Deburring equipment for stainless steel plate for power distribution cabinet production

A deburring, stainless steel technology, applied in metal processing equipment, grinding/polishing equipment, grinding slides, etc., can solve the problems of high production cost, cumbersome operation, poor deburring effect, etc., and achieve good deburring effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

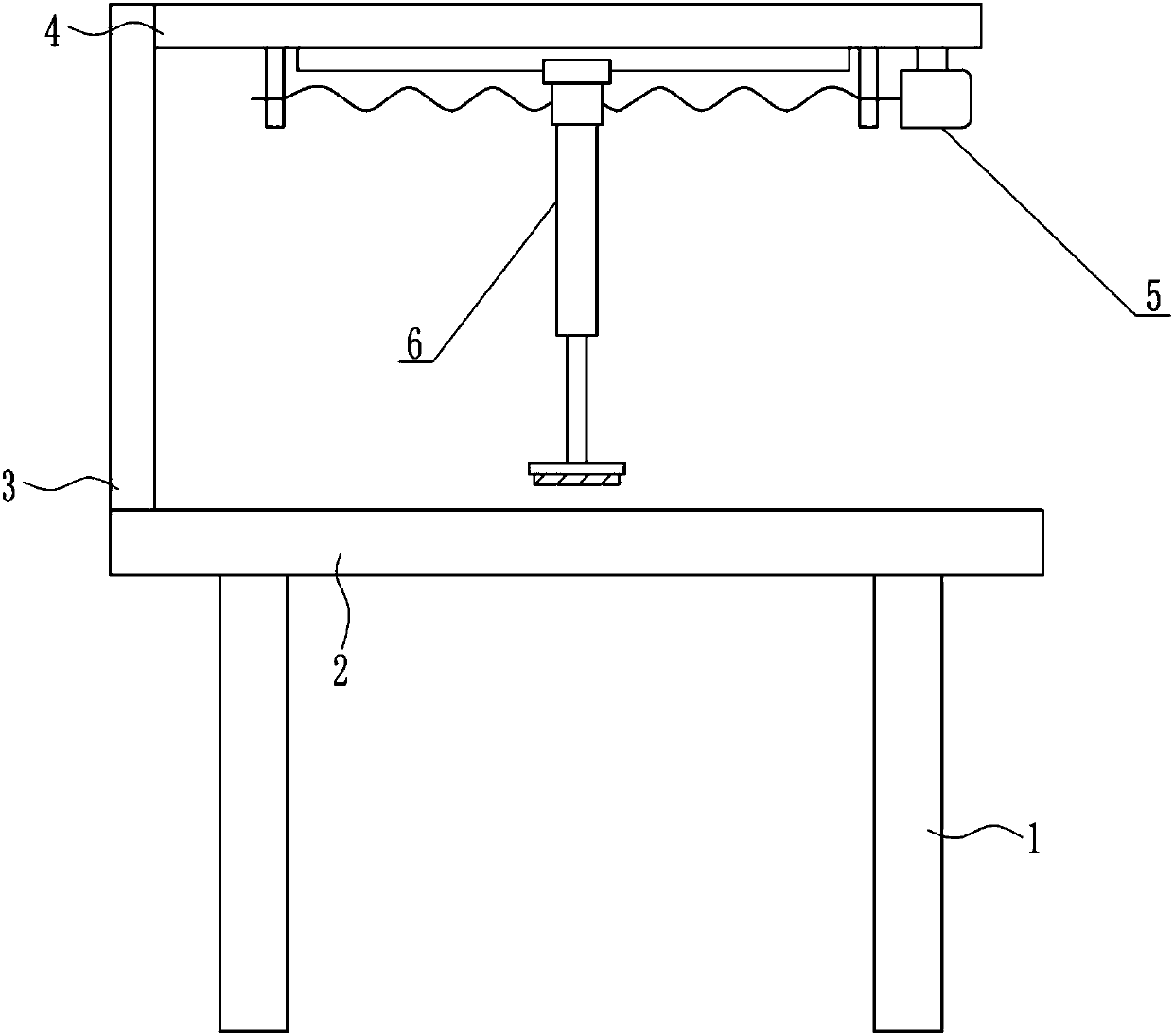

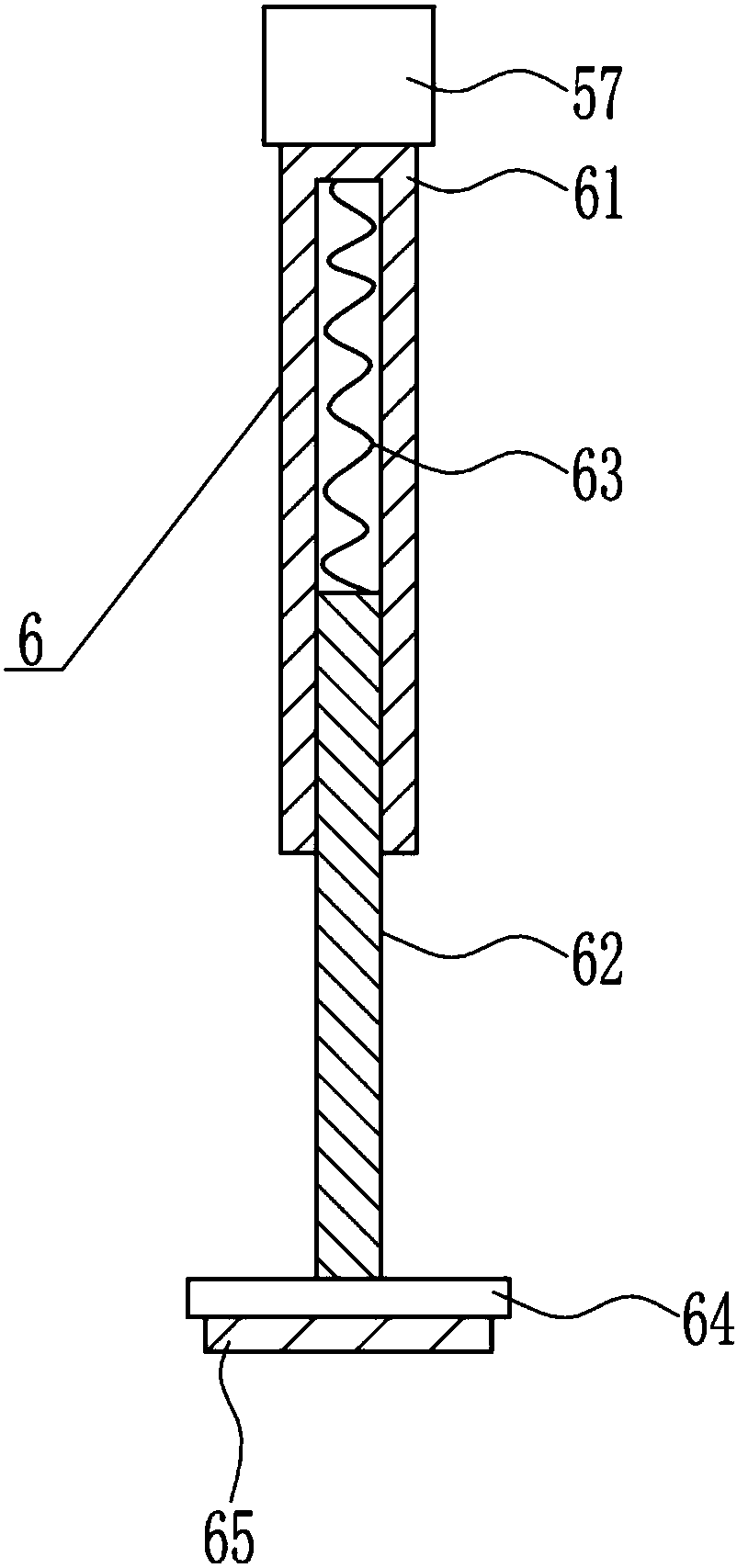

[0037] A stainless steel plate deburring equipment for power distribution cabinet production, such as Figure 1-8 As shown, it includes a support leg 1, a placement plate 2, a bracket 3, a top plate 4, a left and right moving device 5 and a deburring device 6. The top of the support leg 1 is horizontally connected with the placement plate 2 by means of bolt connection, and the top of the placement plate 2 is left The side is vertically installed with a support 3 by means of bolt connection, and the top of the right side of the support 3 is horizontally connected with a top plate 4 by means of bolt connection. Deburring device6.

