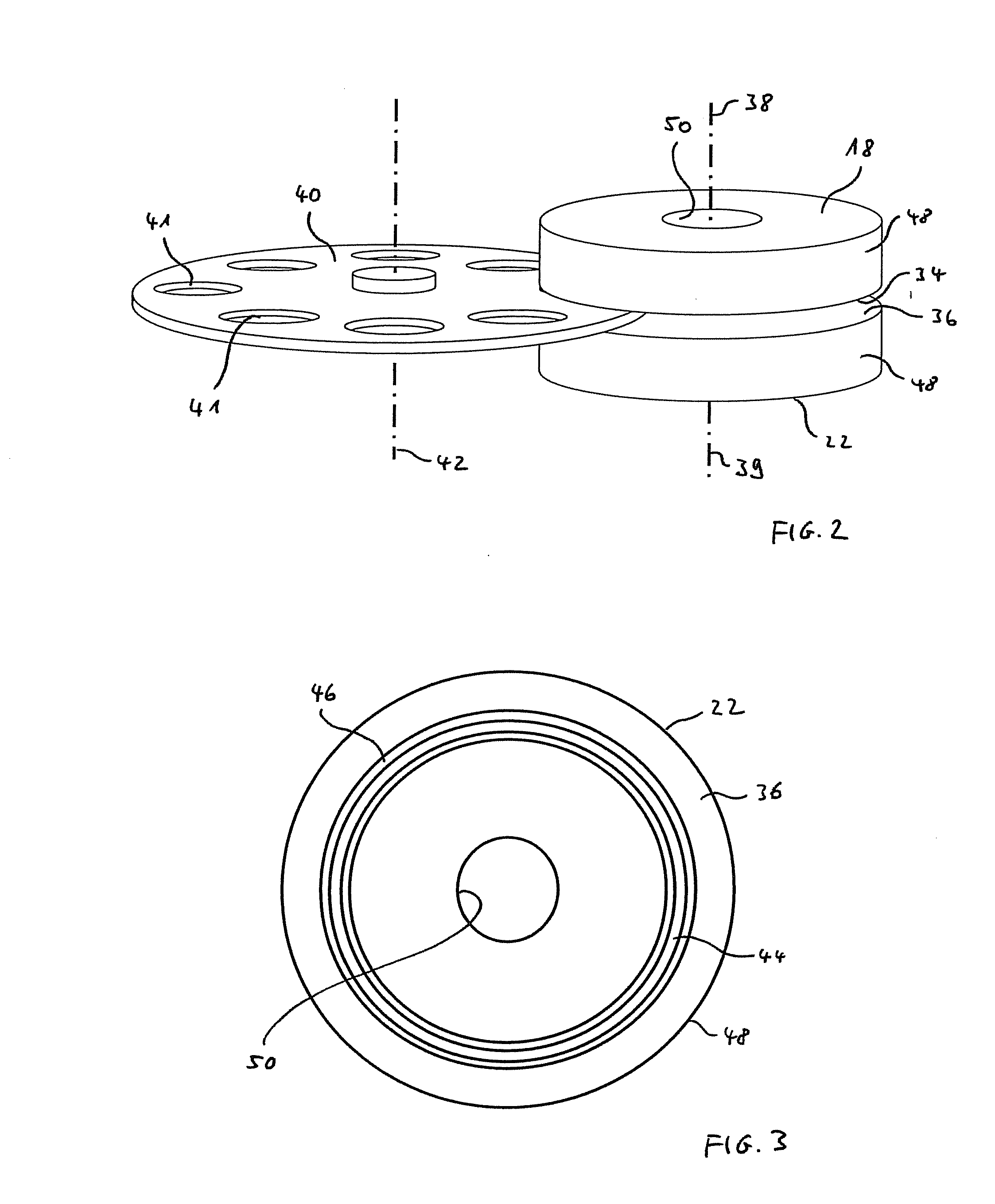

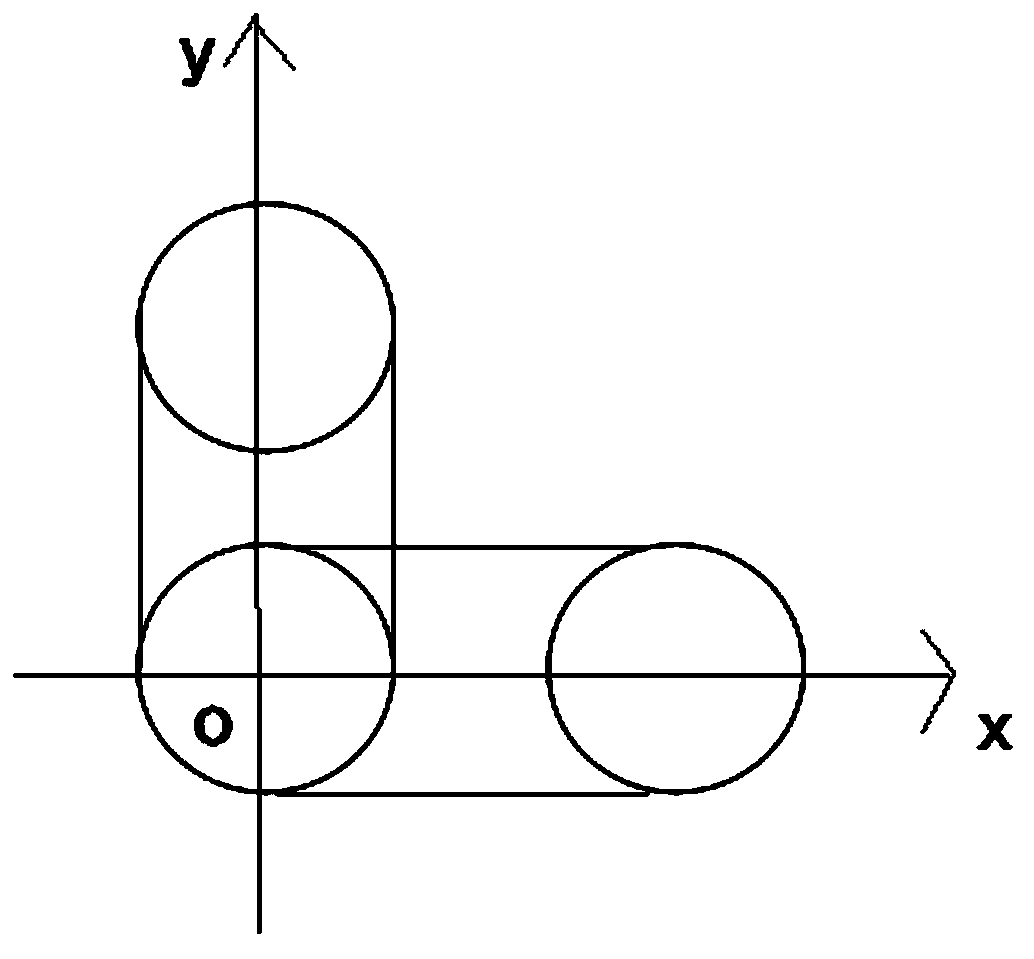

Apparatus for Double-Sided, Grinding Machining of Flat Workpieces

InactiveUS20110300785A1Improve deburring effectIncrease flexibilityEdge grinding machinesPolishing machinesMachining processEngineering

The invention relates to an apparatus for the double-sided, grinding machining of flat workpieces with an upper and a lower work disk, each of which has a work surface with a grinding layer, wherein the work surfaces form a work gap amongst themselves, in which workpieces can be ground, wherein at least one of the work disks is rotatably drivable by means of a driving mechanism, and further having a device for guiding the workpieces in the work gap. It is provided according to the invention that debarring means are arranged on at least one of the work disks, which are designed to deburr the workpieces during their machining in the apparatus.

