Spring tool for deburring of bearing holder

A bearing cage and deburring technology, which is applied in the directions of tools, manufacturing tools, and tool holder accessories for lathes, can solve the problems of omission, high deburring cost, low efficiency, etc., and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

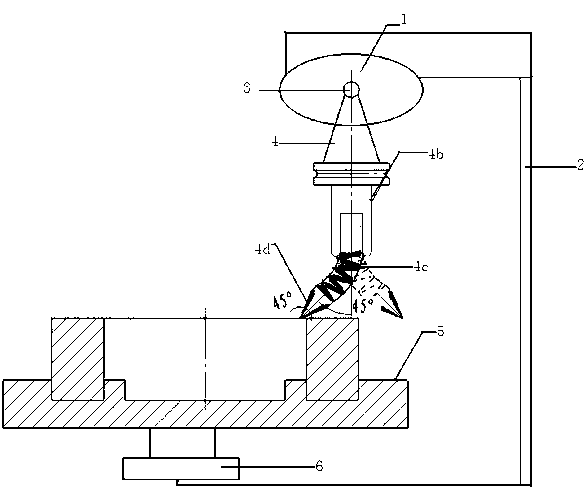

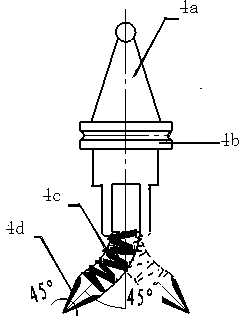

[0014] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

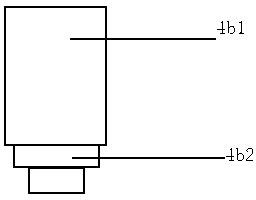

[0015] Spring cutters for deburring bearing cages, e.g. figure 1 As shown, it includes a speed regulating motor 1, a frame 2, a rotating shaft 3, a tool structure 4, a turntable 5 and a speed regulating motor 2 6, and the speed regulating motor 1 is fixedly installed on the upper end of the frame 2, and the speed regulating motor 1 is connected to the rotating shaft 3. The rotating shaft 3 drives the tool structure 4 to rotate, and the rotating direction is clockwise or counterclockwise.

[0016] A turntable 5 is arranged at the lower end of the frame 2, and the bearing cage is fixed on the turntable 5. The rotation of the turntable 5 is controlled by the speed-regulating motor 2 6 at its lower part, and its rotation direction is opposite to that of the rotating shaft 3, which is conducive to improving the deburring efficiency ,Improve prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com