Embodiment 2

[0039] A stainless steel plate deburring equipment for power distribution cabinet production, such as Figure 1-8 As shown, it includes a support leg 1, a placement plate 2, a bracket 3, a top plate 4, a left and right moving device 5 and a deburring device 6. The top of the support leg 1 is horizontally connected with the placement plate 2 by means of bolt connection, and the top of the placement plate 2 is left The side is vertically installed with a support 3 by means of bolt connection, and the top of the right side of the support 3 is horizontally connected with a top plate 4 by means of bolt connection. Deburring device6.

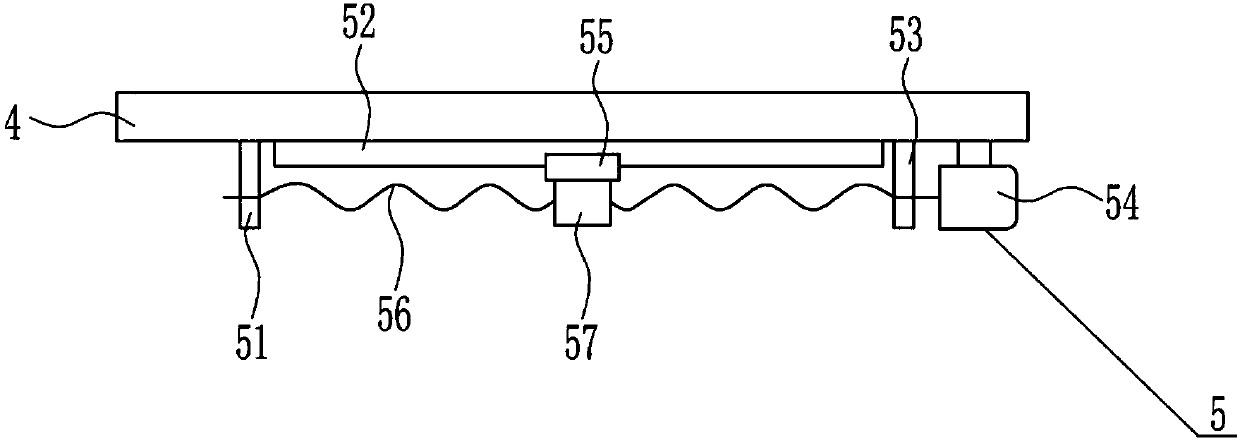

[0040] The left and right moving device 5 includes a left bearing seat 51, a slide rail 52, a right bearing seat 53, a first motor 54, a slider 55, a screw mandrel 56 and a nut 57, and the bottom of the top plate 4 is installed by bolts from left to right. There is a left bearing seat 51, a slide rail 52, a right bearing seat 53 and a first motor 54,...

Embodiment 3

[0042] A stainless steel plate deburring equipment for power distribution cabinet production, such as Figure 1-8 As shown, it includes a support leg 1, a placement plate 2, a bracket 3, a top plate 4, a left and right moving device 5 and a deburring device 6. The top of the support leg 1 is horizontally connected with the placement plate 2 by means of bolt connection, and the top of the placement plate 2 is left The side is vertically installed with a support 3 by means of bolt connection, and the top of the right side of the support 3 is horizontally connected with a top plate 4 by means of bolt connection. Deburring device6.

[0043] The left and right moving device 5 includes a left bearing seat 51, a slide rail 52, a right bearing seat 53, a first motor 54, a slider 55, a screw mandrel 56 and a nut 57, and the bottom of the top plate 4 is installed by bolts from left to right. There is a left bearing seat 51, a slide rail 52, a right bearing seat 53 and a first motor 54,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com