Owner:PETER WOLTERS GMBH

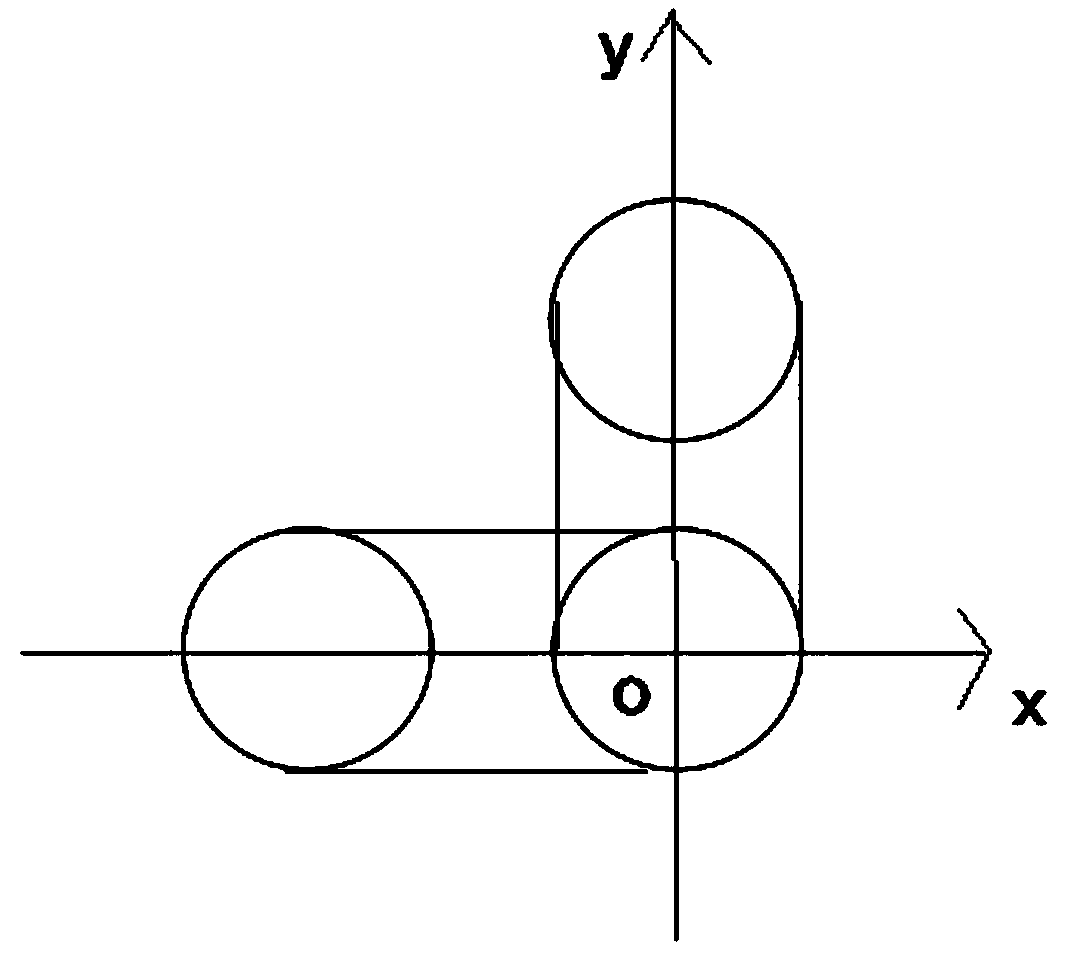

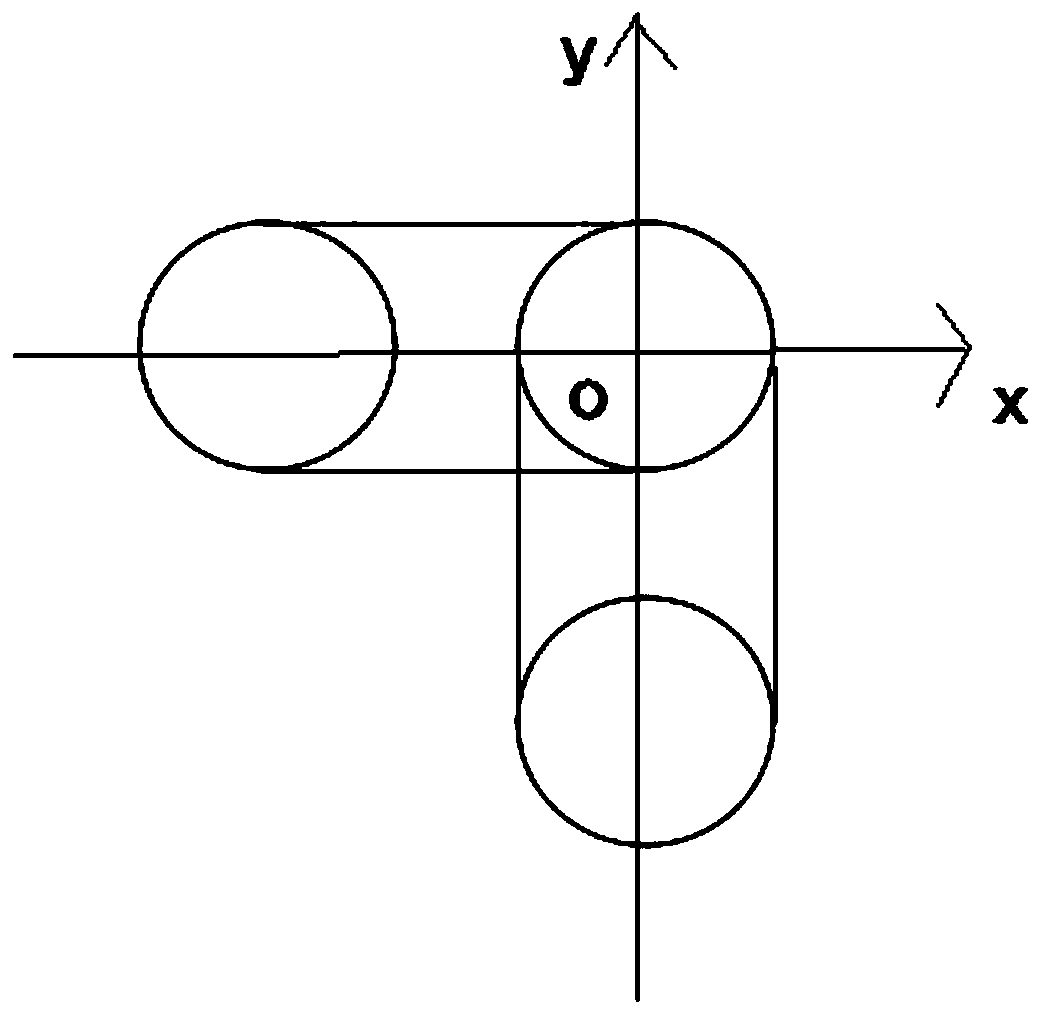

L-shaped slotted hole machining method based on PCB

ActiveCN111010802AQuality improvementAvoid it happening againPrinted circuit manufactureFour quadrantsRectangular coordinates

The invention provides an L-shaped slotted hole processing method based on a PCB, and the method comprises the following steps: splitting an L-shaped slotted hole into a transverse slotted hole and alongitudinal slotted hole according to the processing steps, building a rectangular plane coordinate system with the intersection point of the two slotted holes as an original point to form four quadrants, and judging the quadrant where an included angle formed by the transverse slotted hole and the longitudinal slotted hole is located; if in the first quadrant, realizing the condition that the machining sequence is that the longitudinal slotted hole is firstly machined and then the transverse slotted hole is machined; if in the second quadrant, realizing the condition that the machining sequence is that the transverse slotted hole is firstly machined and then the longitudinal slotted hole is machined; if in the third quadrant, realizing the condition that the machining sequence is that the longitudinal slotted holes are machined firstly and then the transverse slotted holes are machined; if in the fourth quadrant, realizing the condition that the machining sequence is that the transverse slotted hole is firstly machined and then the longitudinal slotted hole is machined; manufacturing a drill belt; and dividing the L-shaped slotted hole into two sections of one-way slotted holes to be slotted. A special cutter path is arranged, so that burrs are avoided.

