Paint removing method and paint removing equipment for surface of metal hanging rack

A metal and paint stripping technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as environmental pollution, poor paint stripping effect, etc., to avoid polluting the soil, eliminating waste gas emissions, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

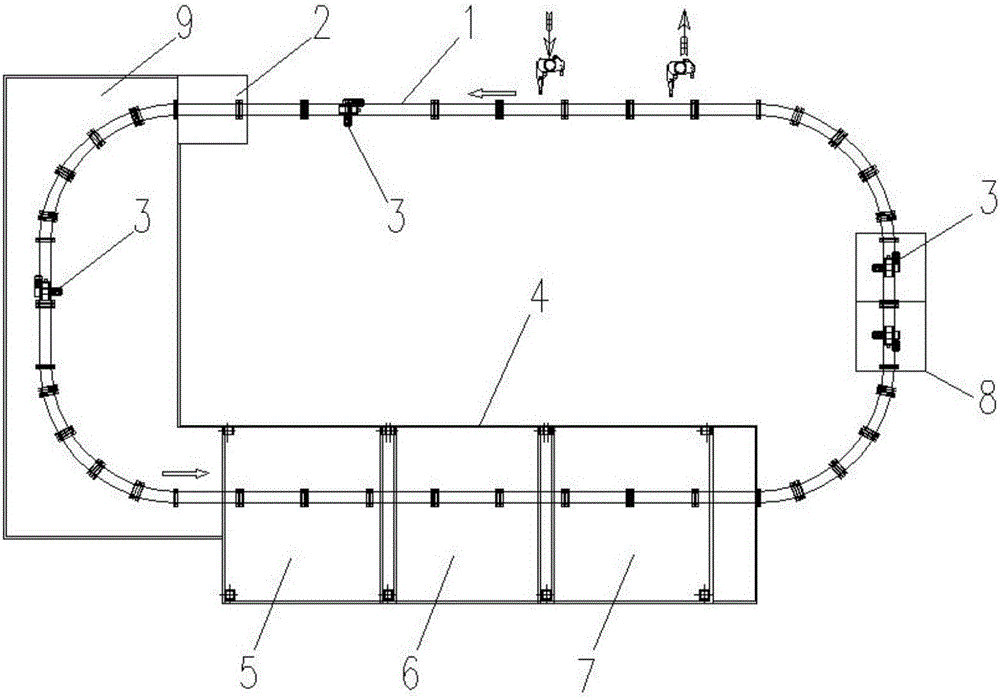

[0043] The technical scheme of the paint stripping equipment of the present invention includes a circular track 1, a self-propelled car 3, a liquid nitrogen tank 2, a metal particle impact bin 4, and a control system. The circular track 1 is horizontally suspended in the liquid nitrogen tank 2 and the metal particle impacts Right above the warehouse 4, the liquid nitrogen tank 2 contains liquid nitrogen. The self-propelled trolley 3 is arranged on the circular track 1 and can move along the circular track 1. The self-propelled trolley 3 is provided with a clamping mechanism for clamping metal hangers, A hoisting mechanism for controlling the up and down movement of the clamping mechanism and a driving mechanism for driving the metal hanger to rotate along its own longitudinal center axis;

