Pipe cutting machine with deburring function

A technology of deburring and pipe cutting machine, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, transportation and packaging, etc. It can solve the problems of low production efficiency and long time consumption, and achieve high production efficiency, short time consumption and continuous Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

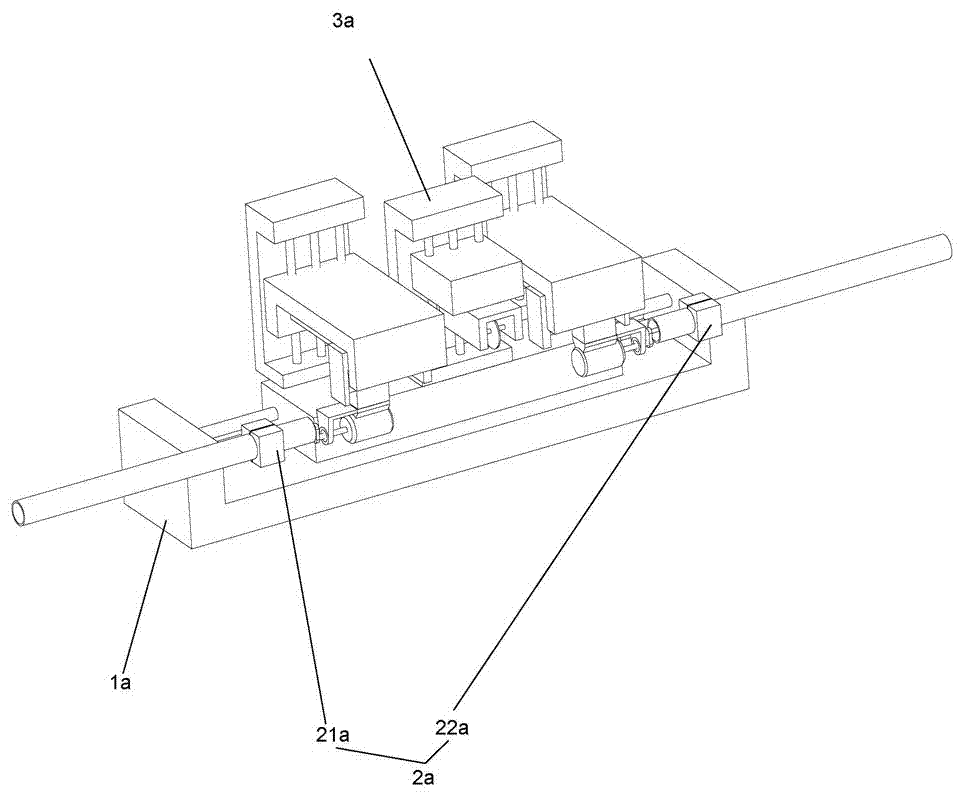

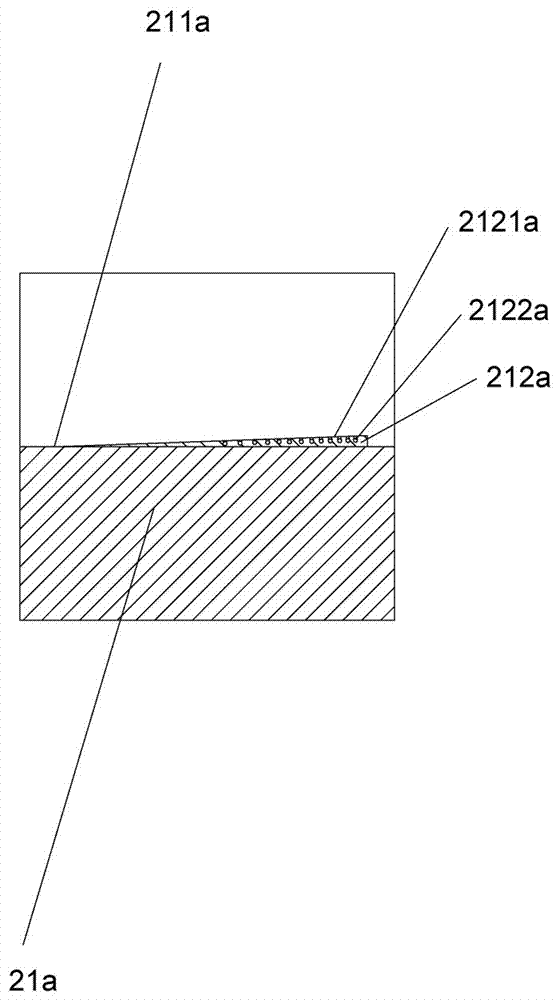

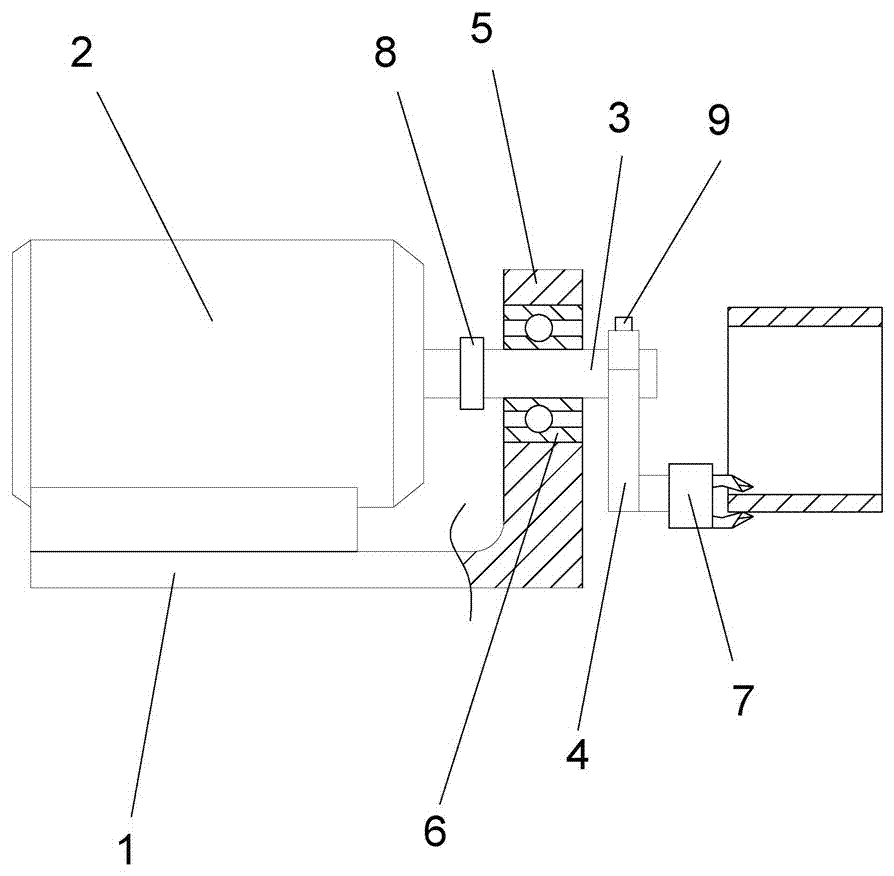

[0035] Embodiment 1: as Figure 1-Figure 7 As shown, a pipe cutting machine with deburring includes a frame 1a, an exhaust pipe clamping device 2a arranged on the frame 1a, and an exhaust pipe clamping device 2a arranged on the frame 1a. The cutting mechanism 3a above the clamping device 2a that can approach or move away from the exhaust pipe is characterized in that the exhaust pipe clamping device 2a includes a first clamping seat 21a, which can be close to or away from the first clamping seat The second clamping seat 22a of 21a also includes the two sides of the cutting mechanism 2a which are arranged on the frame 1a and can be close to or away from the first clamping seat 21a and the second clamping seat respectively. 22a deburring device, the first detection mechanism installed on the frame 1a for detecting whether the cutting mechanism 3a cuts off the exhaust pipe, drives the second clamping seat 22a away from or close to the first The first driving mechanism of the cla...

Embodiment 2

[0046] Embodiment 2: In order to improve the shaping effect, the mouth of the exhaust pipe can be properly heated to increase the deformability at the mouth of the pipe. Preferably, the device also includes a heating device, and the heating device can adopt a heat gun or an electric heating device. Heating wire. Therefore, the heating device can indirectly improve the deburring efficiency.

[0047] All the other are with embodiment 1.

Embodiment 3

[0048] Embodiment 3: A weight block 9 is fixedly arranged at the end of the rotating handle 4 away from the deburring tool 7 . The weight block 9 makes the center of mass of the turning handle 4 approach the center of rotation as much as possible, and the turning handle 4 rotates more stably. Correspondingly, the deburring cutter 7 is just more stable, and the deburring effect is just better. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com