Owner:广州广合科技股份有限公司

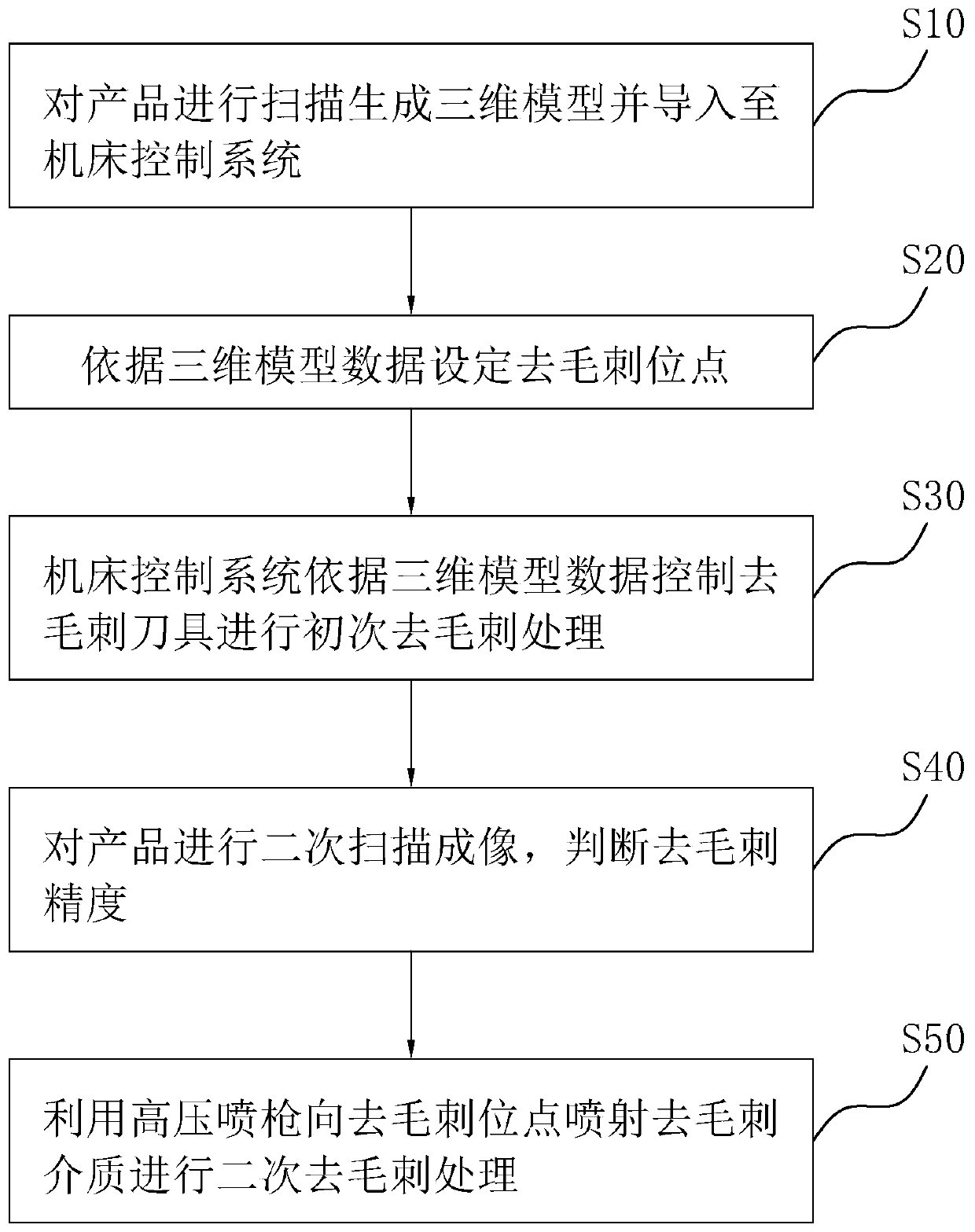

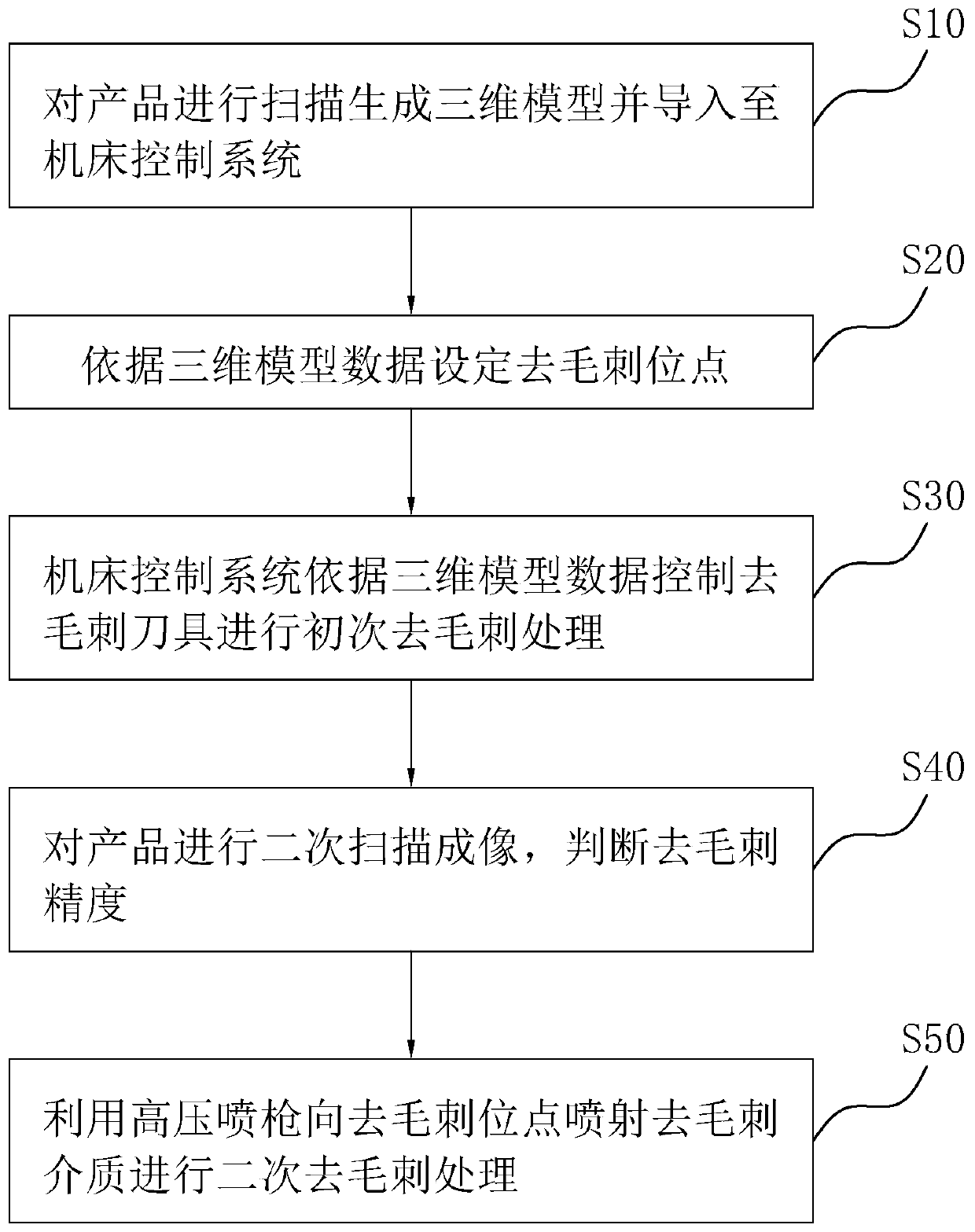

Automatic burr removing machining technology

InactiveCN109968132ARemove completelyReduce workloadEdge grinding machinesGrinding work supportsControl systemEngineering

The invention relates to an automatic burr removing machining technology. The technology comprises the steps that a product to be machined is fixedly clamped to an automatic machine tool, and the surface of the product to be machined is scanned and recognized so that a three-dimensional model of the product to be machined can be generated and guided into a machine tool control system; burr removing position points are set according to data of the three-dimensional model; the machine tool control system controls a burr removing cutter to cut or grind the burr removing position points accordingto the data of the three-dimensional model to carry out primary burr removing treatment; and a high-pressure spraying gun is utilized for spraying burr removing media to the burr removing position points to carry out burr removing treatment on the burr removing position points. According to the technology, the machine tool control system controls the burr removing cutter to be moved to carry out grinding and cutting, primary burr removing treatment is carried out on the product, then by means of the high-pressure spraying gun, the burr removing media are sprayed to the burr removing position points, the position, difficult to make contact, of the cutter is polished, thus the manual workload is reduced, and the working efficiency and the burr removing effect are removed.

