L-shaped slotted hole machining method based on PCB

A processing method and technology of slot holes, which are applied in the direction of electrical components, printed circuit manufacturing, printed circuits, etc., can solve the problems of lost man-hours and losses, and achieve the effects of improving the overall quality, avoiding burrs, and enhancing the effect of deburring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for machining L-shaped slots based on PCB, characterized in that, comprising the steps:

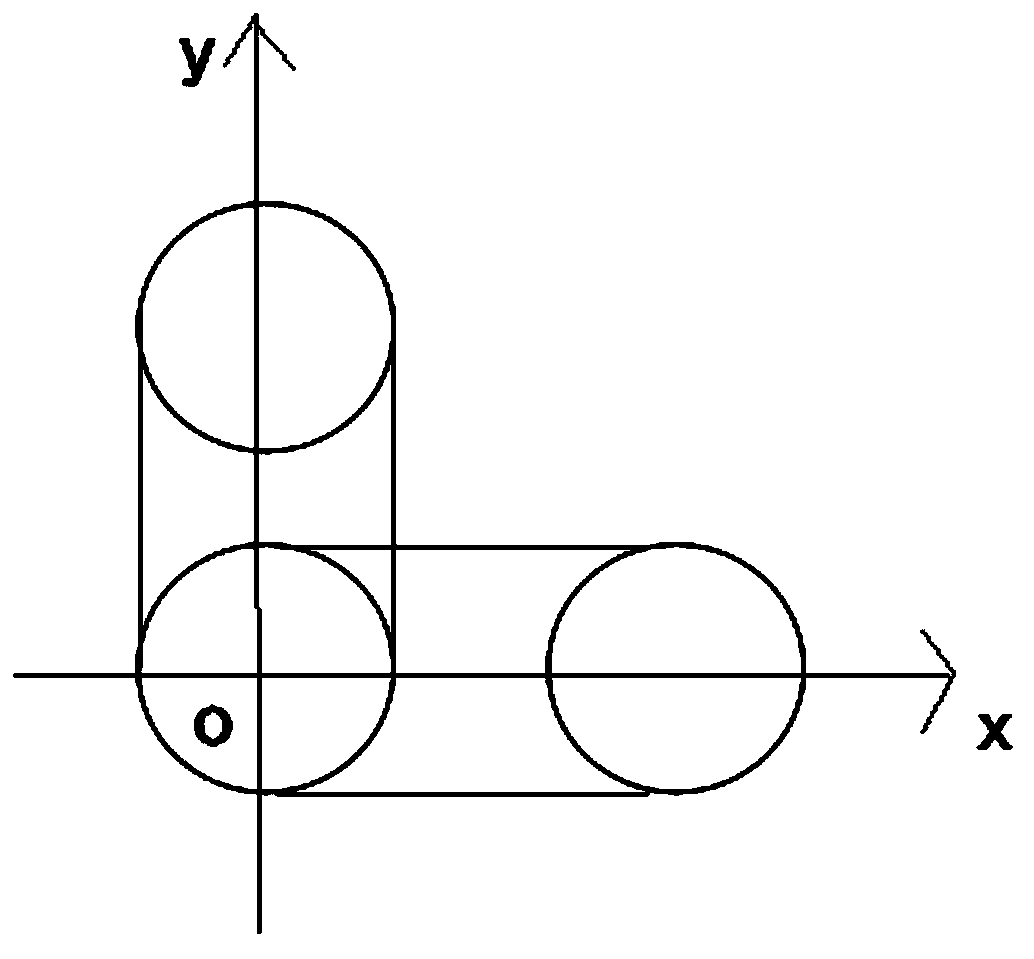

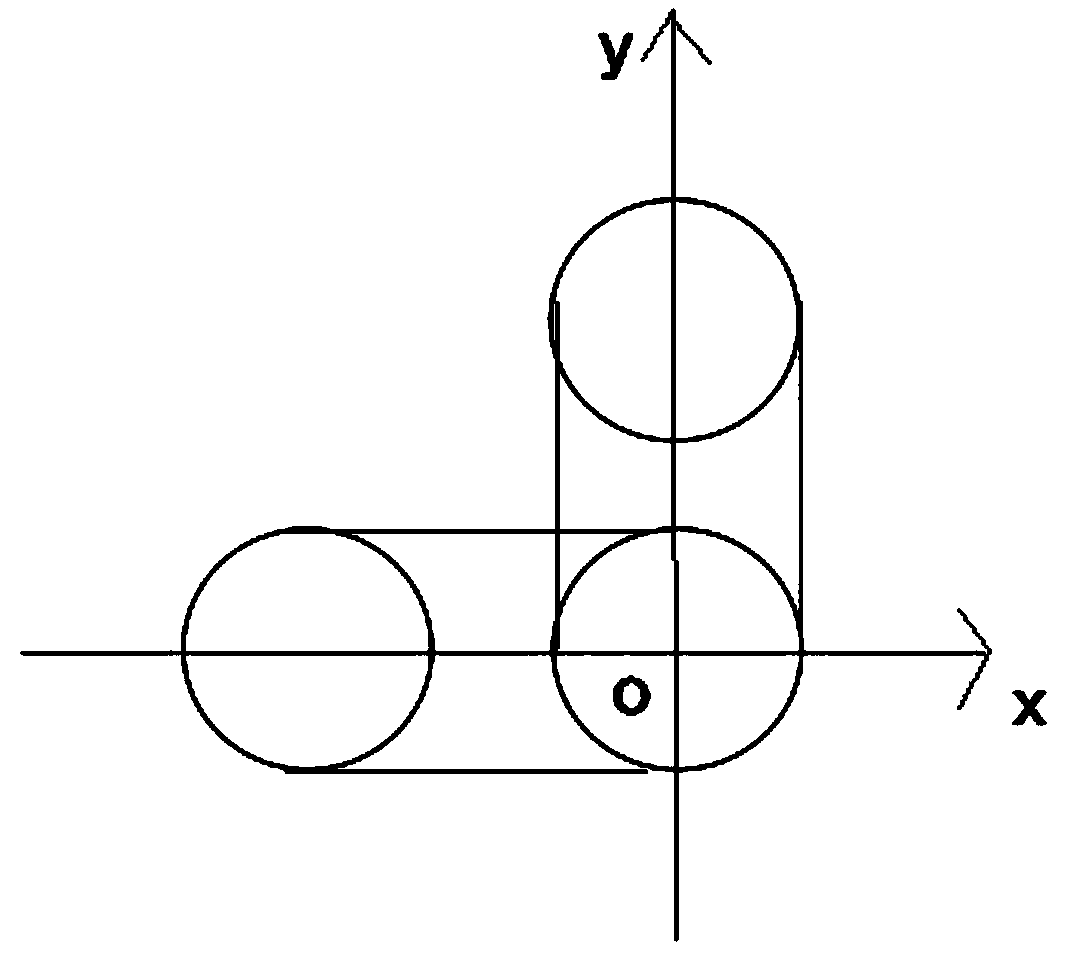

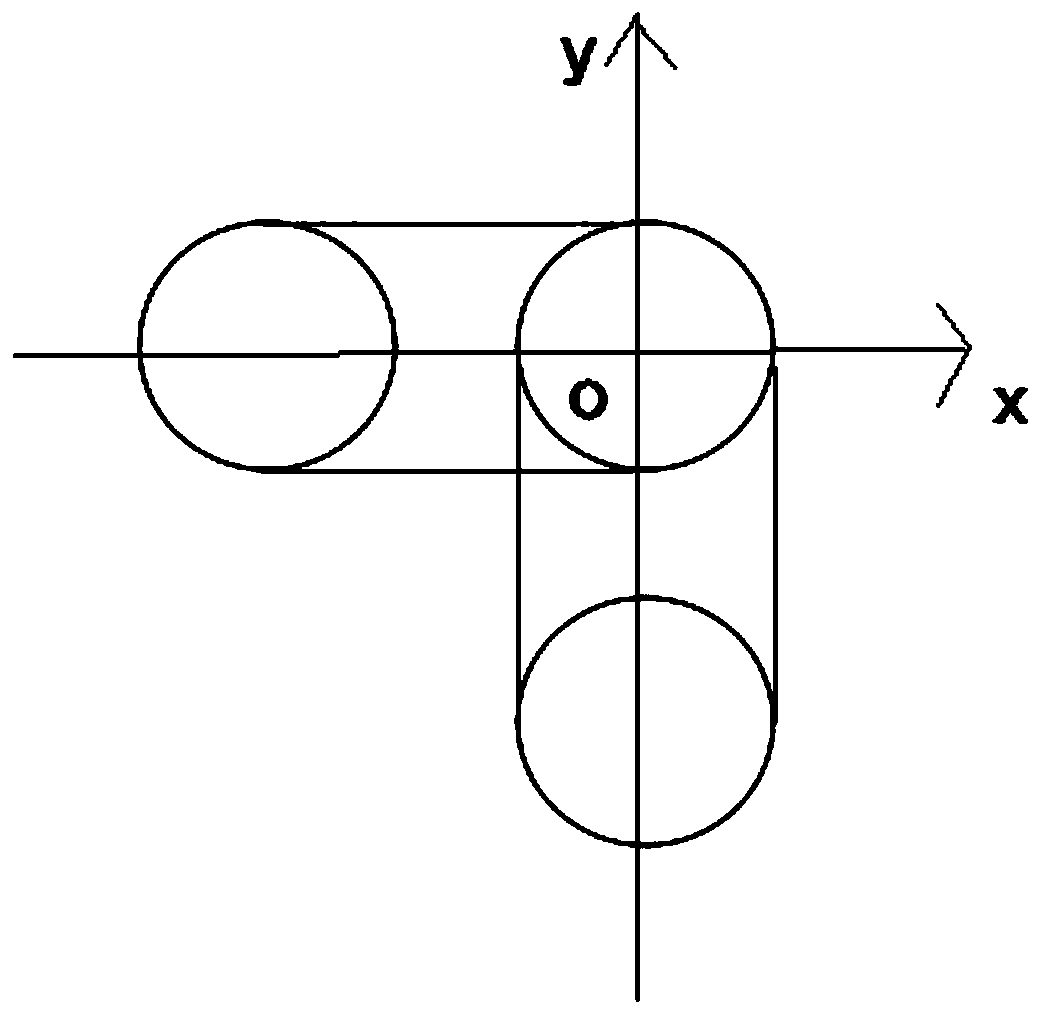

[0036] S1. Divide the L-shaped slot into horizontal slots and longitudinal slots according to the processing steps, establish a plane Cartesian coordinate system with the intersection of the two slots as the origin to form four quadrants, and determine the gap between the horizontal slot and the longitudinal slot. The quadrant of the angle;

[0037] S2, according to the judgment in the S1 step, if the angle formed by the transverse slot and the longitudinal slot is in the first quadrant, the processing sequence is to process the longitudinal slot first, and then process the transverse slot;

