Automobile brake disc thickness detection apparatus

A technology of thickness detection and detection device, applied in the direction of mechanical thickness measurement, etc., can solve the problems of inconvenient operation, low detection efficiency, low detection accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

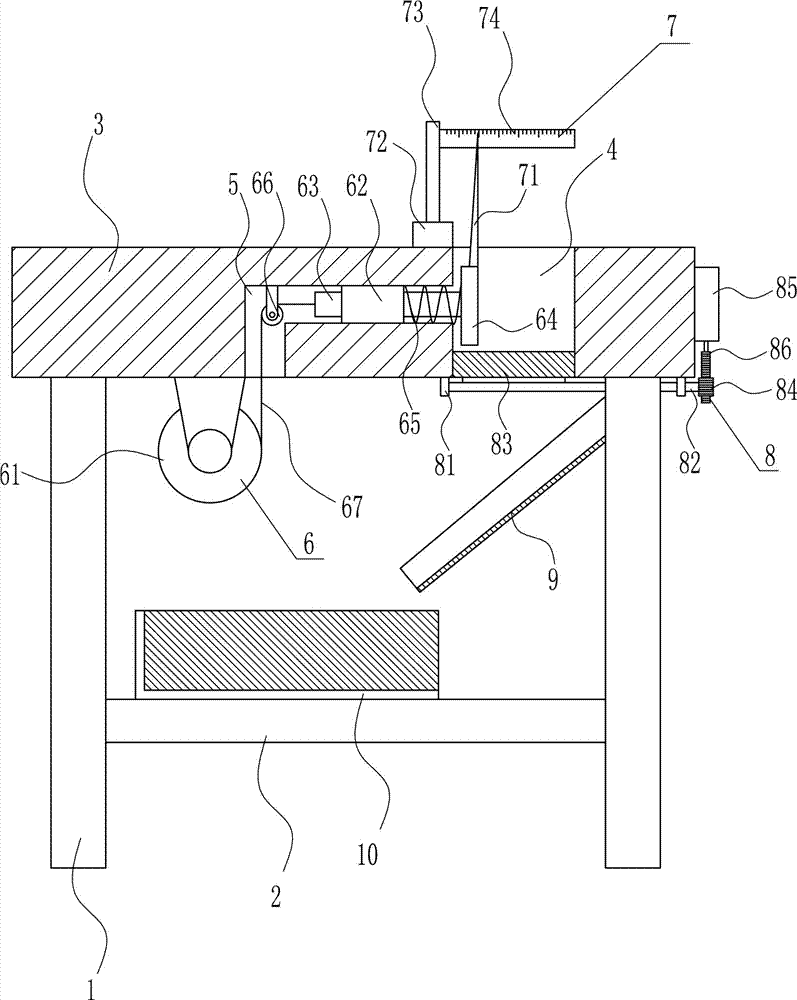

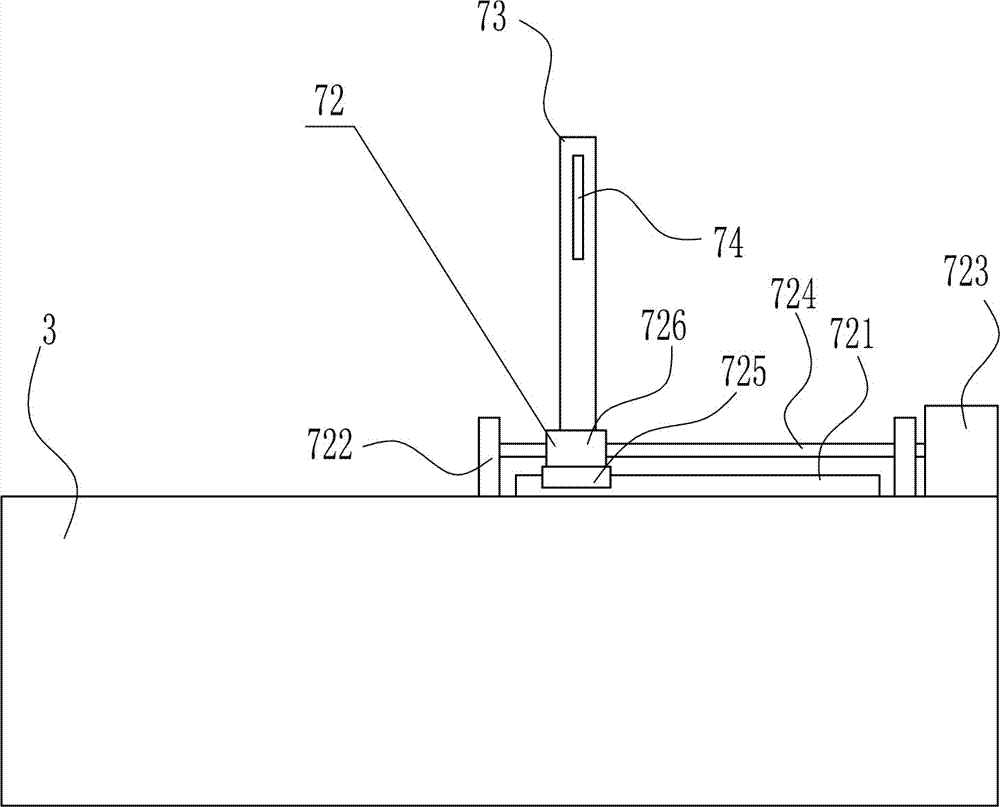

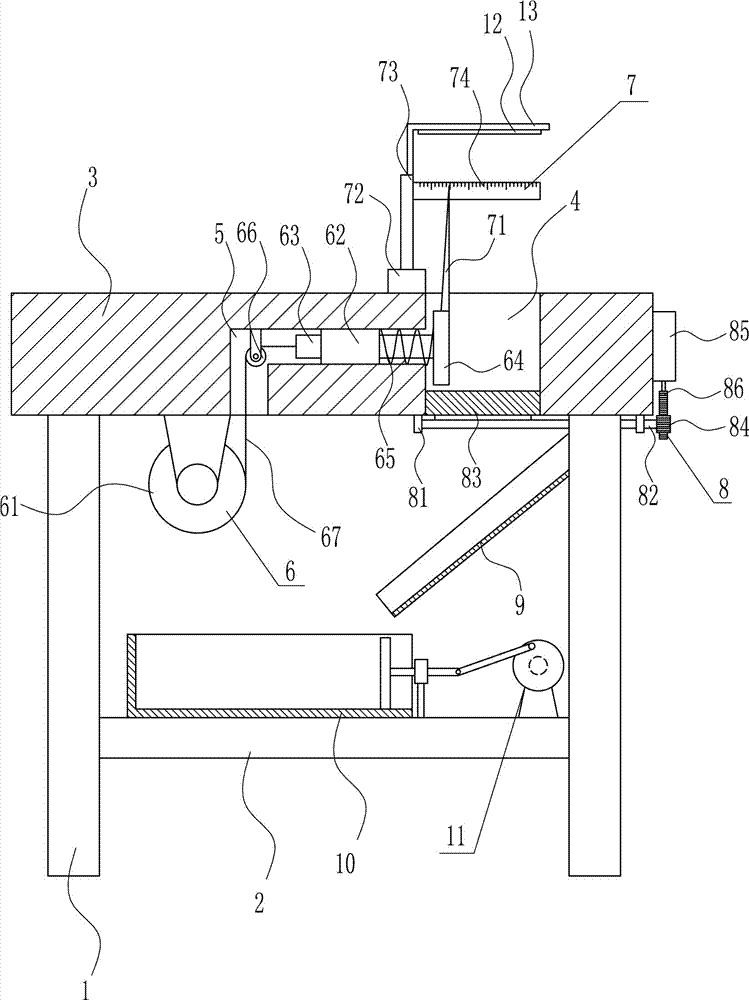

[0036] A device for detecting the thickness of an automobile brake pad, such as Figure 1-7 As shown, it includes a support frame 1, a horizontal support 2, a detection platform 3, a fixing device 6, a detection device 7 and a discharge device 8, the bottom of the support frame 1 is horizontally connected with the horizontal support 2, and the top of the support frame 1 is horizontally connected with a The detection platform 3 has a detection groove 4 on the right side of the detection platform 3, and an installation groove 5 is opened on the detection platform 3 on the left side of the detection groove 4. The installation groove 5 is L-shaped, and the installation groove 5 communicates with the detection groove 4. The installation groove A fixing device 6 is installed in the 5 , a discharge device 8 is provided under the detection tank 4 , and a detection device 7 is provided on the top of the detection platform 3 .

Embodiment 2

[0038] A device for detecting the thickness of an automobile brake pad, such as Figure 1-7 As shown, it includes a support frame 1, a horizontal support 2, a detection platform 3, a fixing device 6, a detection device 7 and a discharge device 8, the bottom of the support frame 1 is horizontally connected with the horizontal