Deburring machine

A deburring machine and machine head technology, which is applied to surface polishing machine tools, machine tools suitable for grinding workpiece planes, metal processing equipment, etc., can solve problems such as low efficiency, difficulty in controlling the weight of hands, and inability to meet the quality requirements of workpieces, etc. , to achieve the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

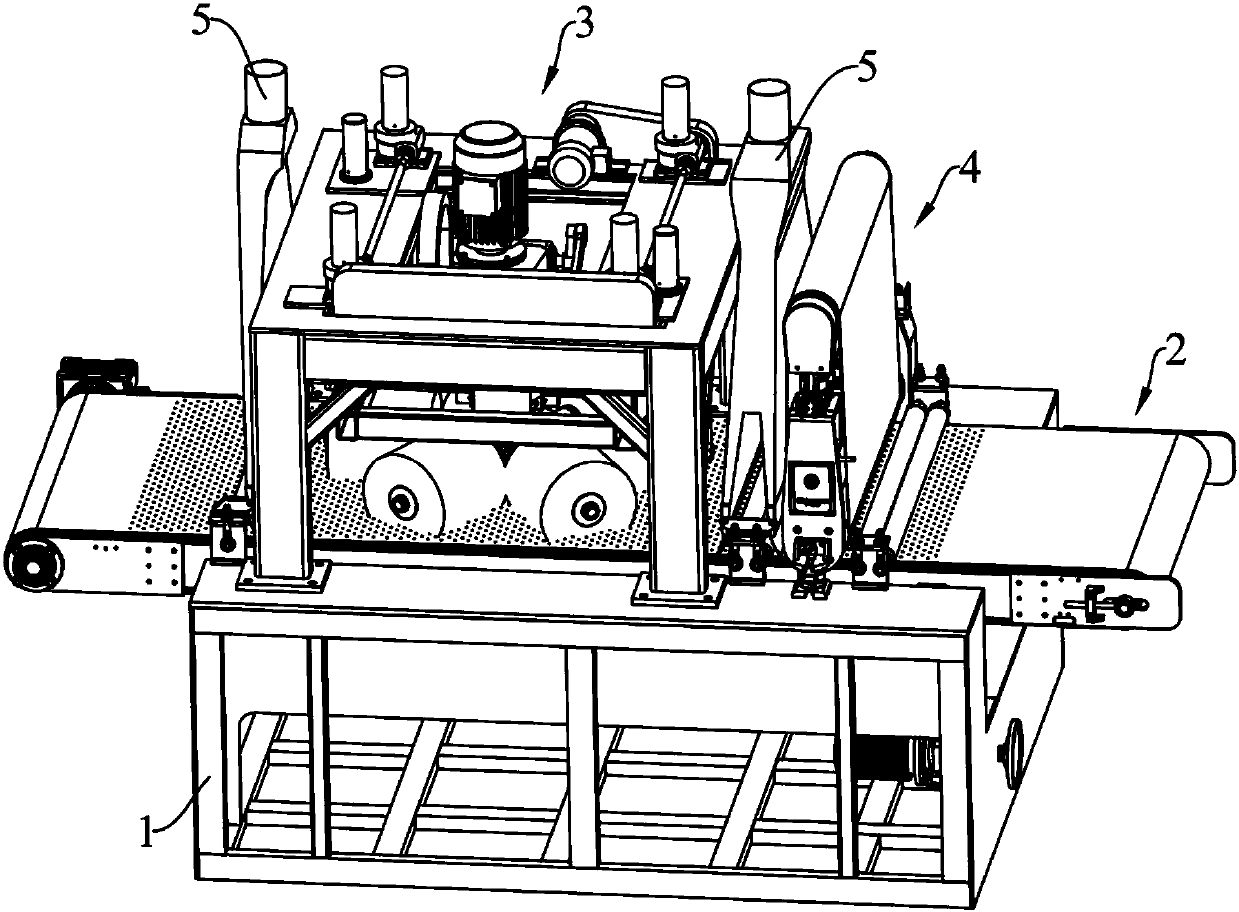