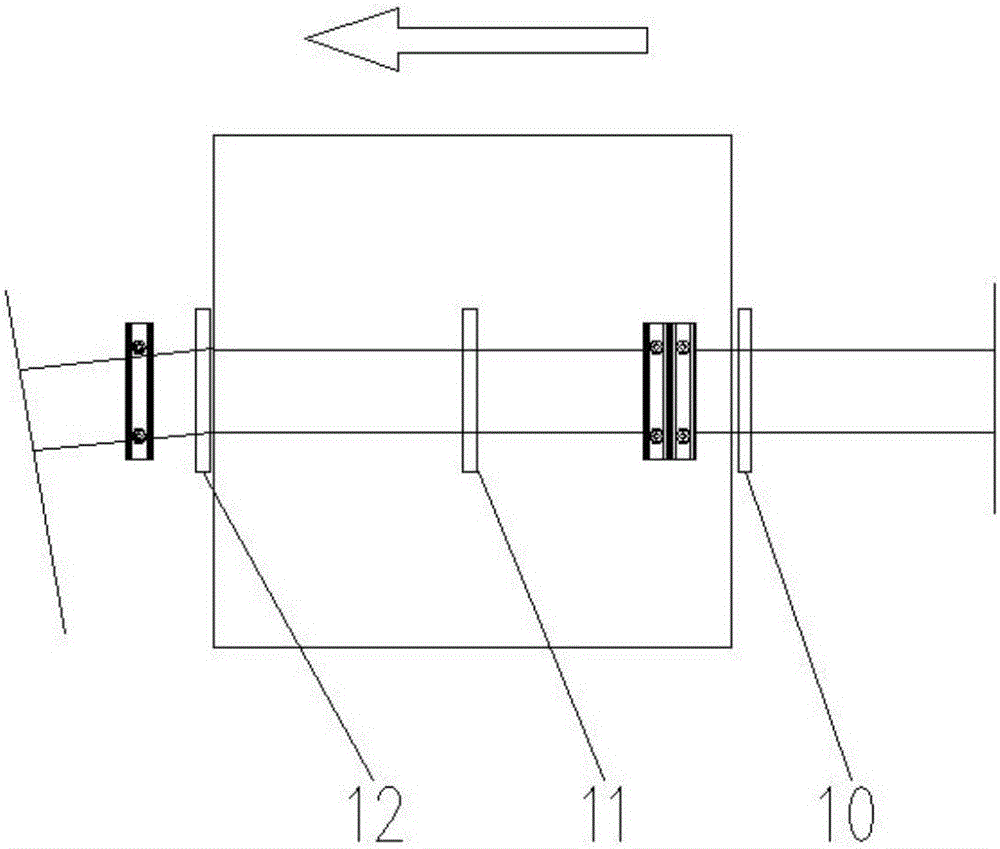

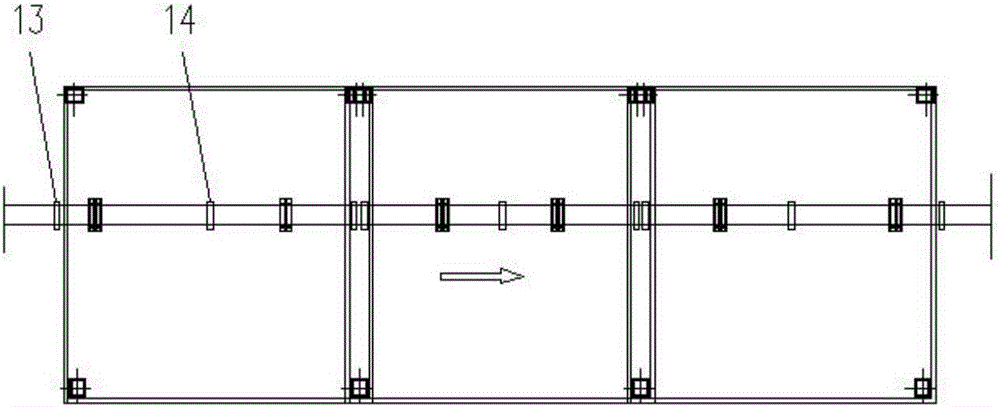

[0044] The metal particle impact bin 4 includes a bin body and a shot blasting mechanism 16 capable of ejecting projectiles into the bin body. The top of the bin body is provided with an openin...

Embodiment 2

[0053] On the basis of the first embodiment, the shot blasting mechanism 16 can also be set up in another way: an opening is opened on one side wall of the large particle impact chamber 5, medium particle impact chamber 6, and small particle impact chamber 7, each A group of multi-degree-of-freedom manipulators 21 are provided at each opening, and a shot blasting mechanism 16 is provided at the cantilever end of the multi-degree-of-freedom manipulator 21, and extends into the metal particle impact bin 4 from the opening.

[0054] At the same time, protective clothing is also needed at the opening, and the multi-degree-of-freedom manipulator 21 is covered inside the protective clothing, and the protective clothing is connected to the opening. To reflect the structure of the multi-degree-of-freedom manipulator, the protective clothing is omitted in the drawings.

[0055] The multi-degree-of-freedom manipulator 21 in this embodiment can perform multi-angle shot blasting around the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com