Automatic burr removing machining technology

A processing technology and deburring technology, which is applied to metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve problems such as low work efficiency, incomplete burr removal, and large manual workload, so as to reduce workload and improve Work efficiency and deburring effect, complete deburring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

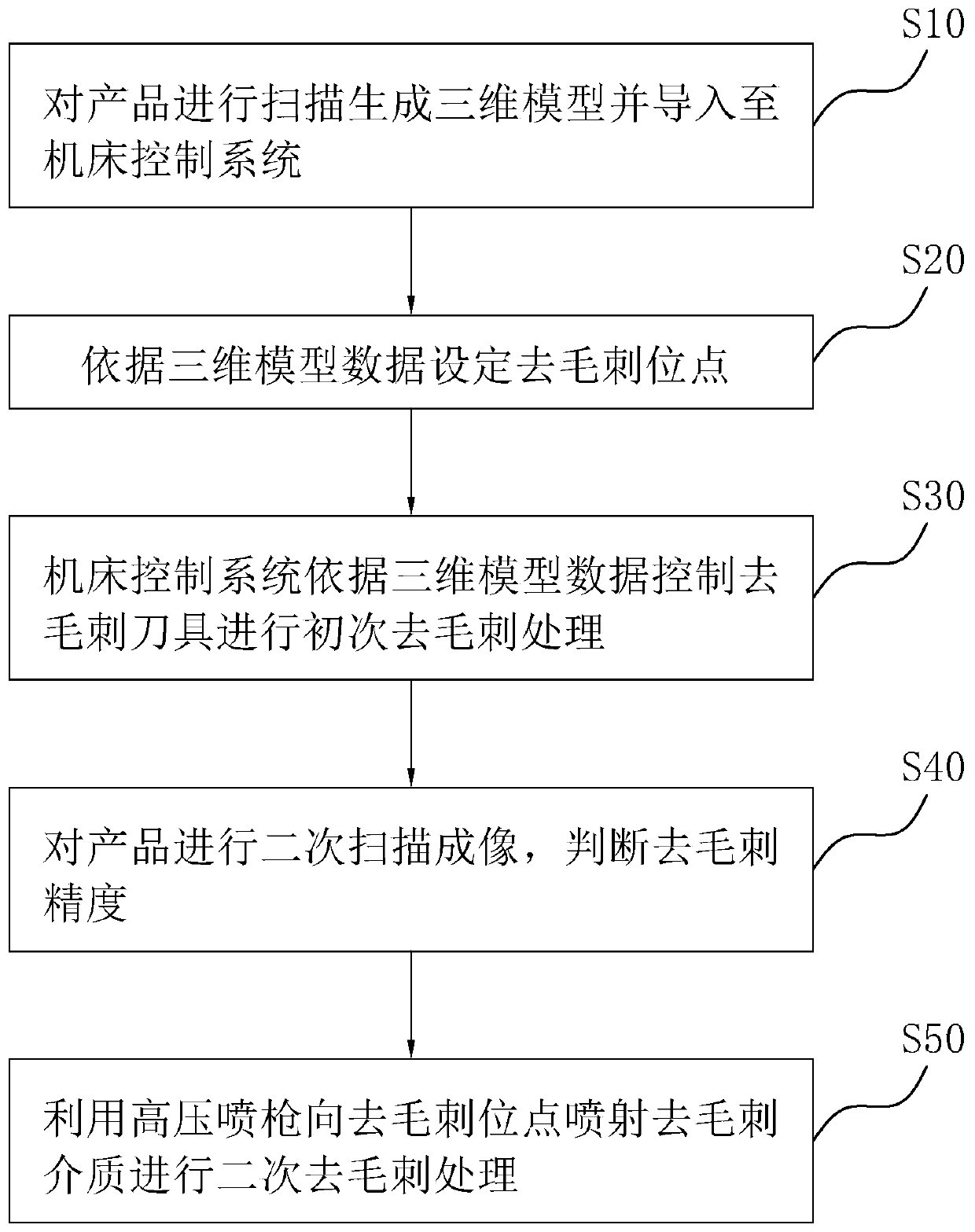

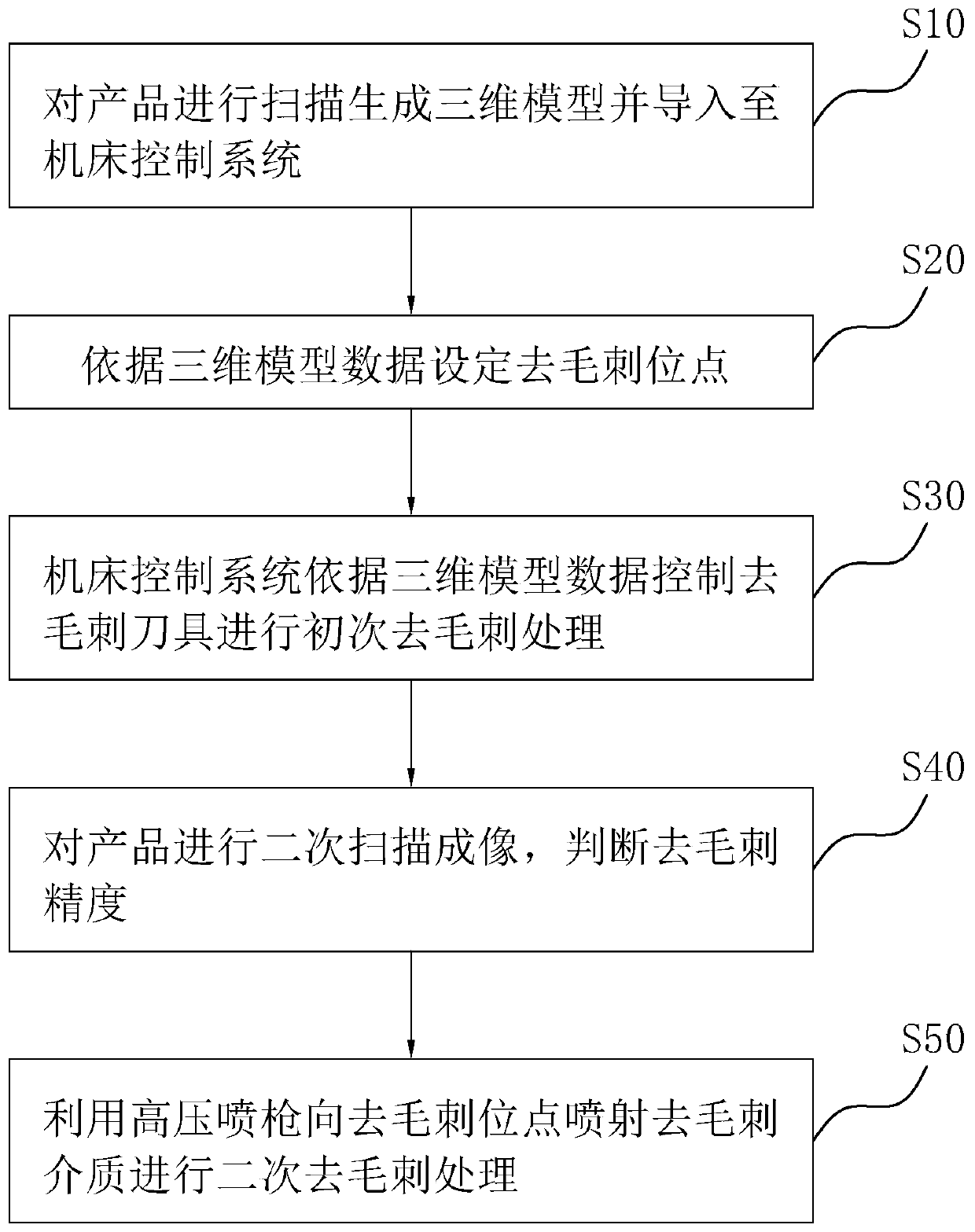

[0026] An automated deburring process, such as figure 1 shown, including the following steps:

[0027] S10, clamping and fixing the product to be processed on the automatic machine tool, scanning and identifying the surface of the product to be processed to generate a three-dimensional model of the product to be processed and importing it into the machine tool control system.

[0028] Specifically, first use the 3D imaging device connected to the machine tool control system to scan and image the product to be processed, and generate 3D model data based on the imaging information and import it into the machine tool control system. The 3D imaging device can use 3D imaging scanners and other equipment, and 3D modeling The equipment communicates with the machine tool control system through data lines or wireless networks;

[0029] After receiving the 3D model data, the machine tool control system establishes the processing coordinate system and generates the position information ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com