Automatic deburring machine for steel plate

A technology of deburring machine and steel plate, applied in the direction of grinding frame, grinding slide plate, grinding feed movement, etc., can solve the problem of low work efficiency, and achieve the effect of not easy to change, flattening, and deburring. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

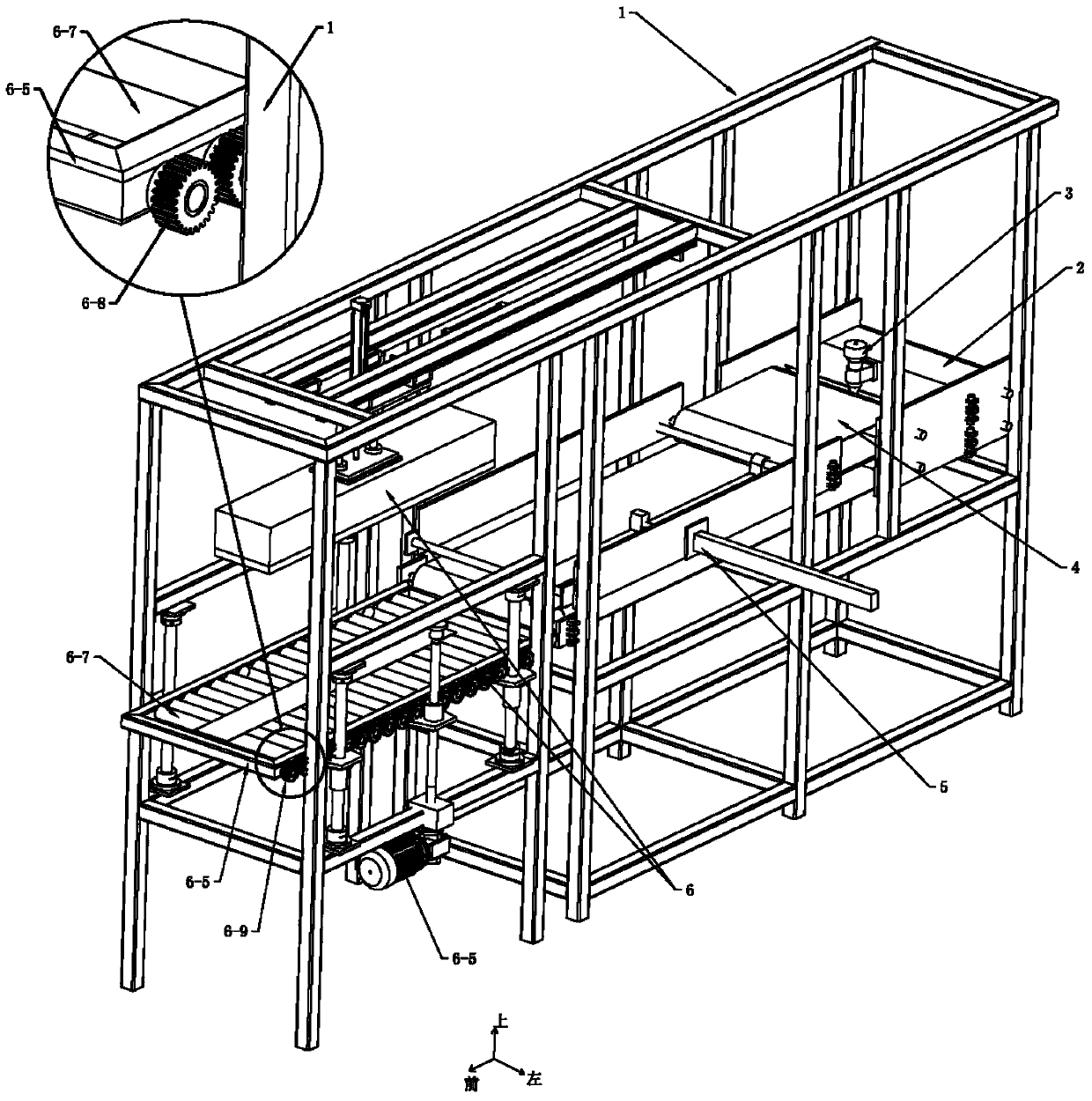

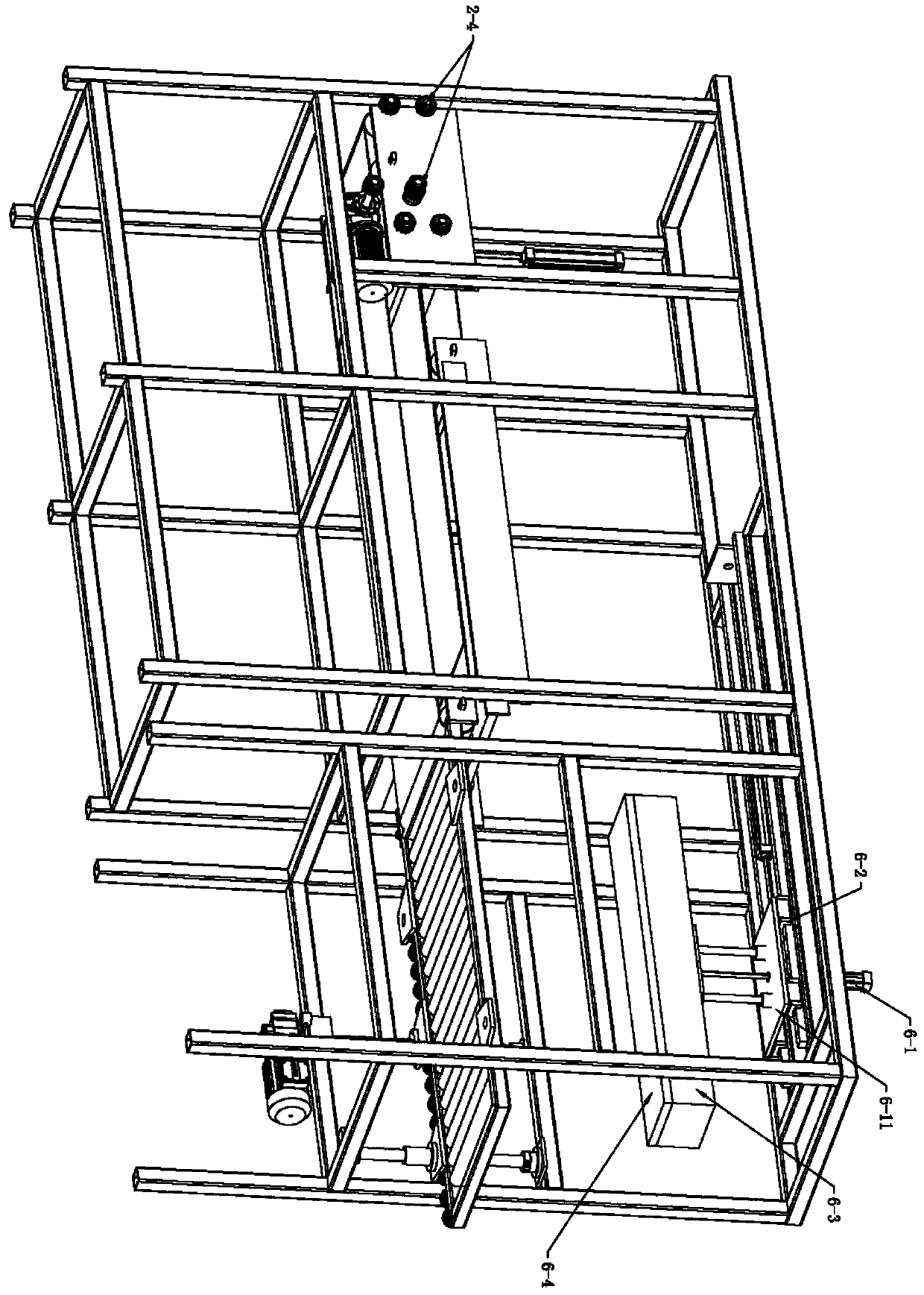

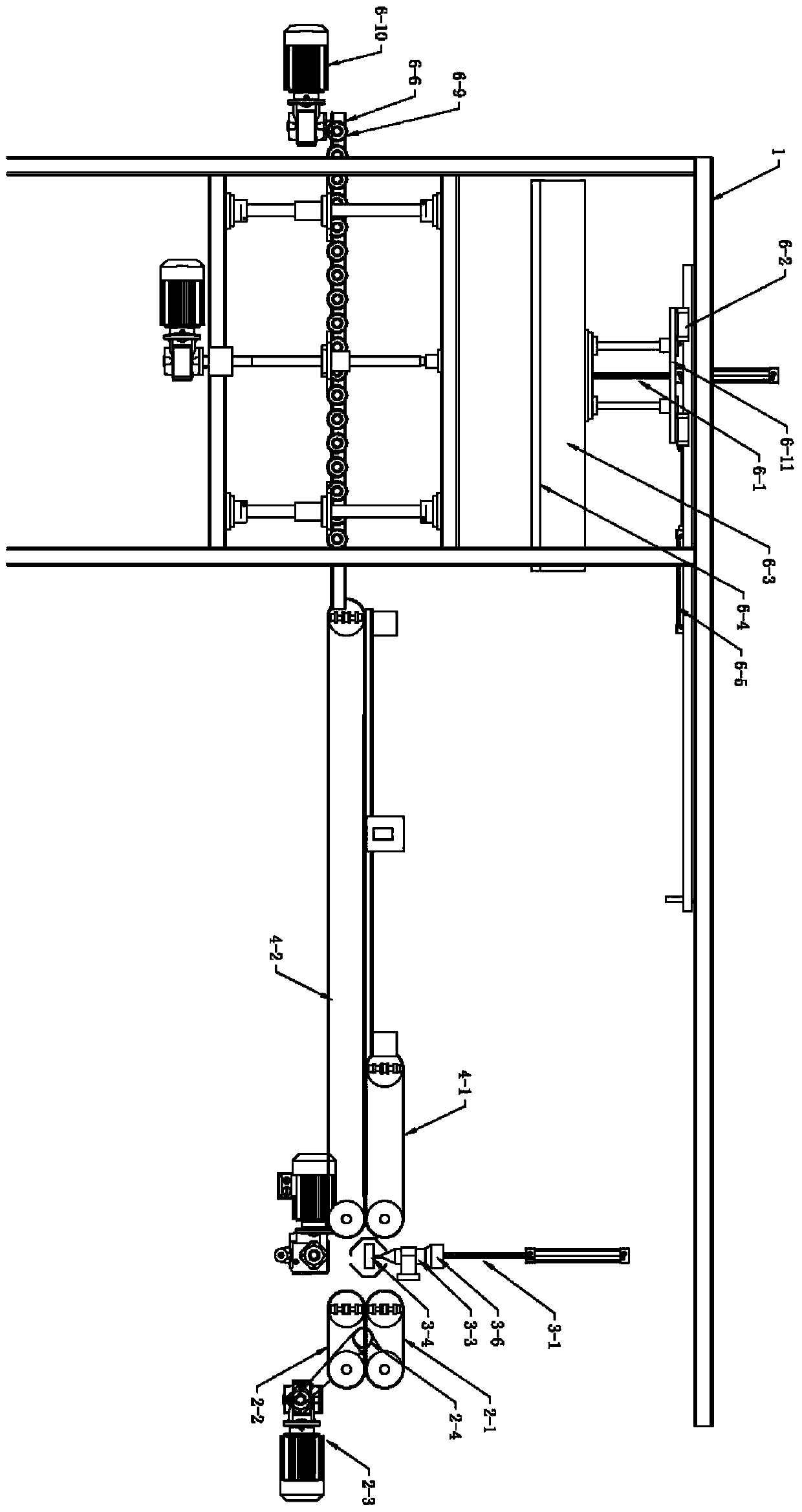

[0042] see Figures 1 to 9 , the steel plate automatic deburring machine in this embodiment is provided with a frame 1, a feeding mechanism 2, a front and rear end surface grinding device 3, a flattening feeding device 4, a limit side grinding device 5 and a deburring device for the upper and lower surfaces, wherein the Material mechanism 2, front and rear end surface grinding device 3, flattening feeding device 4, limit side grinding device 5, and upper and lower surface deburring devices are installed on frame 1 in sequence from front to back, and all electrical components are controlled and operated by PLC system , The steel plate automatic deburring machine of the present invention realizes the coherent operation of removing the burrs on the four sides and the upper and lower surfaces of the steel plate, has a high degree of automation, saves labor, has high efficiency and improves efficiency, and has a good deburring effect.

[0043] In this embodiment, the feeding mechan...

Embodiment 2

[0049] The main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the dust shields 3-7 are arranged as arc-shaped plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com