[0038] S3, according to the judgment in the step S1, if the angle formed by the transverse slot and the longitudinal slot is in the second quadrant, the processing sequence is to process the transverse slot first, and then process the longitudinal slot;

[0039] S4, according to the ...

Embodiment 2

[0045] On the basis of embodiment 1, technical scheme has been carried out automatic improvement, and its concrete improvement scheme is as follows:

[0046] The rotation direction of the tool is set in the drill belt parameter as clockwise rotation.

[0047] For the L-shaped groove located in the first quadrant, the tool path for making the drill tape is: from the end of the longitudinal slot far away from the origin, the tool is fed to the origin to complete the longitudinal slot, and then the tool is fed from the origin to the positive direction of the X axis Complete the horizontal slot.

[0048] For the L-shaped groove located in the second quadrant, the tool path for making the drill tape is: from the end of the horizontal slot far away from the origin, the tool is fed to the origin to complete the horizontal slot, and then the tool is fed from the origin to the positive direction of the Y axis Complete the longitudinal slot.

[0049] For the L-shaped groove located in...

Embodiment 3

[0053] On the basis of embodiment 1 or embodiment 2, technical scheme has been improved as follows:

[0054] The tool path for making the drill tape is as follows: each slot hole is firstly slotted and then slotted.

[0055] The tool diameter of the grooving tool is 1.1 mm.

[0056] The diameter of the expanding tool is 1.3mm.

[0057] The tool path for making the drill tape is: After completing the slotting process and expanding process of the horizontal slot hole / longitudinal slot hole of the L-shaped slot hole, after obtaining the complete slot hole, proceed to the longitudinal slot hole / horizontal slot hole processing process .

[0058] In order to make the size of the slot hole more accurate and ensure the side wall of the slot hole to be smoother, the slotting process of the unidirectional slot hole is divided into two steps: the slotting process and the slotting process. While improving the quality of the slot hole, it can more effectively avoid the generation of bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com