Drum-type deburring device for small part

A drum type, deburring technology, applied in machine tools suitable for grinding workpiece edges, surface polishing machine tools, grinding machines, etc., can solve the problems of low work efficiency, poor deburring effect, time-consuming and labor-intensive, etc. Good deburring effect and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

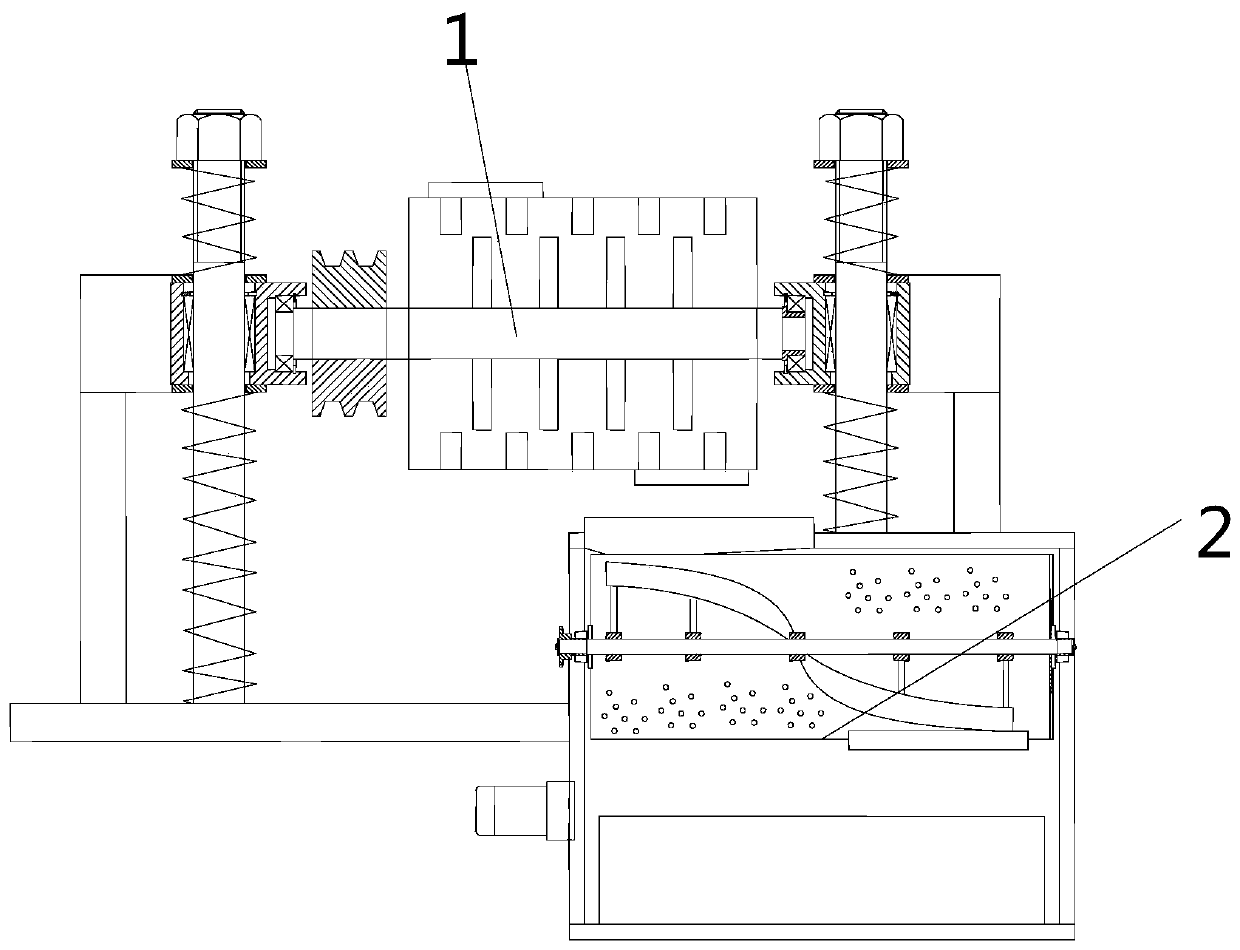

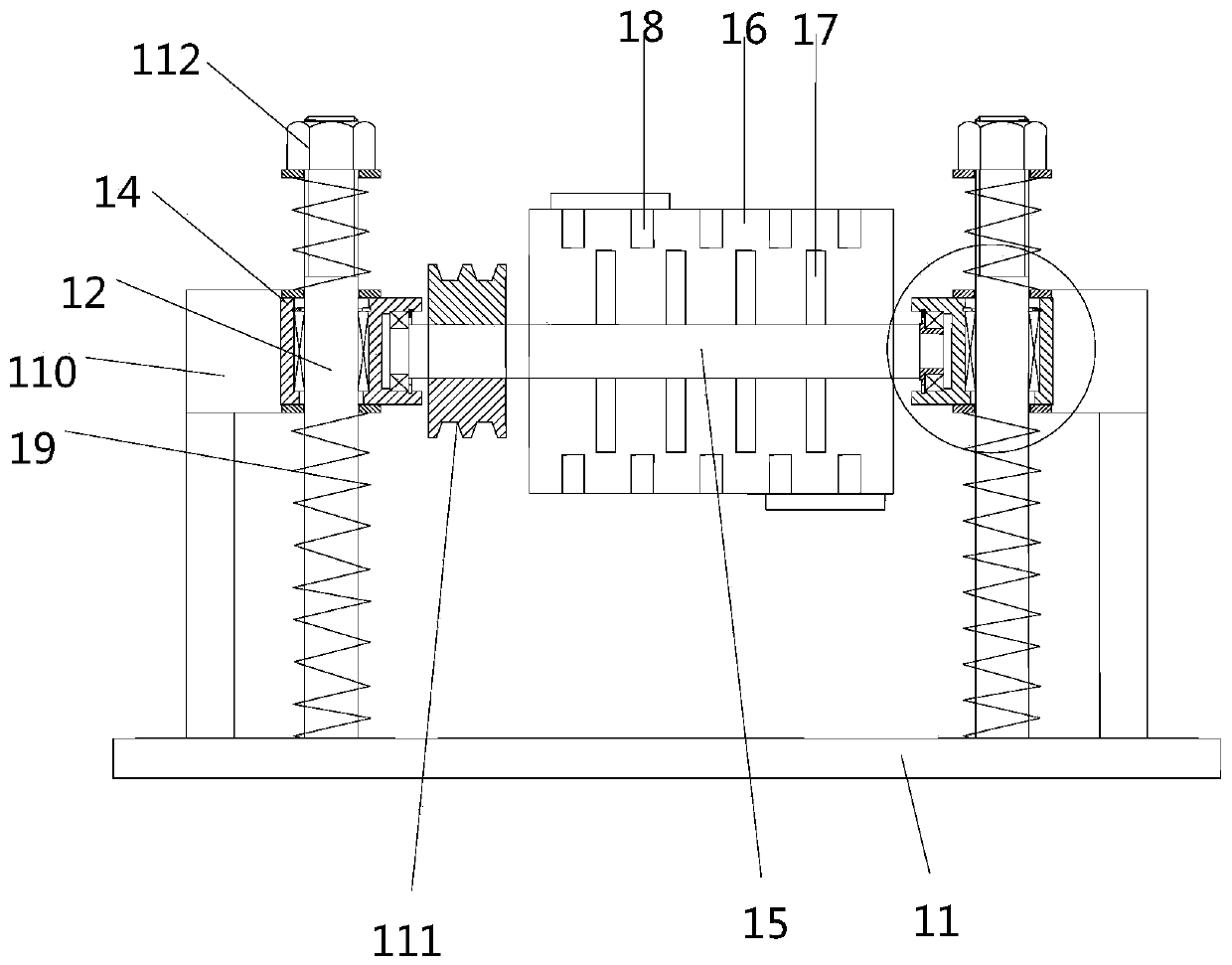

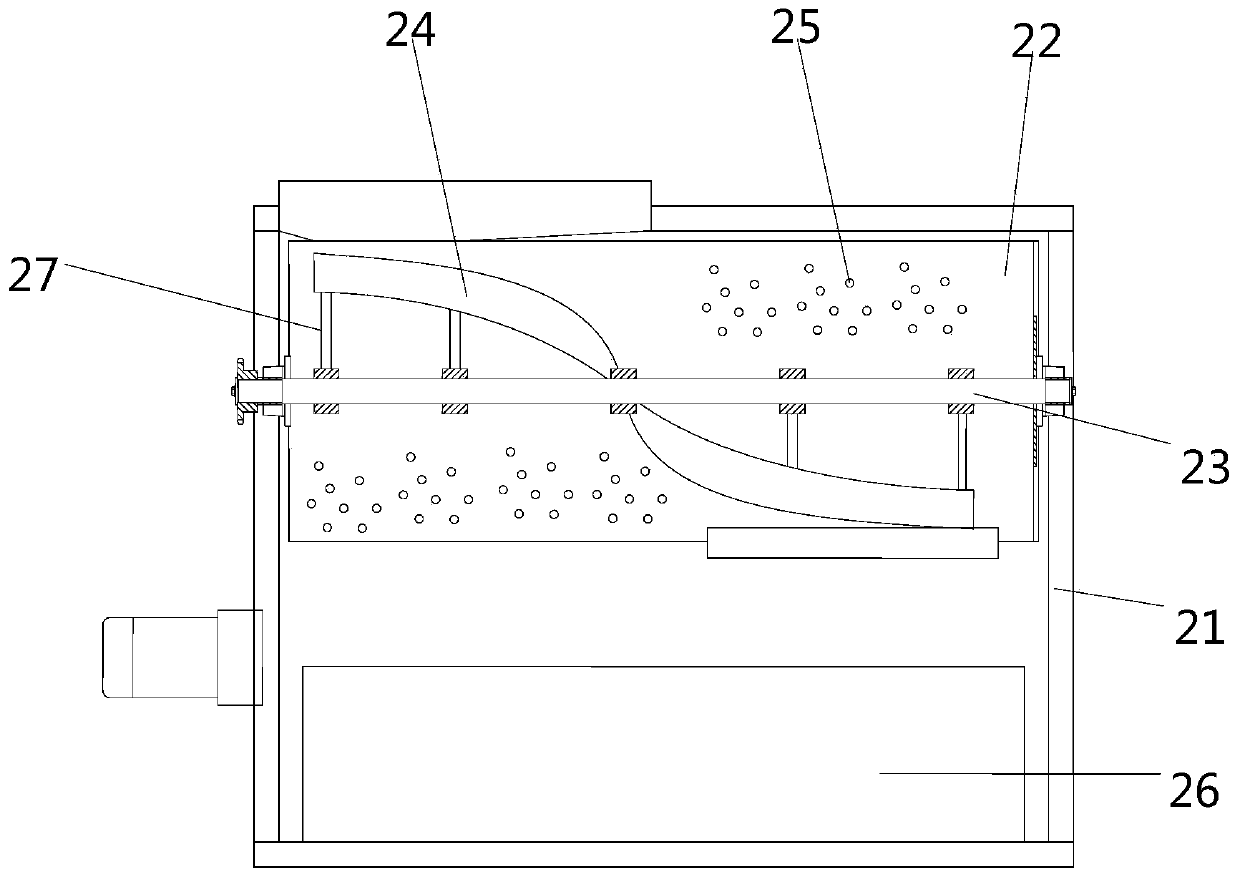

[0017] Embodiment: the drum type deburring device of small parts, structure such as Figure 1 to Figure 5 As shown, a drum deburring mechanism 1 is included, and the discharge port of the drum deburring mechanism 1 is connected with an abrasive separation mechanism 2; There are sliders 14 with built-in sliding sleeves 13 on the top, bearing seats are arranged on the sliders 14, and a rotating shaft 15 is arranged through the bearing seats. A roller 16 fixed to the rotating shaft 15 is arranged on the rotating shaft 15, and is located on the rotating shaft 15 in the roller 16. The first stirring blade 17 is provided, the inner wall of the drum 16 is provided with the second stirring blade 18, the upper and lower sides of the slider 14 are provided with a compression spring 19 sleeved on the column 12, and the slider 14 is also connected with a reciprocating vibration device 110, the rotating shaft 15 on one side of the drum 16 is provided with a transmission device; the abrasiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com