support 2, and the top of the support frame 1 is horizontally connected with a The detection platform 3 has a detection groove 4 on the right side of the detection platform 3, and an installation groove 5 is opened on the detection platform 3 on the left side of the detection groove 4. The installation groove 5 is L-shaped, and the installation groove 5 communicates with the detection groove 4. The installation groove A fixing device 6 is installed in the 5 , a discharge device 8 is provided under the detection tank 4 , and a detection device 7 is provided on the top of the detection platform 3 .

[0039] Fixing device 6 comprises electric reel 61, first g...

Embodiment 3

[0041] A device for detecting the thickness of an automobile brake pad, such as Figure 1-7 As shown, it includes a support frame 1, a horizontal support 2, a detection platform 3, a fixing device 6, a detection device 7 and a discharge device 8, the bottom of the support frame 1 is horizontally connected with the horizontal support 2, and the top of the support frame 1 is horizontally connected with a The detection platform 3 has a detection groove 4 on the right side of the detection platform 3, and an installation groove 5 is opened on the detection platform 3 on the left side of the detection groove 4. The installation groove 5 is L-shaped, and the installation groove 5 communicates with the detection groove 4. The installation groove A fixing device 6 is installed in the 5 , a discharge device 8 is provided under the detection tank 4 , and a detection device 7 is provided on the top of the detection platform 3 .

[0042] Fixing device 6 comprises electric reel 61, first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com