Owner:SUZHOU JOYO METAL TECH CO LTD

Pipe cutting machine with deburring function

ActiveCN106964984AImprove continuityShort timeOther manufacturing equipments/toolsVehicle componentsEngineeringExhaust pipe

The invention discloses a pipe cutting machine with a deburring function. The pipe cutting machine comprises a rack, an exhaust pipe clamping device arranged on the rack and a cutting mechanism which is arranged on the rack, located above the exhaust pipe clamping device and has the function of being close to or away from an exhaust pipe. The exhaust pipe clamping device comprises a first clamping seat and a second clamping seat capable of being close to or away from the first clamping seat and furthermore comprises a deburring device arranged on the rack, a first detection mechanism, a first drive mechanism, a second detection mechanism and a pair of second drive mechanisms, wherein the first detection mechanism is arranged on the rack and is used for detecting whether the cutting mechanism cuts off the exhaust pipe or not, the first drive mechanism is used for driving the second clamping seat to be away from or close to the first clamping seat, the second detection mechanism is used for detecting whether the second clamping seat is moved in place or not, and the second drive mechanisms are used for driving the deburring device to be close to or away from the first clamping seat and the second clamping seat correspondingly. After pipe cutting is completed, the deburring action is performed immediately, continuity is good, the process of unloading on the pipe cutting machine and the process of loading on a deburring machine are omitted, time consumption is short, and production efficiency is high.

Owner:浙江新诚汽车部件有限公司

HDPE corrugated pipe rapid clamping device and using method thereof

InactiveCN112589590AImprove the efficiency of grinding and deburringFast positioningEdge grinding machinesGrinding drivesStructural engineeringMaterials science

The invention discloses an HDPE corrugated pipe rapid clamping device and a using method thereof. The device comprises a bottom plate, vertical plates are fixedly arranged at the two sides of the topof the bottom plate correspondingly, a transverse plate is fixedly connected to the surfaces of the adjacent sides of the two vertical plates, a first air cylinder is fixedly arranged at the bottom ofthe transverse plate, and a clamping mechanism is arranged at the bottom of the output end of the first air cylinder; and pushing mechanisms are arranged at the left side and the right side of the output end of the first air cylinder correspondingly, and the clamping mechanism comprises a first connecting rod. A clamping plate is pushed by a second air cylinder to be matched with the bottom plateto form a semicircular through hole used for containing a corrugated pipe body, under the action of a first air cylinder, clamping and fixing of the corrugated pipe body are completed while the distance between the corrugated pipe body and a grinding disc is adjusted, the distance is accurately controlled, the positioning speed is high, and the fixing effect is good; and the sliding phenomenon cannot occur during grinding, so that the grinding and deburring efficiency of the corrugated pipe body is greatly improved, and the deburring effect is good.

Owner:RONGCHENG PIPE IND

Copper strip edge burr removing and machining device

InactiveCN106736955AImprove stabilityGood deburring effectEdge grinding machinesGrinding machine componentsWire brushEngineering

The invention discloses a copper strip edge burr removing and machining device. The device comprises a base, the two sides of the top of the base are each provided with a motor fixing rack, the inner side of each motor fixing rack is provided with a motor, a rotary shaft is arranged in the center of the top of each motor, the outer wall of each rotary shaft is sequentially provided with a first bearing disc, a polishing block and a second bearing disc from top to bottom, the bottom of each first bearing disc and the top of each second bearing disc are each provided with a tray through first bolts. According to the device, when the motors are arranged at the top of the base, and the first bearing discs, the second bearing discs and the polishing blocks are arranged on the rotary shafts of the motors, in the cooperation of the trays arranged on the first bearing discs and the second bearing discs, wire brushes arranged on the trays, and arranged supporting elements and compressing elements, the copper strip edge burr removing and machining device has the advantages of being high in stability, good in burr removing effect, high in burr removing speed and high in burr removing efficiency when used.

Owner:WUXI DONGHE METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com