Multifunctional blanking device for magnetic cores

A blanking device and multi-functional technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of low deburring efficiency, large labor occupation, unsatisfactory deburring effect, etc., and achieve high deburring efficiency , The effect of improving the deburring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

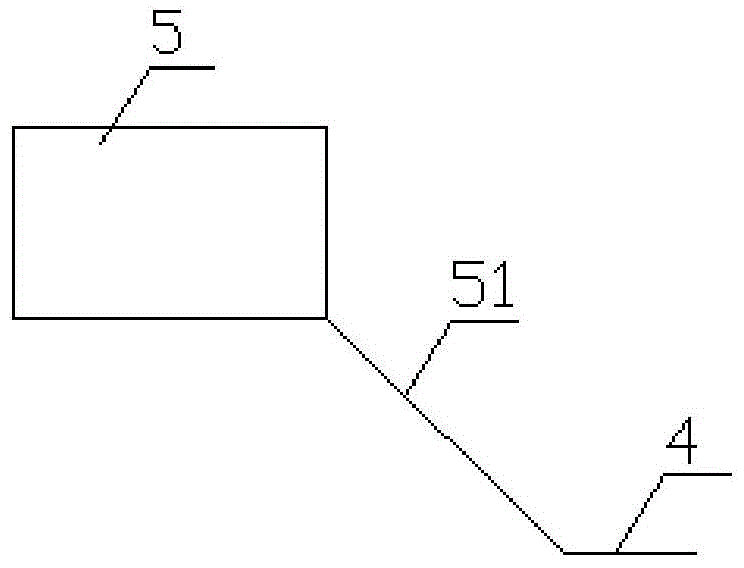

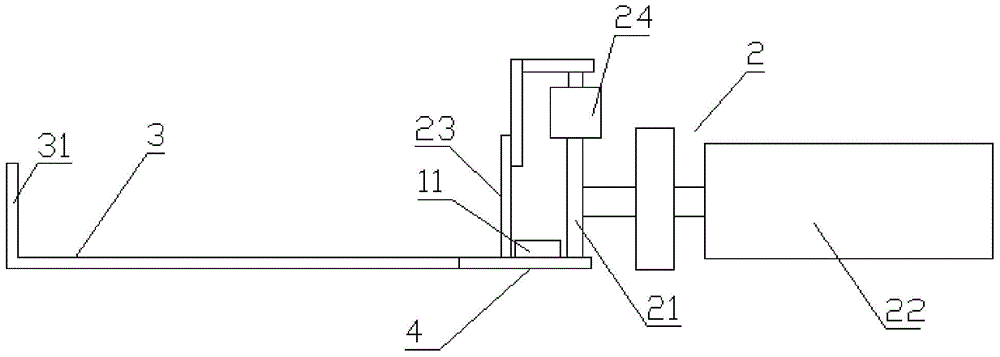

[0021] Example 1, such as figure 1 As shown, a multifunctional blanking device of a magnetic core includes a magnetic core conveyor belt 4 horizontally arranged below the discharge port of the magnetic core press 5, and the magnetic core conveyor belt is connected between the discharge port of the magnetic core press 5 and the magnetic core conveyor belt 4 is provided with a downwardly inclined conveying track 51, and the magnetic core 11 punched and formed by the magnetic core press 5 is transferred to the magnetic core conveyor belt 4 via the conveying track 51, and the magnetic cores 11 are arranged on the magnetic core conveyor belt 4 It is a row and continuous horizontal conveying.

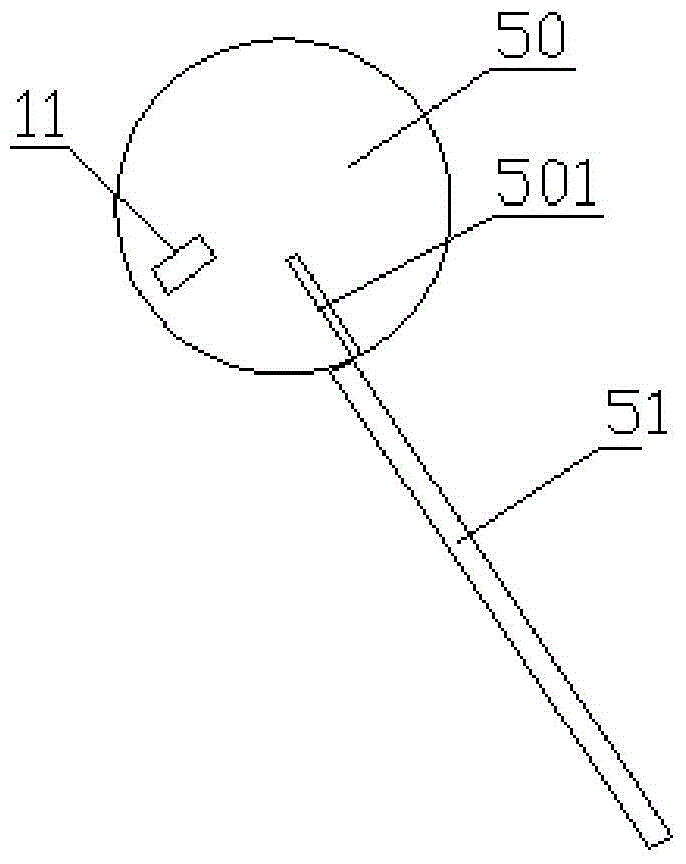

[0022] Such as figure 2 As shown, what it shows is the magnetic core 11 that needs to be transported in a different direction and adopts a magnetic core press in the form of a turntable to form the magnetic core. The turntable rotates to the discharge port, and the conveying track 51 adopt...

Embodiment 2

[0027] Embodiment 2 is different from embodiment 1, such as Figure 4 and Figure 5 As shown, the conveying track 51 does not have the reversing function, and the conveying track 51 is an inclined downward conveyor belt structure driven by power, and at the same time, a magnetic core deburring device 1 for removing magnetic core burrs is provided above the conveying track 51 , the magnetic core deburring device 1 includes a brush 15, the bristles of the brush 15 are in contact with the magnetic core 11 transported on the transport track 51, the brush 15 is installed on the fixed bracket 12, wherein the bristles of the brush 15 Also choose soft bristles. If the bristles of the brush are hard, it is easy to cause scratches on the surface of the magnetic core.

[0028] The fixed bracket 12 is provided with a vibrating motor 14, and the vibrating motor 14 drives the brush 15 to vibrate through a vibrating mechanism. The fixed support 12 is a bridge structure, and the columns on ...

Embodiment 3

[0030] Embodiment 3 is different from the above two embodiments, such as Figure 6 As shown, the conveyor track includes a vertical conveyor belt 511 and an inclined track 512. The lower end of the vertical conveyor belt 511 is connected to the inclined track 512, and the inclined track 512 is arranged obliquely downward. The discharge port of the core press 5 is provided with a magnetic body along the magnetic core conveying direction on the back side of the vertical conveyor belt 511, and the magnetic body makes the magnetic core adsorb on the conveying plane of the vertical conveyor belt 511, and the vertical conveyor belt 511 After being transported to the inclined rail 512, the magnetic core on the upper rail slides on the inclined rail 512 by gravity.

[0031] Further, the inclined track 512 can also adopt the direction-changing track in Embodiment 1, so that the magnetic core 11 can turn over during the conveying process and be transported to the magnetic core conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com