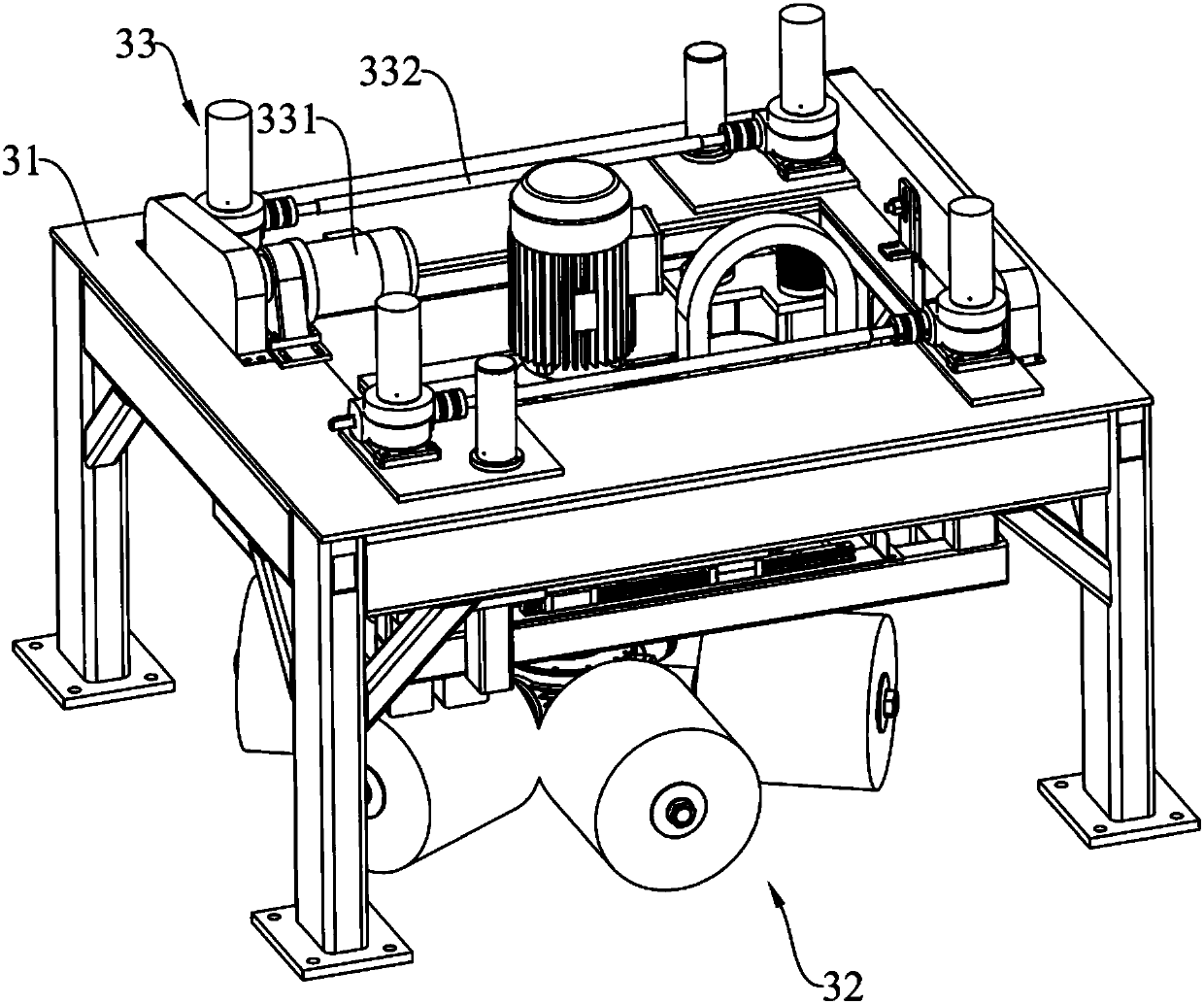

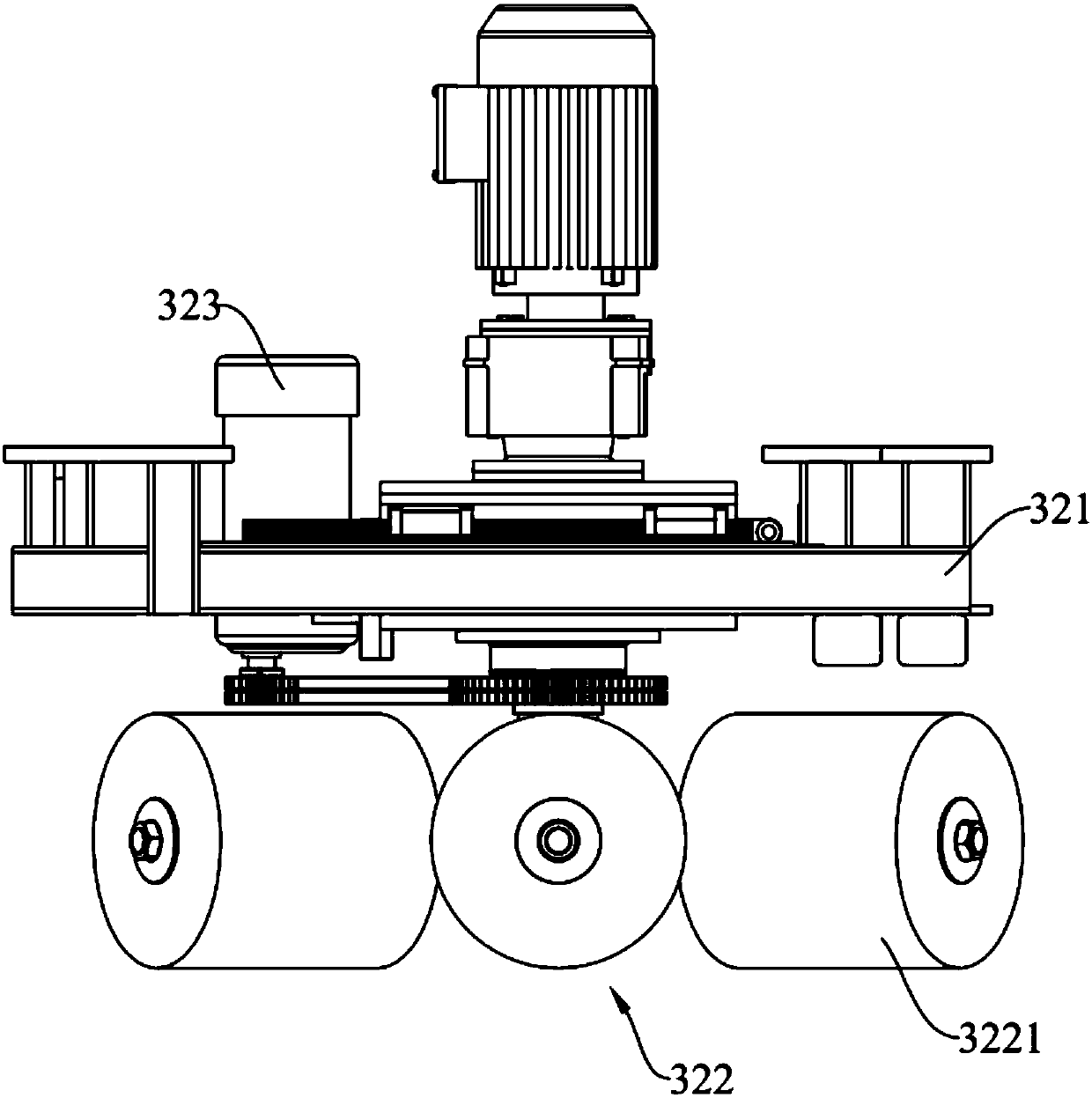

[0041] Such as figure 1 As shown, the deburring machine includes a machine base 1 and a conveying device 2 installed on the machine base 1, a universal roller brush grinding head 3, an abrasive belt grinding head 4 and a dust collection cover 5, wherein the conveying device 2 is used to convey the workpiece, the universal roller brush grinding head 3 and the abrasive belt grinding head 4 are located on the upper part of the conveying device 2 and arranged at intervals, and are used to grind the workpiece on the conveying device 2 to remove the workpiece Surface burrs, and processing of workpieces such as wire drawing, deslag removal and descaling. According to the actual needs of the workpiece to be processed, one or more universal roller brush grinding heads 3 and one or more abrasive belt grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com